The Definitive Guide to Technic Car Stacker: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for technic car stacker

In an increasingly crowded marketplace, sourcing a reliable technic car stacker can be a daunting challenge for B2B buyers. With the rapid growth of urban vehicle ownership, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for efficient parking solutions is at an all-time high. This guide aims to demystify the complexities of selecting the right technic car stacker, offering insights into various types, applications, and the vetting process for suppliers.

From two-post and four-post car lifts to advanced automated systems, understanding the nuances of each option is crucial for maximizing space and minimizing costs. Additionally, we will explore the cost factors associated with different models and how to align your purchasing strategy with your operational needs. By equipping international B2B buyers with actionable insights and a comprehensive understanding of the market, this guide empowers informed purchasing decisions, ensuring that your investment in a technic car stacker meets both current and future demands.

Whether you are a dealership in Germany or a logistics provider in Nigeria, navigating the global market for technic car stackers has never been more accessible. With this guide, you can confidently tackle the challenges of vehicle storage and optimize your operations for success.

Understanding technic car stacker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Two-Post Car Stackers | Compact design, typically accommodates 2 vehicles. | Residential garages, small workshops | Pros: Space-efficient, easy access. Cons: Limited height and weight capacity. |

| Four-Post Car Stackers | Stable structure for up to 4 vehicles, heavier loads. | Commercial buildings, car showrooms | Pros: High storage capacity, long-term reliability. Cons: Requires more floor space. |

| Automated Car Stackers | Fully automated systems, often integrated with smart tech. | Urban parking facilities, luxury residential | Pros: Minimal manual operation, maximizes space. Cons: Higher initial investment, maintenance complexity. |

| Semi-Automatic Car Stackers | Manual loading with automated lifting mechanisms. | Valet parking services, busy commercial areas | Pros: Cost-effective, efficient. Cons: Requires operator training, potential for user error. |

| Pit Parking Lifts | Vehicles stored below ground, preserving surface space. | High-end residential, luxury developments | Pros: Aesthetic appeal, independent access. Cons: High installation costs, potential drainage issues. |

What Are the Characteristics of Two-Post Car Stackers?

Two-post car stackers are designed to provide a compact solution for parking two vehicles vertically. They feature a simple structure with two vertical columns supporting the lifting platform, making them ideal for residential garages and small workshops. When considering a purchase, B2B buyers should evaluate their space constraints, as these stackers require less footprint than other types. However, they typically have lower weight capacities and may not be suitable for larger vehicles.

How Do Four-Post Car Stackers Differ in Functionality?

Four-post car stackers are robust systems that can accommodate up to four vehicles, offering greater stability and higher weight capacities than their two-post counterparts. These stackers are commonly used in commercial settings like car showrooms and multi-story parking facilities. Buyers should consider the need for long-term vehicle storage solutions, as these stackers provide reliability but require more floor space. Their ability to handle heavier loads makes them a preferred choice for businesses with diverse vehicle types.

What Makes Automated Car Stackers a Smart Investment?

Automated car stackers represent the cutting edge of parking technology, utilizing sophisticated systems to lift and park vehicles with minimal human intervention. These systems are particularly beneficial in urban settings where space is at a premium. B2B buyers must weigh the higher initial investment against the potential for increased efficiency and reduced labor costs. While they offer significant space-saving benefits, maintenance and system integration can be complex, requiring specialized support.

Why Choose Semi-Automatic Car Stackers for Your Business?

Semi-automatic car stackers combine manual loading with automated lifting mechanisms, providing a balance between cost-effectiveness and efficiency. They are suitable for valet parking services and high-traffic commercial areas where time-saving solutions are essential. Buyers should consider the need for operator training, as these systems require some manual input. While they are generally more affordable than fully automated systems, potential user errors during operation should be factored into the decision.

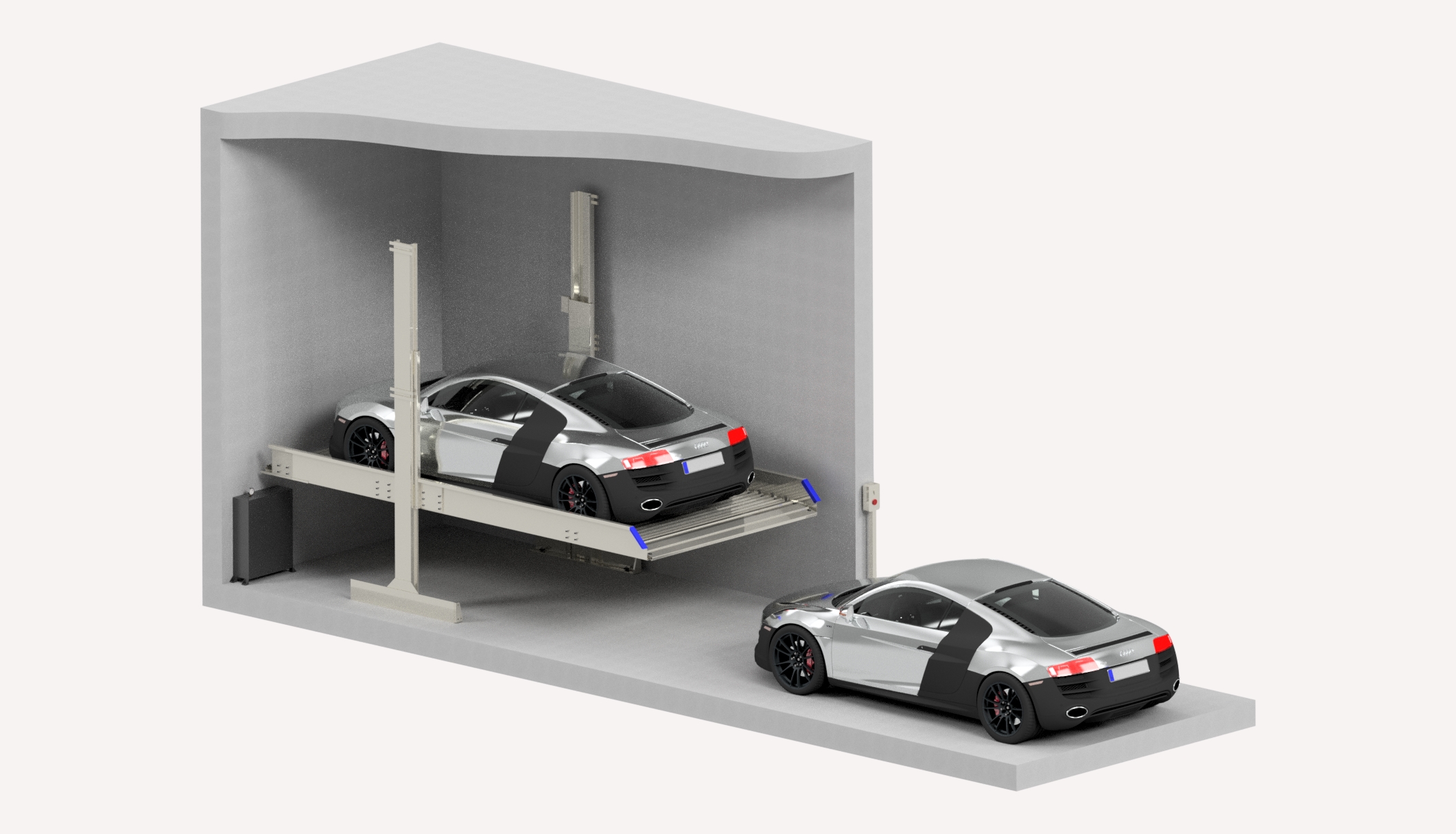

What Are the Benefits of Pit Parking Lifts?

Pit parking lifts store vehicles below ground, preserving the aesthetic appeal of the surface area. This type of stacker is ideal for luxury residential developments and high-end properties where space is limited. Buyers must account for higher installation costs and potential drainage issues associated with underground systems. However, the independent access these lifts provide can significantly enhance the user experience, making them a desirable option for upscale developments.

Key Industrial Applications of technic car stacker

| Industry/Sector | Specific Application of technic car stacker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Retail | Display and storage of models and prototypes | Maximizes space while enhancing product visibility | Durability, load capacity, and ease of assembly |

| Urban Development | Efficient parking solutions in high-density areas | Reduces footprint and construction costs | Compliance with local regulations and safety standards |

| Logistics and Warehousing | Organization of vehicles in storage facilities | Improves inventory management and space utilization | Customization options and scalability |

| Educational Institutions | Hands-on learning for engineering and design students | Fosters creativity and practical skills | Availability of instructional materials and support |

| Event Management | Showcase vehicles at exhibitions and trade shows | Attracts attention and enhances branding | Portability and ease of setup |

How is the technic car stacker utilized in the automotive retail sector?

In the automotive retail sector, the technic car stacker is employed to display models and prototypes efficiently. By stacking vehicles vertically, retailers can maximize showroom space, enabling them to showcase a larger selection of cars without overcrowding. This not only enhances product visibility but also creates a more organized and aesthetically pleasing environment for customers. For international buyers, particularly in regions like Africa and Europe, sourcing stackers that are durable and easy to assemble is crucial, ensuring they can withstand varying environmental conditions and facilitate quick setups.

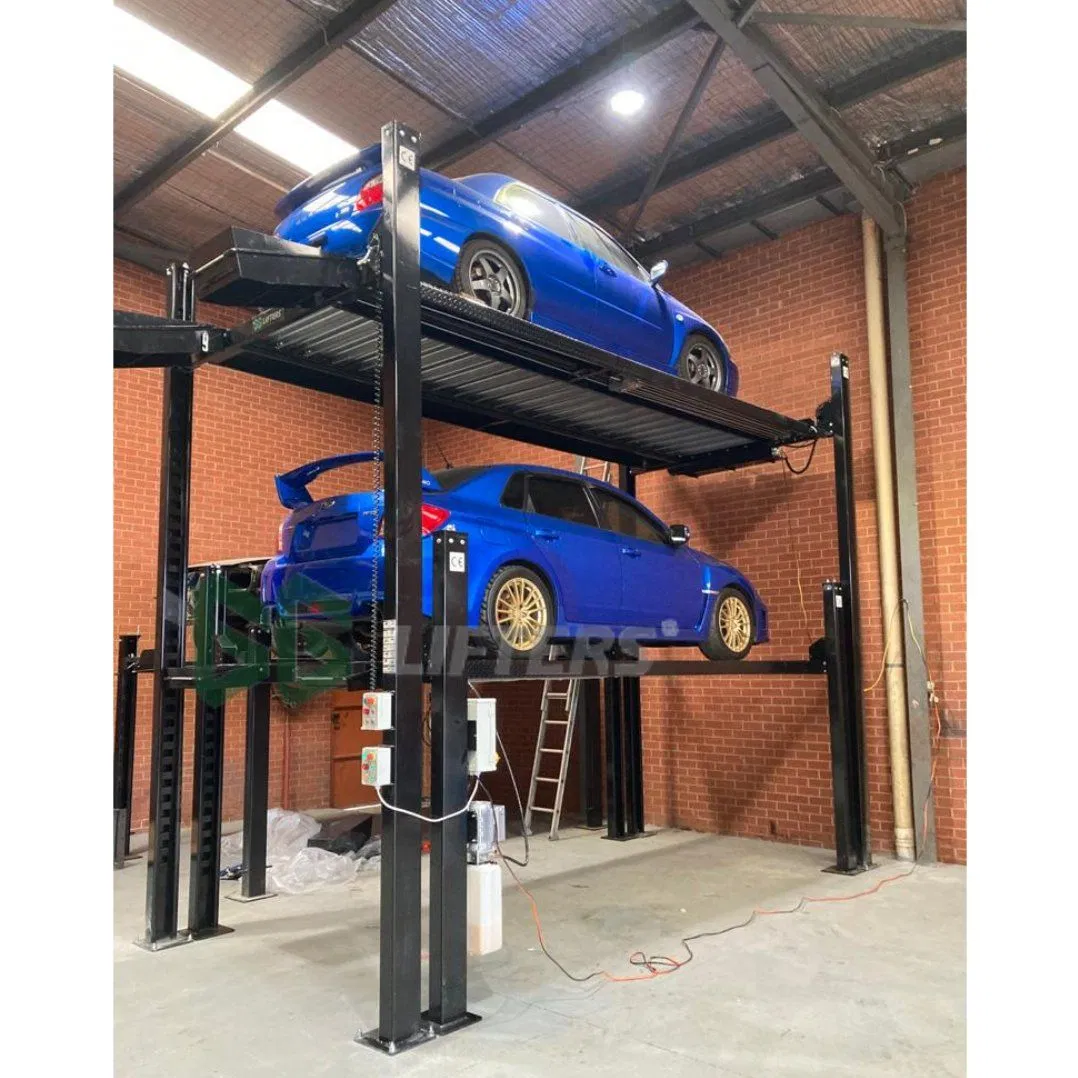

Illustrative image related to technic car stacker

What role does the technic car stacker play in urban development projects?

Urban development projects often face challenges related to limited parking space in densely populated areas. The technic car stacker provides a solution by allowing multiple vehicles to be parked in a single footprint, thereby optimizing space and reducing construction costs. This efficiency is particularly valuable in urban centers in South America and the Middle East, where land prices are high. Buyers must consider local regulations and safety standards when sourcing these stackers, ensuring compliance while also meeting the specific needs of their projects.

How does the technic car stacker enhance logistics and warehousing operations?

In logistics and warehousing, the technic car stacker is vital for organizing vehicles in storage facilities. By enabling vertical stacking, businesses can improve inventory management and maximize the use of available space. This is especially beneficial for companies operating in regions with high operational costs, such as Europe and parts of Africa. Buyers should focus on customization options and scalability when sourcing stackers, allowing them to adapt to changing inventory levels and operational requirements.

In what ways does the technic car stacker support educational institutions?

Educational institutions leverage the technic car stacker as a hands-on tool for engineering and design students. It offers a practical means to understand mechanical systems and design principles. By incorporating stackers into their curriculum, schools can foster creativity and practical skills among students, preparing them for future careers in engineering and automotive design. When sourcing stackers for educational purposes, institutions should ensure the availability of instructional materials and support to maximize the learning experience.

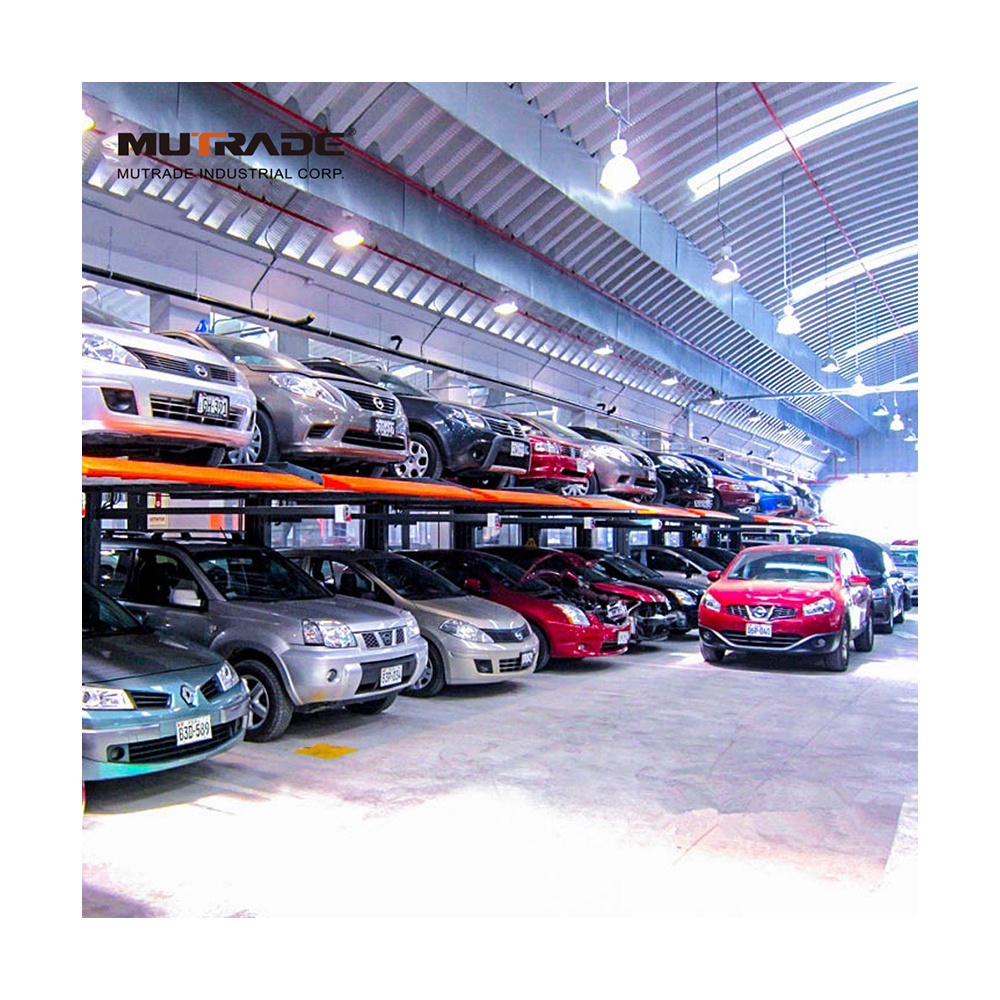

Illustrative image related to technic car stacker

How can event management benefit from the technic car stacker?

Event management companies utilize the technic car stacker to effectively showcase vehicles at exhibitions and trade shows. By creating visually appealing displays, stackers attract attention and enhance branding for participating businesses. Portability and ease of setup are critical factors for event managers when sourcing these stackers, as they often need to be transported between various locations and assembled quickly to meet event schedules.

3 Common User Pain Points for ‘technic car stacker’ & Their Solutions

Scenario 1: Limited Space in Urban Environments

The Problem: Many B2B buyers in urban areas face the challenge of maximizing limited parking space. With increasing vehicle ownership and high demand for parking, businesses must find innovative solutions to utilize vertical space effectively. Traditional parking solutions can be cumbersome and inefficient, leading to wasted space and increased operational costs. Buyers often struggle to identify a car stacker that meets their specific space requirements while providing reliable performance.

The Solution: To address this issue, buyers should consider investing in a modular technic car stacker designed for urban settings. Opt for stackers that can accommodate various vehicle sizes and configurations, allowing flexibility in design. It’s crucial to assess the stacker’s dimensions and ensure it can fit within the allotted space while adhering to local building regulations. Collaborating with manufacturers who offer customizable solutions can also help tailor the stacker to the unique needs of the business. Additionally, conducting a thorough site assessment will help buyers determine the most efficient layout, maximizing the number of vehicles stored without compromising accessibility.

Scenario 2: Maintenance and Downtime Concerns

The Problem: Another pain point for B2B buyers is the concern over maintenance and potential downtime associated with technic car stackers. Businesses rely on these systems for daily operations, and any malfunction can lead to significant disruptions, impacting customer satisfaction and revenue. Buyers often find it challenging to source parts or service providers that can quickly address maintenance needs, leading to extended periods of inoperability.

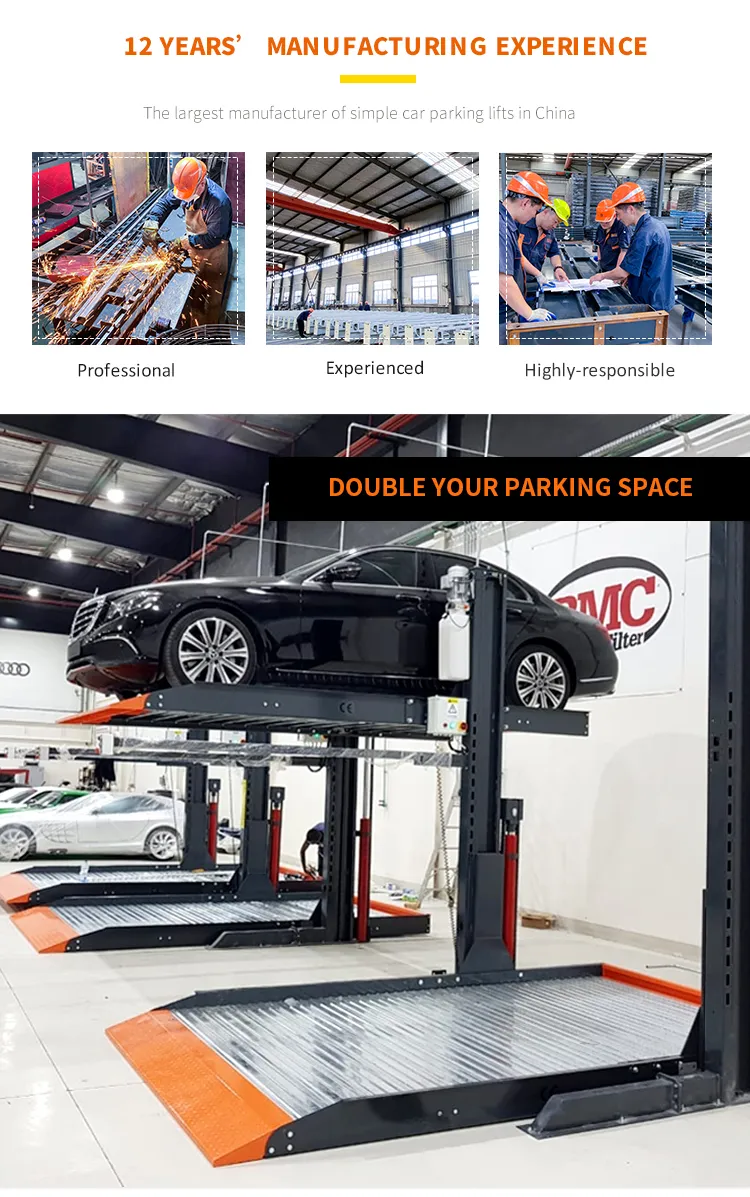

Illustrative image related to technic car stacker

The Solution: To mitigate maintenance issues, buyers should prioritize selecting technic car stackers from reputable manufacturers that offer comprehensive warranties and customer support. It’s advisable to conduct due diligence by reviewing service records and seeking testimonials from existing customers regarding maintenance experiences. Establishing a preventative maintenance schedule is essential; this should include regular inspections and servicing by certified technicians. Furthermore, investing in training for staff on basic troubleshooting and upkeep can empower them to address minor issues before they escalate, ensuring smoother operations and reducing downtime.

Scenario 3: Integration with Existing Systems

The Problem: As businesses grow, they often encounter challenges when integrating new technic car stackers with their existing parking management systems or workflows. Buyers may face compatibility issues, leading to inefficiencies and increased operational complexity. The lack of seamless integration can hinder data collection, reporting, and overall management of parking assets, causing frustration among staff and management alike.

The Solution: To ensure successful integration, buyers should work closely with vendors to choose technic car stackers that come equipped with advanced technology and compatibility options. Before purchasing, conduct a thorough analysis of the existing systems and identify any specific requirements for integration. This could involve consulting IT experts or hiring third-party services specializing in parking management solutions. Additionally, buyers should opt for stackers that support real-time data transfer and reporting capabilities, enhancing overall operational efficiency. Regular training sessions for staff on utilizing the integrated systems effectively will further streamline operations and improve user experience.

Strategic Material Selection Guide for technic car stacker

When selecting materials for technic car stackers, it’s essential to consider various properties and how they align with performance requirements, manufacturing capabilities, and regional compliance standards. This analysis focuses on four common materials: PLA (Polylactic Acid), PETG (Polyethylene Terephthalate Glycol-Modified), ABS (Acrylonitrile Butadiene Styrene), and Aluminum. Each material has distinct characteristics that can influence the functionality and suitability of the car stacker in different environments.

What are the Key Properties of PLA for Technic Car Stackers?

PLA is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. It has a lower melting temperature (around 180-220°C) and is relatively easy to print. PLA is known for its rigidity and good surface finish, making it suitable for detailed designs.

Illustrative image related to technic car stacker

Pros and Cons:

– Advantages: PLA is cost-effective, environmentally friendly, and offers excellent printability. It also provides good dimensional stability.

– Disadvantages: However, it has lower heat resistance and can become brittle over time, especially when exposed to moisture.

Impact on Application:

PLA is best suited for indoor applications where temperature and humidity are controlled. It may not be ideal for environments with high heat or moisture, which could compromise the structural integrity of the car stacker.

Considerations for International Buyers:

For buyers in regions like Africa or South America, the availability of PLA may vary. Compliance with local environmental regulations can also impact its adoption.

How Does PETG Compare for Technic Car Stackers?

PETG is a strong, durable thermoplastic that combines the ease of printing of PLA with the strength and flexibility of ABS. It has a higher temperature resistance (up to 80°C) and is less brittle, making it suitable for functional parts.

Pros and Cons:

– Advantages: PETG is resistant to impact and has good chemical resistance, making it ideal for outdoor use. It is also less prone to warping during printing.

– Disadvantages: The printing process can be more complex, requiring precise settings to avoid stringing.

Illustrative image related to technic car stacker

Impact on Application:

PETG is suitable for applications that require durability and resistance to environmental factors, such as outdoor displays or areas with variable temperatures.

Considerations for International Buyers:

In regions like Europe, compliance with standards such as DIN EN ISO 527 for tensile properties may be necessary. Buyers should also consider local sourcing options for PETG to minimize costs.

What Role Does ABS Play in Technic Car Stackers?

ABS is a widely used thermoplastic known for its toughness and impact resistance. It has a higher melting point (around 210-250°C) and is often used in applications requiring durability.

Illustrative image related to technic car stacker

Pros and Cons:

– Advantages: ABS is very strong and can withstand higher temperatures, making it suitable for heavy-duty applications.

– Disadvantages: It can emit fumes during printing, requiring good ventilation, and may warp if not printed on a heated bed.

Impact on Application:

ABS is ideal for environments where the stacker may experience mechanical stress or higher temperatures, such as in garages or workshops.

Considerations for International Buyers:

Buyers in the Middle East or Africa should ensure compliance with local safety and environmental regulations when using ABS, as well as consider the availability of adequate printing facilities.

How Does Aluminum Enhance Technic Car Stackers?

Aluminum is a lightweight metal known for its strength-to-weight ratio and corrosion resistance. It is often used in structural applications where durability and low weight are critical.

Pros and Cons:

– Advantages: Aluminum is highly durable and can withstand extreme temperatures, making it suitable for both indoor and outdoor applications.

– Disadvantages: The cost of aluminum can be significantly higher than plastics, and the manufacturing process can be more complex.

Illustrative image related to technic car stacker

Impact on Application:

Aluminum is ideal for high-end applications where aesthetics and performance are crucial, such as luxury car stackers in upscale residential or commercial settings.

Considerations for International Buyers:

For buyers in Germany or other European countries, compliance with standards like EN 573 for aluminum alloys is essential. Additionally, the availability of aluminum fabrication services should be assessed.

Summary Table

| Material | Typical Use Case for technic car stacker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Indoor models with detailed designs | Environmentally friendly and easy to print | Brittle and low heat resistance | Low |

| PETG | Outdoor or functional parts | Strong, durable, and chemical resistant | More complex printing process | Medium |

| ABS | Heavy-duty applications in garages | High toughness and temperature resistance | Emits fumes, requires ventilation | Medium |

| Aluminum | High-end, aesthetic applications | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | High |

This guide provides a comprehensive overview of material options for technic car stackers, tailored to the needs of international B2B buyers across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for technic car stacker

What Are the Main Stages of Manufacturing Technic Car Stackers?

The manufacturing process of technic car stackers involves several critical stages that ensure quality and functionality. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Prepared?

The manufacturing of technic car stackers typically begins with the selection of high-quality materials, such as PLA or PETG for 3D-printed models. These materials are chosen for their durability, printability, and suitability for the intended use. In this stage, raw materials are sourced from reputable suppliers and undergo quality checks to ensure they meet specifications. This includes testing for consistency in diameter and density, which are crucial for achieving precise print results.

Once the materials are approved, they are prepared for the next stage. For 3D printing, this involves converting raw filament into suitable formats, ensuring proper storage conditions to avoid moisture absorption, and calibrating printers for optimal performance.

How Are Technic Car Stackers Formed?

The forming stage is where the actual production begins. For technic car stackers, this typically involves advanced 3D printing techniques. The design files, created using CAD software, are sliced to prepare for printing. This process involves determining layer height, infill density, and support structures to optimize strength and aesthetics.

Illustrative image related to technic car stacker

In the case of mechanical stackers, forming might involve traditional manufacturing processes such as metal stamping, CNC machining, or injection molding. These methods allow for high precision in creating the structural components that make up the stacker. Each component is produced according to strict design specifications to ensure compatibility and functionality.

What Does the Assembly Process Entail?

Following forming, the assembly of technic car stackers takes place. This stage can vary significantly based on the complexity of the design. For 3D-printed models, assembly often involves connecting multiple printed parts using adhesives or mechanical fasteners. The assembly process must be executed with precision to ensure that the stacker functions as intended.

For mechanical systems, assembly includes the installation of hydraulic components, motors, and control systems. Every assembly line should have trained personnel who follow detailed assembly instructions to minimize errors and ensure that each stacker meets design specifications.

How Is the Finishing Stage Conducted?

Finishing is the final stage of manufacturing, where the product is prepared for delivery. This includes post-processing steps such as sanding, painting, or applying coatings to enhance durability and aesthetics. For 3D-printed models, this might also involve removing support structures and smoothing surfaces for a polished look.

Quality checks are performed during this stage to ensure that the product meets the required standards. Any defects identified during finishing can lead to rework or scrapping of components, emphasizing the importance of meticulous attention to detail.

Illustrative image related to technic car stacker

What Are the Key Quality Assurance Practices in Technic Car Stacker Manufacturing?

Quality assurance (QA) in the manufacturing of technic car stackers is paramount to ensure that the final products meet international standards and customer expectations. Key QA practices include adherence to international standards, implementation of quality checkpoints, and testing methodologies.

Which International Standards Are Relevant for Quality Assurance?

International standards such as ISO 9001 play a crucial role in maintaining quality throughout the manufacturing process. ISO 9001 outlines a framework for quality management systems, emphasizing continuous improvement and customer satisfaction. Compliance with this standard demonstrates a commitment to quality and can enhance a manufacturer’s credibility in international markets.

In addition to ISO standards, industry-specific certifications such as CE marking for products sold in Europe and API standards for mechanical systems can be critical. These certifications ensure that products meet safety and performance requirements specific to their application, providing additional assurance to buyers.

What Are the Quality Checkpoints Throughout the Manufacturing Process?

Quality control (QC) checkpoints are vital in identifying defects early in the production process. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC checks the quality of components as they are formed and assembled. This includes monitoring the 3D printing process for layer adhesion and structural integrity.

- Final Quality Control (FQC): At this stage, finished products undergo thorough inspections and testing to ensure they meet design specifications and functional requirements.

These checkpoints help to catch defects early, reducing waste and enhancing overall product quality.

What Testing Methods Are Commonly Used for Technic Car Stackers?

Testing methods for technic car stackers vary depending on the design and intended use. Common testing methods include:

Illustrative image related to technic car stacker

- Functional Testing: Ensuring that the stacker operates correctly under load, including testing hydraulic systems for leaks and operational efficiency.

- Durability Testing: Subjecting the stacker to stress tests to evaluate its structural integrity over time and under varying conditions.

- Safety Testing: Ensuring that the stacker complies with safety standards, which may involve testing for stability and load-bearing capabilities.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is essential to ensure product reliability. Here are actionable steps:

-

Request Documentation: Buyers should ask for quality management system documentation, including ISO certifications and internal QC procedures.

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. This could be done through on-site visits or by hiring third-party inspection services.

-

Review Quality Reports: Suppliers should provide comprehensive quality reports that detail findings from IQC, IPQC, and FQC stages. This transparency can build trust and assure buyers of the product quality.

-

Third-Party Inspections: Engaging third-party inspection companies to conduct random checks can further validate the supplier’s claims and ensure that the stackers meet international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing technic car stackers. Understanding the regulatory requirements of different regions, such as CE compliance in Europe and local certifications in Africa or South America, is crucial. Additionally, considering factors like language barriers, cultural differences in business practices, and local market conditions can impact the effectiveness of QC measures.

By staying informed and proactive in quality assurance practices, B2B buyers can ensure they partner with reliable manufacturers, ultimately leading to successful business outcomes and satisfied end-users.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘technic car stacker’

Introduction

Navigating the procurement of a technic car stacker requires a structured approach to ensure that you select the right model for your needs. This checklist will guide you through essential steps, from defining your specifications to evaluating suppliers, ensuring a seamless sourcing experience tailored to your operational requirements.

Illustrative image related to technic car stacker

Step 1: Define Your Technical Specifications

Clearly outline your needs regarding the technic car stacker. Consider factors such as the dimensions of the vehicles, weight capacity, and the intended use (e.g., display vs. storage).

– Vehicle Specifications: Make sure the stacker can accommodate the size and weight of the vehicles you plan to store.

– Functionality: Decide if you need features like adjustable heights or modular designs for flexibility.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in car stacking technology. Understanding current market dynamics helps you identify innovative solutions that can enhance efficiency.

– Technological Advancements: Look for stackers that utilize advanced hydraulic systems for smoother operation and durability.

– Sustainability: Consider eco-friendly options that align with your corporate social responsibility goals.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from businesses in similar industries or regions.

– Reputation: Assess online reviews and testimonials to gauge supplier reliability.

– Experience: Prefer suppliers with extensive experience in car stacking systems, as they are more likely to understand your specific needs.

Step 4: Verify Certifications and Compliance

Ensure that suppliers have the necessary certifications and comply with local and international standards for safety and quality.

– Safety Standards: Check if the stacker meets relevant safety regulations in your region.

– Quality Assurance: Look for ISO certifications or other quality management standards that indicate a commitment to excellence.

Step 5: Request Prototypes or Samples

If possible, ask suppliers for prototypes or samples of the technic car stacker. This step allows you to assess the quality and functionality before committing to a bulk order.

– Testing: Evaluate how the prototype fits your requirements in terms of space, usability, and design.

– Feedback: Involve your team in the testing process to gather diverse insights.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms. Consider factors beyond just price, such as warranty, maintenance support, and delivery timelines.

– Comprehensive Packages: Ensure that the pricing includes installation and any necessary training.

– Long-term Relationships: Discuss potential for future collaborations or discounts for bulk purchases.

Step 7: Finalize the Purchase Agreement

Carefully review and finalize the purchase agreement to avoid misunderstandings. Ensure that all terms, including delivery schedules and payment conditions, are clearly outlined.

– Documentation: Keep a record of all communications and agreements for future reference.

– Contingencies: Discuss what happens in case of delays or defects in the product to protect your investment.

By following this checklist, you can approach the procurement of a technic car stacker with confidence, ensuring that you make an informed decision that meets your operational needs.

Comprehensive Cost and Pricing Analysis for technic car stacker Sourcing

What Are the Key Cost Components in Technic Car Stacker Sourcing?

When sourcing technic car stackers, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences pricing. Common materials for technic car stackers include PLA and PETG plastics for 3D-printed models, as well as steel or aluminum for mechanical systems. Higher-quality materials often command a premium but provide durability and better performance.

-

Labor: Labor costs can vary widely depending on the region and the complexity of the assembly process. For instance, labor costs in Europe may be higher than those in Africa or South America, impacting the overall pricing strategy.

-

Manufacturing Overhead: This includes costs related to production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these costs, but they also depend on the scale of production.

-

Tooling: Custom tooling can be a significant upfront investment, especially for unique designs or specifications. Buyers should consider whether the supplier has existing tooling or if new tools will need to be created, which can add to initial costs.

-

Quality Control (QC): Ensuring that the stackers meet quality standards requires investment in QC processes. This includes inspections and testing to verify that the products meet the required specifications and certifications.

-

Logistics: Transportation costs can vary based on the shipping method, distance, and whether the goods are shipped via air or sea. Import duties and taxes should also be factored into the total logistics cost.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on the competition, market demand, and the buyer’s negotiation skills.

What Factors Influence Pricing for Technic Car Stackers?

Several factors can influence the final pricing of technic car stackers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should evaluate their needs and consider negotiating for better pricing based on volume.

-

Specifications and Customization: Custom features, such as specific dimensions, weight capacities, or design modifications, can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Premium materials and certifications can lead to higher prices but may also enhance product reliability and safety. Buyers should weigh the long-term benefits against initial costs.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers with a proven track record may charge higher prices but offer better service and quality assurance.

-

Incoterms: Understanding the shipping terms is crucial for calculating the total cost. Different Incoterms (e.g., FOB, CIF) can affect who bears the shipping costs and risks, influencing the overall price.

What Are the Best Buyer Tips for Sourcing Technic Car Stackers?

To ensure cost-efficiency and value when sourcing technic car stackers, buyers should consider the following tips:

-

Negotiation: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may be willing to offer discounts or better terms to secure bulk purchases.

-

Total Cost of Ownership (TCO): Evaluate the TCO, including initial purchase price, maintenance, and operational costs. Sometimes, a higher upfront cost can lead to lower TCO over the product’s lifespan.

-

Pricing Nuances for International Buyers: For buyers from regions like Africa, South America, or the Middle East, consider currency fluctuations and import tariffs that may affect overall costs. Establishing a good relationship with suppliers can help mitigate these risks.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including their production capabilities, lead times, and customer reviews. This will help ensure that you are choosing a reliable partner.

Disclaimer on Indicative Prices

Please note that pricing for technic car stackers can vary widely based on the factors discussed above. It is advisable to obtain quotes from multiple suppliers and conduct a detailed cost analysis tailored to your specific sourcing needs.

Alternatives Analysis: Comparing technic car stacker With Other Solutions

Understanding Alternatives to the Technic Car Stacker

As businesses seek innovative solutions for efficient vehicle storage, the technic car stacker emerges as a popular choice. However, several alternative methods and technologies can achieve similar objectives, each with distinct advantages and drawbacks. This section compares the technic car stacker with alternative solutions, enabling B2B buyers to make informed decisions based on their specific needs.

| Comparison Aspect | Technic Car Stacker | Mechanical Car Parking System | Automated Car Parking System |

|---|---|---|---|

| Performance | Space-efficient, suitable for small models | High capacity, ideal for multiple vehicles | Extremely efficient, can handle large volumes |

| Cost | Low-cost, DIY-friendly | Moderate to high initial investment | High initial costs, but lower long-term costs |

| Ease of Implementation | Simple assembly, user-friendly | Requires professional installation | Complex setup, requires infrastructure |

| Maintenance | Minimal, mainly cleaning | Regular checks needed, moderate maintenance | Low maintenance, automated systems manage upkeep |

| Best Use Case | Small collections, hobbyists | Commercial spaces, residential complexes | High-density urban environments, large facilities |

In-Depth Analysis of Alternatives

Mechanical Car Parking System

Mechanical car parking systems, such as those offered by Harding Autopark Systems, provide an effective solution for stacking multiple vehicles vertically. These systems can accommodate 2 to 4 vehicles in the footprint of a single parking space, making them ideal for commercial use in urban areas where space is at a premium. The main advantages include high capacity and reliable performance, but they come with moderate to high initial costs. Installation typically requires professional assistance, and regular maintenance is necessary to ensure optimal functionality.

Automated Car Parking System

Automated car parking systems represent the pinnacle of vehicle storage technology. These systems operate without human intervention, utilizing robotics to park and retrieve vehicles efficiently. While they offer unparalleled efficiency and can handle a significant volume of cars, the initial investment is considerably higher than other options. Moreover, the complexity of installation means that these systems are often best suited for large-scale operations in high-density urban areas. The low maintenance requirements post-installation can offset the initial costs over time, making them an attractive option for businesses looking to maximize efficiency.

Making the Right Choice for Your Needs

When considering a vehicle storage solution, it’s crucial for B2B buyers to evaluate their specific requirements, such as the volume of vehicles, available space, and budget constraints. The technic car stacker is an excellent choice for hobbyists and small collections due to its affordability and ease of assembly. In contrast, mechanical and automated car parking systems cater to commercial spaces needing higher capacity and efficiency, albeit at a higher cost and complexity.

Ultimately, the decision should align with the operational goals and financial resources of the business. By thoroughly assessing these alternatives, buyers can select a solution that not only meets their immediate needs but also positions them for future growth in an increasingly competitive market.

Illustrative image related to technic car stacker

Essential Technical Properties and Trade Terminology for technic car stacker

What Are the Key Technical Properties of a Technic Car Stacker?

When considering the purchase of a technic car stacker, understanding its technical specifications is essential for making informed decisions. Here are several critical properties to look for:

-

Material Grade

– Common materials for technic car stackers include PLA and PETG, known for their durability and printability. PLA is biodegradable and easy to work with, while PETG offers higher impact resistance and flexibility. Selecting the right material impacts the stacker’s longevity and performance, particularly in environments with varying temperatures and humidity levels. -

Load Capacity

– The load capacity indicates the maximum weight the stacker can safely support. For example, certain models can accommodate vehicles weighing between 2000 kg to 3600 kg. Understanding load capacity is crucial for ensuring the stacker can handle the intended vehicles without risk of failure, which is especially important for commercial applications. -

Dimensions and Tolerance

– The dimensions refer to the overall size of the stacker, including height, width, and depth, while tolerance reflects the permissible limit of variation in these dimensions. For a technic car stacker designed to hold models approximately 28 cm long, precise measurements ensure a snug fit, preventing damage to both the vehicles and the stacker itself. -

Assembly Configuration

– Many stackers are designed for modular assembly, allowing for adjustments based on specific needs. This feature is important for B2B buyers looking for flexibility in their storage solutions, as it enables customization of the stacker’s height and width. -

Print Settings and Profiles

– Optimal print settings, such as layer height and infill percentage, determine the stacker’s structural integrity. For instance, a layer height of 0.2 mm is often used for balance between detail and print time. Understanding these settings helps buyers ensure they can produce stackers that meet their durability and aesthetic requirements. -

Safety Features

– Look for stackers equipped with safety mechanisms such as overload protection and automatic shut-off systems. These features are vital for preventing accidents and ensuring the safety of operators and vehicles, particularly in high-traffic environments.

What Are Common Trade Terms Related to Technic Car Stackers?

Understanding industry jargon can significantly enhance communication and negotiation in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of technic car stackers, knowing the OEM can help buyers assess quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– The minimum number of units a supplier is willing to sell. This term is crucial for budgeting and inventory management, especially for businesses looking to scale operations or optimize storage solutions. -

RFQ (Request for Quotation)

– A formal request sent to suppliers asking for the price of specific goods or services. Submitting an RFQ for technic car stackers allows buyers to compare pricing and features from multiple vendors, aiding in making cost-effective decisions. -

Incoterms (International Commercial Terms)

– These are standardized trade terms used in international transactions to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms is vital for understanding shipping, insurance, and liability, which can impact total costs and delivery timelines. -

Lead Time

– The period between placing an order and receiving it. For technic car stackers, shorter lead times can be crucial for businesses that need to quickly adapt to changing market demands or project timelines. -

Customization Options

– Refers to the ability to modify standard products to meet specific customer requirements. For technic car stackers, customization may include adjustments in size, color, or additional features, making it essential for buyers to evaluate these options based on their unique needs.

Incorporating these technical specifications and trade terms into your purchasing strategy will not only streamline the acquisition process but also ensure that you select the most appropriate technic car stacker for your operational needs.

Navigating Market Dynamics and Sourcing Trends in the technic car stacker Sector

What Are the Current Market Dynamics in the Technic Car Stacker Sector?

The technic car stacker market is experiencing robust growth, driven by increasing urbanization and the need for efficient space utilization in densely populated areas. Global car production is on an upward trend, with forecasts suggesting that vehicle ownership will reach approximately 1.5 billion by 2024, intensifying the demand for innovative parking solutions. This situation is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where traditional parking infrastructure struggles to keep pace with rising vehicle numbers. For international B2B buyers, particularly those in countries like Nigeria and Germany, the shift towards mechanical and automated parking systems presents a significant opportunity to invest in space-efficient solutions like car stackers.

Emerging trends indicate a growing preference for hydraulic car stackers, which offer advantages such as larger lifting capacities and smoother operations. Buyers are increasingly seeking customizable solutions that can accommodate varying vehicle sizes and weights. Additionally, technological advancements in automation and smart parking systems are shaping the future of the sector, with features such as mobile app controls and integrated monitoring systems becoming more common. As the market evolves, B2B buyers must stay informed about these developments to ensure they select the most appropriate and cost-effective solutions for their unique requirements.

How Can Sustainability and Ethical Sourcing Impact the Technic Car Stacker Market?

Sustainability is becoming a critical factor in the decision-making process for B2B buyers in the technic car stacker market. The environmental impact of manufacturing processes and the materials used in car stackers is under increasing scrutiny. Companies are now more than ever expected to adopt practices that minimize waste and reduce carbon footprints. This trend is particularly relevant for buyers in regions with stringent environmental regulations or those catering to eco-conscious consumers.

Ethical sourcing is equally essential, as it ensures that the materials used in car stackers are obtained responsibly. B2B buyers should prioritize suppliers who demonstrate transparency in their supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability. Additionally, opting for ‘green’ materials, such as recycled plastics or sustainably sourced metals, can significantly enhance a company’s brand image and appeal to environmentally aware customers.

What Is the Evolution of the Technic Car Stacker Sector?

The evolution of the technic car stacker sector can be traced back to the early developments in mechanical engineering and automation. Initially, car stackers were rudimentary devices designed primarily for industrial applications, focusing on maximizing storage efficiency. As urbanization increased and vehicle ownership surged, the demand for more sophisticated solutions grew.

By the late 20th century, advancements in hydraulic technology and automation led to the creation of more versatile and user-friendly car stackers. These innovations enabled parking systems to accommodate a wider variety of vehicles while enhancing safety and reliability. Today, the market is characterized by a diverse range of products that cater to both residential and commercial needs, with ongoing research and development aimed at improving efficiency, reducing costs, and integrating smart technologies.

Illustrative image related to technic car stacker

This trajectory highlights the importance of staying abreast of technological advancements and market trends, ensuring that B2B buyers can make informed decisions that align with their strategic objectives and operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of technic car stacker

-

How do I choose the right technic car stacker for my needs?

When selecting a technic car stacker, consider factors such as the dimensions and weight of the vehicles you plan to store, available space, and the type of operation (manual or automated) that suits your business model. Evaluate the stacker’s lifting capacity, stability, and safety features. It’s also essential to review the manufacturer’s specifications and certifications to ensure compliance with local regulations. Finally, consult with suppliers about customization options to meet specific requirements for your facility. -

What are the common customization options available for technic car stackers?

Customization options for technic car stackers can include adjustments in height, load capacity, and platform size to accommodate different vehicle types. Some manufacturers offer tailored designs for unique spaces or specific operational needs, such as integrating safety features or enhancing loading/unloading efficiency. Additionally, you may request modifications for color, branding, and additional features like automated controls or remote monitoring systems. Engaging with your supplier early in the design process can ensure that your needs are met. -

What are the typical minimum order quantities (MOQs) for technic car stackers?

Minimum order quantities (MOQs) for technic car stackers vary by supplier and product type. Generally, MOQs can range from one unit for standard models to several units for customized options. It’s advisable to discuss your requirements directly with the supplier, as some may offer flexibility in MOQs depending on your business’s specific needs and potential for future orders. This dialogue can also help establish a long-term relationship with the supplier. -

What payment terms should I expect when purchasing technic car stackers?

Payment terms for technic car stackers typically vary by supplier and may include options such as advance payment, a deposit with the balance upon delivery, or payment upon receipt. Some suppliers may offer financing options or payment plans for larger orders. It’s crucial to clarify these terms upfront, including any potential for discounts on bulk purchases or loyalty programs. Always ensure you have a written agreement that outlines payment schedules to avoid any misunderstandings. -

How can I ensure quality assurance when sourcing technic car stackers?

To ensure quality assurance, select suppliers that have established quality control processes and industry certifications, such as ISO standards. Request samples or references from previous clients to evaluate the stacker’s performance and reliability. Additionally, consider arranging for third-party inspections or audits of the manufacturing facilities if you’re purchasing in bulk. Establishing clear quality expectations in your contract, including warranties and service agreements, will also protect your investment. -

What logistics considerations should I keep in mind when importing technic car stackers?

When importing technic car stackers, consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Work with suppliers who have experience in international shipping to ensure compliance with local laws and efficient delivery. Be mindful of lead times, as production and shipping can vary significantly based on location and logistics providers. It’s also wise to establish a clear communication channel with your freight forwarder to track your shipment and address any issues promptly. -

What are the advantages of using hydraulic car stackers over other types?

Hydraulic car stackers are favored for their ability to lift heavier loads smoothly and efficiently. They typically offer better stability and safety, with overload protection systems that prevent accidents. Additionally, hydraulic systems are generally quieter, making them suitable for residential or noise-sensitive environments. The maintenance requirements for hydraulic stackers are often lower than those for mechanical systems, which can reduce operational costs in the long run. Understanding these advantages can help you make an informed decision based on your operational needs. -

How do I vet suppliers when sourcing technic car stackers internationally?

Vetting suppliers for international purchases involves researching their reputation, customer reviews, and industry experience. Request documentation of their certifications, manufacturing capabilities, and any relevant compliance with international standards. Engage in direct communication to assess their responsiveness and willingness to address your concerns. Additionally, consider visiting their facilities if feasible, or request virtual tours. Establishing a clear understanding of their production processes and after-sales support can help ensure you partner with a reliable supplier.

Top 5 Technic Car Stacker Manufacturers & Suppliers List

1. Hippo – Technic Car Stacker

Domain: makerworld.com

Registered: 2014 (11 years)

Introduction: {“name”:”Technic Car Stacker”,”designer”:”Hippo”,”category”:”Toys & Games > Construction Sets”,”description”:”Designed to stack Technic vehicles, creating a space-saving display that resembles a car stacker or lift. Maximizes vertical space while keeping models easily accessible. Specifically designed for Technic models 28 cm (11 in.) long.”,”tested_models”:[“#42161 – Lamborghini Huracán Tecnica”,…

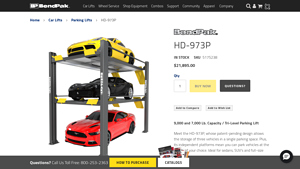

2. BendPak – HD-973P Three-Level Parking Lift

Domain: bendpak.com

Registered: 1997 (28 years)

Introduction: BendPak HD-973P Three-Level Parking Lift – Car Stacker

– Starting Price: $21,895.00

– Capacity: 9,000 lbs (lower deck), 7,000 lbs (upper deck)

– Design: Patent-pending, allows storage of three vehicles in a single parking space

– Platforms: Independent operation for varied vehicle heights and spacing

– Safety Features: Multi-position safety locks (4 inches apart), anti-fall spring-loaded safety ca…

3. Park Plus Inc – Double Stacker Parking Lift

Domain: parkplusinc.com

Registered: 2001 (24 years)

Introduction: {“DP003_DOUBLE_STACKER”:{“description”:”Two (2) level parking lift for storing cars vertically.”,”features”:[“Robust commercial design”,”Height and width flexibility”,”Unique safety customizations”,”No chains or cables”]},”SP100_SUSPENDED_PLATFORM”:{“description”:”Two (2) level parking lift for storing cars vertically.”,”features”:[“Building integration options”,”Independent platform operation”,”F…

4. Harding APS – Mechanical Parking Solutions

Domain: hardingaps.com

Registered: 2023 (2 years)

Introduction: Mechanical Parking Solutions: Parklift 411 (Stacker), Parklift 450 (Pit Stacker), Tri/Quad Lift (Stackers), Wöhr Combilift 542 (Puzzle Lift), Wöhr Combilift 543 (Puzzle Lift with Pit), Wöhr Combilift 551 (Puzzle Lift), Wöhr Multiparker 730 (Fully Automated), Wöhr Levelparker 590 (Fully Automated), Carparx™ Subterranean Residential, Custom Mezzanine Lift, Custom Display Tower, Custom Lab System.

5. LEGO – Technic Tank Steering System

Domain: bricks.stackexchange.com

Registered: 2009 (16 years)

Introduction: LEGO Technic tank steering system; uses two motors to drive each side of the track; allows for forward, backward, and turning movements; simpler than systems with dual differentials; potential issues with driving straight due to motor speed variations; adjustments needed for consistent performance on different surfaces; dual-differential drive can improve straight movement.

Strategic Sourcing Conclusion and Outlook for technic car stacker

The strategic sourcing of technic car stackers presents a vital opportunity for international B2B buyers to optimize vehicle storage solutions across diverse markets. By investing in these innovative stacking systems, businesses can significantly enhance space efficiency, reduce operational costs, and address the growing parking challenges in urban environments. With the global demand for vehicles rising and urban congestion worsening, the need for smart, cost-effective parking solutions has never been more pressing.

As industries in Africa, South America, the Middle East, and Europe evolve, embracing advanced mechanical parking systems will be crucial for maintaining competitiveness. Strategic sourcing not only ensures access to high-quality products but also fosters partnerships with reliable suppliers that understand regional market dynamics and specific needs.

Looking ahead, now is the time for B2B buyers to explore the benefits of technic car stackers. By prioritizing strategic sourcing, you can position your business to thrive in a landscape where efficient parking solutions are essential. Engage with trusted manufacturers and distributors today to discover how technic car stackers can transform your vehicle management strategy and contribute to sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to technic car stacker

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.