The Definitive Guide to Toroidal Transformer Dimensions Chart: Cost, Materials & Top…

Introduction: Navigating the Global Market for toroidal transformer dimensions chart

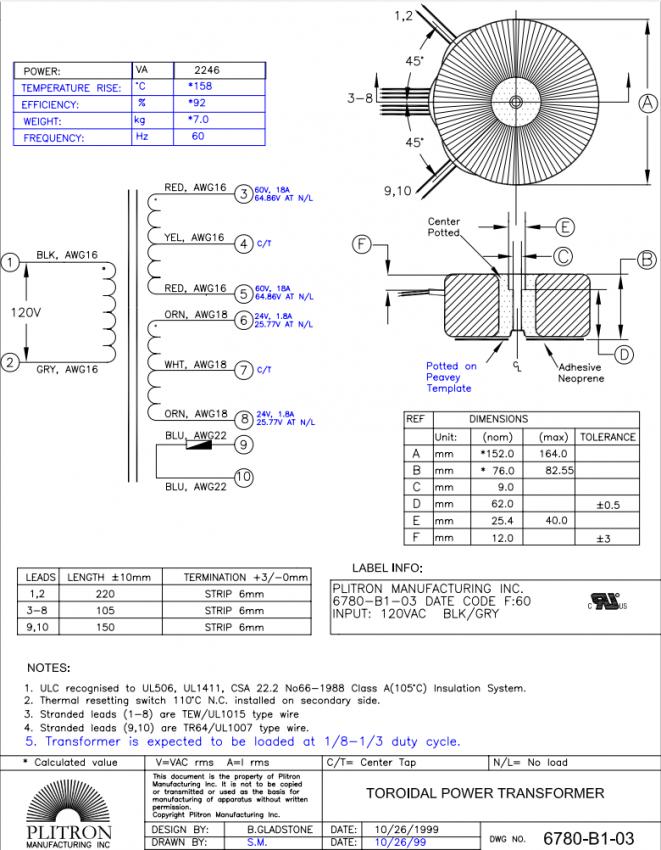

Navigating the complexities of sourcing a toroidal transformer dimensions chart can be a daunting task for international B2B buyers. With varying specifications across manufacturers and regions, pinpointing the ideal transformer for specific applications is critical yet challenging. This guide aims to streamline your procurement process by providing a comprehensive overview of toroidal transformers, covering essential dimensions, power ratings, efficiency, and regulatory approvals.

In this guide, we delve into the types of toroidal transformers available, their diverse applications—from medical devices to industrial machinery—and the nuances of supplier vetting. Each section is crafted to empower buyers from Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Germany, with the knowledge required to make informed purchasing decisions.

By understanding the intricate details of toroidal transformer dimensions and specifications, you will be better equipped to assess product offerings, negotiate effectively, and ultimately enhance operational efficiency. Our goal is to provide actionable insights that help you navigate the global market confidently, ensuring that your procurement aligns with both quality standards and budgetary constraints. Whether you are looking for high-efficiency solutions or specific regulatory compliance, this guide serves as your go-to resource in the dynamic world of toroidal transformers.

Understanding toroidal transformer dimensions chart Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Toroidal Transformers | Compact design, high efficiency, low electromagnetic interference | Industrial machinery, audio equipment | Pros: Space-saving, efficient; Cons: Higher initial cost. |

| Medical-Grade Toroidal Transformers | Enhanced insulation, safety features, compliance with medical standards | Medical devices, healthcare equipment | Pros: High reliability, safety; Cons: More expensive due to stringent regulations. |

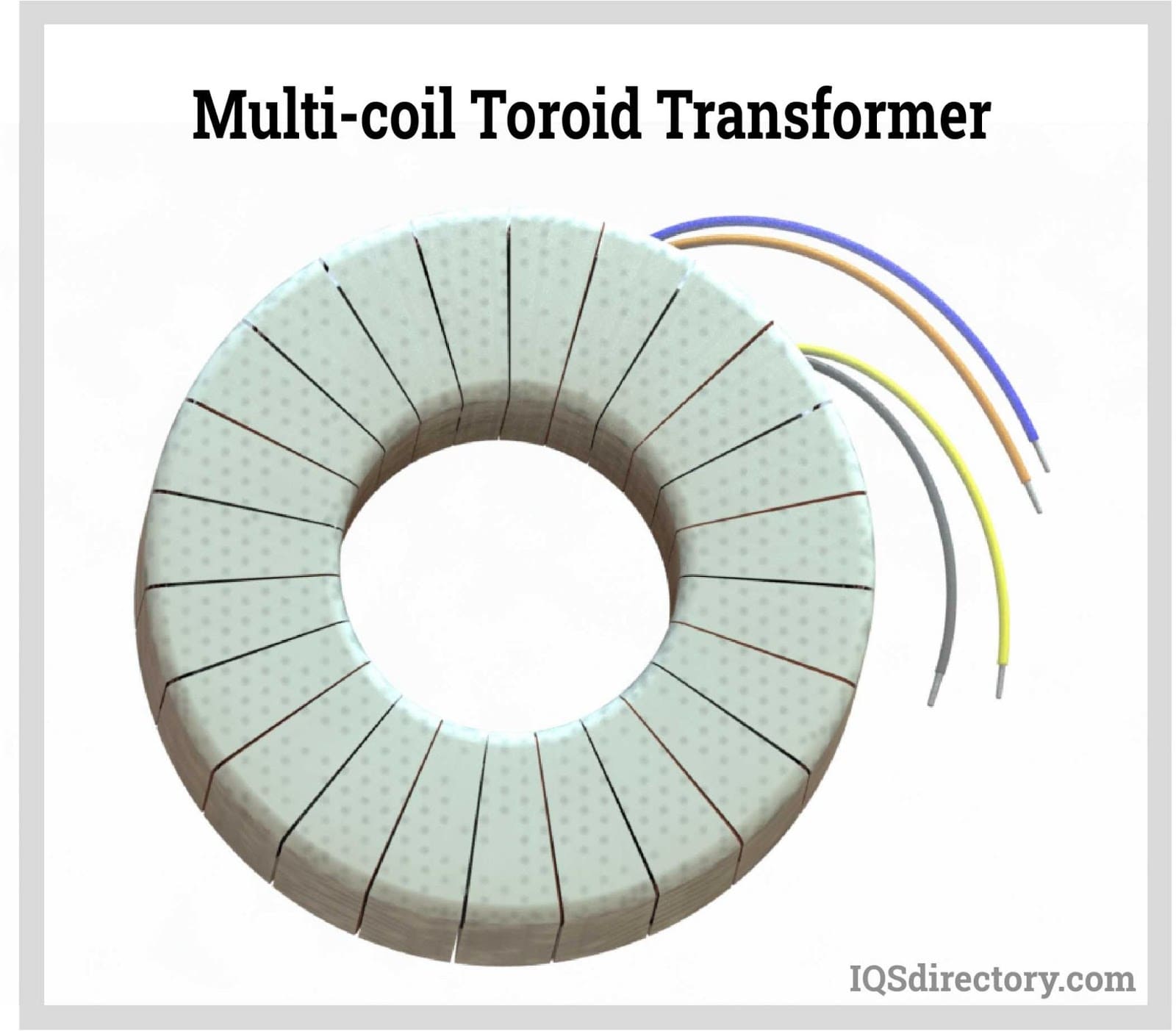

| Low Profile Toroidal Transformers | Slim design, lightweight, suitable for tight spaces | Consumer electronics, compact devices | Pros: Space-efficient, versatile; Cons: Limited power capacity compared to standard designs. |

| Custom Toroidal Transformers | Tailored specifications for unique applications | Specialized industrial applications | Pros: Meets specific requirements; Cons: Longer lead times and higher costs. |

| High-Power Toroidal Transformers | Large power ratings, robust construction | Heavy machinery, power distribution | Pros: Handles high loads efficiently; Cons: Bulky and may require more extensive mounting solutions. |

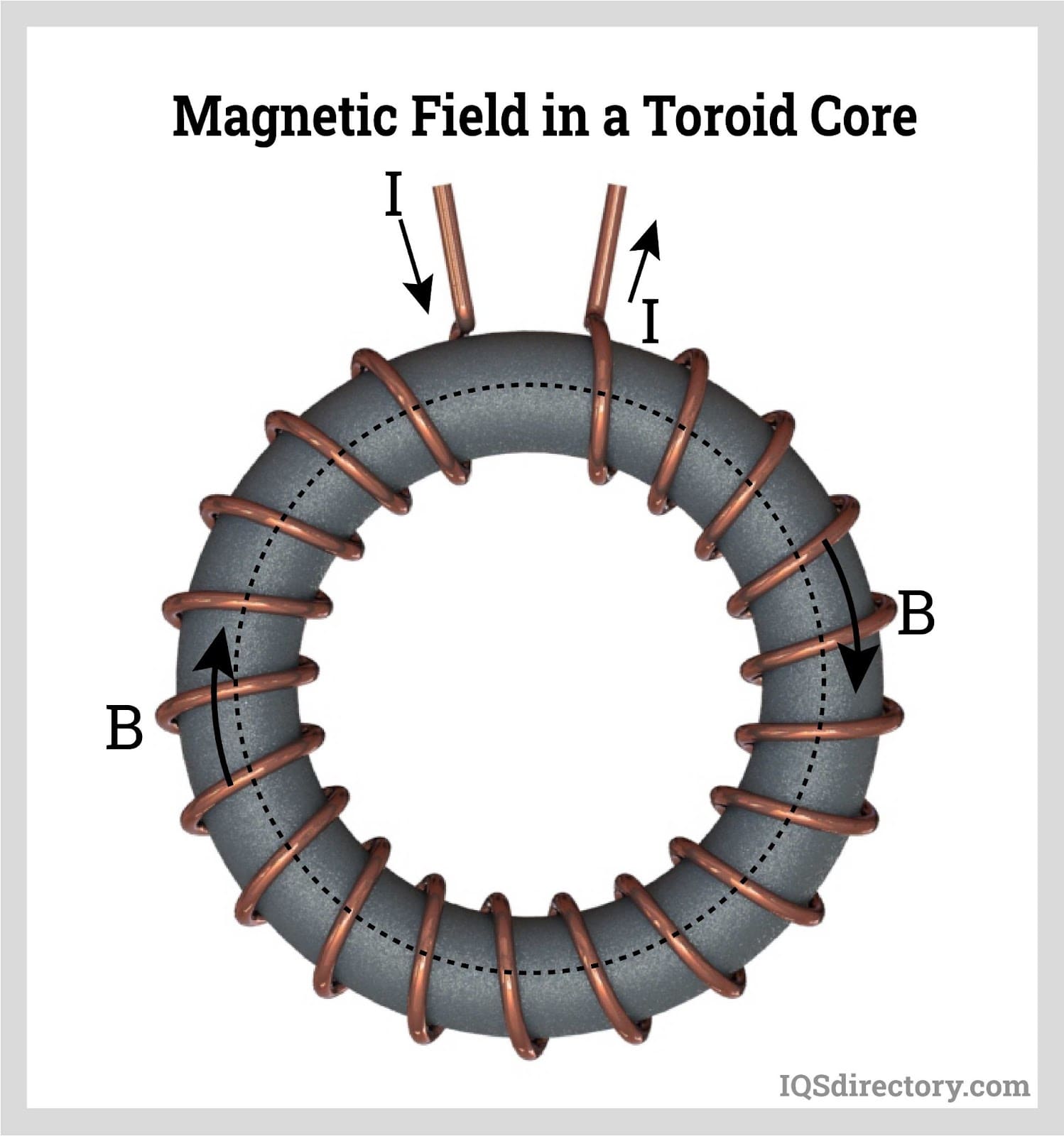

What Are the Characteristics of Standard Toroidal Transformers?

Standard toroidal transformers are widely recognized for their compact design and high efficiency. They are characterized by a ring-shaped core that minimizes electromagnetic interference, making them ideal for industrial machinery and audio equipment. When purchasing, B2B buyers should consider their specific power requirements and the initial investment, as these transformers often have a higher upfront cost compared to traditional designs but provide long-term savings through energy efficiency.

How Do Medical-Grade Toroidal Transformers Differ from Standard Variants?

Medical-grade toroidal transformers are designed with enhanced insulation and safety features to comply with strict medical standards. These transformers are crucial in medical devices and healthcare equipment, ensuring high reliability and safety. B2B buyers in the healthcare sector should prioritize these transformers for their applications, keeping in mind that the cost may be higher due to the additional safety certifications and materials used.

What Makes Low Profile Toroidal Transformers Suitable for Compact Devices?

Low profile toroidal transformers are engineered for slimness and lightweight construction, making them ideal for consumer electronics and compact devices. Their space-efficient design allows integration into tight spaces without compromising performance. Buyers should assess their power capacity needs, as these transformers may not support as high a load as standard models. However, their versatility in various applications can justify the investment.

Why Consider Custom Toroidal Transformers for Specialized Applications?

Custom toroidal transformers offer tailored specifications to meet unique B2B requirements. They are particularly valuable in specialized industrial applications where standard models may not suffice. While they provide the advantage of meeting specific needs, buyers should be aware of the potential for longer lead times and increased costs associated with custom manufacturing.

What Are the Advantages of High-Power Toroidal Transformers?

High-power toroidal transformers are designed to handle substantial power ratings and are constructed robustly for demanding applications such as heavy machinery and power distribution. Their ability to efficiently manage high loads makes them a preferred choice in industrial settings. However, buyers should consider the bulkiness of these transformers and the need for appropriate mounting solutions, which can add to installation complexity.

Key Industrial Applications of toroidal transformer dimensions chart

| Industry/Sector | Specific Application of toroidal transformer dimensions chart | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Audio Equipment | Designing high-fidelity audio amplifiers | Enhanced sound quality with reduced electromagnetic interference | Efficient production capabilities and compliance certifications (UL, CE) |

| Medical Devices | Powering diagnostic and therapeutic equipment | Ensures reliable performance and safety in critical applications | Need for medical-grade specifications and certifications |

| Renewable Energy | Integration in solar inverters and wind turbine systems | Optimizes energy conversion efficiency and reduces footprint | Compatibility with various voltage ratings and environmental standards |

| Industrial Automation | Used in control panels and automation systems | Improves energy efficiency and reduces heat generation | Customization options for specific voltage and current requirements |

| Telecommunications | Power supply for communication infrastructure | Increases reliability and minimizes signal distortion | Sourcing transformers that meet international standards for durability |

How is the ‘toroidal transformer dimensions chart’ utilized in the audio equipment industry?

In the audio equipment sector, the toroidal transformer dimensions chart is essential for engineers designing high-fidelity amplifiers. These transformers are preferred for their compact size and ability to minimize electromagnetic interference, which is crucial for maintaining sound quality. Buyers need to ensure that the transformers meet specific power ratings while also adhering to international safety certifications. This is particularly important for international buyers from regions like Europe and the Middle East, where compliance with regulations such as CE and UL is mandatory.

What role do toroidal transformers play in medical devices?

In the medical device industry, toroidal transformers are vital for powering diagnostic and therapeutic equipment. The dimensions chart aids manufacturers in selecting the appropriate transformer size and power rating to ensure reliable operation in critical healthcare settings. Medical-grade transformers must meet stringent safety standards, and buyers should prioritize sourcing from suppliers that can provide certifications like IEC 60601. This is particularly pertinent for buyers in regions such as Africa and South America, where access to reliable medical equipment is essential.

Illustrative image related to toroidal transformer dimensions chart

How are toroidal transformers applied in renewable energy systems?

The renewable energy sector utilizes toroidal transformers in solar inverters and wind turbine systems to enhance energy conversion efficiency. The dimensions chart helps engineers determine the optimal size and specifications for these applications, ensuring that the transformers can handle varying voltage levels while maintaining a minimal footprint. Buyers must consider sourcing transformers that are compatible with different environmental conditions, especially in regions with extreme weather, ensuring reliability and durability in their renewable installations.

In what ways do toroidal transformers enhance industrial automation?

In industrial automation, toroidal transformers are commonly found in control panels and automation systems, where they contribute to improved energy efficiency and reduced heat generation. The dimensions chart aids in identifying the right transformers that fit within the design constraints of automation equipment. Buyers in this sector should focus on sourcing transformers that allow for customization to meet specific voltage and current requirements, which is vital for optimizing system performance across diverse industrial applications.

How do telecommunications benefit from toroidal transformers?

Telecommunications infrastructure relies on toroidal transformers for power supply, ensuring reliability and minimizing signal distortion. The dimensions chart is a crucial tool for engineers to select transformers that meet the specific power requirements of communication systems. Buyers in this sector should prioritize sourcing transformers that comply with international durability standards, as equipment reliability is critical in maintaining uninterrupted communication services, especially in fast-developing regions like Africa and South America.

3 Common User Pain Points for ‘toroidal transformer dimensions chart’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Size Transformer

The Problem: B2B buyers often face challenges in selecting the appropriate size of toroidal transformers for their applications. With various specifications such as power ratings, dimensions, and efficiency ratings, it can be overwhelming to find the right fit. For instance, a company in the audio equipment manufacturing sector might need transformers that not only meet power requirements but also fit within specific design constraints. The wrong choice can lead to inefficiencies, increased costs, and potential performance issues.

The Solution: To effectively utilize a toroidal transformer dimensions chart, buyers should start by clearly defining their application requirements. This includes understanding the power needs (in VA), voltage specifications, and any size limitations imposed by their device design. By cross-referencing these parameters with the dimensions chart, buyers can identify transformers that meet their specifications. It’s also advisable to consult with manufacturers or suppliers for recommendations based on the selected transformer’s efficiency and regulatory approvals (e.g., UL, CE, CSA) to ensure compliance and reliability in their specific applications. Moreover, requesting samples or prototypes can aid in validating the dimensions and performance before final procurement.

Scenario 2: Misalignment Between Performance Expectations and Specifications

The Problem: Many B2B buyers encounter issues where the performance of toroidal transformers does not align with their expectations, particularly regarding efficiency and voltage regulation. A manufacturer may order transformers based on a chart but later find that the actual performance does not meet the operational standards needed for sensitive equipment, such as medical devices or high-end audio systems. This discrepancy can lead to increased operational costs and customer dissatisfaction.

The Solution: To mitigate this risk, buyers should not only rely on the dimensions chart but also delve into detailed performance specifications, such as voltage regulation percentages and efficiency ratings, which are often included in the charts. Prior to finalizing orders, buyers should engage in discussions with their suppliers about the operational environment and any unique requirements their applications may have. It’s beneficial to conduct thorough testing on transformers once received, ensuring they meet the required standards before implementation. For critical applications, consider using transformers that offer higher efficiency ratings, as they can lead to lower operational costs over time.

Scenario 3: Challenges in Global Sourcing of Toroidal Transformers

The Problem: International B2B buyers, particularly from regions like Africa, South America, and the Middle East, often struggle with sourcing toroidal transformers that meet both technical specifications and regional compliance standards. Variations in local regulations, shipping logistics, and differences in transformer standards can complicate the procurement process. This can lead to delays, increased costs, and challenges in maintaining supply chain integrity.

The Solution: To navigate these complexities, buyers should prioritize working with suppliers who have a robust understanding of international standards and can provide products that comply with local regulations. Utilizing a comprehensive toroidal transformer dimensions chart that includes certification marks (e.g., CQC, UL, CE) can help in identifying compliant products. Establishing relationships with local distributors who understand the market can facilitate smoother logistics and provide insights into the best practices for sourcing. Additionally, leveraging technology for real-time inventory checks and procurement tracking can help ensure that buyers receive the correct products promptly and can adapt quickly to any changes in demand or regulations. Regularly reviewing and updating procurement strategies based on market trends and supplier capabilities will also enhance sourcing efficiency.

Strategic Material Selection Guide for toroidal transformer dimensions chart

What Are the Key Materials for Toroidal Transformers in B2B Applications?

When selecting materials for toroidal transformers, several factors influence the performance and suitability of the final product. Here, we analyze four common materials used in the construction of toroidal transformers, focusing on their properties, advantages and disadvantages, and specific considerations for international B2B buyers.

1. Silicon Steel

Key Properties: Silicon steel is a critical component in toroidal transformers due to its high magnetic permeability and low hysteresis loss. It typically operates effectively at temperatures up to 150°C and can handle high magnetic flux densities.

Illustrative image related to toroidal transformer dimensions chart

Pros & Cons: This material is durable and provides excellent efficiency, making it ideal for high-performance applications. However, it can be more expensive than other materials and requires precise manufacturing techniques to ensure optimal performance.

Impact on Application: Silicon steel is particularly suitable for applications requiring high efficiency and low energy losses, such as audio equipment and industrial machinery.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as DIN and IEC for electrical safety and performance.

2. Copper Wire

Key Properties: Copper wire is essential for the windings in toroidal transformers due to its excellent electrical conductivity and thermal properties. It can handle high current loads and has a melting point of approximately 1,085°C.

Illustrative image related to toroidal transformer dimensions chart

Pros & Cons: The primary advantage of copper is its superior conductivity, which minimizes energy losses. However, copper is susceptible to corrosion if not properly insulated, and it can be relatively expensive compared to alternatives like aluminum.

Impact on Application: Copper is ideal for applications requiring high efficiency and reliability, such as medical devices and high-fidelity audio systems.

Considerations for International Buyers: Buyers should consider the need for corrosion-resistant coatings, especially in humid environments prevalent in parts of Africa and South America. Compliance with standards such as UL and CE is also crucial.

3. Polyester Film Insulation

Key Properties: Polyester film is commonly used for insulation in toroidal transformers. It provides excellent dielectric strength and thermal resistance, withstanding temperatures up to 130°C.

Illustrative image related to toroidal transformer dimensions chart

Pros & Cons: This material is lightweight and cost-effective, offering good insulation properties. However, it may not be suitable for high-temperature applications beyond its rated limits.

Impact on Application: Polyester film insulation is suitable for standard applications but may not be ideal for extreme environments where higher thermal resistance is required.

Considerations for International Buyers: Buyers should verify that the insulation meets international standards for electrical safety and thermal performance, especially in stringent markets like Germany.

4. Ferrite Cores

Key Properties: Ferrite cores are made from ceramic materials that exhibit high magnetic permeability and low electrical conductivity. They perform well at high frequencies and are often used in applications requiring compact designs.

Illustrative image related to toroidal transformer dimensions chart

Pros & Cons: Ferrite cores are lightweight and can be manufactured in various shapes, making them versatile. However, they can be brittle and less durable compared to silicon steel cores.

Impact on Application: Ferrite cores are ideal for high-frequency applications, such as RF transformers and inductors, where size and weight are critical factors.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards for magnetic materials, particularly in regions where electromagnetic compatibility is regulated.

Summary Table of Material Selection for Toroidal Transformers

| Material | Typical Use Case for toroidal transformer dimensions chart | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | High-performance industrial applications | High magnetic permeability and efficiency | Higher manufacturing complexity and cost | High |

| Copper Wire | Medical devices, audio equipment | Superior electrical conductivity | Susceptible to corrosion, higher cost | High |

| Polyester Film Insulation | Standard electrical applications | Cost-effective and lightweight | Limited thermal resistance | Medium |

| Ferrite Cores | High-frequency applications | Lightweight and versatile | Brittle and less durable | Medium |

This material selection guide provides B2B buyers with critical insights into the properties and considerations of various materials used in toroidal transformers. Understanding these factors can lead to better decision-making and optimized product performance in diverse applications.

In-depth Look: Manufacturing Processes and Quality Assurance for toroidal transformer dimensions chart

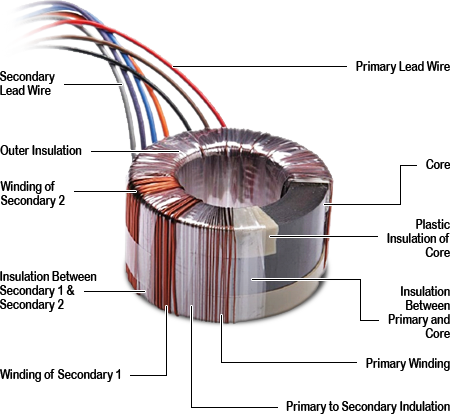

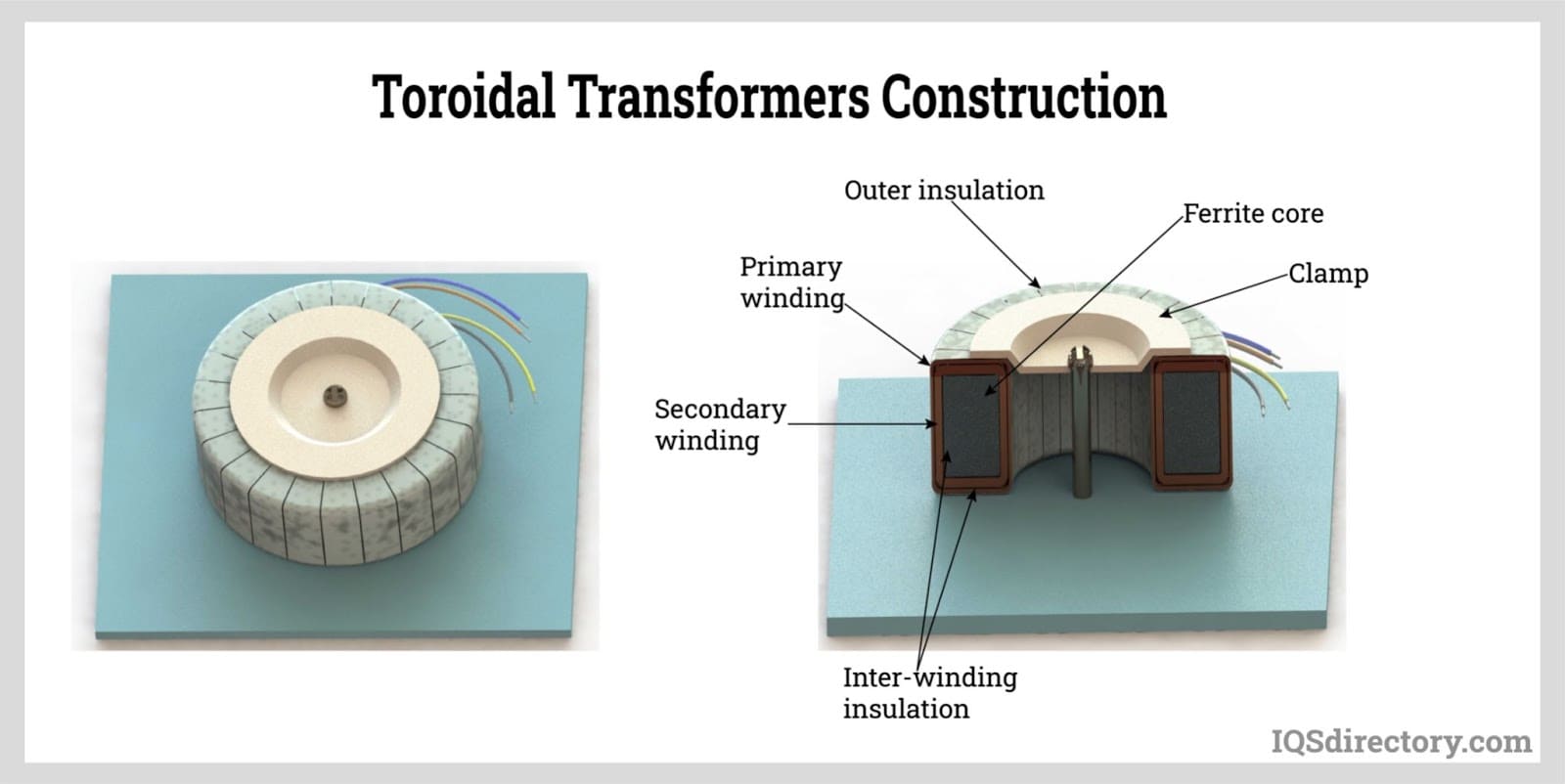

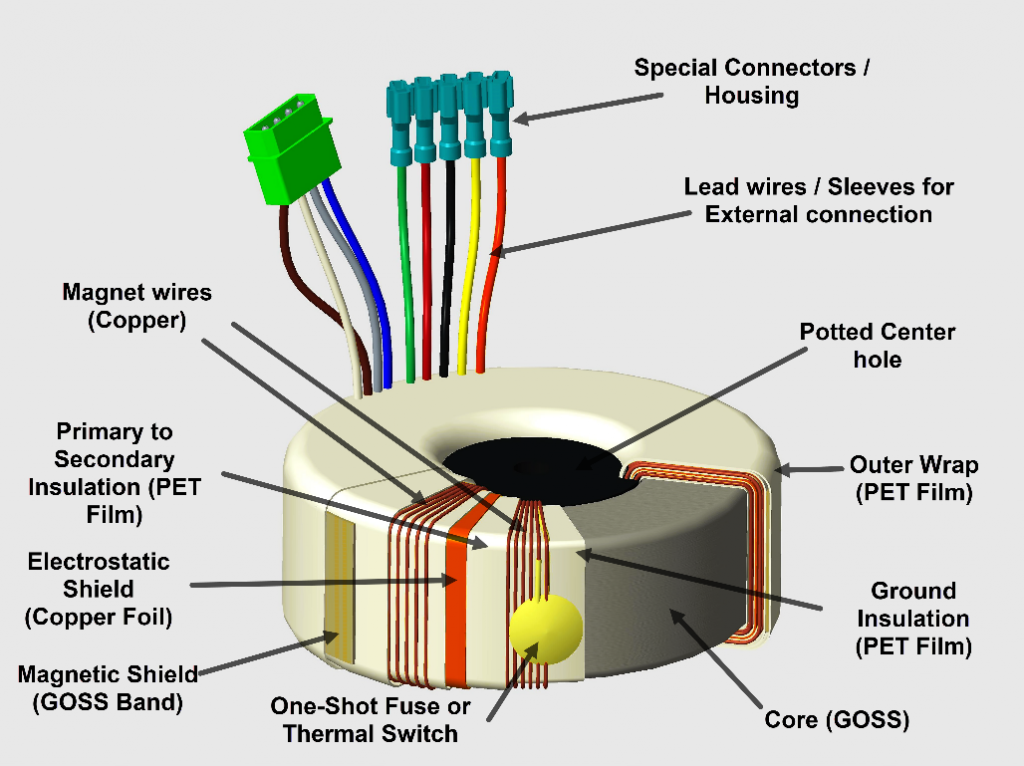

What Are the Key Stages in the Manufacturing Process of Toroidal Transformers?

The manufacturing of toroidal transformers involves several critical stages, each ensuring the final product meets the required specifications and performance standards. The main stages include material preparation, core forming, assembly, and finishing.

Material Preparation

The process begins with sourcing high-quality materials, particularly grain-oriented silicon steel strips, which are essential for constructing the transformer core. These strips are selected for their magnetic properties and are typically available in precise widths to accommodate different transformer sizes. The steel undergoes a treatment process, including a thin inorganic coating that enhances interlaminar resistance, essential for reducing energy losses during operation.

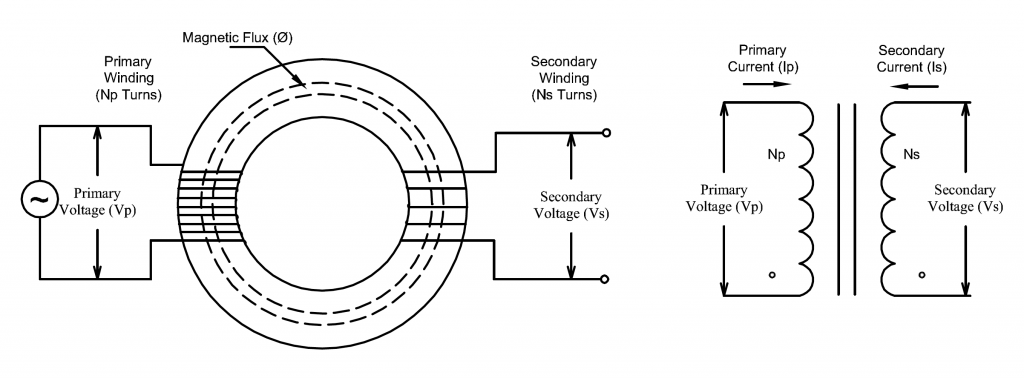

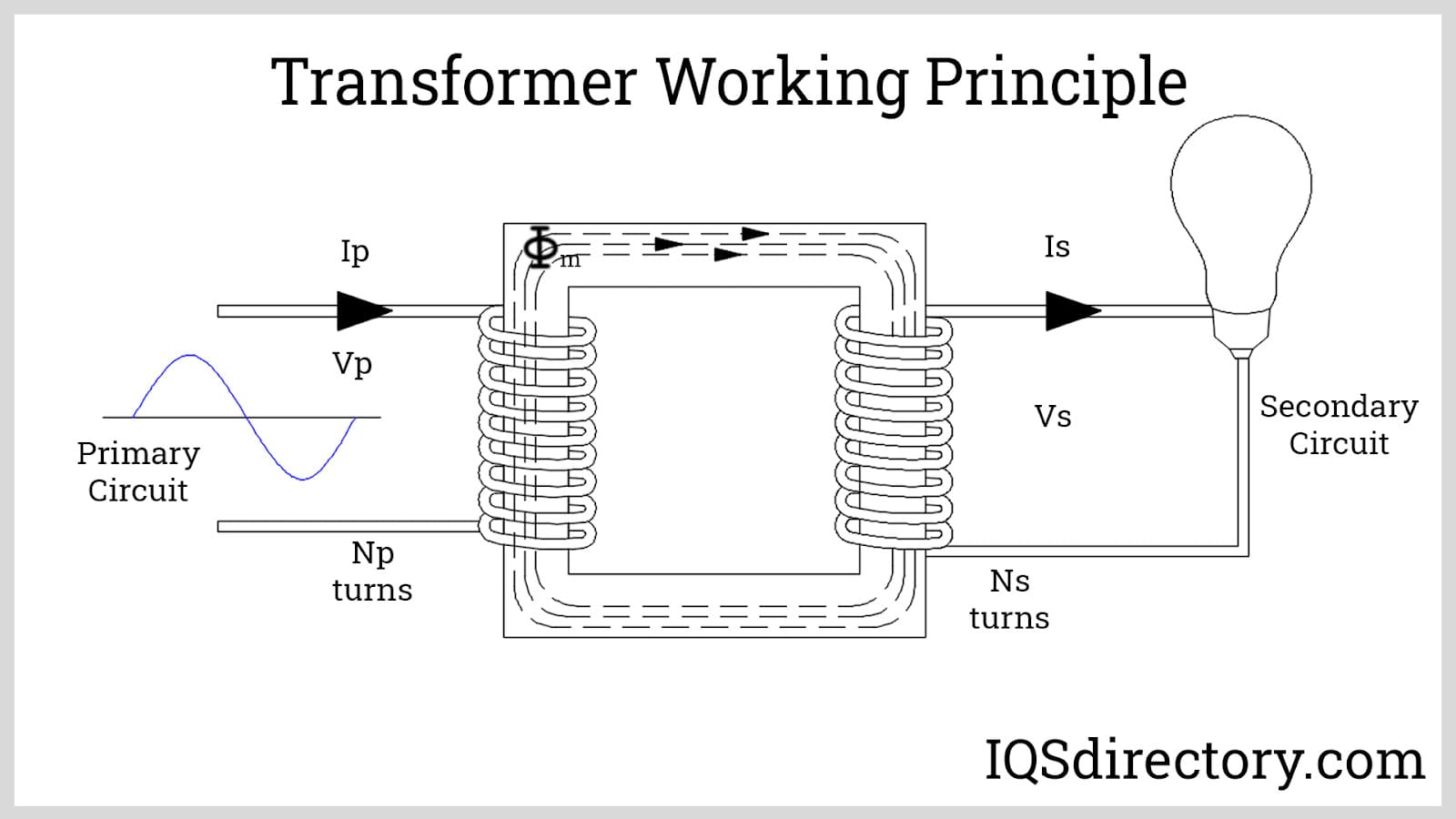

Core Forming

Once the materials are prepared, the core is formed by tightly winding the steel strips around a mandrel. This step is crucial as it determines the core’s magnetic efficiency. The winding process is performed under controlled tension to maintain the integrity of the core shape, which is then secured through spot welding. The formed core is subjected to an annealing process, where it is heated and cooled to relieve any mechanical and magnetic stresses that may have developed during winding. This ensures that the core has optimal magnetic properties.

Assembly

The assembly stage involves winding the primary and secondary coils onto the prepared core. This is typically done using a toroidal winder, which ensures uniform winding and minimizes flux leakage. Insulation layers are applied between the windings to enhance safety and performance, with specific materials chosen based on the application requirements. This stage is crucial, as improper winding can lead to inefficiencies and increased losses.

Illustrative image related to toroidal transformer dimensions chart

Finishing

The final stage includes applying additional insulation and protective coatings. This ensures durability and protection against environmental factors. The transformers are then tested for electrical performance, including voltage regulation and efficiency, before they are packaged for shipment. Proper finishing not only enhances the aesthetic appeal but also ensures compliance with safety standards.

How Is Quality Control Implemented in Toroidal Transformer Manufacturing?

Quality control (QC) is an integral part of the manufacturing process, particularly for products like toroidal transformers that must meet stringent international standards. The QC process typically involves several checkpoints and adherence to international and industry-specific standards.

What International Standards Apply to Toroidal Transformers?

For international B2B buyers, compliance with standards such as ISO 9001 is crucial. This standard focuses on quality management systems and ensures that manufacturers maintain consistent quality throughout their production processes. Additionally, certifications like CE, UL, and CSA are vital for electrical products, indicating compliance with safety and performance standards recognized in different regions, including Europe and North America.

What Are the QC Checkpoints in the Manufacturing Process?

The QC process can be divided into three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival. Samples are tested to ensure they meet specified standards before being accepted into the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed to monitor critical parameters such as winding tension, insulation thickness, and core temperature. This proactive approach helps identify defects before the final assembly.

-

Final Quality Control (FQC): After assembly, transformers undergo rigorous testing to evaluate their performance against predefined specifications. Tests may include efficiency, voltage regulation, and insulation resistance. This final check ensures that only products meeting quality benchmarks are shipped to customers.

What Testing Methods Are Commonly Used for Quality Assurance?

Several testing methods are implemented to ensure the quality and reliability of toroidal transformers. Common methods include:

-

Electrical Testing: This includes tests for short circuits, open circuits, and insulation resistance. These tests help confirm that the transformer can operate safely and efficiently under load.

-

Thermal Testing: Transformers are subjected to thermal cycling tests to evaluate their performance under varying temperature conditions. This is particularly important for applications in extreme environments.

-

Mechanical Testing: Vibration and shock tests assess the robustness of the transformer, ensuring it can withstand physical stresses during transportation and installation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify supplier QC practices. This can include:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control processes, and adherence to safety standards. This firsthand experience can provide insights into the supplier’s commitment to quality.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the testing protocols and results. These reports should outline the standards met and any certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These inspections can be scheduled at various stages of production to ensure compliance with international standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various certification requirements and quality expectations specific to their regions. For instance, products shipped to the European market must comply with CE marking regulations, while those going to North America may need UL or CSA certifications. Understanding these nuances is essential to ensure that the transformers meet local regulations and standards.

Additionally, buyers should be aware of the potential for differing quality expectations based on regional practices. For example, manufacturers in Europe may adhere to stricter environmental and safety standards than those in other regions. It is beneficial for buyers to communicate their quality expectations clearly and ensure that suppliers are capable of meeting them.

By understanding these manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions, ensuring they select reliable suppliers for toroidal transformers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘toroidal transformer dimensions chart’

In the competitive landscape of B2B procurement, sourcing a reliable toroidal transformer dimensions chart is crucial for making informed decisions. This guide provides a structured approach to ensure you acquire the right specifications and supplier information tailored to your needs.

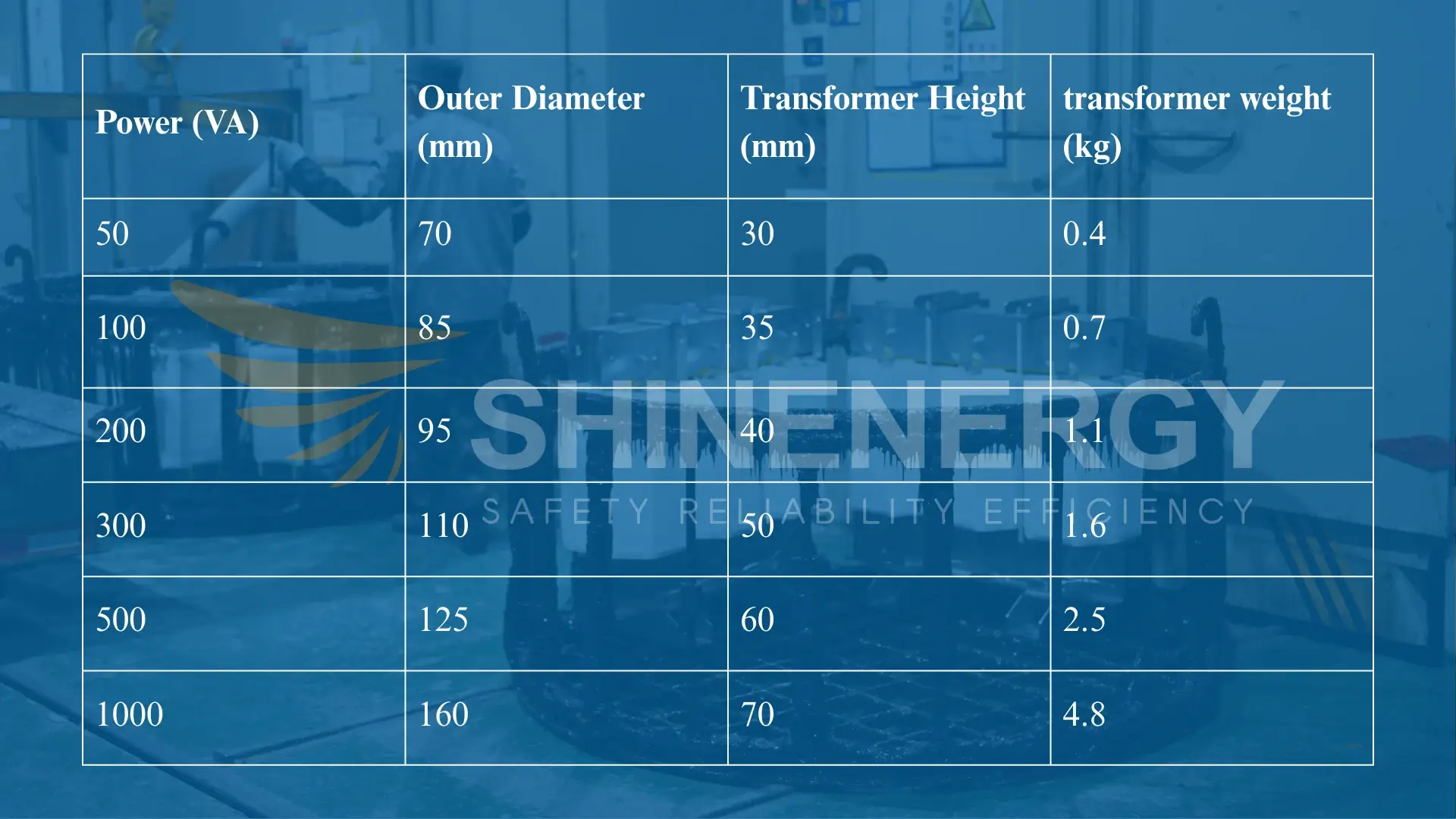

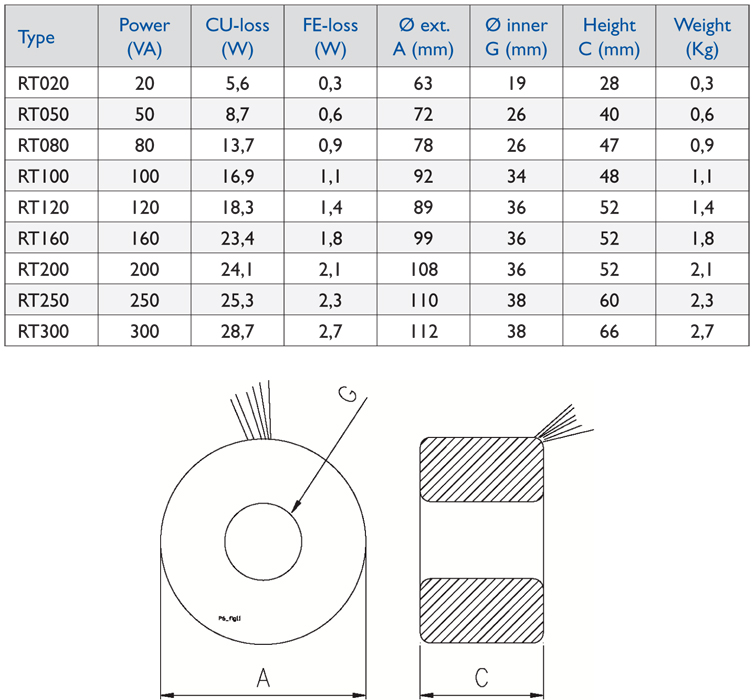

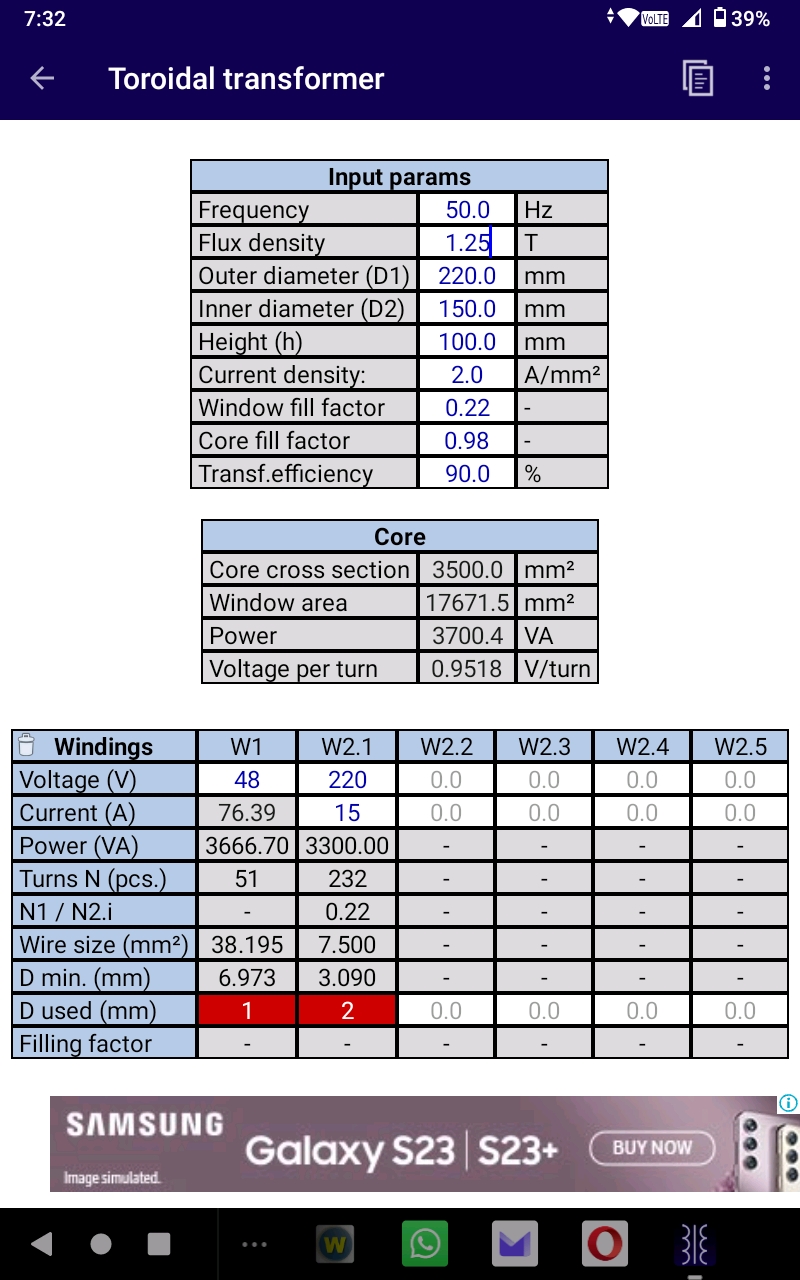

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. Consider factors such as power ratings (VA), dimensions (outer diameter and height), and efficiency ratings. Defining these specifications upfront will streamline the sourcing process and ensure that potential suppliers can meet your operational needs.

Illustrative image related to toroidal transformer dimensions chart

Step 2: Research Applicable Standards and Certifications

Familiarize yourself with industry standards and certifications relevant to toroidal transformers. Look for certifications such as UL, CE, and CSA, which indicate compliance with safety and performance standards. This not only enhances product reliability but also assures compliance with international regulations, particularly important for buyers in regions like Europe and the Middle East.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure they align with your technical and business requirements. Request detailed company profiles, case studies, and references from businesses within your industry. Analyzing their experience and reputation will help mitigate risks associated with supplier reliability.

Step 4: Request Detailed Dimensions Charts

When engaging with suppliers, specifically request their dimensions charts for toroidal transformers. Ensure the charts include critical information such as outer diameter (OD), height, weight, and power ratings. This data is essential for comparing options and ensuring the selected transformer fits within your design constraints.

Step 5: Verify Production Capabilities

Assess the supplier’s production capabilities to ensure they can meet your volume and timeline requirements. Inquire about their manufacturing processes, quality control measures, and lead times. Suppliers with robust production capabilities can better accommodate large orders and customization requests, which is vital for maintaining project timelines.

Step 6: Assess Cost and Value

While price is a significant factor, consider the overall value offered by the supplier. Analyze not only the cost of the toroidal transformers but also the quality, service, and support provided. A slightly higher price may be justified if the supplier offers superior quality or better customer service, particularly for critical applications.

Step 7: Establish Clear Communication Channels

Ensure that you have established effective communication channels with your selected supplier. Clear communication is vital for addressing any questions, technical issues, or changes in order specifications. Regular updates and open lines of communication can prevent misunderstandings and foster a strong supplier relationship.

By following this checklist, B2B buyers can navigate the sourcing process for toroidal transformers more effectively, ensuring they secure the right products that meet their operational requirements and standards.

Illustrative image related to toroidal transformer dimensions chart

Comprehensive Cost and Pricing Analysis for toroidal transformer dimensions chart Sourcing

What Are the Key Cost Components in Sourcing Toroidal Transformers?

When sourcing toroidal transformers, several cost components contribute to the overall pricing structure. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary materials include high-grade silicon steel for the core and copper wire for windings. The quality of these materials directly affects performance, efficiency, and durability, which can also influence pricing. Premium materials may incur higher costs but offer better electrical properties and longevity.

-

Labor: Labor costs encompass the skilled workforce required for manufacturing, assembly, and quality assurance. Skilled labor is particularly important for tasks such as winding the transformers, which demands precision to maintain efficiency and minimize losses.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. A well-optimized manufacturing process can help lower these overheads, translating into more competitive pricing.

-

Tooling: Specialized tooling for manufacturing toroidal transformers can be a significant upfront cost, especially if custom designs are involved. The amortization of these costs over production volume can significantly impact pricing.

-

Quality Control: Rigorous QC processes ensure that each transformer meets performance standards and certifications. The costs associated with testing and certification can vary based on the required approvals (e.g., UL, CE) and impact overall pricing.

-

Logistics: Shipping and handling costs are also crucial, particularly for international buyers. Factors such as packaging, transportation mode, and distance to the destination can add substantial costs.

-

Margin: Finally, suppliers will apply a margin to cover their business risks and ensure profitability. This can vary based on market conditions and competition.

How Do Price Influencers Affect Toroidal Transformer Sourcing?

Various factors can influence the pricing of toroidal transformers, particularly for international B2B buyers.

-

Volume/MOQ: The minimum order quantity (MOQ) and order volume directly affect pricing. Higher volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their project needs while optimizing costs.

-

Specifications and Customization: Custom transformers tailored to specific applications often come at a premium. Buyers should clearly define their specifications to avoid unnecessary customization costs.

-

Material Quality and Certifications: Transformers with higher efficiency ratings and certifications often command higher prices. Buyers should weigh the long-term benefits of these features against the initial costs.

-

Supplier Factors: The reputation, reliability, and location of suppliers can also impact pricing. Local suppliers might reduce logistics costs, while established suppliers may provide better warranties and support.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define responsibilities for shipping, insurance, and tariffs. Different terms can affect total landed costs significantly.

What Are Effective Buyer Tips for Negotiating Toroidal Transformer Prices?

-

Negotiate: Always approach suppliers with a clear understanding of your needs and market pricing. Leverage competitive offers to negotiate better terms and prices.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just upfront costs. Evaluate performance, reliability, and maintenance needs over the product’s lifecycle to make informed decisions.

-

Pricing Nuances for International Buyers: Be aware of exchange rates, import duties, and taxes that may affect the final cost of your transformers. Building these into your budget can prevent unexpected expenses.

-

Request Quotes from Multiple Suppliers: Obtaining quotes from various suppliers can provide insights into market rates and help identify the best value options.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and potential discounts on future orders.

Disclaimer for Indicative Prices

It is essential to note that pricing for toroidal transformers can vary widely based on the factors outlined above. Always request detailed quotes tailored to your specific requirements and ensure clarity on all terms and conditions before finalizing any agreements.

Alternatives Analysis: Comparing toroidal transformer dimensions chart With Other Solutions

Introduction: Exploring Alternatives to Toroidal Transformer Dimensions Charts

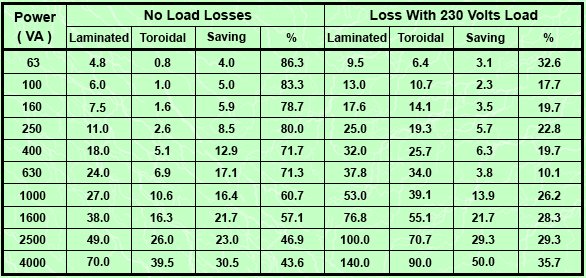

In the realm of electrical engineering and power distribution, the choice of transformer technology plays a pivotal role in achieving desired performance outcomes. While toroidal transformers are widely recognized for their efficiency and compact design, several alternative solutions exist that also serve similar purposes. This analysis will compare toroidal transformer dimensions charts with two viable alternatives: traditional E-I laminated transformers and digital transformer sizing software. Understanding the strengths and weaknesses of each option will aid B2B buyers in making informed decisions tailored to their specific applications and operational needs.

Comparison Table

| Comparison Aspect | Toroidal Transformer Dimensions Chart | E-I Laminated Transformer Dimensions Chart | Digital Transformer Sizing Software |

|---|---|---|---|

| Performance | High efficiency with low losses | Moderate efficiency; larger footprint | Highly accurate simulations |

| Cost | Generally higher upfront cost | Lower initial cost | Subscription or one-time fee |

| Ease of Implementation | Straightforward; physical dimensions | Established, but larger installation space | Requires technical expertise |

| Maintenance | Low maintenance needs | Moderate; may require more upkeep | Minimal; software updates only |

| Best Use Case | High-performance applications | General-purpose applications | Complex design and analysis needs |

Detailed Breakdown of Alternatives

E-I Laminated Transformers

E-I laminated transformers have been a staple in power applications for decades. They are typically less expensive than toroidal transformers, making them a cost-effective choice for projects with budget constraints. However, their larger physical size can present installation challenges, especially in space-constrained environments. Furthermore, E-I transformers are less efficient, leading to higher operational losses over time. While suitable for general-purpose applications, their performance may not match the efficiency levels offered by toroidal designs, particularly in high-demand scenarios.

Illustrative image related to toroidal transformer dimensions chart

Digital Transformer Sizing Software

Digital transformer sizing software offers a modern approach to transformer selection and design. This technology allows engineers to simulate various transformer parameters and configurations, enabling highly accurate predictions of performance under different conditions. The primary advantage of this solution is its ability to provide tailored designs that meet specific operational requirements, potentially leading to cost savings in both installation and operation. However, it requires a certain level of technical expertise to utilize effectively, which may not be available in all organizations. Additionally, there may be ongoing subscription costs associated with using the software.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers evaluating transformer solutions, the decision should hinge on their specific operational requirements, budget constraints, and technical capabilities. Toroidal transformers excel in high-efficiency applications where space is at a premium, making them ideal for advanced electronics and sensitive power applications. E-I laminated transformers may appeal to those seeking cost-effective solutions for less demanding environments. Meanwhile, digital transformer sizing software provides an innovative option for organizations that prioritize precision and customization in their transformer design processes. By carefully weighing these alternatives, buyers can select the solution that best aligns with their strategic objectives and operational realities.

Essential Technical Properties and Trade Terminology for toroidal transformer dimensions chart

What Are the Essential Technical Properties of a Toroidal Transformer Dimensions Chart?

When evaluating toroidal transformers, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications that should be considered:

Illustrative image related to toroidal transformer dimensions chart

-

Nominal Power Rating (VA)

This indicates the transformer’s capacity to handle electrical load, measured in Volt-Amperes (VA). For B2B buyers, selecting the appropriate power rating is vital to ensure that the transformer can support the intended application without overheating or failing. Properly sizing a transformer can enhance efficiency and longevity. -

Outer Diameter (OD) and Height

The physical dimensions of a toroidal transformer, specifically its outer diameter and height, are critical for installation. These measurements dictate how the transformer fits within a designated space, which is especially important for OEMs (Original Equipment Manufacturers) who need to adhere to specific design constraints in their products. -

Copper and Core Losses

Copper losses refer to energy lost as heat in the windings due to resistance, while core losses are linked to the magnetic core material. Understanding these losses helps in assessing the efficiency of the transformer. B2B buyers should prioritize transformers with lower losses to reduce energy costs and improve performance. -

Weight

The weight of the transformer can influence shipping costs and installation requirements. For international buyers, particularly those in regions like Africa and South America, understanding the weight implications can aid in logistics planning and cost management. -

Voltage Regulation and Efficiency

Voltage regulation percentage indicates how well the transformer maintains its output voltage under varying load conditions. Efficiency percentages reveal how much input power is converted to output power. Both metrics are essential for buyers looking to optimize energy use and ensure reliable performance in their applications.

Which Trade Terminology Should B2B Buyers Know for Toroidal Transformers?

Familiarity with industry-specific jargon can enhance communication with suppliers and facilitate smoother transactions. Here are some common terms that are particularly relevant:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding the OEM context is essential for buyers who require customized transformers for specific applications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps B2B buyers plan their orders, balancing inventory costs with production needs, particularly when procuring large, specialized equipment like toroidal transformers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, effectively crafting an RFQ can lead to better pricing and terms, enhancing overall procurement efficiency. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers engaged in cross-border procurement, ensuring clarity on delivery obligations. -

CQC, UL, CE, CSA Approvals

These certifications indicate compliance with safety and quality standards in various markets. Buyers should verify that transformers meet relevant certifications to ensure they are suitable for their intended applications and comply with regulatory requirements. -

Thermal Protection

This feature refers to mechanisms that prevent overheating, typically in the primary circuit. Knowing about thermal protection options can help buyers select transformers that enhance operational safety and reliability in demanding environments.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, optimize procurement processes, and ensure the transformers meet their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the toroidal transformer dimensions chart Sector

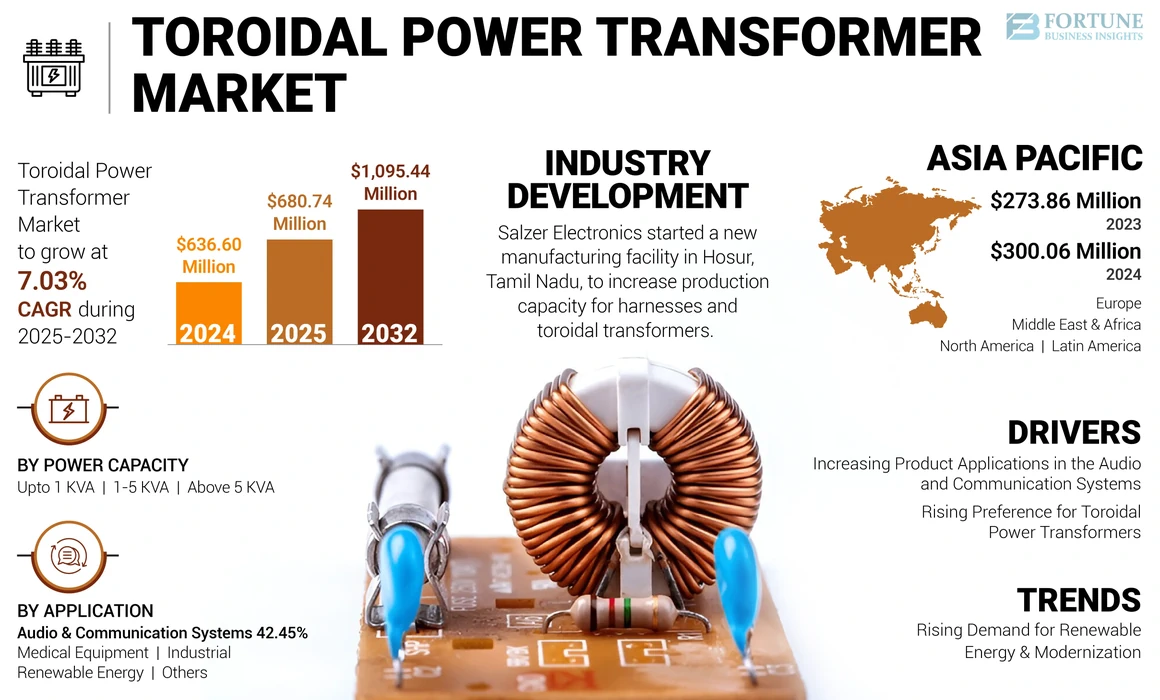

What Are the Current Market Dynamics and Key Trends in the Toroidal Transformer Dimensions Chart Sector?

The global market for toroidal transformers is witnessing notable growth, driven primarily by advancements in technology and an increasing demand for energy-efficient solutions across various industries. International B2B buyers from regions like Africa, South America, the Middle East, and Europe (including countries such as Saudi Arabia and Germany) are actively seeking high-performance, compact transformers that meet stringent efficiency standards. This demand is fueled by the rise of renewable energy sources, electric vehicles, and smart grid technologies, which necessitate transformers that minimize energy loss and optimize space utilization.

Emerging trends in sourcing highlight a shift towards customization and innovation. Suppliers are increasingly offering tailored solutions that align with specific application requirements, such as medical devices, audio equipment, and industrial machinery. Additionally, the integration of smart technologies into transformer design is becoming a key selling point, allowing for enhanced monitoring and control capabilities. For buyers, understanding the dimensions and power ratings of toroidal transformers is essential for efficient product selection, as these factors directly influence performance, weight, and overall system integration.

Illustrative image related to toroidal transformer dimensions chart

Furthermore, the competitive landscape is evolving, with both established manufacturers and new entrants vying for market share. Buyers should be aware of regional suppliers that may offer cost-effective solutions without compromising quality. As the market matures, strategic partnerships and collaborations among manufacturers, distributors, and end-users will become increasingly vital to navigate the complexities of the supply chain effectively.

How Are Sustainability and Ethical Sourcing Impacting the Toroidal Transformer Sector?

Sustainability has emerged as a pivotal consideration for B2B buyers in the toroidal transformer sector. The environmental impact of manufacturing processes, particularly in the production of electrical components, has garnered attention from stakeholders committed to reducing their carbon footprints. Buyers are now prioritizing suppliers who implement eco-friendly practices, such as using recyclable materials and adopting energy-efficient manufacturing techniques.

Ethical sourcing plays a crucial role in this landscape. Businesses are increasingly scrutinizing their supply chains to ensure that raw materials are sourced responsibly and that labor practices adhere to ethical standards. This shift is particularly relevant for international buyers, who must navigate varying regulations and standards across different countries. Certifications such as ISO 14001 for environmental management and materials with ‘green’ certifications can serve as indicators of a supplier’s commitment to sustainability.

Additionally, the demand for transparency in sourcing is on the rise. Buyers are looking for detailed information on the supply chain, from the sourcing of raw materials to the final product. As a result, manufacturers that can provide comprehensive documentation regarding their sourcing practices are likely to gain a competitive advantage.

What Is the Historical Context of Toroidal Transformers in B2B Applications?

The evolution of toroidal transformers dates back to the mid-20th century when their unique design began to gain traction in various applications. Unlike traditional transformers, toroidal transformers feature a ring-shaped core that minimizes electromagnetic interference and enhances efficiency. This design allows for a compact form factor, making them particularly appealing for applications where space is at a premium.

Illustrative image related to toroidal transformer dimensions chart

Over the years, advancements in materials science and manufacturing techniques have further improved the performance and reliability of toroidal transformers. The introduction of grain-oriented silicon steel cores and precision winding processes has significantly reduced energy losses, making these transformers a preferred choice in sectors ranging from medical devices to audio equipment. As industries continue to evolve, the demand for innovative and efficient transformer solutions is expected to drive further advancements in toroidal transformer technology, solidifying their role in the global marketplace.

In summary, understanding the market dynamics, prioritizing sustainability, and recognizing the historical development of toroidal transformers are essential for B2B buyers seeking to make informed sourcing decisions in this rapidly evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of toroidal transformer dimensions chart

-

How do I determine the right toroidal transformer size for my application?

To choose the appropriate toroidal transformer size, consider the power requirements of your application, typically measured in volt-amperes (VA). Refer to a dimensions chart that correlates power ratings with physical dimensions, including outer diameter (OD) and height. Additionally, factor in the efficiency and voltage regulation of the transformer. If you are uncertain, consult with the manufacturer to ensure that you select a transformer that meets your specific voltage and current needs while optimizing space and performance. -

What specifications should I look for in a toroidal transformer?

Key specifications include power rating (VA), dimensions (OD and height), efficiency percentage, and weight. It’s also essential to consider voltage regulation, thermal protection features, and certifications such as UL or CE. Depending on your application, you may require custom features like electrostatic shielding or medical-grade insulation. Always ensure that the transformer meets the required standards for your industry to guarantee safety and reliability. -

How can I customize a toroidal transformer to fit my unique requirements?

Most manufacturers offer customization options for toroidal transformers. You can specify dimensions, power ratings, and additional features such as thermal protection or magnetic shielding. Discuss your unique requirements with the supplier, providing details about your application and performance needs. Be prepared to share your expected load conditions and any certifications needed. Request prototypes to test before finalizing your order, ensuring the transformer meets your specifications. -

What are the minimum order quantities (MOQ) for toroidal transformers?

Minimum order quantities vary by supplier and can depend on the complexity of the transformer and the level of customization required. Standard models typically have lower MOQs, while custom designs may require larger orders. When sourcing from international suppliers, consider factors such as production lead times and shipping costs. Always clarify MOQ terms before placing an order to ensure they align with your project needs and budget. -

What payment terms should I expect when sourcing toroidal transformers internationally?

Payment terms can vary significantly between suppliers. Common options include upfront payment, partial payment upon order confirmation, and the balance before shipment. Some suppliers may accept letters of credit or payment through escrow services for larger orders. Always negotiate payment terms that protect your interests and ensure a smooth transaction. It’s prudent to establish clear agreements on payment schedules and methods before finalizing your order. -

How do I vet suppliers for toroidal transformers?

To vet suppliers, start by reviewing their certifications, such as ISO or IEC compliance, which indicate adherence to quality standards. Request references from previous clients and examine their track record in delivering quality products on time. Additionally, consider their experience in your industry and their ability to offer custom solutions. Visiting their manufacturing facility or requesting samples can also provide insight into their operational capabilities and product quality. -

What logistics considerations should I keep in mind when importing toroidal transformers?

When importing toroidal transformers, consider shipping methods, customs duties, and lead times. Work with suppliers who can provide clear shipping options and estimated delivery timelines. Ensure that all necessary documentation, including import permits and compliance certificates, is in order to avoid delays at customs. It’s also advisable to use a reliable freight forwarder familiar with your region’s regulations to streamline the logistics process. -

What quality assurance measures should I look for in toroidal transformers?

Quality assurance measures should include rigorous testing for efficiency, voltage regulation, and thermal performance. Suppliers should have quality control protocols in place, such as testing samples from each production batch. Additionally, inquire about their return and warranty policies. A reputable supplier will provide documentation proving compliance with relevant safety standards, ensuring that the transformers are safe and reliable for your applications.

Top 4 Toroidal Transformer Dimensions Chart Manufacturers & Suppliers List

1. Hilltech – Toroidal Transformers

Domain: hill-tech.com

Registered: 2005 (20 years)

Introduction: Toroidal Transformers by Hilltech Sales Corporation offer several advantages, including improved efficiency due to a shorter mean length per turn, which reduces I2R losses. The transformers are constructed using a core made from grain-oriented electrical grade silicon steel, wound tightly and annealed to relieve mechanical and magnetic stresses. Key features include:

– Low Profile Miniature 50/60…

2. Standex Electronics – FPT Series Power Toroidal Transformers

Domain: standexelectronics.com

Registered: 1998 (27 years)

Introduction: FPT Series Power Toroidal Transformers are designed for high efficiency and low electromagnetic interference. They feature a compact design, lightweight construction, and are suitable for various applications including medical, industrial, and consumer electronics. The transformers are available in multiple power ratings and configurations, ensuring versatility for different needs. They are also c…

3. Shinenergy – Transformer Specifications Guide

Domain: shinenergy.net

Registered: 2010 (15 years)

Introduction: Transformer Sizes: How to Choose the Right Specification. Key product details include: 1. Types of Transformers: Dry Type, Isolation, Single Phase, Three Phase, Step Down, Step Up, kVA Transformers (e.g., 250KVA, Control, High Frequency, K-factor, Liz Wire, Power Frequency). 2. Inductors: Custom Inductors, AC Inductors (e.g., 32KHZ, Amorphous Core, MPP Core, DC Boost Inductors, Common Mode Choke, …

4. Bridgeport Magnetics – Toroidal O-Core Power Transformers

Domain: bridgeportmagnetics.com

Registered: 2003 (22 years)

Introduction: {‘product_name’: ‘Toroidal O-Core Power Transformers’, ‘features’: ‘Lowest possible profile, diameter to height ratio of 3:1, less insulation required, lighter and smaller than regular toroidal transformers, same electrical benefits as regular toroidal cores, wound from a steel strip with circular cross section.’, ‘applications’: ‘Suitable for designs requiring a small footprint, can be used in th…

Strategic Sourcing Conclusion and Outlook for toroidal transformer dimensions chart

The dimensions and specifications of toroidal transformers are crucial for international B2B buyers in optimizing their procurement strategies. By understanding the relationship between physical size, power ratings, and efficiency, businesses can make informed decisions that enhance performance while minimizing costs. Strategic sourcing not only ensures access to high-quality components but also strengthens supplier relationships, paving the way for better negotiation terms and delivery times.

As global markets become increasingly interconnected, buyers from regions such as Africa, South America, the Middle East, and Europe must stay abreast of evolving trends and technologies in transformer design. This is particularly important in sectors requiring precision, such as medical and audio equipment manufacturing.

Looking ahead, the demand for compact, efficient, and high-performance toroidal transformers is set to rise. To stay competitive, companies should prioritize building resilient supply chains and consider leveraging local and international suppliers to meet their specific requirements. Engage with trusted manufacturers to explore custom solutions that align with your operational goals. Now is the time to take proactive steps towards enhancing your sourcing strategy for toroidal transformers—seize the opportunity to elevate your business capabilities today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.