The Definitive Guide to Wm Dolls: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for wm dolls

In an increasingly competitive landscape, sourcing high-quality WM dolls can present unique challenges for international B2B buyers. Factors such as fluctuating material costs, compliance with regional regulations, and the need for customization make the procurement process complex. This guide serves as a comprehensive resource, detailing various types of WM dolls—including realistic, customizable, and silicone options—while also exploring their diverse applications across different markets.

With insights into supplier vetting, cost analysis, and industry trends, this guide empowers buyers from regions such as Africa, South America, the Middle East, and Europe, including Brazil and Saudi Arabia, to make informed purchasing decisions. By understanding the nuances of the WM doll market, including the growing demand for interactive and themed products, buyers can identify reliable suppliers and negotiate favorable terms.

Moreover, the guide addresses critical considerations such as compliance with safety standards and the importance of quality assurance protocols, ensuring that businesses can effectively navigate the complexities of international trade. As the global market for WM dolls is poised for significant growth, informed decision-making will be key to capitalizing on emerging opportunities. This guide aims to equip you with the knowledge necessary to thrive in this dynamic market, transforming challenges into opportunities for success.

Understanding wm dolls Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Realistic WM Dolls | Highly lifelike appearance, often made from silicone | Collectibles, adult entertainment | Pros: High demand for realism; Cons: Higher cost |

| Customizable WM Dolls | Options for personalization in appearance and features | Gifts, promotional items | Pros: Attracts niche markets; Cons: Longer lead times for production |

| TPE WM Dolls | Made from thermoplastic elastomer, softer feel | Budget-friendly options, mass production | Pros: Cost-effective; Cons: Less durable than silicone |

| Mini WM Dolls | Smaller scale models, often collectible | Toys, display items | Pros: Easy to ship and store; Cons: Limited market appeal |

| WM Dolls with Heating | Incorporates heating elements for a realistic touch | Adult market, therapeutic applications | Pros: Unique selling proposition; Cons: Higher complexity in manufacturing |

What Are the Characteristics of Realistic WM Dolls?

Realistic WM Dolls are crafted to mimic human features with exceptional detail, often using high-quality silicone. This type appeals primarily to collectors and the adult entertainment industry, where lifelike representation is paramount. When purchasing, B2B buyers should consider the material quality, manufacturing certifications, and compliance with safety standards. The initial investment may be higher, but the potential for premium pricing can yield significant returns.

How Do Customizable WM Dolls Meet Market Demands?

Customizable WM Dolls allow buyers to personalize various features, such as hair color, eye type, and body shape. This flexibility caters to diverse consumer preferences, making them ideal for promotional items and gifts. B2B buyers should focus on manufacturers that offer robust customization options and reliable production timelines. While these dolls can attract niche markets, longer lead times may affect inventory management.

Why Choose TPE WM Dolls for Budget-Friendly Solutions?

TPE WM Dolls are an economical alternative, made from thermoplastic elastomer, providing a softer feel compared to silicone. These dolls are suitable for mass production, appealing to buyers looking for budget-friendly options. B2B purchasers should evaluate the durability and safety certifications of TPE products, as they may not withstand wear and tear as well as silicone models. However, the lower price point can facilitate higher volume sales.

What Are the Advantages of Mini WM Dolls in the Market?

Mini WM Dolls are compact, collectible figures that cater to both children and adult collectors. Their smaller size makes them easier to ship and store, reducing logistics costs. B2B buyers should consider market trends for mini collectibles and assess the potential for themed series or collaborations. Although their market appeal may be limited compared to larger dolls, they can serve as effective promotional items.

How Do WM Dolls with Heating Enhance Consumer Experience?

WM Dolls with heating features provide a unique selling point by simulating body warmth, enhancing realism for users. This type is particularly popular in the adult market and therapeutic applications. B2B buyers must ensure that manufacturers adhere to safety standards for electronic components and consider the added complexity of production. While these dolls can command higher prices, they also require thorough market research to gauge consumer interest.

Key Industrial Applications of wm dolls

| Industry/Sector | Specific Application of wm dolls | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Medical Training Manikins | Enhances training efficiency for healthcare professionals | Compliance with medical safety standards, customizable features for specific training scenarios |

| Entertainment | Collectible Figures and Dolls | Drives revenue through themed merchandise and collector demand | Licensing agreements, quality assurance, and market trends in pop culture |

| Retail | Customizable Dolls for E-commerce | Increases customer engagement and personalization options | MOQ flexibility, reliable supply chain, and customization capabilities |

| Education | Educational Toys and Learning Aids | Supports child development through interactive play | Safety certifications, educational value, and age-appropriate designs |

| Adult Industry | Realistic Companionship Dolls | Provides alternatives for emotional support and companionship | Material safety certifications, discreet packaging, and cultural sensitivity in marketing |

How Are wm Dolls Used in Healthcare Training Applications?

In the healthcare sector, wm dolls are employed as medical training manikins, which simulate real-life scenarios for healthcare professionals. These dolls can be customized to represent various medical conditions, enhancing the realism of training sessions. By using these manikins, hospitals and training institutions can improve the effectiveness of their educational programs, ensuring that staff are well-prepared for real-world situations. Buyers in this sector must ensure compliance with medical safety standards and seek manufacturers that offer customizable features tailored to specific training needs.

What Role Do wm Dolls Play in the Entertainment Industry?

In the entertainment industry, wm dolls serve as collectible figures and themed merchandise, appealing to fans of various franchises. These dolls can be designed to represent characters from movies, series, or video games, driving revenue through sales to collectors and enthusiasts. For businesses, securing licensing agreements is crucial to ensure the authenticity of the products. Moreover, maintaining high-quality standards is essential to meet consumer expectations and capitalize on market trends, particularly in regions with a robust pop culture presence.

How Can Retailers Benefit from Customizable wm Dolls?

Retailers are increasingly incorporating wm dolls into their e-commerce platforms, offering customizable options to enhance customer engagement. By allowing customers to personalize their dolls, retailers can differentiate themselves in a competitive market and increase sales. Key considerations for sourcing include flexibility in minimum order quantities (MOQs), a reliable supply chain to meet demand, and the ability to provide various customization options. Retailers should also prioritize quality assurance to ensure product satisfaction and repeat business.

In What Ways Do wm Dolls Support Educational Objectives?

In educational settings, wm dolls are utilized as interactive toys and learning aids that foster child development. These dolls can teach children about social skills, empathy, and role-playing, making them valuable tools in both homes and classrooms. For international buyers, it is crucial to ensure that the dolls meet safety certifications for children’s toys and are designed with educational value in mind. Manufacturers should also provide age-appropriate designs that cater to diverse educational needs across different cultures.

How Are wm Dolls Utilized in the Adult Industry?

In the adult industry, wm dolls are designed as realistic companionship options, catering to individuals seeking emotional support. These dolls can serve as alternatives to traditional relationships, offering companionship without the complexities of human interaction. Businesses in this sector must prioritize material safety certifications to ensure product quality and user safety. Additionally, considerations around discreet packaging and culturally sensitive marketing strategies are vital to appeal to a diverse international audience while respecting local norms and values.

3 Common User Pain Points for ‘wm dolls’ & Their Solutions

Scenario 1: Navigating Compliance Challenges for WM Dolls

The Problem: B2B buyers often face hurdles related to compliance and safety regulations when sourcing WM dolls, especially for markets in Europe and North America. Each region has its own stringent regulations, such as EN71 in Europe and ASTM F963 in the U.S., which dictate safety standards for toys. Buyers can struggle to verify if their suppliers’ products meet these requirements, risking potential legal issues and costly recalls if non-compliant products are distributed.

The Solution: To mitigate compliance risks, B2B buyers should conduct thorough due diligence on potential suppliers. Start by requesting detailed documentation of compliance certifications for the specific markets where the dolls will be sold. Ensure that suppliers can provide ISO 8124 safety compliance certificates and third-party testing results for phthalates, heavy metals, and flammability standards. Establish a checklist of required certifications and insist on compliance audits for manufacturing partners. Utilizing third-party compliance verification services can also provide an added layer of assurance, enabling buyers to confidently source WM dolls that meet safety regulations.

Scenario 2: Addressing Quality Control Issues in Manufacturing

The Problem: Quality control is a significant concern for businesses sourcing WM dolls, particularly when dealing with international suppliers. Variability in manufacturing processes can lead to defects, which not only affect customer satisfaction but can also tarnish a brand’s reputation. For instance, issues like poor joint articulation or material inconsistencies can result in higher return rates and increased operational costs.

The Solution: To ensure consistent quality, establish robust quality assurance protocols with your suppliers. This includes setting clear performance benchmarks, such as maintaining an acceptable quality level (AQL) of 2.5 for final shipments and verifying that production lines are ISO 9001-certified. Conduct regular factory audits and in-process quality checks at multiple manufacturing stages to catch defects early. Additionally, consider implementing a vendor scorecard system to evaluate supplier performance over time, focusing on defect rates and responsiveness to quality issues. Building strong relationships with your suppliers can also foster a culture of quality, encouraging them to prioritize standards in their operations.

Scenario 3: Managing Supply Chain Volatility and Costs

The Problem: B2B buyers frequently encounter supply chain volatility, particularly with the fluctuating costs of raw materials like silicone and ABS resin used in WM dolls. Tariff changes, especially between major manufacturing hubs like China and the U.S., can lead to unexpected price increases and delays, complicating inventory management and pricing strategies for retailers.

The Solution: To better manage supply chain risks, buyers should diversify their supplier base and explore alternative manufacturing locations that may offer more stable pricing, such as Vietnam or Mexico. Establishing long-term contracts with suppliers can also lock in pricing and ensure availability, helping to mitigate the impacts of raw material cost volatility. Furthermore, implementing a just-in-time inventory system can reduce holding costs while providing flexibility to respond to market changes. Regularly review market trends and forecasts for raw materials, and maintain open communication with suppliers regarding potential disruptions. This proactive approach will enable buyers to adapt quickly and maintain operational efficiency despite external pressures.

Strategic Material Selection Guide for wm dolls

What Are the Key Materials Used in WM Dolls and Their Properties?

When selecting materials for WM dolls, international B2B buyers must consider various factors, including product performance, manufacturing complexity, and compliance with regional standards. Here, we analyze four common materials used in the production of WM dolls: silicone, thermoplastic elastomer (TPE), PVC, and ABS.

How Does Silicone Perform as a Material for WM Dolls?

Silicone is a popular choice for high-end WM dolls due to its realistic feel and durability. It is highly resistant to temperature fluctuations and UV light, making it suitable for various environments. Silicone also exhibits excellent flexibility, allowing for lifelike movement and posing capabilities.

Pros: Silicone is durable, non-toxic, and hypoallergenic, making it safe for skin contact. Its ability to withstand high temperatures and resist degradation adds to its longevity.

Cons: The manufacturing process for silicone dolls can be complex and costly, requiring specialized molds and techniques. Additionally, silicone is heavier than other materials, which may affect shipping costs.

Impact on Application: Silicone dolls are often preferred in markets that value realism and safety, such as Europe and North America, where compliance with safety standards like ISO 10993 is critical.

What Are the Benefits of Using Thermoplastic Elastomer (TPE) in WM Dolls?

TPE is a versatile material that combines the properties of rubber and plastic, making it an excellent choice for dolls requiring flexibility and softness. It is less expensive than silicone and easier to mold, which can reduce production costs.

Illustrative image related to wm dolls

Pros: TPE is lightweight, cost-effective, and provides a realistic touch. It also has good elasticity and can be produced in various colors, enhancing customization options.

Cons: TPE is less durable than silicone and may degrade faster with exposure to heat and sunlight. It is also more susceptible to tearing and may require careful handling.

Impact on Application: TPE dolls are often marketed in regions with price-sensitive consumers, such as parts of Africa and South America, where affordability is key. Compliance with ASTM F963 is essential for safety in these markets.

Why Is PVC Used in the Production of WM Dolls?

Polyvinyl chloride (PVC) is a widely used plastic in the toy industry, known for its rigidity and strength. It is often utilized for the internal structures of dolls, providing support and durability.

Pros: PVC is cost-effective and easy to manufacture, allowing for mass production. It can be molded into intricate shapes, making it suitable for detailed designs.

Cons: PVC is less flexible than silicone or TPE and can be prone to cracking under stress. Additionally, concerns about phthalates in PVC have led to stricter regulations in many markets.

Impact on Application: Buyers in Europe and North America must ensure that PVC dolls comply with EN71 and ASTM standards, which may require additional testing for harmful substances.

How Does ABS Compare as a Material for WM Dolls?

Acrylonitrile Butadiene Styrene (ABS) is a strong and lightweight plastic that is commonly used for the rigid parts of dolls, such as heads and joints. It offers good impact resistance and can be easily colored.

Pros: ABS is highly durable and can withstand significant wear and tear. Its ease of molding allows for complex designs, making it ideal for detailed dolls.

Cons: ABS can be more expensive than PVC and may require additional processing steps, such as painting or coating, to achieve the desired finish.

Impact on Application: ABS is favored in markets with stringent quality expectations, such as Europe, where compliance with safety regulations is paramount. Buyers should ensure that ABS products meet the necessary standards for safety and quality.

Summary Table of Material Selection for WM Dolls

| Material | Typical Use Case for WM dolls | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | High-end, lifelike dolls | Durable and realistic feel | Higher manufacturing complexity | High |

| TPE | Affordable, flexible dolls | Cost-effective and customizable | Less durable than silicone | Medium |

| PVC | Structural components | Cost-effective and easy to mold | Prone to cracking and regulatory concerns | Low |

| ABS | Rigid parts and joints | Strong and impact-resistant | More expensive and requires processing | Medium |

This guide provides a comprehensive overview of the materials commonly used in WM dolls, equipping B2B buyers with the knowledge needed to make informed decisions based on their target markets and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for wm dolls

What Are the Main Stages of WM Dolls Manufacturing Processes?

The manufacturing process of WM dolls involves several critical stages that ensure the final product meets the desired quality and specifications. These stages include material preparation, forming, assembly, and finishing.

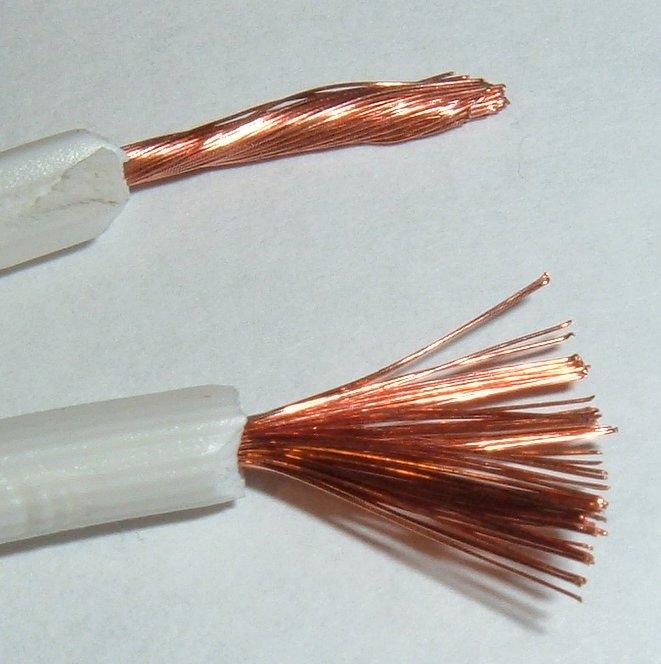

Illustrative image related to wm dolls

1. Material Preparation: What Materials Are Used for WM Dolls?

WM dolls are primarily made from silicone and TPE (thermoplastic elastomer). The selection of materials is crucial, as they impact the doll’s realism, durability, and safety. Manufacturers typically source high-quality, phthalate-free silicone and TPE to comply with international safety regulations. This stage includes:

- Material Sourcing: Identifying and acquiring raw materials that meet safety and quality standards.

- Batch Testing: Conducting tests to ensure the materials comply with standards such as ISO 10993 for medical-grade silicone, ensuring they are safe for skin contact.

2. Forming: How Are WM Dolls Shaped and Molded?

Forming is a crucial phase where the prepared materials are shaped into doll components. This stage employs advanced techniques such as:

- Injection Molding: Used for creating intricate parts like joints and facial features. This method allows for high precision and consistency.

- 3D Printing: Increasingly used for custom doll components, enabling manufacturers to produce unique designs efficiently.

During forming, manufacturers ensure that molds are carefully designed to minimize defects and ensure uniformity across production runs.

3. Assembly: How Are the Components of WM Dolls Joined?

Once the components are formed, the assembly process begins. This stage involves:

- Joint Assembly: Connecting various parts, including limbs and heads, ensuring the joints are articulated correctly for flexibility and poseability.

- Quality Checks: Implementing in-process quality checks (IPQC) to identify any issues early in the assembly process.

This stage is critical for ensuring that the dolls can withstand movement and maintain their integrity over time.

4. Finishing: What Final Touches Are Applied to WM Dolls?

The finishing stage focuses on the aesthetic and functional aspects of the dolls. Key activities include:

- Surface Treatment: Applying coatings or treatments to enhance the doll’s appearance and protect the material.

- Detailing: Painting, hair application, and adding accessories to create realistic features.

Final quality checks (FQC) are conducted to ensure that the dolls meet the expected standards before they are packaged for shipment.

What Quality Assurance Practices Are Essential for WM Dolls?

Quality assurance (QA) is paramount in the production of WM dolls, as it ensures compliance with international standards and customer satisfaction. Manufacturers must adhere to several relevant quality standards and implement rigorous QA practices.

1. What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with various international quality standards, including:

- ISO 9001: This standard pertains to quality management systems and emphasizes customer satisfaction and continuous improvement. Manufacturers certified under ISO 9001 demonstrate a commitment to quality at all stages of production.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- ASTM F963: A safety standard for toys in the U.S., ensuring that products are free from hazardous materials.

Understanding these standards helps buyers assess supplier reliability and product safety.

2. What Are the Key Quality Control Checkpoints in WM Dolls Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Conducting regular inspections during production to identify defects early.

- Final Quality Control (FQC): A comprehensive inspection of finished products to ensure they meet all quality and safety standards.

These checkpoints are essential for maintaining high-quality output and minimizing defects.

3. How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can adopt several strategies to verify supplier quality control practices:

- Factory Audits: Conducting on-site audits to assess production processes, quality management systems, and compliance with international standards.

- Quality Reports: Requesting detailed quality reports that outline testing results, defect rates, and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services to evaluate product quality before shipment, providing an unbiased assessment of the supplier’s quality control measures.

These actions help buyers ensure that their suppliers maintain high standards and deliver reliable products.

What Are the Common Testing Methods Used in Quality Assurance for WM Dolls?

Manufacturers utilize various testing methods to ensure that WM dolls meet quality and safety standards. Common methods include:

Illustrative image related to wm dolls

- Material Testing: Evaluating raw materials for compliance with safety regulations, including tests for phthalates, heavy metals, and flammability.

- Durability Testing: Conducting drop tests and joint movement tests to assess the dolls’ resilience and longevity. For example, dolls should withstand a minimum of 50,000 movement cycles without failure.

- Colorfastness Testing: Ensuring that colors remain vibrant and do not fade after prolonged exposure to UV light, typically tested over 500 hours.

These tests are vital for validating the product’s quality and ensuring it meets customer expectations.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions have varying compliance requirements, such as EN71 for Europe and GB 6675 for China. Buyers must ensure that suppliers are familiar with and can meet these regulations.

- Cultural Considerations: Understanding local market preferences and safety standards can influence purchasing decisions. Buyers should communicate their specific requirements clearly to suppliers.

- Tariff and Trade Considerations: Fluctuations in tariffs and trade agreements can affect pricing and availability. Buyers should stay informed about geopolitical developments that may impact their supply chains.

By being aware of these nuances, B2B buyers can better navigate the complexities of sourcing WM dolls from international suppliers.

Conclusion

Understanding the manufacturing processes and quality assurance practices for WM dolls is essential for B2B buyers aiming to source high-quality products. By familiarizing themselves with the stages of production, relevant international standards, and effective quality control measures, buyers can make informed decisions that lead to successful partnerships with manufacturers. As the global market for collectible dolls continues to grow, maintaining high standards of quality and safety will be crucial for success in this competitive industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wm dolls’

To assist B2B buyers in procuring WM dolls effectively, this step-by-step checklist outlines essential actions for a successful sourcing process. Understanding these steps will help you navigate the complexities of international purchasing and ensure that you select the right products and suppliers for your market.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical specifications. This includes material composition, size, and features such as joint articulation or any electronic components. Having detailed specifications ensures that your suppliers understand your requirements, reducing the risk of receiving products that do not meet your needs.

- Material Types: Specify whether you need silicone, TPE, or other materials, as each has different qualities and price points.

- Functional Features: Decide on features like heating elements or voice capabilities that can differentiate your product in the market.

Step 2: Verify Supplier Certifications

Ensuring that potential suppliers hold the necessary certifications is critical to maintaining product safety and compliance. Look for certifications that align with international standards, such as ISO 8124 for safety compliance and ISO 10993 for medical-grade silicone.

- Safety Compliance: Confirm that suppliers can provide documentation proving adherence to safety standards relevant to your target markets (e.g., EN71 for Europe).

- Quality Management: Check for ISO 9001 certification to ensure that the supplier follows quality management practices.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to ensure reliability and quality. Request company profiles, product samples, and references from other B2B buyers in your industry.

- Supplier Track Record: Look for suppliers with a proven history of reliability, such as those with over five years in business and high ratings from other buyers.

- Production Capacity: Confirm that the supplier can meet your volume requirements, especially if you are looking for large orders.

Step 4: Assess Compliance with Local Regulations

Different regions have varying compliance requirements for toys and dolls. Familiarize yourself with the regulations applicable to your target market to avoid legal issues.

- Documentation Requirements: Ensure that suppliers can provide documentation proving compliance with local safety standards.

- Material Safety: Verify that materials used are free from harmful substances, especially if you are targeting markets with stringent regulations.

Step 5: Analyze Pricing and MOQs

Understanding the pricing structure and minimum order quantities (MOQs) is vital for budgeting and inventory management. Analyze the cost per unit, including hidden fees such as shipping and customs duties.

- Volume Discounts: Inquire about price breaks for larger orders, as significant savings can often be achieved with higher MOQs.

- Total Cost of Ownership: Consider not just the unit price but also logistics costs and potential tariffs when calculating your overall expenditure.

Step 6: Implement Quality Assurance Protocols

Establishing quality assurance protocols will help ensure that the products you receive meet your specifications and standards. Request details on the supplier’s quality control processes and inspection standards.

- Inspection Standards: Look for suppliers who adhere to AQL (Acceptable Quality Limit) standards, ideally at 2.5 or lower.

- In-Process Checks: Ensure that the supplier conducts quality checks at multiple stages of production to catch defects early.

Step 7: Confirm After-Sales Support and Warranty

After-sales support is crucial for maintaining a good relationship with your supplier and ensuring customer satisfaction. Confirm the availability of warranties and support services before finalizing your order.

- Warranty Terms: Look for suppliers that offer a minimum two-year warranty on their products.

- Parts Availability: Ensure that the supplier maintains a high inventory rate for replacement parts to facilitate quick resolutions for any issues that may arise.

By following this checklist, B2B buyers can streamline their sourcing process for WM dolls, ensuring they select the best products and suppliers while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for wm dolls Sourcing

What Are the Key Cost Components in Sourcing WM Dolls?

Understanding the cost structure of WM dolls is essential for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. WM dolls are typically made from silicone or TPE, with silicone being more expensive due to its durability and realistic feel. The rising prices of raw materials, particularly silicone and ABS resin, can impact overall costs.

-

Labor: Labor costs vary by region. Manufacturers in countries with lower labor costs, such as China and Vietnam, can offer competitive pricing. However, labor quality and skill level also play a crucial role in the final product’s quality.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and maintenance. Efficient production lines and economies of scale can help reduce these costs.

-

Tooling: Custom molds for WM dolls can range from $3,000 to $15,000, depending on complexity. Buyers should factor in these costs, especially for unique designs or large orders.

-

Quality Control (QC): Implementing stringent QC protocols is vital for ensuring product reliability. Compliance with international standards (e.g., ISO 9001) may incur additional costs but is essential for maintaining product integrity.

-

Logistics: Shipping and handling costs can vary widely based on distance, mode of transport, and volume. Buyers should consider Incoterms to understand who bears responsibility for shipping costs and risks.

-

Margin: Suppliers typically mark up their prices to cover operational costs and generate profit. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Affect WM Dolls Pricing?

Several factors influence the pricing of WM dolls, which are crucial for B2B buyers to consider:

-

Volume/MOQ: Minimum order quantities (MOQs) significantly affect pricing. Suppliers often provide better rates for larger orders, so buyers should evaluate their capacity to scale orders to leverage volume discounts.

-

Specifications and Customization: Customized dolls may incur additional costs for unique features or designs. Buyers should clearly outline specifications to avoid unexpected charges.

-

Quality and Certifications: Products that meet stringent safety and quality certifications (e.g., EN71 for Europe) can demand higher prices. Buyers should assess whether the added cost for certified products aligns with their market needs.

-

Supplier Factors: Supplier reliability, experience, and ratings can influence pricing. Established suppliers with a proven track record may charge higher prices but offer better quality assurance and service.

-

Incoterms: The choice of Incoterms can affect overall costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers anticipate total landed costs.

What Are the Best Negotiation Strategies for Buyers in Different Regions?

B2B buyers should adopt specific strategies tailored to their regional contexts:

-

Negotiate with Transparency: Clearly communicate your budget and expectations. Suppliers appreciate honesty, which can foster stronger relationships and better deals.

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also shipping, duties, and potential warehousing costs. This holistic view can help in evaluating supplier proposals effectively.

-

Leverage Local Market Knowledge: Buyers from regions like Africa and South America should utilize their understanding of local trends and consumer preferences to negotiate better terms.

-

Timing is Key: Recognize peak seasons for manufacturing and shipping. Placing orders during off-peak periods can yield better pricing and availability.

What Are Important Pricing Nuances for International Buyers?

Navigating the complexities of international sourcing requires awareness of specific pricing nuances:

-

Currency Fluctuations: Currency exchange rates can significantly impact costs. Buyers should consider locking in rates or negotiating terms that account for potential fluctuations.

-

Tariff Implications: Be aware of tariffs and trade policies that could affect import costs. Staying updated on international trade agreements can provide insights into cost-saving opportunities.

-

Cultural Sensitivity: Understanding cultural nuances in negotiation styles can enhance communication and lead to more favorable outcomes.

In summary, a comprehensive understanding of the cost structure, price influencers, and effective negotiation strategies will empower B2B buyers to make informed sourcing decisions in the competitive WM dolls market.

Alternatives Analysis: Comparing wm dolls With Other Solutions

Exploring Alternatives to WM Dolls: A Comparative Analysis

In the rapidly evolving market of collectible dolls and figures, businesses often seek alternatives to WM Dolls for various applications, such as entertainment, education, and therapeutic purposes. Understanding these alternatives is crucial for B2B buyers looking to make informed purchasing decisions that align with their specific needs and market demands.

Comparison Table

| Comparison Aspect | WM Dolls | Custom Action Figures | Interactive Plush Toys |

|---|---|---|---|

| Performance | High realism and customization options; durable materials | High durability; customizable features | Engaging interactivity; softer materials |

| Cost | $200 – $800 per unit | $10 – $50 per unit | $15 – $100 per unit |

| Ease of Implementation | Requires specific supplier relationships; longer lead times | Generally straightforward; flexible sourcing | Simple design; mass production availability |

| Maintenance | Low maintenance; cleaning recommended | Low maintenance; minimal care needed | Moderate; requires battery replacements for interactive features |

| Best Use Case | Collectors, adult markets, therapeutic uses | Gift markets, promotional items, collectors | Children’s toys, educational settings, therapy tools |

Detailed Breakdown of Alternatives

Custom Action Figures

Custom action figures represent a viable alternative for businesses looking for personalized merchandise. They can be tailored to specific character designs or branding needs, making them suitable for promotional campaigns or collector items. The primary advantage lies in their affordability and ease of sourcing, especially for smaller businesses. However, they may lack the high-end realism and detailed craftsmanship found in WM Dolls, making them less appealing for niche markets focused on adult collectors or therapeutic applications.

Interactive Plush Toys

Interactive plush toys offer a softer, more engaging option for the younger demographic or therapeutic environments. These toys often incorporate sound and motion, providing a level of interactivity that can enhance user engagement. Their lower price point and widespread availability make them accessible for businesses targeting educational or entertainment sectors. However, they may not meet the quality expectations of adult collectors, as their realism and durability may not match that of WM Dolls.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between WM Dolls and alternative solutions, B2B buyers should carefully consider their target market and the intended use of the product. If the goal is to cater to adult collectors or therapeutic applications, the investment in WM Dolls may yield better returns due to their high realism and customization capabilities. Conversely, for businesses aiming to attract younger audiences or looking for cost-effective promotional items, custom action figures or interactive plush toys may be more suitable. Analyzing performance, cost, ease of implementation, and maintenance will guide buyers toward making the best decision for their unique business needs.

Essential Technical Properties and Trade Terminology for wm dolls

What Are the Critical Technical Specifications for WM Dolls?

When sourcing WM dolls, understanding the essential technical properties can significantly influence purchasing decisions. Here are key specifications to consider:

1. Material Composition

WM dolls are primarily made from silicone or thermoplastic elastomer (TPE). Each material has distinct characteristics; silicone is known for its durability and realism, while TPE offers a softer touch and is generally less expensive. For B2B buyers, knowing the material can help assess product quality and compliance with safety regulations.

2. Joint Articulation Points

The number of articulation points is crucial for poseability and realism. A minimum of 12 joint points is recommended for functional dolls. This specification is essential for manufacturers targeting adult collectors or interactive markets, as it affects the doll’s usability and appeal.

Illustrative image related to wm dolls

3. Compliance Certifications

Documentation such as ISO 8124 (safety for toys) or ISO 10993 (biocompatibility for skin contact) is vital. These certifications ensure that the products meet international safety standards, which is particularly important in regions like Europe and North America where regulations are stringent. Non-compliance can lead to costly recalls and damage to brand reputation.

4. Durability Testing

Performance benchmarks, including drop-test results and UV resistance ratings, are critical for quality assurance. For instance, a minimum drop height resilience of 1.5 meters ensures that dolls can withstand everyday handling. B2B buyers should prioritize suppliers who provide these metrics, as they indicate product longevity and reduce the risk of returns.

5. Weight Tolerance

Understanding the weight specifications is essential, especially for life-size dolls. Manufacturers should specify the weight limit for safe handling and transportation. This property is particularly important for logistics planning and can influence shipping costs.

6. Customization Options

The ability to customize dolls with different features (hair, skin tone, accessories) can be a competitive advantage. Buyers should inquire about the supplier’s capacity for custom orders and the associated minimum order quantities (MOQs). This flexibility can meet diverse market demands and enhance customer satisfaction.

What Are Common Trade Terms in the WM Dolls Industry?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are sold under another company’s brand. In the WM dolls industry, this means that a manufacturer can produce dolls based on a buyer’s specifications, which can be beneficial for companies looking to expand their product lines without investing in production facilities.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cash flow. Understanding MOQs helps buyers negotiate better terms and plan their purchasing strategy effectively.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer solicits price proposals from suppliers for specific products. This process allows buyers to compare pricing and terms from multiple suppliers, ensuring they get the best deal for WM dolls.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in global trade. Understanding Incoterms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for B2B transactions, as they clarify who is responsible for shipping costs and risks at various stages of the shipping process.

5. AQL (Acceptable Quality Level)

AQL is a statistical measurement used to determine the maximum number of defective items acceptable in a sample batch. For WM doll manufacturers, maintaining an AQL of 2.5 or lower is crucial for quality assurance, as it ensures that products meet customer expectations and reduce returns.

6. Supply Chain Transparency

This term refers to the clarity and traceability of the supply chain processes from raw materials to the final product. For B2B buyers, ensuring supply chain transparency can mitigate risks related to compliance, ethical sourcing, and quality control, ultimately leading to stronger supplier relationships.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, mitigate risks, and enhance their sourcing strategies in the competitive WM doll market.

Navigating Market Dynamics and Sourcing Trends in the wm dolls Sector

What Are the Current Market Dynamics and Key Trends in the WM Dolls Sector?

The global market for collectible dolls, including WM Dolls, is projected to reach approximately $24.8 billion by 2028, with a compound annual growth rate (CAGR) of 6.3%. This growth is primarily fueled by increasing disposable incomes, the influence of pop culture, and advancements in manufacturing technologies. Emerging B2B technology trends include the integration of 3D printing for customizable doll components and the utilization of artificial intelligence in interactive dolls, which enhance user engagement.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the robust demand for thematic dolls, especially in horror and anime genres, which have shown a significant increase in margins—22% higher than generic alternatives. However, navigating this dynamic market requires an understanding of raw material price volatility, particularly for silicone and ABS resin, as well as compliance with stringent international regulations. Tariff fluctuations between the U.S. and China have prompted some manufacturers to relocate production to countries like Vietnam and Mexico, creating opportunities for buyers to diversify their supply chains.

How Does Sustainability and Ethical Sourcing Impact the WM Dolls Sector?

In today’s marketplace, sustainability and ethical sourcing are not just buzzwords but essential components of B2B procurement strategies. The environmental impact of production processes for WM Dolls, particularly concerning plastic waste and resource consumption, is becoming increasingly scrutinized. As a result, many manufacturers are transitioning to phthalate-free PVC and biodegradable plastics in response to tightening regulations in Europe and the U.S.

For B2B buyers, sourcing from suppliers who hold ‘green’ certifications, such as ISO 14001 for environmental management, can enhance brand reputation and meet growing consumer demand for sustainable products. Ethical supply chains are also critical, as buyers must ensure compliance with labor laws and fair working conditions. This focus not only mitigates risks associated with potential backlash from unethical practices but also aligns with the values of a socially conscious consumer base. Establishing partnerships with suppliers committed to sustainability can provide a competitive edge in a crowded market.

What is the Brief Evolution and History of WM Dolls in the B2B Market?

The evolution of WM Dolls traces back to the early 2000s when the demand for realistic and customizable dolls began to surge, fueled by advancements in materials and manufacturing techniques. Initially focused on traditional dolls, the industry has since diversified to include silicone and thermoplastic elastomer (TPE) variants, catering to a broader range of consumer preferences.

Illustrative image related to wm dolls

The rise of online marketplaces has further transformed the B2B landscape, allowing international buyers to access a plethora of suppliers and products. This democratization of sourcing has enabled smaller businesses in regions like Africa and South America to compete alongside established players in Europe and the Middle East. As the market continues to evolve, embracing technology and sustainability will be crucial for maintaining a competitive edge and meeting the demands of an increasingly discerning customer base.

Frequently Asked Questions (FAQs) for B2B Buyers of wm dolls

-

How do I ensure the quality of WM dolls before placing a bulk order?

To ensure the quality of WM dolls, conduct thorough supplier vetting. Request product samples and review technical specifications, such as material certifications and safety compliance documents (ISO 8124, ASTM F963). Implement quality assurance protocols by verifying the supplier’s production standards, including ISO 9001 certification and AQL 2.5 inspection standards for final shipments. Additionally, consider factory audits and check for positive customer feedback or reviews to gauge reliability. -

What are the minimum order quantities (MOQs) for WM dolls?

Minimum order quantities for WM dolls can vary significantly by supplier and product type. Typically, MOQs can range from as low as 1 box for collectibles to 5,000 pieces for custom plastic dolls. It’s essential to discuss MOQs directly with suppliers during negotiations, as some may offer flexibility for first-time buyers or bulk orders. Understanding the MOQ will help you assess your budget and storage capabilities before making a commitment. -

What payment terms should I expect when sourcing WM dolls internationally?

Payment terms for international orders often include options such as advance payment, letter of credit, or payment upon delivery. Commonly, suppliers may require a deposit (30-50%) upon order confirmation, with the balance due before shipment. It’s crucial to clarify these terms in your initial discussions to avoid misunderstandings. Additionally, consider using secure payment methods to mitigate risks associated with international transactions. -

How can I customize WM dolls to meet my market needs?

Customization options for WM dolls can include alterations in design, size, color, and material. Many manufacturers offer bespoke services, allowing you to tailor dolls to specific demographics or themes, such as horror or anime. When discussing customization, provide clear specifications and ask about the minimum order quantities required for custom designs. Ensure that the manufacturer has experience with similar projects to achieve the desired quality and uniqueness. -

What logistics considerations should I keep in mind when importing WM dolls?

When importing WM dolls, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose between air freight for faster delivery or sea freight for cost-effective bulk shipping. Understand the import duties and taxes applicable in your region, as these can significantly impact overall costs. Establish a reliable logistics partner familiar with international trade to streamline the shipping process and ensure compliance with local regulations. -

What are the key compliance requirements for selling WM dolls in my region?

Compliance requirements vary by region. In Europe, ensure products meet EN71 standards, while in the U.S., ASTM F963 applies. For dolls intended for skin contact, medical-grade silicone certification (ISO 10993) is essential. Always ask suppliers for third-party testing documentation covering phthalates, heavy metals, and flammability standards. Compliance with these regulations is crucial for market entry and to avoid potential legal issues. -

How can I assess the reliability of a WM doll supplier?

To assess supplier reliability, check their business credentials, such as years in operation and customer ratings. Look for verified suppliers with a proven track record in the industry, ideally with experience exporting to your region. Request references from previous clients and examine their response times to inquiries. Conducting factory audits or third-party assessments can also provide insights into their manufacturing practices and quality control measures. -

What trends should I be aware of in the WM doll market?

Stay informed about market trends such as the growing demand for customizable and interactive dolls, driven by technological advancements like AI and 3D printing. The market is projected to reach $24.8 billion by 2028, with a significant focus on horror and anime themes. Additionally, sustainability is becoming increasingly important, with manufacturers exploring biodegradable materials. Understanding these trends will help you position your offerings effectively and capitalize on emerging opportunities.

Top 2 Wm Dolls Manufacturers & Suppliers List

1. Accio – Realistic & Customizable WM Dolls

Domain: accio.com

Registered: 1997 (28 years)

Introduction: WM Dolls: Realistic, Customizable & Silicone Options | Premium Collections. Categories include Realistic WM Dolls, Customizable WM Dolls, Silicone WM Dolls, TPE WM Dolls, Mini WM Dolls, Life-size WM Dolls, WM Dolls with Heating, WM Dolls with Voice, and WM Dolls with Movable Joints. Pricing ranges from $0.35 to $880. Minimum order quantities (MOQ) start at <5. Verified suppliers with 5+ years of e…

2. WMDOLL – High-End Realistic Dolls

Domain: wmdoll.ca

Registered: 2018 (7 years)

Introduction: This company, WMDOLL – High-End Realistic Dolls, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for wm dolls

As the global market for collectible dolls continues to expand, strategic sourcing of WM dolls presents a unique opportunity for international buyers. With projected growth of 6.3% annually, the demand for customizable and realistic dolls, especially those made from sustainable materials, is on the rise. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who demonstrate compliance with international safety standards and offer high-quality materials, such as medical-grade silicone and phthalate-free plastics.

Leveraging partnerships with verified manufacturers can ensure quality assurance and compliance with regional regulations, thus mitigating risks associated with raw material volatility and intellectual property challenges. Furthermore, staying abreast of emerging trends—like the integration of AI in dolls and the growing popularity of horror and anime themes—can provide competitive advantages in this dynamic market.

In conclusion, the future of WM dolls is bright, and now is the time for B2B buyers to engage with reliable suppliers and diversify their product offerings. By making informed sourcing decisions today, businesses can position themselves favorably for tomorrow’s market demands. Embrace the potential of strategic sourcing to drive growth and innovation in your product lineup.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.