Top 1 Bracket For Metal Pole Suppliers (And How to Choose)

Introduction: Navigating the Global Market for bracket for metal pole

In the ever-evolving landscape of international trade, sourcing the right bracket for metal poles can be a daunting challenge for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. With a myriad of options available, including different types, materials, and applications, navigating this global market requires a strategic approach. This guide aims to demystify the complexities associated with procuring metal pole brackets by providing in-depth insights into various product categories, their specific applications, and essential considerations for supplier vetting.

Throughout this guide, we will explore the diverse range of brackets tailored for different pole sizes and uses, such as mounting brackets for signage, lighting, and fencing. Additionally, we will delve into critical factors such as cost analysis, quality assurance, and supplier reliability—key elements that empower B2B buyers to make informed purchasing decisions. By understanding the nuances of the global market for metal pole brackets, international buyers can not only enhance their procurement strategies but also ensure that their investments yield long-term benefits.

Whether you are a buyer in Saudi Arabia looking for durable outdoor solutions, or a company in Brazil seeking cost-effective options for industrial applications, this comprehensive guide equips you with the knowledge to navigate the complexities of sourcing effectively and confidently.

Understanding bracket for metal pole Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wrap Around Bracket | Designed to encircle poles, allowing for secure attachment. | Street lighting, signage, and utility poles. | Pros: Strong support, versatile. Cons: May require precise fitting. |

| Side Angle Bracket | Fixed at an angle to provide lateral support. | Solar panel mounts, flag poles. | Pros: Allows for unique positioning. Cons: Limited to specific applications. |

| Side Tenon Bracket | Features a tenon for easy pole insertion. | Outdoor advertising, decorative lighting. | Pros: Quick installation, robust design. Cons: May not suit all pole types. |

| Dock Mount Bracket | Specifically designed for securing poles on docks. | Marine applications, boat mooring. | Pros: Corrosion-resistant, stable. Cons: Limited to marine environments. |

| Ground Sleeve Bracket | Allows for easy pole removal and installation. | Temporary installations, event setups. | Pros: Flexibility for seasonal use. Cons: Not suitable for permanent fixtures. |

What are the Characteristics of Wrap Around Brackets for Metal Poles?

Wrap around brackets are engineered to encircle metal poles, providing a robust and secure attachment method. This design is particularly useful in applications such as street lighting and signage, where stability and durability are paramount. B2B buyers should consider the material quality and dimensions to ensure compatibility with specific pole sizes. These brackets are versatile and can accommodate various mounting options, but precise fitting is essential for optimal performance.

How Do Side Angle Brackets Offer Unique Solutions?

Side angle brackets are distinguished by their ability to provide lateral support at an angle. This feature makes them ideal for applications like solar panel mounts and flag poles, where unique positioning is required. When purchasing, B2B buyers should evaluate the angle specifications and load-bearing capacity to match their project needs. While these brackets offer flexibility in design, their specialized application may limit their use in more conventional setups.

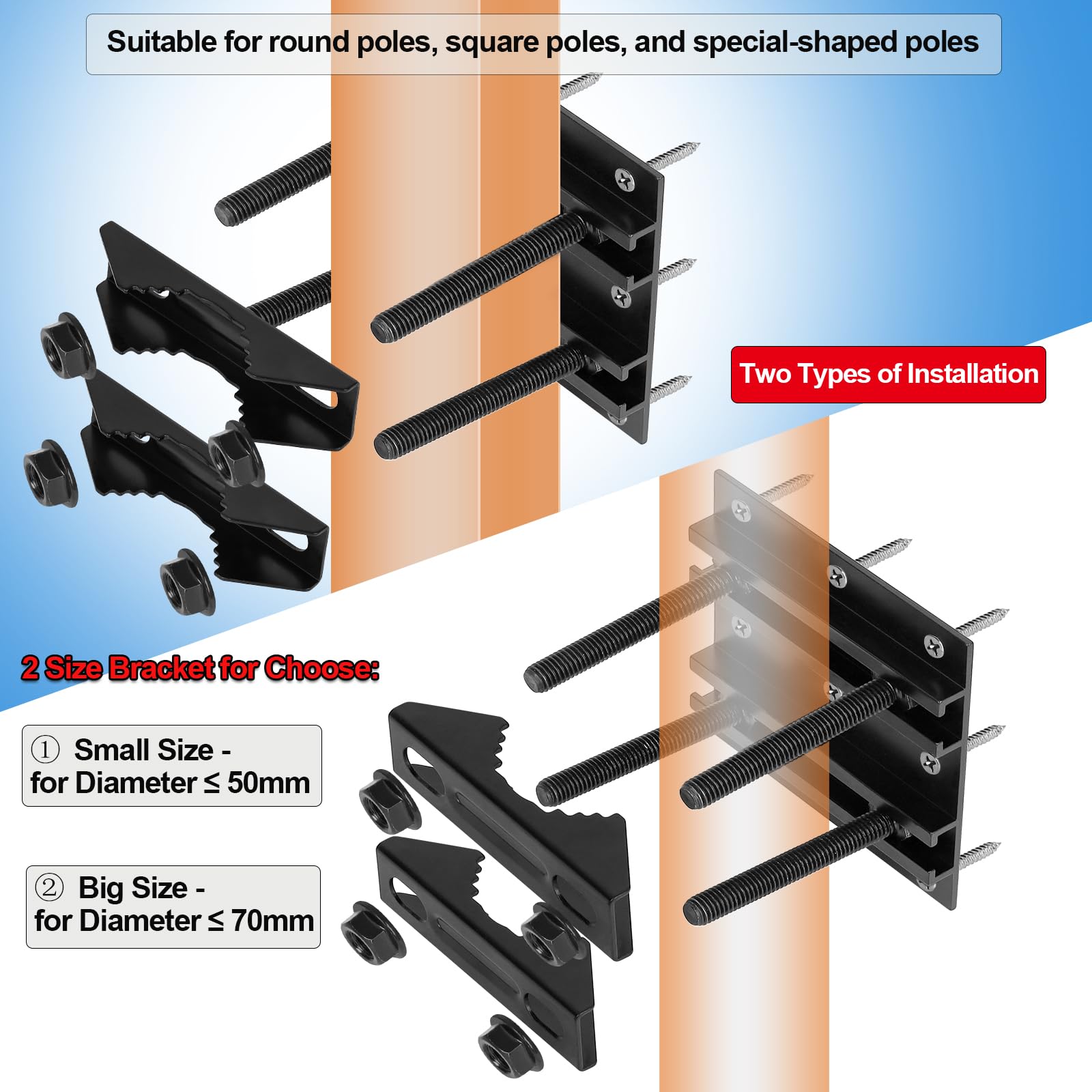

Illustrative image related to bracket for metal pole

What are the Benefits of Side Tenon Brackets?

Side tenon brackets come with a tenon that allows for straightforward pole insertion, simplifying the installation process. They are commonly used in outdoor advertising and decorative lighting applications, where quick setup is beneficial. Buyers should focus on the bracket’s load capacity and compatibility with different pole materials. While the ease of installation is a significant advantage, these brackets may not be suitable for all pole types, necessitating careful selection.

Why Choose Dock Mount Brackets for Marine Applications?

Dock mount brackets are specifically designed for securing poles in marine environments, providing stability and resistance to corrosion. These brackets are essential for applications such as boat mooring and marine signage. B2B buyers in the marine industry should prioritize materials that withstand harsh weather conditions and saltwater exposure. While they offer excellent stability, their use is generally limited to marine settings, which may not suit other applications.

How Do Ground Sleeve Brackets Enhance Flexibility?

Ground sleeve brackets allow for the easy removal and installation of poles, making them ideal for temporary setups such as events or seasonal displays. This flexibility is particularly valuable for businesses that require frequent adjustments or relocations. When considering these brackets, B2B buyers should assess the sleeve’s durability and compatibility with various pole sizes. Although they offer significant flexibility, ground sleeves are not recommended for permanent installations due to their design.

Illustrative image related to bracket for metal pole

Key Industrial Applications of bracket for metal pole

| Industry/Sector | Specific Application of bracket for metal pole | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Mounting antennas and communication devices on poles | Enhanced signal strength and coverage | Durability in harsh weather, compatibility with various pole sizes |

| Construction | Supporting temporary structures like scaffolding | Improved safety and stability for workers | Load capacity, ease of installation, and material strength |

| Renewable Energy | Securing solar panels and wind turbines | Increased energy efficiency and reliability | Corrosion resistance, adaptability to different mounting angles |

| Transportation | Attaching signage and lighting along roadways | Enhanced visibility and safety for drivers | Compliance with local regulations, material specifications |

| Event Management | Setting up decorative flags and banners | Increased visibility and engagement at events | Lightweight design, ease of transport, and setup efficiency |

How Is ‘Bracket for Metal Pole’ Used in Telecommunications?

In the telecommunications sector, brackets for metal poles are essential for securely mounting antennas and communication devices. This application ensures optimal signal strength and coverage, which are critical for service providers. Buyers in this industry must consider the durability of the brackets to withstand harsh weather conditions, as well as their compatibility with various pole sizes to ensure proper installation.

What Role Do Brackets Play in Construction Projects?

In construction, brackets are vital for supporting temporary structures such as scaffolding. They provide enhanced safety and stability for workers, reducing the risk of accidents on job sites. B2B buyers in this field should focus on the load capacity of brackets, ease of installation, and the strength of materials used, as these factors directly impact the overall safety and efficiency of construction projects.

How Are Brackets Used in Renewable Energy Applications?

Brackets for metal poles are increasingly used in the renewable energy sector to secure solar panels and wind turbines. This application not only enhances energy efficiency but also ensures the reliability of these installations. Buyers should prioritize brackets that offer corrosion resistance and adaptability to various mounting angles, especially in regions with diverse climates, such as Africa and the Middle East.

Why Are Brackets Important for Transportation Signage?

In the transportation industry, brackets are used to attach signage and lighting along roadways, which is crucial for enhancing visibility and safety for drivers. The specific requirements for sourcing these brackets include compliance with local regulations and adherence to material specifications that ensure durability and longevity, especially in high-traffic areas across Europe and South America.

How Do Brackets Benefit Event Management?

For event management, brackets for metal poles are used to set up decorative flags and banners, drawing attention and increasing engagement at events. The lightweight design and ease of transport are critical factors for buyers in this industry, as they streamline setup processes and enhance the overall event experience. Ensuring that these brackets are efficient to install and remove can significantly impact event logistics.

Illustrative image related to bracket for metal pole

3 Common User Pain Points for ‘bracket for metal pole’ & Their Solutions

Scenario 1: Incompatibility with Existing Structures

The Problem: Many B2B buyers face the challenge of sourcing brackets for metal poles that are compatible with their existing structures. This is particularly relevant for businesses in construction and infrastructure development, where they may need to retrofit or integrate new poles into older systems. Buyers often find themselves frustrated when the brackets they purchase do not fit properly or require extensive modifications, leading to wasted time and resources. Compatibility issues can arise from variations in pole diameter, mounting configurations, or material differences.

The Solution: To mitigate these issues, buyers should conduct thorough compatibility assessments before making a purchase. This involves measuring existing pole diameters and understanding the specifications of the mounting surfaces. Engaging with suppliers who offer customizable solutions or a range of sizes can also be beneficial. Additionally, buyers should request detailed product specifications and installation guidelines. For instance, opting for adjustable brackets or those with multiple mounting options can provide flexibility, ensuring a better fit with existing structures. Collaborating with suppliers who provide technical support during the selection and installation process can further alleviate these compatibility concerns.

Scenario 2: Durability Concerns in Harsh Environments

The Problem: Businesses operating in regions with extreme weather conditions, such as high winds, heavy rains, or corrosive environments, often struggle with the durability of metal pole brackets. This is especially true for buyers in industries like telecommunications and outdoor advertising, where brackets must withstand significant stress. The failure of inadequate brackets can lead to costly downtime, safety hazards, and damage to associated equipment.

The Solution: Buyers should prioritize sourcing brackets made from high-grade materials specifically designed for harsh environments. For example, stainless steel or powder-coated finishes can offer enhanced corrosion resistance, while thicker gauge metals can provide better structural integrity against wind forces. It is advisable to consult with manufacturers about the specific environmental conditions the brackets will face. Additionally, regular maintenance and inspection schedules should be established to ensure the longevity of the brackets. Suppliers that offer warranties or performance guarantees can provide added peace of mind, ensuring that investments are protected against premature failure.

Illustrative image related to bracket for metal pole

Scenario 3: Installation Complexity Leading to Delays

The Problem: The installation process of brackets for metal poles can often be more complex than anticipated, leading to project delays. This is a common pain point for contractors and project managers who rely on timely installations to meet deadlines. Complicated assembly instructions, insufficient hardware, or the need for specialized tools can all contribute to increased labor costs and frustration among crews.

The Solution: To streamline the installation process, buyers should seek brackets that come with comprehensive installation instructions and all necessary hardware included. It may be beneficial to look for suppliers who provide detailed video tutorials or on-site training. Choosing brackets designed for ease of installation, such as those with pre-drilled holes or integrated fastening systems, can significantly reduce the time required for setup. Furthermore, engaging with suppliers who offer customer support can help resolve installation issues quickly, minimizing downtime. By investing time in planning and sourcing the right products, businesses can avoid costly delays and enhance overall project efficiency.

Strategic Material Selection Guide for bracket for metal pole

When selecting materials for brackets designed to support metal poles, several factors come into play, particularly for international B2B buyers. The choice of material directly affects the performance, durability, and cost-effectiveness of the brackets. Below, we analyze four common materials used in the manufacturing of these brackets: steel, aluminum, stainless steel, and plastic composites.

What Are the Key Properties of Steel for Brackets?

Steel is a widely used material for brackets due to its high strength and durability. It can withstand significant loads and is suitable for various environmental conditions. Steel brackets typically have a temperature rating that allows them to perform well in both high and low-temperature environments. However, steel is prone to corrosion, especially in humid or saline environments, which can be a critical factor in regions like coastal areas of South America or the Middle East.

Illustrative image related to bracket for metal pole

Pros and Cons of Steel:

– Pros: High strength-to-weight ratio, cost-effective, readily available.

– Cons: Susceptible to rust and corrosion without proper treatment, heavier than alternatives, which may complicate installation.

How Does Aluminum Compare for Bracket Applications?

Aluminum is known for its lightweight and corrosion-resistant properties, making it an excellent choice for outdoor applications. It is particularly advantageous in regions with high humidity or salt exposure, such as coastal areas in Africa or the Middle East. Aluminum brackets can handle moderate loads effectively and are often used in applications where weight is a concern.

Pros and Cons of Aluminum:

– Pros: Lightweight, excellent corrosion resistance, easy to fabricate.

– Cons: Lower strength compared to steel, can be more expensive depending on alloy used.

What Advantages Does Stainless Steel Offer for Bracket Durability?

Stainless steel combines the strength of steel with enhanced corrosion resistance, making it suitable for harsh environments. This material is particularly beneficial for brackets exposed to chemicals or extreme weather conditions. Stainless steel brackets are commonly used in applications where hygiene is critical, such as in food processing or healthcare facilities.

Pros and Cons of Stainless Steel:

– Pros: Exceptional corrosion resistance, high strength, aesthetic appeal.

– Cons: Higher cost compared to carbon steel and aluminum, may require specialized fabrication techniques.

When Are Plastic Composites Suitable for Brackets?

Plastic composites are increasingly being utilized in bracket manufacturing due to their lightweight and corrosion-resistant properties. They are particularly advantageous in applications where electrical insulation is required. While they may not support heavy loads as effectively as metals, they are suitable for lightweight structures or temporary installations.

Pros and Cons of Plastic Composites:

– Pros: Lightweight, resistant to corrosion and chemicals, good electrical insulation.

– Cons: Lower load-bearing capacity, less durable in extreme temperatures, may degrade over time under UV exposure.

Summary of Material Selection for Brackets

International B2B buyers must consider various factors when selecting materials for brackets for metal poles, including local environmental conditions, regulatory compliance, and cost. Understanding the properties and applications of each material can help buyers make informed decisions that align with their specific needs.

Illustrative image related to bracket for metal pole

| Material | Typical Use Case for bracket for metal pole | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications in construction | High strength and load capacity | Prone to rust without treatment | Medium |

| Aluminum | Outdoor signage and lightweight structures | Excellent corrosion resistance | Lower strength than steel | Medium to High |

| Stainless Steel | Marine applications and food processing | Exceptional durability and hygiene | Higher cost and fabrication complexity | High |

| Plastic Composites | Temporary installations and electrical insulation | Lightweight and corrosion-resistant | Limited load-bearing capacity | Low to Medium |

This analysis provides a comprehensive overview of material selection for brackets, helping B2B buyers navigate their options effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for bracket for metal pole

What Are the Key Stages in the Manufacturing Process of Brackets for Metal Poles?

The manufacturing process for brackets designed to support metal poles typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial to ensuring the structural integrity and functionality of the final product.

-

Material Preparation: The first step is selecting high-quality raw materials, often steel or aluminum, known for their strength and durability. The materials are sourced from reputable suppliers, and their quality is assessed through initial inspections to ensure they meet specified standards. This step may also involve cutting materials to the required dimensions based on design specifications.

-

Forming: In this stage, the prepared materials undergo various forming processes such as bending, stamping, or welding. Advanced machinery, such as CNC (Computer Numerical Control) machines, is often used to achieve precise shapes and sizes. This ensures that each bracket is manufactured to exact specifications, which is essential for compatibility with different pole types and installation scenarios.

-

Assembly: After forming, the components are assembled. This may involve welding different parts together or using mechanical fasteners like bolts and nuts. Quality control checks are performed during assembly to ensure that all components fit correctly and that there are no defects.

-

Finishing: The final stage involves applying protective coatings, such as powder coating or galvanization, to enhance corrosion resistance and aesthetic appeal. This is particularly important for outdoor applications where exposure to the elements can lead to rapid deterioration. Finishing processes are also subjected to quality checks to ensure uniform application and adherence to standards.

How Is Quality Assurance Implemented in Bracket Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, particularly for brackets that must meet international standards and perform reliably in diverse environments. Here are the key components of a robust QA system for bracket manufacturing:

-

International Standards Compliance: Many manufacturers adhere to international quality management standards, such as ISO 9001, which emphasizes a systematic approach to managing quality. Compliance with these standards assures B2B buyers that the manufacturer has established processes for continuous improvement and customer satisfaction.

-

Industry-Specific Certifications: Depending on the application, brackets may also need to comply with industry-specific standards, such as CE marking for products sold in Europe, or API standards for oil and gas applications. These certifications verify that the products meet regulatory and safety requirements.

-

Quality Control Checkpoints: Effective quality control is typically divided into several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the necessary specifications.

– In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested to detect any deviations from quality standards.

– Final Quality Control (FQC): After finishing, products undergo thorough inspection and testing to confirm they meet all design and performance specifications before shipment.

What Testing Methods Are Commonly Used for Metal Pole Brackets?

Various testing methods are employed to ensure that metal pole brackets can withstand operational demands. Some of the most common tests include:

-

Load Testing: This involves applying a predetermined weight to the bracket to ensure it can support the intended load without deforming or failing. Load tests simulate real-world conditions and help verify the bracket’s strength and durability.

-

Corrosion Resistance Testing: Given that many brackets are used outdoors, testing for corrosion resistance is critical. This may involve salt spray tests or immersion tests to evaluate how well the protective coatings hold up under adverse conditions.

-

Dimensional Inspection: Precision is vital in manufacturing brackets. Dimensional checks ensure that all parts are within specified tolerances, which is crucial for proper fit and function.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are several strategies to consider:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. This can involve reviewing documentation, inspecting facilities, and observing production practices.

-

Requesting Quality Reports: Suppliers should be willing to share their quality control documentation, including inspection reports, testing results, and compliance certifications. These documents can help buyers assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These inspections can be conducted at various stages of the manufacturing process, providing an additional layer of assurance.

What Are the Nuances of Quality Certification for International Buyers?

For international B2B buyers, understanding the nuances of quality certification is essential. Different regions may have varying requirements, and navigating these can impact procurement decisions.

-

Regional Compliance: Buyers should be aware of specific regulations and standards that apply in their region. For example, products sold in the European market must comply with CE marking, while those in the Middle East may require specific certifications aligned with local regulations.

-

Understanding Certification Processes: Each certification process can vary in complexity and time frame. Buyers should ensure they understand the implications of these processes on lead times and costs.

-

Language and Documentation: Language barriers and varying documentation standards can pose challenges in international transactions. Buyers should seek suppliers who can provide documentation in a language they understand and ensure that all specifications are clearly defined.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for brackets for metal poles is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bracket for metal pole’

Introduction

Sourcing the right bracket for metal poles is crucial for ensuring structural integrity and functionality in various applications, from construction to outdoor signage. This guide provides a practical checklist to help B2B buyers make informed procurement decisions, ensuring that the chosen brackets meet technical requirements while being cost-effective and reliable.

Illustrative image related to bracket for metal pole

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the metal pole brackets you need. Consider factors such as load capacity, dimensions, material type, and environmental conditions where the brackets will be used.

– Load Capacity: Determine the weight the brackets must support, factoring in dynamic loads from wind or other forces.

– Material Type: Choose materials that resist corrosion, especially in humid or coastal areas.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in metal pole brackets. Look for companies with a proven track record in your industry.

– Industry Experience: Suppliers with experience in your sector are more likely to understand your specific needs.

– Geographic Reach: Ensure they can deliver to your location, considering shipping times and costs, particularly if you are sourcing from regions like Africa or South America.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that your shortlisted suppliers hold relevant certifications and quality standards. This step is vital for ensuring that the products meet safety and performance benchmarks.

– ISO Certifications: Look for suppliers certified under ISO 9001, which indicates a commitment to quality management.

– Product Compliance: Ensure that the brackets comply with local and international standards relevant to your industry.

Step 4: Request Samples

Once you’ve narrowed down your options, request samples of the brackets to assess quality firsthand. This allows you to evaluate the fit and finish, as well as the overall durability.

– Material Inspection: Check for any defects in the material and the robustness of the design.

– Testing Under Load: If possible, conduct load testing to ensure the brackets can handle the specified weights.

Step 5: Analyze Pricing and Terms

Carefully analyze the pricing structure and payment terms from each supplier. It’s essential to understand the total cost of ownership, which includes shipping and any potential tariffs.

– Bulk Pricing: Inquire about discounts for bulk orders, which can significantly reduce your costs.

– Payment Terms: Favorable terms can improve your cash flow, so consider suppliers who offer flexible payment options.

Step 6: Review Customer Feedback and References

Seek out feedback from previous customers or request references from the suppliers. This step provides insight into the supplier’s reliability and the performance of their products.

– Online Reviews: Check platforms like Trustpilot or industry-specific forums for unbiased reviews.

– Direct References: Ask the supplier for contact information of past clients in similar industries to get firsthand accounts of their experiences.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure that all terms are documented in a purchase agreement. This should include pricing, delivery schedules, and warranty information.

– Clear Terms: Ensure all expectations are clearly defined to avoid misunderstandings later.

– Warranties and Support: Confirm warranty periods and the availability of customer support for future inquiries or issues.

By following this checklist, B2B buyers can streamline their sourcing process for metal pole brackets, ultimately leading to more effective and reliable procurement decisions.

Comprehensive Cost and Pricing Analysis for bracket for metal pole Sourcing

Understanding the cost structure and pricing dynamics of brackets for metal poles is essential for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, price influencers, and strategic tips for buyers to enhance their procurement decisions.

What Are the Key Cost Components in Bracket Manufacturing?

The cost structure for brackets for metal poles includes several critical components:

-

Materials: The primary materials used in bracket production often include steel, aluminum, or other alloys. The choice of material significantly affects cost; for instance, stainless steel may incur higher expenses due to its corrosion resistance but offers durability, which can justify the investment.

-

Labor: Labor costs vary based on the location of manufacturing. Regions with higher wage standards may see increased labor costs, which can impact the final pricing of the brackets.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment. Overhead can vary widely depending on the efficiency of the manufacturing process and the technology employed.

-

Tooling: Custom tooling for specific designs can represent a significant upfront cost. Buyers should consider whether the tooling cost is amortized over large production runs to reduce the per-unit cost.

-

Quality Control (QC): Ensuring that brackets meet safety and performance standards is crucial. QC processes can add to manufacturing costs but are essential for compliance, especially in regulated markets.

-

Logistics: Transportation and shipping costs can greatly influence the total cost, particularly for international shipments. Factors like distance, mode of transport, and shipping terms (Incoterms) will affect logistics expenses.

-

Margin: Suppliers will add a markup to cover their costs and profit. Understanding the typical margin in the industry can provide insight into fair pricing.

What Factors Influence Pricing for Brackets?

Several factors can influence the pricing of brackets for metal poles:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to maximize their cost efficiency.

-

Specifications and Customization: Custom designs or specific specifications can increase costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can command premium prices. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: The agreed terms for shipping can significantly impact the overall cost. Terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risks, influencing the final price.

What Tips Can Help Buyers Negotiate Better Prices?

-

Leverage Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger orders or longer-term contracts. Building a relationship can also lead to better terms and pricing.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the brackets, including installation, maintenance, and potential replacements. A lower initial price may not always translate to cost savings over time.

-

Understand Pricing Nuances for International Markets: Currency fluctuations, import duties, and local regulations can impact pricing for international buyers. Staying informed about these factors can help in budgeting and negotiations.

-

Request Detailed Quotes: Ask suppliers for breakdowns of pricing to understand where costs are allocated. This transparency can provide leverage in negotiations and help identify potential areas for cost savings.

-

Evaluate Supplier Performance: Research potential suppliers’ track records regarding quality and delivery times. A reliable supplier can save costs associated with delays and defects.

In conclusion, a comprehensive understanding of the cost structure, pricing influencers, and strategic negotiation tips can empower international B2B buyers to make informed decisions in sourcing brackets for metal poles. By considering these factors, buyers can optimize their procurement strategies and achieve better outcomes.

Alternatives Analysis: Comparing bracket for metal pole With Other Solutions

Exploring Alternatives for Supporting Metal Poles

In the realm of mounting solutions for metal poles, various alternatives exist that can meet the diverse needs of B2B buyers. While a bracket for metal poles is a popular choice, it’s essential to understand how it stacks up against other viable options. This analysis will explore two alternative solutions: pole mounting systems and ground anchors, providing insights on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Bracket For Metal Pole | Pole Mounting System | Ground Anchor |

|---|---|---|---|

| Performance | High stability, suitable for various environments | Excellent for heavy-duty applications | Good for moderate loads, less stable in soft soil |

| Cost | Moderate ($15 – $130) | Higher ($100 – $300) | Lower ($20 – $60) |

| Ease of Implementation | Simple installation with basic tools | Requires more complex installation | Relatively easy, but requires digging |

| Maintenance | Low maintenance required | Low, but may need checks for heavy loads | Moderate, may require repositioning in unstable soil |

| Best Use Case | General use in light to moderate load applications | Industrial or commercial settings with heavy loads | Temporary structures or areas with unstable soil |

What Are the Advantages and Disadvantages of Pole Mounting Systems?

Pole mounting systems are engineered for heavy-duty applications, making them ideal for commercial and industrial settings where stability and load-bearing capacity are paramount. These systems often consist of multiple brackets or supports that distribute weight more evenly across the pole. However, the complexity of installation can be a drawback, often requiring specialized tools and expertise. Additionally, the cost can be significantly higher than standard brackets, which may deter budget-conscious buyers.

How Do Ground Anchors Compare?

Ground anchors offer a lower-cost alternative for securing poles, particularly in environments where soil conditions may not support traditional mounting methods. They work by embedding into the ground and providing stability through friction and tension. While they are easier to install than pole mounting systems, their performance can be compromised in soft or unstable soil conditions, making them less suitable for heavy-duty applications. Maintenance may also be necessary, as shifting soil can affect anchor positioning over time.

Choosing the Right Solution for Your Needs

When selecting a mounting solution for metal poles, B2B buyers should consider their specific requirements, including load capacity, environmental conditions, and budget constraints. A bracket for metal poles provides a versatile option for many applications, while pole mounting systems are better suited for heavy-duty needs. Ground anchors can be a cost-effective solution for temporary or less demanding installations. Assessing these factors will enable buyers to make informed decisions that align with their operational needs.

Essential Technical Properties and Trade Terminology for bracket for metal pole

What Are the Key Technical Properties of Brackets for Metal Poles?

When sourcing brackets for metal poles, understanding the technical properties is crucial for ensuring product performance and compatibility. Here are some essential specifications to consider:

1. Material Grade

Brackets are often made from various materials including stainless steel, galvanized steel, and aluminum. Each material offers different levels of strength, corrosion resistance, and weight. For example, stainless steel is ideal for outdoor applications due to its high resistance to rust, making it suitable for regions with high humidity or rainfall. Selecting the appropriate material can impact the longevity and functionality of the bracket in different environments.

2. Load Capacity

Load capacity refers to the maximum weight the bracket can support without failure. This specification is critical for ensuring that the bracket can safely hold the poles and any additional attachments, such as signage or lighting fixtures. Buyers should assess the weight and dynamic loads the bracket will encounter during use to ensure safety and compliance with industry standards.

3. Tolerance

Tolerance defines the permissible limits of variation in a physical dimension of the bracket, such as thickness or width. High tolerance levels ensure precise fits, which is essential for stability and performance. Poor tolerance can lead to misalignment, which can compromise the integrity of the installation.

4. Finish

The finish of the bracket, such as powder-coated or galvanized, affects both aesthetic appeal and corrosion resistance. A powder-coated finish offers a wide range of colors and can provide additional protection against the elements, while galvanized finishes are typically used for their rust resistance in harsh environments. This choice can significantly influence the lifespan of the bracket in different geographical locations.

5. Compatibility

Compatibility is essential for ensuring that the bracket fits the specific pole diameter and type. Brackets may have various mounting styles and configurations, such as side or top mounting. Understanding compatibility helps prevent costly errors in procurement and installation.

What Are Common Trade Terms in the Bracket for Metal Pole Industry?

Familiarity with industry terminology can streamline communication and enhance the purchasing process. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. In the context of brackets, an OEM might manufacture specific brackets that are then sold under another brand. Understanding OEM relationships can help buyers identify quality and reliability in their suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for buyers to understand as it affects inventory management and cost. For international buyers, meeting MOQ can lead to better pricing per unit, but it also requires careful planning to avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products or services. This is a standard practice in B2B purchasing that enables buyers to compare prices and terms from multiple suppliers, fostering competitive pricing and better deals.

Illustrative image related to bracket for metal pole

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) specify who is responsible for shipping, insurance, and tariffs, which can significantly impact total costs.

5. Lead Time

Lead time refers to the time between placing an order and receiving the product. Understanding lead times is essential for inventory management, especially for projects with tight deadlines. It allows buyers to plan effectively and avoid delays in their operations.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the right brackets for their metal pole applications while navigating the complexities of international procurement efficiently.

Navigating Market Dynamics and Sourcing Trends in the bracket for metal pole Sector

What Are the Key Market Dynamics and Trends in the Bracket for Metal Pole Sector?

The global market for brackets used in metal poles is experiencing notable growth, driven by several factors, including urbanization, infrastructure development, and the increasing demand for reliable mounting solutions in various applications. In regions such as Africa, South America, the Middle East, and Europe, buyers are seeking high-quality, durable products that can withstand environmental challenges, such as extreme weather conditions. In particular, countries like Saudi Arabia and Brazil are focusing on enhancing their infrastructure to support economic growth, creating a fertile ground for businesses involved in the supply of metal pole brackets.

Emerging trends highlight the integration of technology in sourcing and manufacturing processes. Advanced manufacturing techniques, such as 3D printing and automation, are streamlining production, allowing for customization and rapid prototyping. Furthermore, the rise of e-commerce platforms is transforming how B2B buyers source products, making it easier to compare prices, quality, and supplier reliability across international markets. This digital shift is essential for buyers looking to make informed decisions while navigating the complexities of global supply chains.

Illustrative image related to bracket for metal pole

Additionally, sustainability is becoming a significant factor in purchasing decisions. Many international buyers are prioritizing suppliers that offer eco-friendly materials and sustainable manufacturing processes, reflecting a broader commitment to responsible sourcing practices.

How Important Is Sustainability and Ethical Sourcing in the Bracket for Metal Pole Sector?

Sustainability and ethical sourcing are increasingly critical in the B2B landscape for metal pole brackets. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are now more conscious of the ecological footprint of their purchases and are actively seeking suppliers that utilize sustainable practices.

For instance, companies are adopting materials with lower environmental impacts, such as recycled metals or sustainably sourced raw materials. Certifications such as ISO 14001 (Environmental Management) or LEED (Leadership in Energy and Environmental Design) are becoming essential benchmarks for buyers looking to verify the sustainability claims of their suppliers. These certifications not only help in minimizing environmental impact but also enhance the brand image of companies committed to sustainability.

Moreover, ethical supply chains are gaining traction, with buyers demanding transparency and accountability from their suppliers. This shift underscores the importance of robust supply chain management that prioritizes fair labor practices and responsible sourcing. In a competitive marketplace, companies that can demonstrate their commitment to sustainability and ethical sourcing are more likely to attract and retain B2B clients.

What Is the Evolution of the Bracket for Metal Pole Sector?

The bracket for metal pole sector has evolved significantly over the past few decades. Initially, brackets were primarily functional, designed to hold poles securely in place without much consideration for aesthetics or material innovation. As the demand for more versatile and durable solutions grew, manufacturers began to experiment with various materials and designs to enhance performance.

The introduction of advanced materials, such as corrosion-resistant alloys and high-strength plastics, has transformed the durability and lifespan of metal pole brackets. Furthermore, the digitalization of the supply chain has enabled greater customization and rapid response to market demands, allowing businesses to adapt quickly to changing consumer preferences.

In recent years, the focus has shifted towards integrating sustainability into the product development process. As awareness of environmental issues has increased, manufacturers have started to prioritize eco-friendly practices, from sourcing materials to production methods, shaping a more responsible industry. This evolution reflects broader societal changes and highlights the importance of aligning business practices with sustainable development goals.

Frequently Asked Questions (FAQs) for B2B Buyers of bracket for metal pole

-

How do I select the right bracket for metal poles?

Choosing the right bracket for metal poles involves considering several factors, including pole diameter, intended use (e.g., signage, lighting, or structural support), and environmental conditions (like wind or snow loads). It’s essential to match the bracket’s specifications with your pole’s dimensions and the load it must support. Additionally, assess the material quality, as galvanized or powder-coated options may offer better durability against corrosion, especially in humid or coastal environments. -

What are the common materials used for metal pole brackets?

Metal pole brackets are typically made from materials such as stainless steel, aluminum, and galvanized steel. Stainless steel is known for its corrosion resistance and strength, making it ideal for outdoor applications. Aluminum is lightweight and rust-resistant, suitable for portable setups. Galvanized steel offers a balance of strength and cost-effectiveness, often used in commercial and industrial settings. When selecting materials, consider the environmental factors where the brackets will be installed. -

What customization options are available for metal pole brackets?

Many suppliers offer customization options for metal pole brackets, including sizes, shapes, and finishes. Customization may also extend to specific load capacities and installation features. When inquiring about customization, provide detailed specifications regarding your application needs. Additionally, ask about lead times for custom orders, as they may differ from standard products, impacting your project timelines. -

What are typical minimum order quantities (MOQs) for metal pole brackets?

Minimum order quantities can vary widely based on the supplier and the type of bracket. Generally, MOQs may range from a few dozen to several hundred units for standard products. For custom designs, MOQs might be higher due to setup costs. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that align with your project requirements, especially if you are testing a new product. -

How do I ensure quality assurance when sourcing metal pole brackets internationally?

To ensure quality assurance when sourcing internationally, conduct thorough supplier vetting by checking certifications, previous client reviews, and factory audits. Request samples before placing large orders to evaluate the product quality firsthand. Additionally, consider using third-party inspection services to assess the goods before shipment. Establish clear quality control standards and communicate them to your supplier to minimize discrepancies. -

What payment terms are typically available for international purchases of metal pole brackets?

Payment terms for international purchases can vary widely among suppliers. Common options include advance payment, letter of credit, or payment upon delivery. Some suppliers may offer net 30 or net 60 terms for established buyers. It’s crucial to clarify payment terms upfront and ensure they align with your cash flow needs. Additionally, inquire about currency options to avoid exchange rate fluctuations that could affect costs. -

What logistics considerations should I be aware of when importing metal pole brackets?

Logistics considerations include shipping methods (air vs. sea), customs regulations, and lead times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Ensure compliance with import regulations in your country, including tariffs and necessary documentation. Collaborate with a reliable freight forwarder who understands the complexities of international shipping to streamline the process. -

How can I address potential delays in the supply chain for metal pole brackets?

To mitigate potential delays in the supply chain, maintain open communication with your suppliers and logistics partners. Establish buffer stock levels to accommodate unexpected demand fluctuations or supply interruptions. Implement a contingency plan that includes alternative suppliers or products. Regularly review your supply chain processes to identify bottlenecks and improve efficiency, helping to minimize the impact of delays on your projects.

Top 1 Bracket For Metal Pole Manufacturers & Suppliers List

1. Renzel – Indoor/Outdoor Pole Mounting Bracket Kit

Domain: renzelusa.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Indoor/Outdoor Pole Mounting Bracket Kit”, “product_number”: “20793”, “base_price”: “$70.27”, “material”: “Aluminum / Stainless Steel”, “diameter_range”: “3” thru 16″”, “band_length”: “52””, “features”: [“Includes two steel zip ties”, “Sign mounting brackets for snap frames”, “Suitable for indoor and outdoor use”, “Durable support against wind and vibrations”, “Easy installation …

Strategic Sourcing Conclusion and Outlook for bracket for metal pole

In navigating the complex landscape of sourcing brackets for metal poles, international buyers must prioritize strategic partnerships that enhance supply chain efficiency and product quality. The diverse applications of these brackets—from construction to event management—demand a thorough understanding of local market needs and regulatory standards. By focusing on suppliers that offer customization and robust support, buyers can ensure that they acquire solutions tailored to their specific requirements.

Furthermore, leveraging digital platforms for sourcing can streamline procurement processes, enabling buyers to compare products and negotiate better terms. As the global market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, maintaining agility in sourcing strategies will be crucial.

Looking ahead, the demand for innovative and sustainable solutions in bracket design and manufacturing is expected to rise. International buyers are encouraged to stay ahead of trends by fostering relationships with forward-thinking suppliers. By doing so, they not only enhance their operational capabilities but also contribute to a more sustainable future in infrastructure development. Engage with your suppliers today to explore how strategic sourcing can transform your business landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.