The Definitive Guide to Spider Crane: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for spider crane

Navigating the complexities of sourcing spider cranes can be a daunting challenge for international B2B buyers, especially when considering the unique demands of diverse markets across Africa, South America, the Middle East, and Europe. These innovative mini cranes, designed to excel in tight and confined spaces, offer unparalleled versatility and strength, making them indispensable for industries such as construction, glazing, and steel erection. However, understanding the various models, applications, and specifications is crucial for making informed purchasing decisions.

This comprehensive guide delves deep into the spider crane market, providing valuable insights into the different types and series available, their lifting capacities, and their suitability for specific applications. Additionally, it covers critical aspects such as supplier vetting, maintenance considerations, and cost analysis to empower buyers with the knowledge needed to navigate their procurement process confidently.

By equipping B2B buyers with actionable information, this guide aims to facilitate smarter investments in spider cranes, ensuring that businesses in regions like Saudi Arabia and Germany can optimize their operational efficiency while minimizing risk. Whether you are looking to rent or purchase, understanding the landscape of spider cranes will enhance your strategic planning and project execution, ultimately contributing to your company’s success in an increasingly competitive global market.

Understanding spider crane Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pick & Carry Series | Compact design, max capacity of 5,070 lbs | Material handling, construction sites | Pros: Versatile; Cons: Limited lifting capacity compared to larger models. |

| 094 Series | Lightweight, boom length of 18.0 ft, 1,900 lbs max capacity | Indoor installations, HVAC work | Pros: Ideal for tight spaces; Cons: Lower lifting capacity. |

| 300 Series | Medium-sized with a boom length of 47.8 ft, 6,680 lbs max capacity | Steel erection, glazing, and general construction | Pros: Balance of power and size; Cons: May require more setup space. |

| 500 Series | Longer boom (59.1 ft) and higher capacity (8,920 lbs) | Heavy-duty lifting, industrial applications | Pros: Great for larger loads; Cons: Less maneuverable in confined spaces. |

| 1006 Series | High-capacity (20,000 lbs) with a boom length of 78.0 ft | Major construction projects, heavy lifting | Pros: Exceptional lifting power; Cons: Requires larger operational footprint. |

What are the Characteristics and Suitability of the Pick & Carry Series Spider Crane?

The Pick & Carry Series spider cranes are designed for versatility, featuring a compact design that allows for easy maneuverability in confined spaces. With a maximum lifting capacity of 5,070 lbs, they are ideal for material handling tasks on construction sites. Buyers should consider their need for portability versus lifting capacity, as these cranes excel in tight environments but may not handle heavier loads.

How Does the 094 Series Stand Out for Indoor Applications?

The 094 Series is particularly suited for indoor installations, boasting a lightweight structure and a boom length of 18.0 ft. With a maximum capacity of 1,900 lbs, this model is perfect for HVAC work and other low-weight applications. B2B buyers should assess their specific indoor lifting needs and the space constraints they face, as this model is designed specifically for tight access environments.

Why Choose the 300 Series for Steel Erection and Glazing?

The 300 Series spider crane strikes a balance between size and lifting capacity, with a boom length of 47.8 ft and a maximum capacity of 6,680 lbs. This makes it an excellent choice for applications such as steel erection and glazing. Buyers should evaluate the operational requirements of their projects, as this model offers a good mix of power and maneuverability, making it suitable for both medium and larger jobs.

What Advantages Does the 500 Series Provide for Heavy-Duty Lifting?

With a boom length of 59.1 ft and a capacity of 8,920 lbs, the 500 Series spider crane is designed for heavy-duty lifting tasks. It is well-suited for industrial applications where larger loads are a frequent requirement. However, B2B buyers should consider the trade-off between lifting power and maneuverability, as this model may be less effective in confined spaces compared to smaller variants.

What Makes the 1006 Series Ideal for Major Construction Projects?

The 1006 Series is a powerhouse, capable of lifting up to 20,000 lbs with a boom length of 78.0 ft, making it ideal for major construction projects. Its exceptional lifting power allows it to handle the heaviest materials and equipment. Buyers need to be aware that while this crane offers unmatched capacity, it requires a larger operational footprint and may not be as easily maneuverable as smaller models, which could impact site logistics.

Key Industrial Applications of spider crane

| Industry/Sector | Specific Application of spider crane | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting materials in confined spaces | Maximizes space efficiency, reducing project timelines | Load capacity, compact design, and availability of rental options |

| Glazing | Installing glass panels in high-rise buildings | Ensures precision and safety in delicate installations | Reach height, stability features, and ease of operation |

| Steel Erection | Positioning heavy steel beams in tight urban sites | Enhances workflow and reduces manual labor requirements | Lifting capacity, maneuverability, and local service support |

| Event Management | Setting up stages and structures in limited-access areas | Streamlines setup process, improving event logistics | Portability, setup speed, and rental availability |

| Maintenance & Repair | Accessing hard-to-reach machinery for repairs | Minimizes downtime and operational disruptions | Load capacity, ease of transport, and availability of trained operators |

How is a Spider Crane Used in the Construction Industry?

In the construction sector, spider cranes are invaluable for lifting materials in confined spaces where traditional cranes cannot operate. Their compact design allows them to navigate tight urban environments, ensuring that projects remain on schedule. For international buyers, particularly in regions like Africa and the Middle East, sourcing a spider crane that can handle local terrain challenges while providing sufficient lifting capacity is crucial. Furthermore, the option to rent these cranes can significantly reduce upfront costs.

What Role Does a Spider Crane Play in Glazing Applications?

Spider cranes are essential for the glazing industry, particularly for installing large glass panels in high-rise buildings. Their precise maneuverability ensures that delicate glass is handled safely and efficiently, minimizing the risk of damage. Buyers from South America and Europe should consider models that offer high reach and stability features to meet the demands of urban construction sites. Additionally, understanding local regulations regarding lifting operations is key to ensuring compliance and safety.

How Do Spider Cranes Facilitate Steel Erection?

In steel erection, spider cranes excel in positioning heavy beams in urban areas where space is at a premium. Their ability to operate in confined spaces allows for smoother workflows, significantly reducing the reliance on manual labor. For businesses in regions like Germany, sourcing cranes with robust lifting capacities and excellent maneuverability is vital. Buyers should also evaluate the availability of local support services to ensure operational efficiency.

What Advantages Do Spider Cranes Offer in Event Management?

For event management, spider cranes are indispensable for setting up stages and structures in locations with limited access. Their portability and quick setup capabilities streamline the logistics of event preparation, making them a preferred choice for organizers. Buyers from various regions should look for rental options that provide flexibility and immediate availability, as well as cranes that are easy to transport and operate in diverse environments.

How Are Spider Cranes Utilized for Maintenance and Repair?

In maintenance and repair applications, spider cranes provide access to machinery in hard-to-reach areas, significantly reducing downtime. Their compact size allows them to fit into tight spaces, making them ideal for industrial settings or buildings with limited access points. International buyers should prioritize cranes that offer a good balance of lifting capacity and portability, as well as consider the training and certification of operators to ensure safe operation in their specific environments.

3 Common User Pain Points for ‘spider crane’ & Their Solutions

Scenario 1: Limited Access to Confined Spaces

The Problem: Many construction and maintenance projects require lifting equipment that can operate in tight or confined spaces, such as inside buildings, on rooftops, or in crowded urban areas. Traditional cranes are often too large or cumbersome, leading to increased project delays and higher labor costs. For B2B buyers, this presents a significant challenge when selecting lifting solutions that can navigate these limitations while maintaining efficiency and safety.

The Solution: To effectively address this challenge, buyers should consider the unique advantages of spider cranes, specifically their compact design and dual-track chassis that allow for operation in narrow areas. When sourcing a spider crane, it’s crucial to assess the specific dimensions of the worksite and the crane’s capabilities, including its lifting capacity and boom length. By opting for models with adjustable outriggers and a low-profile design, buyers can ensure that the crane can safely operate in various environments, minimizing the risk of accidents. Additionally, renting a spider crane for trial use in different scenarios can provide valuable insights into its performance and adaptability, helping buyers make informed purchasing decisions.

Scenario 2: High Operational Costs Due to Inefficient Equipment

The Problem: For companies operating in construction or heavy lifting industries, using equipment that is not optimized for specific tasks can lead to high operational costs, including fuel consumption, maintenance, and labor. This inefficiency is particularly concerning for B2B buyers who need to remain competitive in price-sensitive markets like those in Africa or South America, where margins can be tight.

The Solution: B2B buyers should prioritize selecting the right spider crane model that fits their specific lifting requirements. Many spider cranes come with various engine options, including electric motors that are ideal for indoor use without emissions. Buyers should also evaluate the crane’s features, such as its maximum lifting capacity and reach, to ensure that they are not overpaying for unnecessary capabilities. Investing in training for operators can further enhance efficiency; a well-trained operator can maximize the crane’s capabilities, reducing the time and cost associated with each project. Additionally, establishing a routine maintenance schedule can prevent unexpected breakdowns, ensuring the crane remains operational and cost-effective over the long term.

Scenario 3: Safety Concerns with Heavy Lifting Operations

The Problem: Safety is a paramount concern in the lifting industry, especially when dealing with heavy loads in precarious environments. The risk of tipping, overloading, and operator error can lead to accidents, resulting in injuries and costly project delays. B2B buyers need to ensure that the equipment they choose incorporates robust safety features to protect their workforce and assets.

The Solution: When selecting a spider crane, buyers should prioritize models equipped with advanced safety systems such as moment limiters and load indicators. These features automatically alert operators when approaching maximum load capacities, significantly reducing the risk of accidents. Additionally, incorporating wireless remote controls can allow operators to maintain a safe distance from the load while ensuring precise maneuvering. Buyers should also implement a comprehensive training program for all operators that includes familiarization with the crane’s safety systems, ensuring that the team understands how to operate the equipment safely and effectively. Regular safety audits and compliance checks can further enhance safety on-site, aligning with industry standards and regulations, which is especially critical for international projects in regions with stringent safety laws.

Strategic Material Selection Guide for spider crane

What Are the Key Materials Used in Spider Crane Manufacturing?

When considering the strategic material selection for spider cranes, several materials stand out due to their unique properties and performance characteristics. Understanding these materials can significantly influence purchasing decisions for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe.

How Does Steel Contribute to Spider Crane Performance?

Steel is a primary material used in the construction of spider cranes, particularly for the frame and structural components. Its key properties include high tensile strength, excellent durability, and resistance to deformation under heavy loads. Steel can withstand high temperatures and pressures, making it suitable for various lifting applications.

Pros: Steel’s strength-to-weight ratio allows for robust designs without excessive weight, facilitating easier mobility and maneuverability in confined spaces. It is widely available and relatively cost-effective compared to other materials.

Cons: However, steel is susceptible to corrosion, especially in humid or saline environments, which may necessitate protective coatings. Additionally, the manufacturing process can be complex, involving welding and machining, which may increase lead times.

Impact on Application: Steel’s strength makes it ideal for heavy lifting tasks, such as construction and industrial applications. However, buyers in coastal regions should consider corrosion-resistant treatments to prolong the crane’s lifespan.

What Role Does Aluminum Play in Spider Crane Design?

Aluminum is increasingly being utilized in the manufacturing of spider cranes, particularly for components that require a lightweight yet strong material. Key properties of aluminum include low density, excellent corrosion resistance, and good thermal conductivity.

Pros: The lightweight nature of aluminum enhances the crane’s portability and ease of transportation. Its corrosion resistance is particularly beneficial for cranes operating in harsh environments, such as coastal or industrial areas.

Cons: On the downside, aluminum has a lower tensile strength compared to steel, which may limit its use in high-load applications. Additionally, aluminum is generally more expensive than steel, impacting overall project budgets.

Impact on Application: Aluminum is suitable for applications where weight savings are critical, such as indoor or rooftop lifting. Buyers should assess the load requirements carefully to ensure aluminum components meet their operational needs.

Why Is Composite Material Gaining Popularity in Spider Cranes?

Composite materials, which combine two or more constituent materials, are becoming popular for specific components of spider cranes. These materials can offer tailored properties, such as enhanced strength-to-weight ratios and improved fatigue resistance.

Pros: Composites are lightweight and resistant to corrosion, making them ideal for applications in challenging environments. They can also be molded into complex shapes, allowing for innovative designs.

Cons: The primary drawback is the higher cost and complexity of manufacturing composite materials. Additionally, they may not have the same load-bearing capacity as metals, which can limit their application.

Impact on Application: Composites are particularly useful in non-structural elements or where weight reduction is critical. Buyers must ensure that the performance characteristics align with their specific lifting requirements.

What Are the Benefits of Using High-Strength Plastics in Spider Cranes?

High-strength plastics are increasingly being considered for non-load-bearing components of spider cranes, such as housings and covers. Their key properties include lightweight, corrosion resistance, and excellent impact resistance.

Pros: High-strength plastics are resistant to chemical corrosion, making them suitable for various environmental conditions. They are also easy to manufacture and can be produced in large quantities at a lower cost.

Cons: The main limitation is their lower strength compared to metals, which restricts their use in structural applications. Furthermore, high temperatures can affect their performance, leading to deformation.

Impact on Application: These materials are ideal for components that require protection from environmental factors without adding significant weight. Buyers should consider the operating conditions to ensure compatibility.

Summary of Material Selection for Spider Cranes

| Material | Typical Use Case for spider crane | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural frame and load-bearing parts | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight components | Lightweight and corrosion-resistant | Lower tensile strength than steel | High |

| Composite | Non-load-bearing components | Tailored properties and design flexibility | Higher manufacturing complexity | High |

| High-Strength Plastic | Protective housings and covers | Chemical resistance and lightweight | Lower strength compared to metals | Medium |

This material selection guide aims to equip B2B buyers with the insights necessary to make informed decisions when sourcing spider cranes, ensuring optimal performance and longevity in diverse operational environments.

In-depth Look: Manufacturing Processes and Quality Assurance for spider crane

What Are the Main Stages of Manufacturing a Spider Crane?

The manufacturing process for spider cranes involves several critical stages that ensure each unit meets the high standards required for performance and safety. Understanding these stages can help B2B buyers assess the quality and reliability of potential suppliers.

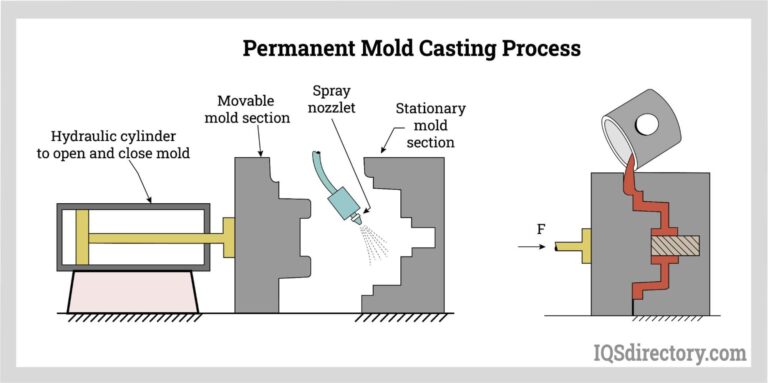

Material Preparation: How Are Components Selected and Processed?

The first step in manufacturing spider cranes is material selection. Manufacturers typically use high-strength steel alloys to ensure durability and structural integrity. The materials undergo rigorous quality checks to confirm they meet specific mechanical properties such as tensile strength and yield strength.

Once selected, the materials are prepared through processes such as cutting and machining. CNC (Computer Numerical Control) machines are often employed for precision cutting, which is essential for creating components that fit together seamlessly during assembly. This stage is crucial because any defects in material preparation can compromise the crane’s overall performance.

What Forming Techniques Are Used in Spider Crane Production?

Forming is the next step in the manufacturing process, where raw materials are shaped into usable components. Various techniques, such as stamping, bending, and welding, are employed.

For spider cranes, the chassis and boom sections are typically formed using advanced welding techniques to ensure a strong bond. Robotic welding systems are commonly utilized to enhance precision and consistency. This automation reduces human error and improves production efficiency.

Additionally, manufacturers may employ hydroforming techniques for specific parts, allowing for more complex shapes without compromising material strength. This approach is particularly beneficial for the spider crane’s outriggers, which need to be both lightweight and robust.

How Does Assembly Work in Spider Crane Manufacturing?

The assembly process is where all the manufactured components come together. This stage often begins with the chassis, where the crawler tracks are attached, followed by the installation of the boom and other critical components like the engine and hydraulic systems.

Manufacturers typically use a combination of manual and automated assembly techniques. For example, while some parts may require skilled technicians for assembly, robotic systems can be utilized for repetitive tasks, such as fastening and aligning components.

Quality control checks are integrated throughout the assembly process. For instance, each major assembly may be subjected to dimensional inspections to ensure conformity to design specifications. This is vital for ensuring the crane operates safely and effectively.

What Finishing Processes Are Important for Spider Cranes?

Finishing processes enhance the aesthetic and protective qualities of spider cranes. Common finishing techniques include painting, powder coating, and galvanizing. These processes not only improve the crane’s appearance but also protect it from environmental factors such as corrosion and wear.

Manufacturers often apply coatings that meet international standards for durability and environmental compliance. For instance, powder coatings provide a tough, weather-resistant finish that is crucial for outdoor applications.

Final inspections are conducted to ensure that the finish meets quality standards and that there are no defects. This is an essential step before the cranes are packaged and shipped to clients.

What Quality Assurance Standards Are Applicable to Spider Crane Manufacturing?

Quality assurance is a fundamental aspect of spider crane production, with several international and industry-specific standards governing the process.

How Does ISO 9001 Apply to Spider Crane Manufacturing?

ISO 9001 is an internationally recognized standard that outlines the requirements for a quality management system. Manufacturers of spider cranes often pursue ISO 9001 certification to demonstrate their commitment to quality and customer satisfaction. This certification involves regular audits and assessments to ensure compliance with the standard.

What Other Industry-Specific Certifications Should Buyers Look For?

In addition to ISO 9001, other certifications may be relevant, including CE marking for compliance with European safety standards and API (American Petroleum Institute) certifications for cranes used in oil and gas applications. These certifications indicate that the spider cranes meet stringent safety and performance standards.

What Are the Key Quality Control Checkpoints in Spider Crane Production?

Quality control checkpoints are critical throughout the manufacturing process to ensure that each crane meets safety and performance standards. Key checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous checks during the manufacturing process help identify any defects early, reducing rework and ensuring adherence to specifications.

- Final Quality Control (FQC): Before shipping, a comprehensive inspection is conducted, which may include functional testing, load testing, and dimensional checks to ensure the crane operates as intended.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some actionable steps:

-

Request Certification Documents: Buyers should ask for copies of relevant certifications such as ISO 9001, CE, or API. These documents provide insight into the manufacturer’s commitment to quality.

-

Conduct Supplier Audits: On-site audits allow buyers to assess manufacturing processes and quality control measures firsthand. This can include checking IQC, IPQC, and FQC practices.

-

Review Quality Control Reports: Suppliers should provide regular reports detailing quality control findings, including any deviations from standards and corrective actions taken.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and the overall condition of the cranes before purchase.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers must be aware of specific nuances when it comes to quality control for spider cranes. For example, compliance with local regulations and standards may vary significantly across regions. Understanding these differences can help buyers avoid potential legal and operational challenges.

Additionally, logistical considerations such as shipping and handling can impact the quality of the cranes upon arrival. Buyers should ensure that suppliers have robust packaging and transport processes in place to prevent damage during transit.

By thoroughly understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting spider crane suppliers, ensuring they invest in reliable and high-quality lifting equipment.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spider crane’

This guide serves as a practical checklist for B2B buyers seeking to procure spider cranes, ensuring that you make informed decisions throughout the sourcing process. Spider cranes, known for their compact design and versatility, require careful consideration of various factors, from technical specifications to supplier reliability. Follow these steps to streamline your procurement process.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, outline the specific requirements for your spider crane. Consider factors such as lifting capacity, boom length, and operational environment (indoor vs. outdoor).

– Lifting Capacity: Ensure the crane can handle the maximum weight you expect to lift.

– Boom Length: Assess the reach required for your projects, particularly in confined spaces.

Step 2: Research Industry Standards and Compliance

Verify that the spider cranes you are considering comply with international safety and operational standards. Understanding the necessary certifications can protect your investment and ensure operational safety.

– ISO Certification: Look for suppliers that adhere to ISO standards, which indicates quality management practices.

– Local Regulations: Familiarize yourself with any regional compliance requirements that may affect crane operation.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to ensure they are reputable and reliable. Request detailed company profiles, product catalogs, and references from other buyers in your industry.

– Case Studies: Ask for examples of previous projects similar to yours to gauge the supplier’s experience.

– Customer Feedback: Look for testimonials or reviews that highlight the supplier’s reliability and service quality.

Step 4: Inspect Equipment Options

Once you have shortlisted potential suppliers, arrange to inspect the spider cranes they offer. This step is crucial for verifying the condition and specifications of the equipment.

– Physical Inspection: Check for any signs of wear or damage that could affect performance.

– Demonstration: If possible, request a live demonstration to assess the crane’s capabilities in action.

Step 5: Compare Pricing and Financing Options

Gather quotes from multiple suppliers to compare pricing. Be sure to consider total cost of ownership, which includes maintenance, parts, and potential financing options.

– Transparent Pricing: Ensure that the quotes cover all potential costs, including delivery and installation.

– Financing Plans: Explore flexible payment options or leasing arrangements that may better suit your budget.

Step 6: Review After-Sales Support and Service

Evaluate the after-sales support offered by suppliers. Reliable service and support can significantly impact your operational efficiency.

– Maintenance Services: Inquire about routine maintenance plans and the availability of spare parts.

– Training Programs: Check if the supplier provides training for your operators to ensure safe and effective crane use.

Step 7: Finalize Contract Terms

Once you have selected a supplier, carefully review and negotiate the contract terms before finalizing the purchase. Ensure that all your requirements are documented.

– Warranty Clauses: Look for warranties that cover both parts and labor, providing peace of mind.

– Delivery Timelines: Clarify delivery schedules and any penalties for delays to avoid disruptions in your project timelines.

By following this checklist, B2B buyers can navigate the complexities of sourcing spider cranes effectively, ensuring a successful procurement process that meets their operational needs.

Comprehensive Cost and Pricing Analysis for spider crane Sourcing

What Are the Key Cost Components for Sourcing Spider Cranes?

When considering the procurement of spider cranes, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The materials used in manufacturing spider cranes significantly impact the overall cost. High-quality steel and specialized alloys are typically employed for structural integrity, while advanced components like hydraulic systems contribute to performance. Buyers should assess the quality of materials as this influences durability and maintenance requirements.

-

Labor: Labor costs encompass both direct and indirect expenses associated with manufacturing. Skilled labor is required for assembly, testing, and quality assurance, which can vary widely based on geographic location. In regions such as Europe and the Middle East, labor costs may be higher due to strict regulations and skilled labor availability.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help in reducing these overheads, thus influencing the final price of the crane.

-

Tooling: Custom tooling for specific models or modifications can significantly add to initial costs. Buyers should inquire about tooling charges, especially if customization is required for unique lifting applications.

-

Quality Control (QC): Rigorous QC processes ensure the reliability and safety of spider cranes. Costs related to testing and certification can be substantial, especially for cranes intended for heavy-duty applications. Buyers should verify the certifications and quality standards met by the supplier.

-

Logistics: Transportation costs can vary based on the distance from the manufacturing site to the buyer’s location. International shipping, customs duties, and insurance are critical considerations, particularly for buyers in Africa and South America who may face longer supply chains.

-

Margin: Suppliers typically include a profit margin in their pricing, influenced by market demand, competition, and the perceived value of the product. Understanding the supplier’s positioning can aid in negotiations.

How Do Price Influencers Affect Spider Crane Sourcing?

Several factors can influence the pricing of spider cranes:

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Understanding the minimum order quantity (MOQ) is crucial for buyers looking to optimize their procurement strategy.

-

Specifications and Customization: Higher specifications and tailored features can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Cranes made from premium materials with recognized quality certifications may come at a premium. However, investing in higher quality can lead to lower maintenance costs and longer equipment life.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers with a track record of performance may charge more, but they often offer better after-sales support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining responsibilities and costs related to shipping and customs. This can greatly affect the total landed cost of the crane.

What Are the Best Practices for Negotiating Spider Crane Prices?

-

Research and Benchmarking: Conduct market research to understand the typical pricing for spider cranes. This equips buyers with knowledge to negotiate effectively.

-

Leverage Volume Purchases: If possible, combine orders with other businesses to meet MOQs and achieve volume discounts.

-

Discuss Total Cost of Ownership (TCO): Emphasize the importance of TCO, which includes purchase price, maintenance, and operational costs over the crane’s lifecycle. This approach can justify a higher initial investment if it leads to lower long-term costs.

-

Clarify Payment Terms: Negotiate favorable payment terms, such as extended payment periods or financing options, to ease cash flow challenges.

-

Evaluate Multiple Suppliers: Obtain quotes from various suppliers to compare pricing and service offerings. This competitive approach can lead to better pricing and terms.

Conclusion

When sourcing spider cranes, understanding the cost components and price influencers is paramount for international B2B buyers. By leveraging negotiation strategies and focusing on total cost of ownership, buyers can make more informed decisions that align with their operational needs and budget constraints. It is essential to approach each procurement opportunity with a clear strategy, considering both immediate costs and long-term value.

Alternatives Analysis: Comparing spider crane With Other Solutions

Understanding Alternative Lifting Solutions for B2B Buyers

When it comes to lifting solutions in confined spaces or challenging environments, the spider crane is a popular choice due to its compact design and impressive lifting capabilities. However, several alternative solutions can also meet similar needs. This section provides a comprehensive analysis of spider cranes compared to other viable lifting methods, enabling B2B buyers to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | ‘Spider Crane’ | Mini Crawler Crane | Forklift |

|---|---|---|---|

| Performance | Lifts up to 20,000 lbs; excellent for tight spaces | Lifts up to 8,000 lbs; versatile but less compact | Lifts up to 20,000 lbs; efficient on flat surfaces |

| Cost | Moderate to high initial investment; rental options available | Lower initial cost; maintenance may add up | Generally lower upfront cost; high operational costs |

| Ease of Implementation | Requires minimal setup; can be operated in various environments | Straightforward setup; may require operator training | Easy to use; requires stable ground for optimal performance |

| Maintenance | Low maintenance; routine checks recommended | Moderate maintenance; wear and tear on tracks | Regular maintenance needed; higher downtime risks |

| Best Use Case | Ideal for construction, glazing, and tight urban spaces | Suitable for outdoor and indoor work in varied terrains | Best for material handling in warehouses and open areas |

Detailed Breakdown of Alternatives

Mini Crawler Crane

Mini crawler cranes are designed for versatility and efficiency in both indoor and outdoor settings. They typically have a lower initial purchase price compared to spider cranes, making them attractive for budget-conscious projects. However, while they can lift significant weights (up to 8,000 lbs), they may not match the compactness of spider cranes, limiting their access to ultra-tight spaces. Maintenance can also become a concern due to the wear on tracks, especially in rugged conditions.

Forklift

Forklifts are widely used for material handling in warehouses and construction sites. They can lift heavy loads (up to 20,000 lbs) and are generally more affordable upfront. However, their performance is largely dependent on stable, flat ground, which limits their application in uneven or confined spaces. While easy to operate, forklifts can incur high operational costs, especially if used in demanding environments that require frequent maintenance.

Conclusion: How to Choose the Right Lifting Solution

Choosing the right lifting solution requires a careful assessment of your specific operational needs, budget constraints, and environmental conditions. Spider cranes offer unique advantages in confined spaces and tight urban areas, making them ideal for specialized tasks. Mini crawler cranes provide a balance of versatility and cost-effectiveness, suitable for a range of applications. Forklifts, while potentially less expensive, are best suited for stable environments. By evaluating these factors, B2B buyers can select the most appropriate lifting solution that aligns with their project requirements and operational goals.

Essential Technical Properties and Trade Terminology for spider crane

What Are the Key Technical Properties of a Spider Crane?

When considering a spider crane for your project, understanding its technical specifications is crucial for ensuring it meets your operational needs. Here are some essential properties:

-

Load Capacity

This refers to the maximum weight the crane can safely lift, typically measured in pounds or tons. Spider cranes can range from 1,900 lbs to over 20,000 lbs, depending on the model. Knowing the load capacity is vital for B2B buyers as it determines the crane’s suitability for specific tasks, such as construction, glazing, or steel erection. -

Boom Length

The boom length is the distance the crane can extend to lift loads. For spider cranes, this can vary from approximately 18 ft to 81 ft. A longer boom allows for greater reach, which is particularly important in tight spaces where maneuverability is limited. Buyers should assess project requirements to select a crane with an appropriate boom length. -

Outrigger Configuration

Spider cranes utilize a spider-like outrigger design that enhances stability on uneven surfaces. The configuration allows the crane to operate in confined areas and on slopes, which is advantageous for projects in urban settings or sites with obstacles. Understanding outrigger functionality is essential for ensuring safe and efficient operation. -

Engine Type

Different models may offer varying engine types, including diesel and electric options. Electric models are particularly beneficial for indoor use, minimizing emissions and noise pollution. B2B buyers should consider the engine type based on the work environment and local regulations regarding emissions. -

Weight and Dimensions

The overall weight and dimensions of a spider crane affect its transportability and the space required for operation. Compact models are designed to fit through standard doorways, making them ideal for indoor applications. When selecting a crane, consider the logistical aspects of transporting and maneuvering it on site. -

Safety Features

Modern spider cranes are equipped with advanced safety systems, including load limiters and tilt alarms. These features help prevent accidents by alerting operators when they approach maximum capacity or unsafe operating angles. Investing in cranes with robust safety features is crucial for protecting workers and minimizing liability.

What Are Common Trade Terms Related to Spider Cranes?

Understanding industry jargon can facilitate smoother transactions and clearer communications between buyers and suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment that may be marketed under another company’s brand. In the context of spider cranes, knowing the OEM can help buyers ensure they are getting quality equipment backed by reliable service and support. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding the MOQ is essential for budgeting and inventory management, especially when considering purchasing or renting multiple units. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. When procuring spider cranes, sending an RFQ can help buyers compare costs and features, leading to more informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in shipping and freight transactions. Familiarity with Incoterms is crucial for B2B transactions involving spider cranes, as they dictate who is responsible for shipping costs, insurance, and risk during transportation. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for project planning, particularly in industries where delays can significantly impact schedules. -

Certification Standards

These are industry-specific standards that a product must meet to ensure safety and performance. Certifications can vary by region, so B2B buyers should verify that the spider crane complies with local regulations and industry standards, ensuring it is safe for use in their specific applications.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when selecting spider cranes, ensuring they meet their operational requirements while adhering to industry standards.

Navigating Market Dynamics and Sourcing Trends in the spider crane Sector

What Are the Key Trends Influencing the Spider Crane Market?

The global spider crane market is experiencing significant growth, driven by urbanization, infrastructure development, and the need for efficient lifting solutions in confined spaces. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly turning to spider cranes for their versatility and compact design. These cranes are particularly beneficial in urban construction projects, where space is limited and traditional cranes cannot operate effectively.

Emerging technologies are also reshaping the market landscape. The integration of advanced telematics and remote control systems allows for enhanced operational efficiency and safety, enabling operators to manage lifting tasks more effectively from a distance. Furthermore, the rise of rental services provides a flexible financial model for businesses, allowing them to access cutting-edge equipment without the burden of upfront capital investment. This trend is especially prevalent in markets like Saudi Arabia and Germany, where construction firms seek to optimize their resource allocation and reduce overhead costs.

Another significant trend is the focus on customization. Many manufacturers are now offering tailored solutions that cater to specific industry needs, such as construction, steel erection, and glazing. This adaptability is crucial for buyers looking to maximize their investment while ensuring compliance with local regulations and safety standards.

How Is Sustainability Shaping Sourcing Decisions in the Spider Crane Sector?

Sustainability has become a central concern for B2B buyers in the spider crane sector, prompting companies to adopt environmentally responsible practices in their sourcing strategies. The environmental impact of construction equipment is under scrutiny, and businesses are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint. This shift is particularly relevant for buyers in Europe, where stringent regulations around emissions and sustainability are in place.

Ethical sourcing is also gaining traction, with buyers seeking to ensure that their supply chains are transparent and socially responsible. Companies that can provide certifications for green materials or sustainable manufacturing processes are likely to stand out in a competitive market. For instance, manufacturers that utilize recyclable materials or energy-efficient production methods can appeal to eco-conscious clients looking to align their operations with global sustainability goals.

Moreover, the demand for ‘green’ certifications is rising. Buyers are increasingly looking for equipment that meets environmental standards, such as those set by the International Organization for Standardization (ISO) or other recognized bodies. This trend not only helps companies enhance their corporate social responsibility profiles but also aligns with the growing consumer demand for sustainable practices across various sectors.

What Is the Historical Context of Spider Cranes and Their Evolution?

The evolution of spider cranes has been marked by advancements in engineering and design, which have significantly enhanced their functionality and application in the construction sector. Initially developed to address the limitations of traditional cranes in confined spaces, spider cranes have evolved into versatile lifting solutions capable of handling a wide range of loads while maintaining compact dimensions.

The introduction of lightweight materials and sophisticated hydraulic systems has further improved their performance, making them indispensable in urban construction projects. As the demand for efficient and flexible lifting solutions continues to rise, spider cranes are becoming a staple in the toolkit of construction firms worldwide, reflecting a broader trend towards innovation and efficiency in the industry.

This historical context is crucial for B2B buyers as it highlights the ongoing improvements in technology and design, ensuring that they are investing in equipment that meets current and future market demands. Understanding the evolution of spider cranes allows buyers to make informed decisions based on the latest advancements and industry standards.

Frequently Asked Questions (FAQs) for B2B Buyers of spider crane

-

How do I choose the right spider crane for my project needs?

Selecting the right spider crane involves assessing several factors, including lifting capacity, boom length, and the specific application requirements. For example, if your project involves working in confined spaces, models with a compact design and lower weight are ideal. Evaluate the load weights and dimensions you will be lifting and match them with the crane’s specifications. Additionally, consider the type of terrain and whether the crane will be used indoors or outdoors, as this can impact the model’s performance and safety features. -

What are the key features to look for in a spider crane?

When sourcing a spider crane, prioritize features such as lifting capacity, boom extension, stability, and safety systems. Look for cranes with robust outriggers that provide stability on uneven ground and safety features like load limit indicators and alarms. A remote control system can enhance usability, especially in tight spaces. It’s also beneficial to check for compatibility with additional attachments that may be required for your specific lifting tasks. -

What are the typical lead times for purchasing a spider crane internationally?

Lead times for purchasing a spider crane can vary based on the supplier’s location, model availability, and shipping logistics. Typically, you can expect a timeframe ranging from a few weeks to several months. To minimize delays, ensure that you communicate clearly with your supplier about your project timelines and any urgent requirements. It’s also helpful to confirm their inventory status and shipping capabilities to your region. -

Are there customization options available for spider cranes?

Yes, many suppliers offer customization options for spider cranes to meet specific project requirements. Customizations may include modifications to the crane’s lifting capacity, boom length, or additional safety features. When discussing your needs with suppliers, be clear about your specifications and the intended applications. This will help them provide the best solutions and ensure that the crane meets your operational demands. -

What are the minimum order quantities (MOQs) for spider cranes?

Minimum order quantities for spider cranes can vary significantly among suppliers and depend on the model and customization. Some suppliers may have a MOQ of one unit, while others might require a larger order for specific models or configurations. It’s advisable to discuss your needs directly with the supplier to understand their policies and explore potential flexibility in order quantities. -

What payment terms should I expect when purchasing a spider crane?

Payment terms for spider cranes can differ based on the supplier and your location. Common terms include a deposit upfront, followed by the balance upon delivery or completion of installation. Some suppliers may offer financing options or installment payments for larger purchases. Be sure to negotiate terms that align with your budget and cash flow while ensuring that they are documented in your purchase agreement. -

How can I ensure the quality of the spider crane before purchase?

To ensure the quality of a spider crane before purchase, conduct thorough research on the supplier’s reputation and product reviews. Request product certifications, warranty details, and maintenance records. If possible, visit the supplier’s facility or request a demonstration of the crane in operation. Additionally, inquire about the quality assurance processes they have in place to ensure that their cranes meet industry standards. -

What logistics considerations should I keep in mind for international shipping of spider cranes?

When planning for international shipping of spider cranes, consider factors such as shipping method, customs regulations, and import duties. Work closely with your supplier to understand the logistics involved, including packaging and transport options that protect the crane during transit. Ensure that all documentation is in order to facilitate smooth customs clearance. It’s also prudent to plan for potential delays and have a contingency strategy in place for your project timeline.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Spider Crane Manufacturers & Suppliers List

1. Maeda – Spider Cranes

Domain: maeda-minicranes.com

Registered: 2016 (9 years)

Introduction: SPIDER CRANES: Light and compact body with supportive outriggers for lifting on any site. Models include: MC104C (0.995t x 1.1m), MC174C (1.72t x 1.0m), MC285C (2.82t x 1.4m), MC305C (2.98t x 2.5m), MC405C (3.83t x 2.7m), MC815C (8.09t x 2.4m). Features include compact body for indoor use, optional electric motor for clean operation, lightweight design for easy transport, and durable winch with di…

2. Jekko – Minicrane

Domain: jekkousa.com

Registered: 2012 (13 years)

Introduction: {“Minicrane”: {“description”: “Telescopic mini crawler cranes with outriggers designed for easy transport and utmost handiness. Suitable for slopes, stairs, passageways, and difficult-to-reach places. Requires minimal set-up, providing time and cost savings along with elevated safety and improved lifting performance.”, “models”: [“SPX309”, “SPX328”, “SPX509”, “SPX532”, “SPX650”, “SPX1280”]}, “Mini…

3. GGR Group – UNIC Mini Cranes

Domain: ggrgroup.com

Registered: 2006 (19 years)

Introduction: Mini Spider Cranes – UNIC mini cranes can lift up to 10 tonnes and start at only 595mm wide. The UNIC URW-1006 is the world’s strongest mini crane with a 10 tonne capacity. Other models include: UNIC URW-806-3 (8t capacity, 25.5m height, 1.67m width), UNIC UM445 (4t capacity, 17.5m height, 750-1110mm width), UNIC URW-094 (0.995t capacity, 5.6m height, 0.595m width), UNIC URW-095 (0.995t capacity, …

4. United Rentals – Mini Crawler Crane

Domain: unitedrentals.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “Mini Crawler Crane”, “Height”: “42 ft. 6 in.”, “Maximum Capacity”: “2 Tons (3,998 lbs)”, “Vertical Reach”: “42 ft. 6 in.”, “Horizontal Reach”: “34 ft. 6 in.”, “Power Source”: “Electric Powered”, “Description”: “Efficiently lift and transport piping, equipment, and other materials with these mobile crawler cranes. These cranes are secured to the ground at multiple points for incre…

5. SPYDER – URW706 Mini Crane

Domain: upanddown.ca

Registered: 2011 (14 years)

Introduction: {“product_name”: “SPYDER CRANE URW706”, “type”: “mini crane”, “max_lifting_capacity”: “13,330 lbs”, “weight”: “17,940 lbs”, “width”: “61 inches”, “max_working_height”: “71 ft”, “features”: [“Electronic Display Load Moment Indicator”, “On-board Self Diagnostic Computer System”, “Full Function Wireless Remote”, “360-degree rotation”, “Quick Disassemble System”]}

6. Great Lakes Lifting – Spydercrane URW295

Domain: greatlakeslifting.com

Registered: 2009 (16 years)

Introduction: Product Name: Spydercrane URW295

Type: Mini Crawler Crane

Maximum Lifting Capacity: 6,450 lbs. @ 4.6 ft.

Working Radius: 1.5 ft. to 28 ft.

Dimensions (W x H x L): 2.0 x 4.6 x 9.0 ft.

Weight: 4,100 lbs.

Engine Options: Gas, gas/electric, gas/propane, diesel, diesel/electric

Tip Height: 29 ft.

Running Speed: 1.4 MPH

Features: 360-degree continuous rotation, remote control operation, infinitely varia…

7. UNIC Cranes – Compact Lifting Solutions

Domain: uniccranes.com

Registered: 2009 (16 years)

Introduction: URW-094: Capacity 0.995t x 1.5m, Max Lifting Height 5.6m, Max Working Radius 5.17m, Weight 1000kg; URW-095: Capacity 0.995t x 3.5m, Max Lifting Height 8.8m, Max Working Radius 8.41m, Weight 1850kg; ECO-UNIC-CBE: Capacity (095) 0.995t x 3.5m, Capacity (295) 2.9t x 1.4m, Max Lifting Height 8.9m, Max Working Radius 8.41m, Weight 2350kg; ECO-UNIC-WBE: Capacity (095) 0.995t x 3.5m, Capacity (295) 2.9t …

8. Unic Spydercrane – UR-W706

Domain: cranenetwork.com

Registered: 2000 (25 years)

Introduction: {“manufacturer”:”Unic Spydercrane”,”models”:[{“model”:”UR-W706″,”year”:2025,”price”:”$194,900″,”estimated_monthly_payment”:”$3,473″},{“model”:”URW376″,”year”:2025,”price”:”$134,900″,”estimated_monthly_payment”:”$2,404″,”condition”:”Reduced”},{“model”:”UR-W295″,”year”:2016,”price”:”$69,900″,”estimated_monthly_payment”:”$1,245″},{“model”:”UR-W295″,”year”:2025,”price”:”$84,900″,”estimated_monthly_pay…

Strategic Sourcing Conclusion and Outlook for spider crane

As the demand for efficient and versatile lifting solutions continues to grow across various industries, the strategic sourcing of spider cranes emerges as a pivotal consideration for international B2B buyers. These mini cranes offer remarkable adaptability in confined spaces, allowing for seamless operations in diverse environments such as construction, steel erection, and glazing. Their compact design and impressive lifting capacities—ranging from 1,900 lbs to over 20,000 lbs—enable businesses to optimize project efficiency while minimizing logistical challenges.

Investing in spider cranes not only enhances operational capabilities but also signifies a commitment to innovative technologies that can drive productivity and safety. By strategically sourcing these advanced lifting solutions, companies can position themselves to meet the evolving demands of their markets, particularly in regions like Africa, South America, the Middle East, and Europe, where infrastructure development is rapidly advancing.

Looking ahead, B2B buyers are encouraged to explore partnerships with reputable suppliers and distributors to leverage the full potential of spider cranes. By doing so, organizations can ensure they remain competitive in an increasingly dynamic marketplace. Embrace the future of lifting solutions—invest in spider cranes today and elevate your business operations to new heights.