The Definitive Guide to Stamp Die: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for stamp die

In today’s competitive landscape, sourcing the right stamp die can pose significant challenges for international B2B buyers. Whether you are a manufacturer in Nigeria or a craft supplier in Saudi Arabia, understanding the nuances of this intricate market is essential for making informed decisions. This comprehensive guide delves into the diverse types of stamp dies available, their various applications, and the essential factors to consider when vetting suppliers. From cost analysis to quality assurance, we aim to equip you with the knowledge necessary to navigate the global market effectively.

As the demand for customized and innovative stamping solutions grows, so does the complexity of sourcing. Buyers must contend with a myriad of options, each with its own specifications, capabilities, and pricing structures. This guide not only highlights the different categories of stamp dies, such as metal dies and stamp-and-die combos, but also provides insights into the latest trends and technologies shaping the industry.

By empowering you with actionable insights, this guide ensures that you can make strategic purchasing decisions that align with your business goals. Whether your focus is on enhancing product offerings or optimizing production efficiency, understanding the global landscape of stamp die sourcing is crucial for success. Join us as we explore the essential elements that will help you thrive in this dynamic market.

Understanding stamp die Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear Stamps | Transparent material for precise alignment | Crafting, scrapbooking, packaging | Pros: Easy to position; Cons: Less durable than traditional rubber. |

| Metal Dies | Durable steel construction for intricate designs | Card making, product packaging | Pros: Long-lasting; Cons: Higher initial investment. |

| Hybrid Stamp & Die Combos | Combines stamping and die-cutting in one set | Multi-functional crafting | Pros: Cost-effective; Cons: Limited to specific designs. |

| Rubber Stamps | Traditional option with a solid base | Custom branding, promotional items | Pros: Versatile; Cons: Requires additional tools for use. |

| Foam Stamps | Lightweight and flexible, ideal for detailed impressions | Educational tools, art projects | Pros: Easy to handle; Cons: May wear out faster. |

What Are Clear Stamps and Their Benefits for B2B Buyers?

Clear stamps are made from transparent materials that allow users to see exactly where they are placing the stamp, making them ideal for precision work. This type of stamp is particularly suited for crafting, scrapbooking, and packaging, where accurate placement is crucial. For B2B buyers, the ease of alignment can lead to more efficient production processes. However, while clear stamps are user-friendly, they may not be as durable as traditional rubber stamps, which could impact long-term usage.

How Do Metal Dies Differ and What Are Their Applications?

Metal dies are crafted from durable steel, allowing for intricate designs that can withstand repeated use. They are widely used in card making and product packaging, making them essential for businesses that prioritize quality and detail in their products. B2B buyers should consider the initial investment, as metal dies tend to be more expensive than other options. However, their longevity and ability to produce consistent results can justify the cost over time.

What Advantages Do Hybrid Stamp & Die Combos Offer?

Hybrid stamp and die combos combine the functionality of both stamping and die-cutting in a single set, catering to a wide range of crafting needs. These products are particularly appealing to businesses that require versatility in their creative processes, as they can save on costs and space. While these combos are cost-effective, buyers should be aware that they may be limited to specific designs, which could restrict creativity in some cases.

Why Choose Rubber Stamps for Your Business Needs?

Rubber stamps are a traditional choice known for their versatility across various applications, including custom branding and promotional items. Their solid base provides a reliable stamping experience, making them a favorite among businesses seeking a classic option. However, buyers should note that using rubber stamps often requires additional tools, such as ink pads, which can add to the overall cost and complexity of the stamping process.

What Are the Benefits of Foam Stamps in Educational and Art Projects?

Foam stamps are lightweight and flexible, making them ideal for detailed impressions in educational tools and art projects. Their ease of handling makes them suitable for various applications, including crafting and teaching materials. While foam stamps are user-friendly, B2B buyers should consider their potential for quicker wear compared to more durable options like metal dies. This aspect may affect long-term cost-effectiveness in high-volume usage scenarios.

Key Industrial Applications of stamp die

| Industry/Sector | Specific Application of stamp die | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision stamping for metal components | Enhances production efficiency and reduces waste | Supplier reliability, material quality, and lead times |

| Electronics | Die-cutting for circuit boards | Increases accuracy and reduces production costs | Compliance with international standards and certifications |

| Packaging | Custom dies for packaging solutions | Improves branding and product presentation | Material compatibility and design flexibility |

| Aerospace | Stamping for lightweight components | Reduces weight while maintaining strength | Advanced technology and quality assurance processes |

| Consumer Goods | Decorative stamping for product design | Differentiates products and enhances appeal | Customization options and turnaround times |

How is ‘stamp die’ used in automotive manufacturing?

In the automotive sector, stamp dies are crucial for producing precision metal components like body panels and structural parts. These dies enable manufacturers to create complex shapes with high accuracy, which is essential for vehicle safety and performance. For international buyers, particularly in regions like Nigeria and Saudi Arabia, sourcing high-quality dies that meet strict automotive standards is critical. Suppliers must demonstrate reliability and offer materials that withstand the rigors of automotive applications while ensuring timely delivery to keep production lines moving.

What role does ‘stamp die’ play in electronics?

In electronics, stamp dies are used for die-cutting circuit boards and components. This application improves the precision and consistency of electronic parts, which is vital for performance and reliability. Buyers from South America and Europe should prioritize suppliers that comply with international quality standards, as this ensures the components will perform as expected in various electronic devices. Additionally, considerations around lead times and the ability to handle custom designs can significantly impact production schedules.

How are ‘stamp die’ utilized in packaging solutions?

Packaging industries leverage stamp dies to create custom shapes and designs that enhance product appeal and branding. By using specialized dies, companies can produce unique packaging that stands out on shelves, attracting consumer attention. For B2B buyers in Africa and the Middle East, sourcing dies that can accommodate various materials, from cardboard to flexible plastics, is essential. Buyers should also consider the flexibility of suppliers to adapt designs quickly, as market trends can shift rapidly in the consumer goods sector.

In what ways does ‘stamp die’ benefit the aerospace industry?

In aerospace manufacturing, stamp dies are instrumental in producing lightweight yet strong components for aircraft. These dies allow manufacturers to create parts that contribute to fuel efficiency and overall performance. International buyers, especially from regions with emerging aerospace industries, must ensure that their suppliers employ advanced technologies and adhere to rigorous quality assurance processes. This guarantees that the components not only meet safety standards but also perform effectively under challenging conditions.

How does ‘stamp die’ enhance consumer goods?

For consumer goods, decorative stamping using dies adds a unique touch to products, helping brands differentiate themselves in competitive markets. This technique allows for intricate designs and branding elements to be integrated into the product itself, enhancing its visual appeal. Buyers from Europe and other regions should look for suppliers that offer customization options and quick turnaround times, as these factors can significantly influence market success. Moreover, ensuring that the materials used are compatible with the intended product is vital for maintaining quality and durability.

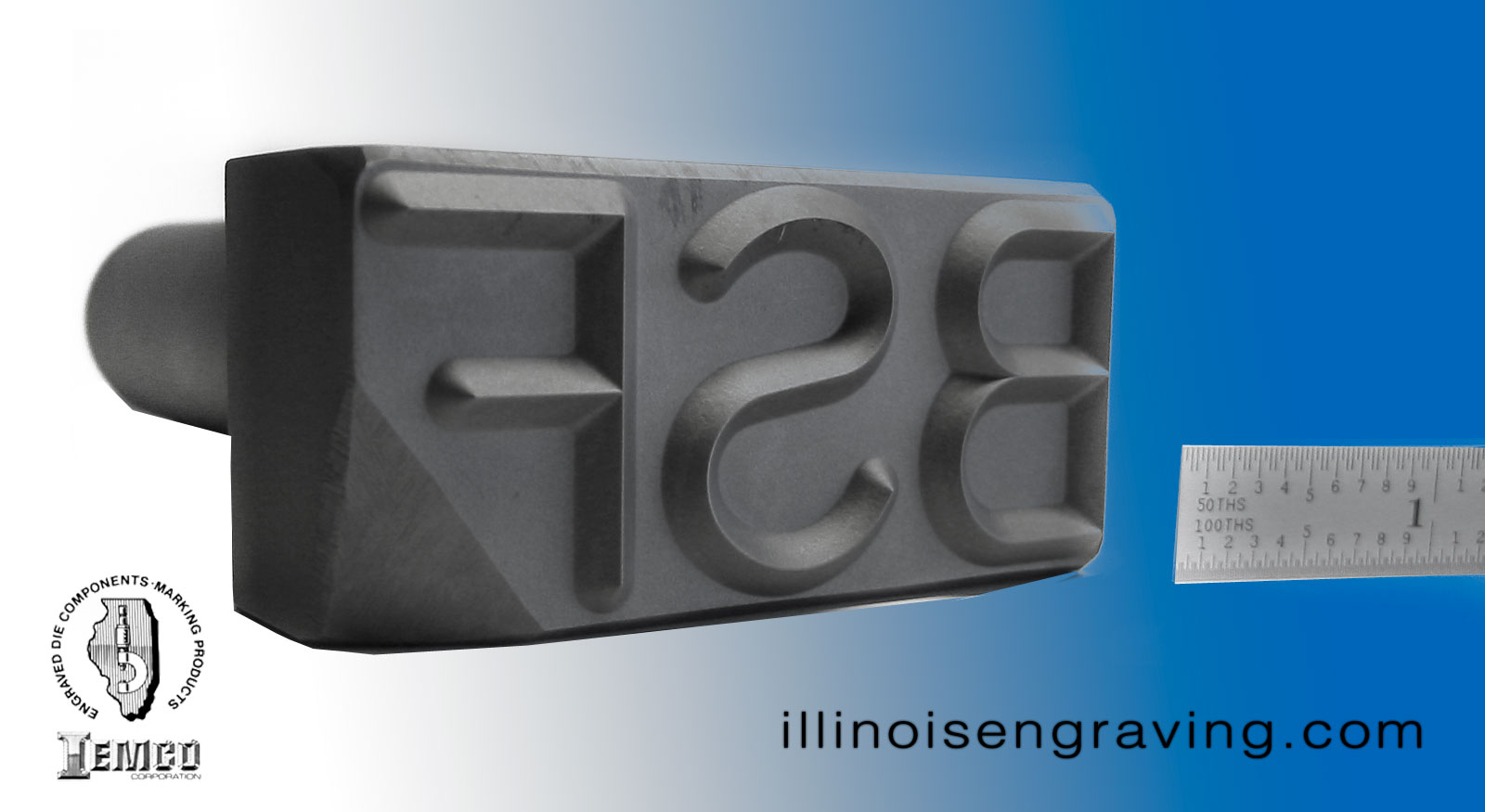

Illustrative image related to stamp die

3 Common User Pain Points for ‘stamp die’ & Their Solutions

Scenario 1: Sourcing Quality Stamp Dies for Diverse Applications

The Problem: B2B buyers often struggle with sourcing high-quality stamp dies that meet their specific production needs. Many suppliers provide generic options that lack the precision and durability required for specialized projects. This can lead to inconsistent product quality, increased production costs, and ultimately, customer dissatisfaction. Additionally, in markets across Africa and South America, logistical challenges can further complicate the procurement process, making it difficult to find reliable suppliers that offer suitable products.

The Solution: To overcome these challenges, buyers should prioritize establishing partnerships with reputable manufacturers that specialize in custom stamp dies. Conduct thorough research to identify suppliers with a proven track record of delivering high-quality products tailored to specific applications. Engage in direct communication with these manufacturers to discuss your unique requirements, including material specifications, design complexities, and production volumes. Request samples before making bulk purchases to evaluate quality firsthand. Furthermore, consider utilizing online platforms that feature user reviews and ratings to gauge supplier reliability and product performance.

Scenario 2: Navigating the Complexity of Custom Designs

The Problem: Another common issue for B2B buyers is the complexity involved in creating custom stamp die designs that align with their branding and product specifications. Many buyers may not have the technical expertise or design resources needed to develop intricate designs, which can lead to delays in product launches and increased costs. Furthermore, miscommunication with manufacturers regarding design specifications can result in errors, necessitating costly reworks or replacements.

Illustrative image related to stamp die

The Solution: To effectively navigate this challenge, buyers should invest in professional design software or collaborate with experienced graphic designers who understand the nuances of die design. It’s crucial to create detailed technical drawings and specifications that clearly outline the desired dimensions, shapes, and functionalities of the stamp dies. Additionally, establish a collaborative feedback loop with your chosen manufacturer to refine designs and ensure they meet production capabilities. Utilizing prototyping services can also help visualize the final product before full-scale manufacturing, minimizing the risk of errors and ensuring alignment with your brand identity.

Scenario 3: Managing Costs and Lead Times in Production

The Problem: Cost management and lead times can be significant pain points for B2B buyers in the stamp die market. Buyers often face fluctuating material costs and extended lead times, especially when sourcing from international suppliers. This unpredictability can disrupt production schedules, affect cash flow, and lead to missed deadlines, ultimately impacting customer satisfaction and competitive positioning in the market.

The Solution: To effectively manage costs and lead times, buyers should implement a strategic sourcing plan that includes multiple suppliers to mitigate risks associated with relying on a single source. Establishing long-term relationships with suppliers can also lead to better pricing and more favorable terms. Additionally, buyers should consider local suppliers who can provide quicker turnaround times, especially for urgent projects. Utilizing inventory management software can aid in tracking material usage and anticipating future needs, allowing for more efficient planning and reduced waste. Finally, maintaining open communication with suppliers regarding project timelines and potential delays can help buyers adjust their production schedules proactively, ensuring timely delivery of products to customers.

Strategic Material Selection Guide for stamp die

What Are the Key Properties of Common Materials Used in Stamp Dies?

When selecting materials for stamp dies, it is essential to consider their properties that directly affect performance. Here, we analyze four common materials: steel, aluminum, brass, and polymer, providing insights into their advantages, limitations, and implications for international B2B buyers.

How Does Steel Perform as a Material for Stamp Dies?

Steel is widely regarded as the standard material for stamp dies due to its exceptional hardness and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Steel dies are resistant to wear and deformation, ensuring a long lifespan even under continuous use.

Pros: Steel offers excellent strength and longevity, making it ideal for high-volume production runs. Its ability to maintain sharp edges enhances precision in stamping.

Cons: The primary drawbacks include higher manufacturing complexity and costs compared to other materials. Additionally, steel can be prone to corrosion if not properly treated, which may be a concern in humid environments.

Impact on Application: Steel is compatible with a wide range of media, including metals and plastics, making it versatile for various industries.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN for quality assurance. In regions like Africa and South America, where humidity can be high, corrosion-resistant coatings may be necessary.

What Are the Benefits of Using Aluminum for Stamp Dies?

Aluminum is another popular choice for stamp dies, particularly in applications where weight and cost are critical factors. It is significantly lighter than steel, which can reduce shipping costs and ease handling during production.

Pros: Aluminum dies are easier to manufacture, allowing for quicker turnaround times. They also have good thermal conductivity, which can be advantageous in certain stamping processes.

Cons: While aluminum is less expensive, it lacks the durability of steel, making it less suitable for high-volume applications. It is also more prone to deformation under extreme pressure.

Impact on Application: Aluminum is often used for softer materials and lower-volume production runs, making it suitable for prototypes or specialized projects.

Considerations for International Buyers: Buyers should be aware of local regulations regarding aluminum use, particularly in the automotive and aerospace sectors, where specific standards may apply.

How Does Brass Compare as a Material for Stamp Dies?

Brass is known for its excellent machinability and corrosion resistance, making it a viable option for specialized stamping applications. Its unique properties allow for intricate designs and fine details in the stamped products.

Pros: Brass offers good wear resistance and a pleasing aesthetic finish, making it popular in decorative applications. It is also less likely to corrode than steel, which is beneficial in various environments.

Cons: The primary limitation of brass is its cost, which is generally higher than steel and aluminum. Additionally, while it is durable, it may not withstand the same level of stress as steel.

Impact on Application: Brass is often used in applications requiring detailed stamping, such as jewelry or decorative items, where appearance is crucial.

Considerations for International Buyers: Compliance with environmental regulations concerning brass production and disposal is vital, particularly in Europe, where stricter standards may apply.

What Role Does Polymer Play in Stamp Die Applications?

Polymer materials, such as thermoplastics, are increasingly being used for stamp dies, especially in industries focused on rapid prototyping and lower-volume production. They offer a lightweight alternative with good flexibility.

Pros: Polymers can be produced quickly and at a lower cost, making them ideal for short runs or testing. They are also resistant to corrosion and can be easily molded into complex shapes.

Cons: The main downside is that polymers may not provide the same level of durability and precision as metal dies, limiting their use in high-stress applications.

Impact on Application: Polymers are well-suited for stamping softer materials, such as paper or thin plastics, and are often used in the packaging industry.

Considerations for International Buyers: Buyers should verify that polymer materials meet local safety and environmental standards, particularly in regions with strict regulations on plastic use.

Summary Table of Material Selection for Stamp Dies

| Material | Typical Use Case for stamp die | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-volume production | Exceptional durability | Higher manufacturing complexity | High |

| Aluminum | Prototypes and low-volume runs | Lightweight and cost-effective | Less durable than steel | Medium |

| Brass | Decorative applications | Good machinability and aesthetics | Higher cost and stress limitations | High |

| Polymer | Rapid prototyping | Quick production and flexibility | Limited durability and precision | Low |

This guide provides a comprehensive overview of material selection for stamp dies, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for stamp die

What Are the Key Stages in the Manufacturing Process of Stamp Dies?

The manufacturing of stamp dies involves several critical stages that ensure precision and quality. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting high-quality materials, typically tool steels or carbide, known for their durability and resistance to wear. These materials are cut into rough shapes using saws or lasers, ensuring they meet the specifications for the final product. In regions like Africa or South America, sourcing reliable materials may require establishing partnerships with local suppliers who adhere to international standards.

-

Forming: This stage involves shaping the prepared materials into the desired die forms. Techniques such as CNC machining, electrical discharge machining (EDM), or stamping are employed to create the intricate details required for the dies. CNC machining is particularly favored for its precision, making it essential for high-quality production. In markets like the Middle East and Europe, where advanced technology is prevalent, manufacturers often leverage the latest CNC machines to ensure efficiency.

-

Assembly: Once the individual components are formed, they are meticulously assembled. This process may involve fitting multiple die parts together, ensuring that they align perfectly for optimal functionality. Skilled technicians typically oversee this stage to address any potential issues that may arise during assembly.

-

Finishing: The final stage is finishing, which involves polishing and coating the dies to enhance their appearance and performance. Processes such as surface hardening, anodizing, or applying protective coatings are common. This stage not only improves the aesthetic appeal but also extends the lifespan of the dies, which is crucial for B2B buyers looking for long-term investments.

How Is Quality Assurance Implemented in Stamp Die Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of stamp dies, particularly for B2B buyers who demand consistency and reliability. A robust QA process typically involves adherence to international standards and specific industry regulations.

-

What Are the Relevant International Standards for Quality Assurance?

Compliance with standards such as ISO 9001 is crucial for manufacturers seeking to establish credibility in the international market. ISO 9001 outlines the requirements for a quality management system (QMS), emphasizing customer satisfaction and continuous improvement. Additionally, industry-specific certifications like CE marking for products sold in Europe or API standards for oil and gas applications can further enhance credibility. -

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process. Common checkpoints include:

– Incoming Quality Control (IQC): This initial phase checks the quality of raw materials before they enter the production process. B2B buyers can request IQC reports to verify material quality.

– In-Process Quality Control (IPQC): Conducted during manufacturing, IPQC involves monitoring processes to ensure they adhere to defined specifications. This stage often includes measurements and inspections to catch defects early.

– Final Quality Control (FQC): This final checkpoint involves comprehensive testing and inspection of the finished product before it is shipped. B2B buyers should seek detailed FQC reports to understand the quality of the dies they are purchasing. -

What Testing Methods Are Commonly Used in Quality Control?

Various testing methods are employed to validate the quality of stamp dies, including:

– Dimensional Inspection: Ensures that the dies meet the specified measurements using tools like calipers and micrometers.

– Material Testing: Assesses the material properties, such as hardness and tensile strength, often performed through destructive and non-destructive testing methods.

– Functional Testing: Evaluates how well the dies perform in actual stamping applications, ensuring they produce the desired outcomes without defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in international markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are several strategies to effectively assess supplier quality:

-

Conducting Audits: Regular audits can help buyers evaluate a supplier’s manufacturing processes and quality management systems. These audits should focus on compliance with international standards and the effectiveness of the QC checkpoints mentioned earlier.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, testing results, and certifications. These documents offer insights into the supplier’s commitment to quality and can help buyers make informed decisions.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspectors can conduct thorough assessments of the manufacturing process, ensuring compliance with international standards and identifying potential issues.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances when it comes to quality control in stamp die manufacturing:

-

Understanding Regional Standards: Different regions may have varying standards and regulations. For instance, while CE marking is critical in Europe, other regions may prioritize different certifications. Buyers should familiarize themselves with the standards relevant to their market to ensure compliance.

-

Cultural Considerations: Communication and cultural differences can impact the quality assurance process. Buyers should establish clear expectations and maintain open lines of communication with suppliers to mitigate misunderstandings.

-

Logistics and Supply Chain Factors: The logistics of transporting dies across borders can introduce quality risks. Buyers should work closely with suppliers to ensure that products are packaged and shipped in a manner that protects their integrity during transit.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and foster successful partnerships with suppliers in the stamp die industry. This knowledge not only enhances product reliability but also contributes to the long-term success of their businesses.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stamp die’

To streamline the procurement of stamp dies, this practical sourcing guide outlines essential steps for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. By following this checklist, you can ensure a smooth and efficient sourcing process that aligns with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure the stamp dies meet your production requirements. Consider the materials, dimensions, and designs you need for your products. This step not only helps in communicating your needs to suppliers but also aids in evaluating their offerings more effectively.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in stamp dies. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential candidates. Focus on suppliers with a proven track record in your region, as they may better understand local regulations and market demands.

Step 3: Evaluate Potential Suppliers

Before making any commitments, it’s essential to vet suppliers rigorously. Request company profiles, product catalogs, and case studies that demonstrate their expertise. Pay particular attention to customer testimonials and references from businesses in your sector to gauge reliability and quality.

- Check for Industry Certifications: Ensure that the suppliers possess relevant certifications that demonstrate compliance with industry standards, which can affect product quality and safety.

Step 4: Request Samples

Always request samples of the stamp dies before finalizing your order. This step allows you to assess the quality and performance of the dies firsthand. Evaluate the samples for precision, durability, and overall craftsmanship to ensure they align with your expectations.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be transparent about your budget and expectations, and inquire about bulk order discounts or long-term partnership agreements. This step is vital for establishing a mutually beneficial relationship.

Step 6: Review Shipping and Logistics Options

Discuss shipping methods and logistics with your chosen supplier to ensure timely delivery. Understand the costs associated with shipping to your location and any potential customs duties or tariffs that may apply. This will help you budget accurately and avoid unexpected expenses.

Step 7: Finalize Contractual Agreements

Before proceeding with the order, ensure all agreements are documented in a formal contract. This should include specifications, pricing, delivery timelines, and any warranties or guarantees. Having a clear contract protects both parties and provides a reference point in case of disputes.

By following this checklist, B2B buyers can enhance their sourcing strategy for stamp dies, ensuring that they secure high-quality products that meet their operational needs while fostering strong supplier relationships.

Illustrative image related to stamp die

Comprehensive Cost and Pricing Analysis for stamp die Sourcing

What Are the Key Cost Components in Stamp Die Sourcing?

When considering the procurement of stamp dies, understanding the cost structure is essential for effective budgeting and financial planning. The primary cost components include:

- Materials: The choice of materials significantly impacts cost. High-quality metals or plastics are generally more expensive, but they can enhance durability and performance.

- Labor: Skilled labor is required for both the design and manufacturing processes. Labor costs can vary significantly based on geographic location and the level of expertise required.

- Manufacturing Overhead: This encompasses utilities, equipment depreciation, and other indirect costs associated with production. It can represent a substantial portion of the total cost, especially in regions with higher operational costs.

- Tooling: This refers to the initial investment in molds and dies necessary for production. Tooling costs can be high but are amortized over larger production runs, making bulk purchases more cost-effective.

- Quality Control (QC): Ensuring the stamp dies meet industry standards involves additional costs associated with testing and inspection. Investing in quality control can prevent costly errors and rework later in the process.

- Logistics: Shipping and handling costs can vary widely depending on distance, shipping methods, and the weight of the dies. International shipping may involve additional customs fees and taxes.

- Margin: Suppliers will add a margin to their costs to ensure profitability. Understanding standard margins in the industry can aid in evaluating supplier quotes.

How Do Price Influencers Affect Stamp Die Costs?

Several factors influence the pricing of stamp dies, which buyers should consider:

- Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Negotiating the MOQ can lead to better pricing, especially for high-demand items.

- Specifications and Customization: Customized dies or those with specific requirements can incur additional costs. Clearly defining specifications can help avoid unexpected expenses.

- Materials Used: The choice of material not only affects the price but also the quality and longevity of the dies. Higher-quality materials may have a higher upfront cost but can lead to reduced total cost of ownership.

- Quality Certifications: Suppliers with recognized quality certifications may charge more, but their products often come with guarantees of reliability and performance.

- Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Engaging with established suppliers may come at a premium but can provide peace of mind regarding quality and service.

- Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining who bears the cost and risk at various stages of transport. Different terms can significantly impact the total landed cost of the dies.

What Are the Best Practices for Negotiating Stamp Die Prices?

To ensure cost-efficiency and favorable terms in stamp die sourcing, consider the following strategies:

- Conduct Market Research: Understanding market rates for different types of dies can provide leverage during negotiations. Be aware of prevailing prices and what constitutes a fair deal.

- Negotiate Terms: Don’t hesitate to negotiate not just on price, but also on payment terms, delivery timelines, and after-sales support. Flexible payment terms can improve cash flow.

- Consider Total Cost of Ownership (TCO): Evaluate the total cost, which includes purchase price, maintenance, and potential downtime costs. A lower upfront cost may not always be the best value if it leads to higher long-term expenses.

- Emphasize Long-Term Relationships: Building a strong relationship with suppliers can lead to better pricing, priority treatment, and improved service over time. Long-term contracts can also lock in prices and reduce volatility.

- Be Aware of Pricing Nuances: For international buyers, exchange rates, tariffs, and import duties can affect overall costs. Understanding these factors is crucial for accurate budgeting.

Conclusion

In summary, a comprehensive understanding of the cost structure, price influencers, and negotiation strategies is essential for international B2B buyers of stamp dies. By being informed and strategic, buyers can optimize their sourcing processes and achieve better value, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. Always remember that indicative prices may vary based on the factors discussed, and it is prudent to seek tailored quotes from suppliers to get the most accurate pricing.

Alternatives Analysis: Comparing stamp die With Other Solutions

In the evolving landscape of manufacturing and design, businesses often seek alternatives to traditional tools and techniques to enhance efficiency and reduce costs. This analysis explores ‘stamp die’ technology in comparison to other viable solutions, enabling B2B buyers to make informed decisions that align with their operational needs.

| Comparison Aspect | ‘Stamp Die’ | Laser Cutting Technology | CNC Machining |

|---|---|---|---|

| Performance | High precision for repetitive tasks | Very high precision, versatile | Excellent precision with complex shapes |

| Cost | Moderate initial investment | Higher upfront costs | High initial investment, ongoing costs |

| Ease of Implementation | Requires specific machinery setup | Requires training and software | Complex setup, requires skilled operators |

| Maintenance | Low maintenance needs | Moderate maintenance required | High maintenance and operational costs |

| Best Use Case | Mass production of uniform items | Prototyping and small batches | Custom parts and intricate designs |

What are the Advantages and Disadvantages of Laser Cutting Technology Compared to Stamp Die?

Laser cutting technology offers superior precision and versatility, making it suitable for a wide range of materials, including metals, plastics, and wood. Its ability to handle intricate designs with ease is a significant advantage. However, the initial investment is typically higher than that of stamp dies, and companies must also consider the ongoing costs associated with maintenance and operation. Additionally, the learning curve for software and operation can be a barrier for some businesses.

How Does CNC Machining Stand Against Stamp Die in Terms of Performance?

CNC machining excels in producing complex shapes and parts with high accuracy, making it ideal for custom manufacturing. It can work with various materials and offers flexibility in design changes. However, like laser cutting, CNC machining involves a high initial setup cost and requires skilled operators to manage the machinery effectively. The maintenance of CNC machines can also be demanding, impacting the overall cost-efficiency for businesses focused on high-volume production.

Conclusion: How Should B2B Buyers Choose Between Stamp Die and Its Alternatives?

When selecting between stamp die and its alternatives, B2B buyers should assess their specific production needs, budget constraints, and the complexity of the designs they intend to produce. For businesses focused on mass production of uniform items, stamp die remains a cost-effective solution. In contrast, for those requiring high precision and flexibility in design, laser cutting or CNC machining may provide better long-term value despite the higher initial investment. Understanding the trade-offs associated with each option will empower buyers to choose the most suitable technology for their operational goals.

Essential Technical Properties and Trade Terminology for stamp die

What Are the Key Technical Properties of Stamp Dies?

Understanding the technical properties of stamp dies is essential for B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

Stamp dies are typically made from high-quality steel or carbide, which significantly impacts durability and performance. Steel dies offer strength and longevity, while carbide dies provide superior hardness and wear resistance. Selecting the right material is crucial for ensuring that the dies can withstand the production environment, especially when dealing with high-volume stamping processes.

2. Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension. For stamp dies, tight tolerances are essential to ensure accuracy and repeatability in the stamping process. In applications where precision is critical, such as automotive or aerospace manufacturing, understanding and specifying the required tolerance levels is vital to maintain quality standards and reduce waste.

3. Hardness

The hardness of a stamp die is typically measured on the Rockwell or Brinell scale. A higher hardness rating generally indicates better wear resistance, which is crucial for high-volume production runs. Buyers must consider the hardness level based on the materials being stamped, as softer materials may require less hard dies, while harder materials necessitate more durable options.

4. Surface Finish

The surface finish of a stamp die can affect the quality of the stamped product. A smoother finish can reduce friction and wear, leading to a longer die life and better product quality. Buyers should evaluate the surface finish based on the end product requirements, as certain applications may need specific finishes to meet aesthetic or functional criteria.

5. Die Life

Die life refers to the duration a die can be used before it needs to be replaced or refurbished. Factors influencing die life include material quality, the complexity of the die design, and the frequency of use. Understanding expected die life helps in budgeting for maintenance and replacements, which is critical for managing production costs.

What Common Trade Terms Should B2B Buyers Know in the Stamp Die Industry?

Navigating the stamp die market requires familiarity with specific industry jargon. Here are some common terms that are important for B2B buyers:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another company’s brand name. In the context of stamp dies, buyers may work with OEMs to obtain dies that meet specific design or functional criteria. Understanding the role of OEMs can help buyers identify reliable sources for high-quality dies.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For stamp dies, MOQs can vary significantly between suppliers, impacting the overall cost and feasibility of a purchase. Buyers should consider their production needs and negotiate MOQs to ensure they can obtain the necessary dies without excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. For stamp dies, an RFQ should include detailed specifications, including material, dimensions, and tolerances. This process allows buyers to compare offers and select the best supplier based on quality, cost, and delivery time.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. These terms specify who is responsible for shipping, insurance, and tariffs, which can significantly affect overall costs and logistics for importing stamp dies. Familiarity with Incoterms helps buyers negotiate better terms and understand their obligations in the supply chain.

5. Lead Time

Lead time refers to the time required from placing an order to receiving the product. For stamp dies, lead times can vary based on complexity, material availability, and supplier capacity. Understanding lead times is crucial for planning production schedules and ensuring timely delivery of components.

By grasping these technical properties and trade terms, B2B buyers can navigate the stamp die market more effectively, ensuring they make informed decisions that align with their production needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the stamp die Sector

Global drivers in the stamp die sector are shaped by several key factors, including technological advancements, shifting consumer preferences, and economic fluctuations. As industries worldwide embrace automation and digitalization, the demand for precision-engineered stamp dies is increasing. International buyers, especially in regions like Africa, South America, the Middle East, and Europe, are recognizing the value of high-quality stamp dies that enhance production efficiency and product quality.

Current and emerging trends in B2B sourcing highlight the importance of flexibility and customization. Businesses are increasingly seeking suppliers that offer tailored solutions, reflecting the diverse needs of different markets. Moreover, e-commerce platforms are transforming how buyers interact with suppliers, enabling seamless transactions and improved access to global resources. This digital shift allows buyers from emerging markets to connect with high-quality suppliers, fostering competitive pricing and innovation.

Furthermore, economic conditions, such as fluctuating raw material costs and trade tariffs, are impacting sourcing strategies. Buyers must remain vigilant about these dynamics to make informed decisions. Companies that invest in understanding market trends and consumer demands are better positioned to navigate these challenges and seize opportunities for growth.

How Are Sustainability and Ethical Sourcing Influencing the Stamp Die Market?

The environmental impact of manufacturing processes in the stamp die sector cannot be overlooked. As global awareness of sustainability grows, B2B buyers are increasingly prioritizing ethical sourcing and environmentally friendly practices. The demand for green certifications and sustainable materials is rising, prompting suppliers to adopt eco-friendly manufacturing processes and materials.

Ethical supply chains are becoming a critical consideration for international buyers. Companies that can demonstrate a commitment to sustainability not only enhance their brand reputation but also attract environmentally conscious customers. For instance, using recyclable materials and minimizing waste during production aligns with the values of many consumers and businesses today.

Moreover, suppliers that obtain certifications, such as ISO 14001 or other recognized environmental standards, can differentiate themselves in a competitive market. Buyers should look for partners who are transparent about their sourcing practices and are willing to share information about their environmental impact. This focus on sustainability and ethics is not just a trend; it is becoming an essential aspect of business strategy in the stamp die sector.

What is the Historical Context of the Stamp Die Sector?

The history of the stamp die sector is rooted in traditional craftsmanship, evolving significantly with advancements in technology. Early stamp dies were handmade, requiring significant skill and time. The industrial revolution marked a turning point, introducing mechanization that increased production efficiency and precision.

In the late 20th century, the rise of computer-aided design (CAD) and computer numerical control (CNC) machining revolutionized the industry. These technologies allowed for more complex designs and quicker production times, catering to the growing demands of various industries, including automotive, electronics, and consumer goods.

Today, the stamp die sector continues to evolve, with innovations such as 3D printing and advanced materials shaping its future. Understanding this historical context provides B2B buyers with insights into the ongoing transformation of the market, enabling them to make strategic sourcing decisions that align with current trends and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of stamp die

-

How do I choose the right supplier for stamp dies?

Selecting the right supplier for stamp dies involves several key steps. First, evaluate their production capabilities and technology to ensure they can meet your specifications. Look for suppliers with a strong reputation, verified by customer reviews or industry certifications. Conduct thorough due diligence, including checking references and previous work. Attend trade shows or industry conferences to meet suppliers in person and assess their products. Finally, consider their responsiveness and willingness to communicate, as this will be crucial for ongoing collaboration. -

What is the typical minimum order quantity (MOQ) for stamp dies?

Minimum order quantities for stamp dies can vary significantly based on the supplier and the complexity of the dies. Generally, MOQs range from 50 to 500 units. Suppliers might offer lower MOQs for standard designs, while custom dies usually come with higher MOQs due to setup costs. When negotiating, clarify the MOQ upfront and inquire about options for smaller orders or samples, especially if you’re testing a new design or supplier. -

What customization options are available for stamp dies?

Customization options for stamp dies include size, shape, and design elements. Most suppliers offer bespoke services where you can provide your artwork or specifications to create unique dies tailored to your needs. Discuss your requirements with the supplier to understand their capabilities and any additional costs involved. Ensure you receive proofs or samples before finalizing production to confirm that the die meets your expectations. -

What payment terms should I expect when sourcing stamp dies?

Payment terms for stamp dies typically include an upfront deposit, ranging from 30% to 50%, with the balance due upon completion or before shipment. Some suppliers may offer more flexible terms for larger orders or long-term partnerships. Always clarify payment methods accepted (e.g., bank transfer, credit card, etc.) and any potential fees for international transactions. Ensure that all terms are documented in your contract to avoid disputes later on. -

How can I ensure quality assurance for my stamp dies?

To ensure quality assurance for stamp dies, request samples or prototypes before full-scale production. Establish clear quality standards and specifications with your supplier, including material quality, dimensions, and tolerances. Implement a third-party inspection process, especially for large orders, to verify that the dies meet your requirements. Regular communication with your supplier during production can also help address any quality issues early in the process. -

What are the logistics considerations for importing stamp dies?

Logistics considerations for importing stamp dies include understanding shipping options, customs duties, and delivery timelines. Evaluate the best shipping method (air vs. sea) based on your budget and urgency. Familiarize yourself with the customs regulations in your country, including any tariffs or import restrictions. Collaborating with a freight forwarder can simplify the process, ensuring that all documentation is in order and that your shipment arrives on time. -

What factors should I consider for international shipping of stamp dies?

When shipping stamp dies internationally, consider factors such as shipping costs, delivery times, and customs clearance procedures. Choose a reliable shipping partner with experience in handling customs documentation and international logistics. Be aware of the regulations regarding the materials used in the dies, as some countries may have specific import requirements. Additionally, factor in insurance options to protect your investment during transit. -

How can I assess the reliability of a stamp die supplier?

To assess the reliability of a stamp die supplier, start by checking their business credentials and industry experience. Look for testimonials and case studies from previous clients, focusing on their ability to meet deadlines and quality standards. Request references and follow up to gain insights into their performance. Additionally, consider their communication practices; a supplier who is responsive and transparent is typically more reliable in managing orders and addressing issues.

Top 7 Stamp Die Manufacturers & Suppliers List

1. Waffle Flower – Postage Collage Die

Domain: waffleflower.com

Registered: 2011 (14 years)

Introduction: {“product_name”: “Postage Collage Die”, “brand”: “Waffle Flower”, “designer”: “Galina Filippenko”, “price”: “$20.00”, “sku”: “421382”, “description”: “This die serves as the base for many of the stencils and stamps in the Postage Collage series by cardmaker Galina Filippenko. Can be used on its own to create the look of postage stamps. The die leaves the 6 stamps connected on 1 panel. You can easi…

2. Hero Arts – Stamp & Die Combos

Domain: heroarts.com

Registered: 1995 (30 years)

Introduction: This company, Hero Arts – Stamp & Die Combos, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. The Stamps of Life – Clear Stamps & Dies

Domain: thestampsoflife.com

Registered: 2008 (17 years)

Introduction: The Stamps of Life offers a variety of clear stamps and dies for cardmaking. Key product categories include: New Products, Clear Stamps (with subcategories like Alphabets, Animals, Backgrounds & Borders, Birthday, Christian Designs, Fall, Family & Friends, Flowers, Food, Holidays, Kids, Life, Little Peeps, Occasions, Sentiments, Specialty, Spring, States, Stephie Doll, Summer, Thank You, Winter), …

4. Altenew – Coordinating Stamp and Die Sets

Domain: altenew.com

Registered: 2014 (11 years)

Introduction: Altenew Coordinating Stamp and Die Sets for Card Making. Price range: $4.99 – $55.09. Types: 210 Dies, 210 Stamps. Stamp Sizes: 2″ x 3″ (20), 3″ x 4″ (4), 4″ x 6″ (7), 6″ x 8″ (7), 8″ x 11″ (2). Stamp Types: Layering (6), Outlined (25), Sentiments (10), Silhouette (2). Die Types: Layering (1), One-Go (1). Die Themes: Floral (21), Nature (10), Words & Letters (8). Stamp Themes: Floral (20), Geometr…

5. Trinity Stamps – Key Products

Domain: trinitystamps.com

Registered: 2017 (8 years)

Introduction: Key product details include: 1. Product Type: Metal Dies 2. Total Metal Dies Available: 303 3. Price Range: $8.99 – $32.99 4. Featured Products: You Take The Cake Die Set ($21.99), Sundae Swirl Alphabet Die Set ($21.99), Slide and Spin Die Set ($19.99), Mini Album Tabs Die Set ($15.99), Circle Frames Die Set ($15.99), Grate Grillin’ Die Set ($23.99), Buildable Burger Die Set – Circle Card Add-On (…

6. Stampin’ Up! – Ornamental Christmas Bundle

Domain: stampinup.com

Registered: 1997 (28 years)

Introduction: [{‘name’: ‘ORNAMENTAL CHRISTMAS BUNDLE’, ‘price’: ‘$51.25’}, {‘name’: ‘CHRISTMAS GREENERY BUNDLE’, ‘price’: ‘$50.25’}, {‘name’: ‘FESTIVE FRIENDS BUNDLE’, ‘price’: ‘$50.25’}, {‘name’: ‘PINE TREE TRIMMINGS BUNDLE’, ‘price’: ‘$33.25’}, {‘name’: ‘DELICATE PINES BUNDLE’, ‘price’: ‘$56.50’}, {‘name’: ‘PET LOVE BUNDLE’, ‘price’: ‘$45.00’}, {‘name’: ‘WORDS FOR THE SEASON BUNDLE’, ‘price’: ‘$49.50’}, {‘nam…

7. Taylored Expressions – Key Products

Domain: tayloredexpressions.com

Registered: 2005 (20 years)

Introduction: Taylored Expressions offers a variety of crafting products including stamps, dies, stencils, paper, ink, tools, and embellishments. Key product highlights include:

1. **Bundles:**

– Disco Vibes Bundle: MSRP $142.49, includes items for creating bold projects.

– Up for a Celebration Bundle: MSRP $107.00, features playful balloons and birthday sentiments.

2. **Stamps:**

– Birthday Bash S…

Strategic Sourcing Conclusion and Outlook for stamp die

In navigating the evolving landscape of stamp die procurement, strategic sourcing emerges as a critical lever for international B2B buyers. By embracing a comprehensive approach that encompasses quality assessment, supplier reliability, and cost-effectiveness, businesses can enhance their competitive edge. The diversity of offerings—from intricate stamp and die combos to standalone cutting dies—affords buyers the opportunity to tailor solutions to their specific market needs.

Investing in strategic sourcing not only fosters strong supplier relationships but also ensures access to innovative designs and timely delivery, crucial for maintaining production schedules. As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality stamp die products will only grow.

Looking ahead, international buyers are encouraged to leverage digital platforms to explore new suppliers and diversify their sourcing strategies. Engaging with manufacturers who prioritize sustainability and innovation will be essential in meeting the evolving preferences of end consumers. This proactive approach will position businesses to capitalize on emerging opportunities and drive growth in the dynamic stamp die market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

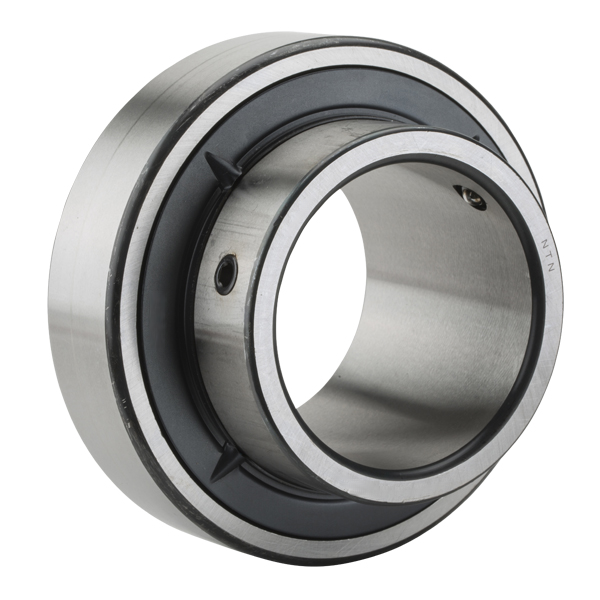

Illustrative image related to stamp die