The Definitive Guide to Small Refrigerator With Lock: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for small refrigerator with lock

In the ever-evolving landscape of international trade, sourcing small refrigerators with locks presents a unique challenge for B2B buyers. As businesses expand across borders—from bustling markets in Nigeria to emerging industries in Brazil—the need for secure, compact refrigeration solutions is becoming increasingly critical. This guide aims to address that need by offering a comprehensive overview of the various types of small refrigerators with locking mechanisms available on the market today.

Within these pages, you will find detailed insights into different models, applications, and key features that cater to diverse business environments, such as hotels, clinics, and offices. We will also explore the importance of supplier vetting, ensuring that you partner with reputable manufacturers who meet quality and compliance standards. Additionally, we will provide a breakdown of costs and financing options, empowering you to make informed purchasing decisions that align with your budget and operational needs.

As you navigate the global market for small refrigerators with locks, this guide serves as a valuable resource, equipping international B2B buyers from Africa, South America, the Middle East, and Europe with the knowledge necessary to select the right products for their business. Ultimately, our goal is to facilitate seamless transactions and foster long-term partnerships in an increasingly competitive marketplace.

Understanding small refrigerator with lock Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mini Fridge with Key Lock | Compact size, typically under 5 cu. ft., manual locking mechanism | Offices, dormitories, hotels | Pros: Affordable, portable, energy-efficient. Cons: Limited storage capacity. |

| Security Lock Mini Fridge | Enhanced locking system, often with digital or combination locks | Medical facilities, laboratories, schools | Pros: High security, prevents unauthorized access. Cons: Higher cost, may require complex installation. |

| Freezerless Mini Fridge with Lock | No freezer compartment, maximizes refrigeration space | Small restaurants, cafes, convenience stores | Pros: More storage for perishable items. Cons: No freezing capability limits versatility. |

| Built-In Mini Fridge with Lock | Designed for cabinetry, often features a sleek finish | Restaurants, bars, luxury hotels | Pros: Aesthetically pleasing, space-saving. Cons: Installation can be complex and costly. |

| Portable Mini Fridge with Lock | Lightweight, designed for mobility, often battery-operated | Outdoor events, catering, travel | Pros: Easy to transport, versatile use. Cons: Limited capacity and cooling efficiency. |

What are the characteristics of a Mini Fridge with Key Lock?

Mini fridges with key locks are compact appliances, usually with a capacity under 5 cubic feet. They are designed for easy placement in various environments, including offices and dormitories. The manual locking mechanism provides basic security, making them suitable for storing personal items or snacks. When considering a purchase, B2B buyers should evaluate the cost-effectiveness and energy efficiency of these units, especially for bulk orders.

How does a Security Lock Mini Fridge differ from other types?

Security lock mini fridges feature advanced locking mechanisms, such as digital or combination locks, enhancing their security features. These fridges are ideal for environments requiring strict access control, such as medical facilities and laboratories. When purchasing, buyers should consider the importance of security in their operations and the potential need for specialized installation or maintenance services, which may affect overall costs.

What makes Freezerless Mini Fridges with Locks suitable for businesses?

Freezerless mini fridges maximize refrigeration space by eliminating the freezer compartment, making them ideal for small restaurants and cafes that require ample space for perishable items. These units are designed for efficient cooling and often come with adjustable shelves. B2B buyers should assess the specific needs of their inventory and consider energy consumption rates to ensure the units align with operational efficiency.

Why choose Built-In Mini Fridges with Locks for commercial settings?

Built-in mini fridges are designed to seamlessly integrate into cabinetry, offering a sleek appearance that suits upscale environments like restaurants and luxury hotels. These fridges often come with advanced cooling technologies and can be customized to fit specific design aesthetics. Buyers should factor in installation costs and the need for professional assistance, as the complexity can vary based on the cabinetry design.

What advantages do Portable Mini Fridges with Locks offer for events?

Portable mini fridges are lightweight and designed for mobility, making them perfect for outdoor events, catering, and travel. Many models are battery-operated, allowing for versatile use in various locations. Buyers should evaluate the balance between portability and capacity, as these units typically offer less storage space and may have limitations in cooling efficiency compared to larger models.

Key Industrial Applications of small refrigerator with lock

| Industry/Sector | Specific Application of small refrigerator with lock | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Medication storage in clinics and pharmacies | Ensures secure storage of sensitive medications, preventing theft and ensuring compliance with regulations. | Must meet healthcare standards for temperature control and security. |

| Education | Dormitory and student housing in universities | Provides a secure space for students to store food and beverages, reducing food waste and promoting healthy eating. | Durability and energy efficiency are key; consider local climate impacts. |

| Hospitality | Guest room mini-bars in hotels | Enhances guest experience by providing secure, accessible refreshments while optimizing space. | Focus on aesthetic appeal and low noise levels for guest comfort. |

| Retail | Storage for specialty items in convenience stores | Protects high-value items from theft while allowing for easy access for staff and customers. | Ensure compliance with local safety regulations and energy efficiency standards. |

| Automotive Service Centers | Storage for beverages and snacks in waiting areas | Improves customer satisfaction by providing refreshments during service wait times. | Consider portability and ease of use for staff in a busy environment. |

How is the ‘small refrigerator with lock’ utilized in the healthcare sector?

In healthcare settings, small refrigerators with locks are vital for storing medications that require strict temperature control. Clinics and pharmacies often face challenges related to medication theft and compliance with regulatory standards. A locked mini fridge ensures that sensitive pharmaceuticals remain secure and at the correct temperature, thus preventing spoilage and ensuring patient safety. Buyers in this sector must prioritize models that meet healthcare regulations and offer reliable temperature monitoring features.

What role do locked refrigerators play in educational institutions?

In universities, particularly in dormitory settings, small refrigerators with locks provide students with a secure place to store food and beverages. This not only helps reduce food waste but also encourages healthier eating habits by giving students easy access to nutritious options. For international buyers, especially in regions with varying climates, durability and energy efficiency are essential considerations to ensure these units can withstand daily use while minimizing operational costs.

How do small refrigerators with locks enhance guest experiences in the hospitality industry?

Hotels utilize small refrigerators with locks in guest rooms to offer a convenient and secure way for guests to store snacks and beverages. This feature not only enhances the overall guest experience but also allows hotels to optimize their space without compromising on service quality. When sourcing for this application, businesses should consider aesthetic appeal and noise levels, as these factors significantly impact guest satisfaction and comfort.

What benefits do retail businesses gain from using locked mini refrigerators?

In retail, particularly in convenience stores, small refrigerators with locks are essential for storing high-value items that may be prone to theft. By providing secure access to these products, retailers can minimize losses while also ensuring that staff can easily restock items. Buyers in this sector should ensure that the refrigerators comply with local safety regulations and are energy efficient to keep operational costs low while maintaining product quality.

Illustrative image related to small refrigerator with lock

How can automotive service centers benefit from locked mini fridges?

Automotive service centers often use small refrigerators with locks in waiting areas to store beverages and snacks for customers. This not only enhances customer satisfaction during service wait times but also adds a touch of hospitality to the business. When sourcing these units, it is important to consider their portability and ease of use, as service centers can be busy environments where staff need to quickly access refreshments for customers.

3 Common User Pain Points for ‘small refrigerator with lock’ & Their Solutions

Scenario 1: Ensuring Security in Shared Spaces

The Problem: In many businesses, particularly in shared environments like offices, coworking spaces, or dormitories, the risk of theft or unauthorized access to perishable items is a significant concern. B2B buyers often face the dilemma of providing employees or residents with access to refrigeration without compromising the security of the items stored inside. This situation can lead to dissatisfaction, waste, and increased costs if food or beverages go missing.

The Solution: Investing in a small refrigerator with a reliable locking mechanism is essential for businesses operating in shared spaces. When sourcing these appliances, buyers should prioritize models with robust locks that are easy to use yet secure enough to deter theft. Additionally, it’s important to consider the refrigerator’s capacity and features to ensure it meets the needs of the users. For instance, a model with a transparent door can help users see what’s inside without opening it, reducing the temptation to access it unnecessarily. Furthermore, educating users on the importance of securing their items and establishing policies for shared refrigerators can enhance security and reduce conflict.

Scenario 2: Managing Energy Efficiency While Maintaining Security

The Problem: Many organizations are under pressure to reduce their energy consumption and operational costs. However, this can be a challenge when it comes to small refrigerators with locks, as some models may consume more energy than others. B2B buyers need to balance the need for security features with energy efficiency to avoid inflated utility bills.

The Solution: When selecting a small refrigerator with a lock, buyers should look for models that are Energy Star certified. These units not only offer enhanced energy efficiency but often come equipped with modern locking mechanisms that do not compromise performance. Additionally, it’s wise to analyze the total cost of ownership, including energy usage over time. Buyers can also consider programmable settings that allow users to control the temperature more efficiently, which can help in maintaining the ideal conditions for stored items without excessive energy use. Regular maintenance, such as cleaning the coils and ensuring proper ventilation, can further enhance energy efficiency.

Scenario 3: Navigating Compliance and Safety Regulations

The Problem: Businesses in sectors such as healthcare, education, and food service often have strict compliance and safety regulations regarding the storage of perishable items. This includes the need for secure storage solutions that prevent unauthorized access while maintaining the integrity of the items. B2B buyers in these industries may struggle to find small refrigerators that meet both security and regulatory requirements.

The Solution: To navigate these challenges, buyers should conduct thorough research into local regulations concerning food storage and safety. Look for small refrigerators that are specifically designed for commercial use and have features that comply with health and safety standards. This may include models with adjustable temperature settings, alarms for temperature fluctuations, and durable construction to withstand frequent use. It’s also beneficial to engage with suppliers who understand industry-specific regulations and can recommend products that meet these requirements. Establishing a clear inventory management system can further ensure compliance by tracking stored items and their expiration dates, minimizing waste, and enhancing safety.

Strategic Material Selection Guide for small refrigerator with lock

When selecting materials for small refrigerators with locks, it is essential to consider their properties, advantages, disadvantages, and how they align with the needs of international B2B buyers. Here, we analyze four common materials: stainless steel, plastic, aluminum, and glass, focusing on their performance and suitability for various applications.

Illustrative image related to small refrigerator with lock

What Are the Key Properties of Stainless Steel for Small Refrigerators?

Stainless steel is renowned for its corrosion resistance, strength, and durability. It typically withstands temperatures ranging from -40°F to 500°F, making it suitable for refrigeration applications. The material’s non-porous surface is easy to clean, which is vital for maintaining hygiene in food storage.

Pros: Stainless steel is highly durable and resistant to rust and staining, ensuring a long lifespan for the refrigerator. It also provides a premium aesthetic that appeals to consumers in various markets.

Cons: The primary drawback is its cost, which is higher than other materials. Additionally, manufacturing processes can be more complex, requiring specialized equipment for cutting and shaping.

Illustrative image related to small refrigerator with lock

Impact on Application: Stainless steel is ideal for environments where hygiene and durability are paramount, such as medical facilities or food service locations.

Considerations for International Buyers: Compliance with international standards like ASTM and ISO is crucial. Buyers from regions like Africa and South America may need to consider local availability and pricing fluctuations.

How Does Plastic Perform in Small Refrigerators?

Plastic is commonly used in the construction of small refrigerators, particularly for internal components and door liners. It offers good insulation properties and is lightweight, making it easier to transport.

Pros: Plastic is cost-effective and can be molded into various shapes, allowing for flexible design options. It also provides decent insulation, which can enhance energy efficiency.

Cons: While plastic is resistant to moisture, it may not be as durable as metals and can be prone to cracking under stress or extreme temperatures.

Impact on Application: Plastic is suitable for non-load-bearing components and can be used in environments with less stringent hygiene requirements.

Considerations for International Buyers: Buyers should ensure that the plastic used complies with local regulations regarding food safety and environmental impact, especially in regions with stringent import standards.

What Are the Benefits of Aluminum in Small Refrigerators?

Aluminum is lightweight and offers good thermal conductivity, making it an efficient material for refrigeration. It is often used for external casings and some internal components.

Pros: The lightweight nature of aluminum makes it easier to handle and transport. It is also resistant to corrosion, especially when anodized, and can be recycled, making it an environmentally friendly option.

Cons: Aluminum can be more expensive than plastic and may dent or scratch more easily than stainless steel.

Impact on Application: Aluminum is suitable for applications requiring lightweight and efficient thermal performance, but it may not be ideal for high-impact environments.

Considerations for International Buyers: Buyers should be aware of the recycling capabilities in their regions, as this can influence the overall sustainability of the product.

Why Is Glass a Viable Option for Small Refrigerators?

Glass is often used for doors or shelves in small refrigerators, providing visibility of the contents while maintaining temperature.

Pros: Glass is non-porous and easy to clean, ensuring hygiene. It also offers a premium look that can enhance the product’s appeal.

Cons: Glass is heavier and more fragile than other materials, making it less suitable for certain applications. It also requires careful handling during manufacturing and transport.

Impact on Application: Glass is ideal for display refrigerators where visibility is essential, such as in retail environments.

Considerations for International Buyers: Buyers should consider the shipping costs associated with glass components, especially in regions where breakage during transport can be a concern.

| Material | Typical Use Case for small refrigerator with lock | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External casing and locking mechanisms | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Internal components and door liners | Cost-effective and lightweight | Less durable than metals | Low |

| Aluminum | External casings and some internal components | Lightweight and good thermal conductivity | Prone to dents and scratches | Medium |

| Glass | Doors and shelves | Aesthetic appeal and hygiene | Heavy and fragile | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for small refrigerator with lock

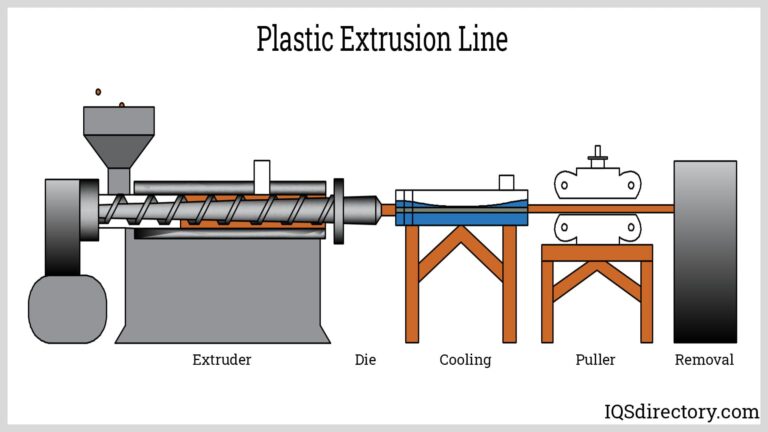

What Are the Key Stages in the Manufacturing Process of a Small Refrigerator with Lock?

The manufacturing process of a small refrigerator with a lock involves several critical stages, each designed to ensure high-quality production and compliance with international standards. The main stages typically include material preparation, forming, assembly, and finishing.

How is Material Prepared for Production?

Material preparation is the first stage, where raw materials such as steel, plastic, and insulation foam are sourced. Suppliers must meet quality standards to ensure durability and performance. For instance, stainless steel is often used for the exterior to prevent corrosion, while high-density foam is utilized for insulation to enhance energy efficiency.

During this phase, manufacturers often conduct Incoming Quality Control (IQC) to assess the quality of materials before they are accepted for production. This step is crucial for maintaining the integrity of the final product and can involve checks for material specifications and certifications.

Illustrative image related to small refrigerator with lock

What Techniques Are Employed in the Forming Stage?

Forming is the next critical stage, where the prepared materials are shaped into the necessary components of the refrigerator. This involves techniques such as stamping, bending, and welding. For example, the exterior shell is typically stamped from metal sheets, while the insulation panels are molded to fit precisely within the frame.

Advanced manufacturing technologies, such as CNC (Computer Numerical Control) machining, are often employed to ensure precision and reduce waste. The forming stage also includes the production of locking mechanisms, which must be engineered for security and durability.

How is Assembly Conducted in Refrigerator Manufacturing?

The assembly stage involves integrating all the formed components into a complete unit. This typically occurs on an assembly line where workers or robotic systems fit together the shell, insulation, cooling system, and locking mechanism.

Quality control at this stage is vital, often referred to as In-Process Quality Control (IPQC). Key checkpoints may include verifying the alignment of components, the functionality of locking mechanisms, and ensuring that cooling systems are installed correctly.

Illustrative image related to small refrigerator with lock

Manufacturers also conduct functional tests to check for leaks in refrigeration systems, ensuring that the unit operates efficiently and meets energy standards.

What Finishing Processes Are Applied to Ensure Quality?

Finishing is the final stage of manufacturing, where the refrigerator undergoes painting, polishing, and surface treatment. This not only enhances aesthetic appeal but also adds protective layers to prevent rust and wear.

At this stage, Final Quality Control (FQC) checks are performed. This includes visual inspections for defects, testing the locking mechanism’s functionality, and ensuring that the refrigerator meets all specified standards before it is packaged for shipment.

What Are the International Quality Standards Relevant to Small Refrigerators?

For B2B buyers, understanding the quality assurance standards that apply to small refrigerators is essential. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

Which Certifications Should B2B Buyers Look For?

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and Energy Star for energy efficiency are critical. These certifications not only ensure compliance with safety and environmental regulations but also enhance the product’s marketability.

B2B buyers should also be aware of other regional certifications that may apply, particularly in Africa, South America, and the Middle East. Understanding these regional requirements can help in selecting suppliers that meet local regulatory standards.

How Can Buyers Verify Supplier Quality Control Processes?

B2B buyers can implement several strategies to verify the quality control processes of suppliers:

-

Audits: Conducting regular audits of the supplier’s manufacturing facilities can provide insight into their quality management practices. This includes evaluating the implementation of quality control checkpoints and the effectiveness of their quality management system.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance metrics, defect rates, and the results of quality assurance tests.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These inspections can cover everything from material quality to final product testing.

-

Certifications Verification: Buyers should verify that the supplier holds the necessary certifications and that these certifications are up-to-date. This can often be done through official certification bodies.

What Are the Common Testing Methods for Quality Assurance in Refrigerators?

Quality assurance in small refrigerators involves various testing methods to ensure reliability and performance:

-

Thermal Performance Testing: This assesses the refrigerator’s ability to maintain temperature under different conditions, ensuring it meets energy efficiency standards.

-

Durability Testing: Simulating real-world conditions to evaluate the robustness of the locking mechanism and overall structure.

-

Safety Testing: Ensuring that electrical components are safe and comply with relevant safety standards to prevent hazards.

-

Energy Consumption Testing: Measuring the refrigerator’s energy usage to confirm compliance with Energy Star ratings or local energy efficiency regulations.

What Unique Considerations Should B2B Buyers in Developing Regions Keep in Mind?

B2B buyers from regions like Africa and South America may face unique challenges, such as varying regulatory environments and logistical issues. It’s crucial to understand local standards and how they might differ from international norms.

Illustrative image related to small refrigerator with lock

Additionally, buyers should consider the availability of after-sales support and warranty services, as these can significantly impact product lifecycle management. Engaging with local suppliers who understand regional requirements can enhance the procurement process and ensure compliance with local regulations.

In summary, a thorough understanding of manufacturing processes and quality assurance practices for small refrigerators with locks is essential for B2B buyers. By focusing on quality standards, supplier verification, and testing methods, buyers can make informed decisions that align with their business needs and regional market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘small refrigerator with lock’

To assist B2B buyers in sourcing small refrigerators with locks, this guide outlines essential steps to ensure a successful procurement process. Understanding the specific requirements and evaluating potential suppliers can lead to effective purchasing decisions that meet security and operational needs.

Illustrative image related to small refrigerator with lock

Step 1: Identify Your Requirements

Begin by clearly defining what you need from a small refrigerator with a lock. Consider factors such as size, capacity (usually under 6 cu. ft.), and specific features like energy efficiency or temperature control. Knowing your needs will help narrow down options and ensure that the selected models meet your operational requirements.

Step 2: Research and Compare Brands

Conduct thorough research on different brands that manufacture locking mini refrigerators. Look for reputable companies known for quality and reliability, as well as those that offer specific features relevant to your market. Pay attention to user reviews and product ratings, particularly from businesses in your region, to gauge performance and satisfaction.

Step 3: Evaluate Energy Efficiency

Given the ongoing emphasis on sustainability, energy-efficient models are a priority. Check for ENERGY STAR ratings or other certifications that indicate lower energy consumption. This not only helps reduce operational costs but also aligns with global sustainability goals, making your procurement more responsible.

Step 4: Understand Security Features

Focus on the locking mechanism’s effectiveness and durability. Evaluate the types of locks available—key locks, combination locks, or electronic locks—and choose one that best fits your security needs. Ensure that the lock is easy to use while providing robust security against unauthorized access.

Step 5: Verify Supplier Certifications

Before finalizing any supplier, confirm that they hold relevant certifications and adhere to international safety and quality standards. This might include ISO certifications or compliance with local regulations. Reliable suppliers should be transparent about their certifications and quality assurance processes.

Step 6: Request Samples or Product Demonstrations

Whenever possible, request product samples or demonstrations to assess the quality and functionality firsthand. This step is vital for understanding how well the refrigerator meets your operational needs and if it aligns with your expectations regarding performance and aesthetics.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, and warranty terms. Ensure that all agreements are documented to avoid misunderstandings later. Establishing clear terms can help protect your investment and ensure a smooth procurement process.

By following this checklist, B2B buyers can confidently source small refrigerators with locks that meet their specific requirements while ensuring quality, security, and efficiency in their operations.

Comprehensive Cost and Pricing Analysis for small refrigerator with lock Sourcing

What Are the Key Cost Components for Sourcing Small Refrigerators with Locks?

When sourcing small refrigerators with locks, understanding the cost structure is crucial for B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The cost of raw materials such as steel for the frame, plastic for the door handle, and insulation materials can significantly impact pricing. High-quality materials often lead to better durability and efficiency, which can justify higher upfront costs.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. In countries with lower labor costs, such as those in parts of Africa and South America, the overall production cost may be lower, but this may also affect quality.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer competitive prices.

-

Tooling: The initial investment in machinery and molds for producing refrigerators can be substantial. Custom designs may require additional tooling costs, which should be factored into the overall pricing strategy.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but also adds to the cost. Buyers should consider suppliers that maintain high QC standards to avoid future warranty claims and returns.

-

Logistics: Transportation and shipping costs can fluctuate based on distance, mode of transport, and current fuel prices. For international buyers, understanding Incoterms is vital to determine who bears these costs.

-

Margin: Suppliers typically mark up prices to ensure profitability. Understanding the market dynamics can help buyers negotiate better terms.

How Do Price Influencers Affect the Sourcing of Small Refrigerators with Locks?

Several factors influence the pricing of small refrigerators, impacting the total cost for B2B buyers:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Suppliers often have minimum order quantities (MOQs), and negotiating these terms can yield better pricing.

-

Specifications and Customization: Custom features such as energy efficiency ratings, specific locking mechanisms, or aesthetic finishes can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Products with certifications such as Energy Star or ISO standards may command higher prices due to their assurance of quality and efficiency. Buyers should weigh the long-term benefits against the initial cost.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge more, but they often provide better after-sales support and reliability.

-

Incoterms: Understanding the terms of shipping and delivery can help buyers manage costs effectively. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate the responsibilities of buyers and sellers, affecting total costs.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are key tips to optimize cost-efficiency:

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and pricing. Building a good relationship with suppliers can lead to more favorable terms over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also ongoing costs such as energy consumption, maintenance, and potential repair costs. Energy-efficient models may have a higher upfront cost but save money in the long run.

-

Understand Pricing Nuances: Be aware of currency fluctuations and economic conditions that may impact pricing. For instance, tariffs and import duties can significantly increase costs for international shipments.

-

Research Local Market Trends: Understanding local demand and supply dynamics can provide leverage in negotiations. Buyers should stay informed about market trends in their specific regions.

-

Quality over Price: While it’s tempting to choose the lowest-cost option, ensure that the product meets required standards and specifications. Investing in quality can prevent costly issues down the line.

By carefully analyzing these cost components, price influencers, and employing strategic buying tips, B2B buyers can make informed decisions when sourcing small refrigerators with locks.

Alternatives Analysis: Comparing small refrigerator with lock With Other Solutions

Introduction: What Are the Alternatives to Small Refrigerators with Locks?

When it comes to securing perishable goods in various business environments, a small refrigerator with a lock is a popular choice. However, there are alternative solutions that can also meet the needs of businesses, particularly in international markets such as Africa, South America, the Middle East, and Europe. This analysis will compare the small refrigerator with lock against two viable alternatives: a portable cooler and a beverage vending machine. Each option has unique advantages and disadvantages that can impact a buyer’s decision.

Comparison Table

| Comparison Aspect | Small Refrigerator With Lock | Portable Cooler | Beverage Vending Machine |

|---|---|---|---|

| Performance | Maintains consistent cooling; secure storage | Limited cooling ability; requires ice or power | Provides variety; instant access |

| Cost | Moderate initial investment; low operating cost | Low to moderate cost; ice needs may add recurring expenses | Higher initial cost; ongoing inventory costs |

| Ease of Implementation | Simple setup; plug-and-play | Requires ice or power source; portable setup | Requires space; need for regular stocking |

| Maintenance | Low maintenance; occasional cleaning | Cleaning and ice replenishment needed | Regular restocking and maintenance required |

| Best Use Case | Secure storage in offices, schools, or clinics | Temporary storage for events or outdoor use | High-traffic areas needing quick access to beverages |

Detailed Breakdown of Alternatives

Portable Cooler

A portable cooler is a versatile option that can be used in a variety of settings, especially for outdoor events or temporary setups. Its primary advantage lies in its affordability and ease of transport. However, portable coolers often rely on ice or electricity, which can limit their cooling efficiency. This option is best suited for short-term use, such as catering events or outdoor activities, where secure storage is not a primary concern. The need for regular ice replenishment can add recurring costs and maintenance.

Beverage Vending Machine

Beverage vending machines offer a different approach to storing and dispensing drinks. They provide immediate access to a variety of beverages, making them ideal for high-traffic environments like offices, schools, and shopping centers. While vending machines can be more expensive to purchase and maintain due to the need for regular restocking and servicing, they eliminate the need for users to handle cash transactions and can increase convenience. However, they do not provide the same level of security for perishable items as refrigerators with locks.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate solution for securing perishable goods, B2B buyers must consider various factors, including performance, cost, and maintenance. A small refrigerator with a lock is ideal for environments where security is paramount, such as healthcare facilities or educational institutions. In contrast, a portable cooler may be a better fit for temporary, less secure applications, while a beverage vending machine excels in convenience and variety but may require a higher investment. Ultimately, the right choice will depend on the specific needs of the business, the intended use case, and the budget available. By weighing these alternatives carefully, buyers can make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for small refrigerator with lock

What Are the Key Technical Properties of a Small Refrigerator with Lock?

When considering the procurement of small refrigerators with locks, it’s essential to understand various technical specifications that can impact performance, security, and suitability for specific applications. Here are some critical properties:

-

Capacity (Cubic Feet)

The capacity of a refrigerator is typically measured in cubic feet and indicates the internal volume available for storage. For small refrigerators, this often ranges from 1.5 to 5.5 cubic feet. Understanding capacity is crucial for B2B buyers to ensure the unit meets their storage needs, whether for personal use in offices or for commercial applications in hospitality. -

Energy Efficiency Rating

Energy efficiency ratings, such as ENERGY STAR, indicate the refrigerator’s energy consumption relative to its cooling performance. An energy-efficient model not only reduces operational costs but also aligns with sustainability goals, which is increasingly important for businesses aiming to minimize their carbon footprint. -

Material and Finish

The exterior material of the refrigerator, typically stainless steel or plastic, affects durability and aesthetic appeal. Stainless steel, for instance, is resistant to corrosion and offers a premium look, making it suitable for high-end settings. Understanding the material can help buyers evaluate the long-term performance and maintenance needs of the unit. -

Lock Type and Security Features

The locking mechanism is a critical feature for units intended for environments where security is paramount, such as offices or shared spaces. Buyers should consider the type of lock (e.g., key lock, combination lock) and additional security features, such as tamper-proof designs, to ensure the safety of stored items. -

Cooling Technology

Different cooling technologies, such as compressor-based or thermoelectric systems, impact the efficiency and noise level of the refrigerator. Compressor systems are generally more effective for cooling larger volumes, while thermoelectric models are quieter and more compact, suitable for personal use. -

Dimensions and Configuration

The size and design of the refrigerator, including height, width, and depth, are essential for fitting the unit into designated spaces. Additionally, configuration options such as reversible doors can enhance usability in various settings.

Which Trade Terminology Should Buyers Know When Sourcing Small Refrigerators?

Understanding industry jargon is vital for effective communication and negotiation in the procurement process. Here are key terms relevant to B2B transactions involving small refrigerators:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of refrigerators, knowing the OEM can provide insights into product quality and reliability, as established brands often have stringent manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This term is crucial for buyers to understand as it can impact inventory management and overall costs. Buyers should negotiate MOQs to align with their purchasing capabilities and storage limitations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific goods or services. It is an essential step in the procurement process, enabling buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers clarify shipping responsibilities, risk, and costs, which is critical when importing refrigerators from other regions. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. This is particularly important for businesses requiring timely deliveries to maintain operations. Buyers should factor in lead times when planning inventory and operational workflows. -

Warranty and Service Agreement

Warranties provide assurances regarding the quality and longevity of the product. Understanding warranty terms, including coverage duration and what is included, is vital for buyers to mitigate risks associated with defects or failures.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and business objectives.

Navigating Market Dynamics and Sourcing Trends in the small refrigerator with lock Sector

What Are the Current Market Dynamics and Key Trends for Small Refrigerators with Locks?

The small refrigerator with lock sector is experiencing a notable surge in demand, driven by several global factors. Increasing security concerns across various industries, such as hospitality, healthcare, and education, have amplified the need for locking refrigeration solutions. In regions like Africa and South America, where theft and safety are significant concerns, the ability to secure perishable goods is paramount. This trend is further supported by the rise in consumer awareness surrounding food safety and hygiene, which has prompted businesses to invest in secure refrigeration options.

Emerging technologies are also shaping the B2B landscape, with manufacturers increasingly integrating smart features into small refrigerators. IoT-enabled models that allow for remote monitoring and control are gaining traction. This not only enhances operational efficiency but also provides businesses with valuable insights into inventory management and energy consumption. Furthermore, energy efficiency remains a critical consideration, with many buyers now prioritizing Energy Star-rated products that lower operational costs and environmental impact.

In terms of sourcing, international buyers are increasingly seeking suppliers that offer a diverse range of options, from compact models ideal for limited spaces to larger units with advanced security features. The ability to customize designs to meet local preferences, including aesthetics and additional functionalities, is becoming a key differentiator in supplier selection.

How Does Sustainability and Ethical Sourcing Impact the Small Refrigerator with Lock Sector?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the small refrigerator with lock market. As global awareness of environmental issues intensifies, businesses are under pressure to reduce their carbon footprints and adopt more sustainable practices. This shift is particularly relevant for manufacturers, who are increasingly focusing on eco-friendly materials and processes. Buyers are encouraged to look for products that utilize recyclable materials and energy-efficient technologies, which can significantly minimize environmental impacts.

Ethical supply chains are equally important. B2B buyers are increasingly demanding transparency in sourcing, with a focus on fair labor practices and responsible manufacturing. Certifications such as ISO 14001 for environmental management and the Energy Star label for energy efficiency are becoming essential criteria in supplier evaluations. These certifications not only affirm a manufacturer’s commitment to sustainability but also enhance brand reputation, making them more attractive to eco-conscious consumers.

Moreover, the adoption of sustainable practices can lead to cost savings in the long run. Products designed with longevity and efficiency in mind often result in lower operational costs, appealing to budget-conscious businesses in emerging markets.

What Is the Brief Evolution and History of Small Refrigerators with Locks?

The concept of small refrigerators with locking mechanisms has evolved significantly since their inception. Initially designed for personal use in dormitories and small apartments, these compact units have found their way into various commercial sectors, including hotels, hospitals, and offices. The primary purpose was to secure valuable items such as medications, snacks, and beverages, catering to the need for convenience and safety.

As technology advanced, manufacturers began to incorporate more sophisticated locking systems and energy-efficient cooling technologies. The integration of digital locks and smart features has expanded their functionality, allowing businesses to monitor temperatures and access remotely. This evolution has positioned small refrigerators with locks as not just practical appliances but essential tools for security and compliance in various industries.

Today, the market is characterized by a diverse range of options, catering to different needs and preferences. This evolution reflects broader trends in consumer behavior and technological advancements, indicating a robust and dynamic future for the small refrigerator with lock sector.

Frequently Asked Questions (FAQs) for B2B Buyers of small refrigerator with lock

-

How do I choose the right small refrigerator with a lock for my business?

When selecting a small refrigerator with a lock, consider your specific needs such as capacity, energy efficiency, and intended use. Evaluate the size that fits your space and the types of items you will store. Look for features like adjustable shelves and temperature control. Additionally, ensure that the locking mechanism is robust enough for your security requirements, especially in environments like offices or shared spaces. -

What is the best energy-efficient small refrigerator with a lock for commercial use?

The best energy-efficient small refrigerators often carry an Energy Star rating, which indicates reduced energy consumption. Models like the Summit Appliance or Danby series are popular choices, combining compact designs with energy efficiency. Ensure they have sufficient cooling capacity for your needs while minimizing operational costs. Check user reviews and specifications to find a model that balances performance and energy savings effectively. -

How can I vet suppliers for small refrigerators with locks?

To vet suppliers, start by researching their reputation through online reviews and industry feedback. Request references from other B2B buyers and inquire about their experience with product quality and customer service. Assess their certifications and compliance with international trade regulations. Additionally, consider visiting their manufacturing facilities if possible, to gain insights into their production processes and quality control measures. -

What are the typical minimum order quantities (MOQ) for small refrigerators with locks?

MOQs can vary significantly based on the supplier and the type of refrigerator. Generally, for small refrigerators with locks, MOQs can range from 10 to 100 units. It’s advisable to communicate directly with potential suppliers to understand their MOQ policies, as some may offer flexibility for first-time buyers or bulk orders. This can also provide leverage in negotiating better pricing or terms. -

What payment terms should I expect when purchasing small refrigerators in bulk?

Payment terms can differ widely among suppliers. Common practices include a deposit (usually 30-50%) upfront, with the balance payable upon shipment or delivery. Some suppliers may offer net terms, such as 30 or 60 days, especially for established business relationships. Always clarify payment methods accepted, such as bank transfers or letters of credit, and ensure that terms are documented in the purchase agreement. -

How can I ensure the quality of small refrigerators with locks before purchase?

To ensure quality, request product samples or visit the supplier to inspect their manufacturing processes. Look for certifications that indicate compliance with international quality standards, such as ISO or CE. Additionally, ask for product testing reports or warranties that cover defects. Establishing clear quality assurance protocols in your purchase agreement can also safeguard your investment. -

What logistics considerations should I keep in mind when importing small refrigerators?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Determine whether you will use air or sea freight based on urgency and budget. Understand the customs regulations of your destination country to avoid delays. Collaborate with a freight forwarder who has experience with appliance imports to navigate the complexities of international shipping, including tariffs and duties. -

Are there customization options available for small refrigerators with locks?

Many manufacturers offer customization options such as branding, color choices, and specific features tailored to your business needs. When discussing with suppliers, specify your requirements, including design elements and functional modifications. Customization may affect the MOQ and lead time, so it’s essential to plan ahead and factor these into your procurement strategy.

Top 1 Small Refrigerator With Lock Manufacturers & Suppliers List

1. Target – Secure Dorm Refrigerators

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Secure Dorm Refrigerators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for small refrigerator with lock

As the demand for small refrigerators with locks continues to rise across various sectors, strategic sourcing has become essential for B2B buyers seeking reliable, secure, and efficient cooling solutions. These compact appliances not only serve practical needs—such as food and beverage storage in schools, offices, and healthcare facilities—but also address safety concerns in environments where access control is paramount.

By leveraging strategic sourcing, international buyers can access a diverse range of products that meet regional preferences and compliance standards. Engaging with reputable manufacturers and suppliers ensures that you acquire high-quality units that are energy-efficient and tailored to your specific market requirements.

Looking forward, the outlook for small refrigerators with locks remains robust, particularly in emerging markets in Africa, South America, the Middle East, and Europe. As consumer awareness of energy efficiency and security increases, investing in these appliances will not only enhance operational efficiency but also contribute to sustainability goals.

Take action today by exploring partnerships with trusted suppliers to secure a competitive edge in your market. Prioritize quality and reliability in your procurement processes to ensure long-term success in meeting the evolving needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.