The Definitive Guide to Sonotube Footing Detail: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for sonotube footing detail

In today’s global construction landscape, sourcing reliable sonotube footing details can pose significant challenges for international B2B buyers. With varying regulations, soil conditions, and climate considerations across regions like Africa, South America, the Middle East, and Europe, ensuring the right foundation for construction projects is critical. This comprehensive guide addresses these complexities by delving into the various types of sonotubes, their applications in different construction scenarios, and the essential factors to consider when vetting suppliers.

Throughout this guide, we will explore the technical specifications of sonotubes, including dimensions, material quality, and load-bearing capacities. Additionally, we will cover the intricacies of cost structures, helping buyers understand pricing dynamics influenced by regional market conditions and supplier capabilities. By providing insights into best practices for installation and maintenance, as well as tips for navigating the procurement process, this guide empowers B2B buyers to make informed purchasing decisions.

Whether you’re a construction manager in Germany seeking to streamline your foundation projects or a contractor in Brazil looking for cost-effective solutions, this guide serves as a valuable resource. With actionable insights and practical advice, it equips you to confidently navigate the global market for sonotube footing details, ensuring your projects stand on a solid foundation.

Understanding sonotube footing detail Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Sonotube Footing | Typically cylindrical, made of cardboard or plastic, various diameters | Residential and light commercial builds | Pros: Cost-effective, easy to install. Cons: Less durable in extreme weather conditions. |

| Reinforced Sonotube Footing | Includes rebar for added strength, designed for heavier loads | Industrial and heavy commercial projects | Pros: High load capacity, suitable for larger structures. Cons: More expensive and labor-intensive to install. |

| Adjustable Sonotube Footing | Features adjustable height to accommodate uneven terrain | Custom construction projects | Pros: Versatile for different terrains, easy to modify. Cons: Installation complexity may increase. |

| Sonotube with Precast Base | Comes with a precast concrete base for enhanced stability | High-rise buildings, bridges | Pros: Superior stability, reduces settling risk. Cons: Higher upfront cost, requires precise installation. |

| Sonotube Foundation System | Integrated system with footings, rebar, and concrete pouring tools | Large-scale construction projects | Pros: Streamlined process, reduces labor time. Cons: Requires careful planning and material sourcing. |

What Are the Characteristics of Standard Sonotube Footings?

Standard sonotube footings are often cylindrical structures primarily made from cardboard or plastic, available in various diameters to fit different project needs. They are commonly used in residential and light commercial construction due to their affordability and ease of installation. Buyers should consider factors such as soil conditions and load requirements when choosing this type, as they may not perform well in extreme weather conditions. This type is ideal for projects where budget constraints are a priority.

How Do Reinforced Sonotube Footings Differ from Standard Options?

Reinforced sonotube footings incorporate rebar to enhance their structural integrity, making them suitable for heavier loads typically found in industrial and commercial applications. The addition of rebar increases the footing’s load capacity and resistance to cracking, providing a more robust solution for larger structures. Buyers must weigh the increased costs and labor associated with installation against the long-term benefits of durability and safety, particularly in regions with challenging environmental conditions.

Why Choose Adjustable Sonotube Footings for Custom Projects?

Adjustable sonotube footings are designed for versatility, allowing for height adjustments to accommodate uneven terrain. This feature makes them particularly valuable in custom construction projects where site conditions may vary significantly. While they offer flexibility, the complexity of installation can increase, requiring skilled labor and careful planning. Buyers should evaluate their project’s specific requirements and the potential need for specialized installation services.

What Are the Advantages of Using Sonotubes with Precast Bases?

Sonotubes with precast bases provide enhanced stability and reduce the risk of settling, making them ideal for high-rise buildings and bridges. This combination ensures a solid foundation that can handle substantial weight and fluctuating environmental conditions. Although the upfront costs may be higher, the long-term benefits of reduced maintenance and increased structural integrity make this option appealing for large-scale projects. Buyers should consider the logistical challenges of transportation and installation when opting for this solution.

How Does a Sonotube Foundation System Streamline Construction?

The sonotube foundation system integrates footings, rebar, and concrete pouring tools into a cohesive package, simplifying the construction process for large-scale projects. This streamlined approach can significantly reduce labor time and enhance efficiency on-site. However, careful planning and material sourcing are essential to ensure compatibility and performance. Buyers should assess their project timelines and available resources to determine if this comprehensive solution aligns with their construction goals.

Key Industrial Applications of sonotube footing detail

| Industry/Sector | Specific Application of sonotube footing detail | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Civil Engineering | Foundation for residential and commercial buildings | Ensures structural stability and longevity, reducing repair costs | Compliance with local building codes and environmental regulations |

| Renewable Energy | Installation of wind turbine bases | Provides robust support for turbines, enhancing energy production | Availability of high-strength materials for challenging terrains |

| Agriculture & Farming | Support for agricultural structures like greenhouses | Facilitates year-round production by providing stable foundations | Resistance to moisture and soil conditions, especially in tropical climates |

| Telecommunications | Base for cell towers and communication equipment | Enhances reliability of services, minimizing downtime | Logistics for transportation to remote locations and installation expertise |

| Infrastructure Development | Support for bridges, walkways, and elevated structures | Improves safety and accessibility, fostering community growth | Engineering specifications tailored to local climate and soil conditions |

How is Sonotube Footing Detail Used in Construction & Civil Engineering?

In the construction and civil engineering sector, sonotube footing details are critical for laying the foundation of both residential and commercial buildings. They provide a reliable method for creating deep, stable footings that ensure structural integrity. By utilizing sonotubes, builders can easily pour concrete to form piers that resist frost heave and shifting soil, which is particularly important in regions with variable climates. Buyers in this sector must ensure that the sonotubes meet local building codes and can withstand specific load requirements, especially in areas prone to earthquakes or heavy winds.

What Role Do Sonotube Footing Details Play in Renewable Energy Projects?

In renewable energy, sonotube footings are essential for supporting wind turbine bases. These foundations must endure substantial forces from wind and weight, making sonotubes a practical choice due to their ability to create strong, level bases. The use of sonotubes minimizes installation time and labor costs, which is crucial for energy projects aiming for quick returns on investment. International buyers should consider sourcing sonotubes that are engineered for high-strength performance, especially in challenging terrains like mountainous or coastal areas.

How are Sonotube Footings Beneficial in Agriculture & Farming?

Sonotube footings are increasingly utilized in agriculture for structures such as greenhouses and barns. They provide stable foundations that can withstand the weight of heavy equipment and protect against soil erosion. This stability allows farmers to maximize productivity throughout the year. Buyers in the agricultural sector should focus on sourcing sonotubes that resist moisture and can adapt to various soil conditions, particularly in tropical regions where heavy rainfall can affect foundation integrity.

In What Ways are Sonotube Footing Details Used in Telecommunications?

In telecommunications, sonotube footings are crucial for the installation of cell towers and other communication equipment. These foundations must be strong enough to support the weight of the tower and withstand environmental stresses, ensuring continuous service. By using sonotubes, companies can streamline the installation process and reduce the risk of future structural issues. Buyers should consider the logistics of transporting sonotubes to remote locations and ensure they have access to skilled labor for installation.

How Do Sonotube Footings Contribute to Infrastructure Development?

Sonotube footings are vital in infrastructure development, particularly for bridges, walkways, and elevated structures. They provide the necessary support to enhance safety and accessibility, which is essential for urban planning and community growth. Buyers in this field must ensure that the sonotubes are designed to meet specific engineering specifications that account for local climate and soil conditions, especially in regions with heavy rainfall or seismic activity. By investing in high-quality sonotubes, infrastructure projects can achieve long-term durability and performance.

3 Common User Pain Points for ‘sonotube footing detail’ & Their Solutions

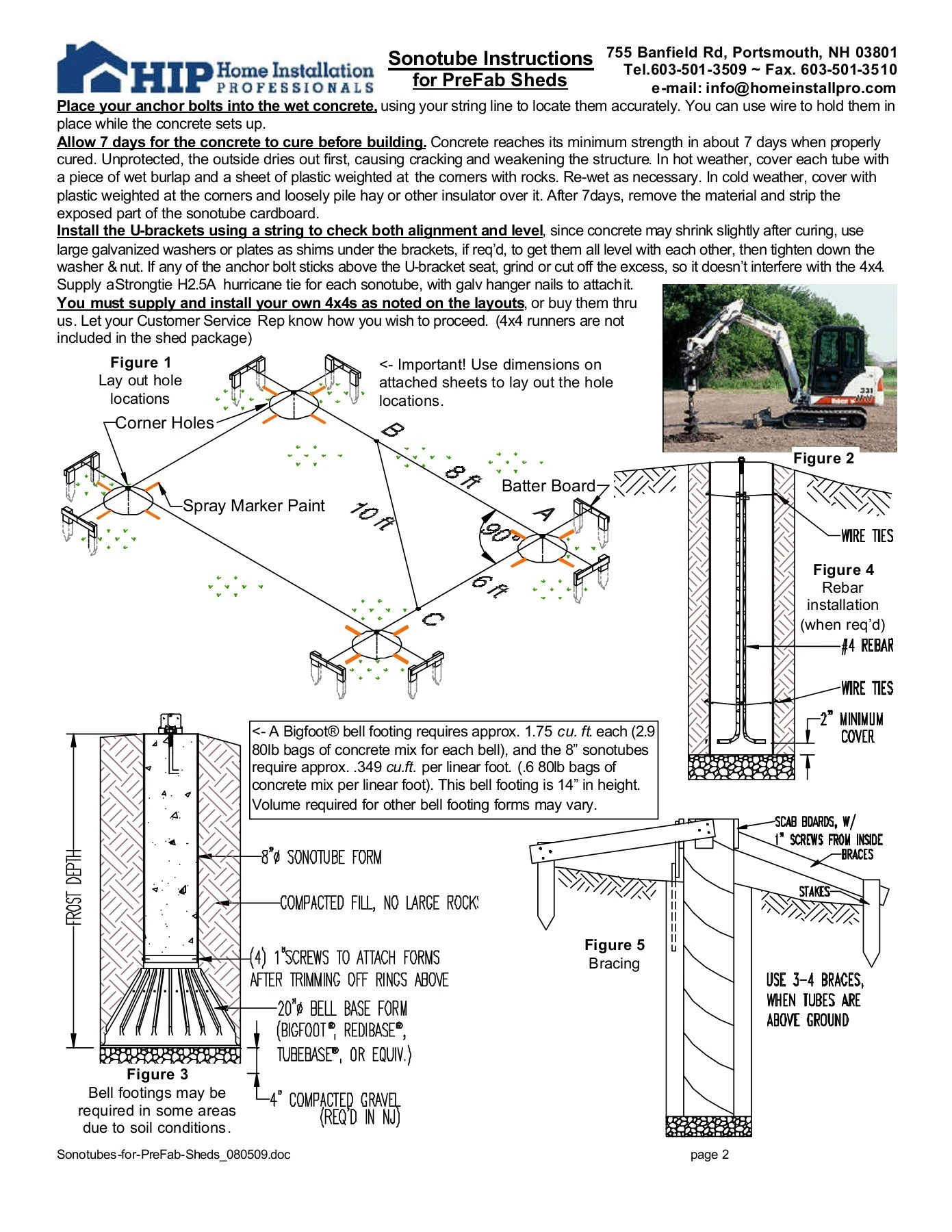

Scenario 1: Navigating Soil Variability in Footing Installation

The Problem: B2B buyers often encounter challenges when installing sonotube footings due to varying soil conditions. For example, in regions with rocky or unstable soil, the difficulty of digging holes can lead to delays and increased labor costs. This variability can also affect the depth and stability of the footings, risking the overall integrity of the structure being built. Buyers may feel overwhelmed by the prospect of needing to adapt their installation methods to suit these conditions, particularly when they lack the necessary equipment or expertise.

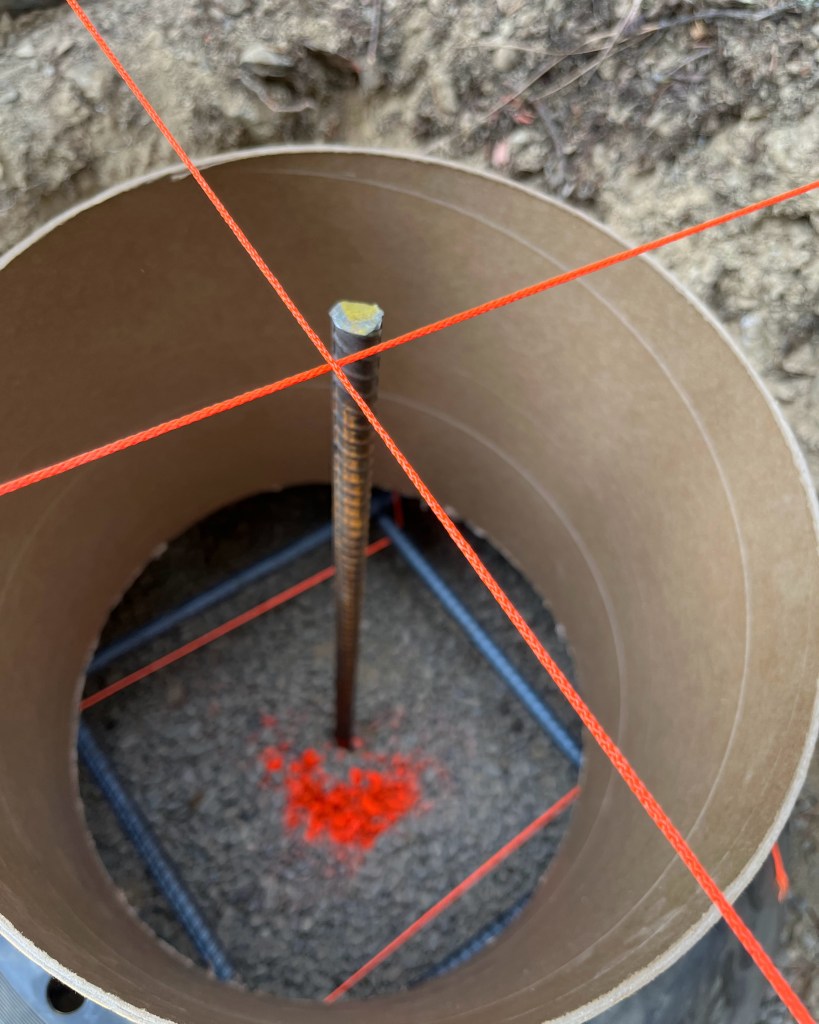

The Solution: To address soil variability, it is crucial to conduct a thorough site assessment before installation. Utilize geotechnical services to analyze soil composition and stability. Based on this analysis, buyers should select the appropriate digging equipment—such as a mini-excavator for rocky soil or a post hole auger for softer ground. Additionally, consider using sonotubes with a wider base or deeper footing to enhance stability in challenging soils. Incorporating rebar into the design not only strengthens the concrete but also offers additional structural support. By proactively addressing these soil challenges, buyers can ensure a smoother installation process and reduce the risk of costly delays.

Scenario 2: Ensuring Accurate Footing Placement and Leveling

The Problem: Accurate placement and leveling of sonotubes are critical for the success of any construction project. B2B buyers often struggle with aligning the sonotubes correctly and ensuring they are perfectly level, especially on uneven terrain. This can lead to structural issues down the line, such as settling or shifting, which can compromise the integrity of the building. Misalignment can also result in significant rework and wasted materials, leading to frustration and increased costs.

The Solution: To enhance accuracy in footing placement, buyers should invest in quality leveling tools, such as laser levels or digital leveling devices, which provide precise measurements for alignment. Before installation, it’s advisable to mark the layout using stakes and string lines to visualize the intended placement of the footings. This method helps in maintaining consistent spacing and alignment. When pouring concrete, ensure that each sonotube is braced securely and double-check alignment throughout the pouring process. Additionally, allowing for a curing period before backfilling can help maintain the integrity of the footings. These steps will mitigate errors and lead to a more stable foundation.

Scenario 3: Managing Weather Conditions During Installation

The Problem: Weather can significantly impact the installation of sonotube footings, particularly in regions experiencing extreme temperatures or heavy rainfall. Buyers may face challenges such as concrete setting too quickly in hot weather or becoming compromised by excess moisture. These conditions can lead to weakened structural integrity and potential project delays, creating a daunting scenario for contractors and project managers alike.

The Solution: To combat weather-related issues, it is essential to plan installations during favorable conditions or to take preventive measures. When working in high temperatures, consider using retarders in the concrete mix to slow down the setting time, allowing for better handling and placement. Conversely, in cooler or wet conditions, ensure that the concrete is protected from moisture by using tarps or temporary shelters. If rain is imminent, schedule the installation to allow for adequate curing time before exposure to moisture. Additionally, consider using high-performance concrete mixes designed to withstand varying weather conditions. By anticipating weather-related challenges, buyers can effectively manage their projects and maintain construction timelines.

Strategic Material Selection Guide for sonotube footing detail

What Are the Key Materials for Sonotube Footing Detail?

When selecting materials for sonotube footing details, various factors such as durability, cost, and environmental conditions play a crucial role. Here, we analyze four common materials used in sonotube applications, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Concrete in Sonotube Applications?

Key Properties: Concrete is the primary material used in sonotube applications due to its compressive strength and durability. It can withstand high pressure and is resistant to various environmental factors, including moisture and temperature fluctuations.

Pros & Cons: The advantages of concrete include its high strength-to-weight ratio, low maintenance, and cost-effectiveness. However, it can be susceptible to cracking under extreme temperature changes and may require reinforcement with materials like rebar for added strength.

Impact on Application: Concrete is compatible with various soil types and can be tailored to meet specific load requirements, making it suitable for diverse applications.

Considerations for International Buyers: Compliance with local standards such as ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) is essential. Buyers in regions like Europe and South America should ensure that the concrete mix meets local regulations for durability and environmental impact.

How Does Steel Reinforcement Enhance Sonotube Footing Performance?

Key Properties: Steel reinforcement, particularly in the form of rebar, significantly enhances the tensile strength of concrete, making it less prone to cracking and structural failure.

Pros & Cons: The primary advantage of steel is its high strength and ductility, allowing it to absorb energy during seismic events. However, it is prone to corrosion if not adequately protected, which can compromise the integrity of the footing over time.

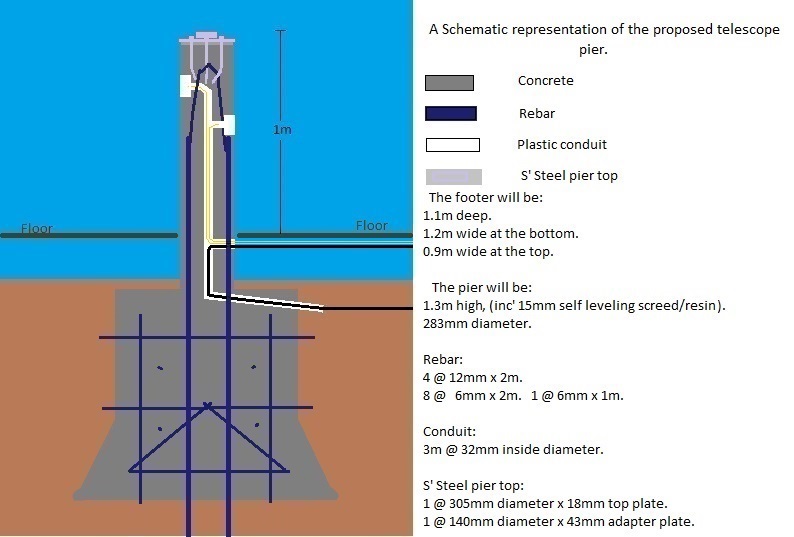

Illustrative image related to sonotube footing detail

Impact on Application: Steel reinforcement is particularly beneficial in areas with high seismic activity or where soil conditions may lead to shifting or settling.

Considerations for International Buyers: Buyers should be aware of local corrosion resistance standards, especially in coastal regions where saltwater exposure is a concern. Compliance with JIS (Japanese Industrial Standards) or similar local standards is also critical.

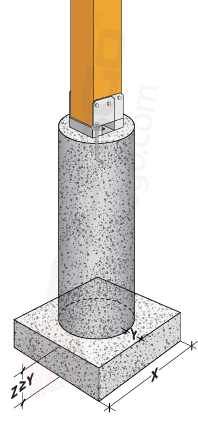

What Role Does Sonotube Material Play in Footing Construction?

Key Properties: Sonotubes are typically made from cardboard or composite materials, designed to be lightweight yet strong enough to hold wet concrete until it sets.

Illustrative image related to sonotube footing detail

Pros & Cons: The main advantage of sonotubes is their ease of use and low cost, making them an economical choice for footing construction. However, they have a limited lifespan and may require additional support in wet conditions to prevent collapse before the concrete sets.

Impact on Application: Sonotubes facilitate the creation of consistent, cylindrical footings, which are essential for load distribution.

Considerations for International Buyers: Buyers should consider the availability of sonotube materials that meet local building codes and standards. In regions with high humidity, moisture-resistant options may be necessary to ensure structural integrity.

How Do Alternative Materials Like Plastic and Fiberglass Compare?

Key Properties: Plastic and fiberglass sonotubes offer lightweight, corrosion-resistant alternatives to traditional cardboard sonotubes. They are designed to withstand moisture and can be reused multiple times.

Pros & Cons: The key advantage is their durability and resistance to environmental factors. However, they can be more expensive than traditional materials and may not provide the same level of structural support without additional reinforcement.

Impact on Application: These materials are particularly useful in regions with high moisture or corrosive environments, where traditional materials may fail.

Considerations for International Buyers: International buyers should ensure that these materials meet local standards for structural integrity and environmental impact. Compliance with regulations in regions like the Middle East, where temperatures can be extreme, is also essential.

Summary Table of Material Selection for Sonotube Footing Detail

| Material | Typical Use Case for sonotube footing detail | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Concrete | Primary material for footings | High strength and durability | Susceptible to cracking | Medium |

| Steel Reinforcement | Enhancing concrete strength | High tensile strength | Prone to corrosion | Medium |

| Sonotube (Cardboard) | Forming footings | Economical and easy to use | Limited lifespan | Low |

| Plastic/Fiberglass | Moisture-resistant footings | Durable and reusable | Higher cost | High |

This strategic material selection guide provides valuable insights for B2B buyers in various international markets, ensuring informed decisions that align with local standards and project requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for sonotube footing detail

What Are the Key Stages in the Manufacturing Process of Sonotube Footing Details?

Manufacturing sonotube footing details involves several critical stages that ensure the final product meets the required specifications for durability and structural integrity. Understanding these stages can help B2B buyers make informed decisions when sourcing materials.

Material Preparation: What Goes Into the Creation of Sonotubes?

The first step in the manufacturing process is the preparation of raw materials. Sonotubes are primarily made from high-quality cardboard or fiberboard, designed to withstand the pressure of wet concrete. Suppliers typically source materials from reputable manufacturers that adhere to strict quality standards.

Once the raw materials arrive at the facility, they undergo inspection for quality assurance. This involves checking for any defects or inconsistencies in the material, such as tears or uneven thickness.

Illustrative image related to sonotube footing detail

How Are Sonotubes Formed and Assembled?

After material preparation, the next stage involves forming the sonotubes. This is typically achieved through a process known as roll forming, where sheets of cardboard are rolled into cylindrical shapes and glued at the seams. The formed tubes must meet specific diameter and length requirements based on the project specifications.

In some cases, manufacturers use a molding technique to create reinforced sonotubes. This method involves layering materials to enhance structural integrity. The assembly stage also includes integrating features such as built-in flanges or reinforcement ribs if required.

What Finishing Techniques Are Applied to Sonotubes?

Once the sonotubes are formed, they go through finishing processes that may include surface treatment and protective coatings. These treatments enhance the tubes’ resistance to moisture and other environmental factors, thereby prolonging their lifespan.

Quality checks are performed during the finishing stage to ensure that all specifications are met. This includes verifying the weight and thickness of the tubes, as well as ensuring that they can withstand the pressures they will encounter during concrete pouring.

What Quality Assurance Measures Are Important for Sonotube Manufacturing?

Quality assurance (QA) is critical in the manufacturing of sonotube footing details to ensure product reliability. Buyers should be aware of relevant international standards and industry-specific certifications that indicate a supplier’s commitment to quality.

Which International Standards Should B2B Buyers Consider?

One of the most recognized international standards for quality management is ISO 9001. Suppliers who have obtained this certification demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

In addition to ISO 9001, buyers should look for compliance with CE marking, which indicates that the product meets EU safety, health, and environmental protection standards. For specific applications in oil and gas, API (American Petroleum Institute) certifications may also be pertinent.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to the manufacturing process of sonotubes. These typically include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During production, various tests are conducted to monitor the manufacturing process, checking for consistency in dimensions and material properties.

-

Final Quality Control (FQC): Before shipment, finished sonotubes undergo comprehensive testing to verify that they meet all specifications and quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure that their suppliers maintain rigorous quality control measures.

What Audit Processes Can Be Implemented?

Conducting audits is one of the most effective ways to verify a supplier’s quality control processes. Buyers should consider scheduling regular audits to assess compliance with international standards and internal quality protocols.

During an audit, buyers should evaluate documentation, production processes, and quality assurance practices. This includes reviewing inspection reports, testing methods, and any corrective actions taken for non-compliance.

How Can Buyers Utilize Reports and Third-Party Inspections?

Requesting quality control reports from suppliers can provide insights into their QA processes and performance metrics. These reports typically include details on inspection results, testing methods, and compliance with standards.

Additionally, engaging third-party inspection agencies can add an extra layer of assurance. These agencies provide unbiased evaluations of the supplier’s manufacturing practices and product quality, ensuring that buyers receive reliable materials.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control and certification.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have specific regulations and standards that suppliers must comply with. For instance, European buyers may prioritize CE marking, while buyers in the Middle East may look for compliance with local building codes. Understanding these regional differences can help buyers select the right suppliers.

What Should Buyers Know About Supply Chain Transparency?

Transparency in the supply chain is crucial for international buyers. They should ensure that suppliers provide clear documentation regarding sourcing, manufacturing processes, and quality control measures. This transparency not only builds trust but also ensures compliance with international standards.

Conclusion: Making Informed Decisions in Sonotube Sourcing

Understanding the manufacturing processes and quality assurance measures for sonotube footing details is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing techniques, as well as the relevant quality control standards, buyers can ensure they are sourcing high-quality products that meet their project needs. Engaging in thorough supplier evaluations and audits can further enhance the reliability of their sourcing decisions, leading to successful project outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sonotube footing detail’

Introduction

This practical sourcing guide is designed for B2B buyers interested in procuring sonotube footing details for construction projects. Sonotubes are essential for creating stable concrete footings, especially in varying soil conditions. By following this step-by-step checklist, you can ensure that you secure high-quality materials and services tailored to your specific construction needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications for your sonotube footings. Consider factors such as the diameter, height, and material requirements based on your project’s load-bearing needs and environmental conditions. Providing detailed specifications helps suppliers understand your exact requirements and ensures they can meet your project standards.

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify potential suppliers of sonotubes and related materials. Utilize online directories, industry trade shows, and professional networks to gather a list of reputable manufacturers and distributors. Focus on suppliers with a strong track record in your region, as local suppliers may better understand the environmental challenges and regulations you face.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier choice, verify their certifications and compliance with international quality standards. Look for certifications such as ISO 9001 or local equivalents that demonstrate adherence to quality management systems. This step is crucial as it ensures that the products you receive will meet the necessary safety and performance standards.

Illustrative image related to sonotube footing detail

Step 4: Request Samples and Product Specifications

Always request product samples and detailed specifications from shortlisted suppliers. Evaluate the quality of the sonotubes, including their thickness and structural integrity, to ensure they meet your project’s demands. Additionally, review technical datasheets for load ratings and installation guidelines, which are essential for proper application.

Step 5: Compare Pricing and Terms of Service

Once you have gathered information from multiple suppliers, compare pricing, payment terms, and delivery options. Ensure that the quotes include all necessary costs, such as shipping and handling fees. A comprehensive comparison will help you identify the most cost-effective solution without compromising on quality.

Step 6: Assess Customer Support and After-Sales Service

Evaluate the level of customer support and after-sales service offered by potential suppliers. A reliable supplier should provide technical assistance during installation and be responsive to any inquiries or issues that arise post-purchase. Strong after-sales support can significantly impact the success of your project.

Illustrative image related to sonotube footing detail

Step 7: Finalize Your Order and Establish a Relationship

After selecting a supplier, finalize your order and establish a solid working relationship. Clear communication about expectations, timelines, and any potential challenges is vital for ensuring a smooth procurement process. Building a long-term relationship with your supplier can lead to better pricing, priority service, and support for future projects.

By following this checklist, B2B buyers can effectively navigate the procurement process for sonotube footings, ensuring that they select the best materials and suppliers for their construction needs.

Comprehensive Cost and Pricing Analysis for sonotube footing detail Sourcing

What Are the Key Cost Components for Sonotube Footing Detail Sourcing?

When sourcing sonotube footing details, understanding the cost structure is paramount. The major components include:

-

Materials: This encompasses the cost of sonotubes, Portland cement, rebar, gravel, and any additional framing materials. Prices can vary based on the type and quality of materials selected. For example, standard cardboard sonotubes are less expensive than high-strength plastic options.

-

Labor: Labor costs can fluctuate depending on the region and the complexity of the installation. Skilled labor may command higher wages, especially in areas with a shortage of construction professionals.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Manufacturers may pass these costs on to buyers, affecting overall pricing.

-

Tooling: The expenses related to the tools required for installation, such as excavators, concrete mixers, and leveling equipment, must also be factored in. Renting equipment can reduce upfront costs but may increase long-term expenses.

-

Quality Control (QC): Ensuring that materials meet specific quality standards can involve additional costs. Certifications and testing may be necessary to comply with regional building codes, particularly in Europe and North America.

-

Logistics: Shipping costs can significantly impact the total price, especially for international buyers. Factors such as distance, weight, and mode of transport (sea, air, land) influence logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely based on market conditions and competition.

What Influences Pricing for Sonotube Footing Details?

Several factors can influence pricing for sonotube footing details:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Buyers should consider consolidating orders to achieve better pricing.

-

Specifications and Customization: Custom-designed sonotubes or specific material requirements can lead to higher costs. Standard products are usually more economical.

-

Materials: The choice of materials greatly impacts pricing. High-quality or specialized materials will cost more but may offer improved durability and performance.

-

Quality and Certifications: Products that meet international quality standards (e.g., ISO, ASTM) may come at a premium. Buyers should weigh the benefits of certified products against cost.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate responsibilities for shipping, insurance, and tariffs, which can influence overall costs.

How Can Buyers Optimize Costs When Sourcing Sonotube Footing Details?

International B2B buyers can employ several strategies to optimize costs:

-

Negotiation: Engage in discussions with suppliers to explore flexible pricing options, especially for larger orders. Understanding market trends can provide leverage in negotiations.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and potential future expenses. A lower upfront cost may not always translate to long-term savings.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local taxes that can affect pricing when sourcing internationally. It’s advisable to calculate the landed cost to accurately assess the total expense.

-

Regional Considerations: Different regions may have varying standards and pricing structures. Buyers from Africa, South America, the Middle East, and Europe should research local suppliers and regulations to make informed decisions.

Disclaimer

The prices discussed in this analysis are indicative and may vary based on current market conditions, regional factors, and specific buyer requirements. It is recommended to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing sonotube footing detail With Other Solutions

Exploring Alternative Solutions to Sonotube Footing Detail

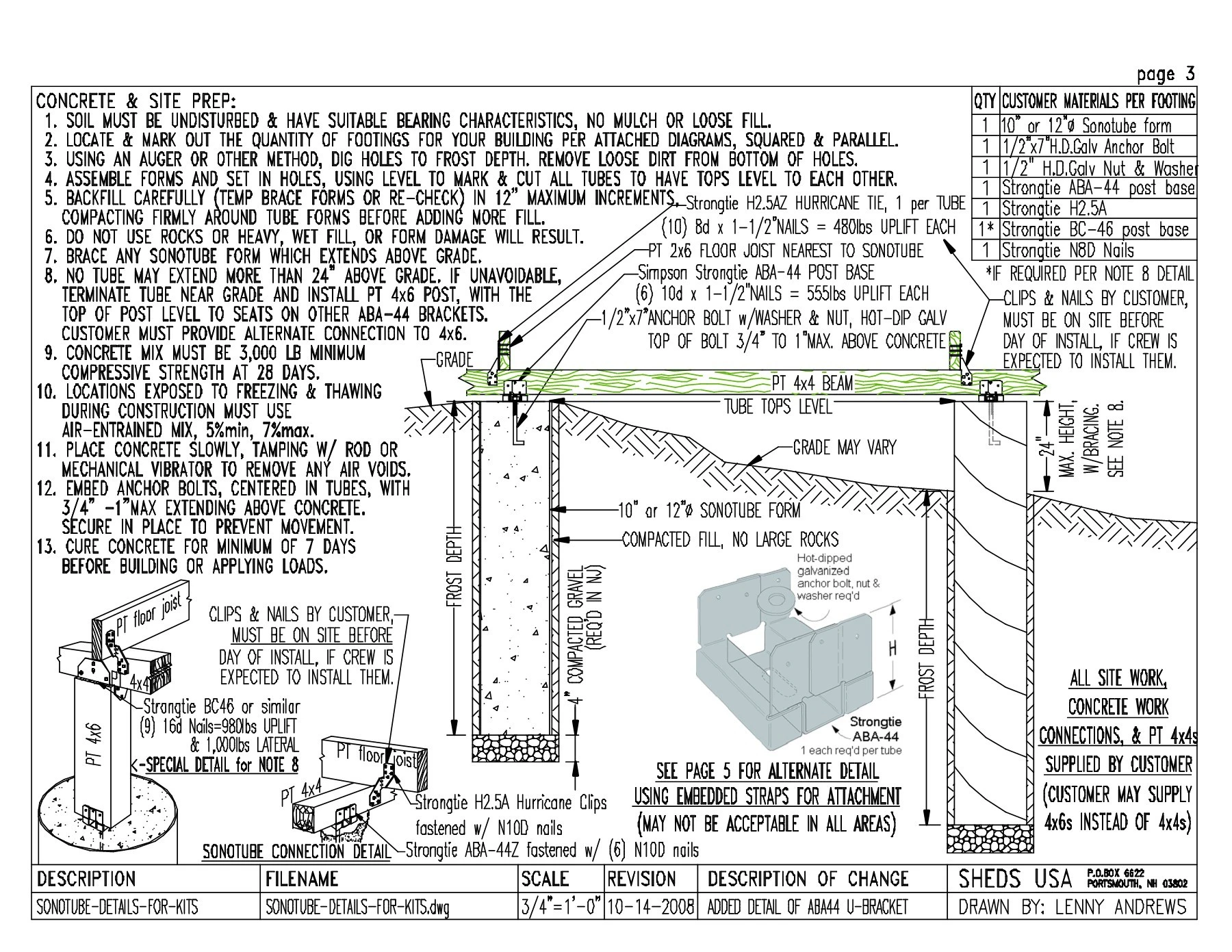

When considering foundational solutions for structures, it’s essential to evaluate various methods beyond the traditional sonotube footing. Each alternative presents unique advantages and challenges, allowing B2B buyers to tailor their choice based on specific project requirements, regional conditions, and budget constraints. This analysis compares sonotube footings against two viable alternatives: concrete piers and helical piles.

Illustrative image related to sonotube footing detail

Comparison Table

| Comparison Aspect | Sonotube Footing Detail | Concrete Piers | Helical Piles |

|---|---|---|---|

| Performance | High load-bearing capacity; suitable for frost-prone areas | Good load distribution; effective for various soil types | Very high load capacity; ideal for unstable soils |

| Cost | Moderate; depends on local concrete prices and labor | Generally lower than sonotubes, but varies with depth | Higher initial costs due to specialized installation equipment |

| Ease of Implementation | Requires excavation, framing, and pouring; labor-intensive | Easier to install; can be placed with minimal excavation | Quick installation; requires specialized machinery but less manual labor |

| Maintenance | Low; durable if correctly installed | Low; may require inspection over time | Low; designed to last without significant maintenance |

| Best Use Case | Ideal for residential decks and small cabins; frost-prone areas | Suitable for lightweight structures and temporary installations | Best for heavy structures and challenging soil conditions |

Detailed Breakdown of Alternatives

What Are Concrete Piers and Their Advantages?

Concrete piers are vertical columns of concrete that support a structure above the ground. They are relatively easy to install, requiring less excavation compared to sonotubes. The lower cost of concrete piers makes them an attractive option for projects with budget constraints. However, their performance can be less effective in frost-prone areas unless they are installed below the frost line. Concrete piers work well for lighter structures but may not be suitable for larger, more complex builds.

How Do Helical Piles Compare?

Helical piles are steel shafts with helical plates that are drilled into the ground to provide support. They are particularly advantageous in unstable soil conditions, offering a high load-bearing capacity. The installation process is quicker than that of sonotubes, as they do not require extensive excavation. However, the cost can be significantly higher due to the need for specialized equipment and skilled labor. Helical piles are ideal for heavy structures and those built in challenging terrains, making them a robust solution for commercial and industrial applications.

Making the Right Choice for Your Project

Selecting the appropriate foundation method requires a thorough understanding of your specific project needs, including load requirements, soil conditions, and budget limitations. For structures in frost-prone areas, sonotube footings provide excellent stability and durability. If cost is a primary concern and the structure is lightweight, concrete piers may be the best option. Conversely, for projects involving heavy loads or unstable soils, helical piles offer a reliable solution despite their higher costs. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their project goals and operational needs.

Essential Technical Properties and Trade Terminology for sonotube footing detail

What Are the Critical Technical Properties of Sonotube Footing Detail?

When considering sonotube footing details for construction projects, understanding the technical specifications is vital. These properties not only ensure structural integrity but also facilitate smoother project execution. Here are some essential specifications:

Illustrative image related to sonotube footing detail

-

Material Grade

Sonotubes are typically made from high-quality cardboard or concrete. The grade of the material affects durability and load-bearing capacity. For instance, a higher-grade sonotube can support greater weight and withstand harsher environmental conditions, making it crucial for buyers to select the appropriate material for their specific applications. -

Diameter and Height

Sonotubes come in various diameters (commonly 8, 10, 12 inches) and heights (often ranging from 3 to 12 feet). The diameter impacts the load distribution and stability of the structure, while the height must comply with local building codes and frost line requirements. Buyers should understand these dimensions to ensure compatibility with their project specifications. -

Load Capacity

The load capacity of a sonotube foundation is a critical factor that determines its suitability for specific structures. Typically expressed in pounds per square foot (PSF), this property is essential for ensuring that the footings can adequately support the intended load of the structure. Understanding load capacity helps avoid costly structural failures. -

Frost Depth Compliance

In regions prone to freezing temperatures, sonotubes must be installed below the frost line to prevent movement caused by freeze-thaw cycles. This property is particularly important in areas with extreme weather conditions, making frost depth compliance a vital aspect of design and construction planning. -

Tolerance Levels

Tolerance levels refer to the allowable deviation from specified dimensions during manufacturing and installation. Proper tolerances ensure that sonotubes fit correctly and maintain structural integrity. Buyers should be aware of these tolerances to ensure that the components will work together seamlessly.

What Are the Common Trade Terms Associated with Sonotube Footing Detail?

Familiarity with industry terminology can streamline communication and negotiations in the B2B sector. Here are several key terms related to sonotube footing detail:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end product. In the context of sonotubes, understanding OEM relationships can help buyers assess quality and reliability, ensuring they source materials from reputable manufacturers. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage their budgets and inventory effectively, especially when dealing with large-scale construction projects. -

RFQ (Request for Quotation)

An RFQ is a formal process in which a buyer requests pricing and terms from suppliers for specific products or services. For buyers involved in sonotube footing projects, issuing an RFQ can facilitate competitive pricing and ensure they receive comprehensive proposals from multiple suppliers. -

Incoterms

International Commercial Terms (Incoterms) are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers navigate shipping logistics, costs, and risk management associated with importing sonotubes from different countries. -

Lead Time

Lead time refers to the amount of time from placing an order to the delivery of the goods. Knowing the lead time for sonotube orders is essential for project planning and scheduling, as delays can significantly impact construction timelines.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions regarding sonotube footing details, ensuring their projects are successful and compliant with industry standards.

Navigating Market Dynamics and Sourcing Trends in the sonotube footing detail Sector

What Are the Current Market Dynamics and Key Trends in the Sonotube Footing Detail Sector?

The sonotube footing detail sector is experiencing significant growth driven by a surge in construction activities worldwide, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key trends include the increasing adoption of prefabricated solutions, which streamline construction processes and reduce labor costs. Additionally, digital technology is reshaping sourcing strategies; construction firms are now leveraging advanced software for project management and procurement, enhancing efficiency and transparency.

Another notable trend is the rising focus on local sourcing. International buyers are increasingly prioritizing suppliers who can provide materials with shorter lead times and reduced transportation costs. This shift is particularly evident in regions like Germany and Brazil, where local production capabilities are being developed to meet the growing demand for construction materials. Furthermore, sustainability considerations are influencing purchasing decisions, with buyers seeking eco-friendly alternatives and materials that comply with green building certifications.

In terms of competition, the market is becoming more fragmented, with a mix of established players and new entrants. This dynamic landscape is encouraging innovation and better pricing strategies. As international B2B buyers navigate these dynamics, understanding regional market conditions and supplier capabilities will be crucial for making informed procurement decisions.

How Is Sustainability Influencing Sourcing Strategies in the Sonotube Footing Detail Sector?

Sustainability is becoming a central theme in the sonotube footing detail sector, as environmental concerns gain prominence among consumers and regulatory bodies alike. The production and disposal of traditional construction materials can have significant environmental impacts, prompting a shift toward sustainable alternatives. Buyers are increasingly looking for suppliers who prioritize ethical sourcing practices, which not only minimize ecological footprints but also support local economies.

The importance of green certifications is rising, with many buyers now requiring materials that meet recognized environmental standards. This trend is particularly relevant in Europe, where regulations on construction materials are stringent. Suppliers who can demonstrate compliance with certifications such as LEED (Leadership in Energy and Environmental Design) or ISO 14001 (Environmental Management) will have a competitive advantage in attracting international clients.

Moreover, the use of recycled materials in the production of sonotubes is gaining traction. Innovations in material science have led to the development of eco-friendly sonotubes that offer the same structural integrity while reducing environmental impact. As sustainability becomes a key differentiator, B2B buyers must evaluate suppliers not just on cost and quality, but also on their commitment to sustainable practices.

Illustrative image related to sonotube footing detail

What Historical Developments Have Shaped the Sonotube Footing Detail Sector?

The sonotube footing detail sector has evolved significantly over the past few decades, driven by advancements in construction technology and changing industry standards. Initially, sonotubes were primarily used for temporary structures, but as their reliability and effectiveness became evident, their application broadened to include permanent foundations for various types of construction projects.

In the early days, sonotubes were primarily made from cardboard, which, while effective, presented challenges in terms of durability and environmental impact. Over time, the introduction of more robust materials, such as plastic and composite options, has enhanced their performance and sustainability. Today, these innovations not only improve the structural integrity of foundations but also align with the growing demand for environmentally friendly construction practices.

As the global construction market continues to expand, understanding the historical context of sonotube applications can provide valuable insights for B2B buyers. Recognizing how technological advancements and sustainability trends have shaped the market will enable buyers to make informed decisions when sourcing materials for their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of sonotube footing detail

-

How do I solve issues with sonotube footing alignment?

Proper alignment of sonotube footings is crucial for structural integrity. To resolve alignment issues, ensure that your digging process is precise and that you use a string line to maintain level measurements. Begin by marking the layout with stakes and string, then double-check all measurements before pouring concrete. If you find misalignment after pouring, it may be necessary to make adjustments with additional materials or to consult with a structural engineer for solutions. -

What is the best sonotube diameter for heavy structures?

For heavy structures, a larger sonotube diameter, typically 12 inches or more, is recommended to distribute weight effectively. The diameter will depend on the load requirements and soil conditions. It is essential to consult local building codes and consider factors such as frost depth and soil type, especially in regions like Europe and North America, to ensure the selected diameter meets safety and structural requirements. -

How can I ensure the quality of sonotubes from suppliers?

To ensure quality, vet suppliers by requesting certifications, product samples, and references from previous clients. Look for suppliers who adhere to international standards, such as ISO certifications, and have a solid reputation in the industry. Additionally, consider arranging for third-party quality inspections, especially for large orders, to verify that the sonotubes meet your specifications before shipment. -

What customization options are available for sonotubes?

Many suppliers offer customization options such as specific lengths, diameters, and wall thicknesses for sonotubes. Depending on your project needs, inquire about reinforced sonotubes or those with specific coatings for added durability. It’s advisable to discuss your requirements upfront with suppliers to ensure they can meet your project’s specifications and timelines. -

What are the minimum order quantities (MOQs) for sonotubes?

Minimum order quantities for sonotubes can vary significantly by supplier and region. Generally, suppliers may require an MOQ ranging from 100 to 500 units, depending on their production capabilities and inventory levels. It’s important to communicate your project needs clearly and negotiate MOQs that align with your budget and project scope, especially when sourcing from international suppliers. -

What payment terms should I expect when sourcing sonotubes internationally?

Payment terms can differ widely among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may offer credit terms depending on your business relationship and order size. Always clarify payment terms upfront and consider using secure payment methods, such as letters of credit, to mitigate risks in international transactions. -

How do logistics impact the sourcing of sonotubes?

Logistics play a crucial role in the timely delivery of sonotubes. Factors such as shipping methods, customs clearance, and local transportation should be considered. For international buyers, it’s vital to work with logistics partners who understand the regulations in your region and can provide reliable shipping timelines. Additionally, plan for potential delays due to customs or local regulations, especially in regions like Africa and South America. -

What are the best practices for storing sonotubes before use?

To maintain the integrity of sonotubes before use, store them in a dry, cool area away from direct sunlight and moisture. Use pallets to elevate them off the ground and avoid contact with the soil, which can lead to degradation. Additionally, ensure that they are stacked securely to prevent tipping or damage. Proper storage practices help ensure that the sonotubes are in optimal condition when it’s time to install them.

Top 6 Sonotube Footing Detail Manufacturers & Suppliers List

1. Reddit – Sonotube Footings for Decks

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 10″ diameter sonotube footings for deck construction.

2. Howe Lumber – 10 x 12′ Sonotube

Domain: cust.howelumber.com

Registered: 1999 (26 years)

Introduction: This company, Howe Lumber – 10 x 12′ Sonotube, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Hansen Pole Buildings – Sonotubes

Domain: hansenpolebuildings.com

Registered: 2002 (23 years)

Introduction: Sonotubes are used in post frame buildings to reduce the amount of concrete needed in holes. They are designed to be placed in large holes, backfilled with concrete, and can help resist uplift from frost heave and wind forces. The effectiveness of sonotubes depends on the embedment depth of the post, which should be below the frost line to prevent movement. The friction between the earth and the p…

4. IQS Directory – Sonotubes®

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Sonotubes® are cylindrical forms made from layered cardboard, often treated with wax or laminate finish, designed for pouring concrete to create structural elements like columns and posts. They are available in various materials including fiber, plastic, and composites, and come in a wide range of sizes from small versions to large tubes several feet in length. Standard Sonotubes® can resist water…

5. DIY Chatroom – Sonotubes for Playset Support

Domain: diychatroom.com

Registered: 2003 (22 years)

Introduction: Sonotubes: 8 inches wide, 3 feet deep; used for supporting a large playset (15 ft x 13 ft, 16 ft high peak) with 16 posts. Installed to frost depth to avoid tree roots. No footing planned under sonotubes. Soil conditions: rocky and clay-like, requiring manual digging.

6. Facebook – Foundation Pier Installation

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Foundation Pier Installation, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for sonotube footing detail

In conclusion, the strategic sourcing of sonotube footing materials is a critical component for successful construction projects, particularly in regions with varying soil conditions and climate challenges. Key takeaways include the importance of selecting high-quality materials, understanding local regulations, and leveraging regional suppliers to optimize costs and logistics. By prioritizing these elements, international buyers can ensure the structural integrity and longevity of their projects while enhancing overall project efficiency.

As the construction industry evolves, there is an increasing demand for innovative solutions and sustainable practices. Buyers from Africa, South America, the Middle East, and Europe should stay informed about emerging technologies and methodologies that can improve footing installation processes. Engaging with local suppliers and industry experts can provide valuable insights and foster partnerships that lead to more resilient infrastructure.

We encourage international B2B buyers to take proactive steps in sourcing their sonotube footing materials. By doing so, they not only enhance their project outcomes but also contribute to the growth of sustainable construction practices in their respective regions. Let’s build a solid foundation for the future together.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.