The Definitive Guide to Wastewater Evaporation Treatment: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for wastewater evaporation treatment

In the rapidly evolving landscape of industrial wastewater management, the challenge of efficiently treating and disposing of wastewater is more critical than ever. As global regulations tighten and sustainability becomes a priority, many businesses are turning to wastewater evaporation treatment as a viable solution. This guide serves as a comprehensive resource for international B2B buyers seeking to understand the nuances of wastewater evaporation treatment, from sourcing reliable suppliers to evaluating the diverse types of evaporators available in the market.

Throughout this guide, we delve into various applications of wastewater evaporation technology, such as concentrating hazardous materials, recovering valuable by-products, and enhancing water conservation efforts. We will also cover essential considerations for supplier vetting, helping you identify reputable manufacturers and service providers who can meet the specific needs of your operations. Additionally, we address cost factors, providing insights into capital investments versus long-term savings associated with efficient evaporation systems.

By empowering B2B buyers, especially those from Africa, South America, the Middle East, and Europe—such as Germany and Nigeria—with actionable knowledge, this guide aims to facilitate informed purchasing decisions. Whether you are a procurement officer or a facility manager, understanding the intricacies of wastewater evaporation treatment will enable you to adopt sustainable practices while optimizing your operational efficiency.

Understanding wastewater evaporation treatment Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vertical Tube Falling Film | Uses vertical tubes for efficient heat transfer; ideal for viscous liquids. | Food processing, petrochemical industries | Pros: High efficiency, low residence time. Cons: Higher initial costs. |

| Horizontal Tube Spray Film | Sprays liquid over horizontal tubes; good for low headroom spaces. | Chemical manufacturing, pharmaceuticals | Pros: Compact design, easy maintenance. Cons: Limited to low viscosity liquids. |

| Forced Circulation Evaporator | Operates under pressure to prevent boiling; good for high solid concentrations. | Mining, wastewater treatment | Pros: Effective for high solids; reduces scaling. Cons: More complex and costly. |

| Mechanical Vapor Compression | Utilizes vapor from the process to reduce energy consumption. | Industrial wastewater treatment, recycling | Pros: Energy efficient, reduces operational costs. Cons: Requires skilled operation. |

| Solar Evaporation Ponds | Relies on solar energy; cost-effective for large-scale applications. | Agriculture, municipal wastewater treatment | Pros: Low operational costs; environmentally friendly. Cons: Weather dependent, requires large land area. |

What Are the Characteristics of Vertical Tube Falling Film Evaporators?

Vertical Tube Falling Film Evaporators are designed for applications involving higher viscosity liquids, making them ideal for industries like food processing and petrochemicals. The design allows for efficient heat transfer as the liquid flows down the tubes, absorbing heat from the steam. When considering this type, B2B buyers should evaluate the initial investment against long-term energy savings and efficiency gains, particularly in high-volume operations.

How Do Horizontal Tube Spray Film Evaporators Work?

Horizontal Tube Spray Film Evaporators feature a design where the liquid is sprayed over horizontal tubes, facilitating effective heat transfer. This type is particularly beneficial in environments with limited vertical space, such as chemical manufacturing and pharmaceuticals. Buyers should consider the viscosity of their wastewater, as this design is more suited for lower viscosity applications, ensuring optimal performance and maintenance.

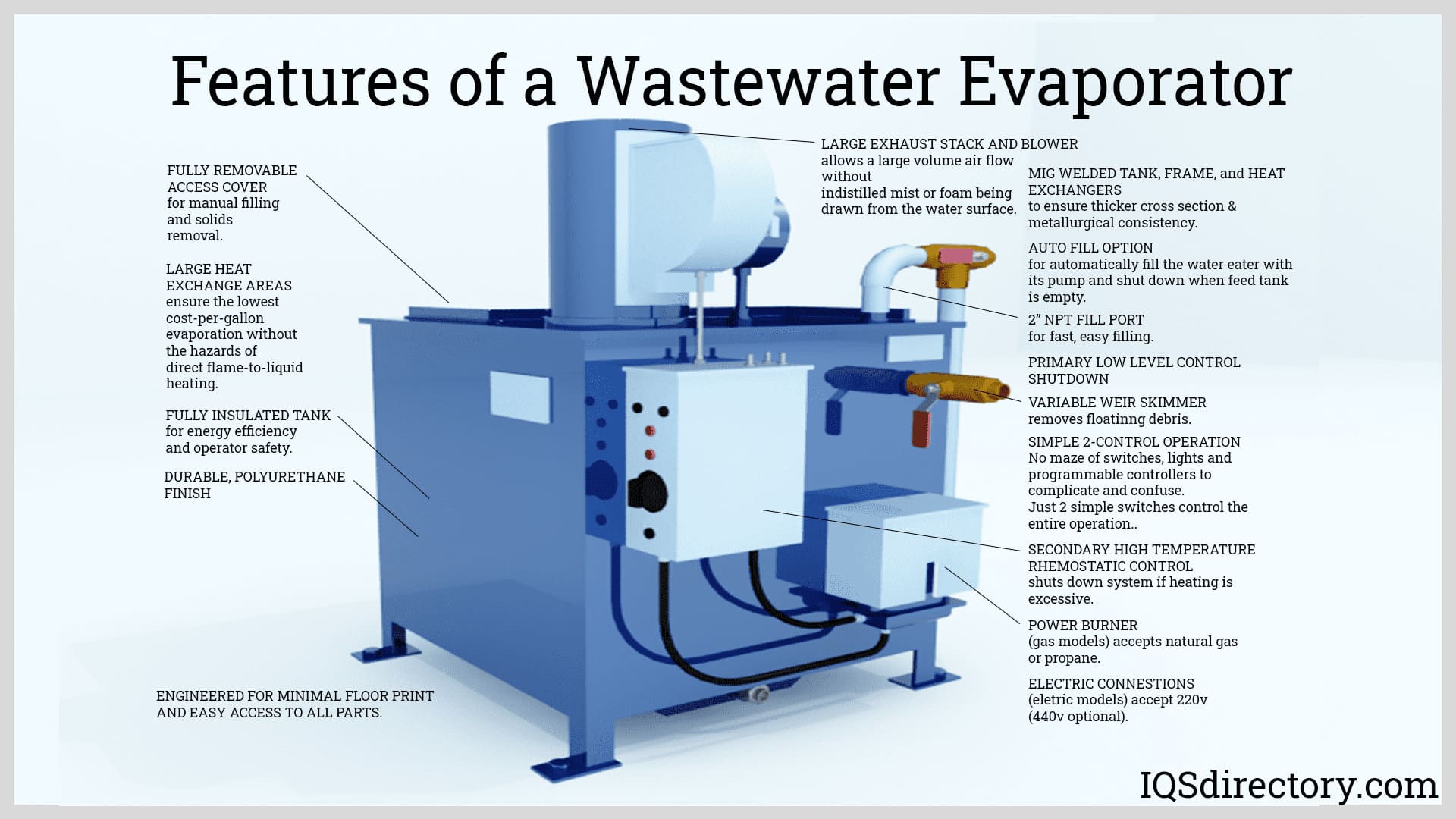

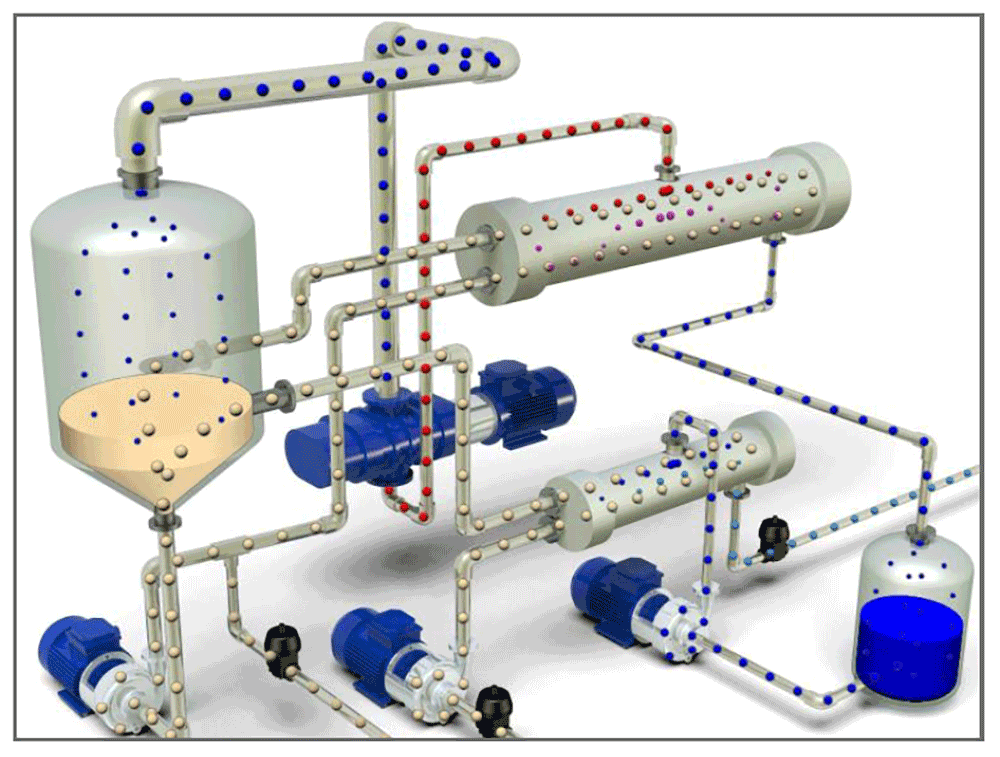

Illustrative image related to wastewater evaporation treatment

What Makes Forced Circulation Evaporators Suitable for High Solids Concentration?

Forced Circulation Evaporators operate under pressure, which prevents boiling and minimizes scaling, making them ideal for applications with high solids concentration, such as mining and wastewater treatment. The ability to handle large amounts of suspended solids is a key feature for buyers in these sectors. However, the complexity and higher costs associated with these systems necessitate careful consideration of the operational budget and maintenance capabilities.

Why Choose Mechanical Vapor Compression Evaporators?

Mechanical Vapor Compression Evaporators utilize vapor from the evaporation process to enhance energy efficiency, making them suitable for industrial wastewater treatment and recycling applications. This method significantly reduces operational costs by minimizing the need for external steam sources. B2B buyers should assess the skill level of their operational team, as these systems require more advanced management and monitoring.

Are Solar Evaporation Ponds a Viable Option for Wastewater Treatment?

Solar Evaporation Ponds leverage natural sunlight to evaporate water, making them a cost-effective solution for large-scale applications like agriculture and municipal wastewater treatment. While they offer low operational costs and are environmentally friendly, the effectiveness of this method is heavily reliant on weather conditions and requires substantial land area. Buyers should weigh these factors against their specific needs and available resources.

Key Industrial Applications of wastewater evaporation treatment

| Industry/Sector | Specific Application of wastewater evaporation treatment | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Treatment of produced water and drilling fluids | Reduces disposal costs and recovers valuable resources | Energy efficiency, scalability, and regulatory compliance |

| Mining | Concentration of tailings and wastewater management | Minimizes environmental impact and recycles water | Robustness, resistance to corrosive materials, and maintenance requirements |

| Food & Beverage | Wastewater treatment from processing plants | Ensures compliance with health standards and reduces waste | Quality of distillate, energy consumption, and system reliability |

| Chemical Manufacturing | Recovery of solvents and concentration of effluents | Reduces raw material costs and minimizes waste disposal | Customization options, energy efficiency, and space requirements |

| Textile Industry | Treatment of dyeing and finishing wastewater | Enhances water reuse and lowers treatment costs | Material compatibility, operational efficiency, and technology adaptability |

How is Wastewater Evaporation Treatment Used in the Oil & Gas Industry?

In the oil and gas sector, wastewater evaporation treatment is pivotal for managing produced water and drilling fluids. This process effectively concentrates contaminants, allowing for the recovery of valuable resources such as oils and salts while significantly reducing disposal costs. Buyers from regions with stringent environmental regulations, like Germany, must prioritize energy efficiency and compliance with local laws when sourcing evaporators.

What Role Does Wastewater Evaporation Play in Mining Operations?

Mining companies often face challenges with tailings and wastewater management. Wastewater evaporation treatment helps in concentrating these effluents, thus minimizing the environmental footprint and facilitating water recycling. For international buyers, particularly in Africa and South America, sourcing equipment that can withstand harsh conditions and has low maintenance costs is essential to ensure operational efficiency.

Why is Wastewater Evaporation Important in the Food & Beverage Sector?

In the food and beverage industry, wastewater evaporation treatment addresses the need for compliance with health and safety standards while reducing waste. This process not only ensures that effluents meet regulatory requirements but also allows for the recovery of water, making it a sustainable option. Buyers should focus on the quality of the distillate produced and the overall reliability of the system when selecting evaporators.

How Does Wastewater Evaporation Benefit Chemical Manufacturers?

Chemical manufacturing often involves the use of solvents and produces hazardous effluents. Wastewater evaporation treatment is used to recover these solvents and concentrate effluents, thereby reducing raw material costs and minimizing waste disposal challenges. Buyers must consider customization options that fit their specific processes and energy efficiency to optimize operational costs.

What Are the Advantages of Wastewater Evaporation in the Textile Industry?

The textile industry generates significant amounts of wastewater, particularly from dyeing and finishing processes. Wastewater evaporation treatment allows companies to enhance water reuse and lower treatment costs, contributing to more sustainable practices. For buyers, it is crucial to evaluate the compatibility of the equipment with various chemicals and the operational efficiency to ensure a seamless integration into existing processes.

3 Common User Pain Points for ‘wastewater evaporation treatment’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance in Wastewater Treatment

The Problem: Many businesses in regions like Africa and South America struggle with stringent environmental regulations surrounding wastewater treatment. B2B buyers often face the challenge of ensuring their wastewater evaporation systems meet local compliance standards, which can vary significantly from one country to another. Failure to adhere to these regulations can lead to hefty fines, project delays, and reputational damage, placing additional stress on procurement teams tasked with selecting the right technology.

The Solution: To effectively navigate regulatory compliance, it’s essential for buyers to conduct thorough research on local and international standards related to wastewater management. Collaborating with local environmental consultants or legal experts can provide insights into specific compliance requirements. When sourcing wastewater evaporation treatment systems, buyers should prioritize vendors who offer equipment certified for compliance with local regulations. Additionally, requesting documentation of past compliance success stories from the vendor can provide reassurance. Implementing a proactive compliance monitoring system after installation can further ensure ongoing adherence to regulations, reducing risks associated with non-compliance.

Scenario 2: Managing High Energy Costs in Wastewater Evaporation

The Problem: Energy costs are a significant concern for businesses using wastewater evaporation treatment, especially in regions where electricity prices are high or unstable. B2B buyers often find that traditional evaporation systems consume substantial amounts of energy, leading to inflated operational expenses. This challenge is compounded in industries that require continuous operation, where energy efficiency directly impacts profitability.

The Solution: To mitigate high energy costs, buyers should consider investing in advanced evaporation technologies that optimize energy use. For instance, systems employing multiple-effect evaporation (MEE) can significantly enhance energy efficiency by reusing vapor from previous evaporation stages. Additionally, incorporating vapor compression technology can further reduce energy consumption by recycling heat. Buyers should work closely with suppliers to assess the energy efficiency ratings of different systems and consider the total cost of ownership rather than just the initial purchase price. Investing in systems that utilize waste heat from other processes can also yield substantial savings, making it vital to analyze existing operations for potential energy recovery opportunities.

Scenario 3: Ensuring Reliability and Maintenance of Evaporation Systems

The Problem: Reliability is critical in wastewater treatment, as system downtime can lead to operational disruptions and increased costs. B2B buyers may experience challenges with the maintenance and performance of their wastewater evaporation systems, especially if they lack adequate support from manufacturers. The fear of unexpected breakdowns can lead to hesitancy in committing to a particular system.

The Solution: To ensure reliability, buyers should prioritize vendors that provide robust after-sales support, including maintenance services and readily available spare parts. Establishing a preventive maintenance schedule can help in identifying potential issues before they escalate into costly breakdowns. Additionally, choosing systems designed with user-friendly interfaces and self-diagnostic features can empower in-house teams to perform routine checks effectively. Buyers should also seek testimonials and case studies from other businesses in similar industries to gauge the reliability of the evaporation systems they are considering. By fostering a strong partnership with the supplier, buyers can enhance system reliability and ensure long-term operational efficiency.

Strategic Material Selection Guide for wastewater evaporation treatment

What Are the Key Materials Used in Wastewater Evaporation Treatment?

In the realm of wastewater evaporation treatment, the selection of materials is crucial for ensuring operational efficiency, longevity, and compliance with international standards. Below, we analyze four common materials used in this application, focusing on their properties, advantages, limitations, and specific considerations for international B2B buyers.

1. Stainless Steel: A Versatile Choice for Evaporators

Key Properties: Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance, and mechanical strength. It typically withstands temperatures up to 800°F (427°C) and pressures of around 150 psi, making it suitable for various evaporation processes.

Pros & Cons: The durability of stainless steel leads to a longer lifespan, reducing maintenance costs. However, it can be more expensive than other materials, which may deter budget-conscious buyers. Additionally, the manufacturing complexity can lead to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of wastewater compositions, including those containing salts and heavy metals. Its non-reactive nature ensures that the end product remains uncontaminated.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East often prefer stainless steel due to its compliance with ASTM and DIN standards. In Africa and South America, the availability of high-quality stainless steel can vary, impacting procurement decisions.

2. Carbon Steel: Cost-Effective Yet Limited

Key Properties: Carbon steel is less expensive than stainless steel and offers good mechanical properties. It can handle moderate temperatures (up to 400°F or 204°C) and pressures but is more susceptible to corrosion.

Pros & Cons: The lower cost makes carbon steel attractive for budget-limited projects. However, its corrosion susceptibility limits its use in highly saline or acidic wastewater, potentially leading to higher maintenance costs over time.

Impact on Application: Carbon steel can be effective for less aggressive wastewater applications but may not be suitable for all conditions, particularly those involving corrosive substances.

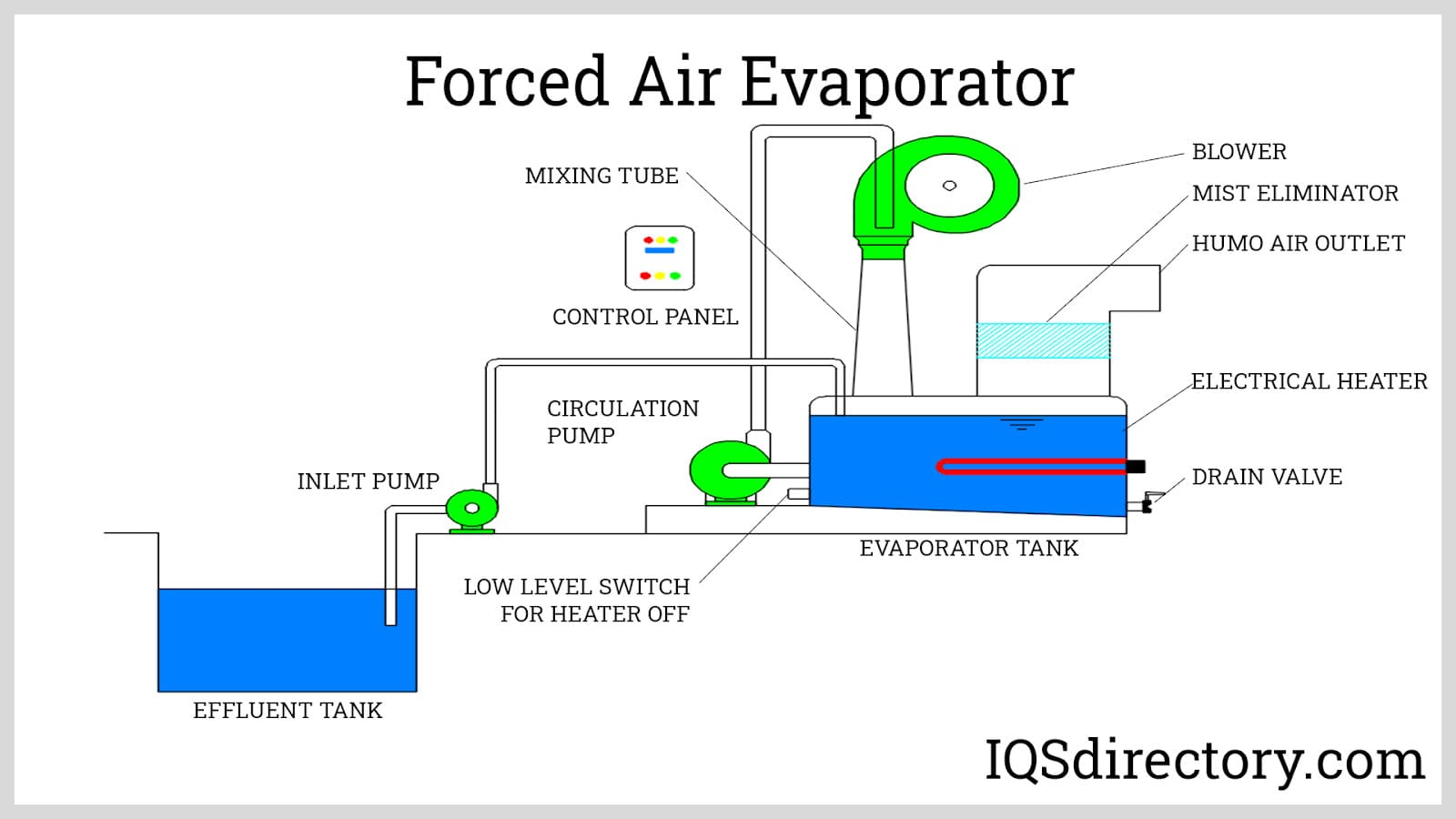

Illustrative image related to wastewater evaporation treatment

Considerations for International Buyers: Buyers in developing regions may find carbon steel more accessible and affordable. However, they must consider the potential for increased maintenance and replacement costs due to corrosion.

3. Titanium: High-Performance Material for Challenging Environments

Key Properties: Titanium boasts exceptional corrosion resistance and can withstand high temperatures and pressures. It is often rated for use in environments exceeding 800°F (427°C) and high-pressure applications.

Pros & Cons: The primary advantage of titanium is its longevity and reliability in aggressive wastewater environments. However, it is significantly more expensive than both stainless and carbon steel, which can be a barrier for many projects.

Impact on Application: Titanium is particularly suitable for treating wastewater with high levels of chlorides or other corrosive agents. Its inert properties ensure that the distillate remains pure.

Considerations for International Buyers: While titanium meets high compliance standards globally, its cost may limit its use in regions with budget constraints, such as parts of Africa and South America. Buyers must weigh the long-term benefits against initial costs.

4. Polypropylene: A Lightweight Alternative

Key Properties: Polypropylene is a thermoplastic known for its excellent chemical resistance and lightweight nature. It can handle temperatures up to 200°F (93°C) but is not suitable for high-pressure applications.

Pros & Cons: The lightweight characteristic of polypropylene makes it easy to install and transport, reducing overall project costs. However, its lower temperature and pressure ratings limit its applications in more demanding environments.

Impact on Application: Polypropylene is ideal for treating less aggressive wastewater streams, particularly in industries like food processing where chemical exposure is minimal.

Illustrative image related to wastewater evaporation treatment

Considerations for International Buyers: Buyers in regions with less demanding wastewater treatment requirements may find polypropylene appealing due to its cost-effectiveness. However, they must ensure compliance with local regulations regarding material use.

Summary Table of Material Selection for Wastewater Evaporation Treatment

| Material | Typical Use Case for wastewater evaporation treatment | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General wastewater treatment, including saline and heavy metal solutions | Excellent corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Carbon Steel | Less aggressive wastewater applications | Cost-effective for budget-limited projects | Susceptible to corrosion | Low |

| Titanium | Aggressive wastewater environments with high chlorides | Exceptional longevity and reliability | Significantly higher initial cost | High |

| Polypropylene | Mild wastewater streams, such as food processing | Lightweight and easy to install | Limited temperature and pressure ratings | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on their specific wastewater treatment needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for wastewater evaporation treatment

What Are the Key Stages in the Manufacturing Process of Wastewater Evaporation Treatment Systems?

The manufacturing process for wastewater evaporation treatment systems involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the efficiency and reliability of the final product.

How Is Material Prepared for Manufacturing Wastewater Evaporation Systems?

Material preparation begins with the selection of high-quality raw materials, typically stainless steel, carbon steel, or specialized alloys that can withstand corrosive environments. Suppliers must provide material certificates to verify compliance with international standards. The materials undergo cutting, welding, and surface treatment to remove impurities, ensuring they meet the necessary specifications for durability and performance.

What Forming Techniques Are Used in Wastewater Evaporation Equipment Production?

Forming is the next phase, where the prepared materials are shaped into components like evaporator chambers, heat exchangers, and piping systems. Common techniques include:

- Welding: Different welding methods such as TIG and MIG are employed to create strong, leak-proof joints. This is crucial for maintaining the integrity of the system under high pressure and temperature.

- Bending and Shaping: Roll forming and press braking are utilized to create custom shapes and sizes necessary for specific designs.

- Machining: Precision machining ensures that all components fit together seamlessly, which is essential for system efficiency.

How Is Assembly Conducted in Wastewater Evaporation Treatment Systems?

The assembly stage involves integrating the various components into a complete system. This is often performed in a controlled environment to minimize contamination and defects. Key steps include:

- Component Verification: Each part is checked against specifications to ensure it meets quality standards before assembly.

- Installation of Control Systems: Automated control systems for monitoring temperature, pressure, and flow rates are integrated at this stage to enhance operational efficiency.

- Final Assembly: Components are assembled according to a systematic procedure, often following detailed engineering drawings to ensure compliance with design standards.

What Finishing Processes Are Essential for Quality in Wastewater Evaporation Treatment Systems?

Finishing processes are crucial for enhancing the durability and performance of the systems. Techniques include:

- Surface Treatment: Processes like passivation or coating are applied to prevent corrosion and improve resistance to chemicals.

- Quality Inspections: The completed systems undergo rigorous quality inspections to ensure they meet design specifications and operational requirements.

What International Standards and Certifications Are Relevant for Quality Assurance?

Quality assurance in the manufacturing of wastewater evaporation treatment systems is governed by several international standards, with ISO 9001 being the most prominent. This standard focuses on ensuring consistent quality in manufacturing processes, which is critical for international B2B buyers.

How Do Industry-Specific Certifications Like CE and API Impact Quality Assurance?

Industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are also vital. CE certification indicates compliance with European health, safety, and environmental protection standards, which is particularly important for buyers in Europe. API certifications ensure that the products meet the rigorous standards required in the oil and gas industry, which often overlaps with wastewater treatment applications.

What Are the Key Quality Control Checkpoints in Manufacturing Processes?

Quality control (QC) is integral to the manufacturing process and typically includes several checkpoints:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications. This includes checking material certifications and conducting visual inspections.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs at various stages. This may involve dimensional checks, weld inspections, and monitoring of machinery performance to ensure adherence to production standards.

-

Final Quality Control (FQC): Once assembly is complete, the entire system undergoes a final inspection. This includes functional testing, pressure testing, and ensuring that all control systems operate correctly.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify a supplier’s quality control practices. Effective methods include:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and compliance with international standards directly.

-

Quality Reports: Requesting detailed quality reports can provide insight into the supplier’s QC processes, including test results and corrective actions taken for any non-conformities.

-

Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing facility can offer an unbiased assessment of the supplier’s quality assurance practices.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it is crucial to understand the nuances of quality control:

-

Regulatory Compliance: Different regions may have specific regulatory requirements, so it’s essential for buyers to ensure that suppliers can meet local compliance standards.

-

Cultural Differences: Understanding the cultural context of suppliers can impact communication and expectations around quality, making it essential to establish clear lines of communication and standards from the outset.

-

Logistics and Shipping Considerations: Quality assurance does not end with manufacturing; shipping and handling practices also impact the final product’s quality. Buyers should confirm that suppliers have protocols in place to protect equipment during transport.

Conclusion: Ensuring Quality in Wastewater Evaporation Treatment Systems

In summary, a robust manufacturing process combined with stringent quality assurance practices is essential for producing effective wastewater evaporation treatment systems. International B2B buyers must prioritize suppliers who adhere to recognized standards, implement rigorous QC checkpoints, and demonstrate a commitment to quality. By understanding these processes, buyers can make informed decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wastewater evaporation treatment’

To streamline the procurement process for wastewater evaporation treatment systems, this guide provides a clear and actionable checklist for B2B buyers. Effective sourcing requires careful planning and consideration of various factors to ensure that the selected equipment meets operational needs while also aligning with budgetary constraints.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is crucial to ensure the selected wastewater evaporation system meets your operational requirements. Consider factors such as the volume of wastewater to be treated, the concentration of contaminants, and the desired output quality.

– Key Metrics: Identify the types of contaminants (e.g., heavy metals, salts) and their concentrations to choose an appropriate technology.

– Performance Standards: Determine the required efficiency rates, such as steam economy and energy consumption.

Step 2: Research Available Technologies

Investigate different evaporation technologies to understand which best suits your needs. Common options include mechanical evaporators, solar evaporation ponds, and hybrid systems. Each has distinct advantages depending on the scale and nature of wastewater treatment.

– Mechanical vs. Solar: Mechanical systems provide consistent performance regardless of weather conditions, while solar options may be more cost-effective in sunny regions.

– Energy Efficiency: Look for technologies that maximize energy recovery and minimize operational costs.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and capability. Request detailed company profiles, including their experience with similar projects and customer testimonials.

– References: Ask for case studies or references from companies in your industry to assess performance and service quality.

– Certifications: Verify that suppliers adhere to industry standards and possess relevant certifications to ensure compliance and quality assurance.

Step 4: Request Quotes and Compare Costs

Solicit detailed quotes from multiple suppliers to facilitate a comprehensive cost comparison. Ensure that quotes include all associated costs, such as installation, maintenance, and potential upgrades.

– Breakdown of Costs: Evaluate not only the initial purchase price but also long-term operational and maintenance costs.

– Hidden Fees: Inquire about any additional fees that may arise during installation or operation.

Step 5: Assess Support and Maintenance Services

Consider the level of support and maintenance services offered by the supplier. Reliable after-sales service is crucial for minimizing downtime and ensuring the longevity of the equipment.

– Service Agreements: Look for suppliers that provide comprehensive service agreements, including routine maintenance and emergency support.

– Training and Resources: Ensure that the supplier offers training for your staff to operate and maintain the equipment effectively.

Step 6: Review Sustainability Practices

In today’s environmentally conscious market, reviewing the sustainability practices of potential suppliers is essential. Choose suppliers that prioritize eco-friendly technologies and practices in their operations.

– Waste Management: Assess how the supplier handles waste by-products and the overall environmental impact of their systems.

– Energy Usage: Evaluate the energy efficiency of the systems offered and consider options that utilize renewable energy sources.

Step 7: Finalize Contracts and Terms

Once you have selected a supplier, carefully review and finalize the contract terms. Pay close attention to delivery timelines, warranty conditions, and payment schedules to avoid potential disputes.

– Clear Terms: Ensure that the contract clearly outlines responsibilities, timelines, and penalties for non-compliance.

– Negotiation: Don’t hesitate to negotiate terms that align with your budget and operational needs.

By following this step-by-step checklist, B2B buyers can make informed decisions when sourcing wastewater evaporation treatment systems, ultimately leading to enhanced operational efficiency and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for wastewater evaporation treatment Sourcing

What are the Key Cost Components in Wastewater Evaporation Treatment?

When analyzing the cost structure of wastewater evaporation treatment, it’s essential to break down the various components that contribute to the overall pricing. The primary cost elements include:

-

Materials: The core materials involve the fabrication of evaporator units, which may include stainless steel, insulation, and heat exchangers. The choice of materials impacts durability and efficiency, with higher-grade materials often leading to increased costs.

-

Labor: Labor costs encompass skilled technicians for manufacturing and installation, as well as ongoing operational personnel. Depending on the region, labor costs can vary significantly, impacting the overall project budget.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and equipment maintenance. Efficient manufacturing processes can help in controlling these costs, but they typically account for a significant portion of the pricing.

-

Tooling: The investment in specialized tools and machinery required for producing evaporators can add to the initial costs. This is particularly relevant for custom designs or advanced technologies.

-

Quality Control (QC): Ensuring that the equipment meets industry standards and regulatory requirements involves rigorous quality control processes, which can add to the overall project cost.

-

Logistics: Transportation and shipping costs, especially for international buyers, can be substantial. Factors like distance, shipping methods, and the need for special handling can influence these costs.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Affect Wastewater Evaporation Treatment Costs?

Several factors can influence the pricing of wastewater evaporation treatment systems:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases can lead to significant discounts. Suppliers often have a MOQ, and negotiating for higher volumes can yield lower per-unit costs.

-

Specifications and Customization: Customized systems designed for specific applications or regulatory compliance can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Materials Quality and Certifications: The choice of materials and any necessary certifications (e.g., ISO, CE) can affect pricing. Higher quality materials generally lead to higher upfront costs but may provide long-term savings through enhanced durability and efficiency.

-

Supplier Factors: Reputation, reliability, and service offerings of the supplier can influence pricing. Established suppliers may charge a premium for their expertise and support.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can significantly impact the total cost. Understanding these terms is crucial for international buyers to avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Better Prices?

B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiation: Engaging in negotiations can often yield better pricing and terms. Buyers should be prepared to discuss their needs and explore options for bulk purchasing or long-term contracts.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not only the purchase price but also installation, maintenance, and operational costs over time. This holistic view can guide purchasing decisions.

-

Pricing Nuances for International Buyers: Currency fluctuations, tariffs, and import duties can affect pricing for international transactions. Buyers should account for these variables in their budgeting.

-

Research and Comparison: Conduct thorough market research to compare prices and offerings from different suppliers. This can provide leverage in negotiations and help identify the best overall value.

Disclaimer on Indicative Prices

It is essential to note that the prices for wastewater evaporation treatment solutions can vary widely based on the factors discussed. Therefore, buyers are encouraged to request detailed quotes from multiple suppliers to obtain the most accurate pricing for their specific needs.

Alternatives Analysis: Comparing wastewater evaporation treatment With Other Solutions

In the quest for efficient wastewater management, understanding various treatment solutions is vital for businesses. Wastewater evaporation treatment is one method, but it is essential to consider alternatives to make informed decisions. This section compares wastewater evaporation treatment with two prominent alternatives: membrane filtration and biological treatment. Each method has its unique strengths and weaknesses, making it crucial for B2B buyers to evaluate them based on their specific operational needs.

| Comparison Aspect | Wastewater Evaporation Treatment | Membrane Filtration | Biological Treatment |

|---|---|---|---|

| Performance | High efficiency in concentrating and recovering water; effective for hazardous materials. | Excellent for removing suspended solids and contaminants; can achieve high purity levels. | Effective for biodegradable waste; can reduce BOD/COD significantly. |

| Cost | Higher initial investment; ongoing energy costs can be significant. | Moderate initial costs; lower operational costs but membrane replacement can be expensive. | Generally lower upfront costs; operational costs depend on energy and maintenance. |

| Ease of Implementation | Requires specialized equipment and infrastructure; can be complex to set up. | Generally easier to implement; modular systems available for various scales. | Straightforward implementation but may require specific environmental conditions. |

| Maintenance | High maintenance due to energy-intensive operation and potential scaling. | Moderate maintenance; membranes require regular cleaning and replacement. | Low maintenance; relies on natural processes but may require monitoring. |

| Best Use Case | Ideal for industries with high salinity or hazardous waste; suitable for water reuse. | Best for industries needing high-quality effluent; effective in food and beverage sectors. | Suitable for municipal and agricultural applications where organic waste predominates. |

What are the Pros and Cons of Membrane Filtration as a Wastewater Treatment Alternative?

Membrane filtration utilizes semi-permeable membranes to separate contaminants from water, achieving high-quality effluent. The advantages include its ability to remove small particles and pathogens effectively, making it suitable for applications requiring stringent water quality standards. However, the operational costs can increase due to the need for periodic membrane cleaning and eventual replacement. Additionally, membrane fouling can occur, necessitating regular maintenance to ensure optimal performance.

Illustrative image related to wastewater evaporation treatment

How Does Biological Treatment Compare to Wastewater Evaporation Treatment?

Biological treatment leverages microorganisms to decompose organic waste, making it a cost-effective solution for managing biodegradable materials. Its strengths lie in lower operational costs and simplicity in implementation, particularly in municipal settings. However, biological treatment may not be as effective for non-biodegradable or hazardous waste, and the process can be sensitive to environmental conditions, requiring careful monitoring to maintain efficiency.

How Can B2B Buyers Choose the Right Wastewater Treatment Solution?

When selecting a wastewater treatment solution, B2B buyers should assess their specific needs, including the type of waste, required water quality, and budget constraints. Understanding the operational environment and regulatory requirements is crucial. For industries dealing with hazardous materials, wastewater evaporation treatment may be the most appropriate choice, while membrane filtration is ideal for those needing high purity. Biological treatment offers a robust option for organic waste management with lower costs. Ultimately, a thorough analysis of each method’s strengths and limitations will empower buyers to make the best decision for their operations.

Essential Technical Properties and Trade Terminology for wastewater evaporation treatment

What Are the Key Technical Properties in Wastewater Evaporation Treatment?

In the realm of wastewater evaporation treatment, understanding critical technical properties is essential for making informed purchasing decisions. These specifications not only influence the operational efficiency of the systems but also impact long-term cost-effectiveness and reliability.

-

Material Grade: The choice of materials used in evaporator construction, such as stainless steel or titanium, is crucial. Stainless steel is commonly used due to its corrosion resistance and durability, while titanium is preferred for highly corrosive environments. Selecting the right material grade ensures longevity and minimizes maintenance costs.

-

Heat Transfer Efficiency: This property measures how effectively an evaporator transfers heat from the vapor to the liquid. A higher efficiency means less energy consumption, leading to lower operational costs. B2B buyers should evaluate the heat transfer coefficients of various systems to ensure they meet their energy-saving goals.

-

Evaporation Rate: This specification indicates the amount of water that can be evaporated per unit of time, often expressed in liters per hour. A higher evaporation rate can lead to quicker processing times and reduced overall treatment duration, making it a key factor in operational throughput.

-

Operating Temperature and Pressure: Understanding the maximum and minimum operating temperatures and pressures is vital for compatibility with existing systems. Equipment that can operate at higher temperatures and pressures often results in improved efficiency and faster processing, which is particularly beneficial in high-demand applications.

-

Steam Economy: This term refers to the efficiency of steam usage in the evaporation process. A system with a steam economy of 2:1 means that one kilogram of steam can evaporate two kilograms of water. Higher steam economy reduces energy costs and enhances system sustainability, which is an important consideration for environmentally conscious businesses.

-

Footprint and Space Requirements: The physical dimensions of the evaporator system can impact installation and operational logistics. Compact designs may be more suitable for facilities with limited space, while larger systems may be necessary for high-volume applications. Assessing footprint requirements can help avoid costly modifications during installation.

What Are Common Trade Terms in Wastewater Evaporation Treatment?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several key terms often encountered in wastewater evaporation treatment.

Illustrative image related to wastewater evaporation treatment

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce equipment or components that are used in another company’s end product. In the context of wastewater treatment, understanding OEM relationships can help buyers identify reliable sources for replacement parts and equipment.

-

MOQ (Minimum Order Quantity): This specification indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to assess whether a supplier can meet their project needs without overcommitting financially.

-

RFQ (Request for Quotation): An RFQ is a formal document that a buyer sends to suppliers requesting pricing for specific products or services. Using RFQs can streamline the procurement process, ensuring that decision-makers receive detailed proposals that facilitate comparison.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping responsibilities, risk management, and cost allocations.

-

TCO (Total Cost of Ownership): This term encompasses all costs associated with acquiring, operating, and maintaining equipment over its lifetime. Evaluating TCO helps buyers make more informed decisions by considering not just the purchase price but also ongoing expenses such as maintenance, energy consumption, and potential downtime.

-

CAPEX (Capital Expenditure): This term refers to the funds used by a company to acquire, upgrade, and maintain physical assets. Understanding CAPEX is essential for buyers when evaluating the financial implications of investing in wastewater evaporation treatment systems.

In summary, grasping both the essential technical properties and common trade terminology related to wastewater evaporation treatment equips B2B buyers with the knowledge necessary to make informed purchasing decisions, optimizing both operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the wastewater evaporation treatment Sector

What are the Key Market Trends Influencing Wastewater Evaporation Treatment?

The global wastewater evaporation treatment market is witnessing significant growth, driven by increasing regulatory pressures, rising water scarcity, and the need for effective waste management solutions. In regions such as Africa, South America, the Middle East, and Europe, the demand for sustainable water treatment technologies is surging. Notably, countries like Germany and Nigeria are focusing on innovative technologies to improve their wastewater management systems, with evaporation being a critical component due to its effectiveness in concentrating contaminants and recovering water.

Emerging B2B technologies, such as advanced mechanical evaporators and vapor compression systems, are revolutionizing the sector. These technologies enhance energy efficiency and reduce operational costs, making them attractive for industries facing strict environmental regulations. The shift towards automation and IoT-enabled systems is also notable, as these innovations facilitate real-time monitoring and maintenance, thereby optimizing performance and reducing downtime.

International B2B buyers are increasingly looking for suppliers who offer not only competitive pricing but also technological advancements and energy-efficient solutions. Additionally, the market is seeing a trend towards modular and scalable systems that can be adapted to various applications, enabling companies to respond quickly to changing environmental regulations and operational needs.

How Can Sustainability and Ethical Sourcing Impact the Wastewater Evaporation Treatment Sector?

Sustainability is at the forefront of the wastewater evaporation treatment sector, as businesses recognize the environmental impact of their operations. Effective wastewater management through evaporation not only minimizes the volume of waste but also conserves water, a crucial resource in many regions facing scarcity. This focus on environmental sustainability is compelling B2B buyers to source technologies that are not only efficient but also environmentally friendly.

Ethical sourcing is becoming increasingly important, with buyers demanding transparency in supply chains. Companies that can demonstrate a commitment to sustainability through certifications such as ISO 14001 for environmental management systems or the use of green materials will have a competitive advantage. Additionally, suppliers that utilize renewable energy sources for their evaporator systems are likely to attract environmentally conscious clients.

Incorporating sustainable practices and ethical sourcing not only enhances a company’s reputation but also meets the growing consumer demand for responsible business practices, making it a vital consideration for B2B buyers in the wastewater treatment market.

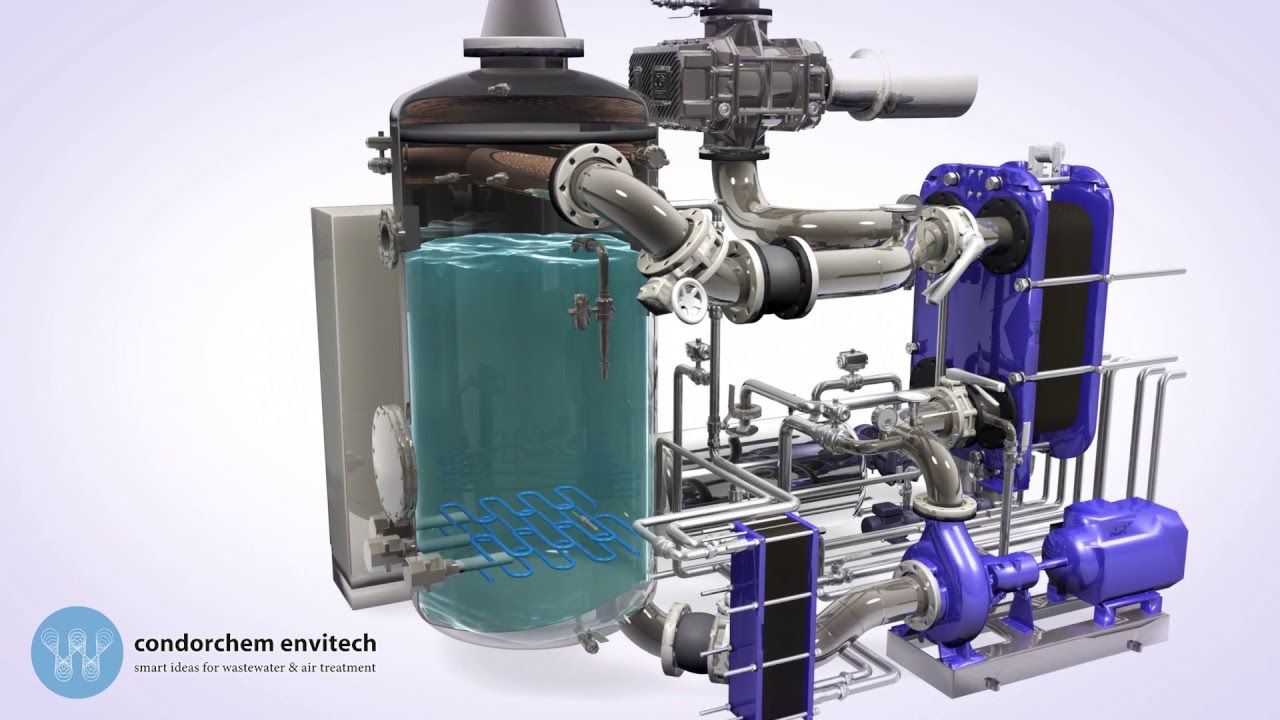

Illustrative image related to wastewater evaporation treatment

What is the Historical Context of Wastewater Evaporation Treatment?

The concept of wastewater evaporation treatment has evolved significantly over the decades. Initially, evaporation was primarily utilized in natural settings, such as solar evaporation ponds, which are still in use today, especially in arid regions. However, the limitations of these systems, including land requirements and inefficiencies, led to the development of mechanical evaporators.

In the late 20th century, advancements in technology allowed for more efficient mechanical systems that could handle a variety of wastewater compositions while significantly reducing energy consumption. The introduction of multi-effect and vapor compression evaporators in the early 2000s further transformed the landscape, enabling industries to optimize their operations while adhering to stringent environmental regulations.

Today, the focus is on continuous improvement and innovation, with ongoing research aimed at enhancing efficiency and reducing the environmental footprint of wastewater evaporation processes. This historical context is essential for B2B buyers as it highlights the importance of selecting advanced, reliable technologies that align with both current trends and future sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of wastewater evaporation treatment

-

How do I select the right wastewater evaporation treatment system for my facility?

Choosing the right wastewater evaporation system depends on several factors, including the volume and type of wastewater, required treatment efficiency, and available space. Assess your specific needs by considering the contaminants present in your wastewater, whether they include heavy metals or salts, and your operational budget. It’s also essential to evaluate the energy consumption of different systems, as this can impact long-term operational costs. Consulting with suppliers and reviewing case studies from similar industries can provide valuable insights for making an informed decision. -

What are the advantages of mechanical vs. solar evaporation systems?

Mechanical evaporation systems offer higher efficiency and reliability compared to solar systems, particularly in regions with inconsistent weather patterns. They can operate year-round, are less affected by environmental conditions, and generally have a smaller footprint. On the other hand, solar evaporation systems can be cost-effective in areas with abundant sunlight and land availability. However, they require more space and may not be suitable for all types of wastewater. Understanding your local climate and operational needs will help determine the best option for your facility. -

What is the typical lead time for procuring a wastewater evaporation treatment system?

Lead times for wastewater evaporation systems can vary significantly depending on the complexity of the system and the supplier’s production capacity. Generally, expect a timeframe of 6 to 12 weeks for standard units, while custom systems may take longer. Factors influencing lead time include design specifications, component availability, and shipping logistics, especially for international orders. To ensure timely delivery, it’s advisable to discuss project timelines and potential delays with your supplier upfront. -

What minimum order quantities (MOQ) should I expect when sourcing evaporation systems?

MOQs for wastewater evaporation systems can vary by supplier, often depending on the scale of production and system specifications. Some manufacturers may offer individual units for smaller operations, while others may require bulk orders to optimize production costs. When sourcing, inquire about MOQs early in the negotiation process to align with your operational needs and budget. If your requirements are below the MOQ, consider partnering with other businesses to combine orders. -

What payment terms are typically offered by suppliers for wastewater treatment systems?

Payment terms can vary widely among suppliers, but common practices include a percentage upfront (usually 30-50%) followed by the balance upon delivery or installation. Some suppliers may offer financing options or installment plans, particularly for larger purchases. It’s essential to clarify payment terms and any potential additional costs (such as shipping or taxes) before finalizing agreements. Establishing clear terms can help avoid misunderstandings and ensure a smoother transaction process. -

How can I ensure the quality of the wastewater evaporation system I am purchasing?

To ensure quality, request certifications and compliance documentation from suppliers, such as ISO or CE certifications. Conducting a thorough vetting process is crucial; this can include reviewing supplier reputation, seeking references, and examining previous projects. Additionally, consider arranging for a factory visit or an inspection of the equipment before shipment. Many suppliers also provide warranties and after-sales support, which can be indicative of their commitment to quality and customer service. -

What logistics considerations should I keep in mind when importing evaporation systems?

When importing wastewater evaporation systems, consider factors such as shipping methods, customs clearance, and potential tariffs. Work with logistics providers experienced in handling industrial equipment to navigate these complexities. Ensure all documentation is accurate and complete to avoid delays at customs. Additionally, plan for potential transportation challenges, particularly if the equipment is large or requires special handling. Engaging with a local partner can help streamline the logistics process and mitigate risks. -

Can wastewater evaporation systems be customized to meet specific operational needs?

Yes, many suppliers offer customization options for wastewater evaporation systems to align with your specific operational requirements. Customization can include modifications to the system’s size, design, or energy efficiency features. Discuss your unique needs with potential suppliers during initial consultations to understand the extent of customization available and any associated costs. Custom solutions can enhance system performance and ensure better alignment with your treatment objectives, providing long-term operational benefits.

Top 5 Wastewater Evaporation Treatment Manufacturers & Suppliers List

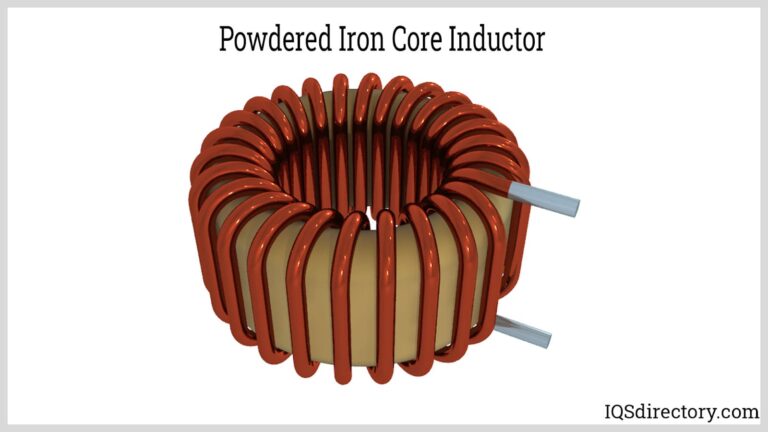

1. IQS Directory – Wastewater Evaporators

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Wastewater evaporators transform water-based waste into vapor, separating impurities and reducing waste volume. They operate using thermodynamics and mass transfer principles, applying thermal energy to liquid waste to vaporize water. Common fuel sources include natural gas, electricity, oil, or steam. Key components include a feed pump for liquid transfer, a heat exchanger for heating, a blower f…

2. ENCON – Wastewater Evaporators

Domain: evaporator.com

Registered: 1996 (29 years)

Introduction: ENCON Evaporators designs and manufactures American-made wastewater evaporators that reduce disposal volume by up to 99%. They have over 30 years of experience and 2,000+ installations worldwide, offering reliable, energy-efficient solutions for industrial wastewater minimization. Key products include: 1. Thermal Evaporator: 8-650 Gallons Per Hour 2. Vacuum Heat Pump Evaporator: 20-70 Gallons Per …

3. Water Maze – Wastewater Evaporation Systems

Domain: wmaze.com

Registered: 1999 (26 years)

Introduction: Wastewater Evaporation Systems by Water Maze can eliminate 95% of hauling costs by concentrating solids and removing water as steam. Feasibility studies are available to determine potential savings for any water sample.

4. Esemag – Wastewater Evaporation Solutions

Domain: esemag.com

Registered: 1996 (29 years)

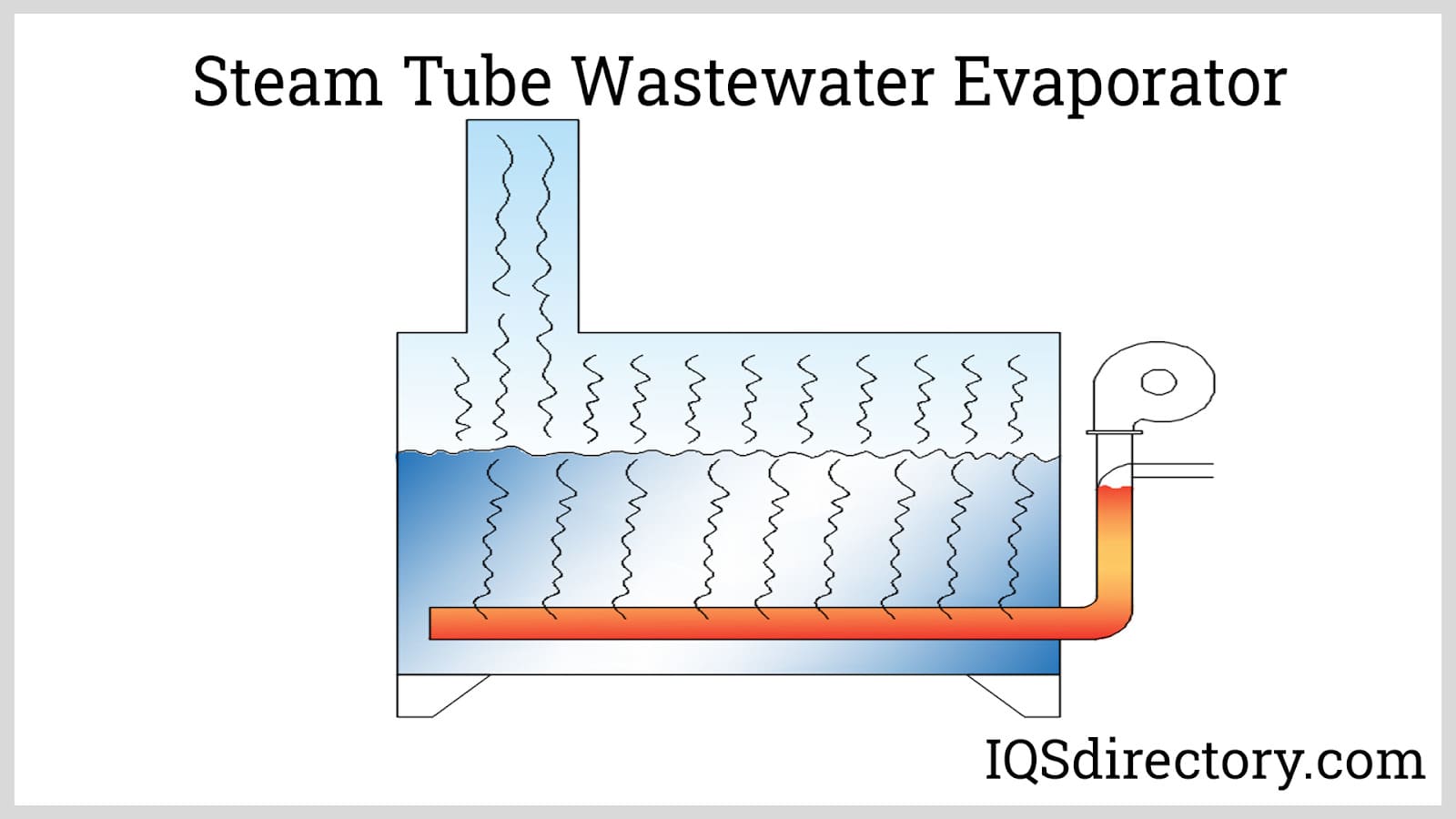

Introduction: Wastewater treatment by evaporation methods include: 1. Natural Evaporation Ponds: Slow, requires large land area, subject to weather, and has odor problems. 2. Forced Air Evaporators: Cost-effective, efficient with preheated waste streams, but not suitable for high dissolved solids and may require air permitting. 3. Boiler Blow-Off Evaporators: Evaporate 2-4 gpm, effective on pretreated waste str…

5. Water Technologies – Energy-Efficient Evaporator

Domain: watertechnologies.com

Registered: 2002 (23 years)

Introduction: Evaporator for wastewater treatment designed to meet strict regulations and address environmental concerns. Key features include:

– Energy-efficient operation, 25 to 50 times more efficient than conventional single-effect, steam-driven evaporators.

– High-grade construction materials for decades of reliable operation.

– Variable waste flow treatment capacity from 10 to 3,000 gallons per minute …

Strategic Sourcing Conclusion and Outlook for wastewater evaporation treatment

What Are the Key Insights for B2B Buyers in Wastewater Evaporation Treatment?

In conclusion, strategic sourcing in wastewater evaporation treatment offers significant opportunities for international B2B buyers. As industries increasingly prioritize sustainability and cost-efficiency, investing in advanced evaporation technologies can facilitate the recovery of valuable resources while minimizing environmental impact. Buyers should consider the diverse types of evaporators, such as vertical tube falling film and forced circulation systems, to match specific operational needs and achieve optimal energy efficiency.

Moreover, understanding the nuances of mechanical vapor compression and the potential of utilizing waste heat can further enhance the economic viability of evaporation solutions. As regions like Africa, South America, the Middle East, and Europe grapple with growing water scarcity and regulatory pressures, the demand for effective wastewater treatment solutions will only intensify.

How Can B2B Buyers Position Themselves for Future Success?

To capitalize on these trends, B2B buyers are encouraged to forge partnerships with reputable suppliers who can deliver innovative and tailored evaporation solutions. By leveraging strategic sourcing, companies can not only improve operational efficiency but also contribute to global sustainability efforts. Embrace this opportunity to stay ahead of the curve in wastewater management—act now to secure your competitive advantage in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to wastewater evaporation treatment

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.