The Definitive Guide to Tech Bench: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for tech bench

In the rapidly evolving landscape of technology-intensive environments, sourcing the right tech bench can significantly enhance operational efficiency and worker productivity. Many businesses face the challenge of finding versatile workstations that cater to diverse applications, from engineering and manufacturing to testing and assembly. This guide serves as a comprehensive resource for international B2B buyers seeking to navigate the complexities of the tech bench market.

We delve into various types of tech benches, highlighting their unique features and applications, including ergonomic designs like sit-to-stand options that promote a healthier workspace. Additionally, we provide insights into supplier vetting processes, ensuring that buyers can confidently select reliable partners who align with their operational needs. Cost considerations are also thoroughly examined, offering strategies for optimizing budgets while investing in high-quality workstations.

By equipping buyers from Africa, South America, the Middle East, and Europe—countries such as Brazil and Germany—with actionable insights and best practices, this guide empowers informed purchasing decisions. Whether you are looking to maximize space utilization, enhance employee comfort, or integrate advanced technology, understanding the key aspects of tech benches will help you make strategic investments that drive business success in a competitive global market.

Understanding tech bench Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Tech Bench | Fixed height, robust design, minimal customization | Manufacturing, assembly lines | Pros: Cost-effective, durable. Cons: Limited ergonomics, less adaptability. |

| Sit-to-Stand Tech Bench | Height-adjustable, ergonomic design, promotes movement | Laboratories, tech support centers | Pros: Enhances comfort, reduces fatigue. Cons: Higher cost, requires electrical setup. |

| Modular Tech Bench | Customizable components, scalable configurations | R&D labs, educational institutions | Pros: Flexible design, future-proofing. Cons: Complexity in assembly, potentially higher upfront investment. |

| ESD-Safe Tech Bench | Anti-static materials, specialized for electronics | Electronics manufacturing, repair stations | Pros: Protects sensitive components, enhances safety. Cons: Limited aesthetic options, may be more expensive. |

| Mobile Tech Bench | Portable design, integrated storage, lightweight materials | Fieldwork, maintenance tasks | Pros: Versatile use, easy transport. Cons: Stability issues, less robust than stationary options. |

What Are the Characteristics and Suitability of Standard Tech Benches?

Standard tech benches are characterized by their fixed height and sturdy construction, making them ideal for environments where stability is crucial, such as manufacturing and assembly lines. These benches typically offer minimal customization options, which can streamline the purchasing process for businesses looking for a straightforward solution. When considering a standard tech bench, buyers should evaluate their specific workflow needs and whether the lack of adjustability might impact technician comfort and productivity.

How Do Sit-to-Stand Tech Benches Improve Ergonomics?

Sit-to-stand tech benches feature height-adjustable designs that allow users to alternate between sitting and standing, promoting better ergonomics and reducing fatigue during long hours of work. These benches are particularly well-suited for laboratories and tech support centers, where tasks may require prolonged focus and attention. B2B buyers should consider the initial investment and potential electrical requirements, as these benches can be more expensive than standard options but offer significant long-term health benefits for employees.

What Advantages Do Modular Tech Benches Offer for Future Growth?

Modular tech benches are designed with customizable components that can be reconfigured as business needs evolve. This flexibility makes them suitable for research and development labs and educational institutions that may experience changes in workflow or equipment. While the initial setup may be more complex and costly, the long-term benefits of adaptability and scalability can provide a compelling value proposition for growing businesses.

What Makes ESD-Safe Tech Benches Essential for Electronics?

ESD-safe tech benches are constructed from anti-static materials, making them essential for electronics manufacturing and repair stations where sensitive components are handled. These benches help protect against electrostatic discharge, which can damage electronic devices. Buyers should weigh the benefits of enhanced safety and protection against the potential limitations in aesthetic options and higher costs compared to standard workbenches.

Why Choose Mobile Tech Benches for Versatile Applications?

Mobile tech benches are lightweight and designed for easy transport, making them ideal for fieldwork and maintenance tasks. They often come with integrated storage solutions, enhancing their functionality. However, buyers should consider the trade-off between portability and stability, as mobile options may not provide the same robustness as stationary benches. This type of bench is perfect for businesses that require flexibility and adaptability in various work environments.

Key Industrial Applications of tech bench

| Industry/Sector | Specific Application of tech bench | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Assembly and testing of electronic components | Streamlined workflows and improved product quality | Ergonomic design, modularity, and power management options |

| Aerospace | Custom workstations for aerospace engineering labs | Enhanced productivity and safety in complex tasks | Compliance with industry standards and durability requirements |

| Automotive | Vehicle diagnostics and repair stations | Efficient tool organization and reduced downtime | Customization options for tools and equipment storage |

| Telecommunications | Installation and maintenance of network equipment | Optimized workspace for technicians | Flexibility in configuration and cable management features |

| Research & Development | Prototyping and testing environments | Improved collaboration and innovation capabilities | Space optimization and adaptability for evolving project needs |

How is Tech Bench Used in Electronics Manufacturing?

In electronics manufacturing, tech benches serve as dedicated workstations for the assembly and testing of components. These workbenches facilitate streamlined workflows by providing a well-organized space where technicians can access tools and equipment efficiently. The modular design of tech benches allows for customization based on specific production needs, ensuring that businesses can adapt to changes in technology or product lines. For international buyers, especially in emerging markets, sourcing tech benches that offer ergonomic features and power management solutions can significantly enhance productivity while ensuring compliance with safety standards.

What Role Does Tech Bench Play in Aerospace?

In the aerospace industry, tech benches are crucial for engineering labs where precision and safety are paramount. They provide customized workspaces for tasks such as assembling intricate components and conducting tests. The ability to configure these workstations according to specific project requirements helps improve productivity and reduces the risk of errors. Buyers from regions like Europe and the Middle East should consider tech benches that meet stringent aerospace standards, ensuring durability and safety features that are essential in high-stakes environments.

How is Tech Bench Beneficial for Automotive Applications?

Automotive service centers utilize tech benches as diagnostic and repair stations, where efficient organization of tools is critical. These workstations help reduce downtime by ensuring that all necessary equipment is within reach and properly arranged. The modularity of tech benches allows for tailored setups that can accommodate various vehicle types and repair needs. For international buyers, especially in South America, it’s important to source benches that provide ample storage solutions and can be easily adapted for different automotive technologies.

What Advantages Does Tech Bench Offer in Telecommunications?

In the telecommunications sector, tech benches are employed for the installation and maintenance of network equipment. These workstations optimize the workspace for technicians, allowing for effective cable management and access to tools required for complex installations. The flexibility to reconfigure the bench layout enhances efficiency and minimizes errors during setup. Buyers should prioritize tech benches with integrated power solutions and modular designs to ensure compatibility with evolving telecommunications technologies.

How Does Tech Bench Support Research & Development?

Tech benches are invaluable in research and development environments where prototyping and testing occur. They foster collaboration by providing a dedicated space for teams to work together on innovative projects. The ability to customize the layout and incorporate various storage solutions enables researchers to maintain an organized and efficient workspace. International buyers should look for tech benches that maximize space utilization and offer adaptability, as R&D projects often require quick adjustments based on ongoing findings.

3 Common User Pain Points for ‘tech bench’ & Their Solutions

Scenario 1: Difficulty in Customizing Workstations for Diverse Tasks

The Problem: Many B2B buyers encounter the challenge of needing a tech bench that can adapt to various tasks and projects. In fast-paced environments like engineering, manufacturing, or tech development, workstations must accommodate different tools and equipment. A one-size-fits-all solution often leads to inefficiencies, with employees wasting time searching for tools or rearranging their workspace to meet the demands of specific projects. This lack of customization can hinder productivity and lead to frustration among technicians who rely on their workstations to perform optimally.

The Solution: To address this issue, consider investing in modular tech bench systems that offer a wide range of customizable components. Look for solutions with adjustable shelving, overhead storage options, and integrated organizational tools such as pegboards and magnetic strips. When sourcing your tech benches, consult with manufacturers who provide configuration guides, enabling you to tailor the workstations to your specific needs. Additionally, ensure that the tech benches have features like sit-to-stand capabilities to promote ergonomics and comfort, allowing users to switch between sitting and standing as they work. This flexibility not only enhances productivity but also supports the health and well-being of employees.

Scenario 2: Managing Cable Clutter and Power Distribution

The Problem: In technology-intensive environments, managing cables and ensuring adequate power distribution can become a significant pain point. With numerous devices requiring power, tangled cables can create safety hazards and lead to operational inefficiencies. B2B buyers often struggle with finding tech bench systems that integrate effective cable management solutions, resulting in a cluttered workspace that distracts employees and can even damage sensitive equipment.

The Solution: To resolve cable management issues, look for tech bench systems equipped with built-in cable management features, such as trays, grommets, and channels. When evaluating options, prioritize benches that include power distribution units (PDUs) designed specifically for tech workstations. These PDUs should allow for easy access to power outlets while keeping cords organized and out of the way. Implementing a clear plan for cable organization will not only enhance the safety of the workspace but also streamline operations, enabling technicians to focus on their tasks without the distraction of tangled wires.

Scenario 3: Ensuring Workplace Safety and Compliance

The Problem: Safety is a critical concern in any B2B environment, especially in tech-intensive settings where the risk of injury is heightened due to the use of heavy equipment and tools. Buyers may find it challenging to ensure their workstations comply with safety standards, leading to potential liabilities and decreased employee morale. Many tech benches lack certifications or safety features, putting both the organization and its employees at risk.

The Solution: When sourcing tech benches, prioritize products that meet recognized safety standards, such as UL or CSA certifications. Look for features that enhance safety, like anti-collision technology in sit-to-stand models, which prevents accidents during height adjustments. Additionally, consider implementing regular safety audits and training sessions for employees on the proper use of equipment. Providing clear guidelines on maintaining a safe workspace can foster a culture of safety within the organization. By investing in compliant, safety-focused tech benches, you not only protect your employees but also enhance overall productivity and job satisfaction.

Strategic Material Selection Guide for tech bench

What Are the Key Properties of Common Materials Used in Tech Benches?

When selecting materials for tech benches, it’s essential to consider properties that directly influence performance, durability, and suitability for specific applications. Below are analyses of four common materials used in tech bench construction: laminate, hardwood, phenolic resin, and steel.

How Does Laminate Perform in Tech Bench Applications?

Laminate surfaces are popular for tech benches due to their versatility and ease of maintenance. They typically exhibit good resistance to scratches, stains, and moisture, making them suitable for various environments. However, they may not withstand extreme temperatures or heavy impacts as well as other materials.

Pros: Laminate is cost-effective, lightweight, and available in a wide range of colors and finishes. It is easy to clean and maintain, which is a significant advantage in busy work environments.

Cons: While laminate is durable for everyday use, it can chip or delaminate under excessive pressure or heat. Its lifespan may be shorter compared to more robust materials.

Impact on Application: Laminate is suitable for general tech bench applications but may not be ideal for environments involving high temperatures or heavy machinery.

Considerations for International Buyers: Compliance with local standards such as ASTM for safety and performance is crucial. Buyers from regions like Europe may prefer laminate that meets specific EU regulations regarding formaldehyde emissions.

What Are the Advantages of Using Hardwood for Tech Benches?

Hardwood, such as maple or oak, is often chosen for its strength and aesthetic appeal. It offers excellent durability and can withstand heavy loads, making it suitable for rigorous applications.

Pros: Hardwood is highly durable, resistant to wear and tear, and can be refinished multiple times, extending its lifespan. Its natural beauty also enhances the workspace’s appearance.

Cons: The cost of hardwood can be significantly higher than laminate or other materials. Additionally, it may require more maintenance to prevent warping or cracking.

Impact on Application: Hardwood is ideal for tech benches used in environments where aesthetics are important, such as design studios or high-end laboratories.

Considerations for International Buyers: Buyers in regions with high humidity, such as parts of South America, should consider the wood’s treatment to prevent moisture absorption. Compliance with local forestry regulations is also essential.

Why Choose Phenolic Resin for Tech Bench Surfaces?

Phenolic resin is a synthetic material known for its exceptional chemical resistance and durability. It can withstand high temperatures and is often used in environments where spills are common.

Pros: Phenolic resin is highly resistant to chemicals, heat, and moisture, making it ideal for laboratory and industrial settings. It is also easy to clean and maintain.

Cons: The initial cost of phenolic resin surfaces can be higher than laminate. Additionally, its weight may require more robust support structures.

Impact on Application: This material is particularly suitable for tech benches in laboratories or manufacturing settings where exposure to harsh chemicals is frequent.

Considerations for International Buyers: Buyers should ensure that phenolic resin products comply with local safety standards, such as those set by DIN in Germany. Awareness of local chemical compatibility is also vital.

What Are the Benefits of Steel in Tech Bench Construction?

Steel is a robust material often used for the structural components of tech benches. It provides high strength and durability, making it suitable for heavy-duty applications.

Pros: Steel is incredibly strong, resistant to impact, and can support heavy equipment without warping. It is also recyclable, aligning with sustainability goals.

Cons: Steel can be prone to corrosion if not properly coated or treated, especially in humid environments. It can also be heavier and more expensive than other materials.

Impact on Application: Steel is ideal for tech benches that need to support heavy machinery or equipment, making it a common choice in manufacturing and assembly environments.

Considerations for International Buyers: Buyers should look for steel that meets international standards for strength and corrosion resistance, such as ASTM A36. In regions with high humidity, additional coatings may be necessary to prevent rust.

Summary Table of Material Selection for Tech Benches

| Material | Typical Use Case for tech bench | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Laminate | General tech bench applications | Cost-effective and easy to maintain | Less durable under extreme conditions | Low |

| Hardwood | Aesthetic-focused environments | Highly durable and visually appealing | Higher cost and maintenance required | High |

| Phenolic Resin | Laboratories and industrial settings | Excellent chemical and heat resistance | Higher initial cost | Med |

| Steel | Heavy-duty applications | Strong and durable | Prone to corrosion without treatment | Med |

This guide serves as a comprehensive overview for international B2B buyers considering material selection for tech benches, emphasizing the importance of performance, compliance, and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for tech bench

What Are the Main Stages of the Manufacturing Process for Tech Benches?

The manufacturing process for tech benches, particularly those designed for technology-intensive environments, involves several key stages that ensure the final product meets the required specifications and quality standards. The typical stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting high-quality materials that meet industry standards for durability and functionality. Common materials include heavy-duty laminates, hardwoods, and metals. The materials undergo rigorous inspections to verify their integrity before moving on to the next stage.

-

Forming: In this stage, the prepared materials are shaped into the necessary components of the tech bench. Techniques such as cutting, bending, and welding are employed. Advanced machinery and precision tools are often used to ensure that components are manufactured to exact specifications, which is crucial for the overall stability and ergonomics of the workbench.

-

Assembly: The assembly stage involves integrating the various components into a cohesive unit. This may include the installation of adjustable legs, power distribution units, and organizational accessories. Assembly is typically performed in a clean environment to minimize contamination and ensure that every part is correctly fitted and securely fastened.

-

Finishing: The final stage of manufacturing includes surface treatments, such as painting, coating, or varnishing, to enhance durability and aesthetics. Quality checks are conducted at this stage to ensure that the finish is uniform and meets the required standards.

How is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is vital in ensuring that tech benches meet international standards and customer expectations. Effective QC involves several checkpoints and standards that must be adhered to throughout the manufacturing process.

-

International Standards: Compliance with international standards, such as ISO 9001, ensures that manufacturers follow a systematic approach to quality management. Additionally, industry-specific standards like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the intended use of the tech bench.

-

Quality Checkpoints: Key quality control checkpoints include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to verify their quality before production begins.

– In-Process Quality Control (IPQC): During manufacturing, various checks are performed to ensure that components are being produced according to specifications.

– Final Quality Control (FQC): Once the tech bench is fully assembled, a comprehensive inspection is conducted to verify the overall quality and functionality. -

Common Testing Methods: Common testing methods include load testing for structural integrity, usability testing to ensure ergonomic design, and electrical safety tests for any integrated power systems. These tests help identify any defects or weaknesses in the product.

What Should B2B Buyers Consider When Verifying Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, it is essential to thoroughly verify the quality control measures of potential suppliers. Here are several strategies to ensure supplier reliability:

-

Conducting Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should inquire about the frequency and scope of these audits to ensure that they are comprehensive.

-

Reviewing Quality Reports: Suppliers should provide documentation that outlines their quality control processes, including test results and compliance with international standards. These reports can serve as a benchmark for evaluating supplier reliability.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality control processes. This is particularly important for buyers in regions with stringent import regulations, as it can help mitigate risks associated with subpar products.

What Are the Unique Quality Control Considerations for International B2B Buyers?

When dealing with international suppliers, B2B buyers must navigate specific quality control nuances that can affect their procurement processes:

-

Cultural and Regulatory Differences: Different regions may have varying standards for quality control. Buyers should be aware of local regulations and industry standards to ensure compliance when importing tech benches. Understanding these differences can prevent costly delays and ensure that products meet local market requirements.

-

Supply Chain Transparency: Buyers should look for suppliers who maintain transparency in their supply chain practices. This includes understanding where materials are sourced, how they are processed, and what quality control measures are in place at each stage.

-

Adaptability and Scalability: Suppliers should demonstrate the ability to adapt their quality control processes in response to changing market demands or specific buyer requirements. The flexibility to scale production while maintaining quality is crucial for B2B buyers looking to grow their operations.

Conclusion

In summary, the manufacturing processes and quality assurance for tech benches are critical components that B2B buyers must thoroughly understand. By focusing on the main stages of manufacturing, implementing effective quality control measures, and considering unique factors relevant to international procurement, buyers can make informed decisions that enhance their operational efficiency and product reliability. Prioritizing these aspects not only safeguards investments but also helps build long-term partnerships with trusted suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tech bench’

To effectively procure a tech bench that meets your organizational needs, it’s essential to follow a structured approach. This guide outlines a step-by-step checklist that will help B2B buyers navigate the complexities of sourcing tech benches, ensuring optimal functionality and value for your investment.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in the sourcing process. Consider factors such as the type of equipment to be used, workspace dimensions, and ergonomic needs. This will help you narrow down options that align with your operational goals and employee comfort.

- Assess Equipment Needs: Identify the tools and technology that will be used on the bench.

- Evaluate Ergonomics: Determine height-adjustable features to promote technician comfort and productivity.

Step 2: Research Available Options

Explore various tech bench systems available in the market. Look for modular designs that can be customized to meet specific needs, as well as options that offer scalability for future growth. Understanding the variety of configurations will empower you to make informed decisions that best suit your requirements.

- Check for Modularity: Ensure the bench can be reconfigured as your needs change.

- Consider Accessory Options: Look for additional features like storage solutions and cable management systems.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s crucial to thoroughly vet suppliers. Request company profiles, case studies, and references from buyers in a similar industry or region. This due diligence ensures that you partner with a reliable provider capable of delivering quality products and services.

- Ask for Testimonials: Reach out to previous clients to understand their experience.

- Review Certifications: Verify that the supplier meets relevant industry standards and certifications.

Step 4: Request Quotes and Compare Prices

Gather quotes from multiple suppliers to understand the price range for the tech benches that meet your specifications. Comparing prices is essential to ensure you’re getting the best value for your investment, but be cautious of extremely low bids that may indicate compromised quality.

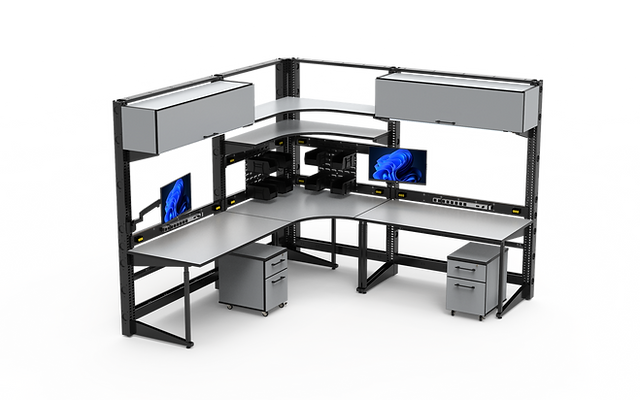

Illustrative image related to tech bench

- Request Detailed Quotes: Ensure all specifications and potential additional costs are included.

- Consider Total Cost of Ownership: Factor in warranties, maintenance, and potential upgrades.

Step 5: Inspect Product Quality and Safety Features

Before finalizing your purchase, ensure that the tech benches adhere to safety standards and quality benchmarks. Look for features such as weight capacity, stability, and ergonomic certifications, which are essential for protecting your workforce and equipment.

- Verify Safety Certifications: Look for compliance with industry standards such as UL or CSA.

- Assess Material Durability: Choose materials that withstand the demands of your specific environment.

Step 6: Plan for Installation and Training

Once you’ve selected a tech bench, consider the logistics of installation and whether training will be required for your staff. Proper installation ensures optimal functionality, while training helps staff utilize the bench effectively, maximizing productivity.

- Coordinate Installation Services: Confirm if the supplier provides installation and setup support.

- Arrange Staff Training: Ensure employees are trained on proper usage and maintenance of the tech bench.

Step 7: Establish a Maintenance Plan

Lastly, develop a maintenance plan to ensure the longevity of your tech bench. Regular upkeep not only prolongs the life of the equipment but also prevents potential disruptions to your operations.

- Schedule Regular Inspections: Create a timeline for routine checks and maintenance tasks.

- Document Maintenance Procedures: Keep a record of maintenance activities for compliance and reference.

By following this checklist, B2B buyers can streamline the procurement process for tech benches, ensuring that they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for tech bench Sourcing

Understanding the cost structure and pricing dynamics of tech bench sourcing is crucial for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, pricing influencers, and offers practical tips for buyers to optimize their sourcing strategies.

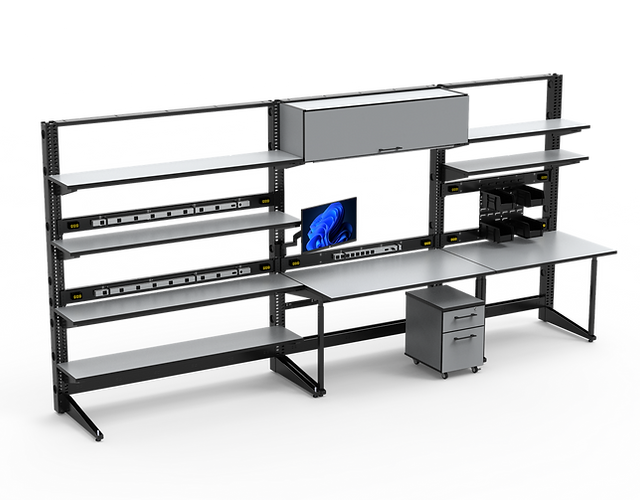

Illustrative image related to tech bench

What are the Key Cost Components in Tech Bench Manufacturing?

The cost structure for tech benches can be broken down into several critical components:

-

Materials: The choice of materials significantly impacts pricing. High-quality laminates, hardwoods, and specialized finishes can increase costs. Additionally, the selection of durable components for ergonomic features, such as sit-to-stand mechanisms, may add to material costs.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and expertise. Skilled labor is often required for assembly and quality control, especially when customizing tech benches to meet specific client needs.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Efficient operations can reduce overhead, leading to more competitive pricing.

-

Tooling: The initial investment in tooling for production can be significant, particularly for custom designs. Buyers should consider these costs when evaluating suppliers.

-

Quality Control (QC): Robust QC processes ensure that the tech benches meet safety and performance standards. Investment in quality assurance can lead to higher upfront costs but ultimately results in lower warranty claims and customer satisfaction.

-

Logistics: Transportation costs, tariffs, and insurance impact the final price. Buyers should assess logistics based on their location and potential shipping partners to optimize costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely based on market positioning and competition.

How Do Price Influencers Affect Tech Bench Sourcing?

Several factors can influence the pricing of tech benches:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to bulk pricing discounts. Buyers should negotiate MOQs to align with their purchasing capabilities.

-

Specifications and Customization: Custom features and specifications can significantly increase costs. Buyers should balance their needs for customization with budget constraints.

-

Materials and Quality Certifications: The use of certified materials (like GREENGUARD) can elevate costs but may be essential for compliance in specific industries. Buyers should weigh the benefits of certifications against their budget.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding shipping terms is vital for calculating total landed costs. Different Incoterms can shift responsibilities and costs between buyers and sellers, impacting overall pricing.

What Are the Best Practices for Negotiating Tech Bench Prices?

B2B buyers can employ several strategies to achieve cost-efficiency:

-

Negotiate Bulk Discounts: If planning to make multiple purchases, negotiating for bulk discounts can significantly reduce costs.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and potential downtime costs associated with the tech bench. A higher upfront cost may yield lower TCO.

-

Research Market Trends: Understanding regional pricing trends can empower buyers during negotiations. Awareness of local market conditions helps in making informed decisions.

-

Build Relationships with Suppliers: Establishing long-term partnerships can lead to better pricing and terms. Suppliers may be more willing to negotiate with buyers who demonstrate loyalty and reliability.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices for tech benches can vary widely, it’s crucial for buyers to understand the intricate cost structure and pricing influencers. By leveraging negotiation strategies and focusing on TCO, B2B buyers can optimize their sourcing processes. Always remember to request detailed quotes and consider all aspects of the procurement process, including logistics and potential tariffs, to ensure a comprehensive understanding of the total investment required.

Alternatives Analysis: Comparing tech bench With Other Solutions

When evaluating workplace solutions for technology-intensive environments, it’s essential to consider alternatives to the Tech Bench workstation system. Each solution brings its unique strengths and weaknesses, catering to different organizational needs. Below is a comparative analysis of Tech Bench against two viable alternatives: Modular Workstations and Fixed Desks.

| Comparison Aspect | ‘Tech Bench’ | Modular Workstations | Fixed Desks |

|---|---|---|---|

| Performance | High, ergonomic design; adjustable height | Versatile; can be configured for various tasks | Generally lower; fixed height limits adaptability |

| Cost | Medium to high; depends on customization | Medium; often more cost-effective due to standardization | Low; basic models are widely available |

| Ease of Implementation | Requires assembly; customizable features may complicate setup | Easy to assemble; many pre-configured options | Simple setup; minimal components involved |

| Maintenance | Moderate; requires occasional checks and adjustments | Low; generally robust with few moving parts | Low; minimal maintenance required |

| Best Use Case | Ideal for tech-heavy environments needing flexibility | Suitable for dynamic workspaces that require adaptability | Best for static work environments with limited need for change |

What Are the Advantages and Disadvantages of Modular Workstations Compared to Tech Bench?

Modular Workstations offer great versatility, allowing businesses to adapt their workspaces to changing needs. They are typically easier to assemble and rearrange, making them ideal for teams that frequently shift roles or tasks. However, they may not provide the same level of ergonomic support or customization as the Tech Bench system, which is specifically designed for technology-intensive tasks. Additionally, while modular systems can be more cost-effective upfront, their longevity and adaptability may not match the durability and ergonomic benefits of Tech Bench.

How Do Fixed Desks Stack Up Against Tech Bench in Terms of Functionality?

Fixed Desks are the most basic option and typically come at a lower price point. They require minimal assembly and are suitable for traditional office environments where tasks do not often change. However, they lack the ergonomic features and adaptability of the Tech Bench system, which can lead to reduced productivity in tech-intensive roles. For organizations that prioritize cost and simplicity over flexibility and ergonomics, fixed desks may suffice, but they may not support the evolving needs of a modern workspace.

Illustrative image related to tech bench

Conclusion: How to Choose the Right Solution for Your Organization’s Needs?

Selecting the right workstation solution depends on your organization’s specific requirements. If your operations are technology-driven and demand flexibility, the Tech Bench offers superior performance and ergonomic benefits. On the other hand, if your workspace requires frequent reconfiguration or a cost-effective solution, Modular Workstations might be more appropriate. For organizations with static roles, Fixed Desks can serve adequately, though they may lack the necessary features for a dynamic tech environment. Ultimately, assess your team’s needs, budget, and the nature of your work to determine the most suitable option.

Essential Technical Properties and Trade Terminology for tech bench

What Are the Key Technical Properties of a Tech Bench?

When selecting a tech bench for your operations, understanding its technical specifications is crucial. Here are some essential properties that should be considered:

1. Material Grade

The material grade of a tech bench significantly influences its durability and functionality. Common materials include steel, aluminum, and laminate. Steel frames provide strength and stability, while laminate surfaces offer ease of cleaning and resistance to wear. Choosing the right material can enhance the workstation’s longevity, which is vital for B2B buyers looking to maximize return on investment.

2. Weight Capacity

Weight capacity is a critical specification that determines how much equipment and tools can be safely stored and used on the tech bench. For instance, a weight capacity of 1,000 lbs, as seen in some sit-to-stand models, is essential for supporting heavy machinery or multiple devices. This property is particularly important for industries that require robust workstations, as exceeding weight limits can lead to accidents and equipment damage.

3. Adjustable Height Mechanism

An adjustable height mechanism, such as the sit-to-stand functionality, allows users to modify the workstation’s height based on their ergonomic needs. This feature promotes comfort and productivity, reducing the risk of workplace injuries. B2B buyers should prioritize this specification to ensure that their workforce can operate efficiently and comfortably.

4. Cable Management Systems

Effective cable management is crucial for safety and organization in technology-intensive environments. Tech benches equipped with integrated cable management systems help minimize clutter and reduce the risk of tripping hazards. This specification is vital for maintaining a clean workspace, which can lead to increased productivity and enhanced safety compliance.

5. Customization Options

The ability to customize a tech bench with various accessories—such as shelving, storage bins, and power distribution units—allows businesses to tailor their workstations to specific needs. Customization enhances usability and can improve workflow efficiency, making it a valuable property for B2B buyers looking for flexible solutions.

What Common Trade Terms Should You Know When Purchasing Tech Benches?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to tech benches:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tech benches, understanding whether your supplier is an OEM can impact the quality and compatibility of components used in your workstations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses looking to purchase tech benches, knowing the MOQ can help in planning budgets and inventory levels, ensuring that you meet supplier requirements while optimizing your purchase volume.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. B2B buyers should utilize RFQs when sourcing tech benches to obtain competitive pricing and ensure that they are making informed purchasing decisions.

Illustrative image related to tech bench

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define responsibilities and risks involved in the transportation and delivery of goods. Familiarity with Incoterms is crucial for international buyers, as they dictate who bears the cost and risk during shipping, helping to avoid misunderstandings in transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is essential for planning and inventory management, especially when sourcing tech benches from international suppliers. This term helps buyers gauge how quickly they can expect to receive their workstations, which is critical for maintaining operational efficiency.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing tech benches for your business needs, ensuring that you select the right solutions for your operational requirements.

Navigating Market Dynamics and Sourcing Trends in the tech bench Sector

What Are the Current Market Dynamics in the Tech Bench Sector?

The tech bench sector is experiencing significant growth fueled by several global drivers, including the rapid expansion of technology-intensive environments and the increasing demand for ergonomic workspaces. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are witnessing a surge in the need for modular and customizable workbench solutions. Key trends include the adoption of sit-to-stand workstations, which not only enhance user comfort but also improve productivity by accommodating diverse working styles. Additionally, advancements in technology are leading to smarter workbench systems integrated with power distribution units (PDUs) and cable management solutions, catering to the sophisticated requirements of modern engineering and manufacturing sectors.

Emerging sourcing trends indicate a growing preference for locally sourced materials and suppliers to mitigate supply chain disruptions, which have been exacerbated by global events. Buyers are increasingly looking for partners who can offer flexibility and rapid response times, particularly in regions where logistics can pose challenges. Furthermore, the emphasis on sustainability is reshaping purchasing decisions, with buyers seeking tech bench solutions that prioritize eco-friendly materials and practices.

How Is Sustainability Shaping the Tech Bench Sourcing Landscape?

Sustainability and ethical sourcing have become paramount in the tech bench sector, driven by a global shift towards environmentally responsible practices. The environmental impact of manufacturing processes, including waste generation and carbon emissions, has prompted businesses to reconsider their supply chains. B2B buyers are now prioritizing vendors who demonstrate a commitment to sustainability through the use of green certifications, such as GREENGUARD or LEED, which assure lower emissions and safer products.

Moreover, the importance of ethical supply chains is gaining traction, particularly in emerging markets where transparency and accountability can be lacking. Buyers are increasingly inclined to partner with companies that adhere to strict ethical standards, ensuring fair labor practices and responsible sourcing of materials. This not only enhances brand reputation but also aligns with the values of environmentally conscious consumers and stakeholders. As such, tech bench manufacturers are investing in sustainable materials, such as recycled metals and low-impact finishes, to meet this rising demand.

What Is the Evolution of the Tech Bench Sector in B2B Context?

The tech bench sector has evolved significantly over the past few decades, transitioning from traditional, static workstations to dynamic, highly customizable solutions. Initially, workbenches were primarily focused on functionality, serving basic needs in manufacturing and engineering environments. However, with the advent of technology and a growing understanding of workplace ergonomics, the sector has seen the introduction of modular designs that allow for flexibility and reconfiguration.

As digitalization and electrification trends gained momentum, tech benches began incorporating advanced features such as integrated power solutions and smart technology, catering to the complex needs of modern workplaces. Today, the tech bench landscape is characterized by a blend of innovation, sustainability, and customization, making it an essential component for businesses looking to enhance productivity and employee well-being in technology-driven environments.

Frequently Asked Questions (FAQs) for B2B Buyers of tech bench

-

How do I choose the right tech bench for my specific needs?

Choosing the right tech bench involves assessing your workspace requirements and the type of tasks to be performed. Consider factors such as size, weight capacity, and customization options. Evaluate the need for features like sit-to-stand functionality, modular designs for future adaptability, and integrated storage solutions. Additionally, consult with suppliers to understand their offerings and seek testimonials from other businesses in similar industries to ensure the selected tech bench enhances productivity and ergonomic comfort. -

What are the key features to look for in a tech bench?

Key features to consider in a tech bench include adjustable height settings for ergonomic flexibility, robust construction for durability, and modular components that allow for customization. Look for integrated power distribution units (PDUs) for efficient power management and cable management systems to reduce clutter. Other valuable features include ample storage options, safety certifications, and the ability to reconfigure the setup as your workspace evolves. -

What is the typical lead time for tech bench orders, especially for international shipping?

Lead times for tech bench orders can vary significantly based on customization and supplier location. Generally, standard models may ship within 4-6 weeks, while customized solutions could take 8-12 weeks. International shipping may introduce additional delays due to customs clearance, so it’s advisable to discuss timelines with your supplier upfront. Planning ahead and allowing for buffer time in your project schedule can help mitigate potential disruptions. -

What are the minimum order quantities (MOQs) for tech benches?

Minimum order quantities for tech benches typically depend on the manufacturer and the specific model. Many suppliers have flexible MOQs, particularly for standard models, which can range from 1 to 10 units. However, customized orders often have higher MOQs due to the production process. It’s essential to communicate your requirements with potential suppliers and negotiate MOQs that align with your business needs. -

How can I ensure the quality of the tech bench before purchasing?

To ensure quality, request samples or visit the supplier’s showroom if possible. Review certifications like UL or CSA that attest to safety and durability standards. Request detailed specifications and warranties that cover defects in materials and workmanship. Additionally, seek references from other clients to gauge their satisfaction with the product’s performance and longevity in their operational settings. -

What payment terms should I expect when purchasing tech benches internationally?

Payment terms can vary widely among suppliers, but typical arrangements include upfront deposits ranging from 30% to 50% with the balance due upon delivery or prior to shipment. Some suppliers may offer flexible payment options such as letters of credit or net 30/60 terms, especially for established relationships. Clarify payment terms in advance to avoid misunderstandings and ensure smooth transactions. -

What logistics considerations should I keep in mind when sourcing tech benches from international suppliers?

When sourcing tech benches internationally, consider shipping methods, costs, and transit times. Confirm whether the supplier handles logistics or if you need to arrange your shipping. Be aware of customs regulations and potential tariffs that may apply to your shipment. Collaborating with a freight forwarder can simplify the logistics process, ensuring compliance and timely delivery to your location. -

How can I customize my tech bench to fit my specific operational needs?

Customization options for tech benches often include adjustable heights, various surface materials, and additional features like integrated storage or power solutions. Discuss your specific operational needs with the supplier to explore available configurations. Many manufacturers offer design consultation services to help you create a tailored solution that enhances functionality and efficiency in your workspace.

Top 4 Tech Bench Manufacturers & Suppliers List

1. Eaton – TechBench Workstation System

Domain: eaton.com

Registered: 1996 (29 years)

Introduction: TechBench is an electronic workstation system designed for technology-intensive environments, combined with TechOrganizer for organizing tools and test equipment. Key features include: modular and scalable configurations, sit-to-stand (STS) options for height adjustment, ergonomic design, and over 500 accessory options. The system is UL 962 & CSA 22.2#68 certified, with a weight capacity of 1,000 …

2. Tech Bench Advisor – Mobile Phone & Electronics Repair

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: Tech Bench Advisor offers mobile phone repair and electronics repair services including data recovery. Their services include appliance repair, frame repair, button & switch repair, charging port repair, digitizer repair, gaming console repair, glass screen repair, headphone jack repair, headphone repair, laptop repair, LCD repair, battery replacement, microphone repair, and water damage repair. T…

3. Sustema – Tech-Bench Heavy-Duty Workbenches

Domain: sustema.com

Registered: 1997 (28 years)

Introduction: Tech-Bench Heavy-Duty Workbenches offer an optimal work environment for IT applications such as computer staging, production units, and IT troubleshooting & repair centers. Features include power bars, data ports, adjustable surfaces, monitor arms, CPU holders, and ESD surfaces. The workbenches are customizable with accessories like CPU holders, phone holders, bins, and power outlets. Built with a…

4. Malwarebytes – TechBench Repair Toolkit

Domain: malwarebytes.com

Registered: 2004 (21 years)

Introduction: Malwarebytes TechBench is a portable computer/PC repair toolkit designed for computer repair shops. It offers a reseller program with two tiers: Basic and Advanced. The Basic tier is free and provides margins of 20-25%, a 15-day trial of the Malwarebytes Toolset, and 5 non-resellable licenses. The Advanced tier costs $349/year and offers margins of 50-72%, access to 18 portable tools, 25 resellabl…

Strategic Sourcing Conclusion and Outlook for tech bench

The integration of strategic sourcing into the procurement of tech bench solutions offers significant advantages for organizations operating in technology-intensive environments. By prioritizing modular and scalable workbench systems like Eaton’s TechBench, businesses can optimize their workspace, enhance productivity, and ensure safety compliance. The ability to customize and adapt workstations to meet evolving operational needs is crucial in today’s fast-paced market, particularly for international buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

Investing in ergonomic solutions, such as sit-to-stand workbenches, not only supports employee well-being but also leads to improved efficiency and performance. As companies navigate the complexities of global sourcing, leveraging the latest in technology and design becomes a key differentiator in achieving competitive advantage.

Looking ahead, international B2B buyers are encouraged to engage with suppliers who understand their unique challenges and can provide tailored solutions. By embracing innovative tech bench systems, organizations can future-proof their operations and foster a more productive and dynamic workplace. Explore your options today and elevate your workspace to meet the demands of tomorrow’s technology landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.