Top 1 Dana Plastic Container Corp Suppliers (And How to Choose)

Introduction: Navigating the Global Market for dana plastic container corp

In the dynamic landscape of global trade, sourcing high-quality blow-molded plastic products can pose significant challenges for international B2B buyers. Dana Plastic Container Corporation stands out as a premier manufacturer, offering a diverse range of containers, bottles, and custom solutions tailored to various industries, including food and beverage, personal care, and industrial applications. This guide aims to equip B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly Brazil and Saudi Arabia—with the essential insights needed to navigate the complexities of sourcing from Dana Plastic Container Corp.

Within this comprehensive resource, you will discover detailed information about the types of products available, their applications across different sectors, and the critical factors to consider when vetting suppliers. Additionally, we will explore cost considerations and best practices for ensuring that your purchasing decisions align with your operational goals. By leveraging this guide, buyers will be empowered to make informed choices, ensuring that they select reliable partners who can deliver superior quality and service.

Dana Plastic Container Corporation’s commitment to innovation and sustainability sets it apart in the market, making it a trusted ally for businesses looking to enhance their product offerings while maintaining a focus on environmental responsibility. As you delve deeper into this guide, you will find actionable insights designed to facilitate successful sourcing strategies tailored to your specific business needs.

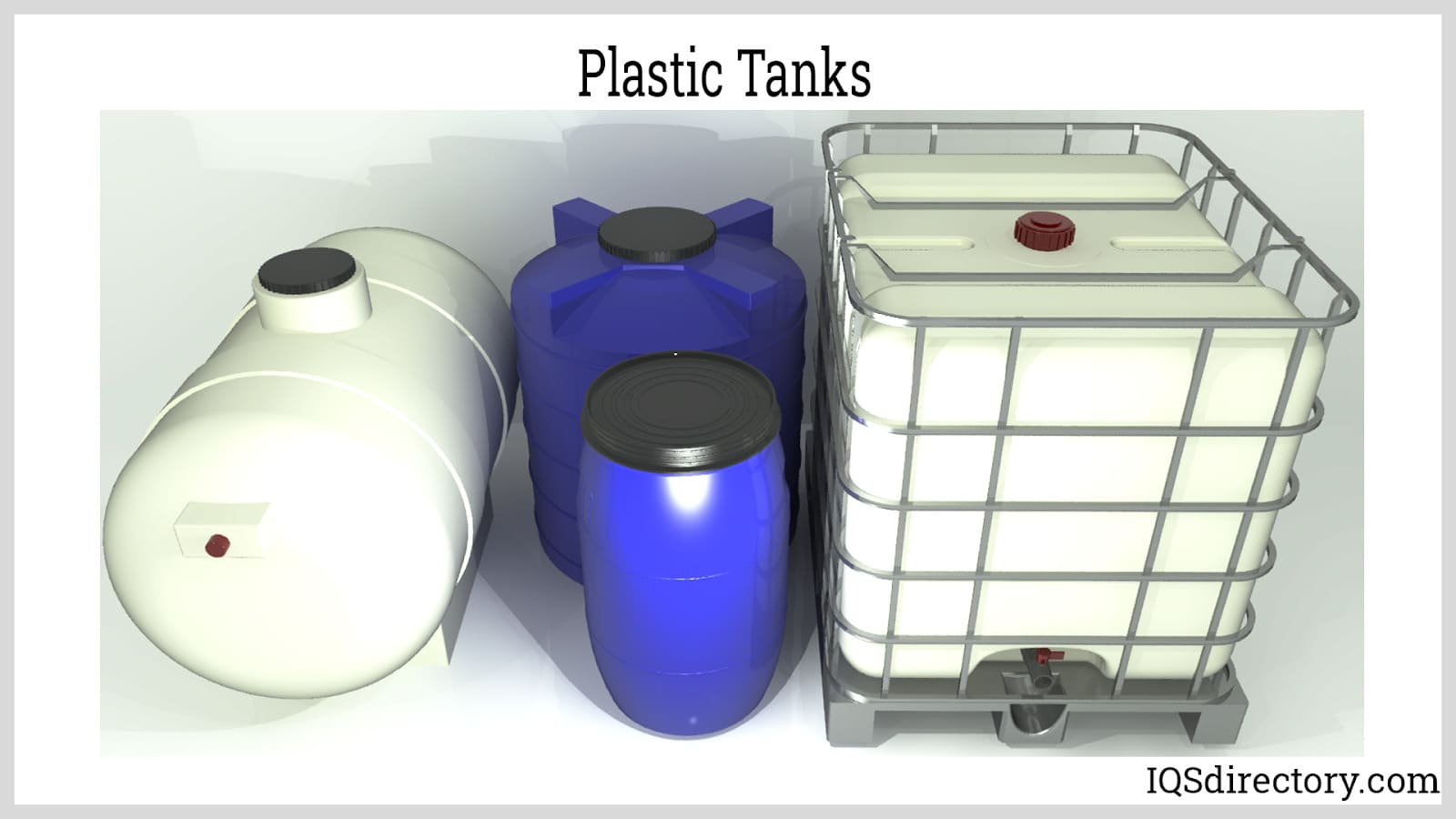

Understanding dana plastic container corp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Blow-Molded Containers | Hollow, lightweight, custom shapes; various sizes available | Food & Beverage, Household Goods | Pros: Versatile, durable; Cons: Limited to specific shapes and sizes. |

| Plastic Bottles | High-density polyethylene (HDPE) or PET materials; custom neck designs | Beverage, Personal Care, Industrial Applications | Pros: Lightweight, recyclable; Cons: Potential for lower durability in extreme conditions. |

| Custom Injection Molded Products | Tailored designs and specifications; precision-engineered components | Medical, Automotive, Electronics | Pros: Highly customizable; Cons: Longer lead times for development. |

| Sprayer Containers | Various sizes and shapes; compatible with different dispensing systems | Agricultural, Cleaning Products | Pros: Efficient dispensing; Cons: May require specific compatibility checks. |

| Eco-Friendly Solutions | Incorporates recycled materials; designed for sustainability | Environmentally-conscious brands | Pros: Appeals to green consumers; Cons: May have higher upfront costs. |

What Are Blow-Molded Containers and Their B2B Relevance?

Blow-molded containers are characterized by their hollow structure and lightweight design, making them suitable for a variety of applications. These containers can be customized in terms of shape and size to meet specific industry needs, particularly in the food and beverage sector. For B2B buyers, the versatility and durability of blow-molded containers make them a preferred choice, although it’s essential to consider that their design is limited to certain shapes, which might not fit all product requirements.

Illustrative image related to dana plastic container corp

How Do Plastic Bottles Serve Different Industries?

Plastic bottles made from HDPE or PET are widely used across multiple sectors, including beverages and personal care products. Their ability to be customized with different neck designs enhances their functionality for various applications. B2B buyers should weigh the benefits of lightweight and recyclable materials against potential durability issues in extreme conditions, which can affect product integrity during transportation or storage.

What Advantages Do Custom Injection Molded Products Offer?

Custom injection molded products allow for precise engineering tailored to specific requirements, making them invaluable in industries such as medical and automotive. Buyers benefit from the ability to create components that perfectly fit their needs, but they should also be prepared for longer lead times associated with the design and production process. Understanding the trade-offs between customization and time-to-market is crucial for effective procurement.

Why Choose Sprayer Containers for Dispensing Needs?

Sprayer containers come in various sizes and shapes, designed for compatibility with different dispensing systems. They are particularly popular in agricultural and cleaning product sectors due to their efficient dispensing capabilities. B2B buyers must ensure compatibility with existing systems to avoid operational disruptions. While sprayer containers offer convenience, they may require additional checks to ensure they meet specific application needs.

How Do Eco-Friendly Solutions Impact Business Decisions?

Eco-friendly solutions from Dana Plastic Container Corp focus on sustainability by incorporating recycled materials into their products. This approach appeals to environmentally-conscious brands looking to enhance their market position. However, B2B buyers should consider that these sustainable options may come with higher upfront costs, potentially affecting budget allocations. Balancing sustainability with cost-effectiveness is key for organizations aiming to improve their environmental footprint.

Key Industrial Applications of dana plastic container corp

| Industry/Sector | Specific Application of dana plastic container corp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Custom bottles and containers for beverages | Enhanced product shelf life and branding potential | Compliance with food safety regulations and material certifications |

| Personal Care and Cosmetics | Jars and bottles for lotions, creams, and perfumes | Attractive packaging that increases customer appeal | Design flexibility and customization options |

| Household Cleaning Products | Durable containers for cleaning solutions | Resistance to chemical degradation and leakage | Compatibility with various cleaning agents and safety standards |

| Pharmaceuticals | Bottles and containers for medications | Ensured product integrity and user safety | Regulatory compliance and traceability requirements |

| Industrial Chemicals | Heavy-duty jugs and tanks for chemical storage | Safe and efficient storage solutions | Material durability and compliance with hazardous material regulations |

How Does Dana Plastic Container Corp Cater to the Food and Beverage Industry?

Dana Plastic Container Corp specializes in manufacturing custom bottles and containers tailored for the food and beverage sector. These products are designed to enhance product shelf life while providing an appealing aesthetic that attracts consumers. For international buyers, especially in regions like Africa and South America, compliance with local food safety regulations is crucial. Understanding the specific material certifications required in these markets can ensure the successful distribution of products that meet both safety and quality standards.

What Solutions Does Dana Provide for Personal Care and Cosmetics?

In the personal care and cosmetics industry, Dana offers a variety of jars and bottles that can be customized for lotions, creams, and perfumes. The visual appeal of these containers can significantly influence consumer purchasing decisions, making attractive packaging essential. Buyers from Europe and the Middle East should consider the design flexibility and customization options available, ensuring that the packaging aligns with branding strategies and meets aesthetic preferences in their target markets.

Illustrative image related to dana plastic container corp

How Are Dana’s Containers Beneficial for Household Cleaning Products?

Dana’s durable containers are ideal for household cleaning solutions, providing resistance to chemical degradation and preventing leakage. This is particularly important for buyers in the Middle East and Africa, where the climate can exacerbate the degradation of lesser-quality packaging. When sourcing these containers, businesses should focus on compatibility with various cleaning agents and adherence to safety standards to ensure that the products remain effective and safe for consumers.

What Role Does Dana Play in the Pharmaceutical Sector?

In the pharmaceutical industry, Dana manufactures bottles and containers that prioritize product integrity and user safety. This is critical for international buyers who must navigate stringent regulatory environments, particularly in Europe and South America. Ensuring that these containers comply with regulatory requirements and traceability standards is vital for maintaining product quality and consumer trust.

How Does Dana Support the Industrial Chemicals Sector?

Dana Plastic Container Corp produces heavy-duty jugs and tanks designed for the safe storage of industrial chemicals. These solutions are engineered for durability, ensuring that they can withstand the rigors of transporting and storing hazardous materials. Buyers from regions with strict environmental regulations, such as Europe, should prioritize sourcing containers that comply with hazardous material regulations, ensuring safety and environmental responsibility.

Illustrative image related to dana plastic container corp

3 Common User Pain Points for ‘dana plastic container corp’ & Their Solutions

Scenario 1: Navigating Complex Customization Needs for Specialized Packaging

The Problem:

B2B buyers in industries such as food and beverage or pharmaceuticals often require highly specialized packaging solutions that meet stringent regulatory standards and specific functional needs. For instance, a beverage company may need custom bottle shapes and sizes that not only comply with health regulations but also enhance brand visibility. This complexity can lead to frustration when suppliers fail to provide the necessary design support or if the initial prototypes do not meet expectations.

The Solution:

To effectively address these customization challenges, buyers should leverage Dana Plastic Container Corp’s extensive design and engineering services. Initiate the process by clearly articulating your specific requirements, including material specifications, size, and functional features. Engage directly with their design team to discuss your vision, and utilize their advanced design software to visualize the product early in the process. Furthermore, take advantage of their prototyping technologies to create test models before full-scale production, ensuring that the final product meets both aesthetic and regulatory standards. This collaborative approach not only streamlines the development process but also mitigates the risk of costly revisions later on.

Scenario 2: Ensuring Quality and Consistency in Supply Chain Management

The Problem:

International buyers often struggle with maintaining consistent quality in their supply chain, particularly when sourcing packaging materials from overseas manufacturers. Variations in product quality can lead to significant operational disruptions and damage to brand reputation, especially in sectors like pharmaceuticals where compliance with safety standards is critical.

The Solution:

Dana Plastic Container Corp’s commitment to quality assurance is a vital resource for buyers looking to ensure consistency in their products. Start by requesting detailed information on their quality control measures, including any ISO certifications and the processes they employ to monitor quality at each stage of production. Consider setting up regular quality audits and establishing communication channels for feedback throughout the production cycle. By fostering a strong partnership with Dana, buyers can leverage their robust quality assurance framework to minimize risks and ensure that every batch of products adheres to the highest standards of quality and safety.

Illustrative image related to dana plastic container corp

Scenario 3: Addressing Sustainability Concerns in Packaging Solutions

The Problem:

As global markets increasingly prioritize sustainability, many B2B buyers face pressure to source eco-friendly packaging solutions. This challenge is particularly relevant in regions such as Europe and South America, where consumers are more environmentally conscious and regulatory frameworks are evolving to support sustainable practices. Buyers may feel overwhelmed by the abundance of options and the complexities of verifying the sustainability credentials of suppliers.

The Solution:

Dana Plastic Container Corp offers eco-friendly practices that can help buyers meet their sustainability goals. Begin by discussing your sustainability objectives with their customer support team, who can provide insights into their use of recycled materials and energy-efficient manufacturing processes. Buyers should inquire about specific eco-certifications and sustainable practices employed in their product lines. Consider opting for products made from recycled content or designs that reduce material usage without compromising quality. By aligning with Dana’s sustainability initiatives, buyers can confidently present their eco-friendly packaging solutions to their customers, enhancing brand loyalty and compliance with regional regulations.

In summary, understanding these common pain points can help B2B buyers effectively navigate their relationship with Dana Plastic Container Corp, ensuring they secure high-quality, customizable, and sustainable packaging solutions tailored to their specific industry needs.

Strategic Material Selection Guide for dana plastic container corp

What Are the Key Materials Used by Dana Plastic Container Corp. for Blow-Molded Products?

Dana Plastic Container Corporation employs various materials in its blow-molded products, each with unique properties and applications. Understanding these materials is crucial for international B2B buyers looking for reliable and efficient solutions.

How Does Polyethylene (PE) Perform in Blow-Molded Applications?

Polyethylene, particularly high-density polyethylene (HDPE) and low-density polyethylene (LDPE), is widely used for manufacturing containers. Key properties include excellent chemical resistance, low moisture absorption, and good impact strength. PE can withstand temperatures up to 120°C (248°F) and is resistant to various acids and bases.

Illustrative image related to dana plastic container corp

Pros: Polyethylene is cost-effective, lightweight, and highly durable, making it suitable for a wide range of applications, including food packaging and household goods. Its recyclability also appeals to environmentally conscious buyers.

Cons: However, it has a lower temperature resistance compared to other plastics and may become brittle at lower temperatures. Additionally, it may not be suitable for applications requiring high structural integrity.

Impact on Application: PE is ideal for applications involving food and beverages, as it complies with FDA regulations. However, international buyers should ensure compliance with local food safety standards.

What Advantages Does Polypropylene (PP) Offer for Container Manufacturing?

Polypropylene is another popular choice for blow-molded products due to its versatility. It exhibits excellent fatigue resistance, high melting temperature (up to 160°C or 320°F), and good chemical resistance, making it suitable for various industries.

Pros: PP is lightweight, has a high strength-to-weight ratio, and is resistant to moisture. It’s particularly useful in applications like automotive parts and industrial containers.

Cons: On the downside, polypropylene can be more expensive than polyethylene and may require more complex manufacturing processes. Additionally, it has lower impact resistance at low temperatures.

Impact on Application: PP is compatible with a wide range of chemicals, making it suitable for industrial applications. Buyers should verify compliance with ASTM standards to ensure product quality.

How Does Polyvinyl Chloride (PVC) Compare in Terms of Performance and Cost?

Polyvinyl Chloride (PVC) is known for its rigidity and strength. It can handle temperatures up to 60°C (140°F) and offers excellent resistance to environmental degradation and chemical exposure.

Illustrative image related to dana plastic container corp

Pros: PVC is highly durable and cost-effective, making it a popular choice for construction and plumbing applications. Its versatility allows for various formulations, including flexible and rigid variants.

Cons: The primary drawback is its environmental impact, as PVC production can release harmful chemicals. Additionally, it may not be suitable for food contact applications unless specifically formulated.

Impact on Application: PVC is commonly used in construction and industrial applications. Buyers from regions with strict environmental regulations should consider alternative materials or formulations.

What Role Does Polyethylene Terephthalate (PET) Play in Blow-Molded Products?

Polyethylene Terephthalate (PET) is increasingly popular for beverage containers due to its excellent clarity and strength. It can withstand temperatures up to 70°C (158°F) and is resistant to impact and moisture.

Pros: PET is lightweight, recyclable, and provides a good barrier against gases, making it ideal for carbonated beverages. Its aesthetic appeal also enhances product marketing.

Cons: However, PET can be more expensive than other plastics and may not be suitable for high-temperature applications. Additionally, it has limited chemical resistance compared to other materials.

Impact on Application: PET is widely accepted in the beverage industry, but international buyers should ensure compliance with local regulations regarding recyclability and food safety.

Summary Table of Material Selection for Dana Plastic Container Corp.

| Material | Typical Use Case for Dana Plastic Container Corp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Food packaging, household goods | Cost-effective and durable | Lower temperature resistance | Low |

| Polypropylene (PP) | Automotive parts, industrial containers | High strength-to-weight ratio | More complex manufacturing | Medium |

| Polyvinyl Chloride (PVC) | Construction, plumbing applications | Highly durable and cost-effective | Environmental concerns | Low |

| Polyethylene Terephthalate (PET) | Beverage containers | Excellent clarity and recyclability | Higher cost and limited chemical resistance | Medium |

This guide provides a comprehensive overview of the materials used in Dana Plastic Container Corp.’s products, equipping international B2B buyers with the insights needed to make informed decisions.

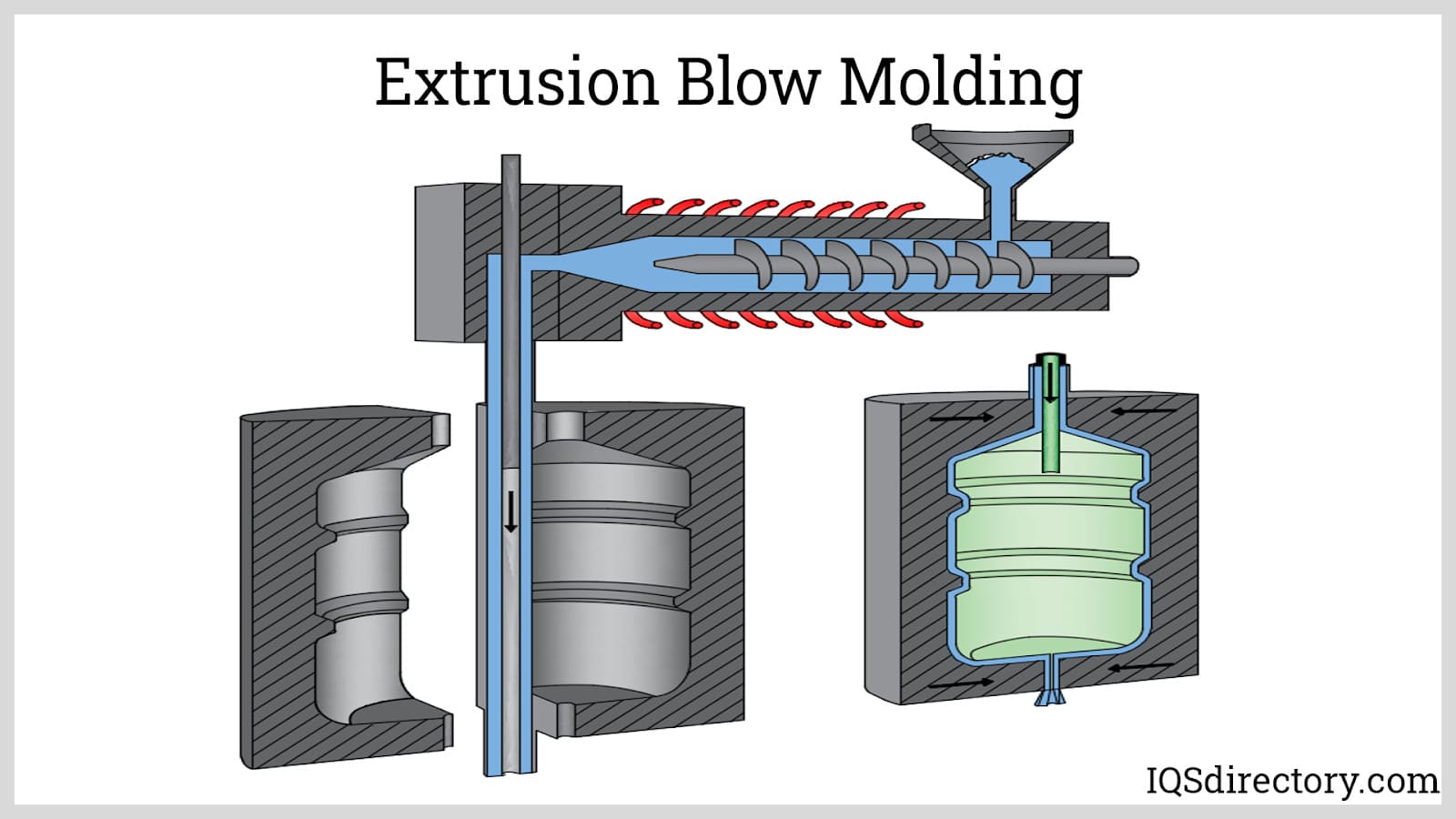

In-depth Look: Manufacturing Processes and Quality Assurance for dana plastic container corp

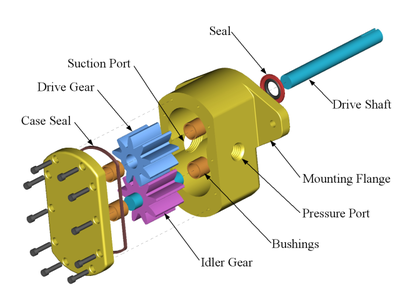

What Are the Key Stages in the Manufacturing Process at Dana Plastic Container Corporation?

Dana Plastic Container Corporation utilizes a systematic and efficient manufacturing process that encompasses several key stages: material preparation, forming, assembly, and finishing. This structured approach ensures the production of high-quality blow-molded plastic products tailored to meet the diverse needs of international B2B buyers.

How Does Material Preparation Play a Role in Product Quality?

The manufacturing process begins with material preparation, where Dana selects high-grade thermoplastic materials such as polyethylene, polypropylene, and PET. These materials are subjected to rigorous quality checks to ensure they meet industry standards. The company prioritizes the use of recycled materials wherever possible, aligning with sustainable practices that are increasingly valued by international buyers.

In this stage, the raw materials are precisely measured and blended, ensuring that each batch meets the specific requirements for strength, durability, and visual appeal. Advanced technology is employed to monitor the material characteristics, providing data that informs the subsequent stages of production.

What Techniques Are Used in the Blow-Molding Process?

The blow-molding stage is where the prepared materials are transformed into finished products. Dana employs state-of-the-art blow molding machinery that uses a process involving heating and inflating a parison, a tube of plastic, to form hollow products. This technique is crucial for producing containers, bottles, and jugs with consistent wall thickness and structural integrity.

The blow molding process at Dana is designed for efficiency and precision. Automated systems reduce human error, while real-time monitoring ensures that any deviations from quality standards are quickly addressed. This level of control is vital for B2B buyers looking for reliability in their supply chain.

How Is Assembly Conducted for Custom Solutions?

Following the blow-molding process, products may require assembly, especially for custom solutions that include additional components such as caps or handles. Dana’s engineering team collaborates closely with clients to design and assemble products that meet specific functional requirements.

The assembly stage may also involve secondary processes such as hot stamping, pad printing, and labeling, allowing for branding and customization. Dana’s commitment to flexibility in this phase enables international clients to receive products tailored to their market needs, enhancing their competitive edge.

What Finishing Processes Ensure Quality and Aesthetics?

The finishing stage is where products undergo additional quality checks and aesthetic enhancements. This may include surface treatments, color matching, and final inspections. Dana employs advanced quality control techniques to ensure that every product not only meets functional specifications but also aligns with the visual standards expected by B2B buyers.

This stage is crucial for maintaining the integrity of the product, as any defects can lead to increased costs and customer dissatisfaction. By focusing on finishing processes, Dana ensures that their products are market-ready and visually appealing, which is particularly important for brands in the food and beverage sector.

How Does Dana Plastic Container Corporation Ensure Quality Assurance?

Quality assurance is an integral part of Dana’s manufacturing philosophy, guided by stringent standards and protocols that align with both international and industry-specific requirements.

Illustrative image related to dana plastic container corp

What International Standards Govern Quality Control?

Dana Plastic Container Corporation is ISO 9001 certified, demonstrating its commitment to maintaining a high level of quality management. This certification requires continuous improvement in processes and adherence to customer requirements, providing B2B buyers with assurance of consistent product quality.

In addition to ISO standards, Dana adheres to other relevant industry-specific certifications such as CE and API, which are critical for clients in sectors like pharmaceuticals and food safety. These certifications not only enhance credibility but also facilitate market entry for international buyers, particularly in regions like Europe and the Middle East.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Dana implements a multi-tiered quality control system, encompassing several checkpoints throughout the manufacturing process:

Illustrative image related to dana plastic container corp

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify any issues in real-time.

- Final Quality Control (FQC): Finished products undergo rigorous testing to confirm they meet all specifications before shipping.

These checkpoints are vital for maintaining product integrity and ensuring compliance with international standards, providing peace of mind for B2B buyers.

What Testing Methods Are Commonly Employed?

Dana employs a range of testing methods, including dimensional checks, tensile strength testing, and environmental stress testing. These tests ensure that products can withstand various conditions and perform reliably in their intended applications. By using state-of-the-art testing equipment and methodologies, Dana can guarantee the quality and durability of its products.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to establish a partnership with Dana can verify the company’s quality control measures through several avenues:

- Audits: Conducting on-site audits allows buyers to assess manufacturing practices and quality control processes firsthand.

- Quality Reports: Requesting detailed quality reports and certifications can provide insights into Dana’s compliance with industry standards.

- Third-Party Inspections: Engaging third-party inspectors can offer an unbiased evaluation of product quality and manufacturing practices.

These strategies are especially important for international buyers in regions like Africa and South America, where quality assurance can significantly impact market performance.

Illustrative image related to dana plastic container corp

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers should be aware of the specific regulatory requirements and cultural expectations that may influence quality assurance practices. For instance, compliance with local regulations in the Middle East or Europe might necessitate additional certifications or documentation.

Moreover, buyers should consider the logistics of shipping and handling, which can affect product quality during transport. Dana’s commitment to quality extends beyond manufacturing, ensuring that products are packaged and shipped in a manner that preserves their integrity.

In conclusion, Dana Plastic Container Corporation’s robust manufacturing processes and comprehensive quality assurance measures position it as a reliable partner for international B2B buyers. By understanding these processes, buyers can make informed decisions that align with their business needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dana plastic container corp’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring products from Dana Plastic Container Corporation, a recognized leader in blow-molded plastic manufacturing. By following this step-by-step checklist, buyers can ensure they make informed decisions that align with their specific needs, quality standards, and sustainability goals.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is essential for successful procurement. Specify the type of blow-molded products you need, such as containers, bottles, or custom solutions, along with material preferences like PET or HDPE. This clarity helps Dana Plastic Container Corp. provide tailored solutions that meet your exact specifications.

Step 2: Research Product Offerings

Before engaging with the supplier, familiarize yourself with Dana Plastic Container Corp.’s product portfolio. Explore their range of containers designed for various industries, including food and beverage, personal care, and industrial applications. Understanding their capabilities will help you identify how their offerings can meet your unique requirements.

Step 3: Evaluate Supplier Certifications

Verifying the certifications of Dana Plastic Container Corp. is crucial for ensuring product quality and compliance. Look for ISO certifications, which indicate adherence to international quality management standards. This step reassures you that the products will meet rigorous quality benchmarks throughout the manufacturing process.

Step 4: Assess Customization Capabilities

Dana Plastic Container Corp. offers extensive customization options. Engage with their design and engineering teams to discuss your specific needs for product design, including size, shape, and functionality. Custom solutions can enhance product performance and align with your branding requirements.

Illustrative image related to dana plastic container corp

Step 5: Request Samples and Prototypes

To gauge the quality of products, request samples or prototypes. This step allows you to evaluate the materials, design, and functionality firsthand. Testing samples can also help you identify any necessary adjustments before placing a larger order, ensuring the final product aligns with your expectations.

Step 6: Understand Pricing and Terms

Before finalizing your order, discuss pricing structures and payment terms with Dana Plastic Container Corp. Ensure you have clarity on volume discounts, shipping costs, and lead times. Understanding these factors is essential for budgeting and planning your supply chain effectively.

Step 7: Evaluate Sustainability Practices

Inquire about Dana Plastic Container Corp.’s commitment to sustainability and eco-friendly practices. Assess their use of recycled materials and energy-efficient manufacturing processes. Partnering with a supplier that prioritizes environmental responsibility can enhance your brand’s reputation and align with global sustainability trends.

By following this checklist, you can navigate the procurement process confidently, ensuring that your partnership with Dana Plastic Container Corporation meets your business’s operational and strategic objectives.

Comprehensive Cost and Pricing Analysis for dana plastic container corp Sourcing

What Are the Key Cost Components in Sourcing from Dana Plastic Container Corp?

When evaluating the sourcing from Dana Plastic Container Corporation, understanding the cost structure is essential. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to dana plastic container corp

-

Materials: The choice of materials significantly impacts cost. Dana utilizes various plastics such as polyethylene and polypropylene, which can fluctuate in price based on market demand and availability. For B2B buyers, it’s crucial to consider the implications of material selection on both the cost and functionality of the final product.

-

Labor: Labor costs involve both direct and indirect labor associated with the manufacturing process. Dana’s commitment to quality and precision necessitates skilled labor, which can increase costs but ultimately results in superior products.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Dana’s advanced blow molding machinery and state-of-the-art facilities contribute to higher overhead costs but also enhance production efficiency and product quality.

-

Tooling: Custom tooling can be a significant upfront investment. The cost is influenced by the complexity of the molds required for specific products. Dana’s experience in custom solutions means that buyers can expect a tailored approach, but they should be prepared for the associated tooling costs.

-

Quality Control (QC): Dana emphasizes stringent QC measures, which involve additional costs. However, this investment ensures that products meet high industry standards, reducing the risk of defects and enhancing buyer satisfaction.

-

Logistics: Shipping costs can vary based on destination, shipping method, and order size. For international buyers, understanding the logistics involved, including tariffs and customs duties, is essential for accurate budgeting.

-

Margin: Dana’s pricing will include a profit margin that reflects its quality, innovation, and customer service. Understanding this margin can help buyers assess the overall value proposition.

What Price Influencers Should Buyers Consider?

Several factors can influence pricing when sourcing from Dana Plastic Container Corp:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to reduced unit costs. Buyers should evaluate their needs to negotiate favorable terms based on volume.

-

Specifications and Customization: Custom products may incur additional costs due to unique tooling and manufacturing processes. Clear communication about specifications can help mitigate unexpected costs.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO) can increase prices but also enhance product reliability. Buyers should weigh the long-term benefits of investing in quality against initial costs.

-

Supplier Factors: Dana’s reputation for customer service and support can justify higher pricing. Buyers should consider the value of ongoing support and collaboration in their sourcing decisions.

-

Incoterms: The choice of Incoterms affects responsibility for shipping costs and risks. Buyers should familiarize themselves with these terms to avoid unexpected expenses.

What Are the Best Negotiation Tips for B2B Buyers?

When negotiating with Dana Plastic Container Corp, international buyers should consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Look beyond initial pricing to evaluate the TCO, which includes maintenance, logistics, and potential downtime costs. This holistic view can guide more informed purchasing decisions.

-

Leverage Volume Discounts: Use projected order volumes as leverage during negotiations to secure better pricing and terms.

-

Build Relationships: Establishing a strong working relationship with Dana can lead to better pricing and service, particularly for repeat orders.

-

Be Aware of Pricing Nuances: International buyers should stay informed about currency fluctuations, shipping costs, and import tariffs that can impact total costs.

-

Request Indicative Prices: Always ask for indicative pricing based on specific requirements. Dana’s team can provide tailored quotes that reflect the unique needs of your project.

Conclusion

Sourcing from Dana Plastic Container Corporation involves understanding a comprehensive cost structure and various pricing influencers. By leveraging insights into costs and employing strategic negotiation techniques, international B2B buyers can maximize value and ensure successful partnerships with Dana.

Alternatives Analysis: Comparing dana plastic container corp With Other Solutions

When evaluating solutions for blow-molded plastic products, it’s essential to consider various alternatives that can meet the specific needs of businesses in different regions. Dana Plastic Container Corporation stands out for its quality and customer-centric approach, but several other options may offer competitive advantages depending on the unique requirements of your business.

| Comparison Aspect | Dana Plastic Container Corp | Alternative 1 Name | Alternative 2 Name |

|---|---|---|---|

| Performance | High-quality, durable products with advanced blow molding technology. | Good quality but may lack customization options. | Offers rapid production but with variable quality. |

| Cost | Competitive pricing with value-added services. | Lower initial cost but fewer features. | Potentially higher costs due to advanced technology. |

| Ease of Implementation | Streamlined processes with dedicated engineering support. | Simpler setup but limited customization. | Advanced systems may require specialized training. |

| Maintenance | Robust support with a focus on quality assurance. | Moderate maintenance needs; less comprehensive support. | Higher maintenance due to complex machinery. |

| Best Use Case | Ideal for industries requiring tailored solutions (food, beverage, personal care). | Suitable for standard products with less variability. | Best for high-volume production runs where speed is critical. |

What Are the Advantages and Disadvantages of Alternative 1: Iceberg Molding?

Iceberg Molding is a viable alternative, particularly for businesses that prioritize cost efficiency over customization. It offers a straightforward production process and can be an excellent choice for standard plastic products. However, Iceberg Molding’s limitations include fewer options for bespoke designs and a potential compromise on the durability of products. This may not align with industries needing high-performance containers, such as food and beverage.

How Does Alternative 2: Hi-Rel Plastics & Molding Compare?

Hi-Rel Plastics & Molding is known for its rapid production capabilities, making it attractive for high-volume projects. Their advanced machinery allows for quick turnaround times, which can be a significant advantage in competitive markets. However, this speed may come at the cost of product quality consistency, potentially leading to higher rejection rates. Businesses must weigh the benefits of fast production against the risks of variable quality, especially in sectors where product integrity is paramount.

What Factors Should B2B Buyers Consider When Choosing Between These Solutions?

B2B buyers should assess their specific needs, including product volume, required customization, and budget constraints. Dana Plastic Container Corp excels in delivering tailored solutions with a strong emphasis on quality and support, making it ideal for sectors with unique requirements. In contrast, alternatives like Iceberg Molding and Hi-Rel Plastics & Molding may serve well for standard products or high-volume demands, respectively. Ultimately, the right choice will depend on balancing performance, cost, and the specific operational needs of the buyer’s industry.

In conclusion, understanding the strengths and weaknesses of Dana Plastic Container Corporation and its alternatives is vital for international B2B buyers. By carefully analyzing the comparison aspects, businesses can make informed decisions that align with their operational goals and ensure they select the best solution for their specific applications.

Illustrative image related to dana plastic container corp

Essential Technical Properties and Trade Terminology for dana plastic container corp

What Are the Key Technical Properties Relevant to Dana Plastic Container Corp?

Understanding the technical specifications of products from Dana Plastic Container Corp is crucial for B2B buyers, especially in industries like food and beverage, pharmaceuticals, and consumer goods. Here are some essential specifications:

1. Material Grade

Dana Plastic Container Corp utilizes a variety of thermoplastic materials, including polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). Each material has distinct properties such as chemical resistance, durability, and recyclability. For example, PET is widely used for beverage containers due to its excellent barrier properties against moisture and gases. Selecting the appropriate material grade is vital for ensuring product performance and compliance with regulatory standards.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of the product. In blow molding, maintaining tight tolerances is essential for ensuring that components fit together correctly and function as intended. For instance, a tolerance of ±0.5 mm might be critical for a container that requires a specific lid fit. Precise tolerances are particularly important in industries like pharmaceuticals, where product integrity can affect safety and efficacy.

Illustrative image related to dana plastic container corp

3. Wall Thickness

The wall thickness of blow-molded products affects their strength, weight, and cost-effectiveness. Thicker walls can enhance durability but may increase material costs and weight, while thinner walls can reduce costs but may compromise strength. Understanding the optimal wall thickness for specific applications helps businesses balance performance and expense, making it a key consideration in the design phase.

4. Capacity and Volume

Dana Plastic Container Corp offers a variety of container sizes to meet different market needs, from small bottles to large tanks. Understanding the required capacity is essential for B2B buyers, as it directly impacts logistics, storage, and end-use applications. For example, a beverage manufacturer may require containers ranging from 250 ml to several liters depending on their product line.

5. Surface Finish

The surface finish of a container can affect its aesthetic appeal, functionality, and labeling options. Dana provides various finishes, such as glossy, matte, or textured, which can influence branding and consumer perception. For instance, a glossy finish might enhance the visual appeal of a product, making it stand out on shelves.

What Are Common Trade Terms Used in the Industry?

Familiarity with trade terminology is essential for navigating B2B transactions effectively. Here are some key terms relevant to Dana Plastic Container Corp:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Dana Plastic Container Corp, they might supply containers that are branded and sold by other companies, highlighting the importance of quality and reliability in their manufacturing processes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers as it can affect inventory management and cash flow. For instance, if Dana has an MOQ of 1,000 units for a specific container, buyers must assess their market demand to avoid over-committing.

3. RFQ (Request for Quotation)

An RFQ is a document that companies use to invite suppliers to bid on supplying specific products or services. In the B2B context, submitting an RFQ to Dana Plastic Container Corp can help buyers obtain detailed pricing and lead time information for customized solutions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce that are widely used in international transactions. These terms define the responsibilities of buyers and sellers in shipping and delivery. Understanding Incoterms is critical for B2B buyers engaging in global trade with Dana, as they influence shipping costs and risk management.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. For B2B buyers, understanding lead times is essential for planning inventory and managing supply chain logistics. Dana Plastic Container Corp’s efficient manufacturing processes can lead to reduced lead times, enhancing competitiveness in fast-paced markets.

Illustrative image related to dana plastic container corp

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that their partnerships with Dana Plastic Container Corp are productive and aligned with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the dana plastic container corp Sector

What Are the Key Market Trends Influencing Dana Plastic Container Corp’s Sector?

The global market for blow-molded plastic products, particularly in sectors such as food and beverage, personal care, and industrial applications, is experiencing significant growth. Key drivers include the increasing demand for sustainable packaging solutions and the rise of e-commerce, which has heightened the need for durable and lightweight packaging. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers that offer innovative solutions tailored to their specific market needs.

Emerging technologies such as automation in manufacturing processes and advancements in material science are reshaping sourcing trends. Buyers are now looking for suppliers that not only provide high-quality products but also leverage these technologies to enhance efficiency and reduce lead times. Additionally, the integration of digital platforms for procurement and supply chain management is transforming how international buyers engage with manufacturers like Dana Plastic Container Corp, facilitating streamlined communication and improved order tracking.

Moreover, the demand for customization is on the rise, as businesses seek unique packaging solutions that can differentiate their products in a crowded marketplace. This trend emphasizes the importance of collaboration between buyers and manufacturers to develop tailored products that meet specific branding and functional requirements.

How Is Sustainability and Ethical Sourcing Impacting the Dana Plastic Container Corp Sector?

Sustainability is no longer just a trend; it is a critical factor in B2B purchasing decisions. Dana Plastic Container Corp is committed to minimizing its environmental impact by incorporating eco-friendly practices into its manufacturing processes. This includes using recycled materials, optimizing energy consumption, and reducing waste throughout the production cycle. For B2B buyers, sourcing from companies that prioritize sustainability not only enhances their brand reputation but also aligns with the increasing regulatory pressures in various markets.

Ethical sourcing has gained traction, with buyers seeking suppliers that maintain transparent supply chains. This trend is particularly relevant in regions such as Europe and North America, where consumers are increasingly aware of the environmental and social implications of their purchasing choices. Certifications such as ISO 9001 and adherence to industry standards ensure that Dana Plastic Container Corp’s products meet rigorous quality and ethical benchmarks, providing buyers with peace of mind regarding their sourcing decisions.

Additionally, as global consumers demand more sustainable products, manufacturers are responding by innovating with biodegradable and compostable materials. This shift is crucial for B2B buyers who aim to reduce their ecological footprint while meeting consumer expectations for responsible packaging solutions.

How Has Dana Plastic Container Corp Evolved to Meet Market Demands?

Founded in 1990, Dana Plastic Container Corp has continually adapted to the evolving demands of the plastic packaging industry. Initially focusing on traditional blow-molded products, the company has expanded its capabilities to include a diverse range of containers catering to various sectors, including food and beverage, pharmaceuticals, and industrial applications. With over three decades of experience, Dana has built a reputation for quality and innovation, becoming a trusted partner for B2B buyers worldwide.

The company has embraced advanced manufacturing technologies, allowing for increased precision and efficiency in production. This evolution not only enhances product quality but also enables the customization that modern buyers require. As the global market shifts towards sustainability, Dana Plastic Container Corp remains at the forefront, integrating eco-friendly practices that align with the values of today’s conscientious consumers and businesses alike.

In summary, Dana Plastic Container Corp stands out in the competitive landscape of blow-molded plastic manufacturing by focusing on quality, innovation, and sustainability, making it a preferred partner for international B2B buyers looking for reliable and responsible sourcing solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of dana plastic container corp

-

How do I ensure the quality of products from Dana Plastic Container Corp?

To ensure product quality from Dana Plastic Container Corp, you can request detailed information about their quality control processes and certifications. The company adheres to stringent quality standards, including ISO 9001:2000 certification, which guarantees consistent product quality. Additionally, consider asking for samples before placing large orders to evaluate the material and craftsmanship firsthand. Engaging in regular communication with their customer support team can also provide insight into their quality assurance practices and any specific requirements you may have. -

What customization options are available for Dana Plastic Container Corp’s products?

Dana Plastic Container Corp offers extensive customization options to meet specific client needs. You can collaborate with their design and engineering teams to create tailored solutions, including different shapes, sizes, and colors for containers and bottles. They utilize advanced design software and prototyping technologies to ensure that your custom products are both functional and visually appealing. For optimal results, it’s advisable to provide clear specifications and examples of what you envision for your products during the initial discussions. -

What are the minimum order quantities (MOQs) for products from Dana Plastic Container Corp?

Minimum order quantities (MOQs) at Dana Plastic Container Corp can vary based on product type and customization requirements. Generally, larger orders may be required for custom designs due to setup costs, while standard products may have lower MOQs. It’s best to directly consult with their sales team to understand the specific MOQs for your desired products. This will help you plan your procurement strategy effectively, especially if you are considering bulk purchases. -

What payment terms does Dana Plastic Container Corp offer for international buyers?

Dana Plastic Container Corp typically offers flexible payment terms that can be negotiated based on the buyer’s credit history and order size. Common options include wire transfers, letters of credit, and payment upon delivery. For international transactions, it’s essential to clarify currency exchange rates and any additional fees that may apply. Engaging in open discussions with their finance team can help establish terms that work for both parties and facilitate smoother transactions. -

How does Dana Plastic Container Corp handle logistics for international shipping?

Dana Plastic Container Corp has established logistics partnerships to facilitate efficient international shipping. They can provide guidance on shipping methods, estimated delivery times, and customs documentation. Depending on your location, they can recommend freight forwarders with experience in handling plastic products. It’s advisable to discuss your shipping requirements early in the order process to ensure compliance with local regulations and to avoid delays. -

What industries does Dana Plastic Container Corp serve, and can they accommodate specific sector needs?

Dana Plastic Container Corp serves a diverse range of industries, including food and beverage, personal care, medical, and industrial applications. They are adept at accommodating specific sector needs, such as compliance with safety regulations and sustainability practices. By communicating your industry requirements clearly, you can leverage their expertise to develop products that not only meet your functional needs but also align with industry standards. -

How does Dana Plastic Container Corp prioritize sustainability in their manufacturing processes?

Sustainability is a core value for Dana Plastic Container Corp. They incorporate eco-friendly practices, such as utilizing recycled materials, optimizing energy consumption, and minimizing waste throughout their manufacturing processes. By prioritizing sustainability, they not only contribute to a greener environment but also appeal to businesses looking to enhance their own sustainability initiatives. Inquire about their specific sustainability practices to understand how they can support your environmental goals. -

What should I consider when vetting Dana Plastic Container Corp as a supplier?

When vetting Dana Plastic Container Corp as a potential supplier, consider their industry experience, product quality, and customer service responsiveness. Review their certifications, such as ISO standards, to assess their commitment to quality assurance. Additionally, seek references or testimonials from existing clients to gauge satisfaction levels. It’s also beneficial to have direct discussions with their team to evaluate their expertise and willingness to collaborate on your specific needs, ensuring a good fit for your business objectives.

Top 1 Dana Plastic Container Corp Manufacturers & Suppliers List

1. Dana Plastic Container Corporation – Blow-Molded Plastic Products

Domain: blowmoldedplastic.com

Registered: 2000 (25 years)

Introduction: Dana Plastic Container Corporation specializes in blow-molded plastic products, offering a diverse range including containers, bottles, jars, jugs, and customized solutions. Their products cater to various industries such as food and beverage, personal care, household goods, and industrial applications. The company emphasizes superior quality, innovative solutions, and customer satisfaction, utili…

Strategic Sourcing Conclusion and Outlook for dana plastic container corp

As Dana Plastic Container Corporation continues to solidify its reputation as a leader in the blow-molded plastic manufacturing space, strategic sourcing remains paramount for international B2B buyers. With a diverse product portfolio catering to various industries, including food and beverage, pharmaceuticals, and consumer goods, Dana offers tailored solutions that meet specific customer needs. Their commitment to quality, innovation, and sustainability ensures that businesses can rely on durable and environmentally responsible products.

For buyers in Africa, South America, the Middle East, and Europe, establishing a partnership with Dana can unlock significant advantages, including access to advanced manufacturing capabilities and comprehensive support services. Leveraging Dana’s expertise in product design and engineering can enhance your operational efficiency and product offerings, making your business more competitive in local and global markets.

Looking ahead, the demand for sustainable packaging solutions will only increase. By aligning with Dana Plastic Container Corporation, you can be at the forefront of this shift, ensuring your supply chain is both resilient and responsible. Engage with Dana today to explore how their innovative solutions can elevate your business and contribute to a sustainable future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.