The Definitive Guide to Used Gutter Machine For Sale: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for used gutter machine for sale

In the rapidly evolving construction landscape, sourcing used gutter machines for sale presents a significant challenge for international buyers. The ability to efficiently manage inventory, reduce costs, and meet client demands is paramount, especially for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, including industrial powerhouses like Germany and Saudi Arabia. This guide aims to illuminate the complexities of the used gutter machine market, providing insights that empower B2B buyers to make informed purchasing decisions.

Throughout this comprehensive guide, we will explore various types of gutter machines, their applications, and the benefits they can bring to your operations. We will delve into the intricacies of supplier vetting, ensuring you identify reliable sources and avoid pitfalls that could impact your investment. Additionally, we will provide an overview of cost considerations, helping you navigate pricing structures and understand the factors that influence the value of used equipment.

By equipping you with the knowledge needed to assess machines effectively, this guide will serve as a vital resource in your quest to enhance operational efficiency and expand your service offerings. Whether you’re looking to upgrade your machinery or enter the market, our insights will help you confidently navigate the global landscape of used gutter machines, driving your business toward greater profitability and success.

Understanding used gutter machine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| K-Style Gutter Machine | Produces 5″ and 6″ K-style gutters; often portable | Residential and commercial roofing | Pros: Versatile, popular design. Cons: Limited to K-style only. |

| Combo Gutter Machine | Capable of producing multiple sizes (e.g., 5″ and 6″) | Versatile applications across sectors | Pros: Flexibility in size options. Cons: May require more maintenance. |

| Half-Round Gutter Machine | Creates half-round gutters, often used in aesthetics | High-end residential projects | Pros: Attractive design, unique profile. Cons: Less common, may limit market. |

| Elbow Machine | Specialized for creating gutter elbows | Essential for gutter installations | Pros: Efficient production of elbows. Cons: Limited standalone use. |

| Downspout Machine | Focused on fabricating downspouts in various sizes | Complements gutter systems | Pros: Completes gutter installation. Cons: May not be needed for all buyers. |

What are the Key Characteristics of K-Style Gutter Machines?

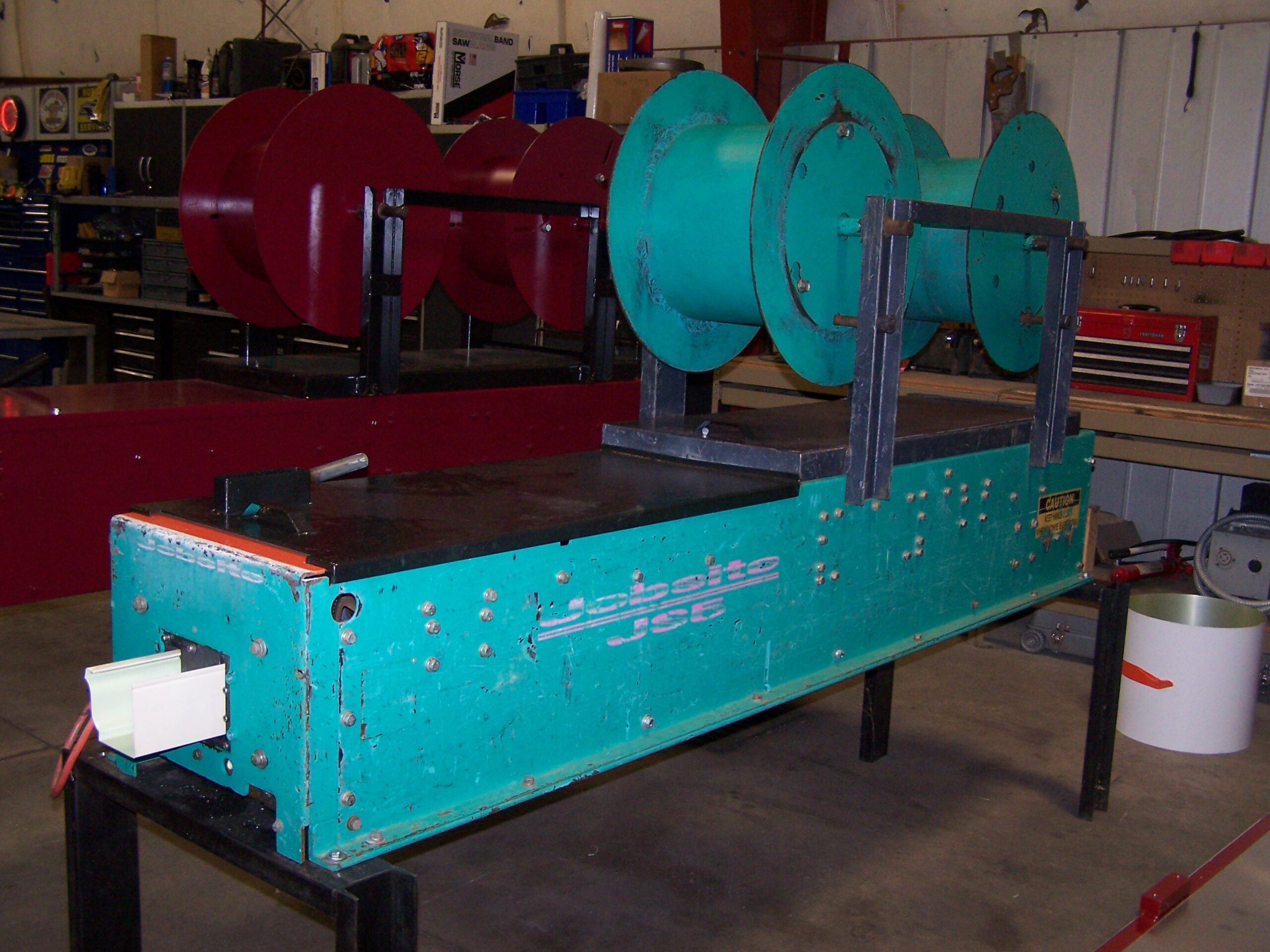

K-Style gutter machines are designed primarily for producing 5-inch and 6-inch K-style gutters, which are the most commonly used in residential and commercial roofing projects. Their portability allows for easy transport to job sites, making them ideal for contractors who need to produce gutters on-site. When purchasing a used K-Style machine, buyers should consider its maintenance history and any included accessories, such as guillotines or spools.

Illustrative image related to used gutter machine for sale

Why Choose Combo Gutter Machines for Versatility?

Combo gutter machines can produce multiple sizes, typically 5″ and 6″, offering flexibility for contractors who work on various projects. This versatility allows businesses to cater to a wider range of customer needs, from residential homes to commercial buildings. Buyers should evaluate the machine’s condition, as well as the availability of spare parts and technical support, to ensure long-term usability.

What Makes Half-Round Gutter Machines Unique?

Half-round gutter machines are designed to create aesthetically pleasing half-round gutters, often used in high-end residential projects. Their unique profile can add significant visual appeal, making them a preferred choice for certain architectural styles. However, buyers should consider market demand for half-round gutters in their area, as this may affect the machine’s profitability in the long run.

How Do Elbow Machines Enhance Gutter Installations?

Elbow machines are specialized equipment used to create the necessary elbows for gutter systems. They enable contractors to produce elbows efficiently, which is essential for proper gutter installation and drainage. While they are crucial for completing gutter systems, buyers should assess whether they need this specialized equipment or if a more general gutter machine will suffice for their operations.

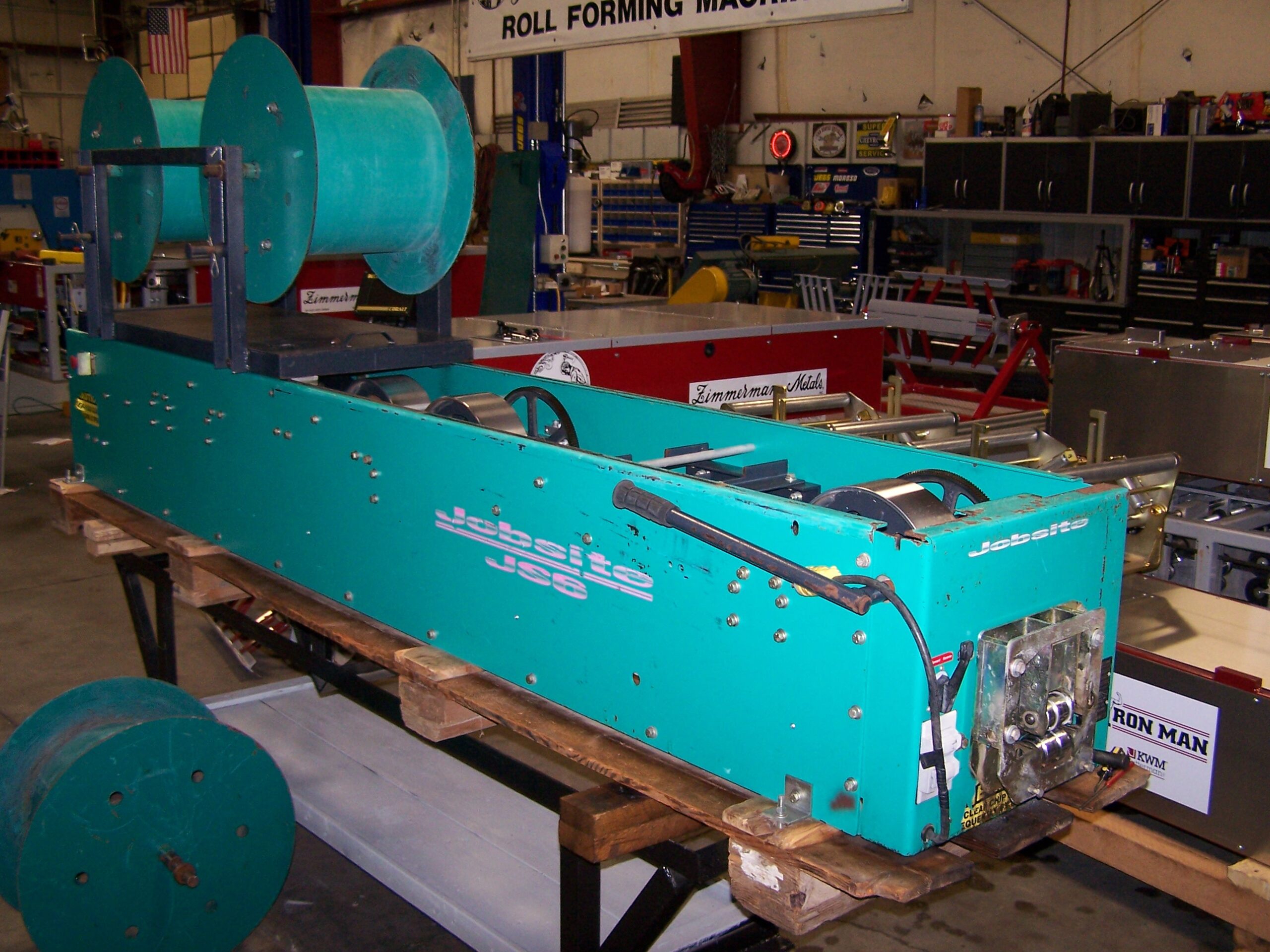

Illustrative image related to used gutter machine for sale

Why Invest in Downspout Machines?

Downspout machines focus on fabricating downspouts in various sizes, which are integral components of any gutter system. While they complement gutter machines, their necessity depends on the specific services offered by a contractor. Buyers should evaluate their current product offerings and client needs to determine if investing in a downspout machine will enhance their service capabilities and profitability.

Key Industrial Applications of used gutter machine for sale

| Industry/Sector | Specific Application of used gutter machine for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Contracting | Manufacturing custom gutters for residential and commercial projects | Streamlines production, reduces lead times, and cuts costs | Ensure machine compatibility with local materials and standards |

| Roofing | Producing seamless gutters for roofing installations | Enhances project efficiency and quality of installations | Look for machines that can handle various gutter profiles |

| Landscaping & Drainage | Creating drainage solutions using custom gutters | Improves water management and property aesthetics | Assess machine durability and ease of transport |

| Manufacturing & Fabrication | Producing gutters for industrial applications | Expands product offerings and meets diverse client needs | Verify machine capacity and gauge compatibility |

| Retail & Distribution | Reselling custom gutters and accessories to contractors | Increases inventory variety and attracts a broader customer base | Check for warranties and service options on used machines |

How Do Used Gutter Machines Benefit the Construction and Contracting Sector?

In the construction and contracting industry, used gutter machines are invaluable for manufacturing custom gutters tailored to specific projects. These machines enable contractors to produce seamless gutters on-site, significantly reducing lead times and associated costs. For international buyers, especially in regions like Africa and South America, it’s essential to consider local material compatibility and adherence to building regulations when sourcing these machines. The ability to customize gutter sizes and styles can also enhance service offerings, thereby increasing profitability.

In What Ways Do Used Gutter Machines Enhance Roofing Projects?

Roofing professionals utilize used gutter machines to create seamless gutters that perfectly fit various roofing systems. This application not only improves the aesthetic appeal of the roofs but also ensures better water management, thereby minimizing the risk of leaks and water damage. Buyers from the Middle East and Europe should prioritize machines that can handle diverse gutter profiles, as this flexibility allows for a wider range of installations. Additionally, understanding the machine’s operational efficiency can further enhance project timelines and overall quality.

What Role Do Used Gutter Machines Play in Landscaping and Drainage Solutions?

Landscaping companies leverage used gutter machines to manufacture custom drainage solutions that effectively manage water runoff, protecting properties from flooding and erosion. This application is particularly relevant in regions prone to heavy rainfall, where effective drainage is critical. For buyers in Europe and Africa, sourcing machines that can produce various gutter sizes and styles is crucial. Furthermore, assessing the machine’s portability can be beneficial for landscaping businesses that operate in multiple locations.

Illustrative image related to used gutter machine for sale

How Can Manufacturing and Fabrication Industries Benefit from Used Gutter Machines?

In manufacturing and fabrication, used gutter machines are employed to produce gutters for industrial applications, such as factories and warehouses. This capability allows businesses to diversify their product offerings and cater to a broader range of clients, which can be a significant competitive advantage. When sourcing these machines, international buyers should verify the machine’s capacity and compatibility with various gauge materials. Additionally, understanding the machine’s maintenance requirements can help ensure long-term operational efficiency.

How Do Retailers and Distributors Utilize Used Gutter Machines?

Retailers and distributors can capitalize on used gutter machines to create custom gutters and accessories for resale to contractors. This application not only enhances inventory variety but also attracts a wider customer base looking for tailored solutions. For businesses in the Middle East and Europe, it is vital to check for warranties and service options when purchasing used machines. Ensuring that the machine can produce high-quality products consistently will help maintain customer satisfaction and loyalty.

3 Common User Pain Points for ‘used gutter machine for sale’ & Their Solutions

Scenario 1: Uncertainty About Machine Condition and Reliability

The Problem: When purchasing a used gutter machine, B2B buyers often grapple with uncertainty regarding the machine’s condition and reliability. This concern is amplified for international buyers who may not have the opportunity to inspect the machine in person. Questions about past maintenance, potential wear and tear, and overall functionality can lead to hesitation in making a purchase, fearing it may result in costly repairs or downtime once the machine is operational.

The Solution: To mitigate these concerns, buyers should prioritize sourcing machines from reputable dealers or platforms that offer detailed listings with comprehensive information on each machine’s history. Look for sellers who provide transparent maintenance records, warranties, or guarantees on their used equipment. Additionally, consider arranging for a third-party inspection service or a video walkthrough of the machine before finalizing the purchase. This proactive approach not only builds confidence in the investment but also ensures that the machine aligns with your operational needs.

Scenario 2: Compatibility with Existing Equipment

The Problem: Another common challenge faced by B2B buyers is ensuring that a used gutter machine is compatible with their existing operations, including other machinery and tools. Buyers may encounter difficulties if the machine requires specific power sources, attachments, or materials that differ from what they currently use. This can lead to additional unexpected costs and delays, undermining the efficiency of their projects.

The Solution: Before purchasing, it is crucial to conduct a thorough analysis of your current equipment and operational requirements. Create a checklist that includes the specifications of your existing machinery, such as power requirements (110V vs. 220V), compatible gutter sizes, and any necessary attachments or accessories. Engage in discussions with the seller to clarify these specifications and confirm compatibility. Additionally, consider seeking expert advice or consulting with other contractors who have experience with similar machines. This due diligence will help ensure that your new gutter machine integrates seamlessly into your workflow, minimizing disruption and maximizing productivity.

Scenario 3: Navigating Price and Value Expectations

The Problem: Buyers of used gutter machines often find themselves navigating a complex landscape of pricing, leading to confusion about fair market value. With varying prices based on condition, brand, and included features, it’s challenging to determine whether a deal is genuinely advantageous or if it might lead to overpayment for a subpar machine. This issue is particularly pronounced in international transactions where local market insights may be lacking.

The Solution: To establish a clear understanding of fair pricing, buyers should conduct thorough market research. Start by examining multiple listings for similar models across various platforms to gauge the average price range. Engage with industry forums or social media groups to gather insights from experienced contractors who can provide anecdotal evidence of what they paid for comparable machines. Additionally, consider negotiating price based on the machine’s condition and any additional features it may include, such as trailers or extra accessories. By arming yourself with data and community insights, you can make informed decisions that align with your budget and operational needs.

Strategic Material Selection Guide for used gutter machine for sale

What Are the Key Materials for Used Gutter Machines?

When considering the purchase of a used gutter machine, the material used in its construction plays a critical role in its performance, durability, and overall value. Below, we analyze four common materials used in gutter machines, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Aluminum Perform in Gutter Machines?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can withstand a range of temperatures, making it suitable for various climates.

Pros & Cons: The durability of aluminum is notable, as it does not rust like steel. However, it can be more expensive than other materials. Manufacturing complexity is relatively low, allowing for efficient production of seamless gutters. Yet, aluminum may not be suitable for very heavy-duty applications due to its lower tensile strength compared to steel.

Impact on Application: Aluminum is compatible with various media, including water and debris, making it ideal for residential and commercial gutter systems. It is particularly effective in areas with moderate rainfall.

Considerations for International Buyers: Buyers from regions like Europe, where standards such as DIN are prevalent, will find aluminum gutters compliant with local regulations. However, in markets like Africa and South America, buyers should ensure that the aluminum used meets local corrosion resistance standards.

Illustrative image related to used gutter machine for sale

What Are the Benefits of Steel in Gutter Machines?

Key Properties: Steel is known for its high strength and durability, with excellent pressure ratings. It can be galvanized to enhance corrosion resistance, making it suitable for harsher environments.

Pros & Cons: The primary advantage of steel is its robustness, making it ideal for heavy-duty applications. However, it is heavier and more prone to rust if not properly coated. The manufacturing process can be more complex due to the need for additional treatments to prevent corrosion.

Impact on Application: Steel gutters are well-suited for industrial applications where high volumes of water flow are expected. They can handle extreme weather conditions, making them a preferred choice in regions with heavy rainfall.

Considerations for International Buyers: Buyers in the Middle East and Africa should ensure that the steel complies with international standards, such as ASTM. Additionally, the cost of shipping heavier steel machines can be a factor to consider in overall project budgets.

Why Choose Vinyl for Gutter Machines?

Key Properties: Vinyl is lightweight, resistant to corrosion, and has good thermal properties. It can handle a range of temperatures without deforming.

Illustrative image related to used gutter machine for sale

Pros & Cons: The main advantage of vinyl is its low cost and ease of installation. However, it is less durable than metal options and can become brittle over time, especially in extreme temperatures. Manufacturing complexity is low, making it accessible for many manufacturers.

Impact on Application: Vinyl gutters are suitable for residential applications in areas with moderate weather conditions. They are less ideal for regions experiencing heavy rainfall or extreme temperatures.

Considerations for International Buyers: In regions like South America, where cost is a significant factor, vinyl may be an attractive option. However, buyers should be cautious about the long-term durability and ensure that the vinyl meets local standards.

How Does Copper Compare in Gutter Machine Materials?

Key Properties: Copper is highly resistant to corrosion and has excellent thermal conductivity. It develops a protective patina over time, enhancing its durability.

Illustrative image related to used gutter machine for sale

Pros & Cons: The aesthetic appeal of copper is a significant advantage, as it can enhance the value of a property. However, it is one of the most expensive materials, and its manufacturing can be complex due to the need for specialized techniques.

Impact on Application: Copper gutters are ideal for high-end residential and commercial applications. They are particularly effective in areas with high humidity, as they resist corrosion well.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer copper for its longevity and aesthetic value. However, the higher cost and potential for theft in some regions should be considered.

Summary Table of Material Selection for Used Gutter Machines

| Material | Typical Use Case for used gutter machine for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Residential and light commercial gutters | Lightweight and corrosion-resistant | Less durable under heavy loads | Medium |

| Steel | Industrial and heavy-duty applications | High strength and durability | Heavier and prone to rust | High |

| Vinyl | Residential applications in moderate climates | Low cost and easy installation | Less durable, can become brittle | Low |

| Copper | High-end residential and commercial systems | Aesthetic appeal and corrosion resistance | High cost and theft risk | High |

This analysis provides a comprehensive overview of material options for used gutter machines, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for used gutter machine for sale

What Are the Main Stages of Manufacturing Used Gutter Machines?

The manufacturing process of used gutter machines involves several critical stages that ensure the machinery meets operational standards and durability requirements. Understanding these stages can help B2B buyers assess the quality and reliability of the machines they intend to purchase.

Illustrative image related to used gutter machine for sale

Material Preparation: What Materials Are Used in Gutter Machine Manufacturing?

The first step in the manufacturing process is material preparation. Gutter machines are typically made from high-quality steel, aluminum, or galvanized metals. These materials are chosen for their strength and resistance to corrosion, which is essential given the outdoor applications of gutter systems. The materials are cut into specific dimensions and treated to enhance durability.

Additionally, suppliers often utilize advanced technologies like laser cutting and CNC machining to ensure precision in the components that will be assembled into the final machine. For international buyers, especially those in regions with varying climatic conditions, understanding the material composition is crucial for assessing long-term performance.

How Is the Forming Process Conducted for Gutter Machines?

Once the materials are prepared, they undergo the forming process. This involves shaping the raw materials into specific profiles required for gutter production. Techniques such as roll forming and bending are commonly used in this stage. Roll forming is particularly popular for producing seamless gutters, as it allows for continuous shaping of metal strips into the desired profile.

Advanced manufacturing techniques like hydraulic pressing may also be employed to create specific bends and curves in the materials. Each forming technique is chosen based on the machine’s intended use, and understanding these methods can help buyers identify machines that align with their production needs.

What Happens During the Assembly Stage of Gutter Machine Production?

The assembly stage is where the various components of the gutter machine come together. This includes integrating the drive systems, electrical components, and forming tools. Skilled technicians or automated systems often carry out this assembly to ensure precision and reliability.

During this phase, it’s essential that all parts are aligned and calibrated correctly. Misalignment can lead to inefficient operation and increased wear and tear. B2B buyers should inquire about the assembly process, as it directly impacts the machine’s performance and longevity.

How Is the Finishing Process Conducted for Gutter Machines?

The finishing stage involves applying protective coatings and completing any final adjustments to the machine. This may include painting, galvanizing, or applying powder coatings to protect against rust and other environmental factors. Quality finishing is vital for enhancing the machine’s appearance and extending its lifespan.

Moreover, during this stage, thorough inspections are typically conducted to ensure that the machine meets all specifications and standards. Buyers should pay attention to the finishing process, as high-quality finishes can indicate a manufacturer’s commitment to quality.

What Quality Assurance Standards Are Relevant for Gutter Machines?

Quality assurance (QA) is a critical component of the manufacturing process for gutter machines. Various international and industry-specific standards apply, ensuring that the machines produced are safe, reliable, and effective.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is one of the most recognized international standards for quality management systems. Compliance with ISO 9001 indicates that the manufacturer has established a robust quality management framework, focusing on continuous improvement and customer satisfaction. B2B buyers should prioritize suppliers who are ISO 9001 certified, as this reflects a commitment to maintaining high-quality production standards.

In addition to ISO certifications, specific industry standards such as CE marking (for European markets) and API (American Petroleum Institute) certifications may also apply, depending on the machine’s design and intended use. Buyers should verify these certifications to ensure compliance with regional regulations.

What Are the Key Quality Control Checkpoints in Gutter Machine Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early and ensure that each machine meets quality standards. Key checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor production quality and address any issues that arise.

- Final Quality Control (FQC): Before shipment, a final inspection ensures that the finished product complies with all specifications and quality standards.

B2B buyers should ask manufacturers about their QC processes and the frequency of inspections at each stage to assess the reliability of the machines.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that a supplier adheres to high-quality standards, B2B buyers can take several steps to verify their quality control practices.

What Audits and Reports Can Buyers Request?

Buyers can request copies of quality management system audits and compliance reports. These documents provide insights into the manufacturer’s adherence to international standards and their commitment to quality. Additionally, asking for references or testimonials from previous clients can help gauge the supplier’s reputation in the market.

Why Is Third-Party Inspection Important for Used Gutter Machines?

Engaging third-party inspection services can provide an unbiased assessment of the machine’s quality. These inspectors can verify that the machine meets specified standards and can identify potential issues that may not be apparent during a surface-level inspection. This step is particularly important for international buyers who may be unable to conduct on-site inspections due to logistical challenges.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate various nuances regarding quality control when sourcing used gutter machines. Differences in regulations, standards, and expectations can impact the purchasing process.

How Do Regional Standards Affect Quality Assurance?

For example, buyers from Europe may focus heavily on CE compliance, while those from the Middle East might prioritize adherence to local standards. Understanding these regional differences is essential for ensuring that the purchased equipment is compliant with local regulations.

Illustrative image related to used gutter machine for sale

Additionally, language barriers and cultural differences can complicate communication regarding quality assurance practices. Buyers should establish clear lines of communication with suppliers and consider working with local representatives who understand the regional market and its requirements.

By understanding the manufacturing processes and quality assurance practices for used gutter machines, B2B buyers can make informed decisions that align with their operational needs and ensure the longevity and reliability of their investments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘used gutter machine for sale’

When considering the procurement of a used gutter machine, a structured approach is essential to ensure you make an informed and profitable investment. This checklist serves as a guide for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. By following these steps, you will be better positioned to find a machine that meets your operational needs while ensuring quality and reliability.

Illustrative image related to used gutter machine for sale

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications you require for your gutter machine. Consider factors such as the types of gutters you intend to produce (e.g., K-style, half-round), the sizes (commonly 5″, 6″, or combination models), and the materials you will use (aluminum, steel). This clarity will help you filter options and focus on machines that best fit your operational requirements.

Step 2: Research Reputable Suppliers

Identifying trustworthy suppliers is crucial for ensuring the quality of your purchase. Look for manufacturers or resellers with a solid reputation in the industry, verified by customer testimonials and reviews. Consider suppliers that specialize in gutter machinery and have a history of serving international markets, as they are more likely to understand the specific needs of your region.

Step 3: Evaluate Potential Machines Thoroughly

Once you have a shortlist of suppliers, dive into evaluating the specific machines they offer. Check the machine’s age, usage history, and maintenance records, as these factors significantly affect performance and durability. If possible, arrange a site visit or request videos demonstrating the machine in action to assess its condition firsthand.

Step 4: Verify Compliance and Certifications

Ensure that the gutter machines comply with local and international standards, particularly if you operate in regions with strict regulations. Look for certifications that indicate the machine meets safety and quality standards, such as CE marking for Europe. This verification can protect you from future liabilities and ensure the machine is suitable for your market.

Illustrative image related to used gutter machine for sale

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable machine, engage in negotiations regarding the price and payment terms. Understand the market rates for used gutter machines in your region to ensure you are getting a fair deal. Additionally, inquire about warranties or return policies, as these can provide added security in your investment.

Step 6: Assess Logistics and Delivery Options

Consider the logistics involved in transporting the machine to your location. Discuss delivery options with the supplier, including shipping methods and associated costs. Ensure that the delivery timeline aligns with your operational needs, and confirm that the machine will be securely packaged to prevent damage during transit.

Step 7: Plan for Installation and Training

After securing your machine, plan for its installation and any necessary training for your staff. Proper installation is vital for optimal performance, so consider hiring professionals if needed. Additionally, if the machine has specific operational nuances, training can help your team maximize productivity and minimize errors.

By following this step-by-step checklist, you can streamline your procurement process for a used gutter machine, ensuring you make a well-informed investment that supports your business objectives.

Comprehensive Cost and Pricing Analysis for used gutter machine for sale Sourcing

What are the Key Cost Components for Used Gutter Machines?

When sourcing used gutter machines, several cost components significantly impact the overall pricing structure.

-

Materials: The type of materials used in gutter machine construction influences cost. Machines made from high-grade steel or aluminum typically command higher prices due to their durability and resistance to corrosion. Additionally, if the machine is equipped with features like guillotines or multiple spools, these add-ons will also affect the price.

-

Labor: Labor costs associated with the refurbishment or maintenance of used machines can vary. Machines that have undergone extensive maintenance and are in good working order can be priced higher. Conversely, machines needing repairs might be less expensive initially but could incur additional costs over time.

-

Manufacturing Overhead: This includes the indirect costs related to producing the machine, such as utilities, facility expenses, and administrative costs. Understanding the supplier’s manufacturing overhead can provide insights into their pricing strategy.

-

Tooling and Quality Control (QC): The presence of specialized tooling and rigorous QC processes can enhance machine reliability and performance. Machines that have undergone thorough QC checks may be priced higher due to the assurance of quality.

-

Logistics: Transportation costs play a significant role, especially for international buyers. Shipping fees, insurance, and potential tariffs should be factored into the total cost.

-

Margin: Suppliers typically add a profit margin on top of their costs. Understanding the typical margins in your region can help you gauge whether the pricing is competitive.

How Do Price Influencers Affect the Sourcing of Used Gutter Machines?

Several factors can influence the pricing of used gutter machines:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to discounts. Suppliers may offer better pricing for larger orders, making it beneficial for companies planning to acquire multiple machines.

-

Specifications and Customization: Machines with specific features tailored to niche markets may be priced higher. Customization can also lead to increased costs, but it may be necessary to meet specific local regulations or customer requirements.

-

Material Quality and Certifications: Machines that comply with international quality standards or have certifications may attract premium pricing. Ensuring that the machine meets local regulations in your country can save costs in the long run.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but offer better warranties and support.

-

Incoterms: Understanding the terms of delivery is crucial. DDP (Delivered Duty Paid) may include all costs, including duties and taxes, while FOB (Free on Board) places more responsibility on the buyer for shipping and customs.

What Buyer Tips Should International B2B Buyers Consider?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance the cost-effectiveness of sourcing used gutter machines:

-

Negotiation: Leverage your purchasing power by negotiating prices, especially if buying multiple machines. Building a relationship with the supplier can also facilitate better terms.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price but the long-term costs associated with maintenance, operational efficiency, and resale value. A slightly more expensive machine may offer better durability and lower operational costs.

-

Pricing Nuances: Be aware of currency fluctuations and how they affect pricing. Additionally, factor in local economic conditions that may impact the supply chain, leading to changes in pricing.

-

Conduct Market Research: Investigate various suppliers and their offerings. Online platforms and trade shows can provide insights into competitive pricing and new technologies.

Disclaimer

Prices for used gutter machines can vary widely based on condition, specifications, and market demand. Always conduct thorough research and consider obtaining multiple quotes to ensure a fair price that aligns with your budget and operational needs.

Alternatives Analysis: Comparing used gutter machine for sale With Other Solutions

Exploring Alternatives to Used Gutter Machines: What Are Your Options?

When considering a used gutter machine for sale, it’s crucial to evaluate alternative solutions that may better suit your business needs. These alternatives can vary in performance, cost, and ease of implementation. Understanding these options enables international B2B buyers to make informed decisions that align with their operational goals.

| Comparison Aspect | Used Gutter Machine For Sale | Custom Fabrication Services | Modular Gutter Systems |

|---|---|---|---|

| Performance | High efficiency for seamless production; variable sizes available | Dependent on the service provider’s capabilities | Allows for quick installation; designed for specific projects |

| Cost | Typically lower initial investment; ongoing maintenance costs | Higher initial costs; pricing varies based on design complexity | Moderate initial investment; savings on installation time |

| Ease of Implementation | Requires training for operators; setup time varies | No setup needed; reliant on the service provider’s timeline | Easy to install; minimal training required |

| Maintenance | Regular maintenance required; parts can be sourced easily | No maintenance; service provider handles all aspects | Minimal maintenance; durable materials reduce wear |

| Best Use Case | Ideal for contractors with consistent gutter needs | Best for unique or large-scale projects requiring custom solutions | Suitable for rapid deployment in residential developments |

What Are the Pros and Cons of Custom Fabrication Services?

Custom fabrication services involve outsourcing gutter production to a specialized provider who can create tailored solutions for specific projects. The main advantage of this approach is the ability to design gutters that meet unique specifications, which can be especially beneficial for complex architectural designs or large-scale constructions. However, the costs can be significantly higher, and reliance on external timelines can lead to delays. For businesses that require a high degree of customization, this option may be worthwhile, but it may not be the most cost-effective for smaller jobs.

How Do Modular Gutter Systems Compare?

Modular gutter systems are prefabricated components that are assembled on-site. They offer quick installation and ease of use, making them an attractive option for contractors who need to complete projects rapidly. These systems are often designed for specific applications, ensuring a good fit for various construction types. However, they may lack the flexibility that a used gutter machine provides for producing custom sizes or styles. For contractors focused on efficiency and speed, modular systems can provide substantial benefits, but they may not be suitable for all types of jobs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right solution requires a thorough assessment of your business operations and project requirements. If your work involves a consistent volume of gutter installations with the need for various sizes and styles, investing in a used gutter machine may be the most practical choice. On the other hand, if your projects frequently require unique designs or high customization, exploring custom fabrication services could be beneficial. For projects with a focus on speed and efficiency, modular gutter systems may serve you best. Ultimately, understanding your specific business needs, project demands, and budget constraints will guide you in making the most informed decision.

Essential Technical Properties and Trade Terminology for used gutter machine for sale

What Are the Essential Technical Properties of a Used Gutter Machine?

When considering the purchase of a used gutter machine, understanding its technical specifications is crucial for making an informed decision. Here are some key properties to look out for:

1. Material Grade

The material grade of a gutter machine refers to the type of metal used in its construction, typically aluminum or galvanized steel. Higher-grade materials offer enhanced durability and resistance to corrosion, which is vital for machines that will be exposed to the elements. For B2B buyers, investing in machines made from superior materials can lead to lower maintenance costs and longer service life.

2. Gauge Thickness

Gauge thickness indicates the metal’s thickness used to produce gutters. Common gauges for aluminum range from .024 to .032 inches, while steel typically varies between 26 to 18 gauge. Thicker gauges provide increased strength and structural integrity, essential for regions with heavy rainfall or snow. Buyers must assess the gauge to ensure the machine meets their specific production requirements and local building codes.

3. Production Speed

This specification measures how quickly the gutter machine can produce sections of gutter per minute. A higher production speed translates to increased efficiency and productivity, which is especially important for contractors aiming to complete jobs within tight deadlines. For B2B buyers, understanding the production speed can help gauge whether a used machine will meet their operational demands.

4. Power Supply

Gutter machines can operate on various power supplies, including electric (110V or 220V) or hydraulic systems. Knowing the power requirements is essential for compatibility with existing shop infrastructure. An electric machine is often easier to integrate into a workshop, while hydraulic systems may provide more power for heavy-duty applications.

5. Weight and Portability

The weight of the machine can affect its portability and ease of transport. Lighter machines are easier to move between job sites, which can significantly impact a contractor’s efficiency. Conversely, heavier machines may offer more stability during operation but can be cumbersome to relocate. Buyers should consider their operational needs and transport capabilities when evaluating weight.

Illustrative image related to used gutter machine for sale

6. Features and Accessories

Additional features such as guillotines, coil spools, and run-out stands enhance the machine’s functionality. These accessories can significantly improve the production process and reduce labor time. For B2B buyers, understanding the included features and their relevance to their specific operations can help in selecting a machine that maximizes productivity.

What Are Common Trade Terms Related to Used Gutter Machines?

Familiarizing yourself with industry-specific terminology can streamline the purchasing process and facilitate clearer communication with suppliers.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When purchasing a used gutter machine, understanding whether parts are OEM can help ensure compatibility and availability for future repairs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For gutter machines, knowing the MOQ can be crucial when considering the purchase of additional accessories or materials, especially if bulk buying is advantageous.

3. RFQ (Request for Quotation)

An RFQ is a document used by businesses to solicit price offers from suppliers for specific products or services. When looking for a used gutter machine, submitting an RFQ can help ensure you receive competitive pricing and detailed specifications from multiple vendors.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is vital when purchasing machines internationally, as they dictate who bears the risk and cost at each stage of transport.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Knowing the lead time for a used gutter machine can help businesses plan their projects effectively and avoid delays.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and financial considerations, ensuring a successful investment in a used gutter machine.

Illustrative image related to used gutter machine for sale

Navigating Market Dynamics and Sourcing Trends in the used gutter machine for sale Sector

What Are the Key Market Dynamics and Trends Influencing the Used Gutter Machine Sector?

The used gutter machine market is experiencing significant growth driven by an increasing demand for efficient construction practices and the rise of local manufacturing capabilities. International buyers, particularly from Africa, South America, the Middle East, and Europe, are seeking cost-effective solutions to meet their construction needs. In regions like Germany and Saudi Arabia, the focus is on high-quality equipment that can handle diverse environmental conditions and project requirements.

Emerging technologies, such as automation and IoT integration, are transforming traditional sourcing methods. These advancements allow for real-time monitoring of machine performance and predictive maintenance, which can significantly reduce downtime and maintenance costs. Additionally, the trend of hybrid machines that can produce multiple gutter profiles is gaining traction, appealing to contractors looking to maximize their investment and versatility.

Market dynamics indicate a growing preference for sustainability in equipment sourcing. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental responsibility. This shift is not only about regulatory compliance but also about aligning with the values of end customers who demand eco-friendly solutions. As a result, international B2B buyers must stay attuned to these trends to make informed purchasing decisions that align with both their operational needs and sustainability goals.

How Is Sustainability Shaping the Sourcing Practices for Used Gutter Machines?

Sustainability is becoming a cornerstone of sourcing practices within the used gutter machine sector. The environmental impact of construction equipment is under scrutiny, with an increasing emphasis on reducing carbon footprints and promoting ethical supply chains. Buyers are encouraged to consider the lifecycle of machines, including energy efficiency, waste reduction, and the recyclability of materials used in production.

Illustrative image related to used gutter machine for sale

The rise of green certifications is also influencing purchasing decisions. Machines that are certified for energy efficiency or those that utilize recycled materials are increasingly favored by conscientious buyers. For instance, gutter machines that can produce products using less energy or that are designed to minimize material waste during production are becoming essential in competitive markets.

Furthermore, ethical sourcing practices are gaining traction, particularly in regions where regulatory frameworks are evolving. Buyers are advised to engage with suppliers who demonstrate transparency in their supply chains and who prioritize fair labor practices. By aligning with suppliers committed to sustainability, businesses not only enhance their corporate social responsibility (CSR) profile but also tap into a growing market of environmentally-conscious consumers.

How Has the Used Gutter Machine Market Evolved Over Time?

The evolution of the used gutter machine market reflects broader trends in the construction and manufacturing sectors. Initially, the market was characterized by limited options and a focus on basic functionality. However, as the demand for customized solutions grew, manufacturers began to innovate, leading to the development of more versatile machines capable of producing various gutter profiles.

Over the years, technological advancements have introduced features such as automated controls, advanced materials, and improved design for durability and efficiency. These innovations have made used gutter machines not only more accessible but also more attractive to international buyers looking to optimize their operations. As a result, the market has expanded significantly, with a diverse array of options now available for businesses of all sizes, from small contractors to large construction firms.

Illustrative image related to used gutter machine for sale

Overall, the used gutter machine market continues to evolve, driven by technological innovation, sustainability concerns, and shifting buyer preferences. International B2B buyers must remain agile and informed to navigate this dynamic landscape effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of used gutter machine for sale

-

How do I evaluate the condition of a used gutter machine before purchase?

When evaluating a used gutter machine, inspect its overall condition, including any visible wear, rust, or damage. Check the machine’s operational history, such as maintenance records and previous usage. Request a demonstration to see the machine in action and ensure all components, like the guillotine and spools, function correctly. Additionally, inquire about the age of the machine and any modifications made. A reputable seller should provide comprehensive information and be transparent about any repairs needed. -

What are the most important features to consider when buying a used gutter machine?

Key features to consider include the machine’s production capacity, the range of gutter profiles it can create (like K-style or half-round), and its compatibility with various materials. Look for machines that come with essential accessories, such as guillotines and run-out stands. Additionally, consider the power source (electric or hydraulic), ease of transport, and the availability of replacement parts. Machines with a good reputation for reliability and durability often provide better long-term value. -

What are common payment terms for purchasing used gutter machines internationally?

Payment terms can vary widely among suppliers, but standard options include upfront payment, a deposit with the balance due upon delivery, or financing arrangements. It’s advisable to negotiate terms that suit your cash flow and financial capabilities. Ensure clarity on payment methods accepted (e.g., bank transfer, credit card, or letters of credit) and consider using escrow services for larger transactions to protect both parties. Always verify the supplier’s credibility before proceeding with any payments. -

How can I ensure the supplier of the used gutter machine is reputable?

To vet a supplier, start by checking their business history and customer reviews. Request references from previous clients and seek out online forums or industry groups for feedback. Additionally, verify their business credentials, such as registration and compliance with local regulations. If possible, conduct a site visit to see their operations firsthand. Utilizing established platforms or trade associations can also help connect you with trustworthy suppliers. -

What logistics considerations should I keep in mind when importing a used gutter machine?

When importing a used gutter machine, consider shipping options, customs regulations, and potential tariffs in your country. Determine the best shipping method based on cost and delivery time, whether by sea or air. Ensure the machine is properly packaged to prevent damage during transit. Be aware of any import permits or inspections required by your local authorities, and factor these into your overall budget and timeline. -

Are there customization options available for used gutter machines?

Many suppliers offer customization options for used gutter machines, allowing you to tailor the equipment to your specific needs. This can include modifications for different gutter profiles, sizes, or additional features like enhanced automation. Discuss your requirements with the supplier to see if they can accommodate your requests. Customization may come at an additional cost and could affect delivery timelines, so plan accordingly. -

What should I expect regarding the warranty and after-sales support for a used gutter machine?

Warranties for used gutter machines can vary significantly depending on the supplier and the machine’s condition. Some may offer a limited warranty covering specific parts for a defined period, while others might not provide any warranty at all. Always inquire about after-sales support, including access to technical assistance, spare parts availability, and service options. A supplier that stands behind their product with robust support can significantly enhance your investment’s value. -

How can I maximize the profitability of using a used gutter machine?

To maximize profitability, ensure that you understand your local market’s demand for different gutter styles and sizes. Invest in training for your staff on machine operation and maintenance to reduce downtime and improve efficiency. Diversify your offerings by providing additional services, such as gutter installation or repair. Finally, maintain strong relationships with suppliers for raw materials to secure competitive pricing and ensure a steady supply, enhancing your overall operational efficiency.

Top 5 Used Gutter Machine For Sale Manufacturers & Suppliers List

1. Gutter Machine – Various Types and Brands

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Gutter machine products for sale on eBay include various types and brands. Key details extracted include:

– Categories: Gutter Machines, Gutter Tools, Gutter Parts and Accessories, Gutter Cleaning Tools.

– Related Searches: Gutters Machine, Used Gutter Tools, Gutter Vacuum, Gutter Cleaner Tool.

– Specific Products: DB15 GUTTER COIL CADDY for 15″ coil (Brand New, Unbranded, $299.99, Free shipping)…

2. New Tech Machinery – New Tech 5 6 Combo Gutter Machine

Domain: usedmetalroofingmachines.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “New Tech 5″ 6″ Combo Gutter Machine”, “Brand”: “New Tech Machinery”, “Model”: “Mach II Combo”, “Category”: “5′ 6′ Combo”, “Condition”: “Used”, “Power”: “Electric”, “Price”: “$6800”, “Description”: “Gutter roll off machine. Mounted in 16′ box trailer. Trailer also for sale at additional cost.”, “Working Condition”: “In good working order”, “Contact Seller”: {“Name”: “Jerry Schultz…

3. K-Mar – Seamless Gutter Machine

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, K-Mar – Seamless Gutter Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Knudson – Used 1700K5 Gutter Machine

Domain: kmarbp.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Used Knudson 1700K5″ Gutter Machine”, “price”: “$3,800.00”, “SKU”: “13178”, “features”: [“2 Uprights”, “1 Spool”, “Rack and Pinion Shear”], “condition”: “Used”, “sale_type”: “Clearance Sale”}

5. Liberty Seamless – Seamless Gutter Machines

Domain: libertyseamless.com

Registered: 1998 (27 years)

Introduction: Seamless gutter machines for sale (new and used). Pipe sizes: 5, 6, and 7 inches. Types of machines include: Half Round Gutter Machine (5-6 inch), K-Style IronMan Gutter Machine (5″, 6″, 5-6 combo), and 7″ Box Gutter Machine. Features: Polyurethane drive system, 3-year parts & labor guarantee, and 1-year parts warranty. Gutter types: Half Round, K-Style, and Box type. Machines can produce continuo…

Strategic Sourcing Conclusion and Outlook for used gutter machine for sale

In conclusion, strategic sourcing of used gutter machines presents a significant opportunity for international B2B buyers aiming to enhance their operational efficiency and profitability. By carefully evaluating various models, such as the KWM Ironman and New Tech Machinery options, businesses can secure reliable equipment that meets their specific needs. Understanding the nuances of machine capabilities, maintenance requirements, and local market demands is essential for maximizing return on investment.

The value of sourcing used gutter machines lies not only in cost savings but also in the ability to offer enhanced services to clients, such as quicker project turnaround times and a wider range of gutter options. This can position your business as a one-stop solution in the gutter installation market, ultimately fostering long-term customer relationships.

As you explore the possibilities in Africa, South America, the Middle East, and Europe, consider the unique challenges and opportunities in your region. Engaging with reputable suppliers and leveraging insights from this guide will empower you to make informed decisions that propel your business forward. Start your journey today by reaching out to trusted vendors and exploring the best options available in the used gutter machine market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.