The Definitive Guide to Three Prong Wire Connector: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for three prong wire connector

In the dynamic landscape of international business, sourcing reliable three prong wire connectors poses a significant challenge for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. These connectors are crucial for ensuring safe and efficient electrical connections across various applications, from automotive to industrial machinery. However, navigating the complexities of product specifications, regulatory compliance, and supplier reliability can be daunting.

This comprehensive guide aims to empower B2B buyers by providing an in-depth exploration of three prong wire connectors, covering a range of essential topics. From understanding the different types of connectors available to identifying their specific applications, we will equip you with the knowledge needed to make informed purchasing decisions. Additionally, we will delve into the critical aspects of supplier vetting, cost considerations, and compliance with international standards, ensuring that you can confidently source products that meet your operational needs.

By leveraging the insights presented in this guide, international B2B buyers can streamline their procurement processes, mitigate risks, and ultimately enhance the reliability and safety of their electrical systems. Whether you are based in Brazil, Saudi Arabia, or elsewhere, this resource is designed to facilitate your journey in sourcing high-quality three prong wire connectors tailored to your business requirements.

Understanding three prong wire connector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automotive 3-Pin Connectors | Compact design, typically weather-resistant, designed for automotive applications. | Automotive wiring harnesses, sensors. | Pros: Durable, reliable in harsh conditions. Cons: Limited to specific automotive uses. |

| Heavy-Duty Connectors | Robust construction, often made from rubber or thermoplastic, designed for high-load applications. | Industrial machinery, outdoor equipment. | Pros: Excellent strain relief, suitable for high amperage. Cons: Higher cost, bulkier size. |

| Female Grounded Connectors | Features a grounding pin, ensuring safety in electrical systems. | Electrical installations, safety applications. | Pros: Enhanced safety, prevents electrical faults. Cons: Requires compatible male connectors. |

| 3-Pin Plugs for LED Lighting | Designed specifically for LED applications, often with specialized wiring. | LED lighting solutions in commercial settings. | Pros: Optimized for energy efficiency, easy installation. Cons: May not be suitable for non-LED applications. |

| Weatherproof Connectors | Sealed design to prevent moisture ingress, ensuring reliability in outdoor settings. | Outdoor lighting, marine applications. | Pros: Resistant to environmental factors, enhances longevity. Cons: Can be more expensive than standard connectors. |

What Are the Characteristics of Automotive 3-Pin Connectors?

Automotive 3-pin connectors are designed with compactness and reliability in mind, making them ideal for various automotive applications such as wiring harnesses and sensor connections. These connectors are typically weather-resistant, ensuring performance in challenging environments. When purchasing, buyers should consider the specific compatibility with vehicle models and the durability required for their applications.

How Do Heavy-Duty Connectors Stand Out?

Heavy-duty connectors are characterized by their robust construction, often utilizing materials like rubber or thermoplastic to withstand high loads. These connectors are commonly used in industrial machinery and outdoor equipment where durability is critical. Buyers should evaluate the amperage requirements and installation space, as these connectors tend to be bulkier and may come at a higher cost.

Why Choose Female Grounded Connectors?

Female grounded connectors feature a grounding pin, which enhances safety by preventing electrical faults. They are widely used in electrical installations where safety is paramount, such as in commercial buildings and industrial settings. Buyers should ensure compatibility with male connectors and assess the specific grounding requirements of their applications.

What Are the Advantages of 3-Pin Plugs for LED Lighting?

3-pin plugs designed for LED lighting applications are optimized for energy efficiency and ease of installation. These connectors are essential in commercial settings where LED lighting solutions are implemented. When considering a purchase, buyers should focus on the specific wiring needs and compatibility with existing lighting systems to ensure seamless integration.

How Do Weatherproof Connectors Enhance Reliability?

Weatherproof connectors are engineered with sealed designs to prevent moisture ingress, making them ideal for outdoor lighting and marine applications. Their resistance to environmental factors significantly enhances their longevity and performance. Buyers should weigh the added cost against the benefits of increased durability, especially in regions prone to harsh weather conditions.

Key Industrial Applications of three prong wire connector

| Industry/Sector | Specific Application of three prong wire connector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electrical connections in vehicle wiring harnesses | Ensures reliable power delivery and safety in vehicles | Compliance with automotive standards and temperature resistance |

| Industrial Equipment | Power supply connections for heavy machinery | Enhances operational efficiency and minimizes downtime | Durability under harsh conditions and compatibility with existing systems |

| Construction | Temporary power supply for construction sites | Provides flexibility in powering tools and equipment | Weather resistance and ease of installation |

| Home Appliances | Wiring for household electrical appliances | Improves safety and functionality of appliances | Adherence to local electrical codes and certifications |

| Renewable Energy | Interconnections in solar panel systems | Supports sustainable energy solutions and reduces costs | Corrosion resistance and compatibility with various energy systems |

How is the Three Prong Wire Connector Used in Automotive Applications?

In the automotive sector, three prong wire connectors are crucial for establishing electrical connections within vehicle wiring harnesses. They are designed to handle multiple signals, ensuring reliable communication between various components such as sensors, lights, and control units. For international buyers, particularly in regions like Brazil and Saudi Arabia, understanding the specific automotive standards and environmental conditions is essential for sourcing connectors that can withstand extreme temperatures and vibrations.

What Role Does the Three Prong Wire Connector Play in Industrial Equipment?

In industrial settings, three prong wire connectors facilitate power supply connections for heavy machinery. These connectors help in establishing a robust electrical system that enhances operational efficiency and minimizes downtime. Businesses in emerging markets, such as those in South America and Africa, should prioritize sourcing connectors that meet industry-specific durability standards to ensure long-lasting performance under challenging conditions.

How Are Three Prong Wire Connectors Utilized on Construction Sites?

Construction sites often require temporary power supply solutions, making three prong wire connectors essential for connecting tools and equipment. These connectors provide flexibility and adaptability in powering various devices, which is crucial for meeting project deadlines. Buyers in the Middle East and Europe should consider weather resistance and ease of installation when sourcing these connectors to ensure safe and efficient operations in diverse environmental conditions.

Why Are Three Prong Wire Connectors Important for Home Appliances?

In the home appliance sector, three prong wire connectors are integral for wiring household electrical devices, enhancing both safety and functionality. These connectors ensure that appliances operate effectively while minimizing the risk of electrical faults. For international buyers, compliance with local electrical codes and certifications is critical when sourcing connectors to guarantee the safety and reliability of household products.

How Do Three Prong Wire Connectors Support Renewable Energy Initiatives?

Three prong wire connectors are vital in renewable energy systems, particularly in solar panel installations where they facilitate interconnections between panels and inverters. This enhances the efficiency of energy transfer and supports sustainable energy solutions. Buyers from regions focusing on renewable energy, such as Europe and parts of Africa, should prioritize sourcing connectors that offer corrosion resistance and compatibility with various energy systems to ensure optimal performance and longevity.

3 Common User Pain Points for ‘three prong wire connector’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Connector for Specific Applications

The Problem: Many B2B buyers encounter challenges when trying to select the appropriate three-prong wire connector for their specific applications. With a wide variety of connectors available, each designed for different uses—such as automotive, industrial, or consumer electronics—buyers often struggle to find the right fit. This can lead to costly errors in procurement, resulting in project delays and increased costs due to returns or replacements.

The Solution: To mitigate these challenges, buyers should take a systematic approach to connector selection. Start by thoroughly understanding the specifications required for your application, including voltage, current rating, and environmental conditions (e.g., exposure to moisture or temperature extremes). It is crucial to consult technical datasheets and compatibility guides provided by manufacturers. Additionally, engaging with suppliers who offer comprehensive technical support can greatly assist in making informed decisions. When sourcing connectors, consider purchasing from reputable suppliers who provide a range of connectors suited for various applications, ensuring you have the flexibility to meet your project needs without unnecessary complications.

Scenario 2: Issues with Connector Durability and Reliability

The Problem: Another common pain point for B2B buyers is the durability and reliability of three-prong wire connectors, especially in harsh operating environments. Connectors that fail due to poor quality can lead to equipment malfunctions, safety hazards, and ultimately, a loss of revenue. Buyers often face the dilemma of choosing between cost-effective options and high-quality connectors that can withstand extreme conditions.

The Solution: To address durability concerns, it is essential to prioritize quality over cost when sourcing three-prong wire connectors. Buyers should look for connectors that are rated for the specific environmental conditions they will face, such as high humidity or exposure to chemicals. Research brands that offer connectors with robust construction materials, such as heavy-duty thermoplastics or metal reinforcements. Moreover, consider connectors with additional protective features, such as strain relief or weatherproof seals, which can enhance their longevity. Establishing a strong relationship with a trusted supplier can also facilitate access to reliable products and ongoing support for any technical issues that may arise.

Scenario 3: Complications with Installation and Maintenance

The Problem: B2B buyers often encounter complications during the installation and maintenance of three-prong wire connectors, particularly when dealing with large-scale projects or complex machinery. Inexperienced technicians may struggle with proper wiring techniques, which can lead to poor connections and increased downtime for troubleshooting and repairs.

The Solution: To streamline installation and maintenance processes, invest in thorough training for your technical staff. This can include workshops or online training modules focused on best practices for installing three-prong wire connectors. Providing technicians with detailed installation guides and diagrams can also aid in reducing errors. Additionally, consider using connectors with user-friendly designs that facilitate easier installation, such as those featuring color-coded wiring or snap-on mechanisms. Regular maintenance checks are crucial; implement a schedule for inspecting connectors to ensure they remain secure and functional. By fostering a culture of training and proactive maintenance, companies can significantly reduce installation complications and enhance operational efficiency.

Strategic Material Selection Guide for three prong wire connector

What Are the Common Materials Used for Three Prong Wire Connectors?

When selecting materials for three prong wire connectors, it is essential to consider their properties and suitability for specific applications. The choice of material can significantly impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of three prong wire connectors.

How Does Polyvinyl Chloride (PVC) Perform in Three Prong Wire Connectors?

Key Properties: PVC is a widely used thermoplastic known for its excellent insulation properties and resistance to moisture, chemicals, and UV light. It typically operates well within a temperature range of -10°C to 60°C.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for many applications. However, it can become brittle over time when exposed to extreme temperatures, leading to potential failures. Its lower temperature rating may not be suitable for high-heat applications.

Impact on Application: PVC is compatible with a variety of media, including water and some chemicals, making it suitable for general-purpose connectors. However, it may not be ideal for applications involving high temperatures or aggressive chemicals.

Considerations for International Buyers: PVC connectors must comply with various standards such as ASTM D1784 and IEC 60670. Buyers from regions like Africa and South America should ensure that the PVC used is free from harmful additives, as regulations may vary significantly.

What Advantages Does Nylon Offer for Three Prong Wire Connectors?

Key Properties: Nylon is a high-performance thermoplastic that provides excellent mechanical strength, flexibility, and resistance to abrasion and chemicals. It can withstand temperatures ranging from -40°C to 120°C.

Pros & Cons: The durability and flexibility of nylon make it suitable for demanding applications. However, it is generally more expensive than PVC, and the manufacturing process can be more complex, leading to higher production costs.

Impact on Application: Nylon connectors are ideal for automotive and industrial applications where mechanical stress and exposure to harsh environments are common. They maintain performance under varying conditions, making them versatile.

Considerations for International Buyers: Compliance with international standards like ISO 9001 and RoHS is crucial for nylon connectors. Buyers in Europe and the Middle East should ensure that the nylon used is sourced responsibly and meets environmental regulations.

Why Is Metal Used in Three Prong Wire Connectors?

Key Properties: Metals such as brass or copper are often used for the conductive components of wire connectors. These materials provide excellent electrical conductivity and mechanical strength.

Pros & Cons: Metal connectors are highly durable and can withstand high temperatures and pressures. However, they are susceptible to corrosion, especially in humid or saline environments, which can affect performance over time.

Impact on Application: Metal connectors are ideal for applications requiring high electrical conductivity, such as in automotive and industrial machinery. However, they may require additional coatings or treatments to enhance corrosion resistance.

Considerations for International Buyers: Compliance with standards like ASTM B16 and ISO 1456 is essential for metal connectors. Buyers from regions with high humidity, such as parts of Africa and South America, should prioritize corrosion-resistant finishes.

How Does Thermoplastic Elastomer (TPE) Compare for Three Prong Wire Connectors?

Key Properties: TPE combines the properties of rubber and plastic, offering excellent flexibility and resilience. It operates effectively within a temperature range of -40°C to 100°C.

Pros & Cons: TPE is highly durable and resistant to UV light and chemicals, making it suitable for outdoor applications. However, it can be more expensive than traditional plastics, which may impact overall project costs.

Impact on Application: TPE connectors are ideal for applications exposed to harsh environmental conditions, such as outdoor lighting and automotive uses. Their flexibility ensures a secure fit, reducing the risk of disconnection.

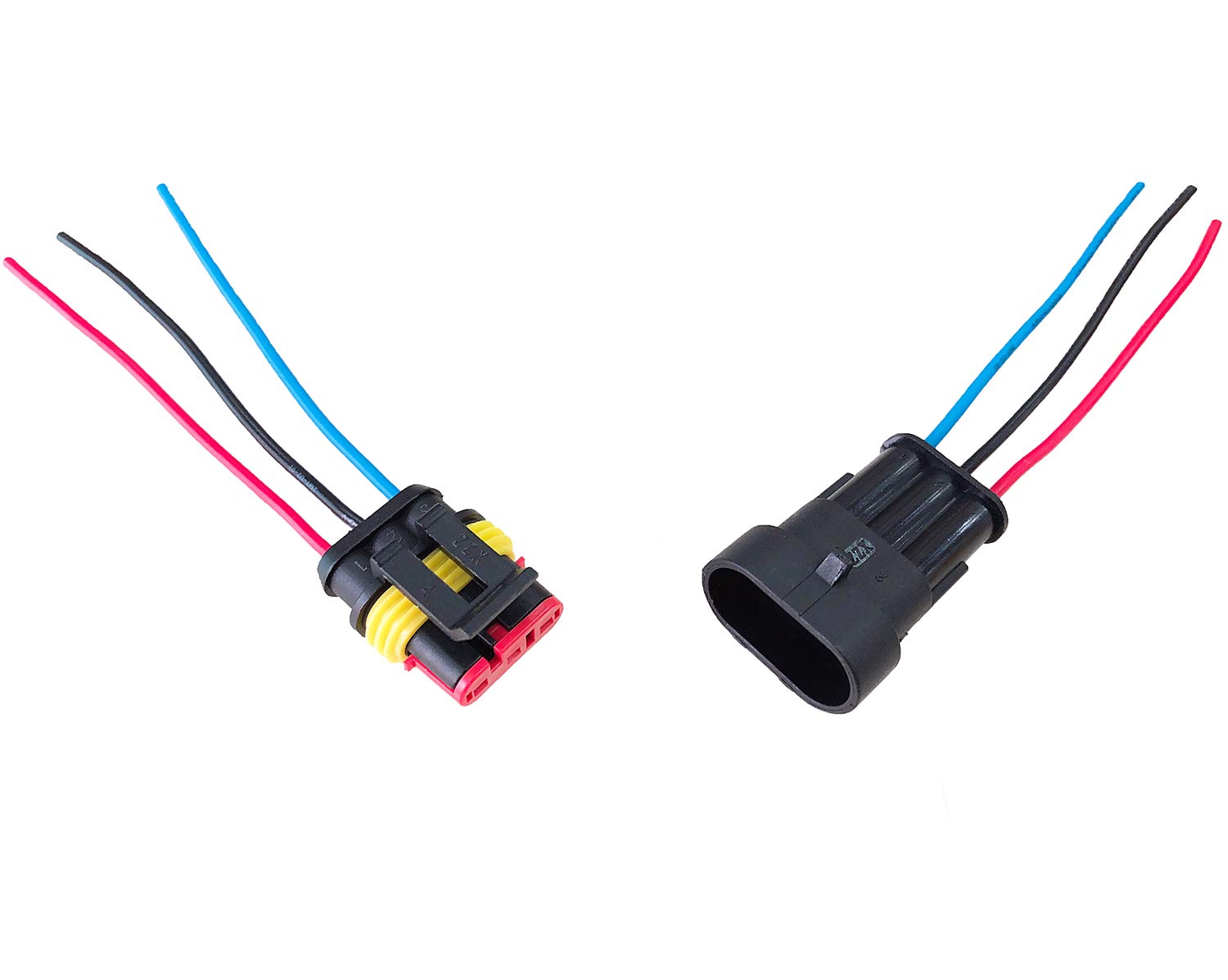

Illustrative image related to three prong wire connector

Considerations for International Buyers: TPE connectors must comply with international standards such as ASTM D624 and IEC 61140. Buyers in the Middle East and Europe should ensure that TPE products meet local environmental regulations.

Summary Table of Material Selection for Three Prong Wire Connectors

| Material | Typical Use Case for three prong wire connector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | General-purpose electrical applications | Cost-effective and easy to manufacture | Brittle at high temperatures | Low |

| Nylon | Automotive and industrial applications | High durability and flexibility | More expensive and complex to produce | Med |

| Metal (Brass/Copper) | High conductivity applications | Excellent electrical conductivity | Susceptible to corrosion | Med |

| Thermoplastic Elastomer (TPE) | Outdoor and harsh environment applications | High durability and UV resistance | Higher cost compared to traditional plastics | High |

This comprehensive analysis provides B2B buyers with valuable insights into the material selection for three prong wire connectors, helping them make informed decisions that align with their specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for three prong wire connector

What Are the Key Stages in the Manufacturing Process of Three Prong Wire Connectors?

The manufacturing of three prong wire connectors involves several critical stages, each ensuring the final product meets the necessary specifications and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality materials, typically copper for the conductors due to its excellent electrical conductivity. Insulation materials, such as PVC or thermoplastic elastomers, are also chosen based on their durability and environmental resistance. Manufacturers often conduct a material inspection to ensure compliance with industry standards, such as RoHS (Restriction of Hazardous Substances).

-

Forming: In this stage, raw materials are shaped into the desired connector form. Techniques such as stamping, molding, or extrusion are commonly used. For example, metal pins are often stamped from copper sheets, while the insulating body is molded using thermoplastics. Precision is crucial here, as the dimensions must align with industry specifications to ensure compatibility with other components.

-

Assembly: Once the components are formed, they undergo an assembly process where the metal pins are inserted into the plastic housing. Automated machines often assist in this stage to increase efficiency and maintain consistency. The assembly process may also include the application of solder or crimping techniques to ensure a secure electrical connection.

-

Finishing: The final stage involves applying surface treatments to enhance the product’s performance and longevity. This can include plating the metal connectors with nickel or tin to improve corrosion resistance. Additionally, labeling or branding may occur during this stage, ensuring compliance with regulatory requirements.

How Is Quality Assurance Implemented During the Manufacturing of Three Prong Wire Connectors?

Quality assurance (QA) is vital throughout the manufacturing process to ensure that products meet both international and industry-specific standards. The implementation of QA typically involves several checkpoints and testing methods.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines the requirements for a quality management system. This certification is recognized globally and assures buyers of consistent quality. Additionally, industry-specific standards like CE marking in Europe or UL certification in the United States can further validate the product’s safety and performance.

-

Quality Control Checkpoints: Quality control (QC) is integrated into various stages of the manufacturing process. Key checkpoints include:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected for defects and compliance with specifications before production begins.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that processes remain within set parameters. This can include monitoring the temperature and pressure during molding or checking the alignment of assembled parts.

– Final Quality Control (FQC): Once the connectors are fully assembled, they undergo final inspections and testing to verify functionality, durability, and safety. This can include electrical testing to measure conductivity and insulation resistance. -

Common Testing Methods: Various testing methods are employed to assess the quality of three prong wire connectors. These include:

– Electrical Testing: Verifying the electrical performance, such as continuity and insulation resistance, is crucial for ensuring safety and functionality.

– Mechanical Testing: Assessing the physical durability of connectors, including pull tests to evaluate the strength of connections.

– Environmental Testing: Simulating conditions such as temperature extremes, humidity, and exposure to chemicals to ensure the connectors can withstand real-world applications.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is essential for building trust and ensuring product reliability.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and QA practices. This can involve on-site visits to assess their facilities, equipment, and adherence to quality standards.

-

Quality Reports and Certifications: Requesting documentation, such as quality reports and certifications, can help validate a supplier’s commitment to quality. Certifications like ISO 9001 or specific product certifications (e.g., UL, CE) demonstrate compliance with recognized standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These inspectors can perform audits, testing, and evaluations according to international standards, providing an added layer of assurance.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances when it comes to quality control, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding these differences can significantly impact procurement decisions.

-

Regulatory Differences: Each region may have unique regulatory requirements for electrical components. For instance, the CE marking is essential in Europe, while UL certification is critical in the United States. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural and Operational Variations: Different regions may have varying approaches to quality assurance. For example, some suppliers may prioritize speed over thorough inspections, which can lead to quality discrepancies. Buyers should assess the supplier’s operational culture and its alignment with their quality expectations.

-

Logistical Considerations: Transporting components internationally can pose challenges, including potential damage or delays. Buyers should work with suppliers who have established quality assurance processes during packaging and shipping to mitigate these risks.

In summary, understanding the manufacturing processes and quality assurance practices for three prong wire connectors is crucial for B2B buyers aiming to source reliable products. By focusing on supplier verification and compliance with international standards, buyers can ensure they receive high-quality connectors that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘three prong wire connector’

When sourcing three prong wire connectors, a systematic approach is essential to ensure quality, compliance, and value for your business. This guide provides a comprehensive checklist to help international B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Begin by identifying the specific requirements for the three prong wire connectors you need. Consider factors such as voltage ratings, wire gauge compatibility, and environmental conditions (e.g., moisture, temperature). This clarity will help you communicate effectively with suppliers and ensure the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers, focusing on their reputation in the industry. Look for suppliers who specialize in electrical components and have a track record of serving businesses in your region, such as Africa, South America, the Middle East, or Europe. Utilize online marketplaces, industry directories, and trade shows to compile a list of reputable vendors.

Step 3: Verify Supplier Certifications

Before making any commitments, ensure that your chosen suppliers hold the necessary certifications. Look for compliance with international standards such as ISO, UL, or CE, which indicate that the products meet safety and quality requirements. This verification reduces the risk of sourcing substandard or non-compliant components.

Step 4: Request Samples for Testing

Once you narrow down your supplier list, request samples of the three prong wire connectors for evaluation. Testing samples allows you to assess the quality, compatibility, and performance of the connectors in your specific applications. Ensure that the connectors can withstand the intended electrical loads and environmental conditions.

Step 5: Evaluate Pricing and Terms

Compare pricing among suppliers, but don’t base your decision solely on cost. Consider factors such as shipping costs, payment terms, and bulk order discounts. Look for suppliers who offer competitive pricing without compromising on quality, and negotiate terms that align with your budget and cash flow needs.

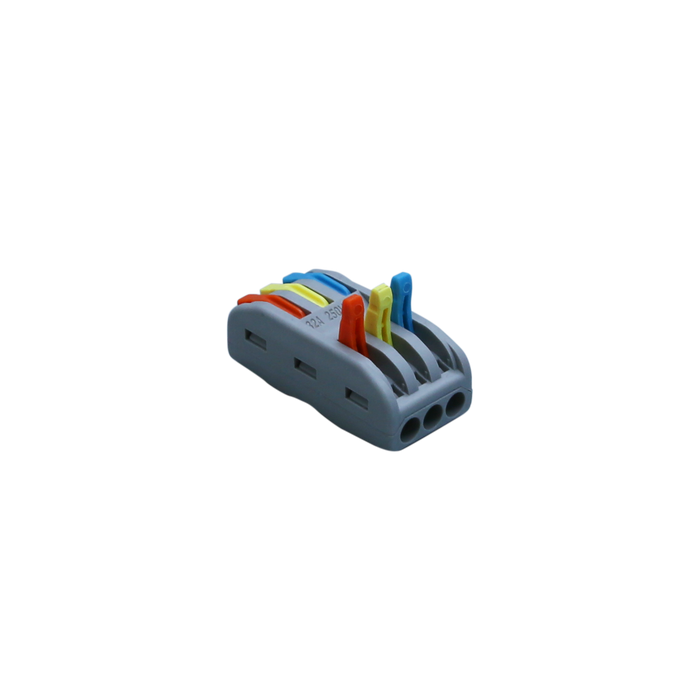

Illustrative image related to three prong wire connector

Step 6: Check Customer Reviews and References

Investigate customer reviews and seek references from businesses that have previously purchased from the suppliers you are considering. Feedback from other buyers can provide insights into the supplier’s reliability, customer service, and overall product quality. Pay attention to any recurring issues highlighted in reviews.

Step 7: Finalize Your Order with Clear Agreements

Once you’ve selected a supplier, finalize your order with a clear written agreement. This should outline product specifications, pricing, delivery timelines, and warranty conditions. Ensure that both parties understand the terms to prevent misunderstandings and establish a solid foundation for a long-term business relationship.

By following these steps, you can streamline the sourcing process for three prong wire connectors, ensuring that you choose the right products and suppliers to meet your business needs.

Comprehensive Cost and Pricing Analysis for three prong wire connector Sourcing

What Are the Key Cost Components of Three Prong Wire Connectors?

When sourcing three prong wire connectors, understanding the cost structure is essential for buyers. The primary cost components include:

Illustrative image related to three prong wire connector

-

Materials: The choice of materials significantly impacts pricing. High-quality plastics, metals, and rubber compounds used in connectors determine their durability and performance. Premium materials often come at a higher cost but can reduce failure rates and improve longevity.

-

Labor: Labor costs vary based on the manufacturing region. Automated processes can lower labor costs, while skilled labor in regions with higher wage standards may increase costs. Understanding the labor dynamics in the supplier’s country can provide insights into overall pricing.

-

Manufacturing Overhead: This encompasses costs related to facility maintenance, utilities, and administrative expenses. Factories with advanced machinery may have higher overhead but can achieve better efficiency and output quality.

-

Tooling: Initial tooling costs for custom connectors can be substantial. These costs are spread over the production run, so larger orders can mitigate the impact on per-unit pricing. Buyers should inquire about the tooling process when considering custom specifications.

-

Quality Control (QC): Rigorous QC processes ensure that products meet industry standards and specifications. This may involve testing and certification, which add to overall costs. Buyers should consider the implications of QC on the reliability of connectors.

-

Logistics: Shipping costs can vary widely depending on the distance, mode of transportation, and shipping terms. Incoterms (International Commercial Terms) influence who bears the cost of freight and insurance, impacting overall pricing.

-

Margin: Supplier margins can vary based on market conditions, competition, and brand reputation. Understanding typical margins in the industry can help buyers gauge whether pricing is competitive.

How Do Price Influencers Affect Three Prong Wire Connector Costs?

Several factors influence the pricing of three prong wire connectors:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer lower prices for larger orders. Buyers should consider their needs and potential future demand when negotiating prices to maximize cost efficiency.

-

Specifications and Customization: Customized connectors can lead to higher costs due to unique tooling and material requirements. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Connectors made with higher-grade materials and those that meet specific certifications (e.g., UL, CE) can command premium prices. Buyers must balance quality needs with budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can affect pricing. Established suppliers may charge more but offer better guarantees and support.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Incoterms determine the responsibilities of buyers and sellers, influencing overall costs.

What Tips Can Help Buyers Negotiate Better Prices for Three Prong Wire Connectors?

International B2B buyers can employ several strategies to ensure cost-effective sourcing of three prong wire connectors:

-

Negotiation: Engage in discussions with multiple suppliers to understand their pricing structures. Leverage competitive quotes to negotiate better terms and prices.

-

Cost-Efficiency: Assess the total cost of ownership, including shipping, duties, and potential tariffs. A lower purchase price may not equate to a lower total cost if logistics and additional fees are high.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and economic conditions in the supplier’s country, as these can impact pricing. Secure fixed pricing agreements when possible to hedge against volatility.

-

Quality Assurance: Prioritize suppliers with robust quality control measures, even if their prices are slightly higher. The long-term savings from reduced failures and replacements can justify the initial investment.

Disclaimer on Pricing

The prices for three prong wire connectors can vary widely based on the factors discussed. The figures referenced in various sources are indicative and can fluctuate based on market conditions, order volumes, and supplier negotiations. Buyers are encouraged to conduct thorough market research and engage directly with suppliers for the most accurate pricing.

Alternatives Analysis: Comparing three prong wire connector With Other Solutions

Introduction: Understanding Alternatives in Wire Connection Solutions

In the realm of electrical connectivity, selecting the right connector can significantly impact performance, safety, and cost-effectiveness. While the three prong wire connector is a popular choice for many applications, there are alternative solutions that may better suit specific requirements. This analysis compares the three prong wire connector with two viable alternatives: the two prong wire connector and the Anderson Powerpole connector. By evaluating these options, B2B buyers can make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Three Prong Wire Connector | Two Prong Wire Connector | Anderson Powerpole Connector |

|---|---|---|---|

| Performance | Excellent for high-power applications due to grounding | Adequate for low-power applications, lacks grounding | High performance with robust current handling capabilities |

| Cost | Moderate ($3 – $15) | Low ($1 – $5) | Higher ($2 – $20) |

| Ease of Implementation | Requires specific wiring knowledge | Simple to install, no special tools needed | Moderate; may require specific tools for assembly |

| Maintenance | Low; durable with minimal wear | Very low; simple design, less prone to failure | Moderate; connectors may need periodic inspection |

| Best Use Case | Heavy-duty electrical applications needing grounding | Basic household devices and low-power tools | High-current applications, renewable energy systems |

Detailed Breakdown of Alternatives

Two Prong Wire Connector: Is It Right for Your Needs?

The two prong wire connector is a straightforward solution primarily used for low-power applications, such as household appliances and light fixtures. Its design is simple, making it easy to install without specialized tools. However, it lacks a grounding prong, which may pose safety risks in high-power or outdoor applications. For buyers focusing on budget and simplicity, this connector is an attractive option; however, it is essential to consider the specific power requirements of the application to ensure safety and functionality.

Anderson Powerpole Connector: A Robust Alternative

The Anderson Powerpole connector stands out as a versatile solution for high-current applications, including renewable energy systems and automotive uses. Known for its reliability and performance, it offers modularity, allowing users to configure connections easily. However, the initial cost can be higher than standard connectors, and proper assembly may require specific tools. This connector is ideal for buyers looking for durability and performance in environments where reliable electrical connections are critical.

Conclusion: Making the Right Choice for Your Application

When selecting a wire connector, B2B buyers should carefully consider their specific application requirements, including power needs, installation environment, and budget constraints. The three prong wire connector offers excellent performance for heavy-duty applications, while the two prong connector may suffice for basic needs. For high-current scenarios, the Anderson Powerpole connector provides robustness and flexibility. By evaluating these alternatives, buyers can choose the most suitable solution that aligns with their operational objectives and safety standards.

Essential Technical Properties and Trade Terminology for three prong wire connector

What Are the Key Technical Properties of a Three Prong Wire Connector?

When sourcing three prong wire connectors, understanding their technical properties is essential for ensuring compatibility and safety in various applications. Here are some critical specifications:

1. Material Composition

The materials used in three prong wire connectors often include thermoplastics and rubber. These materials provide durability, flexibility, and resistance to environmental factors such as moisture and UV light. For B2B buyers, selecting connectors made from high-quality materials ensures longevity and reduces the risk of failure, which can lead to costly downtime in operations.

2. Current Rating

The current rating indicates the maximum amount of electrical current that a connector can safely carry, typically measured in Amperes (A). Connectors are commonly rated between 15A to 30A. Understanding this specification is crucial for buyers to ensure that the connector will handle the electrical load required by the application, preventing overheating and potential hazards.

3. Voltage Rating

Voltage rating denotes the maximum voltage that a connector can handle without risk of electrical breakdown. Common ratings for three prong connectors are 125V or 250V. For international B2B buyers, ensuring that the voltage rating aligns with regional electrical standards is vital for compliance and safety.

4. Wire Gauge Compatibility

This specification refers to the thickness of the wire that the connector can accommodate, usually expressed in American Wire Gauge (AWG). A typical three prong connector may support wire gauges from 14 to 16 AWG. Buyers must consider the wire gauge to ensure proper electrical conductivity and mechanical fit.

5. Strain Relief Features

Strain relief refers to the design elements that prevent mechanical stress on the wires when the connector is pulled or bent. Connectors with built-in strain relief features, such as clamps or rubber grommets, enhance durability and minimize the risk of wire damage. For B2B buyers, this property is critical in applications where movement or vibration is expected.

What Common Trade Terms Should B2B Buyers Know When Purchasing Three Prong Wire Connectors?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms related to three prong wire connectors:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of wire connectors, buyers may seek OEM parts to ensure compatibility with existing equipment, making it important to verify the manufacturer’s specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Buyers should inquire about MOQ when sourcing connectors, as it can significantly impact inventory costs and cash flow. Understanding this term helps buyers plan their purchases according to their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing, availability, and terms for a specific quantity of products. For buyers, issuing an RFQ for three prong wire connectors can lead to competitive pricing and better negotiation leverage.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, insurance, and risk during transit, particularly for international purchases.

5. Certification Standards

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that a product has been tested for safety and compliance with regulatory requirements. Buyers should prioritize connectors that meet relevant certification standards to ensure safety and reliability in their applications.

By understanding these properties and terms, international B2B buyers can make informed decisions when sourcing three prong wire connectors, ultimately enhancing their procurement processes and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the three prong wire connector Sector

What Are the Current Market Dynamics and Key Trends in the Three Prong Wire Connector Sector?

The three prong wire connector market is witnessing significant growth driven by various global factors, including the surge in demand for automotive, industrial, and consumer electronics applications. As industries increasingly rely on efficient electrical connections, the demand for reliable, high-quality connectors has escalated. Key trends influencing this market include the growing adoption of automation and smart technologies, which require advanced wiring solutions. Moreover, as manufacturers strive for greater integration of IoT devices, the need for versatile and durable connectors is paramount.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local market nuances is crucial. Countries such as Brazil and Saudi Arabia are focusing on infrastructure development, which is expected to drive demand for electrical components, including three prong wire connectors. Additionally, the rise of e-commerce platforms has transformed sourcing strategies, enabling buyers to access a broader range of suppliers and products efficiently. The emphasis on customization and adaptability in connector designs is also notable, as businesses seek solutions tailored to their specific applications.

How Is Sustainability and Ethical Sourcing Influencing the Three Prong Wire Connector Market?

Sustainability is becoming a central tenet in the sourcing strategies of B2B buyers. The environmental impact of manufacturing processes and materials used in three prong wire connectors is under increasing scrutiny. Buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, such as reducing waste and utilizing recyclable materials. The adoption of ‘green’ certifications, such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment), is on the rise, indicating compliance with stringent environmental regulations.

Ethical sourcing is equally important, as buyers are keen to ensure that their suppliers adhere to fair labor practices and responsible supply chain management. This focus on ethical procurement not only enhances brand reputation but also mitigates risks associated with supply chain disruptions. Suppliers that can demonstrate transparency in their sourcing and manufacturing processes are likely to gain a competitive edge in the market, appealing to conscientious buyers looking to align with sustainable business practices.

What Is the Brief Evolution of the Three Prong Wire Connector?

The evolution of three prong wire connectors can be traced back to the early 20th century when electrical systems began to standardize. Initially, connectors were rudimentary, designed primarily for basic electrical applications. As technology advanced, so did the complexity and functionality of connectors. The introduction of safety features, such as the grounding prong, significantly enhanced the safety of electrical devices.

Over the decades, the materials used in connectors have also evolved, with modern connectors incorporating durable plastics and metals that withstand environmental stressors. Today, three prong wire connectors are integral components in various applications, from consumer electronics to heavy industrial machinery. This evolution reflects not only technological advancements but also the growing demand for safety, reliability, and efficiency in electrical connections.

In conclusion, the three prong wire connector sector is navigating a complex landscape influenced by technological advancements, sustainability imperatives, and changing market dynamics. B2B buyers must stay informed and adaptable to leverage opportunities in this evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of three prong wire connector

-

How do I ensure the quality of three prong wire connectors from international suppliers?

To ensure the quality of three prong wire connectors from international suppliers, it’s crucial to conduct thorough vetting. Start by requesting samples to assess the product’s quality firsthand. Verify certifications such as UL, CE, or ISO, which indicate compliance with international safety standards. Additionally, consider visiting the supplier’s facility if possible or using third-party inspection services to evaluate their manufacturing processes. Establishing clear quality assurance protocols in your purchase agreements can further protect your interests. -

What is the best material for three prong wire connectors in high-temperature applications?

For high-temperature applications, connectors made from thermoplastic or thermoset materials are often the best choice. These materials can withstand elevated temperatures without deforming or losing functionality. Additionally, look for connectors that feature high-temperature resistance ratings and are designed for electrical insulation. Conducting thermal testing on samples can help ensure they meet the specific thermal requirements of your application. -

How can I customize three prong wire connectors for my specific needs?

Customizing three prong wire connectors typically involves specifying the connector’s size, material, and terminal configuration. Many manufacturers offer customization options, so it’s essential to communicate your requirements clearly, including dimensions, color preferences, and any specific standards that must be met. Be prepared to provide detailed drawings or specifications. Additionally, inquire about lead times for customized orders, as they may differ from standard products. -

What are the typical minimum order quantities (MOQs) for three prong wire connectors?

Minimum order quantities (MOQs) for three prong wire connectors can vary significantly based on the supplier and the specific product. Generally, MOQs can range from 100 to 1,000 units for standard connectors, while custom designs may have higher MOQs. It’s advisable to discuss your needs with potential suppliers to negotiate MOQs that align with your purchasing strategy. Some suppliers may offer flexibility in MOQs for first-time orders or bulk purchases. -

What payment terms should I expect when sourcing three prong wire connectors internationally?

Payment terms when sourcing three prong wire connectors can vary widely depending on the supplier’s policies and the nature of the transaction. Common terms include payment in advance, a 30% deposit with the balance due before shipment, or payment upon delivery. For larger orders, consider negotiating terms that allow for letters of credit or escrow services to mitigate risk. Always ensure that payment terms are clearly outlined in your contract to avoid misunderstandings. -

How do I handle logistics and shipping for three prong wire connectors sourced internationally?

When handling logistics and shipping for international orders of three prong wire connectors, it’s essential to coordinate with your supplier to determine the best shipping method based on cost, delivery time, and reliability. Utilize freight forwarders who specialize in international shipping to manage customs clearance and documentation. Be aware of any import duties or tariffs that may apply to your shipment, as these can impact overall costs. Establishing a clear timeline for delivery will also help manage expectations. -

What should I look for in a supplier of three prong wire connectors?

When selecting a supplier for three prong wire connectors, consider factors such as their industry reputation, production capacity, and experience in your specific sector. Look for suppliers who provide certifications and adhere to international quality standards. Customer service responsiveness is also critical; ensure they can address your inquiries and concerns promptly. Additionally, seek out reviews or testimonials from other businesses to gauge their reliability and service quality. -

Are there specific regulations or standards for three prong wire connectors in different regions?

Yes, three prong wire connectors are subject to various regulations and standards depending on the region. In Europe, for instance, connectors must comply with the CE marking, indicating conformity with health, safety, and environmental protection standards. In the United States, UL certification is often required for electrical products. It’s essential to research and understand the relevant regulations in your target market to ensure compliance and avoid potential legal issues. Consulting with a local expert or legal advisor can be beneficial in navigating these requirements.

Top 2 Three Prong Wire Connector Manufacturers & Suppliers List

1. Sundial Wire – Female Heavy Duty Connector

Domain: sundialwire.com

Registered: 2002 (23 years)

Introduction: {“product_name”: “Female Heavy Duty Connector for 3 Prong Plug”, “color”: “Black”, “type”: “Connector”, “usage”: “Heavy Duty”, “compatibility”: “3 Prong Plug”}

2. 3-Pin Connector – Low-Profile Wire-to-Board

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 3-pin connector, low-profile wire-to-board connector, 1 mm pitch, crimp type. Possible manufacturers include Adam Tech (1SH + 1CH), Amphenol (Minitek 1.00mm), Harwin (M40-301, M40-401, M40-110), JST (SH), Molex (Pico-Clasp), TE (HPI-1), and Wurth (WR-WTB). The connector is used for a DC blower fan (Delta AUB0712HH-C) with unfinished wires.

Strategic Sourcing Conclusion and Outlook for three prong wire connector

In conclusion, the strategic sourcing of three prong wire connectors presents a vital opportunity for international B2B buyers. By prioritizing quality, compatibility, and supplier reliability, businesses can significantly enhance their electrical systems’ efficiency and safety. Buyers should consider the diverse range of products available—from heavy-duty connectors to specialized automotive components—ensuring they select connectors that meet both regulatory standards and operational needs.

Illustrative image related to three prong wire connector

Furthermore, as global supply chains evolve, leveraging local and international suppliers can create competitive advantages, reduce lead times, and optimize costs. It is crucial for businesses in Africa, South America, the Middle East, and Europe to stay informed about market trends and emerging technologies that could impact sourcing decisions.

As we look ahead, the demand for reliable and innovative electrical components will continue to grow. Now is the time for B2B buyers to take proactive steps in their sourcing strategies, fostering relationships with reputable suppliers and exploring new markets. By doing so, you position your business not only to meet current demands but also to thrive in an increasingly interconnected world. Take action today to secure your supply chain and empower your operations with the best three prong wire connectors available.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.