The Definitive Guide to Spy Camera In Screws: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for spy camera in screws

Navigating the global market for spy cameras in screws presents unique challenges for B2B buyers seeking innovative surveillance solutions. As the demand for discreet and efficient monitoring systems grows, sourcing these covert devices can be daunting, especially when balancing quality, functionality, and cost. This guide delves into the multifaceted world of screw-type spy cameras, offering insights into their diverse applications, ranging from security in commercial spaces to personal safety in various settings.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including key markets such as Germany and Vietnam—will find valuable resources on how to identify reputable suppliers, assess product specifications, and understand pricing structures. We explore the different types of screw cameras available, their technological features, and the importance of compliance with regional regulations.

By leveraging the comprehensive information in this guide, businesses can make informed purchasing decisions that align with their operational needs. Whether you are looking to enhance security measures or integrate advanced surveillance technology into your offerings, this resource empowers you to navigate the complexities of the market with confidence and clarity.

Understanding spy camera in screws Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Phillips Screw Head Pinhole Camera | Indistinguishable from standard Phillips screw; compact design | Security surveillance, retail stores | Pros: Discreet, easy installation. Cons: Limited battery life, no cloud connectivity. |

| Wi-Fi Button & Screw Wearable Camera | Remote access, HD quality, rechargeable battery | Law enforcement, undercover operations | Pros: Live streaming, high-quality recordings. Cons: Requires Wi-Fi for full functionality. |

| USB Port Compatible Screw Camera | USB connectivity, compact size, multiple mounting options | Corporate espionage, facility monitoring | Pros: Versatile installation, easy data transfer. Cons: May require technical know-how for setup. |

| Motion-Activated Screw Camera | Motion detection, energy-efficient recording | Home security, event monitoring | Pros: Saves storage space, less manual oversight. Cons: May miss recordings if motion is infrequent. |

| Multi-Functional Screw Camera | Combines screw functionality with audio and video recording | Investigative journalism, personal security | Pros: Dual functionality, extensive storage options. Cons: Higher upfront cost, potential legal issues. |

What Are the Characteristics and Suitability of Each Type of Spy Camera in Screws?

The Phillips Screw Head Pinhole Camera is designed to blend seamlessly with standard screws, making it ideal for discreet surveillance in retail environments and corporate offices. Its compact size means it can be installed in various locations without drawing attention. However, the lack of cloud connectivity and limited battery life can be drawbacks for businesses requiring continuous monitoring.

The Wi-Fi Button & Screw Wearable Camera stands out for its remote access capabilities and high-definition video quality. This type is particularly suited for law enforcement and undercover operations, where real-time data transmission is crucial. While it offers significant advantages, the necessity for a stable Wi-Fi connection may limit its use in remote locations.

For organizations needing versatile installation options, the USB Port Compatible Screw Camera provides a compact solution that can connect to various devices. This adaptability makes it suitable for corporate espionage and facility monitoring. However, it may require a certain level of technical expertise for effective setup and operation.

The Motion-Activated Screw Camera is designed to conserve storage space by only recording when motion is detected. This feature makes it particularly useful for home security and event monitoring, where continuous recording may not be necessary. However, businesses should consider that it may miss events if motion is infrequent, potentially leading to gaps in surveillance.

Lastly, the Multi-Functional Screw Camera combines audio and video recording capabilities, making it suitable for investigative journalism and personal security. Its extensive storage options allow for prolonged use without frequent data transfers. However, the higher initial investment and potential legal implications of recording in certain jurisdictions may deter some buyers.

In summary, when selecting a spy camera in screws, B2B buyers should carefully assess their specific needs, installation environments, and any technical requirements to ensure they choose the most effective solution for their surveillance objectives.

Key Industrial Applications of spy camera in screws

| Industry/Sector | Specific Application of spy camera in screws | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Security Services | Surveillance in high-risk areas using screw cameras | Enhanced security monitoring and risk mitigation | Ensure high-resolution imaging and reliable power sources |

| Retail | Loss prevention and inventory control | Reduces theft and improves inventory accuracy | Look for discreet design and easy installation options |

| Law Enforcement | Undercover operations and evidence collection | Provides critical video evidence for investigations | Focus on durability and remote access features |

| Hospitality | Monitoring staff and guest interactions | Improves service quality and guest safety | Require compliance with local privacy regulations |

| Construction | Site security and monitoring of equipment | Protects valuable assets and ensures safety compliance | Assess weather resistance and battery life for outdoor use |

How Are Spy Cameras in Screws Used in Security Services?

In the security sector, spy cameras disguised as screws are strategically placed in high-risk areas such as banks, jewelry stores, and critical infrastructure sites. These inconspicuous devices allow for continuous monitoring without alerting potential intruders. By integrating these cameras, businesses can enhance their security measures and provide evidence in case of incidents. Buyers should prioritize high-resolution imaging capabilities and reliable power sources to ensure uninterrupted surveillance.

What Role Do Spy Cameras in Screws Play in Retail Loss Prevention?

In retail environments, screw cameras are deployed in areas prone to theft, such as near entrances, exits, and high-value merchandise displays. Their discreet nature allows for unobtrusive monitoring of customer interactions and employee behavior, significantly reducing instances of shoplifting. The integration of such technology helps businesses maintain accurate inventory levels and enhances overall store security. Buyers should focus on discreet design and ease of installation to maximize effectiveness.

How Do Spy Cameras in Screws Assist Law Enforcement?

Law enforcement agencies utilize screw cameras for undercover operations where maintaining a low profile is crucial. These devices can be hidden in everyday objects, enabling officers to gather evidence without compromising their identity. This technology is vital for capturing real-time interactions and activities, which can be used in court proceedings. Buyers in this sector should prioritize features like durability, remote access, and high-quality video capabilities to meet operational demands.

In What Ways Are Spy Cameras in Screws Used in the Hospitality Industry?

In the hospitality sector, screw cameras are employed to monitor staff interactions and ensure guest safety. These cameras can be installed in common areas, such as lobbies and hallways, to enhance service quality and respond to any incidents swiftly. By using this technology, hotels and resorts can improve their security protocols and provide a safer environment for guests. Buyers should ensure compliance with local privacy regulations and consider the camera’s discreetness and installation flexibility.

How Are Spy Cameras in Screws Beneficial in Construction Sites?

On construction sites, screw cameras serve as an effective solution for monitoring equipment and ensuring safety compliance. By placing these devices in strategic locations, businesses can deter theft of tools and materials while also overseeing worker safety practices. This proactive approach helps protect valuable assets and fosters a culture of accountability among workers. Buyers should assess the camera’s weather resistance and battery life to ensure optimal performance in outdoor environments.

3 Common User Pain Points for ‘spy camera in screws’ & Their Solutions

Scenario 1: Difficulty in Identifying Authentic Spy Cameras Disguised as Screws

The Problem:

B2B buyers often face challenges in distinguishing between genuine screw-type hidden cameras and traditional screws. This difficulty can lead to costly mispurchases and ineffective surveillance solutions. For example, a security company may acquire a batch of screw cameras, only to find that they are non-functional or do not meet their surveillance needs, resulting in wasted time and resources. Additionally, the lack of clear specifications and varying quality across suppliers can further complicate the purchasing process.

The Solution:

To ensure the authenticity and functionality of screw cameras, B2B buyers should prioritize sourcing from reputable manufacturers with a proven track record. Conducting thorough research and requesting samples before bulk purchasing can help validate the quality and performance of the products. Buyers should also look for detailed specifications, such as lens quality, video resolution, and compatibility with existing surveillance systems. Establishing a relationship with a trusted supplier can also provide ongoing support and warranty options, which are critical for maintaining operational integrity. Furthermore, investing in training for staff on how to identify and differentiate genuine screw cameras from standard screws will enhance their purchasing decisions.

Scenario 2: Concerns About Data Privacy and Security with Spy Cameras

The Problem:

As the use of surveillance technology grows, so do concerns about data privacy and security. B2B buyers, especially those in sensitive industries such as law enforcement and corporate security, face the dilemma of ensuring that their surveillance devices, including screw cameras, comply with legal and ethical standards. The risk of inadvertently violating privacy laws or facing backlash over surveillance practices can deter businesses from fully utilizing such technology.

The Solution:

B2B buyers should engage with suppliers who provide comprehensive information about compliance with local and international privacy regulations. Choosing cameras that offer built-in security features, such as encrypted data transmission and secure storage options, can mitigate risks associated with data breaches. Additionally, implementing strict internal policies regarding the use of surveillance equipment and ensuring that employees are trained on privacy best practices can foster a culture of accountability. Regular audits of surveillance practices can also help organizations stay compliant and protect themselves from potential legal issues.

Scenario 3: Limited Battery Life and Power Management in Spy Cameras

The Problem:

Another common pain point for B2B buyers is the limited battery life of screw-type hidden cameras, which can hinder continuous surveillance efforts. For instance, in a retail setting, a security team may find that their screw cameras do not last through long operational hours, leading to gaps in surveillance coverage. The need for frequent recharging or battery replacements can disrupt workflows and increase operational costs.

The Solution:

To address battery life concerns, B2B buyers should prioritize sourcing screw cameras with longer operational periods and options for external power sources. Cameras that support continuous power through USB connections or those that can be integrated into existing electrical systems are ideal for environments requiring extended surveillance. Additionally, selecting models with motion detection capabilities can conserve battery life by only activating recording when movement is detected. Buyers should also consider investing in backup battery packs or alternative power solutions to ensure that surveillance systems remain operational without interruption. Regular maintenance checks on battery health can also help preemptively identify issues before they impact surveillance capabilities.

Strategic Material Selection Guide for spy camera in screws

What Materials Are Commonly Used for Spy Cameras in Screws?

In the development of spy cameras disguised as screws, the choice of materials is crucial for ensuring performance, durability, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of these devices: plastic, stainless steel, brass, and aluminum.

How Does Plastic Perform in Spy Camera Screws?

Plastic is often chosen for its lightweight properties and ease of manufacturing. Key properties include good insulation against electrical interference and a moderate temperature resistance, typically up to 80°C.

Pros: Plastic is cost-effective and can be molded into intricate designs, making it suitable for various applications. It is resistant to corrosion, which is advantageous in humid environments.

Cons: However, plastic can be less durable than metal alternatives and may not withstand high temperatures or mechanical stress as effectively.

Impact on Application: Plastic screws are often used in indoor environments where durability is less of a concern. They are compatible with various electronic components but may not be suitable for high-performance applications.

International Considerations: Buyers from regions with high humidity, such as parts of Africa and South America, should consider moisture-resistant plastics. Compliance with standards like ASTM D638 for tensile properties may also be relevant.

What Advantages Does Stainless Steel Offer for Spy Camera Screws?

Stainless steel is a popular choice due to its high strength and excellent corrosion resistance. It typically withstands temperatures up to 300°C and offers good mechanical properties.

Pros: Its durability makes it ideal for outdoor applications, ensuring long-term functionality even in harsh conditions. Stainless steel is also aesthetically pleasing, which can be a factor in consumer-facing products.

Cons: The primary drawback is the higher cost compared to plastic. Additionally, stainless steel can be heavier, which may not be suitable for all applications.

Impact on Application: Stainless steel screws are particularly effective in environments where exposure to moisture and corrosive elements is a concern, such as coastal areas in Europe and the Middle East.

International Considerations: Buyers should ensure compliance with standards such as ASTM A240 for stainless steel and consider the specific grades suitable for their applications.

Why Choose Brass for Spy Camera Screws?

Brass is another material option, known for its excellent machinability and corrosion resistance. It has a moderate temperature rating, typically around 150°C.

Pros: Brass offers good electrical conductivity, making it suitable for applications requiring electronic connections. Its aesthetic appeal can also be a selling point.

Cons: However, brass is more expensive than plastic and can be less durable than stainless steel in harsh environments.

Impact on Application: Brass screws are often used in decorative or high-end applications where appearance is important, such as in luxury electronics.

International Considerations: Buyers should be aware of the regulations regarding lead content in brass, especially in Europe, where compliance with RoHS standards is critical.

How Does Aluminum Compare in Spy Camera Screws?

Aluminum is valued for its lightweight and strength-to-weight ratio, with a temperature rating of around 150°C.

Pros: It is corrosion-resistant and can be anodized for additional protection, making it suitable for various environments. Its low weight is advantageous for portable applications.

Cons: The main limitation is that aluminum can be more expensive than plastic and may not provide the same level of durability as stainless steel.

Impact on Application: Aluminum screws are often used in applications where weight savings are critical, such as in wearable technology.

International Considerations: Buyers should consider compliance with standards like ASTM B221 for aluminum extrusions and ensure that the alloy used meets their specific requirements.

Summary Table of Material Selection for Spy Camera in Screws

| Material | Typical Use Case for spy camera in screws | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Indoor applications | Lightweight and cost-effective | Less durable under stress | Low |

| Stainless Steel | Outdoor applications | High strength and corrosion resistant | Higher cost and weight | High |

| Brass | Decorative electronics | Good machinability and aesthetic appeal | More expensive and less durable | Med |

| Aluminum | Portable technology | Lightweight and corrosion-resistant | More expensive than plastic | Med |

This guide provides B2B buyers with essential insights into material selection for spy cameras in screws, helping them make informed decisions that align with their specific requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for spy camera in screws

What Are the Key Stages in the Manufacturing Process for Spy Cameras in Screws?

The manufacturing of spy cameras disguised as screws involves a series of critical stages, each designed to ensure that the final product meets both aesthetic and functional requirements. Here’s a breakdown of the main stages involved in the manufacturing process:

Material Preparation

The first step involves selecting high-quality materials that can withstand the rigors of usage while maintaining a discreet appearance. Common materials include high-grade plastics and metals that mimic the look of traditional screws. The materials undergo a thorough quality check to ensure they meet specifications for durability, weight, and finish.

Forming Techniques Used in Manufacturing Spy Cameras

Once the materials are prepared, forming techniques come into play. This stage often involves precision machining processes such as:

-

CNC Machining: Computer Numerical Control (CNC) machines are employed to create the intricate shapes needed for the screw head and housing for the camera lens. This ensures high precision and uniformity across products.

-

Injection Molding: For components made from plastic, injection molding is commonly used. This technique allows for complex shapes to be formed efficiently and is essential for mass production.

-

Stamping: Metal components may be stamped to create the base of the screw. This technique is crucial for ensuring that the metal parts fit perfectly with the camera housing.

Assembly of Spy Cameras in Screws

After forming, the assembly stage begins, where various components are brought together. This often includes:

-

Camera Lens Integration: The miniature camera and lens assembly must be carefully integrated into the screw structure. This requires precision alignment to ensure optimal video capture.

-

Wiring and Electronics: The wiring for power and data transfer is added during this phase. Ensuring that these connections are secure and correctly insulated is critical to product reliability.

-

Quality Assurance Checks: During assembly, continuous quality checks are performed to catch any defects early in the process.

Finishing Touches for Aesthetic and Functional Quality

The final stage is finishing, which includes painting, coating, or polishing the product to enhance its appearance and protect it from environmental damage. The finishing process is crucial for ensuring that the spy camera remains indistinguishable from ordinary screws.

What Quality Assurance Standards Are Relevant for Spy Cameras in Screws?

Quality assurance is vital in the manufacturing of spy cameras in screws, ensuring that products not only meet customer expectations but also comply with international standards. Here are some key standards and practices that B2B buyers should be aware of:

International Standards and Certifications

-

ISO 9001: This widely recognized quality management standard ensures that organizations consistently meet customer and regulatory requirements. Manufacturers should ideally be certified to this standard, demonstrating their commitment to quality.

-

CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with safety, health, and environmental protection standards. This certification is essential for ensuring that the product is safe for use.

-

NDAA Compliance: Particularly relevant for U.S. government contracts, this ensures that the cameras do not use components from certain foreign entities.

Key Quality Control Checkpoints

Quality Control (QC) is typically structured around several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon receipt. This ensures that only materials that meet specified quality standards proceed to the next stages.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to identify defects early. This can include dimensional checks, visual inspections, and functional testing of components.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection ensures that each unit meets the required specifications. This includes functional testing of the camera and its integration into the screw.

What Testing Methods Are Commonly Used in Quality Assurance for Spy Cameras?

Several testing methods are employed to ensure that spy cameras in screws function correctly and meet quality standards:

-

Functional Testing: This includes checking the camera’s video quality, battery life, and connectivity features. It ensures that all functionalities work as intended.

-

Environmental Testing: This assesses how well the product performs under various environmental conditions, such as temperature extremes and humidity.

-

Durability Testing: Conducting stress tests to evaluate the product’s resilience against physical impacts, which is crucial given the potential for wear and tear in everyday use.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are several strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and QC practices. This can include on-site visits and reviews of their quality management systems.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports, including results from various testing methods and any relevant certifications.

-

Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality before shipment. This is particularly useful for large orders where the stakes are higher.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various regulatory landscapes and quality expectations. Here are some nuances to consider:

-

Local Regulations: Different countries have specific regulations regarding the sale and use of surveillance devices. Buyers must ensure that products comply with local laws in their respective markets.

-

Cultural Sensitivity: Understanding cultural attitudes towards surveillance can influence purchasing decisions. Products that are acceptable in one market may not be viewed favorably in another.

-

Logistics and Supply Chain: Consideration of shipping times, customs regulations, and potential tariffs can impact the final cost and availability of products.

By focusing on these aspects of the manufacturing process and quality assurance, B2B buyers can make informed decisions when sourcing spy cameras in screws, ensuring they choose reliable suppliers that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spy camera in screws’

Introduction

This guide provides a comprehensive checklist for B2B buyers looking to source spy cameras disguised as screws. As the demand for discreet surveillance solutions grows globally, particularly in markets across Africa, South America, the Middle East, and Europe, it is essential to approach sourcing with a well-defined strategy. This checklist will help you ensure that you select high-quality, compliant products that meet your operational requirements.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline the technical specifications needed for your spy camera in screws. Consider factors such as resolution, battery life, connectivity options (Wi-Fi or wired), and recording capacity. Having precise specifications will streamline the procurement process and facilitate better communication with potential suppliers.

- Resolution: Look for cameras that offer at least 1080p for clear image quality.

- Battery Life: Assess how long the camera can operate on a single charge, especially for extended use.

Step 2: Research Market Trends and Compliance

Understanding current market trends and compliance requirements is critical. Different regions may have varying regulations regarding surveillance equipment, and knowing these will help you avoid legal issues.

- Local Regulations: Familiarize yourself with laws governing the use of surveillance devices in your target market.

- Market Innovations: Stay updated on technological advancements that could enhance your surveillance capabilities, such as improved image stabilization or advanced motion detection.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your specifications and quality standards. Request detailed company profiles, including their experience in the industry and references from other B2B clients.

- Supplier Credentials: Look for certifications or industry recognitions that validate their expertise.

- Product Reviews: Analyze feedback from other buyers to gauge product reliability and supplier support.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the spy cameras. This step allows you to evaluate the product’s performance firsthand, ensuring it meets your expectations.

- Functionality Testing: Check the camera’s resolution, battery life, and ease of use.

- Disguise Effectiveness: Ensure the camera’s design convincingly resembles a standard screw.

Step 5: Verify Warranty and Support Options

A robust warranty and reliable customer support are crucial when sourcing technology products. Ensure that the supplier offers comprehensive support, including troubleshooting and potential repairs.

- Warranty Terms: Look for warranties that cover a minimum of one year.

- Technical Support: Confirm the availability of support channels, including online resources and dedicated customer service.

Step 6: Negotiate Pricing and Payment Terms

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing and payment terms. Ensure that the costs align with your budget while also considering the value provided.

- Bulk Purchase Discounts: Inquire about discounts for larger orders.

- Payment Flexibility: Discuss payment terms that work for your financial strategy, such as installments or deferred payments.

Step 7: Plan for Post-Purchase Logistics

Finally, consider the logistics of receiving and implementing the spy cameras. Plan for shipping times, customs regulations, and installation requirements to ensure a smooth transition.

- Shipping Arrangements: Confirm the shipping methods and timelines with your supplier.

- Installation Support: Determine if the supplier offers installation assistance or guidelines.

By following this checklist, you can confidently navigate the complexities of sourcing spy cameras disguised as screws, ensuring that you select the best products for your needs.

Comprehensive Cost and Pricing Analysis for spy camera in screws Sourcing

What Are the Key Cost Components in Sourcing Spy Cameras in Screws?

When evaluating the cost structure for sourcing spy cameras embedded in screws, several components must be considered. Materials play a significant role, as the quality and type of components (like lenses, cameras, and screws) can vary widely. For instance, a standard Phillips screw head camera may cost around $16.65, but higher-end models with advanced features or better quality can significantly increase that price.

Labor costs also contribute to the overall expenditure, particularly in regions with varying wage standards. Skilled labor is essential for assembling these intricate devices, where precision is crucial. Manufacturing overhead encompasses the indirect costs associated with production, such as utilities and facility maintenance, which can differ based on the geographic location of the supplier.

Tooling costs are another factor, particularly for custom designs or modifications. If a buyer requires unique specifications, this can drive up initial expenses. Quality Control (QC) is critical in ensuring the functionality and reliability of these devices. This process adds additional costs but is indispensable for maintaining standards, especially when dealing with sensitive surveillance equipment.

Logistics costs can vary depending on the shipping method, distance, and chosen Incoterms. For international buyers, understanding these logistics can prevent unexpected expenses. Finally, the supplier’s margin must also be factored into the final price, which can fluctuate based on market demand and competition.

How Do Price Influencers Affect Sourcing Spy Cameras in Screws?

Several factors influence the pricing of spy cameras in screws. Volume and Minimum Order Quantity (MOQ) are significant; larger orders typically reduce the unit cost due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize costs.

Specifications and customization directly impact pricing. Custom features, such as enhanced camera resolution or specific connectivity options, will likely lead to higher prices. Additionally, the choice of materials—whether opting for high-grade components or more economical alternatives—will also affect overall costs.

Quality certifications can be essential for certain markets, especially in Europe and the Middle East, where compliance with regulations like NDAA is mandatory. Suppliers who can provide certified products may command higher prices but offer peace of mind for compliance-focused buyers.

Furthermore, supplier factors such as reputation, reliability, and production capacity should not be overlooked. A well-regarded supplier may charge more but can provide better quality assurance and service. Lastly, the selected Incoterms can influence total costs, as they dictate who bears responsibility for shipping, insurance, and tariffs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency. Negotiation is key; establishing a solid relationship with suppliers can lead to better pricing and terms. Buyers should be prepared to discuss volume commitments or long-term contracts to negotiate favorable terms.

Understanding the Total Cost of Ownership (TCO) is crucial. This includes not just the purchase price but also maintenance, potential repairs, and warranty considerations. A lower upfront cost may not always equate to better value if long-term expenses are higher.

Buyers should also be aware of pricing nuances in different regions. For example, importing to the EU may involve additional tariffs and compliance checks, while sourcing from regions with lower labor costs could yield significant savings.

Finally, staying informed about market trends and technological advancements can provide leverage in negotiations. Keeping abreast of new product offerings or competitor pricing can empower buyers to make informed decisions, ensuring they achieve the best value in their sourcing of spy cameras in screws.

Disclaimer for Indicative Prices

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and other factors. Always conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing spy camera in screws With Other Solutions

Understanding Alternative Surveillance Solutions

In the realm of surveillance technology, businesses often seek discreet and effective solutions for monitoring their premises or operations. Among these options, spy cameras disguised as screws have gained popularity for their subtlety and functionality. However, several alternatives exist that can also fulfill surveillance needs. This analysis compares spy cameras in screws with other viable solutions to help B2B buyers make informed decisions based on their specific requirements.

| Comparison Aspect | Spy Camera In Screws | Wi-Fi Button & Screw Wearable Camera | Traditional CCTV Systems |

|---|---|---|---|

| Performance | High-resolution video, discreet | HD video, live streaming, portable | High-resolution, extensive coverage |

| Cost | $15-20 per unit | $150-300 per unit | $500 and up per system |

| Ease of Implementation | Simple installation | Moderate; requires setup | Complex; needs professional installation |

| Maintenance | Low; minimal upkeep | Moderate; battery replacement needed | High; regular servicing required |

| Best Use Case | Home security, discreet monitoring | Law enforcement, undercover operations | Business premises, large areas |

Detailed Breakdown of Alternatives

Wi-Fi Button & Screw Wearable Camera

The Wi-Fi Button & Screw Wearable Camera offers a versatile surveillance option, particularly suitable for law enforcement or undercover operations. It features remote live access, allowing teams to monitor situations in real-time. While its performance is commendable with HD video and enhanced sound quality, the cost is significantly higher than spy cameras in screws, ranging from $150 to $300. Additionally, the need for setup and battery management may complicate its use in casual environments. This solution excels in situations requiring mobility and immediate data access, but may not be as discreet as screw-type cameras.

Traditional CCTV Systems

Traditional CCTV systems are a well-established surveillance solution that provides comprehensive monitoring capabilities. They offer high-resolution video and extensive coverage, making them ideal for business premises and larger areas. However, the installation process can be complex and often requires professional assistance, leading to higher costs, typically starting at $500 or more. Maintenance can also be demanding, requiring regular servicing and updates. Although CCTV systems are effective for extensive surveillance needs, their visibility and installation complexity make them less suitable for discreet monitoring compared to screw cameras.

Making the Right Choice for Your Surveillance Needs

When choosing a surveillance solution, B2B buyers should consider their specific needs, including the desired level of discretion, budget, and the environment where the surveillance will take place. Spy cameras in screws are an excellent choice for those prioritizing subtlety and affordability, especially in settings requiring low-profile monitoring. In contrast, the Wi-Fi Button & Screw Wearable Camera is better suited for dynamic environments where mobility and real-time monitoring are critical. Traditional CCTV systems, while robust, are best for larger installations where extensive coverage is necessary. Ultimately, the right solution depends on the unique operational requirements and surveillance goals of the business.

Essential Technical Properties and Trade Terminology for spy camera in screws

What Are the Key Technical Properties of Spy Cameras in Screws?

Understanding the essential technical properties of spy cameras in screws is vital for B2B buyers, especially when evaluating product quality and compatibility. Here are some critical specifications to consider:

1. Focal Length

The focal length, typically measured in millimeters (mm), determines the camera’s field of view and depth of field. For instance, a focal length of 4.3 mm is common in pinhole cameras, allowing for a broad view while maintaining a compact form. This property is crucial for surveillance applications where discretion is necessary, as it affects how much area can be monitored without compromising the camera’s concealment.

2. Resolution

Resolution, often expressed in pixels, refers to the clarity of the image captured by the camera. Higher resolution cameras, such as those offering HD quality, are essential for identifying details in the footage. For businesses, this is important for ensuring that any recorded evidence is clear and usable, particularly in legal or security contexts.

3. Power Source and Battery Life

Spy cameras often rely on rechargeable batteries, which can vary in lifespan. A battery that lasts at least 4 hours is common in portable models, but understanding whether the camera can be connected to a power source for extended use is essential. For businesses that require long-term surveillance, knowing the operational duration helps in planning and deployment.

4. Connectivity Options

Connectivity can include wired connections, such as USB for data transfer, and wireless options like Wi-Fi for remote access. Cameras that support both 2.4 GHz and 5 GHz Wi-Fi networks provide flexibility in deployment. This is particularly important for businesses that need real-time monitoring and accessibility from various locations.

5. Lens Type and Mounting Mechanisms

The type of lens and its mounting mechanism directly influence installation ease and stability. For example, a screw lens that can be easily attached or detached enhances user convenience. Businesses should consider how these factors affect both the installation process and the camera’s ability to remain discreet.

6. Durability and Material Grade

The material used in the construction of the spy camera can affect its durability and performance in different environments. For instance, materials that resist wear and environmental factors enhance the longevity of the product. Understanding material grades is essential for businesses operating in varying climates or harsh conditions.

What Are Common Trade Terms Related to Spy Cameras in Screws?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of spy cameras, knowing whether a product is an OEM part can indicate quality and reliability, as these products often adhere to strict manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for businesses looking to manage inventory costs effectively, especially when testing new products in the market.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, issuing an RFQ for spy cameras in screws can lead to better pricing and terms, as it encourages competition among suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping costs, risk transfer, and delivery points. Being aware of these terms helps in understanding the logistics involved in acquiring spy cameras from different regions.

5. Warranty and Support Terms

Warranty refers to the commitment by the manufacturer to repair or replace a defective product within a specified period. Understanding warranty terms is vital for B2B buyers to mitigate risk and ensure support availability for their investment in surveillance technology.

6. Technical Support

Technical support encompasses the assistance provided by manufacturers to troubleshoot and resolve issues related to their products. Access to reliable technical support is crucial for businesses that depend on spy cameras for security or surveillance, as it ensures operational continuity.

In summary, understanding the technical properties and trade terminology associated with spy cameras in screws is essential for making informed purchasing decisions in the B2B marketplace.

Navigating Market Dynamics and Sourcing Trends in the spy camera in screws Sector

What Are the Current Market Dynamics and Key Trends in the Spy Camera in Screws Sector?

The global market for spy cameras disguised as screws is witnessing significant growth, driven by increasing security concerns and advancements in surveillance technology. Key drivers include the rising demand for discreet monitoring solutions across various sectors such as law enforcement, corporate security, and personal safety. International buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking innovative surveillance solutions that are not only effective but also unobtrusive.

Current trends indicate a shift towards advanced features, such as Wi-Fi connectivity, remote access, and enhanced video quality. For example, products like the Wi-Fi Button & Screw Wearable Camera have become popular due to their ability to provide real-time surveillance without drawing attention. Moreover, the integration of AI and machine learning is paving the way for smarter detection systems, which can identify potential security threats more efficiently.

Emerging sourcing strategies are also reshaping the landscape. International B2B buyers are focusing on direct partnerships with manufacturers to ensure better pricing and quality control. Additionally, the rise of e-commerce platforms facilitates access to a wider range of suppliers, enabling buyers to compare products and negotiate terms more effectively. Understanding these dynamics can help businesses make informed purchasing decisions and stay ahead of the competition.

How Is Sustainability and Ethical Sourcing Addressed in the Spy Camera in Screws Sector?

As sustainability becomes a priority for businesses worldwide, the spy camera in screws sector is also adapting to meet environmental and ethical standards. The production of surveillance devices can have significant environmental impacts, from resource extraction to electronic waste. Therefore, international buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices.

Ethical sourcing involves not only environmental considerations but also the welfare of workers involved in the production process. Buyers are encouraged to seek manufacturers that provide transparent supply chains and comply with international labor standards. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability.

Moreover, innovations in materials and manufacturing processes are paving the way for greener alternatives. For instance, using biodegradable plastics or recycled materials in the construction of spy cameras can reduce the overall environmental footprint. Buyers should actively inquire about the materials used in their products and consider suppliers who are investing in sustainable technologies. This focus on ethical sourcing not only enhances brand reputation but also aligns with the values of an increasingly environmentally conscious consumer base.

What Is the Brief Evolution and History of Spy Cameras in Screws?

The evolution of spy cameras, particularly those disguised as screws, reflects broader technological advancements in surveillance and security. Initially, hidden cameras were bulky and easily detectable, limiting their applications. However, as miniaturization technology progressed, manufacturers began producing more compact and sophisticated devices that could be seamlessly integrated into everyday objects, including screws.

The introduction of digital technology in the late 20th century marked a significant turning point. With the ability to capture high-quality video and audio in small formats, these devices became increasingly popular among various sectors, including law enforcement and private security. The development of wireless technology further enhanced their functionality, allowing for remote monitoring and storage of footage.

Today, the market is characterized by a diverse range of products that cater to different needs, from professional surveillance to personal safety. As technology continues to advance, the future of spy cameras in screws promises even greater integration with smart home systems and enhanced user capabilities, providing international B2B buyers with an ever-expanding array of options to consider.

Frequently Asked Questions (FAQs) for B2B Buyers of spy camera in screws

-

How do I determine the quality of a spy camera in screws?

To assess the quality of a spy camera in screws, consider factors such as the resolution (ideally HD or higher), lens specifications, and build materials. Request samples from potential suppliers to evaluate performance in real-world conditions. Verify the manufacturer’s certifications for quality assurance, and check for customer reviews or case studies that highlight reliability in various environments. Additionally, inquire about warranty terms and post-purchase support to ensure you have recourse in case of defects or performance issues. -

What features should I look for in a spy camera in screws for my business needs?

When selecting a spy camera in screws, prioritize features like resolution (at least 1080p), motion detection, and storage capacity. Consider cameras with Wi-Fi connectivity for remote access and live streaming capabilities. The ability to record audio can also be beneficial. For specialized applications, look for customizable options, such as interchangeable lens types or integration with existing security systems. Ensure the camera is compact and indistinguishable from regular screws to maintain discretion in surveillance applications. -

What are the typical minimum order quantities (MOQs) for spy cameras in screws?

Minimum order quantities for spy cameras in screws can vary significantly by supplier and region. Typically, MOQs range from 50 to 500 units, depending on the manufacturer’s production capabilities and your customization needs. When negotiating with suppliers, express your requirements clearly and inquire about flexibility in MOQs, especially for initial orders or pilot projects. Establishing a good relationship with your supplier may also lead to better terms in future transactions. -

What payment terms are standard for international purchases of spy cameras in screws?

Standard payment terms for international purchases often include options like advance payment, letters of credit, or payment upon delivery. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) based on the buyer’s creditworthiness and relationship with the supplier. It’s advisable to negotiate terms that align with your cash flow and ensure security in the transaction. Consider using secure payment methods to mitigate risks associated with international trade. -

How can I vet suppliers of spy cameras in screws effectively?

To vet suppliers effectively, conduct thorough background checks, including researching their business history, production capabilities, and customer reviews. Request references from past clients and verify their reputation in the industry. Engage in direct communication to gauge their responsiveness and willingness to accommodate your needs. Additionally, consider visiting their manufacturing facility if possible, or request third-party audits to ensure compliance with quality standards and ethical practices. -

What logistics considerations should I keep in mind when importing spy cameras in screws?

When importing spy cameras in screws, consider logistics factors such as shipping methods, customs regulations, and lead times. Evaluate the reliability of shipping partners and consider options for expedited shipping if necessary. Be aware of import duties and taxes applicable in your region to avoid unexpected costs. Ensure that your supplier provides the necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. -

How can I ensure compliance with local regulations regarding surveillance equipment?

To ensure compliance with local regulations on surveillance equipment, familiarize yourself with laws governing the use of hidden cameras in your target market. Regulations may vary significantly by country and region, including restrictions on recording audio or video without consent. Consult legal experts or industry associations to understand the specific requirements applicable to your business. Ensure that your suppliers are also aware of and comply with these regulations to avoid legal complications. -

What customization options are available for spy cameras in screws?

Customization options for spy cameras in screws may include variations in camera resolution, lens types, housing materials, and connectivity features. Some manufacturers offer bespoke solutions tailored to specific applications, such as increased battery life or enhanced low-light performance. When approaching suppliers, clearly communicate your requirements and inquire about their capability to accommodate custom orders. Be prepared for potential lead times and cost implications associated with customized products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Spy Camera In Screws Manufacturers & Suppliers List

1. eBay – Wireless Pinhole Cameras

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Wireless pinhole cameras available on eBay include various models with features such as HD 1080P and 4K resolution, WiFi connectivity, night vision, motion detection, and DVR capabilities. Prices range from approximately ILS 25.35 to ILS 258.80, with options for free international shipping. Most products are brand new and unbranded, with some listings offering best offer options. Popular models in…

2. SuperCircuits – Phillips Screw Head Pinhole Camera Lens

Domain: supercircuits.com

Registered: 1996 (29 years)

Introduction: {“name”: “Phillips Screw Head Pinhole Camera Lens”, “SKU”: “ML-SCREW”, “price”: “$16.65”, “description”: “Indistinguishable from a conventional Phillips screw”, “focal_length_mm”: 4.3, “cloud_enabled”: false, “triGuard”: false, “NDAA_compliant”: false, “shipping_info”: “Ships same business day when ordered by 3:00 pm Central Time. Free Expedited Shipping for most orders over $299.”, “warranty_info…

3. SpyTechStop – Screw-Type Hidden Camera

Domain: spytechstop.com

Registered: 2019 (6 years)

Introduction: This company, SpyTechStop – Screw-Type Hidden Camera, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

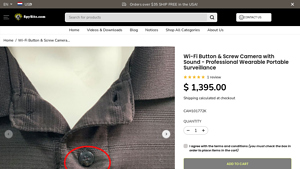

4. Spysite – Wi-Fi Wearable Camera

Domain: spysite.com

Registered: 1996 (29 years)

Introduction: Wi-Fi Button & Screw Wearable Camera | Professional Wearable Portable Surveillance

5. 4G Spy Camera – Mini Screw Camera with Live Stream

Domain: 4gspycamera.com

Registered: 2023 (2 years)

Introduction: 4G WIFI live stream screw spy camera with built-in microphone and speaker. Features double communication, optional screw lens, button lens, and pinhole lens. Mini screw camera disguised as a screw, available in white and black. Supports 256GB SD Card, 2MP resolution, and 3.7MM screw fixed focus lens. Requires external battery (5V 1A). Compatible with Tuya App for live streaming.

6. Cryptomuseum – ScrewCam 1080p Wireless Camera

Domain: cryptomuseum.com

Registered: 2008 (17 years)

Introduction: ScrewCam is a commercial-off-the-shelf (COTS) wireless 1080p camera concealed as a regular screw. It features a built-in WiFi transceiver, allowing connection to local PCs or mobile phones via an existing WiFi network. The device includes a miniature High Definition (HD) camera connected to a miniature WiFi transceiver with a built-in video recorder. It is powered by an internal rechargeable Li-io…

7. Spy Shop – Spy Bolt® Screw

Domain: detective-store.com

Registered: 2011 (14 years)

Introduction: {“name”:”Spy Bolt® screw – spy compartment”,”brand”:”Spy Shop”,”reference”:”59050930″,”description”:”Spy Bolt® is a spy gadget which originates in the times of Cold War. Soviet agents used similar screw-compartments to pass confidential information and microfilms without arousing any suspicions. The compartment looks like an ordinary 3/4” steel screw but has a small space for keeping precious item…

8. Accio – Hidden Screw Cameras

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Hidden Screw Cameras: Top Suppliers & Models with Night Vision. Results from 59000+ products and 8500+ suppliers. Key suppliers include: TENGDAFEI, Dongguan Yufu Hardware Co., Ltd., Shenzhen HTX Technology Co., Ltd., Dongguan Zhonggu Hardware Co., Ltd., Ningbo Haishu Shiqi Starlight Screw Factory, and others. Price range: $0.01 – $98. Minimum order quantities vary from 10 to 10000 pieces. Delivery…

9. The Spy Store – Wireless Indoor Pinhole Cameras

Domain: thespystore.ca

Registered: 2008 (17 years)

Introduction: Wireless Indoor Pinhole Cameras are small, discreet, and typically undetectable devices used for covert recording and surveillance. They come in various shapes, styles, and capabilities, designed for capturing voice and images up close. The product range includes options like the All-in-One Recording Kit, B&W Wired Pen Covert Camera, Button and Screw wired CCD Color Camera set, and many others, wi…

Strategic Sourcing Conclusion and Outlook for spy camera in screws

In navigating the dynamic landscape of spy camera sourcing, particularly for screw-type models, international B2B buyers must prioritize strategic sourcing to ensure quality and compliance. The integration of these discreet surveillance devices into various applications—from security installations to covert operations—highlights their growing relevance. Buyers should focus on suppliers that offer robust warranties, technical support, and quick shipping options, which can enhance operational efficiency and reduce downtime.

Moreover, understanding the market’s nuances, including potential challenges like counterfeit products and technological obsolescence, is crucial. Engaging with reputable manufacturers and conducting thorough due diligence can mitigate risks associated with sourcing these specialized devices.

Looking ahead, the demand for advanced surveillance solutions in regions such as Africa, South America, the Middle East, and Europe is expected to rise. Buyers are encouraged to leverage this momentum by exploring innovative products that incorporate the latest technology while maintaining discreet functionality. By aligning sourcing strategies with market trends, businesses can secure a competitive edge and foster long-term partnerships. Now is the time to invest in reliable suppliers and stay ahead in the evolving surveillance landscape.