The Definitive Guide to Star Carabiner Acrylic: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for star carabiner acrylic

The global market for star carabiner acrylic presents unique challenges for B2B buyers seeking to source high-quality, aesthetically appealing products that also meet specific functional needs. As international buyers from regions such as Africa, South America, the Middle East, and Europe (including countries like Saudi Arabia and Nigeria) navigate this vibrant market, they often face hurdles in identifying reliable suppliers, understanding pricing structures, and evaluating product applications. This guide serves as a comprehensive resource, detailing various types of star carabiner acrylic, their applications in diverse industries, and the essential criteria for vetting suppliers effectively.

Buyers will gain insights into the production processes, including custom options and design specifications that can enhance product offerings in competitive markets. Additionally, we will explore the cost implications of sourcing these products, allowing businesses to make informed purchasing decisions that align with their budgetary constraints and market expectations.

With a focus on actionable strategies, this guide equips B2B buyers with the knowledge necessary to navigate the complexities of the star carabiner acrylic market. By leveraging this information, businesses can ensure they select the right products that not only meet their operational needs but also resonate with their target customers, ultimately driving sales and fostering growth in their respective markets.

Understanding star carabiner acrylic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Full Bleed Acrylic Carabiner | Double-sided printing, vibrant colors, 70mm wide | Promotional items, event giveaways | Pros: Highly customizable; eye-catching design. Cons: Longer processing and shipping times. |

| Shiny Star Acrylic Carabiner | Glossy finish, available in various pastel colors | Fashion accessories, keychains, decorative items | Pros: Attractive appearance; lightweight. Cons: Susceptible to scratches; limited durability. |

| Functional Star Carabiner | Durable design with keyring holes, practical use | Outdoor gear, camping equipment, safety harnesses | Pros: High functionality; versatile use. Cons: May lack aesthetic appeal for some buyers. |

| Decorative Star Acrylic Carabiner | Unique shapes and designs, used primarily for aesthetics | Gift items, personal accessories | Pros: Distinctive look; great for branding. Cons: Limited practical application. |

| Molded Star Carabiner | Customizable molds for production, shiny finish | Manufacturing, DIY projects | Pros: Tailored to specific needs; cost-effective. Cons: Requires additional processing time. |

What are the Characteristics of Custom Full Bleed Acrylic Carabiners?

Custom Full Bleed Acrylic Carabiners are designed for those seeking vibrant and visually striking products. They feature double-sided printing with a full bleed finish, allowing for seamless designs that capture attention. Typically measuring 70mm wide, these carabiners are ideal for promotional items or event giveaways, making them a popular choice among businesses looking to enhance brand visibility. Buyers should consider the longer processing and shipping times associated with customization when planning their orders.

How Do Shiny Star Acrylic Carabiners Stand Out?

Shiny Star Acrylic Carabiners are characterized by their glossy finish and availability in various pastel colors, appealing to buyers in the fashion and accessory markets. These carabiners serve as stylish keychains or decorative items, making them suitable for retail environments and personal gifting. However, while they are lightweight and visually appealing, they may be prone to scratches, which could affect their longevity in high-use scenarios.

Illustrative image related to star carabiner acrylic

What Makes Functional Star Carabiners a Practical Choice?

Functional Star Carabiners are designed with practicality in mind, featuring durable designs equipped with keyring holes. They are commonly used in outdoor gear, camping equipment, and safety harnesses, catering to businesses focused on rugged applications. Their versatility and high functionality make them a reliable choice for B2B buyers. However, businesses should note that these carabiners may not appeal to those prioritizing aesthetics over utility.

Why Choose Decorative Star Acrylic Carabiners?

Decorative Star Acrylic Carabiners offer unique shapes and designs that primarily serve aesthetic purposes. They are often used as gift items or personal accessories, perfect for brands looking to create memorable and distinctive products. Their ability to enhance branding through unique designs is a significant advantage. However, buyers should be aware that their practical applications may be limited compared to more functional options.

What are the Benefits of Molded Star Carabiners?

Molded Star Carabiners provide a cost-effective solution for manufacturers and DIY enthusiasts. They come with customizable molds that can produce shiny finishes, allowing for tailored designs that meet specific market demands. While they offer the advantage of being adaptable to various requirements, buyers should consider the additional processing time needed to create the final product, which could affect project timelines.

Key Industrial Applications of star carabiner acrylic

| Industry/Sector | Specific Application of star carabiner acrylic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Keychains and gear attachments for camping and hiking | Lightweight, durable, and customizable for branding | Ensure UV resistance and weather durability for outdoor use |

| Promotional Products | Customizable keychains for corporate branding | Enhances brand visibility and customer loyalty | Look for suppliers offering bulk orders and quick turnaround times |

| Fashion Accessories | Decorative elements in bags and apparel | Aesthetic appeal and unique designs | Source from manufacturers who provide diverse design options |

| Event Management | Event badges and lanyards for conferences and festivals | Practical for organization and enhances attendee experience | Verify production timelines and shipping capabilities for international events |

| Pet Products | Leashes and harness attachments for pets | Safe and stylish options for pet owners | Check for non-toxic materials and compliance with safety standards |

How is star carabiner acrylic utilized in outdoor recreation?

In the outdoor recreation industry, star carabiner acrylic is predominantly used for keychains and gear attachments, providing a lightweight and durable option for hikers and campers. These carabiners can be customized with vibrant colors and branding, making them not only functional but also a marketing tool for outdoor gear companies. Buyers in this sector should consider sourcing products that offer UV resistance and weather durability, ensuring they withstand the elements during outdoor activities.

What role does star carabiner acrylic play in promotional products?

Star carabiner acrylic serves as an effective promotional product, often used as customizable keychains that enhance brand visibility. Companies can imprint logos or slogans, creating a practical giveaway that reinforces their brand identity. For B2B buyers in this sector, it is crucial to find suppliers that can accommodate bulk orders and offer rapid production and shipping times, especially for marketing campaigns or events.

Illustrative image related to star carabiner acrylic

How is star carabiner acrylic integrated into fashion accessories?

In the fashion accessories market, star carabiner acrylic is utilized as decorative elements on bags and apparel, adding a unique aesthetic appeal. Their customizable nature allows fashion brands to create distinctive designs that resonate with consumers. Buyers should prioritize sourcing from manufacturers that offer a variety of design options and can accommodate specific color schemes to align with current fashion trends.

What benefits does star carabiner acrylic provide in event management?

Event management companies frequently use star carabiner acrylic for creating event badges and lanyards. These carabiners facilitate organization and provide attendees with a practical way to carry identification and access passes. When sourcing for this application, it is essential to verify production timelines and shipping capabilities to ensure timely delivery for international events, especially in regions like Africa and the Middle East.

How does star carabiner acrylic enhance pet products?

In the pet products industry, star carabiner acrylic is used for leashes and harness attachments, offering both safety and style for pet owners. These carabiners provide a secure way to attach accessories to pet gear while also allowing for customization. Buyers in this sector should ensure that the materials used are non-toxic and comply with safety standards, as pet safety is paramount.

3 Common User Pain Points for ‘star carabiner acrylic’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Acrylic Carabiners

The Problem: B2B buyers often face significant difficulties ensuring the quality of star carabiner acrylic products, especially when sourcing from international suppliers. Variations in material quality, finishes, and manufacturing processes can lead to inconsistencies that affect the final product’s durability and appearance. This can result in increased returns, dissatisfied customers, and potential damage to the buyer’s brand reputation. For example, a buyer might receive products that have scratches, poor color vibrancy, or faulty mechanisms, complicating their inventory management and customer satisfaction efforts.

Illustrative image related to star carabiner acrylic

The Solution: To mitigate quality control challenges, B2B buyers should establish a robust supplier evaluation process that includes requesting samples before placing large orders. This allows for firsthand inspection of product quality, finish, and functionality. Furthermore, it’s beneficial to ask suppliers about their manufacturing processes, quality assurance measures, and any certifications they hold. Buyers can also implement a quality inspection protocol upon receiving shipments, checking for defects and ensuring products meet the specified standards. Establishing long-term relationships with reliable suppliers can also enhance consistency, as trusted vendors are more likely to understand and meet your specific quality expectations over time.

Scenario 2: Managing Shipping Delays and Costs for International Orders

The Problem: International B2B buyers often encounter unexpected shipping delays and high costs when ordering star carabiner acrylic products. This can disrupt inventory flow, lead to stockouts, and affect customer orders, particularly in regions with less reliable logistics infrastructures. For instance, a buyer in Nigeria may face prolonged shipping times from a supplier in Europe, which can lead to missed sales opportunities and increased operational costs.

The Solution: To address these challenges, buyers should consider working with suppliers who offer transparent shipping options, including estimated delivery times and costs upfront. Utilizing a logistics partner that specializes in international shipping can also streamline the process. Additionally, consolidating orders to minimize shipping frequency can help lower overall costs. Buyers should also explore local suppliers or regional distributors who can provide faster delivery times and potentially lower shipping fees. Implementing inventory forecasting tools can assist in better planning for stock levels, allowing businesses to maintain adequate inventory even during shipping delays.

Scenario 3: Customization and Design Limitations

The Problem: B2B buyers often desire customized designs for star carabiner acrylic products to meet specific branding needs. However, they may encounter limitations in the customization options available from suppliers, such as restrictions on color choices, size variations, or engraving capabilities. This can hinder their ability to create unique products that resonate with their target market, leading to a less competitive edge in their offerings.

The Solution: To overcome these customization challenges, buyers should proactively communicate their design needs to suppliers and inquire about their flexibility in customization. Many manufacturers are willing to work on bespoke designs but may require minimum order quantities or longer lead times. Buyers can also explore multiple suppliers to find those that specialize in custom products and have a track record of delivering quality results. Collaborating closely with design teams during the product development phase can also ensure that the final product aligns with branding goals. Utilizing design software or online tools to visualize and refine concepts before production can further streamline the customization process.

Illustrative image related to star carabiner acrylic

Strategic Material Selection Guide for star carabiner acrylic

When selecting materials for star carabiner acrylic products, it’s essential to consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in the production of star carabiners, highlighting their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Acrylic in Star Carabiner Production?

Acrylic, often referred to as PMMA (Polymethyl Methacrylate), is a widely used material for star carabiners due to its excellent optical clarity and lightweight nature. Acrylic has good temperature resistance, typically performing well in environments ranging from -40°C to 80°C. It is resistant to UV light, making it suitable for outdoor applications. However, it is less impact-resistant than polycarbonate, which may be a consideration in high-stress applications.

How Does Polycarbonate Compare as a Material for Star Carabiners?

Polycarbonate is another popular choice for star carabiners. It boasts superior impact resistance compared to acrylic, making it suitable for environments where durability is paramount. Polycarbonate can withstand temperatures from -40°C to 120°C, providing a broader operational range. However, it is generally more expensive than acrylic and can become yellowed or scratched over time if not treated with protective coatings.

What Advantages Does Nylon Offer for Star Carabiner Applications?

Nylon is a synthetic polymer that offers excellent tensile strength and flexibility. It is more resistant to abrasion than both acrylic and polycarbonate, making it ideal for applications requiring high durability. Nylon can operate effectively in temperatures ranging from -40°C to 100°C. However, it is susceptible to UV degradation and may require additional treatments for outdoor use. The cost of nylon is typically moderate, but its manufacturing complexity can increase overall production costs.

What Role Does Metal Play in Star Carabiner Design?

Metal, particularly aluminum or stainless steel, is sometimes used in conjunction with acrylic for added strength and functionality. Metal carabiners can handle higher loads and are less likely to break under stress. They are resistant to corrosion, especially stainless steel, making them suitable for marine or humid environments. However, they are heavier than acrylic and can increase shipping costs. The price point for metal components is generally higher, which may affect the overall cost of the product.

Illustrative image related to star carabiner acrylic

Considerations for International B2B Buyers

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding compliance with local standards is crucial. Materials must meet specific regulations, such as ASTM, DIN, or JIS standards, depending on the destination market. Buyers should also consider the environmental impact of their material choices, as sustainability is becoming increasingly important in global supply chains. Additionally, shipping logistics and costs can vary significantly based on material weight and dimensions, influencing the final pricing strategy.

| Material | Typical Use Case for star carabiner acrylic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Lightweight promotional items | Excellent optical clarity | Less impact-resistant than others | Low |

| Polycarbonate | High-stress outdoor applications | Superior impact resistance | More expensive and prone to yellowing | High |

| Nylon | Durable keychains and accessories | High abrasion resistance | Susceptible to UV degradation | Medium |

| Metal | Heavy-duty applications | High load capacity and corrosion resistance | Heavier and increases shipping costs | High |

This strategic material selection guide provides valuable insights for B2B buyers in understanding the nuances of material properties, advantages, and limitations when sourcing star carabiner acrylic products. By considering these factors, buyers can make informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for star carabiner acrylic

What Are the Main Stages of Manufacturing Star Carabiner Acrylic?

The manufacturing process for star carabiner acrylic involves several key stages that ensure both quality and functionality. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

Illustrative image related to star carabiner acrylic

Material Preparation: What Types of Acrylic Are Used?

The first step in the manufacturing process is the selection and preparation of acrylic materials. High-quality acrylic sheets are preferred for their clarity, strength, and aesthetic appeal. Manufacturers typically source acrylic from reputable suppliers to ensure consistency in quality. The sheets are then cut into specific dimensions, often using laser cutting technology for precision. This stage may also involve the addition of colorants or finishes, depending on the desired final product.

How Are Star Carabiners Formed?

Once the materials are prepared, the next stage is forming the acrylic into the desired shape. This can involve various techniques such as injection molding, which is ideal for producing complex shapes quickly and efficiently. For star-shaped carabiners, specialized molds are created to ensure that each piece maintains the intended design. The forming process must be closely monitored to avoid defects that could impact the product’s functionality.

What Steps Are Involved in Assembly?

After forming, the individual components of the star carabiner are assembled. This may involve attaching keyring holes or other accessories that enhance usability. Depending on the design, assembly can be a manual or automated process. Quality control checkpoints are critical at this stage to ensure that all components fit correctly and that the assembly meets design specifications.

How Is the Finishing Process Executed?

The finishing stage is crucial for achieving the final look and feel of the star carabiner. This can involve polishing, coating, or printing designs directly onto the acrylic surface. Techniques like UV printing may be used for vibrant, long-lasting colors. Additionally, a thorough inspection is performed to identify any surface imperfections or inconsistencies in color, ensuring that only products that meet quality standards are packaged for shipping.

What Quality Control Measures Are Essential for Star Carabiner Acrylic?

Quality assurance in manufacturing is vital for maintaining product integrity and meeting international standards. B2B buyers should be aware of the quality control measures that reputable manufacturers implement.

Which International Standards Should Buyers Consider?

Manufacturers of star carabiner acrylic often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a manufacturer’s commitment to continuous improvement and customer satisfaction. Additionally, for products sold in specific markets, certifications such as CE marking (for European markets) or API standards (for specific industries) may be relevant.

What Are the Key Quality Control Checkpoints?

Quality control typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken to monitor the production process. This helps in identifying any deviations from quality standards early in the process.

-

Final Quality Control (FQC): After assembly and finishing, a final inspection is conducted to ensure that the finished product meets all quality requirements before packaging and shipping.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control measures of potential suppliers:

-

Requesting Documentation: Buyers should ask for quality assurance documentation, including certificates of compliance with international standards.

-

Conducting Audits: On-site audits allow buyers to observe the manufacturing process and quality control measures firsthand. This can also establish a relationship of trust between buyer and supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

What Are the Common Testing Methods for Star Carabiner Acrylic?

Testing methods play a crucial role in ensuring that star carabiners meet safety and functionality standards. Here are some common testing methods that manufacturers may employ:

-

Mechanical Testing: This includes tensile strength tests to assess the material’s durability and load-bearing capacity. Such tests ensure that the carabiner can withstand the intended weight without failure.

-

Visual Inspection: A thorough visual inspection is performed to identify any cosmetic defects, such as scratches or uneven finishes, which could affect the product’s appeal.

-

Functional Testing: This involves testing the carabiner’s locking mechanism and overall usability to ensure it operates smoothly under various conditions.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing star carabiner acrylic from international suppliers, B2B buyers should consider several nuances:

-

Customs and Import Regulations: Different countries have varying regulations regarding imported goods. Buyers should be aware of customs duties and taxes that may apply.

-

Supplier Reputation: Researching the supplier’s reputation within the industry can provide insights into their reliability and product quality. Online reviews and industry certifications can be helpful.

-

Communication and Support: Clear communication regarding quality expectations and support for any issues that arise post-purchase is essential for maintaining a good supplier relationship.

By understanding the manufacturing processes and quality assurance measures involved in producing star carabiner acrylic, B2B buyers can make informed decisions and ensure they are sourcing high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘star carabiner acrylic’

This guide provides a structured approach for B2B buyers looking to source star carabiner acrylic products effectively. By following this checklist, buyers can ensure they are making informed decisions, minimizing risks, and securing quality products that meet their specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes dimensions, weight capacity, and design specifications of the star carabiner acrylic. Understanding these parameters helps streamline the sourcing process and ensures that potential suppliers can meet your needs.

- Considerations: Think about customization options, such as color, printing, and finish. Identify the intended use—whether for promotional items, keychains, or functional gear—as this will influence your specifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in acrylic products. Focus on those with a proven track record in the industry and positive customer reviews.

- Where to Look: Utilize online marketplaces, trade directories, and industry-specific forums. Pay attention to suppliers who demonstrate experience in your target markets, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Credentials

Before proceeding with any orders, vet your shortlisted suppliers. Request documentation such as business licenses, certifications, and quality assurance processes.

- Why It Matters: Validating supplier credentials protects you from potential risks associated with subpar products. Ensure that suppliers can provide compliance with international standards relevant to your industry.

Step 4: Request Samples

Always request samples of the star carabiner acrylic products before placing a bulk order. This step is crucial for assessing the quality, design, and durability of the products.

- What to Look For: Examine the finish, color vibrancy, and overall craftsmanship. Ensure that the sample meets your specifications and expectations. Take note of any imperfections, as they could indicate quality control issues.

Step 5: Negotiate Terms and Conditions

Once satisfied with a supplier, initiate discussions on pricing, payment terms, and delivery schedules. Clearly outline your expectations regarding order quantities and lead times.

- Important Aspects: Be aware of shipping costs, potential customs duties, and return policies. Establishing clear terms upfront can prevent misunderstandings and ensure a smoother transaction.

Step 6: Plan for Quality Control

Implement a quality control process to monitor the production and delivery of your star carabiner acrylic orders. This can include periodic inspections and establishing quality benchmarks.

- Why This Is Essential: Quality control helps to ensure that the products you receive consistently meet your standards and reduces the likelihood of defects that could affect your business reputation.

Step 7: Build a Long-Term Relationship

After a successful transaction, consider establishing a long-term partnership with your supplier. Consistent communication and feedback can lead to better pricing and improved service in the future.

- Benefits of Relationships: A strong supplier relationship can enhance your supply chain efficiency and provide access to new product innovations and customization options that may benefit your business.

By following this checklist, B2B buyers can confidently navigate the sourcing process for star carabiner acrylic products, ensuring they make informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for star carabiner acrylic Sourcing

What Are the Key Cost Components for Sourcing Star Carabiner Acrylic?

When sourcing star carabiner acrylic, understanding the cost structure is crucial for B2B buyers to make informed purchasing decisions. The primary components of cost include:

-

Materials: The quality and type of acrylic used significantly influence the overall cost. Higher-grade acrylic may come at a premium but will offer better durability and aesthetics, which can be vital for branding.

-

Labor: Labor costs vary depending on the region of production. In countries with lower labor costs, the overall price of the carabiners might be more competitive. However, this can also impact the quality of workmanship.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities, equipment maintenance, and administrative expenses. Efficient production processes can help keep these costs down.

-

Tooling: The initial setup costs for molds and cutting tools can be significant, especially for customized designs. Buyers should consider these costs when evaluating suppliers, particularly if they require unique designs or specifications.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to costs but is essential for maintaining brand reputation. Buyers should inquire about the QC measures employed by suppliers.

-

Logistics: Shipping costs can vary widely based on distance, shipping methods, and the volume of the order. For international buyers, understanding Incoterms and choosing the right shipping options can mitigate unexpected expenses.

-

Margin: Suppliers will add their markup to cover costs and ensure profitability. Understanding the typical margins in the acrylic carabiner market can help buyers assess whether they are getting a fair price.

What Influences the Pricing of Star Carabiner Acrylic?

Several factors can influence the pricing of star carabiner acrylic:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often result in lower per-unit costs. Buyers should negotiate MOQs to ensure they are purchasing at a price point that meets their budget.

-

Specifications and Customization: Custom designs, such as unique shapes or prints, can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., safety standards) can lead to increased costs but may also justify a higher price point due to enhanced durability and compliance.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers with a track record of quality may charge more but can offer peace of mind.

-

Incoterms: Understanding Incoterms is vital for international transactions. Different terms can affect the total cost by specifying who is responsible for shipping, insurance, and tariffs.

How Can Buyers Negotiate for Better Prices on Star Carabiner Acrylic?

B2B buyers can employ several strategies to negotiate better prices:

-

Research and Comparison: Conduct thorough market research to compare prices from multiple suppliers. This not only provides leverage in negotiations but also helps identify the best value.

-

Volume Discounts: Consider consolidating orders to meet higher MOQs for bulk discounts. This can significantly reduce the per-unit cost and improve overall profitability.

-

Long-term Relationships: Building a long-term relationship with suppliers can lead to better pricing and service terms. Regular orders can justify more favorable pricing.

-

Transparent Communication: Clearly communicate your needs and expectations. Suppliers appreciate transparency and may be more willing to accommodate requests for better pricing if they understand your business model.

-

Total Cost of Ownership (TCO): Evaluate the TCO, including logistics, potential tariffs, and quality-related costs. A slightly higher upfront cost may be justified if it results in lower long-term expenses due to durability and fewer replacements.

Conclusion: What Should International B2B Buyers Keep in Mind?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of pricing and sourcing star carabiner acrylic is essential. Keep in mind that indicative prices can vary widely based on the factors discussed. It is advisable to request quotes from multiple suppliers and assess the total cost implications rather than focusing solely on the unit price. This comprehensive approach will ensure better purchasing decisions and ultimately contribute to business success.

Alternatives Analysis: Comparing star carabiner acrylic With Other Solutions

Exploring Alternatives to Star Carabiner Acrylic

In the world of promotional products and functional accessories, the star carabiner acrylic stands out for its aesthetic appeal and versatility. However, B2B buyers often seek alternatives that may better suit their specific operational needs, budget constraints, or design preferences. This section will compare the star carabiner acrylic to two viable alternatives: metal carabiners and silicone keychains. Each option has unique benefits and drawbacks that can influence purchasing decisions.

| Comparison Aspect | Star Carabiner Acrylic | Metal Carabiner | Silicone Keychain |

|---|---|---|---|

| Performance | Lightweight, durable, vibrant colors; suitable for light loads | High strength, durable; ideal for heavy loads | Flexible, lightweight; limited load capacity |

| Cost | $3.99 each | $1.50 – $5.00 each | $0.50 – $3.00 each |

| Ease of Implementation | Customization available; quick turnaround | Available in bulk; less customization | Easy to produce; minimal setup required |

| Maintenance | Low; easy to clean | Low; rust-resistant options available | Low; resistant to wear and tear |

| Best Use Case | Promotional gifts, fashion accessories | Outdoor activities, climbing, heavy-duty tasks | Casual use, events, giveaways |

In-Depth Analysis of Alternatives

Metal Carabiners

Metal carabiners are a robust alternative, often made from aluminum or stainless steel. They provide superior strength, making them suitable for outdoor activities like climbing and camping. While they can be more cost-effective than acrylic options, their aesthetic appeal may be less vibrant, and they often lack customization features. For businesses focused on rugged applications or requiring heavy-duty solutions, metal carabiners present a compelling option.

Silicone Keychains

Silicone keychains offer flexibility and a wide range of color options, making them an appealing alternative for promotional use. They are typically less expensive than acrylic carabiners and provide ease of production with minimal setup. However, they do not support heavy loads, limiting their use to lighter applications or as decorative items. Businesses aiming for budget-friendly promotional items that are easy to distribute may find silicone keychains to be a suitable choice.

Making the Right Choice for Your Business Needs

When choosing between star carabiner acrylic and its alternatives, B2B buyers should consider their specific requirements. For businesses prioritizing aesthetics and promotional value, star carabiner acrylic may be the ideal choice. Conversely, those requiring durability and strength for outdoor or heavy-duty applications might lean towards metal carabiners. Meanwhile, companies focused on cost-effective, lightweight promotional items could benefit from silicone keychains. By evaluating performance, cost, ease of implementation, maintenance needs, and best use cases, buyers can make informed decisions that align with their operational objectives and target market preferences.

Essential Technical Properties and Trade Terminology for star carabiner acrylic

What Are the Key Technical Properties of Star Carabiner Acrylic?

When considering star carabiner acrylic for your business needs, understanding its technical properties is crucial. Here are several critical specifications:

Illustrative image related to star carabiner acrylic

-

Material Grade

Acrylic is typically graded by its clarity and impact resistance. High-quality acrylic, often referred to as PMMA (Polymethyl Methacrylate), is known for its transparency and durability. A higher-grade acrylic can withstand various environmental conditions, making it suitable for outdoor applications. For B2B buyers, selecting the right material grade ensures that the carabiners will meet their usage requirements and maintain aesthetic appeal over time. -

Dimensions and Tolerance

Precision in dimensions is essential for ensuring that the carabiners fit their intended applications. Common dimensions for star carabiners include widths around 70mm and thicknesses of approximately 2.5mm. Tolerance levels, typically expressed in millimeters, indicate the acceptable variation in these dimensions. For international buyers, adherence to strict tolerances can prevent compatibility issues in assembly or use, enhancing overall product reliability. -

Finish Quality

The finish of acrylic carabiners can vary, with options like full bleed or shiny surfaces. A full bleed finish allows for vibrant, edge-to-edge printing, while shiny finishes can enhance aesthetic appeal. The finish impacts both the product’s visual appeal and its durability against scratches and wear. For B2B buyers, understanding finish quality can guide marketing strategies and customer satisfaction levels. -

Load Capacity

While acrylic is lighter than metal, understanding its load capacity is essential, especially for applications involving weight-bearing. Although specific load ratings may vary, knowing the limits ensures that the product can handle expected usage scenarios without failure. This knowledge is particularly valuable for companies selling or using these products in safety-critical environments. -

UV Resistance

Acrylic is susceptible to UV light degradation over time. Selecting UV-resistant acrylic can prolong the lifespan of the carabiners, especially in outdoor or sunny environments. For B2B buyers, this property is crucial for ensuring that the products maintain their integrity and appearance in various climates, particularly in regions like the Middle East and Africa.

Which Trade Terms Should B2B Buyers Understand for Star Carabiner Acrylic?

Familiarity with industry-specific terminology can enhance your purchasing strategy. Here are several essential trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are sold under another brand’s name. For businesses sourcing star carabiners, working with OEMs can facilitate custom designs and branding opportunities, allowing for differentiation in the marketplace. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cash flow. Understanding MOQs helps businesses align their purchasing strategies with production capabilities and demand forecasts. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. Including detailed specifications for star carabiners in an RFQ can lead to more accurate pricing and better alignment with project requirements. This process is essential for cost control in B2B transactions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. These terms clarify who is responsible for shipping, insurance, and tariffs during transportation. For B2B buyers, understanding Incoterms can mitigate risks and ensure smooth logistics when sourcing star carabiners from global suppliers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. It is crucial for inventory planning and meeting customer demands. For businesses, knowing the lead time for star carabiner acrylic ensures that they can manage their supply chains effectively, particularly in regions with longer shipping durations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their strategic objectives and market needs.

Navigating Market Dynamics and Sourcing Trends in the star carabiner acrylic Sector

What Are the Key Market Dynamics and Trends in the Star Carabiner Acrylic Sector?

The global star carabiner acrylic market is experiencing significant growth, driven by increased demand across various sectors, including fashion, outdoor activities, and promotional products. The rise of personalized and custom products has become a prominent trend, with businesses seeking to differentiate their offerings through unique designs. As a result, suppliers are focusing on customization options, such as double-sided printing and various finishes, catering to specific market needs. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for reliable sourcing partners that can provide high-quality, customizable products efficiently.

Furthermore, technology plays a crucial role in sourcing trends. The adoption of online platforms for bulk orders, streamlined logistics, and enhanced supply chain transparency is reshaping how businesses engage with suppliers. Additionally, the use of 3D printing and laser-cutting technologies is enabling manufacturers to produce intricate designs with reduced lead times. Buyers are also prioritizing suppliers that offer rapid processing and shipping times, as evidenced by trends in global shipping solutions that facilitate quicker delivery to diverse regions like Saudi Arabia and Nigeria.

How Is Sustainability and Ethical Sourcing Shaping the Star Carabiner Acrylic Industry?

Sustainability and ethical sourcing have become paramount in the star carabiner acrylic sector. As consumers and businesses alike become more environmentally conscious, B2B buyers are increasingly scrutinizing the environmental impact of their sourcing decisions. Acrylic, while versatile, poses environmental challenges due to its plastic composition. Therefore, suppliers are beginning to adopt more sustainable practices, such as utilizing recycled materials and minimizing waste during production.

Ethical supply chains are also crucial. Buyers are encouraged to partner with manufacturers that adhere to fair labor practices and are transparent about their sourcing processes. Certifications such as ISO 14001 for environmental management and Fair Trade certification can serve as indicators of a supplier’s commitment to sustainability. By prioritizing these aspects, international buyers can not only enhance their brand reputation but also meet the growing consumer demand for responsibly sourced products.

What Is the Historical Context of the Star Carabiner Acrylic Market?

The use of acrylic in manufacturing decorative and functional items, including carabiners, dates back several decades. Initially popularized for its clarity and durability, acrylic has evolved to become a preferred material in various applications, including fashion accessories and functional tools. The introduction of advanced manufacturing techniques, such as laser cutting and 3D printing, has enabled the production of complex designs that were previously unattainable.

In recent years, the star carabiner acrylic product line has gained traction due to its unique aesthetic appeal and functionality. As businesses recognize the potential for branding through custom designs, the market has expanded, resulting in a growing number of suppliers and increased competition. This evolution reflects broader trends in consumer preferences for personalized, visually striking products that cater to diverse markets worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of star carabiner acrylic

-

How do I solve quality assurance issues when sourcing star carabiner acrylic?

To address quality assurance issues, establish clear quality standards before placing orders. Request samples from potential suppliers to evaluate material quality, craftsmanship, and printing accuracy. Additionally, consider implementing a third-party quality inspection service to assess the products before shipment. This ensures that the carabiners meet your specifications and reduces the risk of receiving subpar items. Regular communication with suppliers about quality expectations can also help in preventing future issues. -

What is the best way to customize star carabiner acrylic for my brand?

The best way to customize star carabiner acrylic is to work closely with suppliers who offer personalized design services. Choose vibrant colors, unique shapes, or specific branding elements that resonate with your target market. Ensure that the supplier can accommodate your design requirements, such as double-sided printing or full bleed finishes. Additionally, review samples of previous custom orders to gauge the supplier’s capabilities and ensure the final product aligns with your branding strategy. -

What are the typical minimum order quantities (MOQs) for star carabiner acrylic?

Minimum order quantities (MOQs) for star carabiner acrylic can vary significantly among suppliers. Generally, MOQs range from 100 to 1,000 units, depending on the supplier’s production capabilities and the complexity of customization. It’s advisable to discuss MOQs during initial negotiations and explore potential discounts for larger orders. Some suppliers may offer flexibility for smaller quantities, especially for first-time buyers or trial orders. -

How can I ensure reliable shipping and logistics for international orders of star carabiner acrylic?

To ensure reliable shipping and logistics, partner with suppliers who have experience in international trade and can provide detailed shipping options. Inquire about shipping times, costs, and any customs duties or taxes that may apply to your destination. Consider using freight forwarders who specialize in your target regions for better logistics management. Regularly communicate with your supplier to track shipments and address potential delays proactively. -

What payment terms should I expect when purchasing star carabiner acrylic?

Payment terms can vary depending on the supplier and your relationship with them. Common terms include a 30% deposit before production, with the remaining balance due upon shipment. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established clients. It’s essential to clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms, to ensure a smooth transaction process. -

How do I vet suppliers for sourcing star carabiner acrylic internationally?

To vet suppliers, start by researching their company background, production capabilities, and customer reviews. Request references from previous clients to gauge their reliability and product quality. Verify certifications that indicate compliance with international standards, such as ISO certifications. Additionally, consider visiting the supplier’s facility or using virtual tours to assess their operations firsthand, ensuring they can meet your production needs. -

What are the common uses of star carabiner acrylic in various industries?

Star carabiner acrylic is commonly used in promotional products, keychains, and bag accessories across various industries, including fashion, outdoor recreation, and corporate branding. They serve as effective marketing tools, allowing businesses to showcase their logos and designs. Additionally, their lightweight and durable nature makes them suitable for outdoor equipment, safety gear, and event giveaways. Understanding the applications can help you target your marketing efforts effectively. -

What factors should I consider when placing a bulk order for star carabiner acrylic?

When placing a bulk order, consider factors such as lead times, production capacity, and potential discounts for larger quantities. Ensure that the supplier can meet your timeline and quality standards. Additionally, verify the shipping logistics and any potential customs regulations that may affect delivery. It’s also wise to confirm the terms of return or refund policies in case of discrepancies or defects in the order.

Top 4 Star Carabiner Acrylic Manufacturers & Suppliers List

1. Etsy – Acrylic Carabiners

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Acrylic Carabiners, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

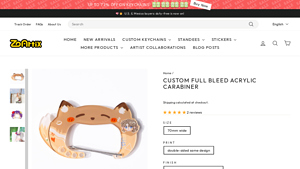

2. Zoartix – Custom Full Bleed Acrylic Carabiner

Domain: zoartix.com

Registered: 2024 (1 years)

Introduction: Custom Full Bleed Acrylic Carabiner

– Price: $3.99 USD

– Size: 70mm wide

– Print: Double-sided same design

– Finish: Full bleed (2.5mm bleed cutting)

– Shipping: Worldwide shipping available

– Processing Time: 5-10 days

– Standard Delivery: 8-13 business days

– Fast Delivery: 6-10 business days

– Expedited Delivery: 3-5 business days

– In stock, ready to ship

3. SH Plaza – Star Acrylic Carabiner

4. Star Kirby – Acrylic Carabiner

Domain: mercari.com

Registered: 2004 (21 years)

Introduction: This company, Star Kirby – Acrylic Carabiner, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for star carabiner acrylic

In the competitive landscape of B2B procurement, strategic sourcing of star carabiner acrylic products presents a unique opportunity for international buyers. By leveraging custom designs and high-quality materials, businesses can enhance their product offerings while meeting diverse consumer demands. The ability to source vibrant, durable acrylic carabiners not only allows for customization but also fosters brand recognition and loyalty through unique promotional items.

As global markets expand, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for distinctive, functional accessories is on the rise. Engaging with reliable suppliers who provide efficient shipping and transparent pricing can streamline your procurement process and reduce lead times. Consider integrating sustainable practices into your sourcing strategy, as eco-conscious products are increasingly favored by consumers.

Looking ahead, now is the time to explore partnerships with manufacturers specializing in star carabiner acrylic. By investing in these products, you position your business to capitalize on emerging trends and consumer preferences. Reach out to suppliers today to discuss your needs and discover how strategic sourcing can elevate your product line and drive growth in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.