The Definitive Guide to Snow Machine For Sale: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for snow machine for sale

In today’s competitive landscape, sourcing snow machines for sale presents a unique challenge for international B2B buyers. With the demand for artificial snow rising in various regions—from ski resorts in Europe to winter-themed entertainment parks in South America—businesses must navigate a complex market filled with diverse products and suppliers. This comprehensive guide addresses these challenges by providing an in-depth look at the different types of snow machines, their applications, and the key factors to consider when making a purchase.

From understanding the technical specifications of snowmakers like the SG6 Xstream to evaluating supplier reliability, this guide equips buyers with the essential knowledge needed to make informed decisions. We delve into critical aspects such as cost analysis, supplier vetting processes, and the importance of after-sales support, ensuring that you can confidently choose a snow machine that meets your operational needs.

Particularly for buyers in Africa, South America, the Middle East, and Europe, this guide highlights regional considerations, including climatic challenges and logistical considerations for importing snowmaking equipment. By synthesizing market insights and practical advice, we empower you to navigate the global market effectively, helping your business capitalize on the growing demand for artificial snow solutions.

Understanding snow machine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Residential Snowmakers | Compact, user-friendly, designed for home use, lower output | Ski resorts, backyard installations | Pros: Affordable, easy setup. Cons: Limited snow volume. |

| Commercial Snowmakers | High output, robust construction, suitable for large areas | Ski resorts, event venues | Pros: High efficiency, large coverage. Cons: Higher cost. |

| Portable Snowmakers | Lightweight, mobile, flexible operation | Temporary events, small ski areas | Pros: Easy transport, quick setup. Cons: Limited capacity. |

| Heavy-Duty Snowmakers | Industrial-grade materials, high pressure, maximum snow output | Large ski resorts, film production | Pros: Maximum efficiency, durable. Cons: Expensive, requires significant infrastructure. |

| Ice Shaving Machines | Converts ice to snow, operates in warmer conditions | Theme parks, entertainment venues | Pros: Can operate above freezing. Cons: Limited snow quality. |

What Are the Key Characteristics of Residential Snowmakers?

Residential snowmakers are designed for ease of use and lower snow output, making them ideal for homeowners or small businesses wanting to create a winter atmosphere. They typically produce snow at a rate sufficient to cover small areas, such as backyards or small ski runs. When considering a purchase, B2B buyers should evaluate the machine’s compatibility with existing water and air supply systems, as well as its operational temperature requirements. Affordability and ease of setup are major advantages, though the limited snow production may not meet the needs of larger venues.

How Do Commercial Snowmakers Stand Out?

Commercial snowmakers are engineered for high efficiency and durability, capable of producing large volumes of snow over expansive areas. They are commonly used in ski resorts and for large events where consistent snow coverage is essential. B2B buyers must consider the initial investment, ongoing maintenance costs, and the necessary infrastructure to support these machines. While they offer significant benefits in terms of snow output and quality, the higher price point can be a barrier for some businesses.

What Advantages Do Portable Snowmakers Offer?

Portable snowmakers are designed for flexibility and mobility, making them suitable for temporary events or smaller ski areas. These machines can be easily transported and set up quickly, allowing for rapid deployment in various locations. However, their snow production capacity is typically lower than that of commercial models. B2B buyers should assess the machine’s weight, ease of transport, and operational requirements to ensure it meets their specific needs. The convenience of portability is a significant advantage, especially for businesses with fluctuating demands.

Illustrative image related to snow machine for sale

What Makes Heavy-Duty Snowmakers Ideal for Large Operations?

Heavy-duty snowmakers are built from industrial-grade materials and can operate under high pressures, producing maximum snow output. They are ideal for large ski resorts or film productions requiring substantial snow coverage. B2B buyers should be prepared for a higher upfront investment and the necessity of robust infrastructure to support these machines. While they offer unparalleled efficiency and durability, the associated costs and complexity may limit their appeal to smaller operations.

How Do Ice Shaving Machines Function in Warmer Climates?

Ice shaving machines create snow by shaving ice, making them suitable for warmer climates where traditional snowmakers may not operate effectively. These machines are often used in theme parks and entertainment venues to create artificial snow experiences. B2B buyers need to consider the quality of snow produced and the operational costs associated with ice procurement. While they provide a unique solution for warmer environments, the snow quality may not match that of traditional snowmaking methods.

Key Industrial Applications of snow machine for sale

| Industry/Sector | Specific Application of snow machine for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Ski Resorts | Creating artificial snow for ski slopes | Ensures consistent skiing conditions year-round | Consider snow volume output, weather adaptability, and maintenance requirements. |

| Event Management | Snow production for winter-themed events and festivals | Enhances guest experience and attracts visitors | Evaluate portability, ease of setup, and power requirements. |

| Film and Television | Snow effects for film sets and photo shoots | Provides realistic winter scenes | Look for models with adjustable snow output and rapid deployment capabilities. |

| Agriculture | Frost protection and soil moisture retention | Protects crops from frost damage and supports growth | Assess temperature requirements and compatibility with existing equipment. |

| Theme Parks | Snow installations for attractions and rides | Creates immersive experiences and seasonal appeal | Focus on durability, safety features, and ease of transport. |

How Are Snow Machines Used in Ski Resorts?

Ski resorts utilize snow machines to create artificial snow, ensuring optimal skiing conditions throughout the winter season. This is particularly crucial in regions with inconsistent snowfall. By having reliable snowmaking capabilities, resorts can extend their operational season and enhance customer satisfaction. Buyers in this sector should focus on machines that offer high snow output and can operate effectively under varying weather conditions, as well as those that require minimal maintenance to reduce operational downtime.

What Role Do Snow Machines Play in Event Management?

In the event management industry, snow machines are employed to create winter-themed environments for festivals, corporate events, and private parties. These machines help to produce a magical atmosphere, attracting more attendees and enhancing the overall experience. For international buyers, especially in warmer climates, sourcing equipment that is portable and easy to set up is crucial. Additionally, understanding the power requirements and snow output capabilities will ensure the chosen equipment meets the specific demands of the event.

How Are Snow Machines Beneficial for Film and Television Productions?

Film and television productions often require snow effects to create authentic winter scenes. Snow machines provide a practical solution for generating snow on set, which is essential for achieving realistic visuals. B2B buyers in this sector should prioritize machines that allow for adjustable snow output and rapid setup, as productions often operate under tight schedules. Furthermore, understanding the compatibility of the snow machines with other equipment on set can streamline the production process.

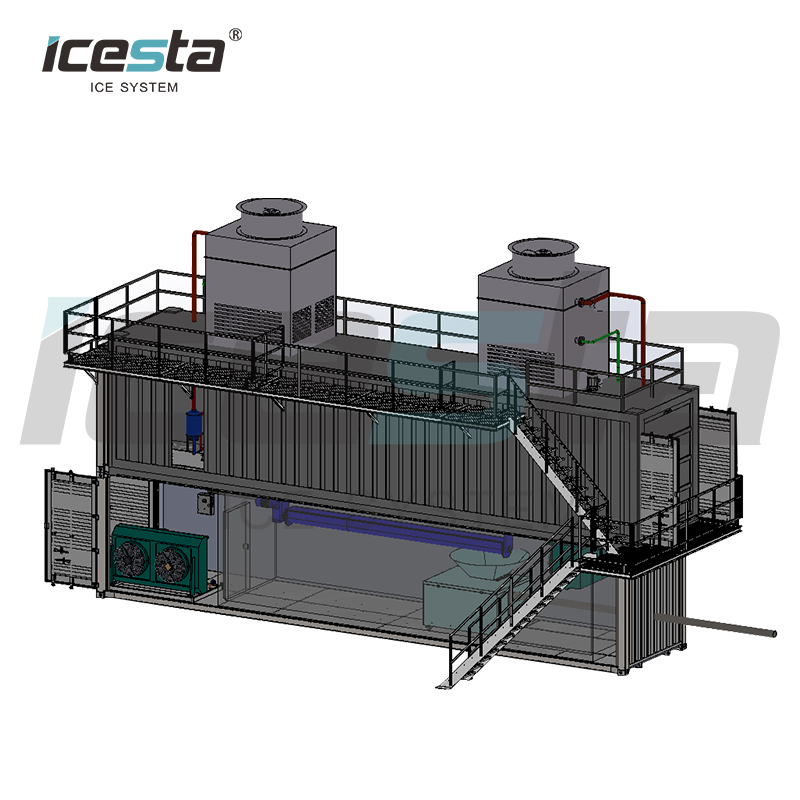

Illustrative image related to snow machine for sale

How Do Snow Machines Support Agricultural Practices?

In agriculture, snow machines can be utilized for frost protection and maintaining soil moisture levels during colder months. By producing snow, farmers can shield crops from frost damage, thereby enhancing yield potential. Buyers in the agricultural sector should consider the operational temperature requirements and ensure that the machines can integrate with existing irrigation systems. Additionally, understanding the local climate conditions will help in selecting the most effective snow-making equipment.

What Advantages Do Snow Machines Offer Theme Parks?

Theme parks use snow machines to create immersive winter-themed attractions, enhancing visitor engagement and seasonal appeal. These installations can transform rides and areas into winter wonderlands, attracting families and tourists. When sourcing snow machines for this application, it is important to focus on durability and safety features, as well as the ease of transport between various attractions. Ensuring that the machines can withstand extensive use without frequent breakdowns is also essential for maintaining operational efficiency.

3 Common User Pain Points for ‘snow machine for sale’ & Their Solutions

Scenario 1: Understanding Snow Machine Specifications for Optimal Performance

The Problem: B2B buyers, especially those new to snowmaking equipment, often struggle with understanding the technical specifications of snow machines. This can lead to purchasing equipment that does not meet their operational requirements, resulting in inadequate snow production. For instance, a ski resort in South America may buy a snow machine that requires a specific water pressure and flow rate that their existing infrastructure cannot support. This not only wastes financial resources but also delays the ability to provide snow for winter sports or themed events.

The Solution: To avoid such pitfalls, it is crucial for buyers to conduct a thorough assessment of their existing resources before making a purchase. This includes evaluating water pressure capabilities, compatibility with air compressors, and the required power supply. Buyers should consult the snow machine’s technical specifications closely, such as the minimum water flow rate (GPM) and the air compressor requirements (CFM). Additionally, leveraging vendor expertise can provide insight into the best machine to suit specific needs. It is advisable to engage in a dialogue with the supplier, asking targeted questions about the machine’s performance under local conditions and any necessary accessories or modifications needed to optimize performance.

Scenario 2: Navigating Seasonal Availability and Operational Constraints

The Problem: Buyers in regions with fluctuating climates face the challenge of seasonal availability of snow machines. For example, a company in Europe might find that snowmaking equipment is in high demand during the winter months, making it difficult to secure the necessary machinery when needed. This can lead to missed opportunities for events or operational delays, directly impacting revenue.

The Solution: To mitigate this issue, buyers should plan their purchases well in advance, ideally during the off-peak season. Establishing a relationship with suppliers for early orders can guarantee availability and potentially secure better pricing. Furthermore, it’s beneficial to understand the lead times for equipment delivery and any necessary setup. Companies may also consider rental options for peak seasons, allowing them to scale their snow production capabilities without the upfront costs associated with purchasing. Engaging in long-term contracts with suppliers can ensure priority access to equipment when demand surges.

Scenario 3: Managing Maintenance and Operational Costs Effectively

The Problem: Another significant pain point for B2B buyers is the ongoing maintenance and operational costs associated with snow machines. Buyers may underestimate the total cost of ownership, which includes not only the initial purchase price but also electricity, water usage, and the costs of maintenance and repairs. For instance, a resort could face unexpected expenses if their snow machine breaks down during peak operational hours, leading to lost revenue and customer dissatisfaction.

The Solution: To effectively manage these costs, buyers should conduct a comprehensive cost analysis before purchasing. This includes estimating ongoing operational costs based on the specific requirements of the chosen snow machine. Investing in energy-efficient models can lead to significant savings in electricity usage over time. Additionally, buyers should implement a proactive maintenance schedule based on the manufacturer’s recommendations to minimize downtime and unexpected repairs. Engaging with the supplier for service contracts or warranties can also help mitigate costs associated with potential equipment failures, ensuring the snowmaking operation remains reliable and efficient.

Strategic Material Selection Guide for snow machine for sale

When selecting materials for snow machines, particularly for international B2B buyers, it is essential to consider various factors that influence performance, durability, and compliance with regional standards. Below, we analyze four common materials used in the construction of snow machines, focusing on their properties, advantages, disadvantages, and implications for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Aluminum in Snow Machines?

Aluminum is widely used in snow machines due to its lightweight and corrosion-resistant properties. It typically has a temperature rating suitable for snowmaking operations, often down to -20°C (-4°F). The material’s excellent strength-to-weight ratio makes it ideal for components like frames and nozzles.

Pros: Aluminum is durable and resistant to corrosion, which is crucial for machines exposed to moisture. It is also relatively easy to manufacture and can be molded into complex shapes, enhancing design flexibility.

Cons: While aluminum is cost-effective, it can be less durable than some alloys or treated metals under extreme conditions. Additionally, its performance can degrade if exposed to certain chemicals, which may affect long-term reliability.

Impact on Application: Aluminum components are compatible with various media, including water and air, essential for snowmaking. However, buyers should ensure that the specific aluminum alloy used meets their operational requirements.

Considerations for International Buyers: Compliance with standards such as ASTM or DIN is crucial when sourcing aluminum parts. Buyers from Europe, for instance, may prioritize materials that meet European safety and environmental regulations.

Illustrative image related to snow machine for sale

How Does Stainless Steel Compare for Snow Machine Components?

Stainless steel is another prevalent material in snow machines, particularly for components that require higher strength and corrosion resistance. It can withstand extreme temperatures and pressures, making it suitable for high-performance applications.

Pros: Stainless steel offers exceptional durability and resistance to rust and corrosion, making it ideal for components exposed to harsh weather conditions. It also has a longer lifespan compared to aluminum.

Cons: The primary drawback is the higher cost associated with stainless steel, which can impact the overall price of the snow machine. Additionally, it is heavier than aluminum, which may affect the machine’s portability.

Illustrative image related to snow machine for sale

Impact on Application: Stainless steel is compatible with various media, including high-pressure water, making it suitable for nozzles and connectors. However, its weight may require additional design considerations for mobility.

Considerations for International Buyers: Buyers should verify that stainless steel components comply with international standards like JIS in Japan or ASTM in the U.S. This ensures quality and performance consistency across different markets.

What Role Does Plastic Play in Snow Machine Design?

Plastics, particularly high-density polyethylene (HDPE) and polypropylene, are increasingly used in snow machines for non-structural components such as housings and covers. These materials are lightweight and resistant to moisture.

Pros: Plastics are cost-effective and can be molded into intricate designs, allowing for versatile applications. They are also resistant to corrosion and can withstand a range of temperatures.

Cons: The main limitation is that plastics may not offer the same level of durability as metals, especially under extreme conditions. They can also degrade over time when exposed to UV light, which is a consideration for outdoor use.

Illustrative image related to snow machine for sale

Impact on Application: Plastic components are generally compatible with water and air but may not withstand high-pressure applications as effectively as metals.

Considerations for International Buyers: Buyers should ensure that the plastics used meet relevant safety and environmental standards, particularly in regions with strict regulations on material safety.

How Does Composite Material Enhance Snow Machine Performance?

Composite materials, such as fiberglass or carbon fiber, are becoming more popular in high-performance snow machines. These materials combine the lightweight properties of plastics with the strength of metals.

Pros: Composites offer excellent strength-to-weight ratios and are resistant to corrosion, making them ideal for various applications. They can also be designed to meet specific performance criteria.

Cons: The primary drawback is the higher manufacturing complexity and cost associated with composites. Additionally, they may require specialized knowledge for repairs and maintenance.

Impact on Application: Composite materials can be used in high-stress areas of the snow machine, enhancing performance. However, compatibility with specific media should be assessed to avoid chemical reactions.

Considerations for International Buyers: Buyers should look for compliance with international standards for composites, ensuring they meet performance and safety criteria relevant to their market.

Summary Table of Material Selection for Snow Machines

| Material | Typical Use Case for snow machine for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frames, nozzles | Lightweight and corrosion-resistant | Less durable under extreme conditions | Medium |

| Stainless Steel | Nozzles, connectors | Exceptional durability and rust resistance | Higher cost and weight | High |

| Plastic | Housings, covers | Cost-effective and versatile | Limited durability under extreme conditions | Low |

| Composite | High-performance components | Excellent strength-to-weight ratio | Higher manufacturing complexity | High |

This analysis provides a comprehensive overview of material options for snow machines, helping international B2B buyers make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for snow machine for sale

What Are the Main Stages of Manufacturing Snow Machines?

The manufacturing process of snow machines involves several critical stages that ensure the production of high-quality equipment. Understanding these stages can help B2B buyers identify reliable suppliers.

1. Material Preparation

The initial stage in the manufacturing of snow machines involves selecting and preparing raw materials. Key materials include high-grade aluminum for the machine’s body and precision-engineered stainless steel for nozzles. The choice of materials is crucial, as they must withstand high pressures and extreme temperatures. Suppliers often conduct material inspections to ensure that all components meet specified standards before proceeding to the next stage.

2. Forming

Once materials are prepared, they undergo various forming processes. Techniques such as CNC machining and die casting are commonly employed to shape the aluminum and steel parts. CNC machining allows for high precision, ensuring that components fit together seamlessly, which is essential for the performance and longevity of the snow machine. This stage may also include the fabrication of internal structures designed to optimize airflow and water distribution.

3. Assembly

After forming, the next step is assembly. This involves bringing together all individual components, including the snowmaking head, air and water hoses, and the stand. The assembly process often utilizes automated systems to enhance precision and efficiency. Skilled technicians oversee the assembly to ensure that each machine meets quality standards. Proper alignment of nozzles and connections is critical in this phase to prevent operational issues.

4. Finishing

The final stage involves finishing processes such as anodizing, painting, and quality inspections. Anodizing aluminum enhances corrosion resistance and provides a durable finish, which is essential for outdoor equipment. This stage often includes surface treatments that improve aesthetics and functionality. After finishing, each machine undergoes rigorous testing to ensure it meets performance specifications.

How Is Quality Assurance Implemented in Snow Machine Manufacturing?

Quality assurance is a fundamental aspect of the manufacturing process for snow machines, ensuring that products are reliable and meet international standards.

Illustrative image related to snow machine for sale

What International Standards Should B2B Buyers Be Aware Of?

For snow machines, compliance with international standards such as ISO 9001 is crucial. This standard focuses on quality management systems and is recognized globally, which assures buyers of a manufacturer’s commitment to quality. In addition, certifications like CE mark indicate compliance with European safety, health, and environmental protection standards, while API standards may apply to certain components, particularly those related to hydraulic systems.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards early. This may include checking the alignment of components during assembly.

-

Final Quality Control (FQC): Once the machines are fully assembled, they undergo final testing to verify performance metrics such as snow production volume and operational safety.

What Testing Methods Are Commonly Used?

Testing methods for snow machines typically include pressure testing, performance evaluations under simulated conditions, and durability tests. For instance, manufacturers may simulate extreme weather conditions to ensure that the snow machines operate effectively. These tests help identify potential weaknesses and ensure that the final product can withstand real-world usage.

Illustrative image related to snow machine for sale

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure that they receive reliable products. Here are effective strategies:

What Should Buyers Look for in Supplier Audits?

Conducting supplier audits can provide valuable insights into a manufacturer’s quality assurance practices. Buyers should look for evidence of compliance with international standards, such as ISO certifications, and request documentation of past audits. This can include internal audit reports and corrective action plans that demonstrate a proactive approach to quality management.

How Can Buyers Utilize Third-Party Inspections?

Engaging third-party inspection services is another effective way to verify quality control. These independent organizations can conduct thorough inspections at various stages of the manufacturing process, providing an unbiased assessment of quality standards. Buyers can request inspection reports that detail findings and any corrective actions taken by the manufacturer.

Illustrative image related to snow machine for sale

What Are the Quality Control Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe may encounter specific challenges related to quality control. Understanding these nuances can help mitigate risks.

How Do Cultural Differences Impact Quality Expectations?

Cultural differences can influence perceptions of quality and reliability. Buyers should communicate their quality expectations clearly and consider establishing quality benchmarks that align with international standards. Engaging local representatives who understand regional nuances can facilitate smoother communication and expectations management.

What Shipping and Compliance Considerations Should Buyers Keep in Mind?

International buyers must also consider shipping logistics and compliance with local regulations. Understanding customs requirements, including necessary documentation for importing machinery, is essential. Additionally, buyers should verify that products meet local safety and environmental regulations, which may vary significantly between regions.

Illustrative image related to snow machine for sale

Conclusion

Understanding the manufacturing processes and quality assurance practices for snow machines is vital for B2B buyers. By familiarizing themselves with these aspects, buyers can make informed decisions, ensuring they partner with reputable suppliers who deliver high-quality products that meet international standards. This knowledge not only helps mitigate risks but also fosters long-term business relationships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘snow machine for sale’

This guide aims to provide B2B buyers with a comprehensive checklist for sourcing snow machines, ensuring informed decisions that align with operational needs and business goals. Whether you’re in the entertainment industry, resort management, or event planning, following these steps will help streamline your procurement process.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your snow machine is crucial. Consider factors such as the desired snow production capacity (e.g., cubic feet per hour), operational temperature range, and compatibility with existing equipment (like pressure washers and air compressors). Establishing these specifications upfront will ensure that you select a machine that meets your operational needs effectively.

Step 2: Research Supplier Options

Explore various suppliers to identify those that specialize in snow machines. Look for companies with a proven track record in the industry, particularly those that provide international shipping to your target market. Pay attention to customer reviews and testimonials to gauge reliability and product performance.

Step 3: Verify Supplier Certifications and Compliance

Before finalizing a supplier, ensure they meet necessary industry standards and certifications. This could include safety certifications, quality management (e.g., ISO), and environmental compliance. Validating these credentials minimizes risks associated with product quality and legal liabilities.

Step 4: Evaluate the Warranty and Support Services

A robust warranty and support service are critical when investing in snow machines. Check the warranty period and what it covers, including parts and labor. Additionally, inquire about technical support availability and response times, as timely assistance can be crucial during peak operational periods.

Step 5: Assess Shipping and Logistics Options

Consider the logistics involved in acquiring your snow machine. Evaluate shipping options, costs, and delivery timelines to your region. Ensure that the supplier can accommodate your preferred shipping method and that they have experience handling international shipments, which can involve customs and import regulations.

Step 6: Request a Product Demonstration or Trial

If possible, request a demonstration of the snow machine or a trial period before committing to a purchase. This allows you to assess the machine’s performance in real-world conditions and verify that it meets your expectations. Additionally, a trial can provide insights into ease of setup and operational efficiency.

Step 7: Compare Pricing and Payment Terms

Finally, conduct a thorough comparison of pricing among shortlisted suppliers. Look beyond the initial purchase price—evaluate total cost of ownership, which includes operational costs, maintenance, and parts replacement. Additionally, clarify payment terms, including deposits, financing options, and any potential discounts for bulk purchases.

By following these steps, B2B buyers can make informed decisions when sourcing snow machines, ensuring that they select the right equipment to meet their business needs while navigating the complexities of international procurement.

Comprehensive Cost and Pricing Analysis for snow machine for sale Sourcing

What Are the Key Cost Components of Snow Machines for Sale?

When analyzing the cost structure of snow machines, several components contribute to the final pricing. The primary cost elements include:

-

Materials: The choice of materials significantly influences production costs. High-quality components such as anodized aluminum, precision machined parts, and specialized nozzles can increase the base price. Suppliers often use materials that enhance durability and efficiency, which can add to the initial investment.

-

Labor: Skilled labor is essential for manufacturing snow machines, particularly for precision assembly and quality control. Labor costs can vary widely depending on the geographic location of the manufacturing facility. In regions with higher labor costs, such as parts of Europe, prices may reflect these expenses.

-

Manufacturing Overhead: This includes costs related to the operation of the manufacturing facility, such as utilities, equipment maintenance, and facility rent. Companies must consider these overheads when calculating the final price of their products.

-

Tooling: Initial investments in tooling and machinery for production can be substantial. For custom or specialized snow machines, tooling costs can be a significant portion of the overall expenses.

-

Quality Control (QC): Implementing stringent quality control measures ensures that the products meet safety and performance standards. The costs associated with QC processes can vary, but they are crucial for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and packaging can greatly influence logistics costs.

-

Margin: Manufacturers and distributors typically add a markup to cover their operational costs and profit margins. Understanding this markup can help buyers gauge the reasonableness of pricing.

What Influences the Pricing of Snow Machines?

Several factors can affect the pricing of snow machines, particularly in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Buyers should inquire about MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Material Quality and Certifications: Products with industry certifications or higher-grade materials often command higher prices. Buyers should assess whether these certifications are necessary for their operational needs.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers may charge more due to their proven track record, while newer companies might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of trade (Incoterms) is essential for international buyers. These terms can affect shipping costs, responsibilities, and risks, influencing the overall price.

How Can Buyers Optimize Their Cost-Efficiency?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips for negotiating and optimizing costs:

-

Negotiate Terms: Engage in discussions about pricing, payment terms, and delivery schedules. Suppliers may offer better deals for larger orders or prompt payments.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance costs, operational efficiency, and expected lifespan to determine the true cost of ownership.

-

Understand Pricing Nuances: Different regions may have varying market dynamics. For instance, suppliers in Europe may offer advanced features that justify higher prices compared to lower-priced models from other regions.

-

Research Local Regulations: Be aware of import duties, taxes, and compliance costs associated with acquiring snow machines. These can significantly impact total expenses and should be factored into the budget.

-

Leverage Local Partnerships: Establishing relationships with local distributors or agents can facilitate smoother transactions and potentially lower costs through shared logistics.

Disclaimer on Indicative Prices

Pricing for snow machines can fluctuate based on market conditions, supplier strategies, and regional demand. The figures provided in this analysis are indicative and should be verified with suppliers for accuracy and current market conditions.

Alternatives Analysis: Comparing snow machine for sale With Other Solutions

Exploring Alternatives to ‘Snow Machine for Sale’

In the quest for effective snow production, businesses and organizations must consider various alternatives to traditional snow machines. These alternatives can vary significantly in terms of performance, cost, ease of implementation, and maintenance. By understanding the strengths and weaknesses of each option, B2B buyers can make informed decisions that best suit their operational needs.

Illustrative image related to snow machine for sale

| Comparison Aspect | Snow Machine For Sale | Ice Shaving Machine | Snowmaking Chemicals |

|---|---|---|---|

| Performance | Produces real snow, approx. 80 ft³/hr | Creates snow-like ice from shaved blocks | Enhances snow quality but requires existing snow |

| Cost | $698 (initial investment) | $1,200 – $5,000 (depending on model) | $100 – $500 (per season) |

| Ease of Implementation | Requires water and air supply, setup needed | Simple operation but needs ice blocks | Requires snow base and proper application |

| Maintenance | Moderate; occasional part replacement | Low; generally durable | Varies; dependent on usage |

| Best Use Case | Ideal for home or small business snowmaking | Best for events and recreational areas | Suitable for enhancing existing snow in warmer climates |

What Are the Advantages and Disadvantages of Ice Shaving Machines?

Ice shaving machines produce snow-like material by shaving ice blocks, making them popular for use in events and amusement parks. Their performance is dependent on the availability of ice blocks, which may not always be feasible, especially in warmer climates. While they are typically straightforward to operate, the initial investment can be higher than snow machines, especially for larger models. However, they require little maintenance, making them a hassle-free option for seasonal use.

How Do Snowmaking Chemicals Work?

Snowmaking chemicals are often used to enhance the quality of snow produced in existing snow bases. They can improve snow texture and longevity, making them an attractive option for ski resorts or areas that already have snow. However, they are not a standalone solution and require a snow base to be effective. The cost can also vary widely based on usage, and they may necessitate additional labor for application.

Conclusion: How to Choose the Right Snow Production Solution

When selecting a snow production method, B2B buyers should assess their specific needs, including budget, desired snow quality, and operational capacity. For those looking to create substantial amounts of real snow, investing in a snow machine may be the best choice. Conversely, if the goal is to enhance existing snow or create temporary snow for events, ice shaving machines or snowmaking chemicals may be more suitable. Ultimately, understanding the unique advantages and limitations of each option will enable businesses to make decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for snow machine for sale

What Are the Key Technical Properties of Snow Machines for Sale?

When evaluating snow machines for commercial or industrial use, understanding the technical specifications is essential for making informed purchasing decisions. Here are several critical properties that B2B buyers should consider:

1. Material Grade

The construction material of a snow machine significantly impacts its durability and performance. High-grade materials such as anodized aluminum or stainless steel provide corrosion resistance and structural integrity under extreme conditions. For instance, anodized aluminum is not only lightweight but also enhances thermal efficiency, which is crucial for effective snow production. Buyers should prioritize machines made from high-quality materials to ensure longevity and reliability.

2. Snow Production Capacity

Snow production capacity is typically measured in cubic feet per hour (ft³/hr) or cubic meters per hour (m³/hr). This metric indicates how much snow the machine can generate within a specific timeframe, which is vital for commercial operations. For example, a snow machine that produces 80 ft³/hr can cover a sizeable area in a relatively short period, making it suitable for ski resorts or events. Understanding this capacity helps buyers align their needs with the machine’s output.

3. Pressure Requirements

Snow machines often require specific air and water pressure to operate efficiently. For example, a machine might need a minimum of 5.4 CFM (cubic feet per minute) at 90 PSI (pounds per square inch) for optimal performance. This specification is crucial because it determines the compatibility with existing compressors and water systems. Buyers should ensure their infrastructure can meet these requirements to avoid operational issues.

4. Temperature Range

The operational temperature range is critical for snow machines, as they typically function best in conditions below freezing (e.g., 29°F or -2°C). Understanding this specification helps buyers assess whether the machine can perform effectively in their local climate. For regions with fluctuating temperatures, this information is essential for planning snow production schedules.

5. Hose Specifications

The quality and specifications of hoses used for air and water supply can affect the machine’s performance. Hoses rated for high pressure (e.g., 3000 PSI) ensure safety and durability during operation. Buyers should consider the hose length and compatibility with their existing systems, as this can impact setup and maintenance.

Illustrative image related to snow machine for sale

What Are Common Trade Terms in the Snow Machine Industry?

Familiarizing oneself with industry jargon can streamline communication and enhance negotiations. Here are several essential trade terms relevant to snow machines:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. In the snow machine industry, knowing whether a manufacturer is an OEM can provide insights into the quality and reliability of the components used in the machines.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it can affect purchasing decisions, inventory management, and overall costs. Understanding the MOQ can help buyers negotiate better terms and align orders with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This process is essential for B2B transactions, allowing buyers to compare offers from different manufacturers and make informed purchasing decisions based on specifications and costs.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is critical for B2B buyers as they outline shipping, insurance, and delivery obligations, thus minimizing risks associated with cross-border transactions.

Illustrative image related to snow machine for sale

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. In the snow machine industry, understanding lead times can help buyers plan their operations, especially in seasonal markets where timely delivery is crucial for maximizing snow production during peak seasons.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting snow machines, ensuring they meet operational needs while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the snow machine for sale Sector

What Are the Current Market Trends Impacting the Snow Machine for Sale Sector?

The snow machine market is experiencing a shift driven by various global factors, particularly relevant for B2B buyers in regions like Africa, South America, the Middle East, and Europe. One major trend is the increasing demand for snowmaking equipment beyond traditional winter sports resorts. With the rise of indoor skiing facilities and winter-themed attractions, there is a growing market for snow machines in non-traditional locales. This expansion is fueled by advancements in technology, enabling more efficient and compact snowmaking solutions that cater to diverse operational needs.

Additionally, international buyers are increasingly prioritizing suppliers that offer fast shipping and comprehensive customer support, which is crucial for operational readiness. Technological advancements in snowmaking, such as external mix designs that enhance efficiency and reduce energy consumption, are also gaining traction. This trend reflects a broader industry push towards maximizing output while minimizing environmental impact.

Furthermore, buyers are showing a preference for equipment that integrates smart technology for monitoring and maintenance, which can significantly reduce downtime and operational costs. As international trade barriers continue to evolve, sourcing from manufacturers with robust global distribution networks will be essential for businesses looking to capitalize on emerging markets.

How Is Sustainability Shaping the Snow Machine for Sale Market?

Sustainability is becoming a cornerstone of the snow machine for sale sector, driven by increasing regulatory scrutiny and consumer demand for environmentally responsible products. Manufacturers are now focusing on reducing the environmental impact of their equipment by utilizing energy-efficient technologies and eco-friendly materials. For instance, snow machines that operate at lower temperatures and use less water are becoming more prevalent, addressing both resource conservation and operational cost concerns.

Moreover, the importance of ethical sourcing in supply chains cannot be overstated. B2B buyers are encouraged to seek suppliers who prioritize sustainable practices throughout their operations. This includes the use of certified green materials and compliance with international environmental standards. Certifications such as ISO 14001 can serve as indicators of a manufacturer’s commitment to sustainability.

Investing in snow machines that meet these green standards not only enhances a company’s brand reputation but also aligns with the growing global emphasis on corporate social responsibility. As sustainability becomes a key differentiator in procurement decisions, buyers who prioritize ethical sourcing are likely to gain a competitive edge.

How Has the Snow Machine for Sale Sector Evolved Over Time?

The evolution of the snow machine market reflects broader trends in technology and consumer preferences. Initially, snowmaking equipment was primarily utilized in ski resorts, but advancements in design and performance have broadened its applications. The introduction of more compact and efficient snowmakers has enabled venues such as amusement parks, hotels, and even residential areas to create artificial snow experiences, transforming the market landscape.

Over the years, the integration of technology has played a pivotal role in this evolution. Modern snow machines are equipped with advanced features such as automated controls and real-time performance monitoring, which improve operational efficiency and user experience. This technological sophistication not only enhances the quality of snow produced but also addresses the challenges posed by varying climatic conditions.

As the market continues to evolve, B2B buyers are presented with a wealth of options tailored to meet diverse needs, from high-capacity commercial machines to user-friendly residential models, ensuring that all stakeholders can find solutions that fit their specific operational requirements.

Frequently Asked Questions (FAQs) for B2B Buyers of snow machine for sale

-

How do I ensure the snow machine meets my business needs?

To ensure a snow machine aligns with your business requirements, consider factors such as production capacity, operating conditions, and compatibility with existing equipment. Assess the volume of snow needed and the environmental conditions in your region, as these will influence the type of machine suitable for your operations. Additionally, inquire about features like energy efficiency and ease of maintenance, as these can impact long-term operational costs. -

What is the best snow machine for commercial use?

The best snow machine for commercial use typically features high output capacity, durability, and efficiency. Models designed for larger-scale operations, such as those producing over 200 cubic feet of snow per hour, are ideal. Look for machines that can operate effectively in varying weather conditions and have flexible water and air supply requirements. It’s also crucial to consider the support and warranty options provided by the manufacturer. -

What are the key specifications to consider when sourcing snow machines?

Key specifications include snow production rate (cubic feet per hour), operational temperature range, power requirements (electricity vs. gas), and compatibility with pressure washers and air compressors. Additionally, evaluate the materials used in construction for durability and ease of maintenance. Understanding these specifications will help you select a machine that meets your performance expectations and operational needs. -

What are the minimum order quantities (MOQ) for purchasing snow machines?

Minimum order quantities can vary significantly based on the manufacturer and the specific model. Typically, MOQs for snow machines range from one unit for smaller suppliers to several units for larger manufacturers. It’s advisable to discuss your requirements directly with suppliers to negotiate terms that fit your business needs, especially if you are looking to place bulk orders. -

What payment terms are generally offered by snow machine suppliers?

Payment terms can differ widely among suppliers. Common options include full payment upfront, a deposit followed by the balance upon delivery, or extended payment terms over a specified period. Ensure to clarify the payment options available before finalizing your order, as this can significantly impact your cash flow and budgeting. -

How can I verify the quality of snow machines before purchasing?

To verify quality, request product samples or demonstrations. Additionally, check for certifications and compliance with international quality standards. Reviews and testimonials from other buyers can provide insight into the machine’s performance and reliability. Establishing direct communication with the manufacturer or supplier can also help clarify any concerns regarding quality assurance processes. -

What logistics considerations should I keep in mind for international shipping of snow machines?

When considering international shipping, evaluate shipping costs, lead times, and customs regulations in your destination country. Ensure that the supplier has experience with international logistics and can provide necessary documentation for customs clearance. Additionally, consider insurance options for your shipment to mitigate risks associated with damage or loss during transit. -

Can snow machines be customized for specific business applications?

Many manufacturers offer customization options to meet unique business needs. Customizations may include modifications to production capacity, design alterations, or additional features like enhanced insulation or specialized nozzles. Discuss your requirements with the supplier to determine available options and any associated costs, ensuring the final product aligns with your operational objectives.

Top 5 Snow Machine For Sale Manufacturers & Suppliers List

1. SG6 – Xstream Snowmaker

Domain: snowathome.com

Registered: 2000 (25 years)

Introduction: {‘name’: ‘SG6 Xstream Snowmaker’, ‘price’: ‘$698.00’, ‘snowmaking_capacity’: ’80 ft³/hr’, ‘coverage_area’: ’50’ x 25’ area with 6” of snow in about 8 hours’, ‘weight’: ’46 lbs’, ‘dimensions’: ‘21.3 x 12.5 x 11.5 inches’, ‘construction_material’: ‘Solid anodized aluminum’, ‘pressure_rating’: ‘5000psi’, ‘nozzles’: ‘Two upper misting nozzles, precision designed stainless steel air nozzle, nucleation …

2. Snowmakers – Snowmaking Equipment

Domain: snowmakers.com

Registered: 1996 (29 years)

Introduction: Snowmaking Equipment: Fan PoleCats (Big throw, simple nozzle), Super PoleCat, Standard PoleCat, Standard PoleCat with Booster Pump, Kid PoleCat, Silent PoleCat, Pumas (Automation and performance), Super Puma, Standard Puma, Fan Wizzards (Big throw, marginal conditions), Super Wizzard, Kid Wizzard, Latitude90 (All-weather snowmaking). Conversion Kits: L30, L60, L120. Automation: SmartSnow7 Software…

3. Yugong Machinery – Snowmaking Machines

Domain: yugongmachinery.com

Registered: 2018 (7 years)

Introduction: This company, Yugong Machinery – Snowmaking Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. eBay – Snow Making Machines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Snow Making Machines available on eBay include various models with specifications such as: 1200W Wireless Remote Snow Maker, 1500W Remote Control Snow Making Machine, 900W Snow Machine with LED, and 2000W Wireless Remote Swing Snow Making Machine. Prices range from approximately $20.00 to $395.00, with many items offering free shipping and returns. Most products are brand new, with some options fo…

5. ATLSpecialFX – Silent Snow Storm Options

Domain: atlspecialfx.com

Registered: 2011 (14 years)

Introduction: Rent or Buy an Artificial Snow Special Effects Machine and Snow Fluid. Key products include: 1. Silent Snow Storm Options – From $315.00 2. S500 Antari Silent Artificial Snow Machine – Options From $499.00 ($1,900.00 retail) 3. T-500 Snow Zone Snow Machine – Options From $199.00 4. T-1500 Blizzard Snow Zone – Snow Special Effect Machines – $3,500.00 5. Let It Snow Snowman – Options From $199.00 6….

Strategic Sourcing Conclusion and Outlook for snow machine for sale

In conclusion, effective strategic sourcing is essential for international B2B buyers looking to invest in snow machines. The SG6 Xstream Snowmaker exemplifies the advancements in snowmaking technology, offering robust performance with a significant output of 80 cubic feet per hour. Buyers should consider factors such as compatibility with existing equipment, operational requirements, and the potential for customization to meet specific market demands.

Moreover, establishing strong supplier relationships can enhance access to timely shipping and support services, crucial for businesses operating in diverse climates across Africa, South America, the Middle East, and Europe. Leveraging global distribution networks can also facilitate cost-effective procurement and ensure product availability during peak seasons.

As the demand for artificial snow continues to grow, particularly in regions with fluctuating temperatures, now is the time for B2B buyers to explore innovative solutions in snowmaking. Embrace the opportunity to elevate your offerings and stay ahead of market trends by investing in high-quality snow machines that meet your business needs. Engage with trusted suppliers to secure the best equipment and support your success in this niche market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to snow machine for sale