Threadless Bolt Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for threadless bolt

In the fast-evolving landscape of industrial manufacturing, sourcing the right threadless bolt can present significant challenges for B2B buyers across diverse regions such as Africa, South America, the Middle East, and Europe. With a myriad of options available, finding a reliable supplier who meets specific quality standards while offering competitive pricing is crucial. This guide aims to demystify the complexities surrounding threadless bolts, providing insights into various types, applications, and supplier vetting processes.

From understanding the technical specifications that matter most to your applications, to exploring cost-effective sourcing strategies, this comprehensive resource will equip you with the knowledge necessary to make informed purchasing decisions. We will delve into the differences between welded and riveted options, highlight common applications in various industries, and offer practical tips for evaluating potential suppliers.

By addressing these key areas, this guide empowers international B2B buyers to navigate the global market effectively, ensuring that they procure the right threadless bolts that not only meet their operational needs but also enhance the efficiency and safety of their projects. Whether you’re in Vietnam, Brazil, or elsewhere, this resource serves as a vital tool for streamlining your procurement process and achieving your business objectives.

Understanding threadless bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Index Bolts | Available in riveted and screwed versions; used for indexing; high spring load capacity | Machinery, fixtures, and tooling | Pros: Versatile for indexing; Cons: Limited to specific applications |

| Weldable Bolts | Designed for welding; can withstand high temperatures; available in steel and stainless steel | Construction, automotive, and aerospace | Pros: Robust for welded joints; Cons: Requires careful heat management |

| Threadless Pins | Smooth, cylindrical design; often used in positioning; can be made from various materials | Assembly lines, jigs, and fixtures | Pros: Easy to install; Cons: Not suitable for high-stress applications |

| Locking Bolts | Feature a locking mechanism to prevent loosening; available in multiple sizes | Heavy machinery and equipment | Pros: Enhanced security; Cons: More complex installation |

| Adjustable Bolts | Can be adjusted for length; offers flexibility in application; typically made from durable materials | Custom machinery and fixtures | Pros: Versatile for varying needs; Cons: Higher cost compared to standard bolts |

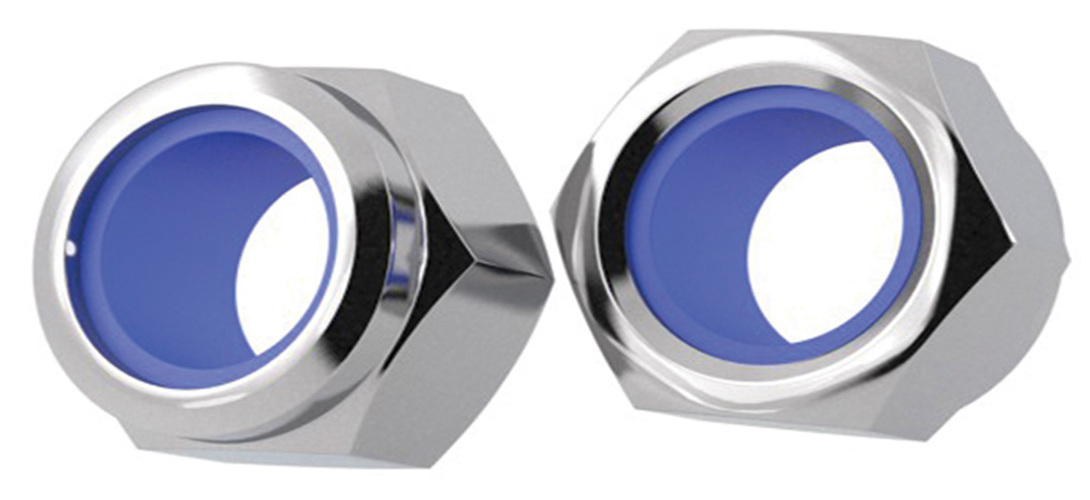

What Are Index Bolts and Their B2B Relevance?

Index bolts are specialized fasteners that are crucial in applications requiring precise positioning or indexing. They come in two main versions: riveted and screwed, allowing for flexibility based on the assembly requirements. The high spring load capacity makes them suitable for machinery and tooling setups. Buyers should consider the specific indexing needs of their applications, as these bolts are designed for precise operations rather than general fastening.

How Do Weldable Bolts Benefit Construction and Automotive Industries?

Weldable bolts are engineered to be integrated into welded structures, providing robust connections that can withstand significant stress. Made from steel or stainless steel, they are ideal for high-temperature applications found in construction and automotive sectors. When purchasing, businesses must ensure they understand the heat management required during welding to avoid compromising the bolt’s integrity.

What Characteristics Make Threadless Pins Suitable for Assembly Lines?

Threadless pins are characterized by their smooth, cylindrical shape, which facilitates easy insertion and removal. They are commonly used in assembly lines and fixture setups where quick adjustments are necessary. While they offer ease of use, buyers should be aware that threadless pins are not suited for applications where high stress or load-bearing is required, making them ideal for lighter-duty tasks.

Why Choose Locking Bolts for Heavy Machinery?

Locking bolts come equipped with mechanisms that prevent loosening during operation, making them essential for heavy machinery and equipment. Their ability to maintain a secure connection under dynamic loads enhances safety and reliability. However, the complexity of installation may deter some buyers, who must weigh the benefits of added security against the potential for higher labor costs during assembly.

How Do Adjustable Bolts Provide Flexibility in Custom Machinery?

Adjustable bolts offer a unique advantage by allowing users to modify their length to fit specific application requirements. This adaptability makes them a preferred choice in custom machinery and fixtures where standard sizes may not suffice. However, the higher cost associated with adjustable bolts can be a consideration for budget-conscious buyers. Understanding the long-term benefits of flexibility versus upfront costs is key when evaluating these fasteners.

Key Industrial Applications of threadless bolt

| Industry/Sector | Specific Application of threadless bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly of machinery components | Enhances assembly speed and precision | Ensure compatibility with existing machinery standards. |

| Automotive | Vehicle chassis assembly | Increases structural integrity and safety | Consider material strength and corrosion resistance. |

| Construction | Temporary scaffolding and structural supports | Provides reliable temporary connections | Assess load-bearing capacity and environmental durability. |

| Aerospace | Aircraft component fastening | Ensures lightweight and robust assembly | Focus on compliance with aviation safety regulations. |

| Renewable Energy | Wind turbine assembly | Supports efficient installation and maintenance | Evaluate resistance to environmental factors like corrosion. |

How Are Threadless Bolts Used in Manufacturing?

In the manufacturing sector, threadless bolts are often employed for the assembly of various machinery components. Their design allows for quick and efficient assembly, which is crucial in high-volume production environments. By eliminating the need for threaded connections, these bolts streamline the assembly process, reducing labor time and potential errors. For international buyers, it’s essential to ensure that the threadless bolts meet specific industry standards and are compatible with existing machinery to avoid costly downtimes.

What Role Do Threadless Bolts Play in Automotive Applications?

In the automotive industry, threadless bolts are vital for securing vehicle chassis components. Their ability to provide strong, reliable connections enhances the structural integrity and safety of vehicles. This is particularly important in regions like Africa and South America, where road conditions can be challenging. Buyers should prioritize sourcing bolts made from high-strength materials that offer corrosion resistance, ensuring longevity and performance in diverse environmental conditions.

How Are Threadless Bolts Utilized in Construction?

Threadless bolts find significant application in the construction sector, particularly for temporary scaffolding and structural supports. They facilitate quick and secure connections, which are essential for maintaining safety and stability during construction projects. For construction firms in the Middle East and Europe, sourcing threadless bolts that can withstand high loads and environmental stresses is crucial. Additionally, buyers should consider the ease of installation and the potential for reusability in future projects.

Why Are Threadless Bolts Important in Aerospace?

In the aerospace industry, threadless bolts are critical for fastening various aircraft components, where weight and strength are paramount. Their lightweight design contributes to overall fuel efficiency, while their robust connections ensure safety and reliability during flight. Buyers in this sector must focus on sourcing bolts that comply with stringent aviation safety regulations and are tested for high-performance standards, particularly in extreme conditions.

How Do Threadless Bolts Support Renewable Energy Initiatives?

In the renewable energy sector, particularly in wind turbine assembly, threadless bolts are essential for ensuring efficient installation and maintenance. They provide reliable connections that can withstand the dynamic forces experienced by turbines. For international buyers, especially those in emerging markets like Brazil and Vietnam, evaluating the environmental durability and ease of maintenance of these bolts is crucial for long-term operational success.

3 Common User Pain Points for ‘threadless bolt’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Threadless Bolts for Custom Applications

The Problem: B2B buyers often struggle to find threadless bolts that meet their specific application requirements, particularly when dealing with custom machinery or fixtures. This issue is exacerbated in regions like Africa and South America, where access to specialized suppliers may be limited. Buyers face challenges in identifying the right materials, sizes, and types, which can lead to delays in production and increased costs.

The Solution: To effectively source threadless bolts, buyers should begin by defining their precise specifications, including dimensions, load capacity, and environmental conditions (such as temperature and corrosion resistance). Engaging with manufacturers that offer customizable solutions can be highly beneficial. For instance, suppliers like Halder Inc. provide a range of options in steel and stainless steel, including both riveted and screwed versions. Buyers should request product samples or detailed technical datasheets to evaluate compatibility before committing to bulk orders. Furthermore, establishing relationships with local distributors can facilitate quicker access to necessary components and reduce lead times.

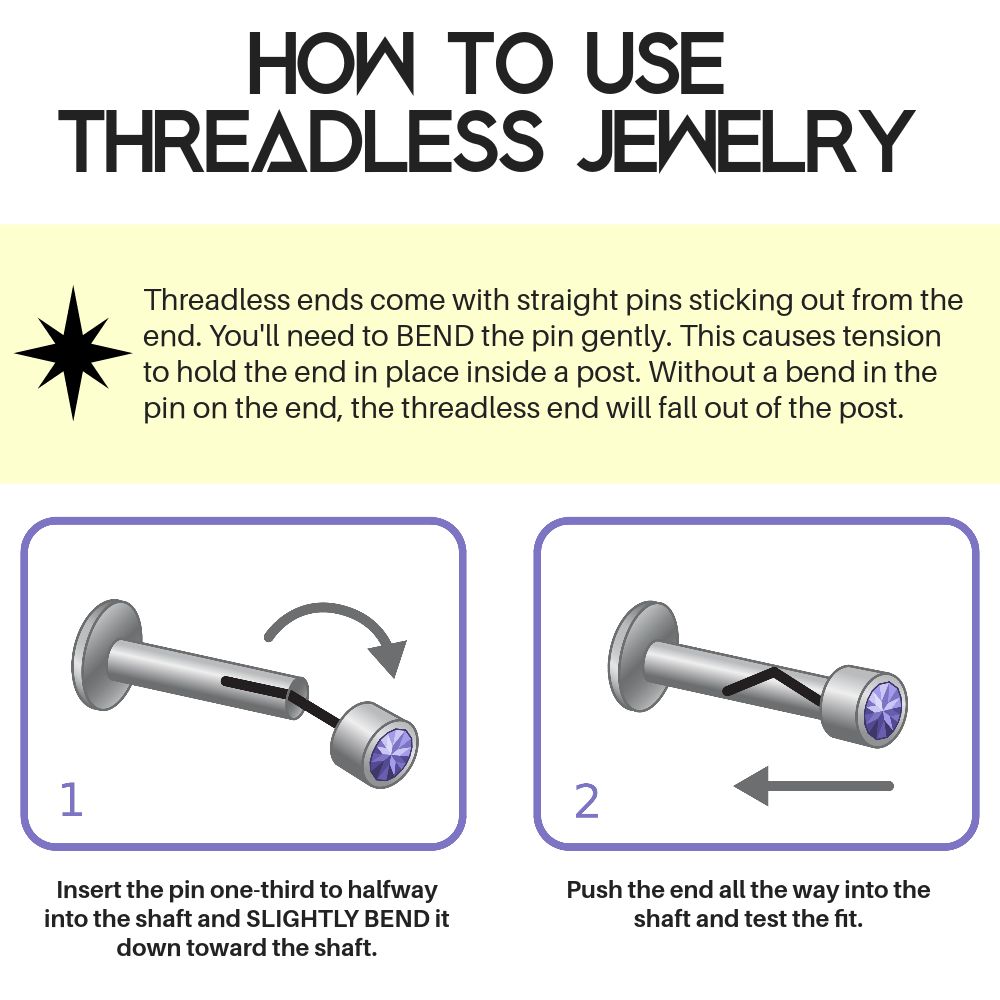

Scenario 2: Inadequate Knowledge of Installation Techniques for Threadless Bolts

The Problem: Many B2B buyers lack the expertise in proper installation techniques for threadless bolts, leading to potential operational failures and safety risks. This is particularly critical in industries such as manufacturing and construction, where improper fastening can result in equipment malfunction or accidents. The complexity of assembly processes can deter buyers from efficiently utilizing threadless bolts.

The Solution: It is essential for buyers to invest in training for their teams on the correct installation and operational procedures associated with threadless bolts. Manufacturers often provide installation manuals and technical support, which should be utilized. Additionally, buyers can consider workshops or training sessions offered by suppliers to enhance their team’s understanding of the installation process. For instance, focusing on the correct welding techniques when using riveted versions can prevent structural damage. Buyers should also document installation procedures and create best practice guides to ensure consistency and safety across their operations.

Scenario 3: Quality Assurance Concerns with Imported Threadless Bolts

The Problem: B2B buyers importing threadless bolts from different regions face significant quality assurance challenges. Variability in manufacturing standards can lead to inconsistencies in product quality, which may affect performance and reliability. This is particularly concerning for industries where safety and precision are paramount, such as aerospace and automotive sectors.

The Solution: To mitigate quality assurance issues, buyers should prioritize sourcing from reputable manufacturers with established quality control processes. This includes requesting certifications such as ISO 9001 or compliance with industry-specific standards. Additionally, conducting thorough due diligence on suppliers before making orders is crucial. Implementing a robust inspection process upon receipt of goods can help identify any discrepancies or defects early. Buyers may also consider collaborating with third-party inspection services to ensure that the products meet their specified requirements before use in critical applications. This proactive approach not only safeguards operational integrity but also enhances trust in the supply chain.

Strategic Material Selection Guide for threadless bolt

What Are the Key Material Options for Threadless Bolts?

When selecting materials for threadless bolts, it is crucial to consider the specific requirements of the application, including environmental conditions, load-bearing capacities, and regulatory compliance. Below, we analyze four common materials used in the production of threadless bolts: carbon steel, stainless steel, aluminum, and brass. Each material has distinct properties, advantages, and limitations that can significantly impact performance and suitability for various applications.

How Does Carbon Steel Affect Threadless Bolt Performance?

Carbon steel is a widely used material for threadless bolts due to its excellent strength and durability. It typically offers high tensile strength and can withstand significant loads, making it suitable for heavy-duty applications. However, carbon steel is susceptible to corrosion, particularly in humid or corrosive environments, unless it is treated or coated.

Pros:

– High strength-to-weight ratio

– Cost-effective compared to other materials

– Easy to manufacture and machine

Cons:

– Prone to rust and corrosion without protective coatings

– Limited resistance to high temperatures compared to other materials

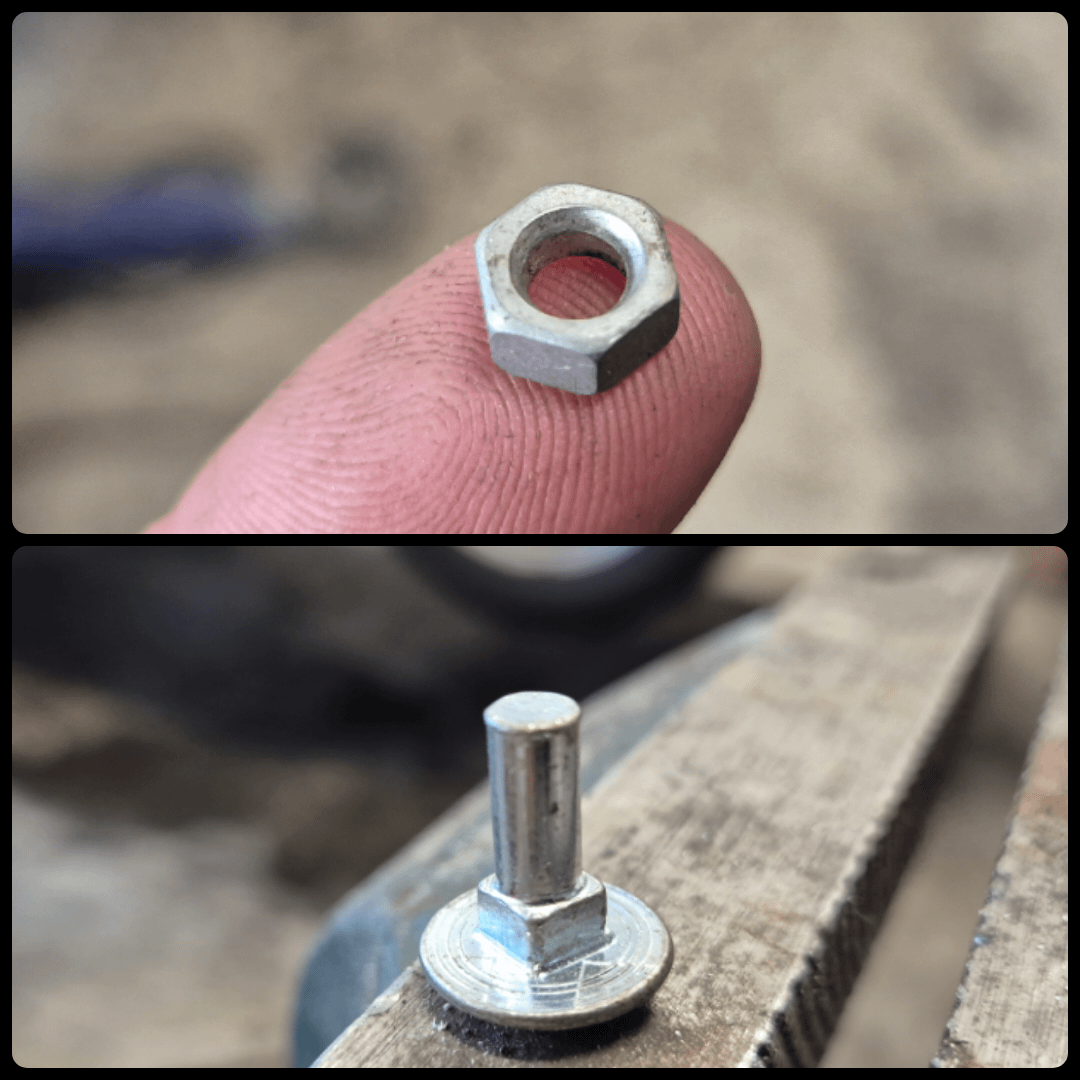

Illustrative image related to threadless bolt

For international buyers, especially in regions like Africa and South America where humidity can be high, it is essential to consider protective coatings and treatments to enhance corrosion resistance. Compliance with standards such as ASTM A36 for structural steel is also vital.

What Advantages Does Stainless Steel Offer for Threadless Bolts?

Stainless steel is known for its superior corrosion resistance, making it an ideal choice for threadless bolts used in harsh environments, including marine and chemical applications. It maintains its strength at high temperatures and is less likely to deform under stress.

Pros:

– Excellent corrosion resistance

– High strength and durability

– Maintains performance at elevated temperatures

Cons:

– Higher cost compared to carbon steel

– More challenging to machine and fabricate

For buyers in the Middle East and Europe, where compliance with standards like ASTM A240 is common, stainless steel offers the advantage of longevity and reduced maintenance costs. The initial investment may be higher, but the long-term benefits often justify the expense.

How Does Aluminum Impact the Use of Threadless Bolts?

Aluminum is a lightweight material that offers good strength and corrosion resistance, making it suitable for applications where weight is a critical factor. It is often used in aerospace and automotive industries, where reducing weight can lead to improved fuel efficiency.

Pros:

– Lightweight and easy to handle

– Good corrosion resistance

– Excellent machinability

Cons:

– Lower tensile strength compared to steel

– More expensive than carbon steel

For international buyers, particularly in regions like Europe and South America, the lightweight nature of aluminum can be a significant advantage in applications where weight reduction is necessary. Compliance with standards such as JIS H 4040 for aluminum alloys is essential for ensuring quality.

What Role Does Brass Play in Threadless Bolt Applications?

Brass is often used for threadless bolts in applications requiring good electrical conductivity and moderate corrosion resistance. It is particularly useful in plumbing and electrical applications, where its anti-corrosive properties are beneficial.

Pros:

– Good resistance to corrosion and tarnishing

– Excellent electrical conductivity

– Easy to machine and form

Illustrative image related to threadless bolt

Cons:

– Lower tensile strength than steel

– Can be more expensive than carbon steel

For buyers in Africa and the Middle East, brass can be an excellent choice for applications involving water or electrical components. Compliance with standards such as ASTM B36 for brass is important to ensure product reliability.

Summary Table of Material Options for Threadless Bolts

| Material | Typical Use Case for threadless bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy machinery, structural support | High strength-to-weight ratio | Prone to corrosion without coating | Low |

| Stainless Steel | Marine, chemical applications | Excellent corrosion resistance | Higher cost, harder to machine | High |

| Aluminum | Aerospace, automotive applications | Lightweight and easy to handle | Lower tensile strength | Medium |

| Brass | Plumbing, electrical components | Good corrosion resistance | Lower strength, higher cost | Medium |

This guide provides a comprehensive overview of the materials used for threadless bolts, helping international B2B buyers make informed decisions based on their specific requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for threadless bolt

What Are the Key Manufacturing Processes for Threadless Bolts?

Manufacturing threadless bolts involves a series of carefully orchestrated stages, each critical to achieving the desired quality and performance. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Threadless Bolt Production?

The journey begins with the selection of appropriate materials, typically high-grade steel or stainless steel, depending on the application and required durability. Material preparation involves sourcing raw materials that comply with international standards, ensuring they are free from defects. Suppliers often conduct thorough inspections of incoming materials (Incoming Quality Control, IQC) to verify their composition and mechanical properties.

Once the materials are accepted, they undergo processes such as cutting and shaping to fit specific dimensions required for the manufacturing of threadless bolts. This stage is crucial as any inconsistencies can affect the performance and reliability of the final product.

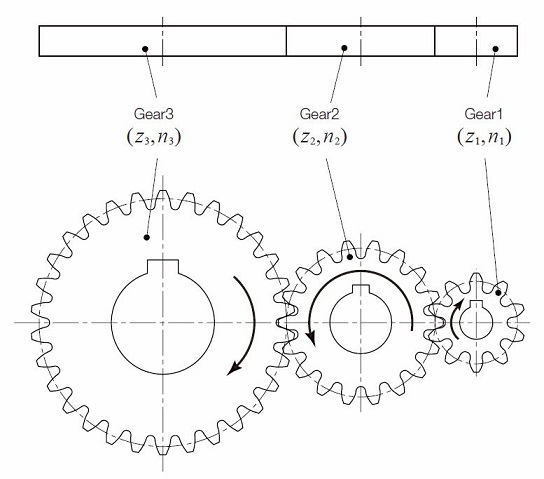

What Forming Techniques Are Used in Threadless Bolt Manufacturing?

The forming stage is where the prepared materials are transformed into the shape of threadless bolts. Common techniques include:

- Precision Casting: This method allows for the creation of complex shapes with high dimensional accuracy. It is particularly useful for producing bolts with specific geometries.

- Forging: This involves shaping the metal using compressive forces, which improves the material’s strength and fatigue resistance. It is often used for bolts that require high load-bearing capabilities.

- Machining: Involves processes like turning, milling, or drilling to achieve precise dimensions and surface finishes. This step is essential for ensuring the bolt fits perfectly in its intended application.

Each of these techniques can be tailored to meet the specific requirements of different industries, from automotive to aerospace.

Illustrative image related to threadless bolt

What Assembly Processes Are Involved in Making Threadless Bolts?

Following the forming process, the assembly of the threadless bolt may take place. Depending on the design, assembly can involve:

- Riveting: This method secures components together without the need for threads, which is ideal for applications where vibration could loosen traditional fasteners.

- Screwing: In cases where disassembly is necessary, a screwed assembly allows for easier maintenance and adjustment.

During assembly, manufacturers often utilize jigs and fixtures to ensure accuracy and repeatability. This is critical in maintaining the integrity of the bolt and ensuring that it meets design specifications.

What Finishing Techniques Are Used to Enhance Threadless Bolts?

Finishing processes are essential for enhancing the corrosion resistance and aesthetic appeal of threadless bolts. Common finishing techniques include:

- Surface Treatment: Processes like galvanization or coating with protective materials can improve durability and resistance to environmental factors.

- Polishing: This step enhances the surface finish, reducing friction and wear during operation.

These finishing touches not only improve the longevity of the bolts but also ensure compliance with specific industry standards.

How Is Quality Assurance Implemented in Threadless Bolt Manufacturing?

Quality assurance is a fundamental aspect of threadless bolt manufacturing, ensuring that every product meets rigorous industry standards. Manufacturers typically adhere to international quality standards such as ISO 9001, which provides a framework for consistent quality management.

What Are the Key Quality Control Checkpoints for Threadless Bolts?

Quality control checkpoints during the manufacturing process include:

- Incoming Quality Control (IQC): This initial stage verifies the quality of raw materials before production begins.

- In-Process Quality Control (IPQC): This involves monitoring the manufacturing process at various stages to detect any deviations from specified standards.

- Final Quality Control (FQC): Conducted post-manufacturing, this stage includes thorough inspections and testing of the finished product to ensure it meets all specifications and is free from defects.

Which Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to ensure the integrity and performance of threadless bolts, including:

- Tensile Testing: Evaluates the strength and ductility of the material.

- Hardness Testing: Measures the material’s resistance to deformation.

- Non-destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing help identify internal flaws without damaging the bolt.

These tests are critical for verifying that the bolts will perform reliably under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must be proactive in assessing the quality control measures of potential suppliers, especially when sourcing from international markets. Here are some strategies:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control measures, and compliance with international standards firsthand.

- Requesting Documentation: Buyers should ask for quality assurance documentation, including test reports, certifications, and compliance with industry standards such as CE or API.

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and the final product.

What Are the Specific Quality Control Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of nuances in quality control. Factors such as local regulations, import standards, and cultural differences can impact quality assurance practices. It is essential to ensure that suppliers are familiar with and compliant with both local and international standards, particularly when it comes to materials and environmental regulations.

Illustrative image related to threadless bolt

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and choose reliable suppliers for threadless bolts that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘threadless bolt’

In this practical sourcing guide, we will provide a step-by-step checklist for B2B buyers looking to procure threadless bolts. This comprehensive approach will help ensure that your procurement process is efficient, cost-effective, and meets your specific technical requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s critical to clearly define the technical specifications of the threadless bolts you need. This includes dimensions, load requirements, materials (e.g., steel or stainless steel), and any specific features like weldability or spring load characteristics. Establishing these criteria early on will help streamline your search and ensure compatibility with your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in threadless bolts. Look for companies with a strong reputation in your industry and check their product catalogs for the specific types of bolts you require. Pay attention to their manufacturing capabilities and whether they offer customization options to meet unique specifications.

Step 3: Evaluate Supplier Certifications

Ensure that your chosen suppliers possess relevant certifications that demonstrate compliance with international quality standards, such as ISO 9001 or RoHS compliance. This step is vital for ensuring product quality and reliability, especially when sourcing from diverse regions like Africa, South America, or Europe. Verify that the suppliers can provide documentation to confirm these certifications.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the threadless bolts to evaluate their quality and performance. Conduct tests to assess their strength, durability, and suitability for your specific applications. This hands-on evaluation will help mitigate risks associated with large-scale procurement and ensure that the products meet your technical requirements.

Step 5: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. Look beyond just the price per unit; consider factors like shipping costs, lead times, and bulk order discounts. Understanding the total cost of procurement will allow you to make an informed decision that aligns with your budget.

Step 6: Check References and Reviews

Before finalizing your supplier choice, check references and reviews from other B2B buyers who have previously worked with the suppliers. This step can provide insights into the supplier’s reliability, customer service, and product quality. Engaging with past clients can offer a clearer picture of what to expect in terms of support and delivery.

Step 7: Finalize the Contract with Clear Terms

Once you have selected a supplier, draft a contract that outlines all agreed-upon terms, including pricing, delivery schedules, and warranty conditions. Ensure that both parties are clear on expectations to avoid misunderstandings later. A well-structured contract will serve as a safeguard for both you and the supplier.

By following these steps, B2B buyers can effectively navigate the procurement process for threadless bolts, ensuring they select the right products and suppliers that meet their operational needs.

Comprehensive Cost and Pricing Analysis for threadless bolt Sourcing

What Are the Key Cost Components in Sourcing Threadless Bolts?

When sourcing threadless bolts, several cost components contribute to the final pricing structure. Understanding these components helps buyers make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for threadless bolts include steel and stainless steel, with stainless steel typically commanding a higher price due to its corrosion resistance and durability. Pricing can also vary based on the material’s quality and certifications.

-

Labor: Labor costs are associated with manufacturing and assembly. In regions with higher labor costs, such as Europe, the overall price for threadless bolts may increase. Conversely, sourcing from countries with lower labor costs can provide cost savings, though this may come with trade-offs in quality or lead times.

-

Manufacturing Overhead: This includes expenses related to the operation of manufacturing facilities, such as utilities, equipment maintenance, and administrative costs. Efficient production processes can help reduce overhead, thereby lowering the final product price.

-

Tooling: Tooling costs are incurred for the creation and maintenance of molds and machinery used in the production of threadless bolts. Custom designs or specifications may require specialized tooling, which can increase costs.

-

Quality Control (QC): Ensuring that products meet specific quality standards incurs additional costs. Rigorous QC processes are essential, especially for applications requiring high precision and reliability, which can further influence pricing.

-

Logistics: Shipping and handling costs, including freight charges and customs duties, are critical considerations. International buyers must factor in the logistics costs associated with transporting goods from the supplier’s location to their own, which can vary significantly based on distance and shipping terms.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can fluctuate based on market demand and competition.

What Influences Pricing for Threadless Bolts?

Several factors can influence the pricing of threadless bolts beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Customized threadless bolts that meet specific requirements may incur additional costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Quality and Certifications: Higher quality materials and certifications (e.g., ISO, RoHS) can increase costs but are essential for applications in regulated industries. Buyers should assess the importance of these factors based on their application needs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can help buyers avoid unexpected costs.

How Can Buyers Optimize Their Sourcing Strategy for Threadless Bolts?

International B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Building a strong relationship with suppliers can lead to better pricing and service.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, warranty, and logistics costs to get a comprehensive view of the total cost.

-

Research Market Trends: Understanding market dynamics, including material availability and global supply chain challenges, can help buyers make timely purchasing decisions.

-

Leverage Technology: Utilize online platforms and tools for price comparisons and supplier evaluations to ensure competitive pricing and quality.

-

Consider Local Sourcing: In some cases, sourcing from local suppliers can reduce logistics costs and lead times, enhancing overall supply chain efficiency.

Disclaimer

Prices for threadless bolts can vary widely based on the factors mentioned above. The information provided is indicative and subject to change based on market conditions and supplier negotiations. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing threadless bolt With Other Solutions

Understanding Alternatives to Threadless Bolts for B2B Applications

In the competitive landscape of industrial solutions, B2B buyers often seek the most effective fastening methods for their projects. While threadless bolts offer unique advantages, it is essential to consider alternative solutions that may better suit specific needs or applications. This analysis compares threadless bolts with two viable alternatives: standard threaded bolts and weldable pins, examining performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to threadless bolt

| Comparison Aspect | Threadless Bolt | Standard Threaded Bolt | Weldable Pin |

|---|---|---|---|

| Performance | High load capacity; quick release | Reliable; adjustable tension | Strong permanent connection |

| Cost | Moderate, varies by material | Generally lower initial cost | Higher due to welding equipment |

| Ease of Implementation | Requires precise alignment | Simple installation with tools | Requires welding skills |

| Maintenance | Low, minimal wear | Moderate, may require retightening | Low, permanent once installed |

| Best Use Case | Quick assembly and disassembly | General-purpose fastening | Heavy-duty applications |

What Are the Advantages and Disadvantages of Standard Threaded Bolts?

Standard threaded bolts are a traditional fastening solution widely used in various applications due to their simplicity and effectiveness. They provide reliable tension and can be adjusted as needed, making them suitable for applications where load requirements may change. The initial cost is generally lower than threadless bolts, and their installation is straightforward with standard tools. However, they may require periodic maintenance to ensure they remain secure, as vibrations or load changes can lead to loosening over time.

How Do Weldable Pins Compare to Threadless Bolts?

Weldable pins are another alternative that offers a robust fastening solution, particularly in heavy-duty applications. These pins are permanently attached through welding, resulting in a strong and stable connection that does not require further maintenance. While they provide excellent performance and stability, the need for welding equipment and skilled labor can significantly increase the overall cost and complexity of installation compared to threadless bolts. Weldable pins are best suited for applications where a permanent solution is required, and adjustments or disassembly are not anticipated.

Conclusion: How Can B2B Buyers Select the Right Fastening Solution?

When choosing the right fastening solution, B2B buyers should consider their specific application requirements, budget constraints, and operational capabilities. Threadless bolts offer advantages in ease of assembly and quick adjustments, making them ideal for applications that require frequent changes. Standard threaded bolts provide a cost-effective and versatile option for general use, while weldable pins excel in providing strong, permanent connections in demanding environments. By evaluating these factors, buyers can make informed decisions that align with their project needs and ensure long-term operational efficiency.

Essential Technical Properties and Trade Terminology for threadless bolt

What Are the Key Technical Properties of Threadless Bolts?

When selecting threadless bolts for industrial applications, understanding their technical properties is crucial for ensuring performance and compatibility with your machinery. Here are some critical specifications to consider:

-

Material Grade

Threadless bolts are commonly made from steel or stainless steel. The choice of material affects strength, corrosion resistance, and overall durability. For instance, stainless steel (such as grade 1.4401) offers superior resistance to rust and is ideal for outdoor or marine applications, while carbon steel may be more cost-effective for indoor uses. -

Load Capacity

This specification refers to the maximum force a bolt can withstand without failing. Load capacity is typically measured in Newtons (N) and varies based on the bolt’s size and material. Understanding load capacity is vital for ensuring that the bolt can handle the operational stresses of your application, preventing premature failure and safety hazards. -

Tolerance

Tolerance indicates the allowable deviation from specified dimensions, which is crucial for ensuring proper fit and function in assembly. For threadless bolts, a common tolerance might be ±0.05 mm. Tight tolerances are essential in precision applications, as they help maintain alignment and reduce wear on associated components. -

Spring Load

Many threadless bolts feature a spring mechanism to assist in locking or indexing. The spring load, measured in Newtons, determines the force required to engage or disengage the bolt. This property is critical for applications where quick adjustments are necessary, such as in machinery setups or fixtures. -

Operating Temperature Range

Knowing the maximum operating temperature is essential, especially in environments subject to extreme heat. For example, many threadless bolts can operate safely up to 250 °C. Exceeding this limit could compromise material integrity and functionality, leading to potential failures. -

Weight

The weight of the bolt can influence the overall weight of the assembly or machinery. Lighter bolts may be preferred in applications where weight savings are critical, such as in aerospace or automotive industries. Understanding the weight can also aid in logistics and shipping considerations.

Which Trade Terms Are Essential When Purchasing Threadless Bolts?

Navigating the procurement of threadless bolts involves familiarity with industry-specific terminology. Here are some key terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that may be marketed by another manufacturer. In the context of threadless bolts, working with an OEM can ensure that you receive high-quality, compatible components tailored to your specific machinery needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, as suppliers often set these limits based on production costs and logistics. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to obtain pricing and terms for a specific quantity of goods. When looking to purchase threadless bolts, an RFQ can help you compare costs and services across multiple suppliers, ensuring you get the best deal. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) helps clarify shipping costs and responsibilities, which is crucial for global sourcing. -

Lead Time

This term refers to the time from placing an order to receiving the goods. Understanding lead times is critical for planning production schedules and ensuring that components are available when needed, particularly in fast-paced industries. -

Compliance Standards

Many industries require components to meet specific compliance standards, such as RoHS or REACH. Knowing whether a supplier’s products meet these regulations is essential for avoiding legal issues and ensuring product safety.

Understanding these properties and terms will empower you to make informed purchasing decisions for threadless bolts, optimizing your supply chain and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the threadless bolt Sector

What Are the Current Market Dynamics and Key Trends Affecting the Threadless Bolt Sector?

The global threadless bolt market is witnessing significant growth, driven by the increasing demand for precision-engineered components across various industries, including automotive, aerospace, and manufacturing. Key trends influencing this market include the rise of automation and advanced manufacturing technologies, which are prompting companies to seek high-quality, reliable fastening solutions. Furthermore, the shift towards lightweight materials, such as aluminum and advanced polymers, is shaping the development of threadless bolts, as industries look to enhance performance while reducing weight.

International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly favoring suppliers that can offer innovative solutions and competitive pricing. The proliferation of e-commerce platforms is facilitating easier access to global suppliers, allowing B2B buyers to source products directly from manufacturers. Additionally, the emphasis on digital transformation is leading companies to adopt advanced sourcing tools, such as AI-driven analytics and supply chain management software, to optimize procurement processes.

Emerging markets are also becoming critical players in the threadless bolt sector, as local manufacturers ramp up production capabilities to meet the growing demand. Countries like Vietnam and Brazil are enhancing their manufacturing sectors, making them attractive sourcing destinations for international buyers seeking cost-effective solutions without compromising on quality.

How Are Sustainability and Ethical Sourcing Influencing Threadless Bolt Procurement?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the threadless bolt sector. As environmental awareness grows, companies are under pressure to adopt sustainable practices throughout their supply chains. This includes sourcing materials that have a lower environmental impact, such as recycled metals or sustainably sourced raw materials.

Moreover, the importance of ethical supply chains is underscored by the increasing scrutiny of labor practices and environmental regulations. Buyers are now prioritizing suppliers that demonstrate compliance with global standards, such as ISO 14001 for environmental management and certifications related to ethical labor practices.

Illustrative image related to threadless bolt

In response to these trends, manufacturers are investing in ‘green’ certifications and materials that promote sustainability. For instance, threadless bolts made from recyclable materials or produced using energy-efficient processes are gaining traction. Buyers should look for suppliers that can provide transparency about their sourcing practices and demonstrate a commitment to reducing their environmental footprint.

What Is the Historical Context of Threadless Bolts in B2B Applications?

The evolution of threadless bolts can be traced back to the early 20th century, where they emerged as a solution for applications requiring quick assembly and disassembly without the complications of traditional threaded fasteners. Initially developed for the automotive and machinery sectors, threadless bolts gained popularity due to their reliability and ease of use.

As manufacturing technologies advanced, threadless bolts evolved to include various materials, such as high-strength steel and stainless steel, catering to the growing demands for durability and corrosion resistance. Over the decades, their applications expanded into diverse fields, including aerospace and construction, where precision and safety are paramount.

Today, threadless bolts are a staple in modern manufacturing, reflecting the ongoing innovation in fastening technology. As industries continue to prioritize efficiency and sustainability, the threadless bolt sector is poised for further growth and adaptation, driven by technological advancements and changing market needs.

Frequently Asked Questions (FAQs) for B2B Buyers of threadless bolt

-

How do I choose the right threadless bolt for my application?

When selecting a threadless bolt, consider factors such as the material (steel or stainless steel), load capacity, and specific operational requirements. Assess the environment in which the bolt will be used, including temperature ranges and potential exposure to corrosive elements. Additionally, evaluate the bolt’s design features, like whether it is riveted or screwed, as this can impact installation and durability. Consulting with manufacturers or technical datasheets can provide insights tailored to your specific use case. -

What is the best material for a threadless bolt in a high-temperature environment?

For high-temperature applications, stainless steel is often the best choice due to its corrosion resistance and ability to withstand elevated temperatures without deforming. Stainless steel bolts can operate effectively in environments up to 250 °C, making them suitable for various industrial applications. Always check the specific material specifications and ensure they align with your operational conditions to avoid premature failure. -

What are the minimum order quantities (MOQ) for threadless bolts?

Minimum order quantities for threadless bolts can vary significantly by supplier and product type. Typically, manufacturers may set MOQs ranging from 100 to 1000 pieces, depending on production costs and inventory management. It’s advisable to directly contact suppliers to discuss your needs, as some may offer flexibility for smaller orders, especially for new customers or in certain regions. -

How can I ensure the quality of threadless bolts from international suppliers?

To ensure quality, vet suppliers thoroughly by checking their certifications (like ISO 9001), customer reviews, and production capabilities. Request samples to evaluate the material and manufacturing quality before placing a large order. Additionally, consider third-party quality assurance inspections and compliance with international standards to mitigate risks associated with international trade. -

What payment terms should I expect when sourcing threadless bolts internationally?

Payment terms can vary by supplier and region, but common practices include advance payments, letters of credit, or payment upon delivery. Some suppliers may offer net 30 or net 60 terms for established customers. It’s crucial to negotiate terms that balance your cash flow needs with the supplier’s requirements, and always clarify the terms in the purchase agreement to avoid misunderstandings. -

How do logistics impact the sourcing of threadless bolts internationally?

Logistics play a critical role in the timely delivery of threadless bolts. Factors such as shipping methods (air vs. sea), lead times, and customs regulations can affect delivery schedules. It’s advisable to work with suppliers who have experience in international shipping and can provide clear timelines. Additionally, consider the total landed cost, including shipping, tariffs, and handling fees, to ensure comprehensive budgeting for your procurement. -

Can threadless bolts be customized for specific applications?

Yes, many manufacturers offer customization options for threadless bolts, including alterations in size, material, and design features. Customization allows you to tailor the bolts to meet the specific requirements of your applications, such as unique load capacities or environmental conditions. Discuss your specifications with potential suppliers to explore available options and any associated costs or lead times. -

What are the common applications for threadless bolts in various industries?

Threadless bolts are widely used in applications such as machinery assembly, automotive manufacturing, and construction. Their ability to provide secure fastening without the need for threading makes them ideal for indexing and positioning components. Industries that require precise alignment and quick assembly often rely on threadless bolts for their efficiency and reliability, making them a versatile choice across sectors.

Top 10 Threadless Bolt Manufacturers & Suppliers List

1. Halder – Index Bolts EH 22120

Domain: halderusa.com

Registered: 2016 (9 years)

Introduction: Index Bolts threadless, weldable – EH 22120. Made of steel or stainless steel. Available in two versions: riveted and screwed. Used for indexing purposes. Technical data includes a size of 8 mm.

2. Reddit – Bolt Threading Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The text discusses bolts that are not fully threaded, specifically mentioning that only the last 1 inch is threaded. It raises a question about the standard threading length for bolts of different sizes (3, 4, 5 inches) and whether a longer bolt would have a proportionally longer threaded section. The conversation touches on technical definitions of bolts versus screws, referencing standards such …

3. Trek – Bontrager Blendr Adjustable Stem Bolt

Domain: trekbikes.com

Registered: 1995 (30 years)

Introduction: Bontrager Blendr Adjustable Threadless Stem Bolt

4. Garage Journal – Threadless Bolt

Domain: garagejournal.com

Registered: 2006 (19 years)

Introduction: Threadless bolt, also referred to as a hitch pin or clevis pin. Features: no threads, hole at the bottom. Suggested sourcing options include farm supply or hardware stores, specifically Tractor Supply or similar stores.

5. Facebook – Barrel Bolt Insights

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Barrel Bolt Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. ASF – B8 Hex Head Threadless Bolt

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {‘item_name’: ‘ASF B8 Hex Head Threadless Bolt’, ‘diameter’: ‘1-1/4″‘, ‘length’: ‘8″‘, ‘condition’: ‘New – Open box’, ‘description’: ‘An item in excellent, new condition with no functional defects. The item may be missing original packaging and may have been used for testing or demo purposes.’, ‘quantity_available’: ‘More than 10’, ‘price’: ‘US $27.00’, ‘shipping_cost’: ‘US $13.00’, ‘shipping_time…

7. Pro Neck BMX – Stainless Steel Bolts

Domain: proneckbmx.com

Registered: 2007 (18 years)

Introduction: Stainless steel bolts for 1-1/8″ threadless stems.

8. Heico Group – Expansion Bolt

Domain: heico-group.com

Registered: 2016 (9 years)

Introduction: Expansion Bolt for threadless bores designed for precise, displacement-controlled, radial preloading. Made of high-strength steel, it features a compact design and operates from one side. Key components include a longitudinally slotted conical sleeve, a conical bolt, and a tensioning element. Advantages include fast assembly, optimum alignment of components, adaptability to hole sizes, and ease of…

9. BP Yes World – Bolt – Threadless End

10. Bicycle Maintenance – Handlebar Stem Bolts

Domain: bicycles.stackexchange.com

Registered: 2009 (16 years)

Introduction: Threadless handlebar stem bolts; options for lubrication include grease, threadlocker, anti-seize, or dry. Grease is commonly used and provides adequate lubrication and corrosion protection. Medium-strength threadlocker can be used to prevent bolts from backing out. Anti-seize is effective in corrosive environments but can be messy and has compatibility concerns with certain metals. Recommendation…

Strategic Sourcing Conclusion and Outlook for threadless bolt

In conclusion, strategic sourcing of threadless bolts presents a substantial opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Understanding the various materials, such as steel and stainless steel, and their respective applications is crucial for optimizing performance and cost-efficiency in manufacturing processes. Buyers should prioritize suppliers that offer robust technical support and compliance with international standards, ensuring product reliability and safety.

Furthermore, engaging with suppliers who provide a range of options—such as riveted and screwed versions—will enhance flexibility in sourcing strategies. As global supply chains evolve, leveraging strategic partnerships with manufacturers can lead to improved lead times and reduced costs.

Looking ahead, the demand for threadless bolts is expected to grow in line with advancements in various industries, including automotive, aerospace, and heavy machinery. We encourage international buyers to actively seek out innovative sourcing solutions that not only meet current needs but also anticipate future trends. By prioritizing strategic sourcing, companies can secure their competitive edge in a rapidly changing marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.