The Definitive Guide to Tapered Head Bolts: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for tapered head bolts

In the ever-evolving landscape of global manufacturing and construction, sourcing high-quality tapered head bolts presents a unique challenge for B2B buyers. These essential fasteners are not only crucial for ensuring structural integrity but also play a vital role in the efficiency of assembly processes. With the diverse range of applications—from agricultural machinery to automotive manufacturing—understanding the nuances of tapered head bolts can significantly impact your operational success. This guide delves deep into the world of tapered head bolts, exploring various types, their specific applications, and critical factors to consider when vetting suppliers.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face distinct challenges in sourcing these components. This guide empowers you with the insights needed to make informed purchasing decisions. We will cover essential topics such as material specifications, pricing strategies, and supplier reputation, enabling you to navigate the complexities of the global market effectively. By understanding the key attributes of tapered head bolts and the factors influencing their cost, you can ensure that your procurement process is not only cost-effective but also aligns with your operational needs. Whether you are looking to enhance product quality or streamline your supply chain, this comprehensive resource is designed to guide you every step of the way.

Understanding tapered head bolts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tapered Head Plow Bolts | Designed with a tapered head for secure fitting | Agricultural machinery, plows | Pros: Strong grip, prevents loosening; Cons: Limited to specific machinery models. |

| Tapered Countersunk Screws | Tapered design allows for flush installation | Electronics, automotive, furniture assembly | Pros: Aesthetic finish, reduces protrusion; Cons: Requires precise drilling for installation. |

| Tapered Socket Head Cap Screws | Hexagonal drive for high torque applications | Industrial machinery, construction | Pros: High strength, easy to drive; Cons: Requires specific tools for installation. |

| Tapered Lag Bolts | Large diameter, designed for wood applications | Construction, decking, heavy-duty fixtures | Pros: Excellent holding power; Cons: May require pre-drilling, not suitable for all materials. |

| Tapered Machine Screws | Fine threads for precision fastening | Machinery, automotive components | Pros: High precision, suitable for tight spaces; Cons: Less effective in softer materials. |

What Are Tapered Head Plow Bolts and Their Applications?

Tapered head plow bolts are specialized fasteners designed with a tapered head that fits snugly into a corresponding tapered hole, ensuring a secure fit. Commonly used in agricultural machinery such as plows, they are essential for mounting components like inner shoes to bars. When purchasing, consider compatibility with specific machinery models, as these bolts often have unique dimensions and requirements. Their strong grip helps prevent loosening during operation, making them ideal for high-vibration environments.

How Do Tapered Countersunk Screws Work?

Tapered countersunk screws feature a tapered head that allows them to sit flush with the surface of the material, providing an aesthetically pleasing finish. These screws are widely used in electronics, automotive applications, and furniture assembly. Buyers should focus on the screw’s diameter and length to ensure compatibility with their projects. While they offer a neat appearance and reduce protrusion, precise drilling is necessary for effective installation, which may require additional tools.

What Are the Benefits of Tapered Socket Head Cap Screws?

Tapered socket head cap screws are designed with a hexagonal drive that allows for high torque applications, making them suitable for industrial machinery and construction projects. Their robust construction provides excellent strength and durability. When sourcing these fasteners, buyers should consider the required tools for installation, as they necessitate a specific hex key. While they are easy to drive and offer high strength, the need for specialized tools may be a drawback for some users.

Where to Use Tapered Lag Bolts?

Tapered lag bolts are characterized by their large diameter and are primarily used in wood applications, such as construction and decking. They provide exceptional holding power, making them ideal for heavy-duty fixtures. Buyers should assess the material being used, as pre-drilling may be necessary to avoid splitting the wood. While their strength is a significant advantage, the requirement for pre-drilling can be a limitation in some applications.

What Are Tapered Machine Screws Suitable For?

Tapered machine screws feature fine threads that allow for precision fastening in tight spaces, making them suitable for various machinery and automotive components. When purchasing, buyers should consider the thread pitch and material compatibility, especially for softer materials where their effectiveness may be diminished. Their high precision is beneficial in applications requiring meticulous assembly, although they may not perform well in softer substrates.

Key Industrial Applications of tapered head bolts

| Industry/Sector | Specific Application of tapered head bolts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Mounting plow components in farming machinery | Enhances durability and performance of agricultural equipment | Ensure compatibility with OEM specifications and consider bulk pricing options. |

| Construction | Securing structural components in heavy machinery | Provides reliable fastening under high-stress conditions | Look for corrosion-resistant materials suitable for outdoor environments. |

| Mining | Fastening conveyor systems and equipment | Increases operational efficiency and reduces maintenance costs | Verify load ratings and resistance to wear in harsh conditions. |

| Automotive | Used in assembly of vehicle parts | Ensures safety and performance in critical automotive applications | Source from suppliers who meet international quality standards. |

| Aerospace | Securing components in aircraft assembly | Critical for safety and reliability in aerospace applications | Compliance with aviation regulations and certifications is essential. |

How Are Tapered Head Bolts Used in Agriculture?

In the agricultural sector, tapered head bolts are crucial for mounting plow components and other machinery parts. These bolts ensure a secure fit, reducing the risk of equipment failure during operation. For international buyers, especially from regions like Africa and South America, sourcing these bolts must consider compatibility with OEM parts to maintain machinery efficiency. Additionally, bulk purchasing can significantly reduce costs, making it a strategic choice for farmers and equipment manufacturers.

What Role Do Tapered Head Bolts Play in Construction?

In construction, tapered head bolts are often utilized to secure structural components in heavy machinery, such as cranes and excavators. Their tapered design allows for a more flush fit, enhancing the aesthetic and structural integrity of the assembly. Buyers in Europe, particularly in countries like Germany, should prioritize sourcing bolts made from corrosion-resistant materials to ensure longevity in various weather conditions. Ensuring compliance with local building codes is also critical to avoid costly rework.

How Are Tapered Head Bolts Essential in Mining Operations?

Mining operations rely heavily on tapered head bolts to fasten conveyor systems and other heavy equipment. These bolts are designed to withstand extreme conditions, ensuring operational efficiency and minimizing downtime due to equipment failure. For businesses in the Middle East and South America, it is vital to verify load ratings and durability against wear and tear, as these factors directly impact productivity and safety in mining environments.

Why Are Tapered Head Bolts Important in the Automotive Industry?

In the automotive sector, tapered head bolts are used extensively in the assembly of various vehicle parts, where they play a critical role in ensuring safety and performance. International buyers must focus on sourcing bolts that meet stringent quality standards to ensure reliability in automotive applications. Additionally, suppliers offering a range of sizes and specifications can better meet the diverse needs of automotive manufacturers, particularly in regions with growing automotive industries like Brazil.

What Are the Aerospace Applications for Tapered Head Bolts?

In aerospace, tapered head bolts are essential for securing components in aircraft assembly, where safety and reliability are paramount. These bolts must comply with strict aviation regulations and certifications, making sourcing from reputable suppliers crucial for international buyers. The aerospace industry also demands high-quality materials that can withstand extreme conditions, so it is important for businesses to consider the technical specifications and certifications of the bolts they procure.

Illustrative image related to tapered head bolts

3 Common User Pain Points for ‘tapered head bolts’ & Their Solutions

Scenario 1: Sourcing Tapered Head Bolts with Specific Specifications

The Problem:

B2B buyers often struggle to find tapered head bolts that meet specific standards and dimensions required for their machinery or equipment. The challenge intensifies when dealing with international suppliers, as differences in manufacturing standards can lead to compatibility issues. For instance, a buyer in Europe might require bolts that conform to DIN standards, while a buyer in South America may need bolts that adhere to ANSI standards. These discrepancies can result in delays, increased costs, and operational inefficiencies.

The Solution:

To effectively source the right tapered head bolts, buyers should start by clearly defining the specifications needed for their application, including diameter, length, thread pitch, and material type. Engaging with manufacturers or suppliers that provide detailed product data sheets can help ensure that all necessary specifications are covered. It’s advisable to request samples before making bulk purchases to verify compatibility. Additionally, leveraging international standards organizations can guide buyers toward reputable manufacturers who comply with the required standards. Utilizing platforms like Alibaba or global trade sites can also help identify suppliers who specialize in the specific types of tapered head bolts needed.

Scenario 2: Installation Challenges Leading to Equipment Downtime

The Problem:

Another common pain point occurs during the installation of tapered head bolts, where improper torque settings or alignment issues can lead to equipment failures. For instance, if bolts are not installed with the correct torque specifications, they may loosen during operation, resulting in costly downtime for repairs. This is particularly critical in heavy machinery and agricultural equipment, where safety and efficiency are paramount.

The Solution:

To mitigate installation challenges, buyers should invest in training for their maintenance teams on the proper installation techniques for tapered head bolts. This includes utilizing torque wrenches to achieve the specified torque settings as per the manufacturer’s guidelines. Providing clear installation instructions, perhaps in the form of a checklist, can enhance the accuracy of the installation process. Additionally, using a thread-locking adhesive can help ensure that bolts remain secure during operation, reducing the risk of loosening. Regular maintenance checks and periodic inspections should also be scheduled to catch any potential issues before they lead to equipment failure.

Illustrative image related to tapered head bolts

Scenario 3: Managing Inventory and Costs of Tapered Head Bolts

The Problem:

B2B buyers often face difficulties in managing inventory levels of tapered head bolts, leading to either excess stock or shortages that disrupt production schedules. The challenge is compounded by fluctuating prices and long lead times from suppliers, which can affect budgeting and project timelines. Buyers may find themselves either over-investing in inventory or scrambling to place urgent orders that incur additional shipping costs.

The Solution:

To optimize inventory management, buyers should adopt a just-in-time (JIT) inventory strategy that aligns with their production schedules. This approach requires close collaboration with suppliers to establish reliable lead times and maintain open lines of communication regarding price changes. Implementing inventory management software can provide real-time data on stock levels and usage rates, allowing for more informed purchasing decisions. Additionally, forming strategic partnerships with key suppliers can help negotiate better pricing and terms, ultimately reducing costs and ensuring a steady supply of tapered head bolts. Regularly reviewing usage trends will also allow businesses to forecast needs more accurately, minimizing both excess inventory and shortages.

Strategic Material Selection Guide for tapered head bolts

What Are the Key Materials for Tapered Head Bolts?

When selecting tapered head bolts for various applications, the choice of material is crucial. Different materials offer unique properties that can significantly affect performance, durability, and compatibility with specific environments. Below, we analyze four common materials used in manufacturing tapered head bolts: carbon steel, stainless steel, alloy steel, and brass.

How Does Carbon Steel Perform in Tapered Head Bolts?

Key Properties: Carbon steel is known for its high tensile strength and hardness. It can withstand considerable pressure and is often treated to enhance its corrosion resistance.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for various applications. However, it is susceptible to corrosion if not properly coated or treated, which can limit its use in harsh environments. Manufacturing complexity is moderate, as carbon steel can be easily machined and formed.

Impact on Application: Carbon steel bolts are suitable for general-purpose applications, especially in construction and automotive sectors. However, they may not be ideal for environments exposed to moisture or corrosive substances.

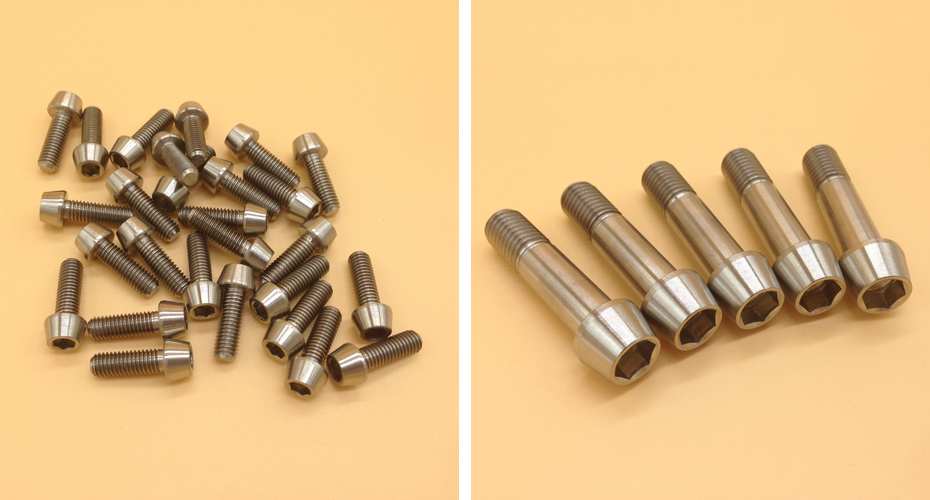

Illustrative image related to tapered head bolts

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or ISO, to avoid issues in quality and safety. In Europe, particularly Germany, adherence to DIN standards is crucial.

What Advantages Does Stainless Steel Offer for Tapered Head Bolts?

Key Properties: Stainless steel boasts excellent corrosion resistance due to the presence of chromium. It also maintains strength at elevated temperatures, making it suitable for high-stress applications.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust, making it ideal for outdoor and marine applications. However, it is generally more expensive than carbon steel and can be more challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel tapered head bolts are commonly used in construction, marine, and food processing industries, where corrosion resistance is paramount.

Considerations for International Buyers: Buyers should be aware of the various grades of stainless steel, such as 304 and 316, which have different corrosion resistance levels. Compliance with international standards is essential, especially in Europe and the Middle East, where quality regulations are stringent.

How Do Alloy Steel Tapered Head Bolts Compare?

Key Properties: Alloy steel is engineered to provide enhanced mechanical properties, including improved strength, toughness, and wear resistance.

Pros & Cons: The main advantage of alloy steel is its ability to withstand extreme conditions, making it suitable for heavy-duty applications. However, it is more expensive than carbon steel and may require specialized manufacturing processes.

Illustrative image related to tapered head bolts

Impact on Application: Alloy steel bolts are often used in high-stress environments, such as in the automotive and aerospace industries. Their enhanced properties make them suitable for applications where safety and reliability are critical.

Considerations for International Buyers: Buyers should consider the specific alloy composition and its implications for performance. Compliance with international standards, such as ASTM or JIS, is vital to ensure product reliability and quality.

Why Choose Brass for Tapered Head Bolts?

Key Properties: Brass is a copper-zinc alloy known for its excellent corrosion resistance and low friction properties.

Pros & Cons: The primary advantage of brass is its resistance to corrosion and its aesthetic appeal, making it suitable for decorative applications. However, it has lower tensile strength compared to steel, which may limit its use in high-stress scenarios.

Impact on Application: Brass tapered head bolts are commonly used in plumbing and electrical applications due to their non-corrosive nature and conductivity.

Considerations for International Buyers: Buyers should be aware of the specific grades of brass and their applications. Compliance with local standards is essential, particularly in regions with strict regulations regarding materials used in plumbing and electrical systems.

Summary Table of Material Selection for Tapered Head Bolts

| Material | Typical Use Case for tapered head bolts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General construction and automotive | Cost-effective | Susceptible to corrosion | Low |

| Stainless Steel | Marine, food processing, outdoor use | Excellent corrosion resistance | Higher cost, machining complexity | High |

| Alloy Steel | Heavy-duty automotive and aerospace | Enhanced strength and toughness | Higher cost, specialized manufacturing | Med |

| Brass | Plumbing and electrical applications | Corrosion resistance, aesthetic appeal | Lower tensile strength | Med |

This guide serves as a comprehensive overview for international B2B buyers, helping them make informed decisions based on material properties, application suitability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for tapered head bolts

What Are the Typical Manufacturing Processes for Tapered Head Bolts?

The manufacturing of tapered head bolts involves several key stages, each crucial for ensuring the final product meets both quality and functionality standards. Understanding these processes can help B2B buyers make informed decisions when sourcing these components.

How Is Material Prepared for Tapered Head Bolts?

Material preparation is the first step in the manufacturing process. Tapered head bolts are typically made from high-strength steel or alloy materials, chosen for their durability and resistance to wear. The raw materials are sourced according to specific standards, such as ASTM or ISO, to ensure uniformity and reliability.

Once the materials are selected, they undergo cutting to the desired lengths, followed by heating. Heat treatment processes such as quenching and tempering may be applied to enhance the material’s mechanical properties. This step is critical, as it affects the tensile strength and hardness of the finished bolt.

What Forming Techniques Are Used in Tapered Head Bolt Production?

After material preparation, the next phase is forming. Tapered head bolts are typically produced using methods such as forging, cold heading, or machining.

- Forging: This is a common technique where heated metal is shaped under pressure. It results in a strong and dense structure, reducing the risk of defects.

- Cold Heading: This method involves shaping the metal at room temperature, which can lead to excellent dimensional accuracy and surface finish.

- Machining: For some applications, particularly those requiring high precision, machining processes like turning and milling are utilized to achieve the final dimensions and features.

Each technique has its advantages, and the choice often depends on the bolt’s intended application and required specifications.

What Finishing Processes Are Essential for Tapered Head Bolts?

Finishing processes are critical for enhancing the appearance, corrosion resistance, and overall performance of tapered head bolts. Common finishing techniques include:

- Surface Treatment: Processes such as plating (zinc or chrome) or coating (powder coating) are applied to improve corrosion resistance.

- Heat Treatment: This is often repeated post-forming to relieve internal stresses and optimize hardness.

- Deburring: This step removes sharp edges and imperfections that could affect assembly or performance.

A well-executed finishing process ensures that the bolts not only meet aesthetic standards but also perform reliably under operational conditions.

What Quality Assurance Measures Are Implemented in Tapered Head Bolt Production?

Quality assurance (QA) is integral to the manufacturing of tapered head bolts. Ensuring that products meet both international standards and customer specifications involves multiple checkpoints throughout the production process.

Which International Standards Are Relevant for Tapered Head Bolts?

Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications may be relevant, such as CE marking for compliance with European safety standards or API certifications for bolts used in oil and gas applications.

These standards help ensure that the products are safe, reliable, and suitable for their intended applications. B2B buyers should verify that their suppliers hold these certifications to ensure quality and compliance.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) checkpoints are implemented throughout the manufacturing process, typically categorized into:

Illustrative image related to tapered head bolts

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During production, random sampling and testing are conducted to monitor the process and identify defects early. This may include dimensional checks and material property tests.

- Final Quality Control (FQC): At this stage, the finished products undergo comprehensive testing, including strength testing, surface integrity checks, and visual inspections to ensure they meet customer specifications.

By maintaining rigorous QC checkpoints, manufacturers can significantly reduce the risk of defects reaching the market.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control measures of suppliers is essential to ensure reliability and performance. Here are several strategies:

- Supplier Audits: Conducting on-site audits can provide insights into a manufacturer’s QC processes and adherence to standards. This is especially important for buyers from regions such as Africa and South America, where supply chain reliability may vary.

- Quality Reports: Requesting detailed quality reports, including testing results and compliance certifications, can help assess a supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s processes and products. This is a valuable step for buyers in the Middle East and Europe, where regulatory compliance is stringent.

What Are the Common Testing Methods for Tapered Head Bolts?

Testing methods play a vital role in ensuring the integrity and performance of tapered head bolts. Common methods include:

- Tensile Testing: This measures the strength of the bolts under tension, ensuring they can withstand required loads.

- Hardness Testing: Various techniques, such as Rockwell or Brinell hardness tests, assess the material’s hardness, which is critical for performance.

- Dimensional Inspection: Calipers and gauges are used to verify that the bolts meet specified dimensions and tolerances.

By understanding these testing methods, buyers can ensure that the bolts they procure meet their stringent operational requirements.

How Do Quality Control and Certification Nuances Affect International Buyers?

International buyers must navigate various nuances in quality control and certification processes. Different regions may have distinct standards, and compliance with local regulations is crucial. For instance, buyers in Germany may emphasize adherence to DIN standards, while those in Brazil might prioritize ABNT compliance.

Furthermore, understanding the implications of certifications such as ISO, CE, and API can help buyers make informed decisions and mitigate risks associated with poor-quality products.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for tapered head bolts is essential for B2B buyers. By focusing on these aspects, buyers can ensure they source high-quality, reliable products suitable for their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tapered head bolts’

In the competitive landscape of B2B procurement, sourcing tapered head bolts requires a methodical approach to ensure quality, compatibility, and cost-effectiveness. This guide serves as a practical checklist for international buyers looking to make informed decisions in their procurement processes.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before starting your search for tapered head bolts. Consider factors such as size, material, thread pitch, and intended application. For example, determine whether you need bolts that can withstand high tensile strength or specific environmental conditions, which can influence the material selection (e.g., stainless steel versus carbon steel).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of tapered head bolts. Utilize online directories, trade shows, and industry-specific forums to compile a list of manufacturers and distributors. Pay attention to their market reputation and product range to ensure they align with your requirements.

- Tip: Look for suppliers that specialize in fasteners and have experience in your industry to increase the likelihood of receiving quality products.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with international standards. Certifications such as ISO 9001 indicate a commitment to quality management systems. This step is essential to ensure that the products meet your safety and performance requirements.

- Sub-bullet: Request documentation that proves adherence to relevant industry standards, such as ASTM or DIN specifications.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the tapered head bolts you intend to purchase. Testing samples allows you to assess the quality, fit, and finish before committing to a larger order. This step is particularly important for critical applications where bolt performance directly impacts safety and functionality.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. Look beyond the unit price; consider factors like minimum order quantities, bulk discounts, and shipping costs. This comprehensive analysis will help you identify the best overall value for your procurement needs.

- Tip: Inquire about lead times and delivery schedules, as these can significantly impact your project timelines.

Step 6: Check References and Reviews

Reach out to other businesses that have previously sourced from your shortlisted suppliers. Customer feedback can provide valuable insights into product quality, service reliability, and supplier responsiveness. This step helps mitigate risks associated with procurement and ensures you choose a trustworthy partner.

Step 7: Finalize the Contract

Once you’ve selected a supplier based on quality, pricing, and references, it’s time to finalize the contract. Ensure that all agreed-upon terms, including specifications, payment conditions, and delivery timelines, are clearly documented. A well-defined contract can protect both parties and facilitate a smoother transaction.

By following these steps, B2B buyers can effectively navigate the sourcing process for tapered head bolts, ensuring they select the right products from reputable suppliers while optimizing costs and operational efficiency.

Comprehensive Cost and Pricing Analysis for tapered head bolts Sourcing

What Are the Key Cost Components in Tapered Head Bolt Sourcing?

When sourcing tapered head bolts, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of raw materials significantly affects the price. Common materials for tapered head bolts include carbon steel and stainless steel, each with varying costs based on global market prices and availability.

-

Labor: Labor costs depend on the region where manufacturing occurs. In areas with higher labor costs, such as parts of Europe, the total cost may be elevated compared to regions with lower labor rates, such as parts of South America or Africa.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, factory maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The initial investment in tooling can be substantial, especially for customized or high-precision tapered head bolts. This cost is often amortized over large production runs, making it critical for buyers to consider minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring the quality of tapered head bolts through rigorous testing and inspection adds to the cost. Certifications like ISO and ASTM can enhance product credibility but may also increase the price.

-

Logistics: Transportation costs can vary widely based on the shipping method, distance, and destination. International buyers must account for customs duties and tariffs, which can impact the total landed cost.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on their business model and market conditions.

How Do Price Influencers Impact Tapered Head Bolt Pricing?

Several factors influence the pricing of tapered head bolts, crucial for buyers to understand:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower unit prices. Buyers should negotiate MOQs to ensure they receive the best possible pricing while meeting their operational needs.

-

Specifications and Customization: Customized bolts that meet specific engineering requirements may incur additional costs. Buyers should weigh the benefits of custom specifications against potential price increases.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can significantly affect pricing. High-quality materials and certifications often justify higher costs due to the enhanced reliability and performance of the products.

-

Supplier Factors: The supplier’s reputation, reliability, and geographical location can also influence pricing. Suppliers with strong track records may charge a premium for their products.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Tapered Head Bolts?

To maximize cost-efficiency when sourcing tapered head bolts, buyers should consider the following strategies:

-

Effective Negotiation: Engage in negotiations with suppliers to secure better pricing or terms. Leverage volume purchases to negotiate discounts, and be open about budget constraints to find mutually beneficial solutions.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the purchase price. Consider factors such as durability, maintenance, and the lifespan of the bolts to assess long-term value.

-

Understand Pricing Nuances for International Sourcing: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences. Market demand, local manufacturing capabilities, and economic conditions can lead to significant price variations.

-

Stay Informed on Market Trends: Keep abreast of global market trends in raw materials and logistics to make informed purchasing decisions. This knowledge can help in anticipating price fluctuations and timing purchases effectively.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and effective sourcing strategies can empower international B2B buyers to make informed decisions when sourcing tapered head bolts. Always remember to check for indicative prices and factor in all associated costs for a clear financial picture.

Alternatives Analysis: Comparing tapered head bolts With Other Solutions

Exploring Alternative Fastening Solutions to Tapered Head Bolts

In the ever-evolving landscape of industrial fastening solutions, businesses often seek alternatives to traditional components like tapered head bolts. Understanding the various options available can help companies optimize performance, reduce costs, and enhance operational efficiency. This analysis compares tapered head bolts against two viable alternatives: flat head socket cap screws and tapered countersunk screws.

| Comparison Aspect | Tapered Head Bolts | Flat Head Socket Cap Screws | Tapered Countersunk Screws |

|---|---|---|---|

| Performance | Excellent load distribution; ideal for plowing applications | Good clamping force; versatile usage | Effective for flush mounting; aesthetic appeal |

| Cost | Generally higher (approx. $39.87 for 5/8-inch x 2-1/2-inch) | Lower cost (approx. $1-$3 each) | Moderate cost (varies by size) |

| Ease of Implementation | Requires specific tools for installation | Standard tools suffice | Standard tools suffice |

| Maintenance | Low maintenance; durable | Moderate; may require periodic checks | Low maintenance; durable |

| Best Use Case | Agricultural machinery, heavy-duty applications | General construction, automotive | Electronics, furniture assembly |

Detailed Breakdown of Alternatives

Flat Head Socket Cap Screws

Flat head socket cap screws are widely recognized for their versatility and ease of use in various applications. They are designed to fit flush with the surface, making them ideal for aesthetic finishes in construction and automotive industries. Their cost-effectiveness is a significant advantage, often priced between $1 and $3 each, making them suitable for projects with budget constraints. However, they may not provide the same load distribution as tapered head bolts, potentially limiting their use in heavy-duty applications.

Tapered Countersunk Screws

Tapered countersunk screws offer a blend of functionality and aesthetic appeal, as they can be installed flush with the surface. This makes them popular in electronics and furniture assembly, where appearance is crucial. They typically have a moderate cost that varies by size, making them an affordable choice for manufacturers looking to balance cost and performance. While they share similar installation requirements with tapered head bolts, they may not withstand the same levels of torque or load, which can be a drawback in demanding applications.

Conclusion: Making the Right Choice for Your Needs

When considering fastening solutions, B2B buyers should evaluate their specific operational requirements. Tapered head bolts excel in heavy-duty scenarios, particularly in agricultural settings, where their load distribution capabilities are essential. Conversely, flat head socket cap screws and tapered countersunk screws provide cost-effective alternatives suitable for general construction and aesthetic applications. Ultimately, the right choice will depend on balancing performance, cost, and the intended use case to ensure optimal efficiency and effectiveness in your projects.

Essential Technical Properties and Trade Terminology for tapered head bolts

Tapered head bolts are essential components in various industrial applications, particularly in agricultural machinery and construction. Understanding their technical properties and industry terminology is crucial for B2B buyers to make informed purchasing decisions.

What Are the Key Technical Properties of Tapered Head Bolts?

-

Material Grade

The material grade of tapered head bolts is vital as it determines their strength and durability. Common materials include carbon steel and stainless steel, with grades often specified according to industry standards (e.g., ASTM or ISO). For B2B buyers, selecting the right material grade ensures that the bolts can withstand specific loads and environmental conditions, reducing the risk of failure. -

Diameter and Length Specifications

Tapered head bolts are available in various diameters and lengths, typically measured in inches or millimeters. For instance, a common size might be 5/8-inch diameter and 2-1/2-inch length. Understanding these specifications is essential for ensuring compatibility with machinery and equipment, as improper sizes can lead to assembly issues and operational inefficiencies. -

Thread Type and Pitch

The thread type (e.g., coarse, fine) and pitch (the distance between threads) are critical for ensuring proper engagement with nuts or tapped holes. This specification affects the bolt’s load-bearing capacity and ease of installation. B2B buyers must pay attention to these details to avoid mismatches that could compromise the integrity of their applications. -

Tolerance Levels

Tolerance refers to the permissible limits of variation in a bolt’s dimensions. It is crucial for ensuring that the bolts fit correctly within their intended assemblies. Tight tolerances are often required in precision applications, while looser tolerances may be acceptable in less critical environments. Understanding tolerance levels helps buyers ensure the right fit and function, thus preventing equipment malfunctions. -

Finish and Coating

The finish or coating on tapered head bolts, such as galvanization or powder coating, plays a significant role in corrosion resistance. This is particularly important for applications exposed to harsh environments. B2B buyers should consider the finish based on the operational conditions to prolong the lifespan of the bolts and reduce maintenance costs.

What Are Common Trade Terms Related to Tapered Head Bolts?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tapered head bolts, OEM specifications are critical for ensuring compatibility with original machinery designs. B2B buyers often seek OEM parts to maintain quality and performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cost efficiency. Understanding MOQ can help buyers negotiate better terms and avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. For tapered head bolts, an RFQ helps buyers gather competitive pricing and terms, enabling them to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. For B2B buyers sourcing tapered head bolts from international suppliers, understanding Incoterms is crucial for managing costs and ensuring timely delivery. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. This term is vital for B2B buyers to plan their operations effectively, especially when dealing with tapered head bolts that may have long manufacturing or shipping times.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the complexities of purchasing tapered head bolts more effectively, ensuring they meet their operational needs while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the tapered head bolts Sector

What Are the Current Market Dynamics and Key Trends in the Tapered Head Bolts Sector?

The global market for tapered head bolts is influenced by several key drivers, including the growth of the construction, automotive, and agricultural sectors. As industries expand, the demand for high-quality fastening solutions has surged, particularly in emerging markets in Africa, South America, and the Middle East. In Europe, countries like Germany and Brazil are investing heavily in infrastructure projects, creating a robust demand for tapered head bolts.

Current sourcing trends indicate a shift towards digital procurement methods, such as online platforms that streamline the purchasing process. Businesses are increasingly leveraging data analytics to forecast demand and manage inventory effectively. Automation and robotics are enhancing manufacturing processes, resulting in higher precision and reduced lead times. Moreover, the rise of Industry 4.0 is pushing manufacturers to adopt smart manufacturing practices, which can improve efficiency and sustainability in the supply chain.

How Is Sustainability and Ethical Sourcing Affecting the Tapered Head Bolts Market?

Sustainability is becoming a critical focus for B2B buyers in the tapered head bolts sector. The environmental impact of manufacturing processes, particularly in terms of energy consumption and waste generation, is under scrutiny. Companies are increasingly expected to adopt ethical sourcing practices, ensuring that materials used in production are obtained responsibly. This trend is particularly relevant for international buyers, who are more likely to partner with suppliers that demonstrate a commitment to sustainability.

Certifications like ISO 14001 (Environmental Management) and adherence to sustainability standards are becoming prerequisites for suppliers. The use of recyclable materials in the production of tapered head bolts, along with innovations in eco-friendly manufacturing techniques, are gaining traction. This not only helps companies reduce their carbon footprint but also enhances their brand reputation in increasingly eco-conscious markets.

What Is the Brief Evolution and History of Tapered Head Bolts in B2B?

The tapered head bolt has evolved significantly since its inception. Originally designed for agricultural applications, these fasteners have found widespread use in various sectors due to their unique design, which allows for a secure fit and efficient load distribution. Historically, the manufacturing processes involved manual labor and limited technology, but advancements in metallurgy and precision engineering have transformed the industry.

Today, tapered head bolts are produced using advanced techniques that ensure high durability and performance. As industries continue to innovate, the design and application of tapered head bolts are expected to evolve further, catering to specific needs across different sectors. This evolution reflects the broader trends in manufacturing and supply chain management, underscoring the importance of adaptability and responsiveness in the B2B landscape.

By understanding these dynamics, international B2B buyers can make informed decisions when sourcing tapered head bolts, ensuring they partner with suppliers that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of tapered head bolts

-

How do I select the right tapered head bolt for my application?

When selecting a tapered head bolt, consider the specific requirements of your application, including the load-bearing capacity, material compatibility, and environmental conditions. Tapered head bolts are often used in agricultural and construction equipment, so ensure the dimensions match your existing components. Additionally, check for industry standards and certifications relevant to your region to guarantee quality and performance. -

What materials are commonly used for tapered head bolts?

Tapered head bolts are typically manufactured from high-strength materials such as carbon steel, stainless steel, or alloy steel. The choice of material depends on the application environment; for example, stainless steel is preferred for corrosive environments, while carbon steel offers excellent tensile strength for heavy-duty applications. Always verify the material specifications with your supplier to ensure compliance with industry standards. -

What customization options are available for tapered head bolts?

Many suppliers offer customization options for tapered head bolts, including size, length, thread type, and material finishes. If you have specific requirements, such as unique dimensions or coatings for corrosion resistance, communicate these needs to your supplier. Customization may involve additional lead time and cost, so plan accordingly to meet your production schedules. -

What are the minimum order quantities (MOQs) for tapered head bolts?

Minimum order quantities for tapered head bolts can vary significantly by supplier and product type. Some manufacturers may have MOQs as low as 100 pieces, while others may require orders of 1,000 or more for customized products. Always inquire about MOQs during your initial discussions to ensure they align with your purchasing needs and budget. -

How can I vet suppliers of tapered head bolts effectively?

Vetting suppliers involves researching their reputation, certifications, and experience in the industry. Look for suppliers with ISO certifications or other relevant quality management standards. Request references from previous clients and evaluate their responsiveness and customer service. Additionally, consider visiting their manufacturing facilities if possible to assess their capabilities firsthand. -

What payment terms should I expect when sourcing tapered head bolts internationally?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common options include upfront payment, partial payment with the balance upon delivery, or letters of credit for larger orders. Always clarify payment terms before placing an order, and ensure they align with your financial processes. Be aware of currency exchange rates and potential transaction fees when dealing internationally. -

What quality assurance measures should I consider for tapered head bolts?

Quality assurance is crucial when sourcing tapered head bolts, especially for critical applications. Ensure the supplier conducts rigorous testing, such as tensile and shear strength tests, and provides certifications for their products. Request samples for inspection before finalizing large orders, and consider third-party inspections for added assurance of quality compliance with your specifications. -

How do logistics and shipping impact the sourcing of tapered head bolts?

Logistics and shipping can significantly affect lead times and costs when sourcing tapered head bolts internationally. Consider factors like shipping methods, customs clearance, and delivery timelines. Collaborate with suppliers who have experience in international shipping and inquire about their logistics partners. Establish clear communication regarding shipping terms and responsibilities to avoid delays and additional charges.

Top 8 Tapered Head Bolts Manufacturers & Suppliers List

1. ProBolt – Tapered Socket Cap Bolts

Domain: probolt-usa.com

Registered: 2009 (16 years)

Introduction: This company, ProBolt – Tapered Socket Cap Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Cutting Components – Taper Head Plow Bolt 5/8-inch x 2-1/2-inch

Domain: cuttingcomponents.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Taper head plow bolt 5/8-inch x 2-1/2-inch (pitman inner shoe to bar)”, “sku”: “458-263”, “price”: “$39.87”, “quantity_required”: “Need (2) to mount inner shoe – C-IH and John Deere”, “nut_part_number”: “458-305”, “additional_part_number”: “458-262”, “replacement_for_oem”: [“K-262”, “9H926H”], “shipping_info”: “In stock”, “shipping_method”: “Common Carrier”}

3. BST – Titanium Tapered Countersunk Head Bolt

Domain: bst-bolt.com

Registered: 2020 (5 years)

Introduction: [{‘name’: ‘Titanium Tapered Countersunk Head Bolt M10 x (1.25mm) x 100mm’, ‘grade’: ‘Titanium Grade 5’, ‘thread_specification’: ‘DIN’, ‘diameter’: ‘M10’, ‘thread_pitch’: ‘1.25mm’, ‘length_under_head’: ‘100mm’, ‘price’: ‘$23.12’, ‘available_colors’: ‘different colors’}, {‘name’: ‘Titanium Tapered Countersunk Head Bolt M10 x (1.50mm) x 100mm’, ‘grade’: ‘Titanium Grade 5’, ‘thread_specification’: ‘DI…

4. Pro-Bolt – Tapered Socket Cap Bolts

Domain: pro-bolt.com

Registered: 1999 (26 years)

Introduction: This company, Pro-Bolt – Tapered Socket Cap Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. eBay – Taper Head Bolts

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Taper Head Bolt listings on eBay include various specifications such as:

– M8-1.25 Metric Hex Bolts, Zinc Grade 8.8, Full Thread, sizes from 10mm to 130mm, priced between $9.81 and $518.31, with free delivery in 2-4 days.

– M30-3.5 Metric Hex Bolts, Zinc Grade 8.8, Full Thread, sizes from 50mm to 200mm, priced between $25.27 and $2,407.06, with free delivery in 2-4 days.

– 3/8-16 x 3-1/2″ Hex Bolt…

6. Better Bolts – Titanium Brake Calipers Bolt

Domain: betterbolts.com

Registered: 2019 (6 years)

Introduction: {“products”: [{“name”: “Brake Calipers Bolt – Mountain – Titanium”, “price”: “$6.40”, “colors_available”: [“Rainbow”, “Oil Slick”, “Gold”, “Black”, “Silver”, “Copper”]}, {“name”: “M6x18mm – Tapered Head – Titanium”, “price”: “$4.60”, “colors_available”: [“Rainbow”, “Oil Slick”, “Gold”, “Black”, “Silver”, “Copper”]}]}

7. Race Tech – Titanium M6x30 Tapered Socket Head Bolt

Domain: racetechtitanium.com

Registered: 2011 (14 years)

Introduction: Titanium M6x30 Tapered Socket Head Bolt (SHCS)

8. Fastener Superstore – Screw Head Styles Guide

Domain: fastenersuperstore.com

Registered: 2004 (21 years)

Introduction: Fastener Guide for Screws – Head Styles: 1. Undercut Binder – Used for electrical applications, allows space for wire connections. 2. Bugle Head – Countersunk style for drywall and wood decking. 3. Button Head – Rounded head for socket driven screws, common with Torx drives. 4. Fillister Head – Smaller diameter, higher profile for deeper slots. 5. Flat Head (82 degrees) – Standard countersunk for …

Strategic Sourcing Conclusion and Outlook for tapered head bolts

In the competitive landscape of industrial fasteners, tapered head bolts represent a critical component for various applications, particularly in sectors such as agriculture, construction, and automotive. The strategic sourcing of these fasteners not only ensures the procurement of high-quality materials but also aids in reducing costs through bulk purchasing and supplier negotiations. By aligning with reliable suppliers, international buyers can secure consistent product availability and access to technical support, which is essential for maintaining operational efficiency.

As markets across Africa, South America, the Middle East, and Europe continue to evolve, the demand for specialized fasteners like tapered head bolts is expected to rise. Buyers should focus on building long-term relationships with manufacturers who can provide customization options, competitive pricing, and responsive service.

Looking ahead, the commitment to strategic sourcing will enable businesses to navigate market fluctuations and enhance their supply chain resilience. Now is the time for international B2B buyers to leverage these insights, optimize their procurement strategies, and ensure they are well-positioned to meet the growing demands of their industries. Engage with suppliers who understand your unique needs and can support your growth in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.