The Definitive Guide to Wire Reel: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for wire reel

In today’s rapidly evolving industrial landscape, sourcing the right wire reel can present significant challenges for B2B buyers. Whether you are looking for robust wire spool dispensers for construction projects in Africa or heavy-duty cable reel stands for manufacturing operations in Europe, understanding the diverse types and applications of wire reels is crucial. This guide is designed to navigate the complexities of the global wire reel market, offering insights into various types of wire reels, their specific applications, and best practices for supplier vetting.

With a focus on cost analysis and quality assurance, this comprehensive resource empowers international B2B buyers from Africa, South America, the Middle East, and Europe—particularly countries like Germany and Saudi Arabia—to make informed purchasing decisions. By delving into the intricacies of wire reel specifications, operational efficiencies, and market trends, buyers can enhance their procurement strategies and ensure they select the most suitable products for their needs.

As you explore this guide, you will gain valuable insights that not only help streamline your sourcing process but also optimize your operational capabilities. Equip yourself with the knowledge to navigate the global market effectively, ensuring you invest wisely in wire reel solutions that align with your business objectives.

Understanding wire reel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Wire Reel | Typically made of plastic or metal; used for general wire storage | Electrical, construction, and manufacturing | Pros: Versatile, cost-effective. Cons: Limited capacity. |

| Powered Cable Reel Stand | Electric drive system for automated dispensing; heavy-duty construction | Industrial cable management and retrieval | Pros: Increases efficiency, ideal for heavy loads. Cons: Higher initial investment. |

| Wire Spool Dispenser | Portable design with wheels; can handle various spool sizes | On-site construction and electrical work | Pros: Mobility, ease of use. Cons: May not support larger reels. |

| Heavy-Duty Cable Reel | Constructed from robust materials; designed for high-capacity loads | Oil & gas, telecommunications, and heavy industries | Pros: Durable, supports large volumes. Cons: Bulkier, requires more space. |

| Collapsible Wire Dispenser | Space-saving design; adjustable for different reel sizes | Retail and small-scale electrical projects | Pros: Compact storage, versatile. Cons: Less stable with larger reels. |

What Are the Characteristics of a Standard Wire Reel?

Standard wire reels are essential for various industries, featuring a simple design usually made from plastic or metal. They are primarily used for storing and dispensing wire and cables in electrical, construction, and manufacturing sectors. When purchasing, buyers should consider the reel’s capacity and material, as these factors influence durability and suitability for specific applications.

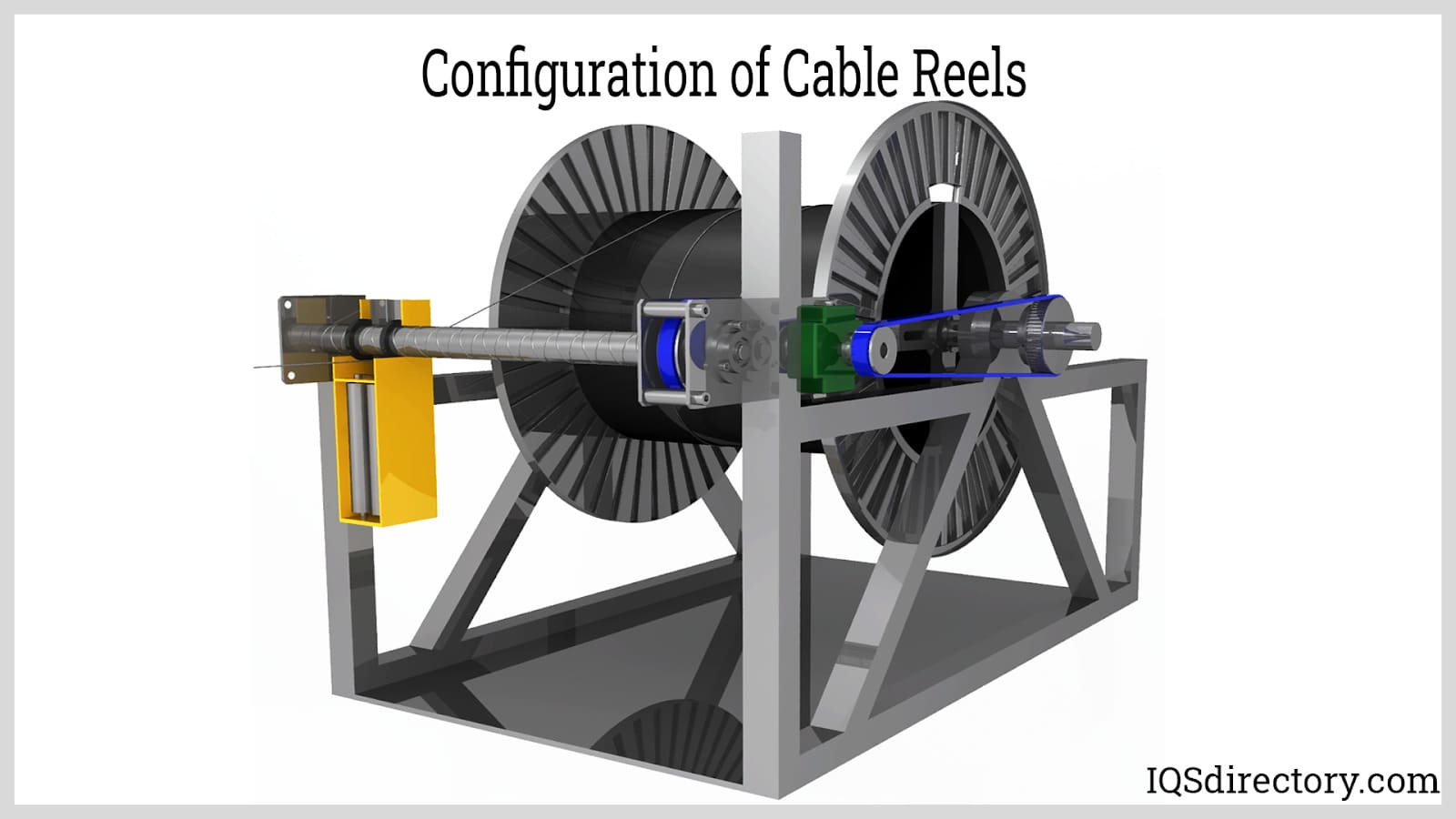

How Does a Powered Cable Reel Stand Enhance Efficiency?

Powered cable reel stands are designed for heavy-duty tasks, equipped with electric drive systems that facilitate automated dispensing and retrieval of cables. These stands are particularly advantageous in industrial settings where large volumes of wire are handled, such as in oil & gas or telecommunications. Buyers should weigh the initial investment against the potential for increased productivity and reduced manual labor.

What Advantages Do Wire Spool Dispensers Offer?

Wire spool dispensers are portable and often equipped with wheels, making them ideal for on-site applications in construction and electrical work. They accommodate various spool sizes, allowing for flexibility in wire handling. Buyers should assess the mobility and ease of use against the dispenser’s capacity, especially if larger reels are frequently used.

Why Choose a Heavy-Duty Cable Reel for Industrial Applications?

Heavy-duty cable reels are built from robust materials to support high-capacity loads, making them suitable for industries like oil & gas and telecommunications. Their durability ensures they can withstand harsh conditions and extensive use. Buyers must consider the space required for these reels, as their size can limit placement options in the workspace.

What Makes Collapsible Wire Dispensers Ideal for Small Projects?

Collapsible wire dispensers offer a space-saving solution for businesses with limited storage. Their adjustable design accommodates different reel sizes, making them versatile for retail and small-scale electrical projects. While they provide convenience, buyers should be mindful of stability issues when used with larger reels, ensuring they meet the demands of their specific applications.

Key Industrial Applications of wire reel

| Industry/Sector | Specific Application of wire reel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical & Telecommunications | Cable management for installations | Streamlines installation processes, reduces downtime | Durability, load capacity, and compatibility with existing systems |

| Construction & Infrastructure | Power supply distribution on job sites | Enhances efficiency in power delivery and reduces risks | Weather resistance, portability, and ease of setup |

| Manufacturing & Assembly | Material handling for assembly lines | Increases productivity and minimizes material waste | Customization options and reel size compatibility |

| Oil & Gas | Transporting and managing drilling cables | Ensures operational safety and efficiency in remote locations | Corrosion resistance and capacity for heavy loads |

| Automotive | Wire harness assembly and storage | Improves organization and speeds up production cycles | Versatile design and ease of access for assembly teams |

How is Wire Reel Used in the Electrical & Telecommunications Industry?

In the electrical and telecommunications sector, wire reels are essential for managing and dispensing cables during installations. They help streamline the installation process by preventing tangles and kinks, which can lead to downtime and increased labor costs. Buyers in this sector should prioritize reels that offer high durability and load capacity to accommodate various cable types. Additionally, compatibility with existing systems is crucial for efficient integration.

What Role Does Wire Reel Play in Construction & Infrastructure?

Wire reels are vital on construction sites for the distribution of power supply cables. They facilitate the organized deployment of electrical wiring, reducing the risk of hazards associated with loose cables. This efficiency not only speeds up project timelines but also enhances safety protocols. Buyers should consider sourcing reels that are weather-resistant and portable to ensure they can withstand harsh environmental conditions while being easy to transport across job sites.

How Do Wire Reels Benefit Manufacturing & Assembly Operations?

In manufacturing and assembly environments, wire reels assist in the handling of materials, particularly in assembly lines. They improve productivity by ensuring that materials are organized and readily accessible, thus minimizing waste and delays. Businesses should look for customizable options that can accommodate various reel sizes and configurations, allowing for seamless integration into their existing workflows.

What Applications Exist for Wire Reels in the Oil & Gas Sector?

In the oil and gas industry, wire reels are crucial for transporting and managing drilling cables in remote locations. They ensure that cables are stored safely and can be deployed quickly, thus maintaining operational efficiency. Buyers should focus on sourcing reels that offer corrosion resistance and the capacity to handle heavy loads, given the rugged environments typical in this sector.

How are Wire Reels Utilized in the Automotive Industry?

Wire reels are used extensively in the automotive industry for assembling wire harnesses. They help keep wires organized and accessible during the production process, leading to faster assembly times and improved quality control. Buyers in this sector should consider the versatility of design and ease of access for assembly teams when sourcing wire reels, as these factors significantly impact operational efficiency.

3 Common User Pain Points for ‘wire reel’ & Their Solutions

Scenario 1: Difficulty in Managing Wire Dispensing Efficiency

The Problem:

In many industrial settings, B2B buyers often encounter inefficiencies when dispensing wire from reels. This can be particularly challenging in environments where multiple technicians are working simultaneously, leading to tangled wires, wasted time, and potential safety hazards. Inadequate wire dispensers can exacerbate these issues, resulting in delays and increased labor costs. Buyers need a solution that streamlines the dispensing process while ensuring safety and ease of use.

The Solution:

To address this challenge, consider investing in high-quality wire reel dispensers designed for ease of use and efficiency. Products like the Tug Wise Extreme, which can hold up to 6000 lbs, provide a robust solution for heavy-duty applications. Implementing a system that incorporates these dispensers will facilitate smooth wire pulling and reduce the chances of tangling. Ensure that dispensers are placed strategically throughout the workspace to minimize movement and downtime. Additionally, training staff on proper wire handling techniques can significantly improve dispensing efficiency and safety.

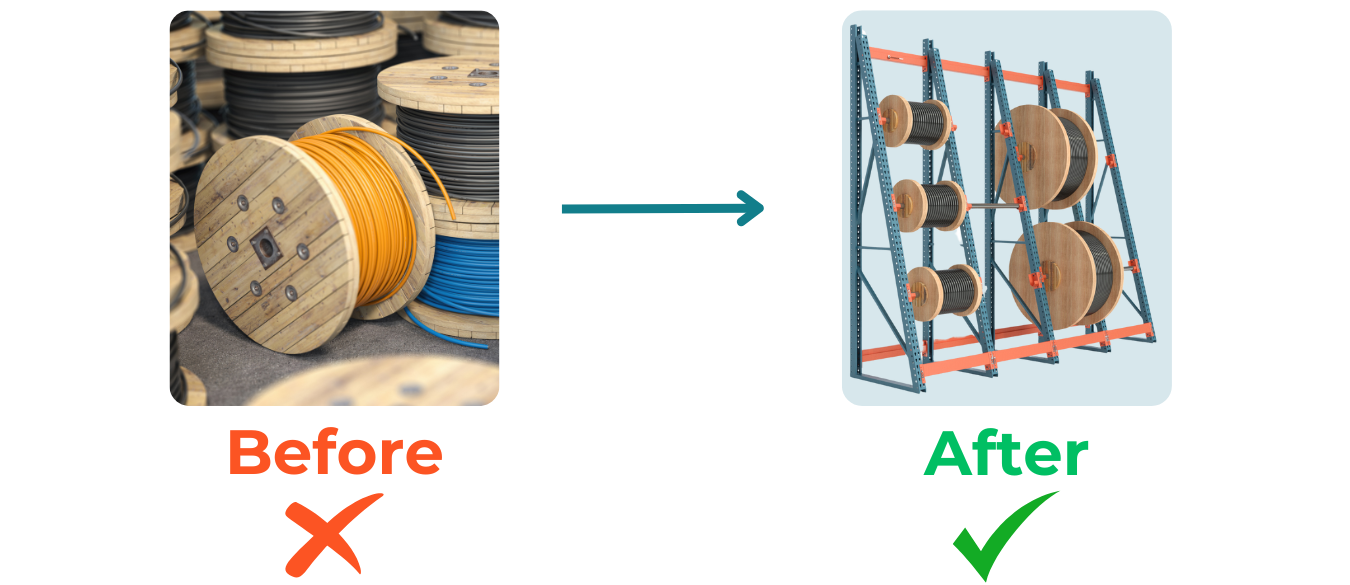

Scenario 2: Inadequate Storage Solutions Leading to Damage

The Problem:

B2B buyers frequently face issues with inadequate storage solutions for wire reels, which can lead to damage over time. Poorly designed storage can result in wires becoming kinked or frayed, which not only affects performance but also poses safety risks. This is particularly critical for companies dealing with high-value cables or specialty wires, where even minor damage can lead to significant financial losses.

The Solution:

To mitigate these risks, buyers should seek heavy-duty wire storage solutions that prioritize protection and accessibility. For instance, investing in a large wire storage and dispensing cart, like Clyde’s Cart, can provide a dedicated space for multiple reels, preventing them from being stacked improperly or exposed to elements that could cause wear. Moreover, implementing a first-in, first-out (FIFO) inventory system ensures older reels are used first, reducing the chances of deterioration. Regular inspections of stored wire can also help identify any potential issues before they become costly problems.

Scenario 3: Challenges with Compatibility and Adaptability

The Problem:

Another common pain point for B2B buyers is the challenge of compatibility between wire reels and existing machinery or setups. Many buyers find that the reels they purchase do not fit seamlessly with their current operational systems, leading to inefficiencies and frustration. This incompatibility can result in additional costs for adapters or modifications, further complicating the procurement process.

The Solution:

To avoid compatibility issues, it is crucial for buyers to conduct thorough research before purchasing wire reels. Look for suppliers that offer custom adaptors or modular systems, which allow for flexibility and compatibility with various setups. For example, Reelpower’s custom adaptors for their cable reel stands ensure that buyers can easily integrate new reels into their existing operations without incurring extra costs. Additionally, maintaining an open line of communication with suppliers can provide insights into the best products for specific needs, ensuring that all equipment works harmoniously together. Consider future needs and scalability when selecting wire reels to ensure longevity and adaptability in your operations.

Strategic Material Selection Guide for wire reel

What Are the Key Materials Used in Wire Reel Manufacturing?

When selecting materials for wire reels, it is essential to consider various factors including performance, cost, and application suitability. Here, we analyze four common materials used in wire reel production: steel, aluminum, plastic, and composite materials. Each material has its unique properties, advantages, and limitations that can significantly impact the end product’s performance and suitability for specific applications.

How Does Steel Perform as a Material for Wire Reels?

Steel is a widely used material for wire reels due to its exceptional strength and durability. It typically has a high tensile strength, allowing it to handle heavy loads and resist deformation under pressure. Steel wire reels can also withstand high temperatures, making them suitable for industrial applications that involve heat exposure.

Pros: Steel offers excellent durability and resistance to wear and tear. It is also relatively cost-effective compared to other metals, making it a popular choice for budget-conscious buyers.

Cons: However, steel is prone to corrosion if not properly treated or coated, which can limit its lifespan in humid or corrosive environments. Additionally, the manufacturing process can be complex, requiring specialized equipment for forming and welding.

Impact on Application: Steel wire reels are ideal for heavy-duty applications, such as construction and industrial settings, where strength is paramount. They are compatible with various media, including electrical wires and heavy cables.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for steel quality, such as ASTM or DIN specifications. In Europe, particularly Germany, buyers may prefer galvanized steel options to enhance corrosion resistance.

What Advantages Does Aluminum Offer for Wire Reels?

Aluminum is another popular material for wire reels, known for its lightweight properties and resistance to corrosion. Aluminum reels are often used in applications where weight is a critical factor, such as in portable or mobile setups.

Pros: The primary advantage of aluminum is its excellent corrosion resistance, which makes it suitable for outdoor applications. It is also easier to handle due to its lightweight nature, reducing transportation costs.

Cons: On the downside, aluminum is generally less strong than steel, which can limit its use in heavy-duty applications. It is also more expensive than steel, which can be a consideration for budget-sensitive projects.

Impact on Application: Aluminum wire reels are ideal for applications involving lighter cables or wires, such as in telecommunications or electrical installations. They are particularly suitable for environments where moisture or corrosive substances are present.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades that meet international standards, such as JIS or ASTM, to ensure product reliability and performance.

How Do Plastic Wire Reels Compare?

Plastic wire reels are gaining popularity due to their versatility and resistance to environmental factors. They are often made from high-density polyethylene (HDPE) or polypropylene, providing a lightweight and cost-effective solution.

Pros: The significant advantage of plastic reels is their resistance to corrosion and chemicals, making them suitable for a wide range of applications. They are also lightweight and easy to manufacture, which can lower production costs.

Cons: However, plastic reels may not offer the same level of strength as metal options, limiting their use in heavy-duty applications. They can also be sensitive to UV exposure, which can lead to degradation over time.

Impact on Application: Plastic wire reels are ideal for lighter applications, such as in residential or small-scale commercial settings. They are compatible with various wire types but may not be suitable for high-stress environments.

Considerations for International Buyers: Buyers should check for compliance with local safety and environmental regulations regarding plastic materials, especially in regions with strict waste management policies.

What Are the Benefits of Composite Materials for Wire Reels?

Composite materials, often a blend of plastics and fibers, are becoming increasingly popular for wire reels due to their unique properties. These materials can offer a combination of strength and lightweight characteristics.

Pros: Composites provide excellent resistance to corrosion and environmental factors while maintaining high strength-to-weight ratios. They are also less prone to deformation compared to traditional plastics.

Cons: The main disadvantage is the higher cost of composite materials, which can impact budget considerations. Additionally, the manufacturing process can be complex, requiring specialized techniques.

Impact on Application: Composite wire reels are suitable for applications where both weight and strength are critical, such as in aerospace or specialized industrial settings.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards and certifications, particularly in regions with stringent safety regulations.

Summary Table of Material Selection for Wire Reels

| Material | Typical Use Case for wire reel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial cables | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight applications | Corrosion resistance and lightweight | Less strength compared to steel | High |

| Plastic | Residential or light-duty use | Corrosion and chemical resistance | Lower strength and UV sensitivity | Low |

| Composite | Specialized industrial use | High strength-to-weight ratio | Higher cost and complex manufacturing | High |

This strategic material selection guide provides insights into the different materials used in wire reel manufacturing, helping B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for wire reel

What Are the Key Stages in the Manufacturing Process of Wire Reels?

The manufacturing process of wire reels encompasses several critical stages, each contributing to the final product’s durability and functionality. Understanding these stages can help B2B buyers evaluate potential suppliers and ensure they are receiving high-quality products.

1. Material Preparation: What Materials Are Used in Wire Reel Manufacturing?

The first step in manufacturing wire reels is material preparation. Typically, manufacturers use high-strength steel or aluminum, depending on the application requirements. For instance, steel is often chosen for its durability and weight-bearing capacity, while aluminum is favored for its lightweight properties and corrosion resistance.

Illustrative image related to wire reel

Suppliers may also conduct a thorough analysis of raw materials to ensure compliance with industry standards. This includes checking for impurities, tensile strength, and other mechanical properties. The quality of the raw material directly influences the performance and lifespan of the wire reels, making this stage crucial.

2. How Is the Forming Process Conducted?

Once the materials are ready, the forming process begins. This stage typically involves cutting, bending, and shaping the raw materials into the desired configurations. Various techniques, such as laser cutting or CNC machining, are used to achieve precision and reduce waste.

In the case of wire reels, the forming process may include rolling the steel or aluminum sheets into cylindrical shapes. Manufacturers often utilize hydraulic presses for this purpose, ensuring that the material is uniformly shaped and stress-free. This step is essential for ensuring that the wire reel can handle the intended load without deformation.

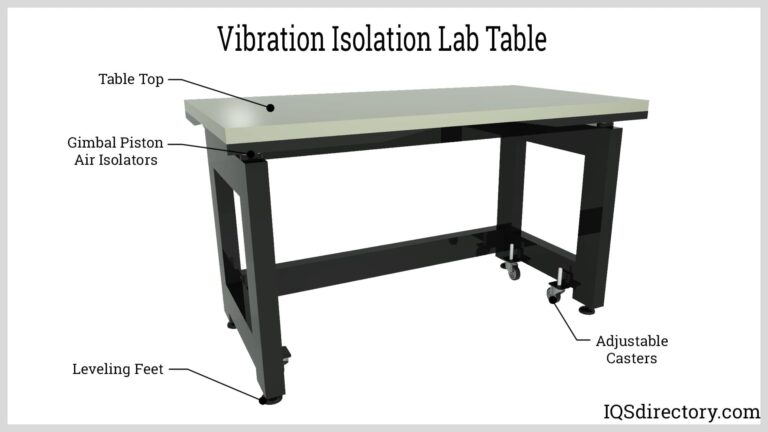

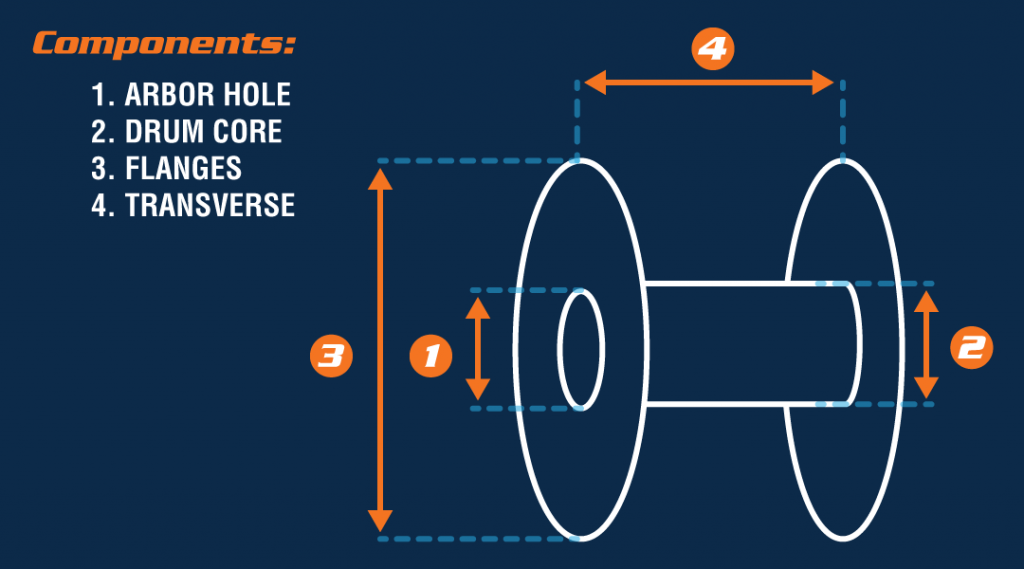

3. What Is Involved in the Assembly of Wire Reels?

After forming, the next stage is assembly, where different components of the wire reel are put together. This may include attaching the reel’s core, flanges, and any additional features like brakes or locking mechanisms. Manufacturers must ensure that all parts fit together seamlessly to maintain structural integrity.

Automated assembly lines are increasingly common in this stage, allowing for faster production rates while maintaining high accuracy. However, manual assembly may still be employed for more complex designs or custom orders. Quality checks during assembly are crucial to identify any misalignments or defects early in the process.

4. How Is the Finishing Process Conducted?

The finishing stage involves treatments that enhance the reel’s durability and aesthetic appeal. Common finishing techniques include powder coating, galvanizing, or painting. These processes not only improve the reel’s appearance but also provide protection against corrosion and wear.

Finishing is vital for wire reels that will be used in harsh environments, such as construction sites or outdoor applications. Manufacturers often conduct tests to ensure that the finishing process meets specific resistance standards, thereby enhancing the product’s longevity.

What Quality Assurance Measures Are Implemented in Wire Reel Manufacturing?

Quality assurance is a cornerstone of the wire reel manufacturing process, ensuring that products meet international standards and customer expectations. For B2B buyers, understanding these measures can help in selecting reliable suppliers.

Illustrative image related to wire reel

1. Which International Standards Are Relevant for Wire Reel Quality Assurance?

Manufacturers often adhere to international quality standards such as ISO 9001, which provides a framework for quality management systems. Compliance with ISO standards indicates that a manufacturer has established processes to ensure product quality and consistency.

Other industry-specific certifications may include CE marking for products sold in the European market, which signifies compliance with safety, health, and environmental protection standards. For buyers in regions like Africa and South America, it is essential to verify that suppliers have the necessary certifications relevant to their markets.

2. What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of production to ensure that products meet quality standards. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the quality of ongoing production. This helps identify any deviations from standards early.

-

Final Quality Control (FQC): After assembly and finishing, a final inspection ensures that the wire reels meet all specifications before shipping.

These checkpoints are crucial in maintaining high-quality standards throughout the manufacturing process.

3. How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can employ several strategies to verify the quality control measures of potential suppliers:

-

Audits: Conducting on-site audits allows buyers to assess manufacturing practices, quality control processes, and compliance with industry standards.

-

Quality Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s QC processes, including test results and compliance records.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality management practices and product quality.

Buyers in regions like Europe and the Middle East may have specific QC expectations and should communicate these clearly during the supplier evaluation process.

What Common Testing Methods Are Used in Quality Assurance for Wire Reels?

Testing methods are integral to the quality assurance process, helping to ensure that wire reels can withstand their intended use. Common testing methods include:

-

Tensile Testing: This evaluates the strength of the wire reel by applying force until failure, ensuring it can handle the required loads.

-

Corrosion Resistance Testing: This assesses the effectiveness of the finishing process in protecting against rust and degradation.

-

Load Testing: Reels are subjected to stress tests to ensure they can support their rated load without failure.

These tests provide critical data that informs buyers about the reliability and performance of the wire reels they intend to purchase.

Conclusion: How to Ensure You Choose a Quality Wire Reel Supplier

For B2B buyers, understanding the manufacturing processes and quality assurance measures of wire reels is vital for making informed purchasing decisions. By focusing on suppliers who adhere to international standards, implement rigorous quality control checkpoints, and utilize effective testing methods, buyers can ensure they receive high-quality products tailored to their specific needs. Engaging in thorough supplier evaluations, including audits and quality checks, further enhances the likelihood of a successful partnership.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire reel’

Introduction

This practical sourcing guide aims to provide B2B buyers with a comprehensive checklist for procuring wire reels. Whether you’re in Africa, South America, the Middle East, or Europe, understanding the key steps in sourcing wire reels will help ensure you make informed decisions that meet your operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to clearly define your technical specifications for wire reels. Consider factors such as the type of wire or cable being stored, the required reel dimensions, and the load capacity. This clarity will help you identify suppliers that can meet your exact needs and avoid potential issues during installation and use.

Illustrative image related to wire reel

Step 2: Research Market Trends

Stay informed about current market trends and innovations in wire reel technology. Understanding advancements such as automated dispensing systems or eco-friendly materials can enhance your operational efficiency. Additionally, being aware of market prices can help you negotiate better deals and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and service expectations. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a solid track record and experience in your specific market to ensure reliability and support.

- Check certifications: Ensure suppliers hold relevant industry certifications that reflect their commitment to quality and safety standards.

- Assess customer service: Evaluate the responsiveness and support offered by suppliers, as this can impact your procurement experience.

Step 4: Request Quotes and Proposals

Once you have shortlisted potential suppliers, request detailed quotes and proposals. Ensure that the quotes include all relevant costs, such as shipping, installation, and any additional accessories needed for the wire reels. Comparing quotes will allow you to assess the value offered by each supplier and make an informed decision.

Step 5: Review Terms and Conditions

Carefully review the terms and conditions of each supplier’s proposal. Pay close attention to payment terms, warranties, and return policies. Understanding these terms will help protect your interests and ensure you have recourse in case of any issues with the products.

Step 6: Conduct a Site Visit (if possible)

If feasible, conduct a site visit to the supplier’s facility. This will give you a firsthand look at their production capabilities and quality control processes. Engaging directly with the supplier can also foster a stronger working relationship and provide insights that may not be evident from documentation alone.

Step 7: Make an Informed Decision

After evaluating all gathered information, weigh the options based on your initial specifications, supplier reliability, cost-effectiveness, and overall value. Making an informed decision at this stage can significantly impact the efficiency and effectiveness of your operations in the long run.

By following this step-by-step checklist, B2B buyers can streamline the sourcing process for wire reels, ensuring they select the best products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for wire reel Sourcing

What Are the Key Cost Components in Wire Reel Manufacturing?

Understanding the cost structure of wire reels is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials like steel, aluminum, and plastics vary in price. For instance, steel reels may cost more due to their durability, while plastic reels are often cheaper but less robust.

-

Labor: Labor costs can fluctuate based on the region and skill level required for manufacturing. In countries with higher labor costs, manufacturers may increase prices, whereas competitive labor markets might yield lower production costs.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and equipment maintenance. Companies with high overhead might pass these expenses onto buyers, affecting the final pricing.

-

Tooling: Custom tooling for specific reel designs can be a significant upfront investment. This cost is often amortized over production runs, influencing unit costs based on order volume.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to production costs. Buyers should inquire about QC measures to understand how they impact pricing.

-

Logistics: Shipping and handling costs vary based on destination, weight, and volume. Buyers should consider these costs as part of the total purchasing decision.

-

Margin: Manufacturers typically apply a profit margin to cover their risks and ensure sustainability. Understanding a supplier’s margin can provide insight into pricing flexibility during negotiations.

How Do Price Influencers Impact Wire Reel Costs?

Several factors influence the pricing of wire reels, particularly for international B2B transactions:

-

Volume/MOQ: Larger orders often lead to bulk pricing discounts. Understanding the minimum order quantity (MOQ) can help buyers negotiate better rates.

-

Specifications and Customization: Customized solutions tailored to specific needs can raise costs. Buyers should balance their requirements with budget constraints.

-

Materials and Quality Certifications: Higher quality materials or compliance with industry certifications can increase costs. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can influence pricing. Established suppliers with a track record of quality may command higher prices but offer greater reliability.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for calculating total landed costs.

What Are Effective Buyer Tips for Negotiating Wire Reel Prices?

For international B2B buyers, particularly those from diverse regions, negotiating wire reel prices can be nuanced. Here are some actionable tips:

Illustrative image related to wire reel

-

Leverage Bulk Orders: If possible, consolidate orders to meet MOQs and negotiate discounts. Suppliers are often more willing to offer better terms for larger commitments.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and potential failures. A slightly higher upfront cost may lead to lower TCO.

-

Understand Regional Pricing Nuances: Prices may vary significantly by region due to local market conditions, currency fluctuations, and economic factors. Buyers should conduct thorough market research to inform their negotiations.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Trust can also facilitate smoother negotiations and greater flexibility in future orders.

-

Be Prepared to Walk Away: If the price does not align with your budget or expectations, be willing to explore other suppliers. This stance can empower your negotiation position.

Conclusion

While this analysis provides a comprehensive overview of the cost structure and pricing dynamics for wire reel sourcing, prices can vary widely based on numerous factors. Therefore, buyers are encouraged to conduct thorough market research and engage in strategic negotiations to secure the best possible terms. Always remember to request indicative pricing and confirm specifics with suppliers for the most accurate estimates.

Alternatives Analysis: Comparing wire reel With Other Solutions

Exploring Alternatives to Wire Reels: What B2B Buyers Should Consider

In the realm of industrial and commercial applications, wire reels are pivotal for managing cables and wires efficiently. However, various alternative solutions exist that may better suit specific operational needs. This analysis compares wire reels against other viable options, enabling B2B buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Wire Reel | Cable Drum | Wire Spool Dispenser |

|---|---|---|---|

| Performance | High, suitable for heavy loads | Moderate, limited by size | High, designed for ease of use |

| Cost | Varies, typically mid-range | Generally lower | Moderate to high |

| Ease of Implementation | Requires setup and space | Simple to deploy | User-friendly, portable |

| Maintenance | Moderate, occasional checks | Low, minimal upkeep | Low, easy to clean |

| Best Use Case | Heavy-duty applications | Light to moderate applications | Residential and commercial use |

What Are the Advantages and Disadvantages of Using a Cable Drum?

Cable drums serve as a lightweight alternative to wire reels, particularly for applications that require more mobility and flexibility. They are often easier to handle and transport, making them suitable for light to moderate workloads. However, their performance may be limited by the size and weight of the cable they can accommodate, which may not meet the demands of larger projects. For businesses focused on smaller operations or needing to frequently relocate equipment, cable drums can provide a cost-effective solution.

How Does a Wire Spool Dispenser Compare?

Wire spool dispensers are another alternative that excels in user-friendliness and mobility. These dispensers are designed to simplify the process of wire management, allowing for quick access and organization. They are particularly advantageous in residential and commercial settings where ease of use is paramount. However, they may not support the heavy loads that wire reels can handle, making them less suitable for industrial applications. For businesses looking for a portable and efficient solution for managing lighter gauge wires, wire spool dispensers can be an excellent choice.

Making the Right Choice for Your Business: What Should You Consider?

When selecting the right solution for managing wires and cables, B2B buyers should consider the specific operational requirements of their projects. If the application involves heavy-duty usage and robust performance, wire reels remain a top choice despite potentially higher costs and maintenance needs. Conversely, for lighter applications or environments that prioritize mobility and ease of use, cable drums or wire spool dispensers may be more suitable and cost-effective.

Ultimately, the decision should align with the business’s operational goals, budget constraints, and the specific demands of the tasks at hand. Careful evaluation of these aspects will ensure that the chosen solution enhances productivity and efficiency in wire management.

Essential Technical Properties and Trade Terminology for wire reel

What Are the Key Technical Properties of Wire Reels?

When sourcing wire reels, understanding their technical properties is crucial for ensuring compatibility and performance. Here are some essential specifications to consider:

Illustrative image related to wire reel

-

Material Grade

Wire reels are commonly made from materials such as steel, aluminum, or plastic. Steel reels, particularly those made from high-grade tubular steel, are preferred for their strength and durability. Aluminum reels are lighter and corrosion-resistant, making them suitable for outdoor applications. Understanding the material grade helps in assessing the reel’s longevity and suitability for specific environments. -

Load Capacity

This specification indicates the maximum weight the reel can safely support. Load capacities can range from a few hundred pounds to several tons, depending on the reel’s design and construction. For B2B buyers, selecting a reel with an appropriate load capacity is essential to prevent equipment failure and ensure safety during operations. -

Reel Diameter and Width

The dimensions of the reel, including its diameter and width, are critical for determining compatibility with the wire or cable being used. Larger reels can hold more wire, which is beneficial for extensive installations, while smaller reels may be better for lighter applications. Accurate measurements help in optimizing storage and dispensing processes. -

Tolerance

Tolerance refers to the allowable variation in the dimensions of the reel and its components. High tolerance levels are crucial for ensuring that the wire fits properly and operates smoothly during dispensing. Inaccurate tolerances can lead to difficulties in wire handling and increased wear on both the reel and the wire. -

Bearing Type

The type of bearings used in the reel affects its operational efficiency and ease of use. Common options include cam roller bearings and ball bearings. Choosing the right bearing type can reduce friction and wear, improving the reel’s lifespan and performance in various applications.

Which Trade Terminology Should B2B Buyers Understand for Wire Reels?

Familiarizing yourself with industry jargon is vital for effective communication and negotiation in the wire reel market. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the wire reel industry, understanding OEM relationships is important for sourcing high-quality products that meet specific performance standards. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For wire reels, MOQs can vary significantly based on the manufacturer and product type. Knowing the MOQ helps buyers plan their inventory and budget accordingly. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. In the wire reel sector, submitting an RFQ allows buyers to compare costs and terms across different suppliers, leading to more informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for B2B buyers to manage logistics and shipping costs effectively when importing wire reels from different countries. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Lead time can vary based on the supplier’s location, production capacity, and shipping methods. For B2B buyers, knowing the lead time is crucial for project planning and maintaining workflow continuity.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting wire reels, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the wire reel Sector

What Are the Key Drivers Influencing the Global Wire Reel Market?

The wire reel market is experiencing robust growth, driven by several global trends. The increasing demand for efficient cable management solutions across various industries—such as telecommunications, construction, and energy—is a significant factor. As businesses expand and technology evolves, the need for reliable and durable wire dispensers and storage solutions has risen. The proliferation of renewable energy projects, particularly in Africa and South America, is also contributing to market dynamics, as these initiatives require extensive wiring and cable management systems.

Emerging technologies such as IoT (Internet of Things) and automation are reshaping sourcing strategies in the wire reel sector. Companies are increasingly adopting automated wire dispensing systems that enhance operational efficiency and reduce labor costs. Furthermore, the trend towards digitalization is prompting B2B buyers to seek suppliers that offer advanced tracking and inventory management capabilities. This shift not only streamlines operations but also enhances supply chain transparency—an essential factor for international buyers, particularly from regions like Europe and the Middle East.

How Are Sustainability and Ethical Sourcing Impacting the Wire Reel Sector?

Sustainability has become a focal point for international B2B buyers, influencing sourcing decisions within the wire reel industry. The environmental impact of manufacturing processes and materials is under scrutiny, driving the demand for eco-friendly products. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through the use of recycled materials, energy-efficient manufacturing processes, and waste reduction strategies.

Ethical sourcing is equally crucial, as businesses recognize the importance of maintaining transparency and fairness within their supply chains. Certifications such as ISO 14001 for environmental management and the Global Recycled Standard (GRS) are becoming essential criteria for suppliers aiming to enter international markets. B2B buyers are encouraged to seek partnerships with manufacturers that prioritize ethical labor practices and sustainable sourcing to ensure compliance with regional regulations and consumer expectations.

What Is the Historical Context of Wire Reel Development?

The evolution of wire reels can be traced back to the early 20th century, when the need for efficient cable storage and dispensing solutions became apparent with the rise of electrical infrastructure. Initially, wire reels were rudimentary, often made from wood or basic metals, focusing primarily on functionality. Over the decades, advancements in materials science and manufacturing processes have led to the development of more sophisticated wire dispensers. Modern wire reels are often constructed from high-strength steel and lightweight composites, designed to withstand heavy loads while ensuring ease of use.

As global industries have evolved, so too have the applications and designs of wire reels. The introduction of specialized reels for specific sectors, such as telecommunications and renewable energy, highlights the ongoing innovation within the industry. Today, wire reels are not only essential tools for managing cables but also integral components in the logistics and supply chain strategies of businesses worldwide. This historical perspective underscores the significance of adapting to market dynamics and technological advancements to meet the ever-changing needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of wire reel

-

How do I choose the right wire reel for my business needs?

Selecting the appropriate wire reel requires assessing several factors, including the type of wire you intend to use, the capacity needed, and the environment in which it will operate. Consider the reel’s material—steel or aluminum—for durability and weight considerations. Additionally, evaluate features like portability, ease of dispensing, and compatibility with existing equipment. Engaging with suppliers for samples or specifications can also help ensure you choose a product that meets your operational requirements. -

What are the common specifications for wire reels?

Wire reels typically come with specifications that include diameter, width, load capacity, and material type. Common diameters range from 40 inches to over 100 inches, while widths can vary based on specific applications. Load capacity is crucial, especially in industrial settings, with options available for light-duty to heavy-duty use. Material choices like galvanized steel or aluminum offer different benefits in terms of weight and corrosion resistance, impacting longevity and performance. -

What customization options are available for wire reels?

Many suppliers offer customization options for wire reels to meet specific business needs. Customizations can include size adjustments, specific materials, and branding with your company logo. Some manufacturers may also provide modifications to the design for enhanced functionality, such as adding wheels for mobility or changing the reel’s core diameter. Discussing your requirements with suppliers during the inquiry stage can lead to tailored solutions that align with your operational goals. -

What is the minimum order quantity (MOQ) for wire reels?

Minimum order quantities for wire reels can vary significantly among suppliers, depending on production capabilities and material availability. Typically, MOQs can range from a few units for standard products to larger quantities for customized orders. It’s advisable to inquire directly with potential suppliers about their MOQs, as many may be flexible, especially for long-term partnerships or bulk orders. Understanding these terms upfront can help you plan your procurement strategy effectively. -

What payment terms should I expect when sourcing wire reels internationally?

Payment terms for international purchases can vary widely based on the supplier and the specific agreement. Common practices include payment in full prior to shipment or a deposit with the balance due upon delivery. Some suppliers may offer letter of credit options for larger orders to mitigate risk. It’s essential to clarify payment methods, currency, and any associated fees during negotiations to ensure smooth transactions and avoid potential misunderstandings. -

How can I vet potential suppliers of wire reels?

Vetting suppliers involves a thorough assessment of their credibility, reliability, and quality standards. Start by checking their industry certifications and customer reviews. Requesting references from previous clients can provide insights into their reliability and service quality. Additionally, visiting their manufacturing facilities or participating in industry trade shows can help you gauge their operational capabilities. Establishing clear communication and responsiveness during initial interactions is also a good indicator of their commitment to customer service. -

What quality assurance measures should I consider when sourcing wire reels?

Quality assurance is critical in ensuring that the wire reels meet industry standards and your specific operational needs. Look for suppliers who have established quality control processes, such as inspections during manufacturing and before shipment. Request documentation for compliance with relevant standards (e.g., ISO certifications) and inquire about warranty policies. Establishing clear specifications and testing protocols can also help in maintaining quality throughout the sourcing process. -

What logistics considerations should I be aware of when importing wire reels?

When importing wire reels, consider factors such as shipping methods, lead times, and customs regulations in your country. Evaluate whether you will use air freight for expedited delivery or sea freight for cost-effectiveness. Understanding import duties and taxes is crucial for budgeting. Collaborating with logistics partners who have experience in handling industrial equipment can streamline the process and mitigate potential delays. It’s also advisable to track shipments and maintain clear communication with suppliers to ensure timely delivery.

Top 8 Wire Reel Manufacturers & Suppliers List

1. Rack-A-Tiers – Wire Spool Dispensers

Domain: rack-a-tiers.com

Registered: 1997 (28 years)

Introduction: Wire Spool Dispensers from Rack-A-Tiers include various models designed for dispensing wire and cable. Key products include: 1. Pocket Spinner – $41.49 USD, adapts standard 1/2″ EMT into a compact wire dispenser. 2. Rack-A-Tiers 2.0 – $116.49 USD, features built-in hex nuts. 3. Racky Pipe Clamp – $18.99 USD, an add-on clamp for dispensers. 4. Racky Relax Seat Cushion – $18.99 USD, padded seat cush…

2. Spoolmaster – Cable Reel Rollers

Domain: spoolmaster.com

Registered: 1996 (29 years)

Introduction: Spool Handling Equipment includes: Cable Reel Rollers, Cable Reel Roller Accessories, Cable Reel Turntables, Forklift Attachments, Cable Wire & Caddies, Wire Spool Carts, Wire Measuring & Coiling Systems, Reusable Spools, Cable Reel Jacks & Bucks, Fish Tapes & Duct Rodders. Specific products include: SMP-RP-MPX (750lb Capacity Unlimited Width Cable Reel Roller – $450), SMP-RP-BTX (2000lb Capacity …

3. Reelpower Industrial – Cable Reel Stands

Domain: reelpowerind.com

Registered: 2017 (8 years)

Introduction: Reelpower Industrial offers a range of cable reel stands and reels, including the following key products: 1. CRS/RPR “COMBO” – Constructed of tubular welded steel, featuring a 2″ diameter solid steel shaft and cam roller bearings. 2. Comp. Reel & Adaptor – Custom adaptors for existing Combo Units for mounting a single compartment paralleling reel, includes a heavy-duty drop-in bracket with a fixed…

4. Cable Ties and More – Cable Spool Reels

Domain: cabletiesandmore.com

Registered: 2006 (19 years)

Introduction: This company, Cable Ties and More – Cable Spool Reels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Hubbell – NEMA 4 Yellow Industrial Reel

Domain: store.hubbell.com

Registered: 1995 (30 years)

Introduction: This company, Hubbell – NEMA 4 Yellow Industrial Reel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Cerrowire – ReelRover

Domain: cerrowire.com

Registered: 1996 (29 years)

Introduction: ReelRover is an innovative electrical wire cable reel designed to improve productivity at distributor and job site levels. Key features include:

– Mobility: Equipped with wheels for easy maneuverability, eliminating the need for forklifts or pallet jacks.

– Smooth payout: Enhances control with transmission and gears, facilitating easier wire handling.

– Job site safety: Improves safety by reducing…

7. Electrical Innovative Products – Wire Dispenser Reels

Domain: wirereels.com

Registered: 2020 (5 years)

Introduction: Wire Dispenser Reels from Electrical Innovative Products Inc. include the following key products: 1. WRD Wire Reel Dispenser – Price: $89.50 2. WRC-2 EIP Portable Universal Steel Wire & Cable Caddy – Price: $59.95 3. RWC-1 (Rotating Caddy) – Price: $49.95 4. 1 Reel Kit – Price: $174.95. Features include: portable and compact design, heavy-duty construction, easy to use and set up, accommodates var…

8. Conductix – Grounding/Static Discharge Cable Reel

Domain: aceindustries.com

Registered: 1997 (28 years)

Introduction: 1. Conductix SDR Series Grounding/Static Discharge Cable Reel – Price: $247.43

2. Conductix Pivot Base for 1200/1400 Series PowerReel – Price: $115.06

3. Conductix 1400 Series PowerReel, Stretch Application-12 AWG/4 Con.-40 ft. – Price: $949.03

4. Conductix 1200 Series PowerReel, 16 AWG/3 Con.- 125V w/50 ft. Cable – Price: $496.31

5. Conductix 1200 Series PowerReel, 12 AWG/4 Conductor -300V w/25 f…

Strategic Sourcing Conclusion and Outlook for wire reel

How Can Strategic Sourcing Enhance Your Wire Reel Procurement?

In summary, effective strategic sourcing for wire reels can significantly elevate operational efficiency and cost-effectiveness for businesses across diverse sectors. By prioritizing quality, durability, and adaptability in wire reel solutions, buyers can streamline their supply chains and reduce downtime. Understanding the specific needs of your industry—whether it’s construction, telecommunications, or manufacturing—enables you to select the most appropriate wire dispensing tools and storage solutions, ultimately enhancing productivity.

Moreover, fostering relationships with reliable suppliers can lead to better pricing, improved service levels, and access to the latest innovations in wire reel technology. As markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, it is crucial to stay ahead of emerging trends and demands.

Looking forward, we encourage international B2B buyers to embrace a proactive approach to sourcing wire reels. Evaluate your current suppliers, explore new partnerships, and invest in advanced solutions to meet your operational challenges. By doing so, you position your business for success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to wire reel

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.