The Definitive Guide to Wire Plant Baskets: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for wire plant baskets

In an increasingly competitive landscape, sourcing high-quality wire plant baskets can pose significant challenges for international B2B buyers. From discerning the right materials and designs to understanding regional preferences, the path to procurement is fraught with complexity. This guide serves as a comprehensive resource for navigating the global market for wire plant baskets, offering valuable insights into various types, applications, and the nuances of supplier vetting. Whether you are looking to enhance your product range with durable hanging baskets or seeking innovative designs for outdoor displays, this guide will equip you with the necessary tools to make informed purchasing decisions.

Our exploration encompasses key factors such as cost considerations, sourcing strategies, and market trends that are particularly relevant to buyers from Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Vietnam. By delving into the specifics of wire plant baskets, this guide empowers businesses to identify reliable suppliers, ensuring that quality and design meet the expectations of their target markets. With actionable insights and expert recommendations, you will be well-prepared to invest wisely in wire plant baskets that not only fulfill aesthetic and functional needs but also drive profitability and customer satisfaction in your respective markets.

Understanding wire plant baskets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wrought Iron Hanging Baskets | Heavy-duty metal construction, often with decorative designs | Retail garden centers, landscaping services | Pros: Durable, aesthetic appeal; Cons: Higher cost than plastic options. |

| Galvanized Wire Baskets | Rust-resistant, lightweight, and suitable for various plants | Nurseries, outdoor events | Pros: Cost-effective, versatile; Cons: Less durable than wrought iron. |

| Old-Fashioned Wire Baskets | Classic design, deep structure for enhanced plant growth | Home gardening, floral displays | Pros: Timeless appeal, excellent drainage; Cons: May require additional liners. |

| Square & Rectangular Baskets | Space-efficient designs for urban settings | Urban gardening, commercial displays | Pros: Maximizes planting area; Cons: Limited aesthetic options compared to round baskets. |

| Decorative Wire Baskets | Unique designs, often with intricate patterns | Specialty stores, events decoration | Pros: Eye-catching, enhances branding; Cons: Typically more expensive. |

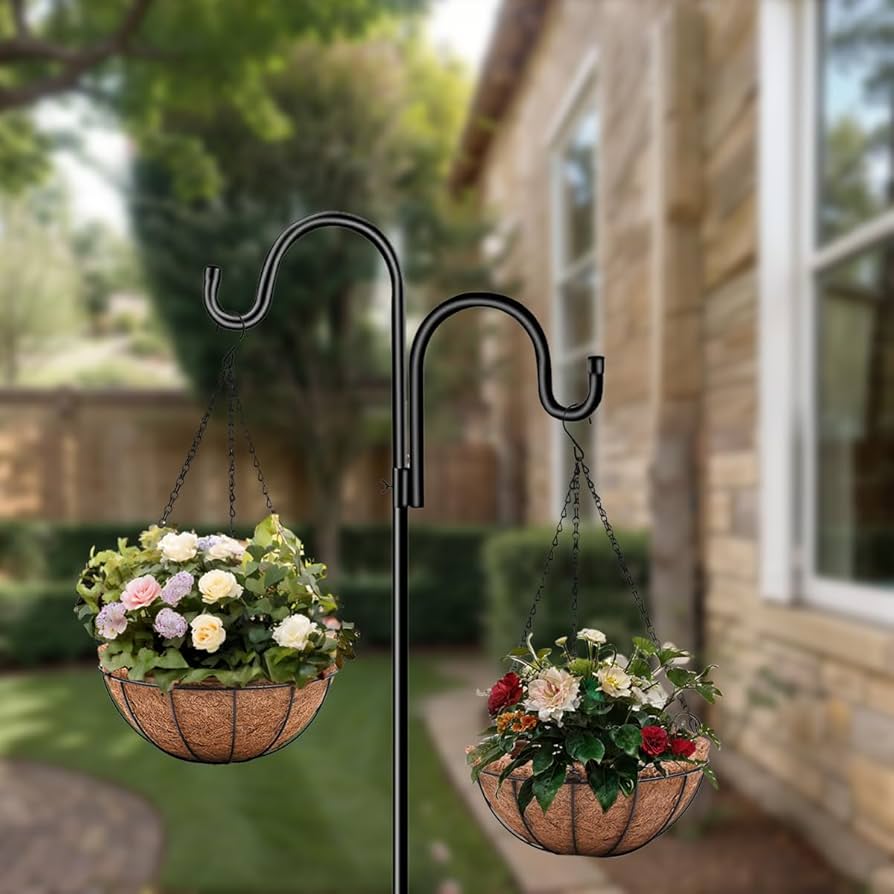

What Are the Characteristics of Wrought Iron Hanging Baskets?

Wrought iron hanging baskets are robust and often feature intricate designs, making them ideal for both functional and decorative purposes. Their heavy-duty construction ensures longevity, making them suitable for retail garden centers and landscaping services. When purchasing, B2B buyers should consider the aesthetic value and durability, although the higher cost compared to plastic options may be a factor.

How Do Galvanized Wire Baskets Stand Out?

Galvanized wire baskets are known for their rust-resistant properties and lightweight nature, making them a popular choice for nurseries and outdoor events. These baskets can accommodate a variety of plants, providing a cost-effective solution for bulk purchases. Buyers should weigh the affordability against the potential for less durability compared to wrought iron, especially for long-term use.

Why Choose Old-Fashioned Wire Baskets?

Old-fashioned wire baskets feature a classic design that allows for deep planting, promoting healthier plant growth. They are commonly used in home gardening and floral displays, appealing to buyers looking for a vintage aesthetic. While they offer excellent drainage, buyers should be mindful that these baskets may require additional liners for optimal performance.

Illustrative image related to wire plant baskets

What Are the Benefits of Square & Rectangular Baskets?

Square and rectangular wire baskets are designed to maximize planting space, making them ideal for urban gardening and commercial displays. Their space-efficient design allows for effective use in limited areas, appealing to B2B buyers focused on maximizing yield. However, the limited aesthetic options may be a drawback for those seeking decorative solutions.

How Do Decorative Wire Baskets Enhance Branding?

Decorative wire baskets often feature unique and intricate designs that can serve as eye-catching displays in specialty stores and event decorations. These baskets not only enhance product visibility but also contribute to branding efforts. However, buyers should consider the typically higher price point, which reflects the craftsmanship and design intricacy involved.

Key Industrial Applications of wire plant baskets

| Industry/Sector | Specific Application of Wire Plant Baskets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Horticulture & Agriculture | Used for hanging plants and herbs in commercial nurseries | Enhances plant growth and visibility, attracting more customers | Durability, weather resistance, and compatibility with various liners |

| Landscaping & Garden Design | Decorative installations in public parks and gardens | Provides aesthetic appeal while allowing for diverse plantings | Customization options and design versatility |

| Retail & Merchandising | Displaying plants and flowers in retail environments | Increases product visibility and enhances customer experience | Sizing, weight capacity, and ease of transport |

| Hospitality & Tourism | Enhancing outdoor dining areas with decorative planters | Creates inviting atmospheres, improving guest satisfaction | Style, material quality, and maintenance requirements |

| Construction & Real Estate | Integrating into building designs for green spaces | Adds value to properties through landscaping features | Compliance with local regulations and integration with existing designs |

How are Wire Plant Baskets Used in Horticulture and Agriculture?

In the horticulture sector, wire plant baskets are essential for nurseries and greenhouses. They are used to hang a variety of plants and herbs, allowing for optimal light exposure and air circulation. This application not only enhances the growth of plants but also showcases them effectively to customers. Buyers in this sector should prioritize baskets made from durable, weather-resistant materials that can withstand various climate conditions, especially in regions like Africa and South America where weather can be unpredictable.

What Role Do Wire Plant Baskets Play in Landscaping and Garden Design?

In landscaping and garden design, wire plant baskets serve as both functional and decorative elements. They are often incorporated into public parks, gardens, and residential landscapes to create visually appealing displays. These baskets allow for diverse planting options, including side planting with coco liners that promote lush growth. For international buyers, sourcing baskets that offer customization options and design versatility is crucial, particularly in regions with distinct cultural aesthetics, such as the Middle East and Europe.

How Do Retailers Utilize Wire Plant Baskets?

Retail environments leverage wire plant baskets to effectively display plants and flowers, enhancing the shopping experience. These baskets not only increase product visibility but also allow for creative merchandising strategies. Businesses in this sector should consider factors such as sizing and weight capacity to ensure the baskets can accommodate a variety of plant types. Additionally, ease of transport is vital for retailers operating in busy urban areas, making sourcing from reliable suppliers essential.

Illustrative image related to wire plant baskets

What Benefits Do Wire Plant Baskets Provide in Hospitality and Tourism?

In the hospitality industry, wire plant baskets are often used to enhance outdoor dining areas, contributing to a welcoming atmosphere. By integrating greenery into their spaces, hotels and restaurants can significantly improve guest satisfaction and create memorable experiences. Buyers in this sector should focus on the style and material quality of the baskets, ensuring they align with the overall aesthetic of their establishments while also considering maintenance requirements to keep the displays looking fresh.

How Are Wire Plant Baskets Integrated into Construction and Real Estate Projects?

In construction and real estate, wire plant baskets are increasingly used in building designs to create green spaces. These installations can add significant value to properties by enhancing their visual appeal and promoting environmental sustainability. Buyers in this sector must ensure that the baskets comply with local regulations and can be seamlessly integrated into existing designs. This is particularly important in markets across Europe and the Middle East, where architectural standards may vary significantly.

3 Common User Pain Points for ‘wire plant baskets’ & Their Solutions

Scenario 1: Sourcing Durable Wire Plant Baskets for Harsh Environments

The Problem: B2B buyers operating in regions with extreme weather conditions, such as the Middle East or parts of Africa, often struggle to find wire plant baskets that can withstand high temperatures, intense sunlight, and occasional heavy rains. Standard baskets may rust, degrade, or become brittle over time, leading to a loss of investment and the need for frequent replacements. This not only impacts budget planning but also affects customer satisfaction when products fail to perform.

Illustrative image related to wire plant baskets

The Solution: To address this challenge, buyers should prioritize sourcing wire plant baskets made from galvanized or powder-coated steel, as these materials offer superior resistance to rust and corrosion. When evaluating suppliers, request detailed product specifications that highlight weather-resistant features. Additionally, consider purchasing baskets with a UV protective coating to extend their lifespan in sunny climates. Building a relationship with manufacturers who provide warranties or guarantees on their products can also ensure quality and reliability, giving buyers peace of mind in their investment.

Scenario 2: Balancing Aesthetic Appeal with Functionality in Wire Plant Baskets

The Problem: In the competitive landscape of retail and landscaping, buyers are often torn between choosing aesthetically pleasing wire plant baskets and those that offer practical benefits like drainage and airflow. A beautiful design might attract customers, but if the baskets lack functionality, plants may not thrive, resulting in dissatisfied end-users and potential loss of sales.

The Solution: To strike a balance between aesthetics and functionality, buyers should look for wire plant baskets that incorporate design features such as built-in drainage holes and breathable liners. When selecting products, consider those that allow for side planting or have a deeper design to accommodate more soil and plant growth. Engaging with suppliers who offer customizable options can also help meet specific aesthetic requirements without compromising on functionality. Additionally, showcasing how these baskets can enhance plant health in marketing materials can help communicate their dual benefits to customers.

Illustrative image related to wire plant baskets

Scenario 3: Managing Inventory and Supply Chain for Wire Plant Baskets

The Problem: Many B2B buyers face the daunting task of managing inventory and supply chain logistics, especially when dealing with multiple suppliers for wire plant baskets. Fluctuating demand, lead times, and inconsistent supply can lead to overstocking or stockouts, impacting cash flow and operational efficiency.

The Solution: To streamline inventory management, buyers should consider consolidating their supplier base and establishing long-term partnerships with manufacturers that can meet their volume requirements. Implementing a just-in-time inventory system can help reduce excess stock while ensuring that products are available when needed. Utilizing technology such as inventory management software can provide real-time data on stock levels and sales trends, enabling informed purchasing decisions. Buyers should also discuss flexible ordering options with suppliers to accommodate seasonal fluctuations in demand, allowing for better cash flow management and operational efficiency.

Strategic Material Selection Guide for wire plant baskets

What Are the Key Properties of Common Materials for Wire Plant Baskets?

When selecting materials for wire plant baskets, understanding the properties and performance of each material is crucial for B2B buyers. Here, we analyze four common materials: galvanized steel, wrought iron, aluminum, and stainless steel. Each material has unique characteristics that influence its suitability for various applications in diverse environments.

How Does Galvanized Steel Perform in Wire Plant Baskets?

Galvanized steel is coated with a layer of zinc to enhance its corrosion resistance, making it a popular choice for outdoor applications. This material can withstand moderate temperatures and is generally resistant to rust, which is crucial for maintaining aesthetic appeal and structural integrity over time.

Pros: Galvanized steel is durable and cost-effective, making it suitable for large-scale production. Its lightweight nature allows for easy handling and installation.

Cons: While it offers good corrosion resistance, galvanized steel may not perform well in extremely humid or saline environments, leading to potential rust over time. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Illustrative image related to wire plant baskets

Impact on Application: Galvanized steel wire baskets are ideal for various plant media, including soil and hydroponic systems, but care should be taken in coastal areas where salt exposure could accelerate corrosion.

What Advantages Does Wrought Iron Offer for Wire Plant Baskets?

Wrought iron is known for its strength and aesthetic appeal, often used in decorative applications. It can withstand high temperatures and has excellent durability, making it suitable for both indoor and outdoor use.

Pros: Wrought iron’s robust nature allows it to support heavier plants and withstand harsh weather conditions. Its classic appearance adds a decorative element to gardens and patios.

Cons: Wrought iron is generally more expensive than other materials, and its weight can make installation more challenging. It also requires regular maintenance to prevent rust, especially in humid climates.

Impact on Application: Wrought iron baskets are compatible with various planting media but are best suited for traditional soil-based setups rather than hydroponic systems due to their weight.

How Does Aluminum Compare in Terms of Performance and Cost?

Aluminum is lightweight, corrosion-resistant, and easy to work with, making it a versatile option for wire plant baskets. It performs well in various environmental conditions and is often used in both commercial and residential settings.

Pros: The lightweight nature of aluminum facilitates easy transport and installation. Its resistance to rust and corrosion makes it ideal for long-term outdoor use.

Cons: While generally durable, aluminum can be less robust than wrought iron or steel, making it less suitable for heavy plants. Additionally, it may be more expensive than galvanized steel.

Illustrative image related to wire plant baskets

Impact on Application: Aluminum wire baskets are compatible with a range of planting media and are particularly effective in hydroponic systems due to their lightweight properties.

What About Stainless Steel for Wire Plant Baskets?

Stainless steel is renowned for its corrosion resistance and strength, making it an excellent choice for outdoor applications. It can withstand extreme temperatures and is highly durable.

Pros: Stainless steel’s resistance to corrosion and staining makes it ideal for various climates, including coastal regions. It also offers a modern aesthetic that appeals to contemporary designs.

Cons: The primary drawback of stainless steel is its cost, which is typically higher than other materials. Additionally, it can be heavier, making installation more labor-intensive.

Impact on Application: Stainless steel baskets are suitable for various planting media, including soil and hydroponics, and are particularly effective in environments where durability is paramount.

Illustrative image related to wire plant baskets

Summary Table of Material Selection for Wire Plant Baskets

| Material | Typical Use Case for wire plant baskets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Outdoor gardens, commercial applications | Cost-effective and durable | Limited corrosion resistance in humid areas | Low |

| Wrought Iron | Decorative gardens, heavy plant support | Strong and aesthetically appealing | Requires maintenance to prevent rust | High |

| Aluminum | Residential gardens, hydroponic systems | Lightweight and corrosion-resistant | Less robust for heavy plants | Medium |

| Stainless Steel | Coastal areas, modern landscapes | Excellent corrosion resistance | Higher cost and heavier weight | High |

This guide provides B2B buyers with actionable insights into material selection for wire plant baskets, emphasizing the importance of understanding the specific needs of their markets and applications.

In-depth Look: Manufacturing Processes and Quality Assurance for wire plant baskets

What Are the Main Stages in the Manufacturing Process of Wire Plant Baskets?

The manufacturing process of wire plant baskets typically comprises several key stages, each critical to producing high-quality products that meet international standards.

-

Material Preparation: The process begins with the selection of appropriate materials, primarily galvanized steel or wrought iron, known for their durability and resistance to rust. These materials are usually sourced from reliable suppliers who can provide certification of quality. The raw materials are then cut to specified lengths according to the design of the wire basket.

-

Forming: In this stage, the cut wire is shaped into the desired basket form. This is often achieved using machinery such as bending machines and welding equipment. Techniques like hand-welding are also employed for intricate designs, ensuring structural integrity. The forming process should be precise to ensure uniformity across batches.

-

Assembly: After forming, the various components of the wire baskets are assembled. This may involve additional welding, as well as the attachment of features like hooks or chains for hanging. Quality control during assembly is crucial, as any misalignment can affect the basket’s functionality and aesthetic appeal.

-

Finishing: The final stage involves applying protective coatings, such as powder coating or galvanization, to enhance weather resistance and visual appeal. The finishing process can also include the addition of liners made from materials like coco coir or synthetic fibers, which improve moisture retention for the plants.

How Do Quality Assurance Practices Ensure High Standards in Wire Plant Basket Manufacturing?

Quality assurance (QA) is integral to the manufacturing of wire plant baskets, ensuring that products meet both international standards and specific customer requirements.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines criteria for quality management systems. Compliance with this standard indicates that the manufacturer has established processes to consistently produce products that meet customer and regulatory requirements. In addition, certifications like CE (Conformité Européenne) may be relevant for products sold in the European market, ensuring compliance with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: The quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During the manufacturing process, random inspections are conducted to assess the quality of the work in progress. This helps identify defects early on.

– Final Quality Control (FQC): Before products are packaged and shipped, a final inspection ensures that they conform to quality standards and specifications. -

Testing Methods: Common testing methods include tensile strength tests, corrosion resistance tests, and visual inspections for weld integrity and finish quality. These tests help ensure that the wire baskets can withstand environmental factors and are safe for use.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source wire plant baskets should take proactive steps to verify the quality control processes of potential suppliers.

Illustrative image related to wire plant baskets

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance systems firsthand. This can provide insights into the supplier’s commitment to quality.

-

Quality Assurance Reports: Requesting documentation that outlines the supplier’s quality control practices, including test results and compliance certifications, is crucial. This information can help buyers understand the supplier’s adherence to international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s production quality. These inspections can occur at various stages of the manufacturing process and can help mitigate risks associated with quality failures.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, face unique challenges when it comes to quality control.

-

Cultural and Regulatory Differences: Different regions may have varying expectations for product quality and safety standards. Buyers should familiarize themselves with local regulations and standards in their target markets to ensure compliance.

-

Communication Barriers: Language differences can lead to misunderstandings regarding product specifications and quality expectations. Establishing clear communication channels and using detailed contracts can help mitigate these issues.

-

Logistical Considerations: The shipping and handling of wire plant baskets can affect their quality. B2B buyers should discuss packaging methods with suppliers to ensure that products are protected during transit.

-

Sustainability Considerations: Increasingly, buyers are looking for suppliers who prioritize sustainable practices. Understanding a supplier’s environmental policies and material sourcing can be an important aspect of quality assurance in today’s market.

Conclusion

Manufacturing wire plant baskets involves a meticulous process that combines skilled craftsmanship with rigorous quality assurance practices. For B2B buyers, understanding these processes and verifying supplier quality control measures are essential steps in ensuring they receive high-quality products that meet their specific needs. By leveraging international standards and conducting thorough assessments, buyers can confidently partner with manufacturers who uphold the highest quality standards in their production processes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire plant baskets’

To effectively source wire plant baskets, B2B buyers must navigate various factors to ensure quality, cost-effectiveness, and alignment with their specific needs. This guide provides a structured checklist to facilitate the procurement process, ensuring that buyers make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the wire plant baskets you need. Consider factors such as size, material (e.g., galvanized metal or wrought iron), and design features. This step is vital as it sets the foundation for your sourcing process and helps in identifying suppliers who can meet your exact requirements.

- Size: Determine the dimensions based on your intended use—hanging, wall-mounted, or freestanding.

- Material: Assess the durability and weather resistance of the materials, especially if the baskets will be used outdoors.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Utilize online directories, trade shows, and industry networks to compile a list of manufacturers and distributors. This step is crucial for ensuring that you have access to a diverse range of products and competitive pricing.

Illustrative image related to wire plant baskets

- Directories: Websites like Alibaba or ThomasNet can be valuable resources for finding reputable suppliers.

- Trade Shows: Attend industry events to meet suppliers in person and evaluate their offerings firsthand.

Step 3: Evaluate Supplier Credentials

Verify the credentials and reliability of potential suppliers. Look for certifications, such as ISO standards, which indicate adherence to quality management practices. This step is essential to ensure that the supplier is legitimate and capable of delivering high-quality products.

- Certifications: Check if the supplier has relevant certifications that demonstrate compliance with international quality standards.

- References: Request references from other B2B clients to gain insights into their reliability and product quality.

Step 4: Request Samples

Always request product samples before making bulk purchases. This allows you to assess the quality, construction, and design of the wire plant baskets. Evaluating samples is critical to ensure that the products meet your specifications and expectations.

- Quality Check: Examine the material strength, finish, and any additional features like liners or hooks.

- Design Evaluation: Ensure the design aligns with your brand aesthetics and functional requirements.

Step 5: Analyze Pricing and Terms

Compare pricing structures and payment terms from different suppliers. Understanding the cost implications is vital for budgeting and profitability. Additionally, consider the terms of sale, including minimum order quantities, shipping costs, and payment options.

Illustrative image related to wire plant baskets

- Pricing Models: Look for transparency in pricing to avoid hidden costs later.

- Negotiation: Be prepared to negotiate terms that align with your budget and cash flow needs.

Step 6: Assess Logistics and Shipping

Evaluate the logistics capabilities of your chosen suppliers. Understand their shipping methods, lead times, and any potential delays that could impact your delivery schedule. This step is crucial for ensuring that you can meet your own customers’ demands promptly.

- Shipping Options: Inquire about different shipping methods and costs, especially for international shipments.

- Lead Times: Confirm the expected lead times for production and delivery to plan your inventory accordingly.

Step 7: Establish a Communication Plan

Set up a clear communication plan with your supplier. Effective communication is key to successful procurement. Establish points of contact, preferred communication methods, and frequency of updates to ensure a smooth sourcing process.

- Regular Updates: Schedule regular check-ins to discuss order status and address any potential issues.

- Feedback Loop: Create a feedback mechanism for ongoing improvements in product quality and service.

By following this structured checklist, B2B buyers can streamline their sourcing process for wire plant baskets, ensuring they find the right products from reliable suppliers while optimizing costs and logistics.

Comprehensive Cost and Pricing Analysis for wire plant baskets Sourcing

What Are the Key Cost Components of Wire Plant Baskets?

When sourcing wire plant baskets, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of wire (e.g., galvanized steel, wrought iron) significantly influences pricing. Higher-quality materials enhance durability but can increase costs. Additional components such as liners (coco coir or synthetic materials) also add to material costs.

-

Labor: Labor costs vary widely based on the production location. Regions with lower wage standards may offer more competitive pricing, but this can affect quality and lead times.

-

Manufacturing Overhead: This includes costs associated with facility operations, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, impacting the final price.

-

Tooling: Custom designs or unique specifications may require specialized tooling, which can be a significant upfront cost. Buyers should consider how these costs affect the total price, especially for custom orders.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and customer satisfaction but can add to costs. Certifications (like ISO or CE) may also increase expenses but provide reassurance regarding product quality.

-

Logistics: Shipping and handling costs are critical, particularly for international orders. Factors such as distance, shipping method, and packaging can significantly influence these costs.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers gauge the reasonableness of quotes received.

How Do Price Influencers Affect Sourcing Decisions?

Several price influencers can affect the cost of wire plant baskets, especially for international buyers:

-

Volume/MOQ: Bulk orders generally yield lower per-unit costs. Establishing a clear Minimum Order Quantity (MOQ) with suppliers can lead to better pricing.

-

Specifications and Customization: Custom features, such as specific sizes or finishes, can significantly increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials Quality and Certifications: Higher-quality materials and recognized certifications can justify a higher price. However, buyers should ensure that the perceived benefits align with their needs and budget.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is vital for calculating the total landed cost. Incoterms dictate responsibility for shipping costs and risks, which can affect final pricing.

What Negotiation Strategies Can International Buyers Use?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to cost savings:

-

Research and Benchmarking: Conduct market research to understand average prices and terms. This data can strengthen your negotiating position.

-

Flexibility in Terms: Be open to adjusting order sizes or payment terms. Offering a larger order or quicker payment can incentivize suppliers to offer better pricing.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the upfront cost. Evaluate factors like durability, maintenance, and logistical expenses to make informed decisions.

-

Long-term Relationships: Building a long-term relationship with suppliers can lead to better pricing over time. Loyalty often results in preferential treatment, including discounts or favorable terms.

What Should Buyers Keep in Mind About Pricing Nuances?

International buyers should be aware of pricing nuances that can impact their sourcing decisions:

-

Currency Fluctuations: Exchange rates can affect final costs. Locking in prices in a stable currency can mitigate risks associated with currency fluctuations.

-

Import Tariffs and Duties: Understanding local regulations regarding tariffs and duties is crucial. These additional costs can significantly impact the final price of imported goods.

-

Seasonal Variations: Prices may fluctuate based on seasonal demand. Planning purchases during off-peak times can lead to cost savings.

Disclaimer

The prices and analysis provided in this section are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. Always conduct thorough research and consult multiple suppliers to obtain the most accurate and favorable pricing.

Alternatives Analysis: Comparing wire plant baskets With Other Solutions

When selecting plant containers, it is essential for B2B buyers to consider various options that can accommodate their specific horticultural needs. Wire plant baskets, known for their durability and aesthetic appeal, face competition from several alternatives. This analysis compares wire plant baskets against two viable alternatives: traditional clay pots and modern plastic planters. Each option has unique characteristics that can influence your purchasing decision.

| Comparison Aspect | Wire Plant Baskets | Traditional Clay Pots | Modern Plastic Planters |

|---|---|---|---|

| Performance | Excellent drainage; supports healthy root systems | Good insulation; retains moisture well | Lightweight; can be designed for drainage |

| Cost | Moderate to high, depending on design and size | Generally low to moderate | Low cost; very budget-friendly |

| Ease of Implementation | Requires liners for planting; easy to hang | Simple setup; heavy and can crack easily | Easy to use; available in many sizes |

| Maintenance | Needs occasional rust treatment; regular cleaning | Requires careful handling; can stain | Minimal maintenance; resistant to UV light |

| Best Use Case | Ideal for hanging plants and decorative displays | Best for traditional gardens and indoor use | Great for bulk planting and outdoor use |

What Are the Advantages and Disadvantages of Traditional Clay Pots?

Traditional clay pots offer good insulation, which helps in maintaining a stable temperature for plant roots. They are also aesthetically pleasing and can add a rustic charm to any setting. However, their porous nature means they can dry out quickly, necessitating frequent watering. Additionally, they are heavy and prone to cracking, which can complicate transport and storage, especially for B2B buyers dealing with large orders.

Illustrative image related to wire plant baskets

How Do Modern Plastic Planters Compare?

Modern plastic planters are lightweight and often come in a variety of colors and designs, making them appealing for buyers looking for versatility. Their resistance to breaking and fading from UV exposure makes them suitable for outdoor use. However, plastic planters can retain heat, potentially stressing plants in extremely hot climates. Additionally, they may not provide the same aesthetic appeal as more traditional materials. For large-scale operations, their low cost and ease of transport can be significant advantages.

Conclusion: Which Plant Container Solution is Right for You?

Selecting the right plant container depends on your specific business needs, including budget, aesthetic preferences, and the types of plants you intend to cultivate. Wire plant baskets are excellent for decorative purposes and offer superior drainage, making them suitable for hanging arrangements. Traditional clay pots add a classic touch but may require more care and attention. Meanwhile, modern plastic planters are an economical choice, particularly for bulk planting, but may lack the charm of natural materials. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their horticultural objectives and operational constraints.

Essential Technical Properties and Trade Terminology for wire plant baskets

What Are the Key Technical Properties of Wire Plant Baskets?

When sourcing wire plant baskets, it’s essential to consider several technical properties that impact both performance and durability. Here are the critical specifications to assess:

-

Material Grade

The most common materials for wire plant baskets include galvanized steel, wrought iron, and stainless steel. Galvanized steel is often preferred for its rust resistance and durability, making it suitable for outdoor use. Wrought iron offers an aesthetic appeal and strength, while stainless steel provides excellent corrosion resistance but at a higher cost. Understanding the material grade is vital as it affects longevity and suitability for various climates. -

Wire Gauge

Wire gauge refers to the thickness of the wire used in the basket’s construction. A lower gauge number indicates thicker wire, resulting in a sturdier basket that can support heavier plants. For example, a 12-gauge wire is more robust than a 16-gauge wire. This property is crucial for buyers needing baskets that can withstand weight and environmental stressors. -

Load Capacity

The load capacity defines the maximum weight a wire basket can hold without compromising its structural integrity. This specification is especially important for B2B buyers in commercial horticulture or landscaping, where large plants or multiple smaller plants may be used. Knowing the load capacity ensures that the selected baskets can support the intended use without risk of failure. -

Finish and Coating

The finish on a wire plant basket can vary, including powder coating, plastic coating, or galvanization. Each finish affects the basket’s resistance to weathering, UV rays, and rust. A well-chosen finish can enhance the aesthetic appeal while extending the product’s lifespan, making it essential for buyers in regions with harsh weather conditions. -

Dimensions and Volume

The size of the wire baskets, including diameter and depth, impacts planting options and overall visual appeal. Standard dimensions vary, but understanding the specific volume of soil each basket can accommodate is crucial for effective planting. Buyers should match dimensions with the intended plant species to ensure optimal growth conditions.

What Are Common Trade Terms Used in Wire Plant Basket Transactions?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some common terms relevant to wire plant baskets:

Illustrative image related to wire plant baskets

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are rebranded by another company. In the context of wire plant baskets, an OEM might produce baskets for a gardening brand, allowing buyers to source high-quality products without investing in manufacturing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it influences purchasing decisions and inventory management. Understanding the MOQ can help businesses assess their budget and storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers. It typically includes specifications, quantities, and terms of delivery. For buyers seeking wire plant baskets, an RFQ helps in comparing offers and negotiating better pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding the delivery of goods. They clarify who bears shipping costs, risks, and responsibilities at various points in the supply chain. Familiarity with Incoterms is essential for international B2B transactions, ensuring clarity in agreements related to wire plant baskets. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. In the context of wire plant baskets, understanding lead times is crucial for planning inventory and meeting project timelines, especially in seasonal markets.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the wire plant baskets Sector

What Are the Key Trends Driving the Global Wire Plant Baskets Market?

The wire plant baskets market is witnessing significant growth, driven by various global dynamics. The increasing demand for urban gardening and sustainable landscaping solutions is one of the primary factors influencing market expansion. As urban areas grow, the need for space-efficient gardening solutions becomes crucial, making wire plant baskets an ideal choice for both residential and commercial settings. Additionally, the rise of e-commerce platforms has made it easier for international B2B buyers, particularly from regions like Africa, South America, and the Middle East, to source these products directly from manufacturers.

Emerging technologies in manufacturing processes, such as automated welding and advanced galvanization techniques, have enhanced the durability and aesthetic appeal of wire plant baskets. These innovations allow suppliers to offer a diverse range of products, catering to various customer preferences and gardening styles. Moreover, trends such as the integration of smart technologies into gardening products—like self-watering systems—are also making their way into the wire plant basket sector, appealing to tech-savvy consumers.

Illustrative image related to wire plant baskets

International buyers are increasingly seeking suppliers who can provide customized solutions tailored to their specific market needs. This includes variations in size, design, and functionality, which can cater to different climatic conditions and consumer preferences. Furthermore, as the global market becomes more interconnected, the importance of logistics and supply chain efficiency continues to grow, prompting buyers to look for reliable shipping partners and suppliers that can deliver products promptly and cost-effectively.

How Is Sustainability Shaping the Sourcing of Wire Plant Baskets?

Sustainability has become a cornerstone of procurement strategies in the wire plant baskets sector. The environmental impact of manufacturing processes is under scrutiny, with buyers increasingly prioritizing suppliers who adopt eco-friendly practices. The use of recyclable materials and energy-efficient production methods is gaining traction, which not only reduces the carbon footprint but also appeals to environmentally conscious consumers.

Ethical sourcing is equally critical, with B2B buyers demanding transparency in the supply chain. This includes understanding the sourcing of raw materials, labor practices, and the overall environmental responsibility of suppliers. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as essential benchmarks for buyers looking to partner with responsible manufacturers.

In addition to traditional materials, innovative alternatives such as recycled metals or sustainably sourced steel are being adopted in the production of wire plant baskets. These materials not only contribute to reducing waste but also resonate with consumers who are increasingly aware of the importance of sustainability in their purchasing decisions. As the market evolves, suppliers who can demonstrate their commitment to sustainability and ethical practices will likely have a competitive advantage.

What Is the Historical Context of Wire Plant Baskets in B2B Sourcing?

The evolution of wire plant baskets can be traced back to traditional gardening practices, where functionality and aesthetics were both essential. Initially crafted from wrought iron and other metals, these baskets served practical purposes, such as drainage and air circulation for plant roots. Over time, as gardening styles evolved and urban spaces expanded, the design of wire plant baskets adapted to meet the needs of modern consumers.

Illustrative image related to wire plant baskets

In recent decades, the introduction of galvanized steel and powder-coated finishes has not only enhanced the durability of wire plant baskets but also allowed for a wider range of designs and colors. This evolution reflects a broader trend in the gardening industry, where aesthetics and functionality are increasingly intertwined. As B2B buyers seek to differentiate their offerings in competitive markets, understanding the historical context of these products can provide valuable insights into consumer preferences and market dynamics.

By recognizing these trends and the importance of sustainability, international B2B buyers can make informed sourcing decisions that align with both market demands and ethical considerations, ensuring long-term success in the wire plant baskets sector.

Frequently Asked Questions (FAQs) for B2B Buyers of wire plant baskets

-

How do I choose the right wire plant basket for my business needs?

Selecting the right wire plant basket involves considering several factors, including the intended use, size, material, and design. For outdoor applications, opt for galvanized or powder-coated options for durability against weather conditions. If you’re targeting high-end markets, consider decorative designs that enhance aesthetic appeal. Additionally, assess your plant varieties to ensure the basket size accommodates root growth. Collaborating with suppliers who offer samples can also help you evaluate quality and suitability before bulk purchasing. -

What are the most common materials used for wire plant baskets?

Wire plant baskets are typically made from galvanized steel, wrought iron, or stainless steel. Galvanized steel is favored for its corrosion resistance, making it ideal for outdoor use. Wrought iron, while heavier, offers a classic aesthetic and durability. Stainless steel, although more expensive, provides excellent longevity and resistance to rust. Understanding the material properties can guide you in selecting baskets that align with your environmental conditions and design preferences. -

What customization options are available for wire plant baskets?

Many suppliers offer customization options such as size, color, and design features. You can request specific dimensions to suit your plants or branding needs. Additionally, some manufacturers provide custom finishes, like powder coating in various colors, to match your aesthetic preferences. Always communicate your requirements clearly to ensure the final product meets your expectations. Requesting prototypes can also help finalize design details before full-scale production. -

What is the minimum order quantity (MOQ) for wire plant baskets?

Minimum order quantities for wire plant baskets can vary significantly between suppliers. Typically, MOQs range from 50 to 500 units, depending on the manufacturer’s production capabilities and your customization requests. It’s essential to discuss MOQs upfront to ensure they align with your business needs. Some suppliers may offer flexibility for first-time buyers or bulk orders, so it’s worth negotiating terms that suit both parties. -

What payment terms should I expect when purchasing wire plant baskets internationally?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may also accept letters of credit or offer payment through secure platforms like PayPal or Alibaba. Understanding the payment structure is crucial, as it can affect your cash flow. Always clarify terms before finalizing the order to avoid unexpected fees or delays. -

How can I ensure the quality of wire plant baskets I order?

To ensure quality, start by vetting potential suppliers through reviews, certifications, and factory visits if feasible. Request samples to evaluate material quality, craftsmanship, and design. Additionally, inquire about their quality assurance processes, including inspections during production and pre-shipment checks. Establishing a clear communication channel for feedback and concerns can also help maintain quality standards throughout the production process. -

What logistics considerations should I keep in mind when importing wire plant baskets?

When importing wire plant baskets, consider shipping methods, costs, and timelines. Air freight is faster but more expensive, while sea freight is cost-effective for bulk orders but takes longer. Ensure you understand customs regulations in your destination country, including duties and taxes. Collaborating with a logistics provider experienced in international trade can streamline the process and help you navigate potential challenges. -

What are the best practices for maintaining wire plant baskets?

To prolong the life of wire plant baskets, regularly check for rust or corrosion, especially in outdoor environments. Clean the baskets periodically with mild soap and water, avoiding harsh chemicals that could damage the finish. Consider applying a protective coating if the baskets are exposed to extreme weather. Proper care ensures your investment remains visually appealing and functional, ultimately enhancing your customer satisfaction.

Top 6 Wire Plant Baskets Manufacturers & Suppliers List

1. A Rustic Garden – Wrought Iron Flower Baskets

Domain: arusticgarden.com

Registered: 1999 (26 years)

Introduction: Wrought Iron Flower Baskets for hanging, decorating, or planting herbs and flowers. Options include:

– Wrought Iron 16″ Samuel Square Basket Decorative Container Planter – $59.95

– Wrought Iron Oval Benny Baskets (3 Sizes) Decorative Containers

– Wrought Iron Octavia Oval Basket Decorative Plant Container – $79.95

– Small Square Strap Basket – Wrought Iron Flower Basket – $44.95

– Wrought Iron Rou…

2. Tropical Plant Products – 20 Wire Hanging Basket

Domain: tropicalplantproducts.com

Registered: 1999 (26 years)

Introduction: {“name”: “20” Wire Hanging Basket”, “size”: “20 inches”, “material”: “galvanized metal”, “price”: “$3.85”, “availability”: “In stock”, “features”: [“sturdy construction”, “hanging abilities”, “ideal for hanging plants”, “customizable with wire 3 way or 4 way options”], “note”: “Other sizes available. Shipping costs may vary; contact for accurate quotes.”}

3. Reddit – Wireframe Hanging Plant Basket

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: – Wireframe hanging plant basket

– Sheet moss for lining the plant basket

– Thin plastic sheeting (e.g., trash bag)

– Three or four six-packs of plants (preferably annuals)

– Potting soil

– Scissors or a sharp knife with a thin blade

– Empty bucket, pot, or wastepaper basket for arrangement

– Large tub for watering

4. Pinterest – Wire Planter Baskets

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Wire planter baskets are versatile garden items that can be transformed into decorative planters. They can be filled with moss or used as a base for DIY projects, such as creating coco liners from recycled materials. Ideas include using thrifted wire baskets for planting, making inexpensive DIY replacements for coconut liners, and utilizing old wool sweaters as liners. These baskets can also be us…

5. Kinsman Garden – Classic Hanging Baskets

Domain: kinsmangarden.com

Registered: 1999 (26 years)

Introduction: Old-Fashioned Hanging Baskets, Decorative Old Fashioned Coco-fiber Very Large Baskets, London Baskets, Conical Hanging Spheres, Freestanding Planter Liners, Classic Urn Planter, Cradle Planter, Cascade Planter, Cauldron Planter, Bowl Garden Welcome Planter, Two-Tier Planter, Pamela Crawford Planter Liners, Basic Basket Liners, Window Box Liners, Basic Basket Liners Without Holes, Imperial Liners, …

6. Garden Your Way – Wire Planters & Hanging Baskets

Domain: gardenyourway.com

Registered: 2022 (3 years)

Introduction: Wire Planters & Liners tagged as outdoor hanging baskets include various sizes and types such as 12″ diameter hanging basket, 14″ dia hanging basket with coco liner, 16″ premium hanging basket, and trough planters. Coco liners are made from natural coco fibers, providing good drainage and moisture retention. Vigoroot liners are made from advanced air-pruning fabric that promotes healthy root syste…

Strategic Sourcing Conclusion and Outlook for wire plant baskets

In conclusion, strategic sourcing of wire plant baskets offers international B2B buyers an opportunity to enhance their product offerings while ensuring quality and cost-effectiveness. By prioritizing durable materials such as galvanized steel and wrought iron, companies can provide their customers with reliable and aesthetically pleasing options for both indoor and outdoor gardening. Understanding regional preferences and the importance of customizable features, such as liners and hanging options, can further enhance product appeal across diverse markets in Africa, South America, the Middle East, and Europe.

The growing trend towards sustainable and eco-friendly gardening solutions underscores the necessity for suppliers to align their sourcing strategies with customer values. As demand for high-quality, versatile wire plant baskets continues to rise, businesses must stay ahead of market trends and invest in innovative designs that facilitate plant health and growth.

International B2B buyers are encouraged to engage with reliable suppliers who demonstrate craftsmanship and sustainability. By fostering partnerships with manufacturers that prioritize quality and innovation, businesses can position themselves effectively in the competitive landscape of gardening products. Now is the time to explore strategic sourcing options that not only meet market demand but also enhance your brand’s reputation for quality and sustainability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to wire plant baskets

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.