Tinsel Wire Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for tinsel wire

In today’s competitive landscape, sourcing high-quality tinsel wire can be a daunting challenge for international B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe. As industries increasingly demand flexible, durable, and efficient wiring solutions, understanding the nuances of tinsel wire becomes essential for businesses looking to enhance their products and operations. This comprehensive guide addresses the key aspects of tinsel wire, from its unique properties and diverse applications to strategic supplier vetting and cost considerations.

Throughout this guide, readers will gain insights into the various types of tinsel wire available, including specifications tailored for specific uses in electronics, telecommunications, medical devices, and more. We will also discuss the critical factors to evaluate when selecting suppliers, such as reliability, quality certifications, and customer support. Furthermore, we will provide an analysis of market trends that could impact pricing and availability, empowering buyers to make informed purchasing decisions that align with their operational needs.

By leveraging the knowledge shared in this guide, B2B buyers can navigate the global market for tinsel wire with confidence, ensuring they procure the best materials for their projects while fostering successful partnerships with suppliers. Embrace the transformative potential of tinsel wire to elevate your business offerings and stay ahead in an ever-evolving marketplace.

Understanding tinsel wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Tinsel Wire | Made from copper or aluminum strands; high flexibility | Electronics, small appliances, audio systems | Pros: Excellent flexibility; Cons: Limited current capacity |

| Braided Tinsel Wire | Features braided strands for enhanced strength | Speaker systems, telecommunications | Pros: Enhanced durability; Cons: More complex manufacturing process |

| Silver-Plated Tinsel Wire | Copper wire coated with silver for improved conductivity | High-end audio equipment, medical devices | Pros: Superior conductivity; Cons: Higher cost |

| Flat Tinsel Wire | Flat cross-section for optimized space usage | Robotics, aerospace applications | Pros: Space-efficient; Cons: Limited in flexibility compared to round wires |

| Multi-Core Tinsel Wire | Contains multiple cores for enhanced signal transmission | High-performance electronics, automotive systems | Pros: Improved signal integrity; Cons: More expensive to produce |

What Are the Key Characteristics of Standard Tinsel Wire?

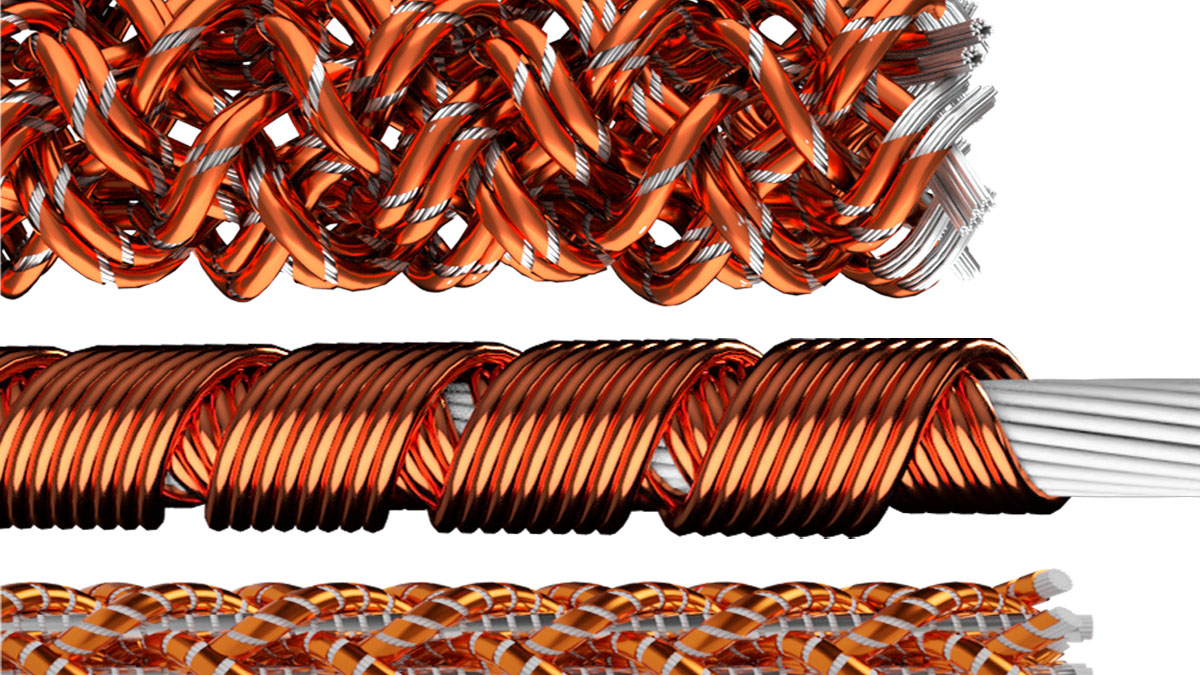

Standard tinsel wire is primarily composed of copper or aluminum strands twisted together to create a highly flexible and durable product. This type is suitable for various applications, including electronics and small appliances where movement and flexibility are essential. Buyers should consider the wire’s current carrying capacity and ensure it aligns with their specific application requirements.

How Does Braided Tinsel Wire Enhance Durability?

Braided tinsel wire features strands that are intricately woven together, providing exceptional strength and resistance to wear and tear. This makes it an ideal choice for speaker systems and telecommunications, where reliability is crucial. When purchasing, B2B buyers should focus on the braid’s material and thickness to ensure it meets the demands of high-stress environments.

Why Choose Silver-Plated Tinsel Wire for High-End Applications?

Silver-plated tinsel wire combines a copper core with a silver coating, significantly enhancing its conductivity. This type is particularly favored in high-end audio equipment and medical devices where signal integrity is paramount. Buyers should weigh the benefits of improved performance against the higher cost associated with silver-plated options.

Illustrative image related to tinsel wire

What Are the Advantages of Using Flat Tinsel Wire?

Flat tinsel wire is designed with a flat cross-section, optimizing space in tight configurations, making it ideal for applications in robotics and aerospace. While it offers space-saving advantages, buyers must consider its reduced flexibility compared to traditional round tinsel wires, which may impact certain applications.

How Does Multi-Core Tinsel Wire Improve Signal Transmission?

Multi-core tinsel wire consists of several cores working together to enhance signal transmission and reduce interference, making it suitable for high-performance electronics and automotive systems. Buyers should evaluate the number of cores and their arrangement to ensure optimal performance for their specific applications.

Key Industrial Applications of tinsel wire

| Industry/Sector | Specific Application of tinsel wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Wiring for telephones and communication devices | Ensures reliable connectivity and clear audio transmission | Look for durability, flexibility, and resistance to fatigue |

| Consumer Electronics | Power cords for small appliances like shavers and clocks | Enhances product lifespan and user convenience | Prioritize lightweight materials and flexible designs |

| Medical Equipment | Wiring in ultrasound probes and monitoring devices | Guarantees precision and reliability in critical applications | Ensure compliance with medical standards and low failure rates |

| Robotics and Automation | Cables for robotic systems and automation machinery | Supports dynamic movements and high-performance requirements | Focus on flexibility and resilience under stress |

| Audio Systems | Speaker tinsel lead wires for sound systems | Improves sound quality and durability in audio applications | Consider conductivity, flexibility, and insulation properties |

How is Tinsel Wire Used in Telecommunications?

In the telecommunications industry, tinsel wire is integral for wiring telephones and communication devices. Its exceptional flexibility allows for seamless installation in various configurations, while its durability ensures long-lasting performance in high-use environments. For international buyers, particularly in regions like Africa and South America, sourcing tinsel wire that can withstand environmental challenges such as humidity and temperature fluctuations is crucial. Ensuring the wire has resistance to metal fatigue will further enhance reliability in communication systems, fostering uninterrupted connectivity.

What Role Does Tinsel Wire Play in Consumer Electronics?

Tinsel wire is commonly utilized in power cords for small appliances, such as electric shavers and clocks. Its lightweight and flexible nature not only enhances user convenience but also reduces the overall weight of the appliances, making them easier to handle. For B2B buyers in the consumer electronics sector, particularly in Europe and the Middle East, it is essential to source tinsel wire that meets specific safety standards while ensuring long-term durability. This helps in minimizing product returns and enhancing customer satisfaction.

Why is Tinsel Wire Important in Medical Equipment?

In medical applications, tinsel wire is employed in ultrasound probes and other critical monitoring devices. The wire’s flexibility and low failure rate are paramount, ensuring precision and reliability in patient care. For international buyers in the medical sector, compliance with stringent regulatory standards is a key consideration. Tinsel wire must not only provide exceptional performance but also adhere to safety and biocompatibility standards, making it a vital component in healthcare technology.

How Does Tinsel Wire Support Robotics and Automation?

In robotics and automation, tinsel wire is essential for connecting power and signals within dynamic systems. Its ability to endure high levels of movement and stress makes it ideal for applications where flexibility and resilience are required. For buyers in industries focused on automation, sourcing tinsel wire that can withstand the rigors of robotic applications is critical. This includes ensuring that the wire maintains conductivity and performance over time, which is vital for operational efficiency and reliability.

What Advantages Does Tinsel Wire Offer in Audio Systems?

Tinsel wire is crucial in audio systems, specifically as speaker tinsel lead wires that connect voice coils to terminals. This application enhances sound quality by improving signal transmission and reducing distortion. For B2B buyers in the audio equipment industry, particularly in regions such as Europe and the Middle East, it is important to consider the wire’s flexibility and durability to ensure optimal audio performance. Additionally, sourcing high-quality tinsel wire that meets industry standards can significantly elevate the overall audio experience for end-users.

3 Common User Pain Points for ‘tinsel wire’ & Their Solutions

Scenario 1: Challenges with Wire Flexibility in Tight Spaces

The Problem: B2B buyers often encounter difficulties when integrating wiring solutions into compact designs, especially in sectors like consumer electronics and medical devices. Tinsel wire, while known for its exceptional flexibility, may still pose challenges in applications with extremely tight spaces or intricate layouts. Buyers may experience frustration as traditional wiring options fail to fit or require excessive strain, leading to potential failures or reduced lifespan of the products.

The Solution: To mitigate these challenges, buyers should leverage the unique structural properties of tinsel wire by choosing the appropriate gauge and insulation type for their specific applications. Prior to procurement, conducting a detailed assessment of the design specifications is crucial. This includes evaluating the bending radius and the overall length required for the installation. By selecting thinner tinsel wire with a flexible insulating jacket, buyers can ensure that the wire can navigate tight corners and maintain optimal performance without compromising on durability. Additionally, consulting with manufacturers about custom solutions tailored to specific dimensions can further enhance integration into complex designs.

Scenario 2: Concerns Over Wire Durability in High-Stress Environments

The Problem: Industries such as aerospace, automotive, and medical equipment manufacturing require wiring solutions that can withstand extreme conditions, including high stress, vibrations, and temperature fluctuations. Buyers often find that traditional wiring materials suffer from metal fatigue, leading to failures that can compromise safety and performance. The challenge lies in sourcing a wire that not only meets the required specifications but also offers long-term reliability in demanding applications.

The Solution: Buyers should prioritize tinsel wire with enhanced durability features, such as those specifically designed for high-stress applications. When sourcing, look for products that emphasize resistance to metal fatigue and include robust insulation options. It’s essential to request detailed performance data from suppliers, including tensile strength and thermal resistance ratings. Establishing a close relationship with manufacturers can also facilitate access to the latest innovations in tinsel wire technology, ensuring that you are using the most advanced materials available. Implementing rigorous testing protocols during the design phase can further safeguard against potential failures in real-world applications.

Scenario 3: Difficulty in Achieving Optimal Electrical Conductivity

The Problem: In applications that demand high-speed data transfer or superior audio quality, such as telecommunications and audio equipment, achieving optimal electrical conductivity is paramount. Buyers may struggle with tinsel wire options that do not provide adequate conductivity, resulting in signal loss, increased distortion, and overall performance degradation. This challenge can lead to dissatisfaction among end-users and diminish the reputation of the buyer’s products.

The Solution: To ensure the highest level of electrical conductivity, buyers should focus on the composition and configuration of the tinsel wire they select. Opt for tinsel wires made from high-purity copper or silver, as these materials significantly enhance conductivity. Additionally, consider the number of strands and the overall thickness of the wire; a larger surface area can improve conductivity. Engaging with suppliers who offer custom braid configurations can also lead to more efficient designs tailored to specific conductivity requirements. Implementing a thorough testing regimen to evaluate signal integrity during the development phase will help ensure that the chosen tinsel wire meets the necessary performance benchmarks before mass production.

Strategic Material Selection Guide for tinsel wire

What are the Key Materials Used in Tinsel Wire Production?

Tinsel wire is primarily composed of various conductive materials, each offering unique properties that cater to specific application needs. Below, we analyze four common materials used in the production of tinsel wire: copper, aluminum, silver, and nickel. Each material’s characteristics, advantages, disadvantages, and implications for international B2B buyers are discussed.

How Does Copper Influence Tinsel Wire Performance?

Copper is the most widely used material for tinsel wire due to its excellent electrical conductivity and mechanical properties. It typically has a temperature rating of up to 200°C and exhibits good resistance to corrosion, particularly when coated.

Pros: Copper’s high conductivity ensures minimal energy loss, making it ideal for audio applications and electronic devices. Its durability and flexibility allow it to withstand repeated bending without breaking.

Illustrative image related to tinsel wire

Cons: The primary drawback of copper is its cost, which can be high compared to other materials. Additionally, copper is susceptible to oxidation, potentially affecting performance over time.

Impact on Application: Copper tinsel wire is highly compatible with various media, including audio signals and electrical currents, making it suitable for consumer electronics and medical devices.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM and JIS, as well as consider the availability of copper in the local market.

What Role Does Aluminum Play in Tinsel Wire?

Aluminum is another popular choice for tinsel wire, particularly in applications where weight reduction is crucial. It has a temperature rating similar to copper but is less resistant to corrosion unless treated.

Pros: Aluminum is lightweight, making it ideal for portable devices. It is also more cost-effective than copper, providing a budget-friendly alternative for manufacturers.

Cons: While aluminum has decent conductivity, it is not as efficient as copper, which may lead to higher resistance and energy loss in certain applications. Its mechanical properties can also be less robust, making it less suitable for high-stress environments.

Impact on Application: Aluminum tinsel wire is often used in consumer electronics and automotive applications, where weight savings are paramount.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades that meet international standards and ensure they are sourcing from reliable suppliers to avoid quality issues.

How Does Silver Enhance Tinsel Wire Quality?

Silver is known for its superior conductivity, making it an excellent choice for high-performance applications. It has a temperature rating similar to copper and exhibits excellent corrosion resistance.

Pros: The key advantage of silver tinsel wire is its exceptional conductivity, which can enhance audio quality and signal transmission in high-end electronic devices.

Cons: Silver is significantly more expensive than both copper and aluminum, which can limit its use in cost-sensitive applications. Additionally, it can tarnish over time, potentially affecting performance.

Impact on Application: Silver tinsel wire is particularly beneficial in high-fidelity audio systems and specialized medical devices where performance is critical.

Considerations for International Buyers: Buyers should consider the cost-benefit ratio when choosing silver and ensure compliance with relevant standards, particularly in regions with stringent regulations.

What Advantages Does Nickel Offer in Tinsel Wire?

Nickel is often used as a coating for other materials, enhancing their corrosion resistance. It has a moderate temperature rating and is resistant to oxidation.

Illustrative image related to tinsel wire

Pros: Nickel-coated tinsel wire offers improved durability and resistance to environmental factors, making it suitable for outdoor applications.

Cons: While nickel improves corrosion resistance, it does not provide the same level of conductivity as copper or silver, which may limit its use in high-performance applications.

Impact on Application: Nickel tinsel wire is commonly used in applications exposed to harsh environments, such as outdoor lighting and industrial equipment.

Considerations for International Buyers: Buyers should ensure that nickel-coated wires meet local compliance standards, particularly in regions with specific regulations regarding metal coatings.

Summary of Material Selection for Tinsel Wire

| Material | Typical Use Case for tinsel wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Audio systems, medical devices | High conductivity | High cost, oxidation susceptibility | High |

| Aluminum | Portable electronics, automotive | Lightweight and cost-effective | Lower conductivity, less durable | Medium |

| Silver | High-fidelity audio, medical applications | Superior conductivity | Very high cost, tarnishing issues | High |

| Nickel | Outdoor lighting, industrial equipment | Corrosion resistance | Lower conductivity | Medium |

This analysis provides B2B buyers with a comprehensive understanding of the materials used in tinsel wire production, helping them make informed decisions based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for tinsel wire

What Are the Key Stages in the Manufacturing Process of Tinsel Wire?

The manufacturing process of tinsel wire involves several critical stages that ensure the final product meets industry standards for flexibility, conductivity, and durability. Understanding these stages is essential for B2B buyers looking to procure high-quality tinsel wire.

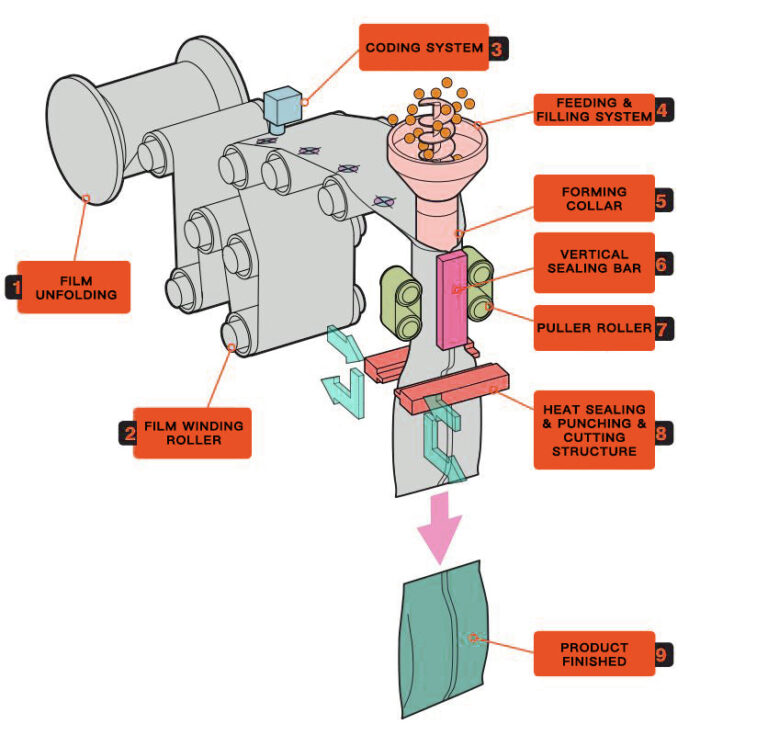

1. Material Preparation

The manufacturing journey begins with the selection of raw materials. Tinsel wire is primarily made from conductive metals such as copper or aluminum. The raw metal is sourced in the form of thin rods or wires, which are then cleaned and treated to remove impurities. This step is crucial, as any contaminants can affect the conductivity and performance of the final product.

2. Forming

In the forming stage, the prepared metal is processed into thin strands. This is typically achieved through a series of drawing operations, where the metal is pulled through progressively smaller dies to achieve the desired diameter. The forming stage may also include the twisting of these strands together, which enhances flexibility and strength. The intertwining technique used in tinsel wire production allows for the creation of a robust yet highly flexible wire, essential for applications where bending and movement are frequent.

3. Assembly

Once the strands are formed, they are assembled around a flexible core. This core can be made from various materials, depending on the specific application requirements. The assembly process involves wrapping the thin metal strands around the core in a specific pattern to maximize flexibility while ensuring structural integrity. This stage may also include the application of an insulating jacket, which protects the wire from environmental factors and prevents short circuits.

4. Finishing

The finishing stage involves several processes aimed at enhancing the wire’s performance and appearance. This may include coating the wire with additional layers of insulation or protective materials. The finished tinsel wire is then cut to length, spooled, and prepared for packaging. Quality checks are integrated throughout this stage to ensure that the wire meets the specified dimensions and performance characteristics.

How Is Quality Assurance Implemented in Tinsel Wire Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final product meets both international standards and customer expectations. For B2B buyers, understanding the QA process is essential for verifying product reliability.

1. What International Standards Are Relevant for Tinsel Wire Quality?

Tinsel wire manufacturers often adhere to several international quality standards, such as ISO 9001, which focuses on effective quality management systems. Compliance with ISO standards indicates that the manufacturer has established processes to ensure consistent quality in their products.

Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the intended application of the tinsel wire. These certifications demonstrate that the wire meets the necessary safety and performance requirements for specific sectors, such as telecommunications or medical devices.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated at multiple stages of the manufacturing process. Key QC checkpoints include:

Illustrative image related to tinsel wire

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is performed to detect any deviations from quality standards. This may involve testing for flexibility, conductivity, and structural integrity at various stages.

-

Final Quality Control (FQC): After the tinsel wire has been finished, a comprehensive inspection is conducted. This includes testing the wire’s electrical properties, mechanical strength, and overall appearance.

3. What Common Testing Methods Are Used for Tinsel Wire?

Various testing methods are employed to ensure the quality of tinsel wire, including:

-

Electrical Conductivity Testing: This test measures how well the wire conducts electricity, which is vital for applications requiring high-speed data transfer.

-

Flexibility Testing: The wire’s ability to bend without breaking is assessed through standardized bending tests.

-

Mechanical Strength Testing: This evaluates the tensile strength and durability of the wire under stress.

-

Visual Inspection: A thorough visual examination is conducted to identify any defects in insulation or the wire’s surface.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, ensuring supplier reliability is paramount. Here are several strategies to verify a supplier’s quality control processes:

1. Conduct Supplier Audits

Requesting an audit of the manufacturing facility can provide valuable insights into the supplier’s quality management systems. During an audit, buyers can assess compliance with international standards, observe QC practices, and evaluate overall production capabilities.

2. Review Quality Control Reports

Ask for detailed QC reports that outline the testing methods used, results obtained, and any corrective actions taken for non-conforming products. This transparency can help build trust in the supplier’s commitment to quality.

3. Engage Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can conduct random checks and provide reports on the quality of the tinsel wire produced.

What Are the Quality Certification Nuances for International Buyers?

When sourcing tinsel wire internationally, buyers should be aware of specific quality certification nuances:

-

Regional Standards Compliance: Different regions may have varying compliance requirements. For example, CE marking is crucial for products sold within the European Union, while other certifications may apply in South America or Africa. Understanding these regional differences is essential for compliance and market entry.

-

Documentation Requirements: Ensure that all necessary documentation, including certificates of compliance and quality assurance reports, are provided by the supplier. This documentation is vital for customs clearance and may be required for local regulations.

-

Traceability: Establishing traceability in the supply chain is critical. Buyers should ensure that suppliers can trace the origin of materials and components used in the manufacturing process, which is particularly important for compliance with international quality standards.

By understanding the manufacturing processes and quality assurance measures for tinsel wire, B2B buyers can make informed decisions and select suppliers that meet their rigorous standards. This diligence not only enhances product reliability but also fosters long-term partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tinsel wire’

To assist B2B buyers in the procurement of tinsel wire, this practical sourcing guide provides a structured checklist designed to streamline the purchasing process. The goal is to ensure buyers make informed decisions that align with their technical requirements and business objectives.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your tinsel wire. This includes factors such as material composition (e.g., copper, silver), wire diameter, flexibility requirements, and insulation type. Having precise specifications ensures that you can communicate effectively with suppliers and receive products that meet your operational needs.

Illustrative image related to tinsel wire

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of tinsel wire. Utilize online platforms, industry directories, and trade shows to compile a list of reputable manufacturers. Look for suppliers with a proven track record in your industry and positive reviews from other B2B clients, particularly in your region.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify the certifications and standards compliance of potential suppliers. Ensure they meet international quality standards, such as ISO certifications, which can indicate a commitment to quality and reliability. This step is crucial to mitigate risks associated with product failure and ensure long-term performance in your applications.

Step 4: Request Samples for Testing

To assess the quality of tinsel wire, request samples from shortlisted suppliers. Testing samples allows you to evaluate critical attributes such as flexibility, conductivity, and durability under stress. This hands-on approach can help identify the best fit for your specific applications and reduce the likelihood of costly errors.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms with potential suppliers. Understanding the total cost of ownership, including shipping and duties, will help you make informed financial decisions. Additionally, negotiate terms that align with your cash flow requirements to facilitate smoother transactions.

Step 6: Assess Lead Times and Delivery Options

Inquire about lead times and delivery options to ensure the suppliers can meet your project timelines. Reliable delivery schedules are essential for maintaining production schedules and meeting customer demands. Confirm that suppliers have robust logistics in place to handle international shipping, especially if you are sourcing from different continents.

Step 7: Establish a Communication Plan

Once you’ve selected a supplier, establish a clear communication plan to facilitate ongoing dialogue throughout the sourcing process. Regular check-ins can help address any concerns promptly and maintain transparency. A solid communication strategy fosters a strong relationship, enhancing collaboration and responsiveness to any changes or issues that may arise.

By following this checklist, B2B buyers can navigate the complexities of sourcing tinsel wire effectively, ensuring they secure high-quality products that meet their technical and operational requirements.

Comprehensive Cost and Pricing Analysis for tinsel wire Sourcing

What Are the Key Cost Components in Tinsel Wire Manufacturing?

Understanding the cost structure of tinsel wire is crucial for B2B buyers looking to make informed purchasing decisions. The primary cost components include:

-

Materials: Tinsel wire is typically made from copper or other conductive metals, which can fluctuate in price due to market demand and availability. The choice of materials directly affects both performance and cost.

-

Labor: Labor costs encompass the wages paid to workers involved in the production process. Skilled labor may be required for the intricate manufacturing techniques involved in creating tinsel wire, impacting overall costs.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help mitigate these overhead costs.

-

Tooling: The initial investment in specialized tools and machinery for tinsel wire production can be significant. This cost is usually amortized over large production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Ensuring that the tinsel wire meets industry standards requires rigorous QC processes. Costs associated with testing and certification can vary depending on the quality and specifications required.

-

Logistics: Transportation and handling costs play a critical role, especially for international shipments. The choice of shipping methods and distances traveled can significantly affect the final price.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. This margin can vary widely depending on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Impact Tinsel Wire Costs?

Several factors can influence the pricing of tinsel wire for international buyers:

-

Volume/MOQ: The minimum order quantity (MOQ) often affects pricing. Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should consider consolidating orders to meet MOQs to take advantage of bulk pricing.

-

Specifications and Customization: Custom specifications, such as specific wire gauges or insulation types, can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials: The choice between standard and premium materials can influence pricing. For instance, silver-plated copper tinsel wire may cost more than standard copper due to enhanced performance characteristics.

-

Quality and Certifications: High-quality standards and relevant certifications (e.g., ISO, RoHS) may increase costs but can provide assurance of reliability, especially in critical applications like medical devices.

-

Supplier Factors: Supplier reputation, service quality, and geographic location also play a role in pricing. Established suppliers with proven track records may charge more due to their reliability.

-

Incoterms: Understanding Incoterms is essential for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of goods.

What Tips Can Help Buyers Negotiate Better Prices for Tinsel Wire?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Leverage Total Cost of Ownership (TCO): Evaluate the long-term costs associated with tinsel wire, including installation, maintenance, and potential replacements. This broader perspective can justify a higher upfront investment in quality products.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to more favorable pricing and terms. Consider long-term contracts or partnerships to secure better rates.

-

Be Transparent About Needs: Clearly communicate your requirements and expectations to suppliers. This can help avoid misunderstandings and additional costs related to customization.

-

Explore Multiple Suppliers: Don’t settle for the first quote. Comparing offers from multiple suppliers can provide leverage in negotiations and lead to better pricing.

-

Stay Informed About Market Trends: Awareness of raw material price trends, technological advancements, and geopolitical factors can provide insights that enhance negotiation power.

Disclaimer on Indicative Prices

Prices for tinsel wire can vary significantly based on the aforementioned factors and market conditions. The information provided is intended for general guidance and should not be considered as fixed pricing. Buyers are encouraged to conduct thorough market research and engage directly with suppliers for accurate and current pricing information.

Alternatives Analysis: Comparing tinsel wire With Other Solutions

Introduction to Alternative Wiring Solutions

In the competitive landscape of B2B wiring solutions, selecting the right material is crucial for optimizing performance, cost, and application suitability. Tinsel wire stands out for its exceptional flexibility and conductivity, but several alternatives also exist. This analysis provides a comparative overview of tinsel wire against two viable alternatives: stranded copper wire and solid copper wire. Each option brings unique advantages and challenges, which can significantly impact decision-making for international buyers.

Comparison Table

| Comparison Aspect | Tinsel Wire | Stranded Copper Wire | Solid Copper Wire |

|---|---|---|---|

| Performance | High flexibility and conductivity | Good flexibility, moderate conductivity | High conductivity, low flexibility |

| Cost | Moderate to high | Moderate | Generally lower |

| Ease of Implementation | Easy to install in tight spaces | Requires careful handling | Straightforward installation |

| Maintenance | Low maintenance, resistant to fatigue | Moderate maintenance due to wear | Low maintenance, durable |

| Best Use Case | Electronics, audio systems, robotics | General wiring, automotive applications | Power transmission, permanent installations |

Detailed Breakdown of Alternatives

Stranded Copper Wire

Stranded copper wire consists of multiple small wires twisted together, providing flexibility while maintaining a decent level of conductivity. This wire type is widely used in various applications, including automotive and general electrical wiring. The primary advantage of stranded wire is its flexibility, making it easier to route in tight spaces compared to solid wire. However, it may require more careful handling to avoid wear and tear, leading to moderate maintenance needs. While its cost is generally moderate, it may not match the performance of tinsel wire in applications demanding high flexibility and low fatigue.

Solid Copper Wire

Solid copper wire features a single, solid conductor, making it an excellent choice for applications requiring high conductivity, such as power transmission. Its primary advantage lies in its durability and lower cost compared to other wiring solutions. Solid wire is straightforward to install and requires minimal maintenance, making it appealing for long-term installations. However, its rigidity limits its use in flexible applications, and it may not perform as well in environments where frequent movement or bending occurs. This inflexibility can lead to breakage under stress, which is a critical consideration for buyers in dynamic applications.

Conclusion: Choosing the Right Wiring Solution for Your Needs

Selecting the appropriate wiring solution involves assessing your specific requirements in terms of performance, cost, and application. Tinsel wire excels in environments demanding flexibility and durability, making it ideal for electronics and audio systems. In contrast, stranded copper wire offers a balance of flexibility and cost-effectiveness, suitable for general wiring tasks. Solid copper wire, while less flexible, provides superior conductivity and durability for fixed installations. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their operational needs and project specifications, ultimately leading to enhanced performance and reliability in their applications.

Essential Technical Properties and Trade Terminology for tinsel wire

What Are the Key Technical Properties of Tinsel Wire?

Understanding the technical specifications of tinsel wire is crucial for B2B buyers aiming to make informed purchasing decisions. Below are several critical properties that define tinsel wire’s performance and suitability for various applications.

1. Material Composition

Tinsel wire is primarily composed of thin metal threads, most commonly copper or aluminum, which are known for their excellent conductivity. The choice of material affects not only the wire’s electrical performance but also its weight and flexibility. Copper tinsel wire, for instance, offers superior conductivity, making it ideal for high-performance audio and communication applications.

2. Flexibility and Bend Radius

One of the standout features of tinsel wire is its exceptional flexibility. This characteristic is quantified by its bend radius, which indicates how tightly the wire can be bent without damaging its structure. A smaller bend radius is essential for applications requiring tight routing in confined spaces, such as in portable devices and intricate electronic systems.

3. Electrical Resistance

Electrical resistance is a critical specification that affects the wire’s conductivity and overall efficiency. Tinsel wire is designed to have low electrical resistance, ensuring minimal energy loss during transmission. This property is particularly important in high-speed data applications, where even slight resistance can lead to performance degradation.

4. Durability and Fatigue Resistance

Tinsel wire exhibits remarkable durability, characterized by its resistance to metal fatigue. This property is vital for applications that involve frequent movement or bending, as it reduces the likelihood of wire failure over time. A durable wire ensures long-term reliability, which is a significant consideration for manufacturers looking to minimize maintenance costs.

5. Insulation Type

The insulation surrounding tinsel wire can vary, impacting its performance in specific environments. Common insulation materials include PVC and rubber, each offering different levels of heat resistance, flexibility, and environmental protection. Understanding the insulation type is essential for ensuring that the wire can withstand the conditions it will face in its intended application.

6. Gauge and Diameter

The gauge or diameter of tinsel wire determines its current-carrying capacity and is an essential factor for compliance with industry standards. A thicker wire generally supports higher current levels, making it suitable for applications requiring robust electrical performance. Buyers should consider the required gauge based on the electrical demands of their specific use case.

Illustrative image related to tinsel wire

What Are Common Trade Terminology and Jargon for Tinsel Wire?

Navigating the procurement process involves understanding industry-specific terminology. Here are several terms frequently encountered in the tinsel wire market.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. In the context of tinsel wire, understanding OEM relationships can help buyers identify reliable suppliers who meet specific quality and performance standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory planning and cost management. Knowing the MOQ helps businesses evaluate whether a supplier can meet their purchasing needs without incurring excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific quantities and specifications of products. For tinsel wire, submitting an RFQ allows buyers to compare costs and negotiate terms, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk, and delivery timelines associated with purchasing tinsel wire from different countries.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the tinsel wire industry, understanding lead times is essential for effective supply chain management and project planning, particularly when working on tight schedules.

6. Customization

Customization in the context of tinsel wire refers to the ability to tailor specifications, such as length, gauge, and insulation type, to meet specific application requirements. Buyers should inquire about customization options to ensure the wire meets their unique needs and standards.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring they select the right tinsel wire for their applications.

Navigating Market Dynamics and Sourcing Trends in the tinsel wire Sector

What Are the Current Market Trends Impacting the Tinsel Wire Sector?

The tinsel wire market is experiencing robust growth driven by several global factors. The increasing demand for lightweight and flexible wiring solutions in sectors such as consumer electronics, automotive, and healthcare is a primary catalyst. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly drawn to tinsel wire’s adaptability and durability, which enhance product performance in diverse applications. Additionally, advancements in manufacturing technologies are enabling suppliers to produce high-quality tinsel wire at competitive prices, making it more accessible to businesses in emerging markets.

Emerging trends include the integration of smart technologies and automation in production processes, which enhance efficiency and reduce costs. As industries increasingly adopt IoT devices, the need for superior connectivity solutions, such as tinsel wire, will grow. Furthermore, the trend towards miniaturization in electronics is pushing for thinner and more flexible wiring options, aligning perfectly with the properties of tinsel wire. B2B buyers should keep an eye on these technological advancements as they can influence sourcing strategies and partnerships.

How Is Sustainability and Ethical Sourcing Shaping the Tinsel Wire Market?

Sustainability has become a crucial consideration in the tinsel wire sector, as environmental impacts and ethical sourcing practices gain prominence among B2B buyers. The production of tinsel wire typically involves metals like copper, which pose significant environmental concerns if not sourced responsibly. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing, ensuring that raw materials are obtained through environmentally sound practices.

Moreover, the demand for ‘green’ certifications is on the rise. Certifications such as ISO 14001 (Environmental Management) and Responsible Business Alliance (RBA) standards help buyers identify suppliers that adhere to sustainable practices. Additionally, there is a growing interest in alternative materials that offer similar properties to traditional tinsel wire while minimizing environmental impact. These materials could include recycled metals or composites designed for lower carbon footprints. B2B buyers should actively seek suppliers that prioritize sustainability in their operations to align with global trends and consumer expectations.

Illustrative image related to tinsel wire

How Has Tinsel Wire Evolved Over the Years?

The evolution of tinsel wire can be traced back to the need for more flexible and durable wiring solutions in various industries. Originally developed for use in telecommunication systems, tinsel wire quickly gained popularity due to its ability to withstand repeated bending and twisting without compromising conductivity. Over the years, advancements in material science have led to the incorporation of high-quality metals and innovative manufacturing techniques, further enhancing the performance characteristics of tinsel wire.

Today, tinsel wire is widely used in applications ranging from consumer electronics to aerospace, reflecting its adaptability and reliability. As market demands continue to shift towards high-performance and sustainable solutions, the ongoing evolution of tinsel wire technology will likely play a critical role in meeting the needs of modern industries. B2B buyers should remain informed about these developments to leverage the benefits of cutting-edge tinsel wire solutions in their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of tinsel wire

-

How do I choose the right tinsel wire for my application?

Choosing the right tinsel wire involves assessing your specific application requirements, such as flexibility, conductivity, and environmental conditions. Consider the intended use—whether for audio systems, medical devices, or robotics—and select the wire material (copper, silver, etc.) that best meets your needs. Additionally, evaluate the wire’s diameter, insulation type, and length to ensure compatibility with your systems. Consulting with suppliers about your requirements can provide valuable insights and recommendations tailored to your application. -

What are the advantages of using tinsel wire over traditional wiring options?

Tinsel wire offers numerous advantages, including exceptional flexibility, durability, and enhanced conductivity. Its unique structure allows it to withstand bending and twisting without compromising performance, making it ideal for applications that require frequent movement. Additionally, tinsel wire’s lightweight design and space-saving efficiency make it easier to integrate into tight spaces. These benefits position tinsel wire as a superior choice for a variety of industries, from consumer electronics to aerospace. -

What is the minimum order quantity (MOQ) for tinsel wire?

The minimum order quantity for tinsel wire can vary significantly among suppliers, often depending on the type of wire, customization options, and manufacturing processes. Typically, MOQs can range from a few hundred meters to several kilometers. When sourcing, it’s essential to discuss your needs with suppliers to determine their MOQ and explore options for smaller orders, especially if you are testing a new product line or entering a new market. -

What payment terms should I expect when sourcing tinsel wire internationally?

Payment terms for international transactions can vary widely based on the supplier and your relationship with them. Common terms include advance payment, letters of credit, or net 30/60/90 days after delivery. It’s advisable to negotiate terms that provide security for both parties. Be sure to consider currency fluctuations, transaction fees, and any import duties that may apply. Clear communication about payment expectations can help avoid misunderstandings and ensure smooth transactions. -

How can I ensure the quality of tinsel wire from suppliers?

To ensure the quality of tinsel wire, it’s essential to vet suppliers thoroughly. Request certifications, such as ISO 9001, that demonstrate adherence to quality management standards. Additionally, inquire about their manufacturing processes, quality control measures, and testing protocols. Obtaining samples before placing a large order can also help assess the wire’s performance and suitability for your application. Regular audits and ongoing communication with suppliers can further enhance quality assurance. -

What logistics considerations should I keep in mind when importing tinsel wire?

When importing tinsel wire, consider factors such as shipping methods, lead times, and customs regulations in your country. Choose reliable logistics partners who understand international shipping and can manage the complexities of customs clearance. Be aware of potential delays and plan for them in your supply chain. Additionally, ensure that the supplier provides the necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate smooth customs processing. -

Can I customize tinsel wire to fit specific requirements?

Yes, many suppliers offer customization options for tinsel wire to meet specific application needs. Customizations can include wire diameter, insulation type, length, and even the metal composition used. When discussing your requirements, provide detailed specifications and, if possible, examples of your application to help suppliers understand your needs better. This collaboration can lead to tailored solutions that enhance performance and efficiency in your projects. -

What industries commonly use tinsel wire, and why?

Tinsel wire is widely used across various industries, including consumer electronics, automotive, medical devices, and telecommunications. Its exceptional flexibility and durability make it ideal for applications requiring frequent movement, such as headphones and robotic systems. In medical applications, tinsel wire’s reliability is crucial for devices like ultrasound probes. The ability to maintain performance under stress and in compact spaces makes tinsel wire a preferred choice in these demanding environments.

Top 1 Tinsel Wire Manufacturers & Suppliers List

1. Midwest Speaker Repair – Tinsel Lead Wire

Domain: midwestspeakerrepair.com

Registered: 2001 (24 years)

Introduction: Product: Tinsel Lead Wire

Description: Lead wires that connect the terminal of the driver to the voice coil. Available in different thicknesses for home audio, pro audio, and car audio speakers and subwoofers.

Price: $2.95 – $3.95 per foot

Variants: Multiple options available on the product page.

Strategic Sourcing Conclusion and Outlook for tinsel wire

As we conclude this comprehensive guide on tinsel wire, it is essential to highlight the strategic advantages that come with sourcing this innovative material. Tinsel wire’s unique structure offers exceptional flexibility, durability, and conductivity, making it an optimal choice for various applications, from consumer electronics to advanced medical devices. By integrating tinsel wire into your supply chain, you can enhance product performance and reliability while also reducing long-term costs associated with replacements and repairs.

For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, the ability to access high-quality tinsel wire can be a game-changer. Strategic sourcing not only ensures that you are getting the best materials at competitive prices but also opens doors to partnerships with leading suppliers who prioritize innovation and customer satisfaction.

Looking ahead, the demand for advanced wiring solutions will continue to grow as industries evolve. Seize this opportunity to elevate your offerings and stay ahead in the competitive market. Engage with trusted suppliers today to explore how tinsel wire can transform your product lines and drive future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.