The Definitive Guide to Stable Braid Rope: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for stable braid rope

In the ever-evolving global market, sourcing stable braid rope presents a unique set of challenges for B2B buyers, particularly those operating in diverse sectors such as construction, arboriculture, and maritime industries. With its exceptional strength-to-weight ratio and impressive durability, stable braid rope is a vital component in various applications, from rigging to heavy lifting. However, navigating the complexities of supplier selection, material specifications, and pricing can be daunting, especially for businesses in regions like Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam.

This comprehensive guide aims to demystify the stable braid rope market by providing valuable insights into the different types available, their specific applications, and best practices for supplier vetting. We will explore critical factors such as breaking strength, UV resistance, and abrasion durability, enabling you to make informed decisions that align with your operational needs. Additionally, we will delve into cost considerations and offer strategies for negotiating favorable terms with suppliers.

By equipping international B2B buyers with the knowledge and tools necessary to navigate this specialized market, this guide empowers you to optimize your purchasing decisions, ensuring that you acquire the highest quality stable braid rope for your projects. Whether you are expanding your supply chain or enhancing your inventory, understanding these dynamics is essential for maintaining a competitive edge in today’s global landscape.

Understanding stable braid rope Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stable Braid Rigging Rope 1/2″ | Double braid construction, 10,400 lbs tensile strength, UV resistant | Arborist rigging, construction, marine use | Pros: High strength-to-weight ratio, low stretch; Cons: Limited to specific applications due to diameter. |

| Stable Braid Rigging Rope 5/8″ | Torque-free, high abrasion resistance, 16,300 lbs tensile strength | Heavy-duty rigging, forestry, rescue operations | Pros: Excellent durability, suitable for heavy loads; Cons: Heavier weight may limit handling ease. |

| Stable Braid Bull Rope 3/4″ | Designed for bull rigging, 20,400 lbs tensile strength, color-coded | Logging, tree removal, heavy lifting | Pros: High visibility, robust for extreme loads; Cons: Bulkier and may require specialized handling. |

| Stable Braid Bull Rope 7/8″ | Superior strength, 29,900 lbs tensile strength, UV resistant | Industrial rigging, towing, marine applications | Pros: Exceptional load capacity, long lifespan; Cons: Higher cost, may be overkill for lighter tasks. |

| Custom Length Stable Braid Rope | Available in various diameters, custom lengths | Versatile applications across industries | Pros: Tailored to specific needs, flexibility in use; Cons: Custom orders may have longer lead times. |

What are the Characteristics of Stable Braid Rigging Rope 1/2″?

The Stable Braid Rigging Rope 1/2″ features a double braid construction with a tensile strength of 10,400 lbs, making it a favored choice among arborists and in construction settings. Its UV resistance and abrasion protection ensure longevity in outdoor applications. Buyers should consider the specific diameter and weight capacity required for their projects, as this rope is particularly suited for lighter rigging tasks.

How Does the Stable Braid Rigging Rope 5/8″ Stand Out?

The 5/8″ variant is designed for heavy-duty applications, boasting a tensile strength of 16,300 lbs. Its torque-free construction minimizes twisting during use, making it ideal for forestry and rescue operations. Buyers should evaluate the load requirements and ensure that the rope’s weight is manageable for their teams, given its robust nature.

Why Choose the Stable Braid Bull Rope 3/4″?

With a tensile strength of 20,400 lbs, the Stable Braid Bull Rope 3/4″ is optimized for logging and heavy lifting tasks. Its color-coded design enhances visibility, a critical feature for safety in busy work environments. Buyers need to consider the handling requirements and whether the bulkiness of this rope aligns with their operational needs.

What Benefits Does the Stable Braid Bull Rope 7/8″ Offer?

The 7/8″ bull rope is engineered for industrial rigging and towing, providing an impressive tensile strength of 29,900 lbs. Its UV resistance ensures durability in harsh conditions, making it suitable for marine applications. While its high capacity is advantageous, buyers should weigh the cost against potential over-specification for lighter tasks.

How Does Custom Length Stable Braid Rope Benefit Buyers?

Custom length stable braid ropes allow businesses to tailor their orders to specific project requirements, accommodating various diameters and lengths. This flexibility is particularly valuable across diverse industries, from construction to forestry. However, buyers should be aware of potentially extended lead times for custom orders and ensure that they have accurate specifications to avoid delays.

Key Industrial Applications of stable braid rope

| Industry/Sector | Specific Application of stable braid rope | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Arboriculture | Tree rigging and lowering | Enables safe and efficient tree removal and maintenance | Ensure high tensile strength and UV resistance for durability |

| Marine & Shipping | Docking and mooring lines | Provides reliable anchoring and mooring for vessels | Look for abrasion resistance and appropriate length/diameter |

| Construction | Heavy lifting and rigging | Facilitates the safe movement of heavy materials on-site | Consider load ratings, splicing options, and weather resistance |

| Entertainment | Stage rigging and aerial performances | Ensures safety and reliability in high-stakes environments | Verify strength ratings and ease of handling for quick deployment |

| Agriculture | Hoisting and securing equipment | Enhances operational efficiency in farming and harvesting | Source ropes that are resistant to chemicals and environmental factors |

How is Stable Braid Rope Used in Arboriculture and What Problems Does It Solve?

In arboriculture, stable braid rope is primarily utilized for tree rigging and lowering. Its low stretch and high tensile strength make it ideal for safely managing heavy branches during pruning or removal. This application minimizes the risk of accidents, ensuring that arborists can work efficiently and safely. Buyers in this sector should prioritize ropes with high UV resistance and durability to withstand outdoor conditions, particularly in regions with intense sunlight, such as parts of Africa and South America.

What Role Does Stable Braid Rope Play in Marine & Shipping Industries?

In the marine and shipping industries, stable braid rope is essential for docking and mooring vessels. The rope’s high strength-to-weight ratio allows for reliable anchoring, essential for maintaining vessel stability in various weather conditions. For international buyers, particularly in coastal regions of the Middle East and Europe, it is crucial to source ropes that offer excellent abrasion resistance to withstand harsh marine environments and saltwater exposure.

Illustrative image related to stable braid rope

How is Stable Braid Rope Beneficial in Construction Applications?

Stable braid rope serves a vital role in construction, particularly for heavy lifting and rigging. It provides the necessary strength to move heavy materials safely and efficiently on job sites, thereby enhancing productivity. Buyers should focus on ropes with verified load ratings and splicing capabilities to ensure safety during operations. Additionally, ropes that resist environmental degradation are particularly beneficial in regions with extreme weather, such as those in South America and Africa.

What is the Importance of Stable Braid Rope in the Entertainment Sector?

In the entertainment industry, stable braid rope is widely used for stage rigging and aerial performances. Its reliability and strength are critical for ensuring safety during live performances, where equipment and performers are often suspended at heights. Buyers should ensure that the ropes are easy to handle and deploy quickly, as time is often of the essence in this fast-paced environment. Sourcing ropes with appropriate strength ratings is essential, especially for performances in larger venues across Europe and the Middle East.

How Does Stable Braid Rope Enhance Agricultural Operations?

In agriculture, stable braid rope is employed for hoisting and securing equipment, significantly improving operational efficiency. This application is particularly beneficial during harvesting, where heavy equipment needs to be maneuvered swiftly and safely. Buyers in this sector should consider ropes that are resistant to chemicals and environmental factors, as agricultural settings can expose materials to various harsh conditions. Sourcing high-quality stable braid rope can lead to improved productivity and reduced downtime in agricultural operations across diverse regions, including Africa and South America.

3 Common User Pain Points for ‘stable braid rope’ & Their Solutions

Scenario 1: Ensuring Optimal Load Management with Stable Braid Rope

The Problem: B2B buyers often struggle with understanding the load capacities of stable braid ropes, which can lead to using ropes that are either over or under-specified for their intended applications. This lack of clarity can result in catastrophic failures, such as equipment damage or safety hazards, especially in high-stakes environments like construction or arboriculture. With varying breaking strengths (ranging from 10,400 lbs to 29,900 lbs), the challenge lies in selecting the right rope without comprehensive knowledge of the specific load requirements and potential safety margins.

Illustrative image related to stable braid rope

The Solution: To effectively manage load requirements, buyers should begin by conducting a thorough assessment of the applications in which the stable braid rope will be utilized. This includes understanding the weight of the loads being lifted, the dynamic forces at play, and the environment in which the rope will operate. A good rule of thumb is to apply a safety factor; typically, the working load limit should be one-fourth of the rope’s breaking strength. For instance, if using a rope with a breaking strength of 20,400 lbs, the maximum safe working load should not exceed 5,100 lbs. Additionally, it is essential to consult with suppliers who can provide detailed specifications, including the rope’s performance under various conditions, to ensure that the chosen rope meets or exceeds the specific requirements of the job at hand.

Scenario 2: Managing Rope Durability and Environmental Resistance

The Problem: Buyers frequently encounter issues with the durability of stable braid ropes, particularly when exposed to harsh environmental conditions like UV radiation, moisture, or extreme temperatures. These factors can lead to rapid degradation of the rope, compromising its strength and reliability over time. This is especially critical for buyers in regions with extreme weather conditions, such as the Middle East or South America, where environmental factors can significantly affect rope performance.

The Solution: To address durability concerns, buyers should prioritize sourcing stable braid ropes that are specifically designed with UV and abrasion resistance features. For instance, ropes with a Samthane coating provide excellent protection against wear and environmental damage. When purchasing, consider the specifications that indicate the rope’s UV resistance and abrasion rating. Additionally, implementing a regular inspection and maintenance schedule will help identify wear and tear before it leads to failure. Buyers can also consider utilizing protective gear, such as sleeves or coverings, to further enhance the longevity of their ropes in particularly harsh conditions.

Illustrative image related to stable braid rope

Scenario 3: Ensuring Proper Splicing Techniques for Safety

The Problem: A common pain point for B2B buyers is the lack of knowledge surrounding proper splicing techniques for stable braid ropes. Improper splicing can significantly reduce the rope’s strength, potentially leading to dangerous situations during use. This is particularly problematic in industries like arboriculture or construction, where the integrity of the rigging system is crucial for safety.

The Solution: To ensure safe and effective use of stable braid ropes, buyers should invest in training for their team on proper splicing techniques or engage professional splicing services from reputable suppliers. It is critical to understand that a correctly executed splice can maintain up to 80-100% of the rope’s original strength, while improper knots can reduce strength by up to 50%. Buyers should also request splicing services directly from the manufacturer or authorized suppliers, who can guarantee that the splices meet industry standards. Providing employees with access to resources, such as instructional videos or workshops on splicing, can further enhance safety and performance in the field.

Strategic Material Selection Guide for stable braid rope

What are the Key Properties of Common Materials Used in Stable Braid Rope?

When selecting stable braid rope for various applications, the choice of material significantly influences performance, durability, and suitability. Here, we analyze four common materials used in stable braid rope: polyester, nylon, polypropylene, and aramid. Each material has distinct properties that can cater to specific industrial needs.

Illustrative image related to stable braid rope

How Does Polyester Perform in Stable Braid Rope Applications?

Polyester is widely used in stable braid ropes due to its excellent abrasion resistance and low stretch characteristics. It has a high tensile strength, typically ranging from 10,400 lbs to 29,900 lbs, making it suitable for heavy-duty applications. Polyester is also UV resistant, which is crucial for outdoor use, and it performs well under varying temperatures, maintaining its integrity in both hot and cold environments.

Pros: Polyester ropes are durable, cost-effective, and resistant to UV degradation and abrasion. They are also easy to splice, which enhances their usability in various rigging applications.

Cons: While polyester has good resistance to moisture, prolonged exposure to water can lead to mildew growth. It also has a lower strength-to-weight ratio compared to nylon.

Illustrative image related to stable braid rope

Impact on Application: Polyester ropes are ideal for outdoor rigging, marine applications, and construction, where UV exposure is a concern. They are compatible with various media, including water and chemicals, but care should be taken in environments with extreme temperatures.

What Advantages Does Nylon Offer for Stable Braid Rope?

Nylon is another popular choice for stable braid ropes, known for its exceptional elasticity and strength. With a tensile strength that can exceed 30,000 lbs, nylon ropes can absorb shock loads, making them suitable for applications requiring dynamic load handling.

Pros: The elasticity of nylon allows it to stretch under load, reducing the risk of sudden breakage. It also has excellent resistance to abrasion and chemicals, making it versatile across different industries.

Illustrative image related to stable braid rope

Cons: Nylon is more expensive than polyester and can degrade under UV exposure over time. It is also more susceptible to moisture absorption, which can lead to a decrease in strength when wet.

Impact on Application: Nylon ropes are commonly used in climbing, rescue operations, and marine environments where shock absorption is critical. However, international buyers should ensure compliance with relevant standards, as nylon may not be suitable for all applications.

How Does Polypropylene Compare as a Material for Stable Braid Rope?

Polypropylene is a lightweight, cost-effective alternative to polyester and nylon. It has a lower tensile strength, typically ranging from 3,000 lbs to 6,000 lbs, but is highly resistant to moisture and floats on water, making it suitable for marine applications.

Pros: Polypropylene ropes are resistant to chemicals and have a low cost, making them an attractive option for budget-conscious buyers. Their lightweight nature also facilitates easier handling.

Cons: The lower strength and UV resistance compared to polyester and nylon limit their use in high-load applications. They can also become brittle over time when exposed to UV light.

Illustrative image related to stable braid rope

Impact on Application: Polypropylene ropes are ideal for temporary applications, such as securing loads or marking areas. Buyers in regions with high humidity or water exposure should consider the limitations of polypropylene in terms of strength.

What Role Does Aramid Play in Stable Braid Rope Manufacturing?

Aramid fibers, such as Kevlar, are known for their high strength and thermal resistance. They can withstand temperatures up to 500°F and have a tensile strength significantly higher than polyester and nylon, making them suitable for extreme conditions.

Pros: Aramid ropes are incredibly strong and have excellent resistance to heat and abrasion. They are ideal for applications that require high performance under extreme conditions.

Cons: The cost of aramid fibers is significantly higher than other materials, and they can be more challenging to splice. Additionally, they are susceptible to degradation from UV exposure.

Illustrative image related to stable braid rope

Impact on Application: Aramid ropes are used in specialized applications, such as aerospace, military, and high-performance sports. International buyers should be aware of the specific certifications required for aramid products.

Summary Table of Material Selection for Stable Braid Rope

| Material | Typical Use Case for stable braid rope | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor rigging, marine applications | Excellent abrasion resistance | Lower strength-to-weight ratio than nylon | Medium |

| Nylon | Climbing, rescue operations | High elasticity and shock absorption | Degrades under UV exposure | High |

| Polypropylene | Temporary securing, marking areas | Lightweight and cost-effective | Lower strength and UV resistance | Low |

| Aramid | Aerospace, military, high-performance sports | Extremely high strength and heat resistance | High cost and UV sensitivity | High |

This guide provides a comprehensive overview of the materials used in stable braid rope, helping international B2B buyers make informed decisions based on their specific requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for stable braid rope

Stable braid rope is a critical component in various industries, including construction, maritime, and arboriculture, due to its strength, durability, and versatility. Understanding the manufacturing processes and quality assurance measures is vital for B2B buyers looking to procure reliable products. This section will delve into the typical manufacturing stages, key techniques employed, and the quality control measures that ensure the rope meets international standards.

What Are the Main Stages of Manufacturing Stable Braid Rope?

The manufacturing process of stable braid rope involves several key stages, each crucial to ensuring the final product meets industry standards for strength and durability.

1. Material Preparation

The initial stage involves selecting high-quality fibers, predominantly polyester, which is known for its strength and resistance to abrasion and UV degradation. The fibers are sourced from reputable suppliers and undergo a thorough inspection to ensure they meet the required specifications for tensile strength and elongation. This step is critical as the quality of raw materials directly impacts the performance of the final product.

Illustrative image related to stable braid rope

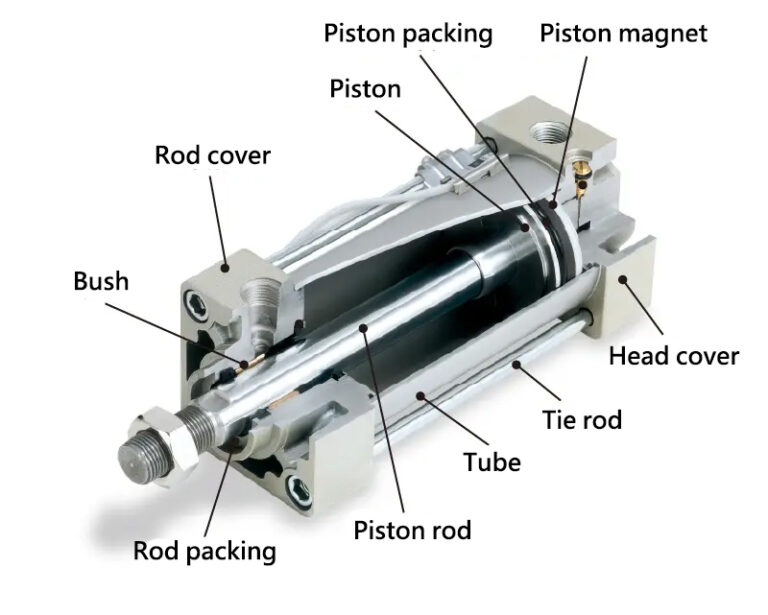

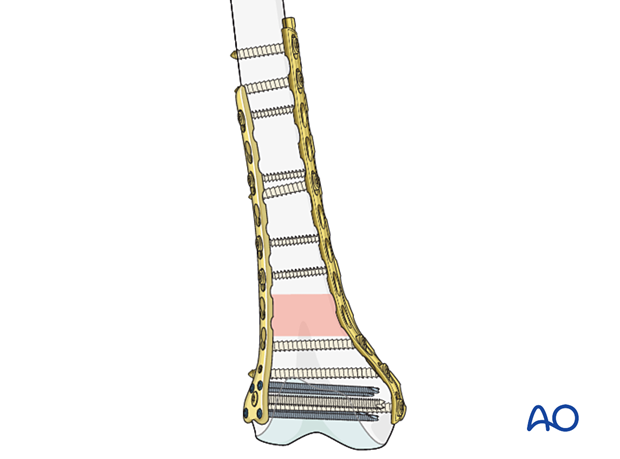

2. Forming the Rope

Once the materials are prepared, they are processed into a double braid construction. This involves braiding a polyester cover over a polyester core. The braiding process is typically executed using advanced machinery that ensures uniform tension and tight construction, which contributes to the rope’s low stretch and torque-free characteristics. The use of state-of-the-art braiding machines allows manufacturers to achieve consistent quality and performance across different batches.

3. Assembly

After the braiding process, the rope is cut to the desired lengths, and any necessary splicing is performed. Splicing is a critical technique that can maintain up to 100% of the rope’s average break strength when done correctly. Trained personnel carry out these splices, adhering to industry standards to ensure safety and reliability. This stage may also involve adding features such as color coding for easy identification, which is particularly beneficial in complex rigging applications.

4. Finishing

The final stage in the manufacturing process involves applying a protective coating, often a polyurethane or Samthane coating, which enhances the rope’s resistance to abrasion, UV rays, and environmental factors. After coating, the rope undergoes a visual inspection to check for any defects or inconsistencies. The finishing process may also include packaging, where the rope is wound into coils and labeled according to its specifications, including diameter, breaking strength, and intended use.

What Quality Assurance Standards Are Relevant for Stable Braid Rope?

Quality assurance in the manufacturing of stable braid rope is governed by various international and industry-specific standards. Compliance with these standards ensures that the rope produced is safe and reliable for use in demanding applications.

International Standards

ISO 9001 is one of the most recognized quality management system standards globally. Manufacturers of stable braid rope often seek ISO 9001 certification to demonstrate their commitment to quality and customer satisfaction. This standard emphasizes continuous improvement and customer feedback, which are essential for maintaining high production standards.

Industry-Specific Standards

In addition to ISO 9001, manufacturers may also comply with specific industry standards, such as CE marking for products sold in Europe and API standards for oil and gas applications. These certifications ensure that the rope meets rigorous safety and performance criteria, making it suitable for critical applications.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is a vital part of the manufacturing process for stable braid rope, involving multiple checkpoints to ensure that each batch meets predetermined specifications.

Incoming Quality Control (IQC)

The first QC checkpoint occurs during the material inspection phase. Incoming materials are tested for tensile strength, elongation, and abrasion resistance. Suppliers must provide documentation verifying that their materials meet the required specifications before they are accepted for production.

In-Process Quality Control (IPQC)

During the manufacturing stages, in-process inspections are conducted to monitor the braiding and assembly processes. This includes checks on the tension of the braiding, the consistency of the splice, and the application of the protective coating. Any deviations from established parameters are addressed immediately to prevent defects in the final product.

Final Quality Control (FQC)

Once the rope is finished, it undergoes a final quality inspection. This includes testing the rope for its breaking strength through destructive testing methods, where samples are subjected to load testing until failure. The results are documented, and any rope that does not meet the required breaking strength is rejected.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

Supplier Audits

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control practices. Buyers should request to review the supplier’s quality management system, including their compliance with ISO 9001 and other relevant standards. Audits can be conducted in person or through third-party inspection agencies, which provide an unbiased evaluation of the supplier’s operations.

Quality Reports

Buyers should also ask for quality assurance reports that detail the testing methods used, the results of batch testing, and any corrective actions taken for non-conforming products. These reports can provide insight into the supplier’s consistency in maintaining quality standards.

Third-Party Inspections

Engaging third-party inspection services can further enhance confidence in the quality of the rope being procured. These services can conduct independent testing and verification of the rope’s specifications, ensuring that it meets the buyer’s requirements before shipment.

What Nuances Should International Buyers Consider Regarding Quality Control?

International B2B buyers should be aware of specific nuances that can impact quality control and product reliability. This includes understanding local regulations and standards, which can vary significantly from one region to another.

Illustrative image related to stable braid rope

Compliance with Local Regulations

Buyers must ensure that the rope meets not only international standards but also any local regulations that may apply in their market. For example, certain countries may have additional safety standards for rigging equipment used in construction or maritime applications.

Cultural and Logistical Considerations

Cultural differences can also influence communication regarding quality expectations. Buyers should establish clear lines of communication with suppliers to ensure that quality requirements are understood and met. Additionally, logistical considerations, such as shipping times and storage conditions, can affect the quality of the rope upon arrival. Buyers should discuss these factors with suppliers to mitigate any potential issues.

By understanding the manufacturing processes and quality assurance measures in place for stable braid rope, B2B buyers can make informed decisions when sourcing products. This knowledge not only enhances procurement strategies but also ensures that the ropes purchased are fit for purpose, ultimately contributing to the safety and efficiency of operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stable braid rope’

To facilitate the effective procurement of stable braid rope, this guide outlines essential steps for B2B buyers. Following this checklist will ensure that you make informed decisions, source quality products, and establish reliable supplier relationships.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the stable braid rope you need. Consider factors such as diameter, tensile strength, and specific applications (e.g., rigging, arborist use). This step is crucial as it helps narrow down options and ensures that the rope will meet the demands of your projects.

Illustrative image related to stable braid rope

- Tensile Strength: Look for ropes with a breaking strength suitable for your intended application, typically ranging from 10,400 lbs to 29,900 lbs depending on the diameter.

- Material Composition: Most stable braid ropes are made from polyester; ensure that the rope has good abrasion and UV resistance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Utilize online directories, industry forums, and trade shows to compile a list of potential vendors. This step is vital to ensure you engage with suppliers who have a proven track record in quality and reliability.

- Supplier Reputation: Look for reviews and testimonials from previous customers.

- Geographical Considerations: Consider suppliers who understand the specific needs of your region, whether it be Africa, South America, the Middle East, or Europe.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that potential suppliers hold relevant certifications. This ensures that the ropes meet industry safety and quality standards. Such certifications are often a reflection of the supplier’s commitment to quality control and customer satisfaction.

- ISO Certifications: Look for suppliers with ISO 9001 certifications, which indicate a quality management system.

- Product Testing: Ensure that the ropes have undergone third-party testing for tensile strength and durability.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to assess the rope’s quality, flexibility, and handling characteristics firsthand. It’s an important step to ensure that the product meets your technical specifications and expectations.

- Testing Conditions: Perform tests under conditions similar to your intended application to evaluate performance.

- User Feedback: Gather input from your team on the usability of the samples.

Step 5: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. This step is crucial for ensuring that you get the best value for your investment while establishing a clear understanding of the supplier’s policies.

- Volume Discounts: Inquire about discounts for bulk purchases or long-term contracts.

- Lead Times: Clarify delivery timelines to align with your project schedules.

Step 6: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the performance of the stable braid rope post-purchase. This ensures that the product meets your expectations throughout its usage lifecycle.

Illustrative image related to stable braid rope

- Regular Inspections: Conduct periodic checks on the rope’s condition to identify any signs of wear or damage.

- Feedback Loop: Establish a channel for your team to report any issues with the rope, facilitating prompt resolutions.

Step 7: Build a Long-Term Relationship

Finally, focus on building a long-term relationship with your supplier. A strong partnership can lead to better pricing, priority service, and collaborative problem-solving in the future.

- Communication: Maintain open lines of communication to address any issues or changes in requirements.

- Loyalty Programs: Inquire about loyalty programs or incentives for repeat business.

By following these steps, B2B buyers can navigate the complexities of sourcing stable braid rope effectively, ensuring they acquire the best products for their operational needs.

Comprehensive Cost and Pricing Analysis for stable braid rope Sourcing

Analyzing the cost structure and pricing dynamics of stable braid rope is essential for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding the various cost components and price influencers can lead to more informed purchasing decisions and better negotiation outcomes.

What Are the Key Cost Components of Stable Braid Rope?

-

Materials: The primary cost driver for stable braid rope is the raw materials, predominantly polyester fibers, which are known for their high strength, low stretch, and resistance to UV degradation. The quality of these materials directly impacts the rope’s performance, durability, and ultimately, its price.

-

Labor: Manufacturing labor costs vary significantly by region. In countries with lower labor costs, such as those in Southeast Asia, the production of stable braid rope can be more cost-effective. Conversely, labor costs in Europe may increase the overall price.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The initial setup for producing stable braid rope, including machinery and equipment, contributes to the tooling costs. Custom tooling for specialized rope specifications can further increase these expenses.

-

Quality Control (QC): Ensuring that each batch of rope meets safety and performance standards is critical. QC processes add to the overall cost, but they are necessary to maintain product integrity and avoid liabilities.

-

Logistics: Transportation costs play a significant role, especially for international shipments. Factors such as distance, shipping method, and local tariffs can influence logistics expenses.

-

Margin: Suppliers typically add a markup to cover their costs and generate profit. This margin can vary based on competition, market demand, and the supplier’s operational efficiencies.

How Do Price Influencers Affect Stable Braid Rope Sourcing?

-

Volume/MOQ: Purchasing in larger quantities often results in lower per-unit costs due to economies of scale. Buyers should consider their needs carefully to negotiate minimum order quantities (MOQs) that align with their operational requirements.

-

Specifications/Customization: Customized ropes, such as those with specific diameters, breaking strengths, or color coding, can lead to higher prices. Buyers should evaluate whether these features are essential for their applications.

-

Material Quality/Certifications: Ropes that meet specific industry standards or certifications may carry a premium price. However, investing in higher-quality products can reduce long-term costs associated with replacements and failures.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record and customer service, while newer companies may offer competitive rates to enter the market.

-

Incoterms: Understanding the terms of sale is crucial for budgeting total costs. Different Incoterms (like FOB, CIF, etc.) affect who bears the shipping and insurance costs, impacting the final price.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Stable Braid Rope?

-

Negotiation: Buyers should be prepared to negotiate terms based on volume, payment options, and delivery timelines. Building long-term relationships with suppliers can lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, replacement, and potential downtime costs associated with lower-quality ropes. A higher upfront investment in quality may yield savings over time.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East may face unique challenges, such as currency fluctuations and import regulations. Understanding these factors can help in budgeting and negotiating effectively.

-

Disclaimer for Indicative Prices: Prices can fluctuate based on market conditions, raw material availability, and geopolitical factors. Always seek updated quotes and be aware that indicative prices may not reflect current market realities.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and strategic sourcing tips is essential for international B2B buyers of stable braid rope. This knowledge enables informed decision-making, ultimately leading to better purchasing outcomes and operational efficiencies.

Alternatives Analysis: Comparing stable braid rope With Other Solutions

In the realm of rigging and lifting solutions, stable braid rope stands out for its unique properties, but buyers often seek alternatives that may better suit their specific applications or budgets. This section explores several viable alternatives to stable braid rope, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Stable Braid Rope | Synthetic Fiber Rope | Steel Cable |

|---|---|---|---|

| Performance | High tensile strength (up to 29,900 lbs), low stretch (under 3%) | Good tensile strength, but higher stretch | Very high tensile strength, minimal stretch |

| Cost | Moderate cost ($1.07 to $3.66 per foot) | Generally lower cost | Higher initial investment |

| Ease of Implementation | Easy to splice and handle | Simple to use, but requires special knots | Requires specialized tools for installation |

| Maintenance | Low maintenance, UV and abrasion resistant | Moderate; may wear faster in harsh conditions | Low maintenance but can corrode if not protected |

| Best Use Case | Arborist work, rigging applications | General lifting and hauling | Heavy-duty industrial applications |

What Are the Advantages and Disadvantages of Synthetic Fiber Rope as an Alternative?

Synthetic fiber ropes, such as those made from nylon or polypropylene, are widely used for various lifting and rigging applications. These ropes offer a good balance of strength and flexibility, making them suitable for general-purpose use. The primary advantage of synthetic fiber ropes is their lower cost compared to stable braid rope. However, they may stretch more under load, which can be a disadvantage in applications requiring precision. Additionally, while they are generally resistant to UV damage, their lifespan may be reduced in abrasive environments.

How Does Steel Cable Compare to Stable Braid Rope?

Steel cable is another alternative that provides exceptional strength and durability. It is particularly advantageous in heavy-duty industrial settings where maximum load-bearing capacity is critical. Steel cables have minimal stretch, ensuring that loads remain stable during lifting operations. However, they come with a higher upfront cost and require specialized tools for installation and maintenance. Additionally, steel cables can corrode if not properly maintained, necessitating regular inspections to ensure safety.

Conclusion: How Should B2B Buyers Choose the Right Rigging Solution?

When selecting a rigging solution, B2B buyers must consider their specific operational needs, budget constraints, and application environments. Stable braid rope is an excellent choice for arborist and general rigging applications due to its high strength, low stretch, and ease of use. For those seeking cost-effective options for lighter loads, synthetic fiber ropes may suffice. Conversely, for heavy-duty applications requiring the utmost strength, steel cables are unmatched. Ultimately, understanding the unique properties and limitations of each alternative will enable buyers to make informed decisions that enhance safety and efficiency in their operations.

Essential Technical Properties and Trade Terminology for stable braid rope

What Are the Key Technical Properties of Stable Braid Rope?

When considering stable braid rope for various applications, understanding its technical specifications is crucial for B2B buyers. Here are essential properties to look out for:

1. Material Composition

Stable braid rope is typically made from high-quality polyester fibers. This material is favored for its durability, resistance to UV rays, and low stretch properties. In B2B contexts, polyester’s resistance to abrasion and environmental factors makes it ideal for industries such as construction, arboriculture, and marine applications, where ropes are subject to harsh conditions.

2. Diameter and Weight

The diameter of stable braid rope can vary, commonly ranging from 1/2 inch to 5/8 inch, impacting both its strength and weight. The weight of the rope, often specified in pounds per 100 feet, plays a crucial role in determining ease of handling and transportation. Buyers must consider the appropriate diameter and weight for their specific applications to ensure optimal performance and safety.

3. Breaking Strength

Breaking strength, or tensile strength, is a critical specification that indicates the maximum load the rope can handle before failure. For instance, stable braid ropes can have breaking strengths ranging from 10,400 lbs to 29,900 lbs depending on the diameter. Understanding this metric helps businesses select the right rope for their load requirements, ensuring safety and preventing equipment failure.

4. Work Load Limit (WLL)

The Work Load Limit is the maximum load that a rope can safely handle during operation, often recommended to be 1/10 to 1/4 of the breaking strength. This specification is vital for buyers as it guides them in determining the safe operational limits of the rope, helping to mitigate risks in various applications.

Illustrative image related to stable braid rope

5. Stretch Characteristics

Stable braid ropes exhibit low stretch, typically under 3% at 30% of tensile strength. This property is essential for applications requiring precision, such as rigging and lifting. B2B buyers should prioritize low-stretch ropes to enhance control and stability during operations.

What Are Common Trade Terms Used in Stable Braid Rope Transactions?

Understanding industry jargon is essential for effective communication and negotiation in the B2B rope market. Here are several commonly used terms:

1. OEM (Original Equipment Manufacturer)

In the context of stable braid rope, OEM refers to companies that produce the ropes for brands that sell them under their own names. Understanding OEM relationships can help buyers evaluate product quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers as it can impact inventory management and cost efficiency.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products, including stable braid ropes. This process helps buyers compare costs and negotiate better deals, ensuring they secure the best value for their needs.

Illustrative image related to stable braid rope

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can aid B2B buyers in understanding shipping costs, risk management, and delivery responsibilities.

5. Splice

A splice is a method of joining two lengths of rope, which is critical for applications requiring strong and secure connections. Buyers should be aware that a well-executed splice can maintain up to 100% of the rope’s strength, making it a vital consideration in rigging applications.

By understanding these key properties and terminology, B2B buyers can make informed decisions when sourcing stable braid rope, ensuring they meet their operational requirements efficiently and safely.

Navigating Market Dynamics and Sourcing Trends in the stable braid rope Sector

What Are the Current Market Dynamics and Key Trends for Stable Braid Rope?

The stable braid rope market is experiencing significant growth driven by a surge in demand across various sectors, including construction, arboriculture, and marine applications. The global push for safety and compliance standards is elevating the importance of high-strength, low-stretch ropes, such as stable braid ropes, which offer superior performance in demanding environments. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Illustrative image related to stable braid rope

Emerging technologies are reshaping sourcing trends, with advancements in manufacturing processes leading to more durable and efficient ropes. Automation in production not only enhances quality but also reduces lead times, which is essential for buyers facing tight project deadlines. Additionally, the rise of e-commerce platforms is enabling easier access to a wider variety of products, allowing buyers to compare options and make informed decisions quickly.

Another key trend is the increasing demand for customized solutions. Buyers are looking for ropes that can be tailored to specific applications, such as specialized splicing or unique color coding for easy identification. As these market dynamics evolve, B2B buyers must stay informed about product innovations and supplier capabilities to maintain a competitive edge.

How Important Is Sustainability and Ethical Sourcing in the Stable Braid Rope Sector?

Sustainability is becoming a cornerstone of B2B procurement, particularly for buyers in environmentally conscious markets. The production of stable braid ropes often involves the use of synthetic materials like polyester, which, while durable and effective, can pose environmental challenges if not sourced responsibly. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices.

One effective approach is to seek out ropes made from recycled or eco-friendly materials. Certifications such as Global Recycled Standard (GRS) or OEKO-TEX® can provide assurance that the products meet environmental and social responsibility criteria. Buyers should also consider the entire lifecycle of the product, including the potential for recycling at the end of its use.

Moreover, transparent supply chains are gaining importance, with buyers favoring suppliers who can provide clear information about their sourcing practices and environmental impact. By prioritizing sustainability, B2B buyers not only contribute to environmental preservation but also enhance their brand reputation and appeal to a growing base of eco-conscious customers.

Illustrative image related to stable braid rope

What Is the Brief Evolution and History of Stable Braid Rope?

Stable braid rope has evolved significantly over the years, initially emerging from the need for robust and reliable rigging solutions in maritime and industrial applications. The traditional materials were often natural fibers, which, while effective, lacked the durability and low-stretch characteristics required for demanding tasks.

With the advent of synthetic fibers in the late 20th century, manufacturers began to produce stable braid ropes using advanced materials like polyester. This innovation marked a pivotal shift, as synthetic ropes offered improved strength, UV resistance, and abrasion protection, making them ideal for various applications, from construction to arboriculture.

Today, stable braid ropes are recognized for their versatility and reliability, with advancements in manufacturing techniques further enhancing their performance characteristics. As the market continues to evolve, the focus on technology and sustainability will likely shape the future of stable braid rope products, ensuring they meet the diverse needs of global B2B buyers.

Illustrative image related to stable braid rope

Frequently Asked Questions (FAQs) for B2B Buyers of stable braid rope

-

How do I choose the right stable braid rope for my application?

Selecting the right stable braid rope depends on the specific requirements of your application, such as load capacity, environmental conditions, and flexibility. Assess the breaking strength needed for your tasks; stable braid ropes are available with breaking strengths ranging from 10,400 lbs to 29,900 lbs. Consider factors like UV resistance and abrasion protection, especially for outdoor use. Additionally, think about the diameter that suits your equipment and application, as different diameters offer various strengths and handling characteristics. -

What is the best stable braid rope for rigging applications?

For rigging applications, the best stable braid rope is one with high tensile strength and low stretch properties. Ropes like the 5/8″ stable braid, which has an average breaking strength of 16,300 lbs, are ideal due to their torque-free construction and excellent abrasion resistance. These features ensure safety and reliability in demanding environments. Always verify the rope’s specifications against your operational requirements to ensure optimal performance. -

What customization options are available for stable braid rope orders?

Many suppliers offer customization options for stable braid rope, including specific lengths, diameters, colors, and splicing services. You can request custom splices to enhance usability, but be aware that certain configurations may have limitations based on the rope type. It’s advisable to communicate your specific needs during the ordering process to ensure the product meets your exact specifications. -

What are the minimum order quantities (MOQ) for stable braid rope?

Minimum order quantities for stable braid rope can vary significantly by supplier and region. Typically, MOQs range from 100 feet to several thousand feet, especially for bulk orders. When sourcing internationally, consider factors like shipping costs and lead times, as larger orders may reduce per-unit costs. Always confirm the MOQ with your supplier to align your purchasing strategy with your operational needs. -

What payment terms should I expect when sourcing stable braid rope internationally?

Payment terms for international purchases of stable braid rope often include options such as advance payment, letters of credit, or payment upon delivery. Terms may vary based on the supplier’s policies, your creditworthiness, and the relationship you have established. It is advisable to negotiate payment terms that offer both security and flexibility, ensuring that they are clear in your purchase agreement to avoid any misunderstandings. -

How can I ensure quality assurance when buying stable braid rope?

To ensure quality assurance when purchasing stable braid rope, request certifications and testing reports from suppliers that verify the rope’s specifications, such as breaking strength and material composition. A reputable supplier should conduct regular quality checks and provide documentation to confirm compliance with industry standards. Additionally, consider seeking references or reviews from other businesses that have sourced from the same supplier to gauge their reliability and product quality. -

What logistics considerations should I be aware of when importing stable braid rope?

When importing stable braid rope, consider logistics aspects such as shipping methods, customs clearance, and delivery timelines. Ensure that you understand the import regulations in your country, including any tariffs or taxes applicable to rope products. Work with a freight forwarder experienced in your industry to streamline the shipping process and avoid delays. Additionally, confirm that the supplier can accommodate your shipping requirements to ensure timely delivery of your order. -

How do I handle potential issues or disputes with my stable braid rope supplier?

In case of issues or disputes with your stable braid rope supplier, maintain clear communication to address concerns promptly. Document all transactions and communications to provide a reference if disputes arise. Familiarize yourself with the supplier’s return and complaint policy before finalizing a purchase. If necessary, consider mediation or arbitration to resolve disputes amicably. Building a strong relationship with your supplier can also help in mitigating potential conflicts in the future.

Top 7 Stable Braid Rope Manufacturers & Suppliers List

1. Samson Rope – Stable Braid

Domain: samsonrope.com

Registered: 2000 (25 years)

Introduction: This company, Samson Rope – Stable Braid, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

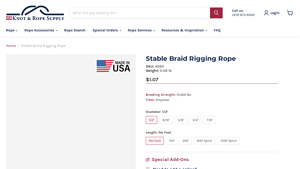

2. Knot and Rope – Stable Braid Rigging Rope

Domain: knotandrope.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “Stable Braid Rigging Rope”, “SKU”: “4084”, “Weight”: “0.08 lb”, “Original Price”: “$1.07 – $3,660.00”, “Current Price”: “$1.07”, “Breaking Strengths”: [“10,400 lbs.”, “13,300 lbs.”, “16,300 lbs.”, “20,400 lbs.”, “29,900 lbs.”], “Fiber Composition”: “Polyester”, “Diameter Options”: [“1/2”, “9/16”, “5/8”, “3/4”, “7/8”], “Length Options”: [“Per Foot”, “150′”, “200′”, “600′ Spool”, “…

3. Samson Rope – Stable Braid Rope

Domain: bartlettman.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Stable Braid Rope”, “diameter”: “1/2 inch”, “brand”: “Samson Rope”, “sku”: “R-1/2X150-SB”, “length_options”: [{“length”: “150 Feet”, “color”: [“Blue”, “Red”], “price”: “$134.55”}, {“length”: “200 Feet”, “color”: [“Blue”, “Red”], “price”: “$179.40”}, {“length”: “600 Feet”, “color”: [“Blue”, “Red”], “price”: “$538.15”}], “construction”: “2 in 1 with polyester cover over polyester c…

4. Wesspur – Stable Braid Rigging Rope

Domain: wesspur.com

Registered: 1998 (27 years)

Introduction: This company, Wesspur – Stable Braid Rigging Rope, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

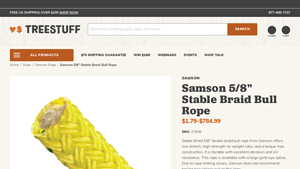

5. Samson – 5/8 Stable Braid Bull Rope

Domain: treestuff.com

Registered: 2006 (19 years)

Introduction: Samson 5/8″ Stable Braid Bull Rope

– Diameter: 5/8″ (17mm)

– Weight: 14 lbs/100ft (20.8kg/100m)

– Specific Gravity: 1.38

– Average Breaking Strength: 16,300lbs (7,400kg)

– Work Load Limit: 3,300lbs (1,500kg)

– Elongation at 10% Average Breaking Strength: 1.1%

– Fiber: Polyester

– Features: Low stretch, high strength-to-weight ratio, torque-free construction, durable, excellent abrasion and UV resi…

6. Samson – Stable Braid Rigging Rope

Domain: riggingwarehouse.com

Registered: 2006 (19 years)

Introduction: {‘Product_Name’: ‘Samson Stable Braid Rigging Rope 1/2″ – Per Foot – Black’, ‘Product_Code’: ‘502-507032200000’, ‘Description’: ‘Samson Stable Braid Coated Rope is a double braid rope with a low stretch, high strength-to-weight ratio, and torque-free construction. It is durable with excellent abrasion and UV resistance. This rope is Polyester fiber, flexible and easy to handle. Uncoated – made wit…

7. Marlow – Raptor Rigging Rope

Strategic Sourcing Conclusion and Outlook for stable braid rope

The strategic sourcing of stable braid rope presents a multitude of benefits for B2B buyers across diverse industries, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the unique properties of stable braid rope—such as its high tensile strength, low stretch, and exceptional abrasion resistance—allows businesses to choose the right products for their specific applications, from rigging to arborist tasks.

By sourcing these ropes from reputable manufacturers, companies can ensure product quality and reliability, ultimately enhancing operational efficiency and safety. As the demand for durable and versatile rigging solutions grows, establishing partnerships with trusted suppliers will be crucial for maintaining a competitive edge in the market.

Looking ahead, international buyers are encouraged to engage with manufacturers who offer comprehensive product information and support, including guidance on proper usage and maintenance. By prioritizing strategic sourcing, businesses can not only meet their immediate needs but also position themselves for long-term success in an evolving marketplace. Explore your options today to secure the best stable braid rope for your applications and elevate your operational capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.