The Definitive Guide to Slam Latch: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for slam latch

In today’s fast-paced global market, sourcing high-quality slam latches can present significant challenges for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, the demand for reliable and efficient locking mechanisms is paramount across various industries, including transportation, manufacturing, and construction. This comprehensive guide delves into the world of slam latches, offering insights into their diverse types, applications, and the nuances of supplier vetting. With a focus on cost considerations and market trends, we aim to empower you to make informed purchasing decisions.

As you navigate the complexities of sourcing slam latches, understanding the different designs—from simple spring-loaded models to robust lockable variants—will be crucial. Each type serves unique purposes, whether securing truck doors or locking storage units. Moreover, knowing how to evaluate suppliers based on reliability, production capabilities, and compliance with international standards can significantly reduce risks associated with your purchases.

By equipping you with the knowledge needed to assess product specifications, compare pricing structures, and identify trustworthy suppliers, this guide is designed to streamline your procurement process. Ultimately, it aims to enhance your operational efficiency and support your business growth in an increasingly competitive marketplace.

Understanding slam latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Slam Latch | Simple engagement mechanism, often spring-loaded | Truck and trailer doors, storage cabinets | Pros: Quick operation; Cons: Limited security options. |

| Lockable Slam Latch | Key-operated locking mechanism | High-security storage, flight cases | Pros: Enhanced security; Cons: Higher cost. |

| Paddle Slam Latch | Integrated paddle handle for easy operation | Equipment cases, toolboxes | Pros: User-friendly; Cons: Bulkier design. |

| Heavy-Duty Slam Latch | Robust construction for high-stress environments | Industrial applications, farm equipment | Pros: Durability; Cons: Heavier, may require more installation space. |

| Adjustable Slam Latch | Versatile design with adjustable components | Custom enclosures, mobile units | Pros: Customizable fit; Cons: Potential complexity in installation. |

What are the Characteristics of Standard Slam Latches?

Standard slam latches are characterized by their straightforward design, featuring a spring-loaded mechanism that allows for quick engagement when a door or panel is closed. They are commonly used in applications such as truck and trailer doors, storage cabinets, and other environments where rapid access is necessary. When considering a standard slam latch, buyers should evaluate the latch’s material and durability, especially if the application involves frequent use or exposure to harsh conditions. While they offer speed and ease of use, standard slam latches may lack advanced security features.

How Do Lockable Slam Latches Enhance Security?

Lockable slam latches incorporate a key-operated locking mechanism, providing an added layer of security for sensitive or valuable items. These latches are ideal for applications requiring secure storage, such as in flight cases or high-security storage units. When purchasing lockable slam latches, B2B buyers should consider the locking system’s reliability and the availability of replacement keys. While they typically come at a higher price point, the enhanced security can justify the investment for businesses needing to protect their assets.

What Benefits Do Paddle Slam Latches Offer?

Paddle slam latches are designed with an integrated paddle handle, facilitating easy operation even in challenging conditions. Their user-friendly design makes them suitable for equipment cases and toolboxes, where quick access is essential. Buyers should assess the latch’s size and compatibility with existing installations. The primary advantages of paddle slam latches include their ergonomic operation and ease of use; however, their bulkier design may require more space than other latch types.

In What Scenarios are Heavy-Duty Slam Latches Necessary?

Heavy-duty slam latches are built to withstand rigorous use in high-stress environments, making them suitable for industrial applications and farm equipment. These latches are typically constructed from robust materials, ensuring longevity and reliability. When considering heavy-duty slam latches, buyers should focus on the latch’s load-bearing capacity and environmental resistance. While they provide exceptional durability, they may also be heavier and require more installation space, which could be a consideration for space-constrained applications.

How Do Adjustable Slam Latches Provide Versatility?

Adjustable slam latches feature a design that allows for customization to fit various door thicknesses and installation requirements. They are particularly useful in custom enclosures or mobile units where flexibility is key. Buyers should evaluate the ease of adjustment and the range of compatibility with different applications. While the ability to customize can be a significant advantage, it may also introduce complexity in installation, which should be factored into the purchasing decision.

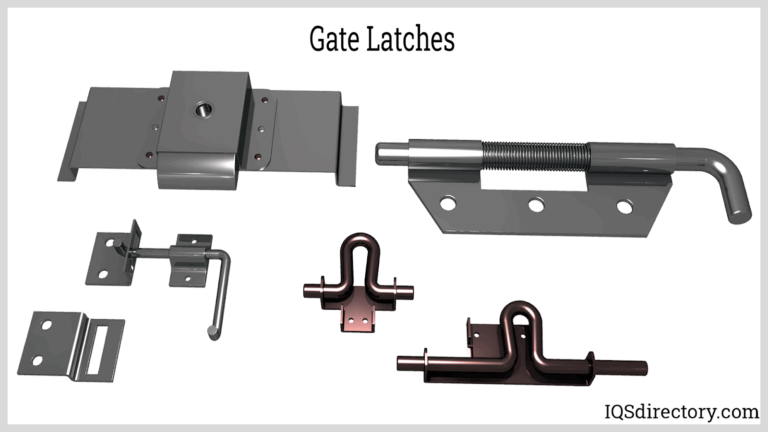

Illustrative image related to slam latch

Key Industrial Applications of slam latch

| Industry/Sector | Specific Application of slam latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Locking mechanisms for cargo trucks and trailers | Enhances security and ensures safe transport of goods | Durability, weather resistance, and compatibility with existing systems |

| Manufacturing | Fastening for machinery covers and access panels | Provides quick access while maintaining safety and security | Material strength, ease of installation, and customization options |

| Agriculture | Securing equipment and tool storage | Protects valuable tools and equipment from theft and damage | Resistance to environmental factors and ease of use |

| Construction | Closure systems for site storage containers | Ensures secure storage of tools and materials on-site | Load capacity, corrosion resistance, and compliance with safety standards |

| Medical Equipment | Locking mechanisms for medical storage cabinets | Ensures compliance with safety regulations and secures sensitive materials | Sterilization compatibility, reliability, and ease of operation |

How Are Slam Latches Used in Transportation & Logistics?

In the transportation and logistics sector, slam latches are critical for securing cargo trucks and trailers. These latches allow for quick locking and unlocking, enabling drivers to efficiently load and unload goods while ensuring that cargo remains secure during transit. For international buyers, particularly in regions like Africa and South America, sourcing slam latches that are durable and weather-resistant is essential, given the diverse climate conditions. Additionally, compatibility with existing locking systems is a key consideration to ensure seamless integration.

What Role Do Slam Latches Play in Manufacturing?

In manufacturing, slam latches are often utilized for fastening machinery covers and access panels. They provide a reliable locking mechanism that allows for quick access to equipment, which is vital for maintenance and operational efficiency. Buyers in the manufacturing sector should prioritize materials with high strength and corrosion resistance, as these factors directly impact the longevity and reliability of the latches in a busy industrial environment. Customization options are also important to meet specific machinery designs.

How Are Slam Latches Beneficial in Agriculture?

In agriculture, slam latches are used to secure equipment and tool storage, protecting valuable items from theft or environmental damage. The ease of operation is particularly beneficial for workers who need quick access to tools while in the field. Buyers should focus on latches that can withstand harsh outdoor conditions, including exposure to moisture and dust. Sourcing latches that are easy to operate with gloves is also a crucial consideration for agricultural applications.

Why Are Slam Latches Important for Construction?

Slam latches find significant applications in construction, particularly for securing site storage containers. These latches ensure that tools and materials are safely stored when not in use, which is essential for preventing loss and maintaining workplace safety. When sourcing slam latches for construction, factors like load capacity and compliance with safety standards should be prioritized. Additionally, materials that resist corrosion and wear from outdoor exposure will enhance the latch’s lifespan.

Illustrative image related to slam latch

How Are Slam Latches Used in Medical Equipment?

In the medical field, slam latches serve as locking mechanisms for storage cabinets that hold sensitive materials and equipment. Ensuring that these cabinets are securely locked is vital for compliance with safety regulations and for protecting patient-related materials. Buyers in the medical sector should consider latches that are compatible with sterilization processes and offer reliable performance. The ease of operation is also essential, as quick access may be needed in urgent situations.

3 Common User Pain Points for ‘slam latch’ & Their Solutions

Scenario 1: Durability Concerns in Harsh Environments

The Problem: Many B2B buyers in sectors such as transportation, construction, or agriculture face significant challenges with the durability of slam latches. For instance, a logistics company operating in a region with extreme weather conditions—like the intense heat of the Middle East or the humidity of South America—may find that standard slam latches fail prematurely. This can lead to operational downtime, increased maintenance costs, and ultimately a negative impact on customer satisfaction.

The Solution: To address durability concerns, buyers should prioritize sourcing slam latches that are specifically designed for harsh environments. Look for products made from high-quality materials such as stainless steel or die-cast aluminum with protective coatings that resist corrosion and wear. Additionally, consider features like weather seals that prevent moisture ingress. Collaborate with suppliers who offer detailed product specifications and can provide testing results to ensure performance under extreme conditions. Furthermore, involving maintenance teams in the selection process can ensure that the chosen slam latches will meet operational needs effectively.

Scenario 2: Installation Complexity and Compatibility Issues

The Problem: Another common pain point arises when B2B buyers encounter compatibility and installation issues with slam latches. For example, a manufacturing company may be retrofitting older equipment with new slam latches, only to discover that the mounting holes do not align or that the latch mechanism does not function smoothly with existing hardware. This not only complicates the installation process but can also lead to costly delays in production.

The Solution: To mitigate installation complexities, it’s critical to engage in thorough planning before purchasing slam latches. Buyers should conduct a detailed assessment of the existing equipment and installation environment. Consider sourcing adjustable or modular slam latches that can accommodate a range of mounting configurations. Suppliers that offer customizable options can be invaluable in these situations. Additionally, providing clear installation guidelines and training for the installation teams can greatly enhance the efficiency of the process. Creating a checklist of compatibility requirements can also streamline decision-making when selecting the right product.

Scenario 3: Security Risks with Standard Latch Designs

The Problem: Security is a paramount concern for many B2B buyers, particularly those in industries like transportation, logistics, and pharmaceuticals, where valuable goods are at risk. Standard slam latches may not provide sufficient security, leading to potential theft or tampering. For instance, a distribution center may find that their slam latches can easily be bypassed, putting their inventory at risk and undermining customer trust.

The Solution: To enhance security, buyers should opt for slam latches that feature advanced locking mechanisms. Look for models that include key locks or electronic locking systems, which provide an added layer of protection. Additionally, consider latches with tamper-proof designs and those that are certified to meet industry security standards. Consulting with security experts can also provide insights into the best practices for securing cargo and equipment. Regular audits of security measures and latch functionality can help identify vulnerabilities before they become significant issues, ensuring that investments in security are effective and provide peace of mind.

Strategic Material Selection Guide for slam latch

What Are the Key Materials for Slam Latch Manufacturing?

When selecting materials for slam latches, it is essential to consider the specific requirements of the application, including durability, corrosion resistance, and manufacturing complexity. Below are analyses of four common materials used in the production of slam latches, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and maintains its integrity under pressure.

Pros & Cons:

The durability of stainless steel makes it ideal for heavy-duty applications, such as truck and trailer doors. However, it tends to be more expensive than other materials, which can impact overall project costs. Manufacturing complexity can also be higher due to the need for specialized tools for cutting and shaping.

Impact on Application:

Stainless steel slam latches are suitable for environments where moisture and chemicals are present, making them ideal for agricultural and marine applications.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 for stainless steel, as well as local regulations regarding material safety and environmental impact.

2. Zinc-Plated Steel

Key Properties:

Zinc-plated steel offers moderate corrosion resistance due to its protective zinc coating. It can withstand temperatures up to 500°F (260°C) and is often used in applications where exposure to the elements is a concern.

Pros & Cons:

This material is generally more affordable than stainless steel, making it an attractive option for budget-conscious projects. However, its corrosion resistance is inferior to that of stainless steel, which may limit its lifespan in harsh environments.

Illustrative image related to slam latch

Impact on Application:

Zinc-plated steel is suitable for indoor applications or environments with minimal exposure to moisture, such as storage facilities.

Considerations for International Buyers:

Buyers should verify that the zinc plating meets standards such as ASTM B633 to ensure quality and longevity, particularly in humid climates prevalent in regions like South America and Africa.

3. Plastic (Polymer)

Key Properties:

Plastic slam latches are lightweight and resistant to corrosion, with the ability to withstand temperatures ranging from -40°F to 180°F (-40°C to 82°C). They are also non-conductive, making them suitable for electrical applications.

Pros & Cons:

The primary advantage of plastic is its low cost and ease of manufacturing, allowing for rapid production and customization. However, plastic latches may not provide the same level of durability as metal options, particularly under heavy loads.

Impact on Application:

Plastic slam latches are ideal for lightweight applications, such as electronic enclosures and portable equipment, where weight savings are crucial.

Considerations for International Buyers:

When sourcing plastic components, buyers should consider compliance with international standards like ISO 9001 for quality management systems and ensure that the materials are suitable for their specific environmental conditions.

4. Die-Cast Aluminum

Key Properties:

Die-cast aluminum offers a good balance of strength, weight, and corrosion resistance. It can withstand temperatures up to 400°F (204°C) and is often used in applications requiring a lightweight yet robust solution.

Pros & Cons:

Aluminum is generally more affordable than stainless steel and provides excellent machinability. However, it may not be suitable for high-stress applications, as it can deform under excessive loads.

Impact on Application:

This material is well-suited for automotive and aerospace applications where weight reduction is essential without compromising strength.

Illustrative image related to slam latch

Considerations for International Buyers:

When sourcing aluminum components, compliance with standards such as ASTM B85 is crucial to ensure quality and performance, especially for buyers in Europe and North America.

Summary Table of Material Selection for Slam Latch

| Material | Typical Use Case for slam latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty applications (trucks) | Excellent corrosion resistance and strength | Higher cost and manufacturing complexity | High |

| Zinc-Plated Steel | Indoor storage facilities | More affordable than stainless steel | Inferior corrosion resistance | Medium |

| Plastic (Polymer) | Lightweight electronic enclosures | Low cost and easy to manufacture | Less durable under heavy loads | Low |

| Die-Cast Aluminum | Automotive and aerospace applications | Good strength-to-weight ratio | May deform under excessive loads | Medium |

This guide provides a comprehensive overview of material options for slam latches, enabling international buyers to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for slam latch

What Are the Key Stages in the Manufacturing Process of Slam Latches?

The manufacturing process of slam latches involves several crucial stages, ensuring that the final product meets both functional and quality standards. The key stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, typically metals such as stainless steel or die-cast aluminum for durability and resistance to corrosion. Suppliers should provide certifications for the materials used, confirming their compliance with industry standards. The materials are then cut and shaped to specific dimensions based on design requirements.

-

Forming: This stage involves various techniques such as stamping, die-casting, or machining to create the necessary components of the slam latch. For instance, die-casting is often employed for producing complex shapes that require minimal post-processing. This technique not only enhances precision but also allows for higher production rates, which is vital for meeting the demands of B2B buyers.

-

Assembly: After forming, the components are assembled. This may include attaching springs, handles, and locking mechanisms. Automated assembly lines are commonly used to increase efficiency and reduce human error. Quality control measures are integrated into this stage to ensure that every latch functions as intended before moving to the next phase.

-

Finishing: The final stage involves surface treatments such as powder coating, anodizing, or galvanization. These processes enhance the aesthetic appeal and provide additional protection against environmental factors. The finishing process is critical for slam latches used in outdoor applications or harsh environments, as it ensures longevity and reliability.

How Is Quality Assurance Implemented in Slam Latch Manufacturing?

Quality assurance in slam latch manufacturing is vital to ensure that products meet international standards and customer expectations. Various methodologies and standards guide the QC process.

Illustrative image related to slam latch

-

International Standards: Many manufacturers adhere to ISO 9001, which focuses on quality management systems. Compliance with this standard indicates that the manufacturer has established processes for consistent quality. In addition, certifications like CE mark and API standards may be relevant depending on the application of the slam latches.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon arrival to ensure they meet specified standards. This includes verification of material certifications and conducting physical tests if necessary.

– In-Process Quality Control (IPQC): During manufacturing, regular checks are performed at various stages to monitor the production process. This may involve measuring dimensions, testing for mechanical properties, and ensuring proper assembly techniques are followed.

– Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted. This includes functional testing of the slam latches to confirm they operate correctly under specified conditions. -

Common Testing Methods: Testing methods can include tensile testing, corrosion resistance tests, and fatigue testing. These methods help determine the durability and reliability of the slam latches under real-world conditions.

What Are the Best Practices for B2B Buyers to Verify Supplier Quality Control?

For B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are some best practices:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This includes evaluating their compliance with ISO standards and other relevant certifications. Audits can be performed by the buyer or through third-party agencies.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand their QC processes. These reports should outline the QC checkpoints, testing methods used, and results from previous inspections.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. This is especially useful for international transactions where on-site inspections may not be feasible.

-

Understanding Certification Nuances: Different regions may have varying quality standards and certifications. For instance, European buyers may prioritize CE marking, while buyers in the Middle East may focus on local regulatory requirements. Understanding these nuances helps buyers make informed decisions.

How Do International Standards Affect Slam Latch Quality Assurance?

International standards play a significant role in shaping quality assurance practices for slam latches. Compliance with these standards not only enhances product reliability but also facilitates market access across different regions.

-

Market Access and Competitiveness: Adhering to international standards like ISO 9001 can enhance a manufacturer’s reputation and competitiveness in global markets. Buyers are more likely to trust suppliers who demonstrate compliance with recognized standards.

-

Risk Mitigation: Implementing rigorous quality assurance processes aligned with international standards helps mitigate risks associated with product failures. This is particularly important for slam latches used in safety-critical applications, such as transportation and industrial settings.

-

Customer Satisfaction: Consistent quality assurance processes lead to higher customer satisfaction. When B2B buyers can rely on the performance and durability of slam latches, it fosters long-term partnerships and repeat business.

Conclusion

Understanding the manufacturing processes and quality assurance practices for slam latches is crucial for B2B buyers aiming to source high-quality products. By focusing on key manufacturing stages, implementing robust QC measures, and verifying supplier practices, buyers can ensure that they procure reliable slam latches that meet their specific needs. Emphasizing compliance with international standards further enhances product quality and market viability, making it easier to establish trust and foster successful business relationships across regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘slam latch’

In this guide, we provide a practical checklist for B2B buyers seeking to procure slam latches. This step-by-step approach will help ensure that you make informed decisions, optimize your sourcing process, and secure high-quality products that meet your operational needs.

Step 1: Define Your Technical Specifications

Start by detailing the specific requirements for the slam latch you need. Consider factors such as the size, material, locking mechanism, and application (e.g., truck doors, storage units, or equipment).

– Material Considerations: Decide whether you need metal (e.g., stainless steel for durability) or plastic (for lighter applications).

– Size Requirements: Ensure the latch fits the intended installation area, as dimensions can vary significantly.

Step 2: Identify Your Budget

Establish a clear budget for your slam latch procurement. Understanding your price range will help narrow down options and prevent overspending.

– Cost Analysis: Review market prices and compare different suppliers to ensure you get competitive rates.

– Consider Total Cost of Ownership: Factor in shipping, installation, and potential maintenance costs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to thoroughly vet potential suppliers.

– Request Documentation: Ask for company profiles, case studies, and references from buyers in similar industries or regions.

– Check Certifications: Ensure suppliers comply with international standards and quality certifications relevant to your industry.

Step 4: Request Samples

Whenever possible, request samples of the slam latches you are considering. This allows you to assess the quality and functionality firsthand.

– Testing for Compatibility: Ensure the sample fits your existing systems and meets your operational requirements.

– Durability Assessment: Check for the latch’s resistance to wear, weather conditions, and stress in your specific applications.

Step 5: Review Terms and Conditions

Before finalizing your order, carefully review the supplier’s terms and conditions.

– Return Policy: Understand the return and warranty policies in case the product does not meet your expectations.

– Delivery Timelines: Confirm lead times to ensure the supplier can meet your project deadlines.

Step 6: Negotiate Pricing and Terms

Engage in discussions with potential suppliers to negotiate pricing and terms.

– Bulk Purchase Discounts: If you’re buying in large quantities, inquire about volume discounts to maximize savings.

– Payment Terms: Discuss flexible payment options that can aid your cash flow management.

Step 7: Finalize Your Order and Monitor Delivery

Once you have selected a supplier and agreed on terms, finalize your order.

– Order Confirmation: Ensure you receive a detailed confirmation that includes all specifications and delivery timelines.

– Track Shipment: Stay in communication with the supplier during the shipping process to manage expectations and address any issues promptly.

By following this checklist, B2B buyers can streamline the sourcing process for slam latches, ensuring that they secure products that align with their technical needs and budgetary constraints.

Comprehensive Cost and Pricing Analysis for slam latch Sourcing

What Are the Key Cost Components for Sourcing Slam Latches?

When sourcing slam latches, understanding the cost structure is critical for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials—such as stainless steel, aluminum, or plastic—significantly affects the cost. Higher-grade materials typically command a premium but offer better durability and performance, which can reduce long-term costs.

-

Labor: Labor costs vary by region and the complexity of manufacturing processes. In regions with lower labor costs, such as some parts of Africa and South America, sourcing can be more economical.

-

Manufacturing Overhead: This includes utilities, maintenance, and administrative expenses. Efficient manufacturers can minimize these costs, allowing for more competitive pricing.

-

Tooling: Initial tooling investments can be substantial, particularly for custom designs. These costs are often amortized over larger production runs, making them less significant per unit in high-volume orders.

-

Quality Control (QC): Ensuring that slam latches meet required specifications is essential. Investing in robust QC processes can prevent costly returns and enhance customer satisfaction.

-

Logistics: Transportation and handling costs must be factored into the total cost. This includes considerations for shipping methods, customs duties, and potential tariffs, especially for international buyers.

-

Margin: Supplier margins can vary significantly based on the manufacturer’s reputation, market demand, and relationship with the buyer. Understanding the typical margins in your specific market can aid in negotiations.

What Factors Influence Slam Latch Pricing?

Several factors impact the pricing of slam latches, particularly for international buyers:

-

Volume/MOQ: Bulk orders typically lead to lower per-unit costs. Manufacturers often offer tiered pricing based on Minimum Order Quantities (MOQs), making it crucial for buyers to assess their needs accurately.

-

Specifications and Customization: Custom features or unique specifications can increase costs. Buyers should clarify their requirements upfront to receive accurate quotes and avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or CE) can elevate costs but may be necessary for specific applications, especially in regulated industries.

-

Supplier Factors: The manufacturer’s location, reputation, and production capacity can influence pricing. Established suppliers with a track record of quality may charge more but offer better reliability.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is vital for cost management. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect who bears shipping costs and risks, impacting overall pricing.

What Are Effective Buyer Tips for Negotiating Slam Latch Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can optimize sourcing costs:

-

Leverage Volume Discounts: If possible, consolidate orders to reach higher quantities that qualify for discounts. This strategy not only reduces costs but also strengthens relationships with suppliers.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the entire cost of ownership, including installation, maintenance, and potential downtime. A slightly higher upfront cost may yield savings over time.

-

Understand Pricing Nuances: Be aware of seasonal pricing trends and market demand fluctuations that could affect costs. Timing your purchases strategically can lead to savings.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better terms and prioritization in production schedules, especially during peak demand periods.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow and reduce financial pressure. Negotiate for longer payment periods or discounts for early payments where feasible.

Conclusion

Understanding the comprehensive cost structure and pricing influencers of slam latches is essential for B2B buyers. By considering the factors outlined above, buyers can make informed decisions that not only optimize purchasing costs but also enhance supplier relationships and ensure product quality. Remember, the prices mentioned in this analysis are indicative and can vary based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing slam latch With Other Solutions

Introduction to Alternative Latching Solutions

In the realm of securing doors, hatches, and drawers, choosing the right latching mechanism is crucial for operational efficiency and security. While slam latches are known for their quick engagement and robust design, several alternative solutions exist that may better suit specific applications or preferences. This analysis will compare slam latches with two viable alternatives: the traditional paddle latch and the sliding bolt latch.

Comparison Table

| Comparison Aspect | Slam Latch | Paddle Latch | Sliding Bolt Latch |

|---|---|---|---|

| Performance | Quick engagement; reliable under impact | Smooth operation; requires manual engagement | High security; suitable for heavy doors |

| Cost | Low to moderate ($3.82 – $67.43) | Moderate ($40.67) | Low to moderate ($0.67 – $30) |

| Ease of Implementation | Easy installation; minimal tools needed | Moderate; requires precise alignment | Moderate; may need additional hardware |

| Maintenance | Low; minimal moving parts | Moderate; may require lubrication | Low; durable with fewer moving parts |

| Best Use Case | Trucks, trailers, medical equipment | Horse stalls, cabinets | Heavy doors, secure storage solutions |

Detailed Breakdown of Alternatives

Paddle Latch

Paddle latches, often used in applications requiring a manual locking mechanism, offer a balance of ease and security. They are typically more complex to install due to the need for precise alignment, which can be a downside in high-traffic environments. However, their smooth operation and ability to secure doors tightly make them ideal for applications such as horse stalls or cabinets. While they are generally more expensive than slam latches, their reliability in specific situations may justify the cost.

Sliding Bolt Latch

Sliding bolt latches provide a traditional locking solution with a focus on security. They are generally very durable and can handle heavy doors effectively, making them suitable for secure storage applications. The cost of sliding bolt latches is often lower than that of paddle latches, but they may require more installation effort, especially in terms of aligning the bolt with the catch. Maintenance is minimal, as they have fewer moving parts, but the need for manual operation can be a drawback in fast-paced environments.

Conclusion: Choosing the Right Latch for Your Needs

When selecting the appropriate latching solution, B2B buyers should consider their specific requirements, including the application, desired security level, and budget constraints. While slam latches offer quick and efficient engagement, alternatives like paddle latches and sliding bolt latches may provide benefits in terms of security or ease of use in particular settings. By weighing the pros and cons of each option, buyers can make informed decisions that enhance their operational efficiency and security.

Essential Technical Properties and Trade Terminology for slam latch

What Are the Essential Technical Properties of a Slam Latch?

Understanding the technical specifications of slam latches is crucial for B2B buyers, as these components play a vital role in ensuring the security and functionality of various applications, from cargo transport to industrial equipment. Here are key properties to consider:

-

Material Composition

Slam latches are commonly made from materials such as stainless steel, zinc-plated steel, and die-cast aluminum. The choice of material affects durability, corrosion resistance, and weight. For example, stainless steel offers high corrosion resistance, making it ideal for marine or outdoor applications, while zinc-plated options are cost-effective for less demanding environments. Selecting the right material can significantly impact the longevity and performance of the latch in specific applications. -

Pin Size

The size of the pin is critical for the latch’s function. Common sizes include 3/8″, 7/16″, and 1/2″. The pin’s size determines how securely the latch engages with the keeper and how it performs under load. Buyers should ensure that the pin size aligns with the application’s requirements, such as the weight of the door or panel it secures. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. Precise tolerances are crucial for ensuring a snug fit between the latch and its corresponding components, which directly affects operational efficiency and security. In applications where a perfect seal or fit is required, understanding tolerance levels helps in avoiding installation issues and ensuring optimal performance. -

Locking Mechanism

Slam latches can come with various locking mechanisms, including key-operated locks and push-button systems. The choice of locking mechanism affects user convenience and security level. For instance, key-operated locks provide enhanced security, making them suitable for cargo applications, while simpler push-button mechanisms may suffice for less critical uses. -

Load Capacity

This specification refers to the maximum weight the latch can securely hold. Load capacity is essential for applications involving heavy doors, such as truck and trailer doors or industrial equipment. Understanding the load capacity ensures that the latch will not fail under operational stresses, thereby preventing accidents and damage. -

Installation Requirements

Some slam latches are designed for easy installation with minimal mechanical processing, while others may require more complex fittings. Knowing the installation requirements helps buyers assess compatibility with their existing systems, facilitating smoother integration and reducing labor costs.

What Are Common Trade Terms Related to Slam Latches?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of slam latches, understanding OEM specifications ensures that the components meet the quality and performance standards required for the intended application. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers, as it can influence inventory management and cash flow. Knowing the MOQ helps companies plan their procurement strategy effectively. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This term is essential for initiating purchasing negotiations. A well-prepared RFQ can help buyers obtain competitive pricing and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, which are widely used in international transactions. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, thus minimizing misunderstandings in cross-border transactions. -

Lead Time

Lead time refers to the time taken from placing an order until the goods are delivered. Understanding lead times is crucial for project planning and inventory management, allowing buyers to align their production schedules with supply availability. -

Customization Options

Many manufacturers offer customization for slam latches, allowing buyers to specify dimensions, materials, and features. Understanding customization options is essential for meeting specific application needs, ensuring that the purchased components fit seamlessly into existing systems.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing slam latches, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the slam latch Sector

What Are the Key Trends Influencing the Slam Latch Market?

The slam latch sector is experiencing significant growth driven by various global factors. The rise in manufacturing and logistics industries, especially in emerging markets in Africa and South America, is increasing the demand for reliable locking mechanisms. Additionally, technological advancements are reshaping sourcing strategies, with digital platforms facilitating direct connections between manufacturers and international buyers. This trend is particularly beneficial for B2B buyers in regions like Europe and the Middle East, who are seeking efficient sourcing solutions and competitive pricing.

Emerging technologies, such as IoT integration in locking mechanisms, are also gaining traction, offering enhanced security and operational efficiency. The ability to monitor and control access remotely is a game-changer for sectors such as transportation, healthcare, and agriculture, which heavily rely on slam latches for security and functionality. Furthermore, the demand for customization is on the rise, with buyers increasingly seeking tailored solutions that meet specific application requirements, driving manufacturers to innovate and diversify their product offerings.

How Important Is Sustainability and Ethical Sourcing in the Slam Latch Industry?

Sustainability is becoming a critical consideration in the slam latch sector, with both buyers and manufacturers recognizing the importance of environmentally friendly practices. The environmental impact of manufacturing processes, particularly in terms of material sourcing and waste generation, is under scrutiny. B2B buyers are increasingly favoring suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials or adopting energy-efficient production methods.

Ethical sourcing is also paramount, as consumers and businesses alike demand transparency in supply chains. Certifications that indicate adherence to environmental and social standards can significantly influence purchasing decisions. Manufacturers are responding by adopting green certifications and utilizing materials that minimize environmental footprints, such as biodegradable plastics and sustainably sourced metals. By prioritizing sustainability, companies not only enhance their brand reputation but also align with the growing global emphasis on corporate responsibility.

How Has the Slam Latch Industry Evolved Over Time?

The slam latch has evolved significantly from its initial use in simple locking mechanisms to become a sophisticated component in various industries. Early slam latches were primarily mechanical devices designed for basic security needs. However, as technology advanced, manufacturers began incorporating features such as corrosion-resistant materials and more complex locking systems. The introduction of modular designs has further increased versatility, allowing for easy installation and customization across different applications.

In recent years, the market has seen the integration of smart technology, enabling remote access and monitoring capabilities, which cater to the demands of modern industries. As the global economy continues to expand, the slam latch industry is poised for further innovation, driven by the need for enhanced security solutions and efficient manufacturing processes. This evolution not only reflects technological advancements but also highlights the industry’s responsiveness to changing market demands and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of slam latch

-

How do I choose the right slam latch for my application?

Choosing the right slam latch involves considering factors such as the latch’s size, material, and intended application. For instance, if you’re securing a heavy-duty truck door, opt for a robust latch made from high-strength materials like stainless steel or zinc-coated options to resist corrosion. Additionally, consider whether you need a lockable feature for added security. Assess the dimensions and compatibility with your existing hardware to ensure a proper fit. Consulting with suppliers who offer customization can help tailor the product to your specific requirements. -

What materials are commonly used in slam latches and their benefits?

Slam latches are typically made from materials like stainless steel, zinc, and die-cast aluminum. Stainless steel is favored for its durability and resistance to rust, making it ideal for outdoor or high-moisture environments. Zinc-coated options provide a balance of strength and corrosion resistance at a lower cost. Die-cast aluminum is lightweight and offers good strength, making it suitable for applications where weight is a concern. Each material has distinct advantages, so selecting one depends on the environmental conditions and load requirements of your application. -

What customization options are available for slam latches?

Many manufacturers offer customization options for slam latches, including size, locking mechanisms, and finishes. You can specify dimensions to fit unique applications, select between key or non-key locking options, and choose finishes that match your product aesthetics. Additionally, some suppliers allow for specific hole placements or adjustments to suit installation needs. Engaging with suppliers directly to discuss your requirements can yield tailored solutions that enhance functionality and appearance. -

What are the minimum order quantities (MOQs) for purchasing slam latches?

Minimum order quantities (MOQs) for slam latches can vary significantly between suppliers and depend on factors such as the complexity of the product and customization requests. Common MOQs range from 50 to 100 units for standard products, while custom orders may have higher MOQs due to production costs. It’s essential to clarify these details with your supplier during negotiations to ensure that the order aligns with your inventory and budgetary constraints. -

What payment terms should I expect when ordering slam latches internationally?

Payment terms for international orders of slam latches typically include options such as advance payment, letters of credit, or net terms (e.g., net 30 or net 60 days). Many suppliers prefer partial payment upfront, especially for custom orders, with the balance due upon shipment or delivery. Always negotiate clear payment terms in your purchase agreement to mitigate risks and ensure a smooth transaction. Additionally, consider currency exchange rates and potential transaction fees when budgeting for international purchases. -

How can I ensure the quality of slam latches from suppliers?

To ensure quality, start by vetting suppliers through industry certifications such as ISO 9001, which indicates a commitment to quality management systems. Request samples to evaluate the latch’s performance and durability firsthand. Additionally, inquire about their quality assurance processes, including materials testing and inspection protocols. Reading reviews and testimonials from other B2B buyers can provide insights into the supplier’s reliability and product quality. Establishing a long-term relationship with a trusted supplier can further enhance quality assurance. -

What logistics considerations should I be aware of when sourcing slam latches?

When sourcing slam latches internationally, consider shipping methods, lead times, and import regulations. Depending on your location, air freight may be faster but more expensive than sea freight. Ensure you understand the lead times for production and shipping, particularly for custom orders. Be aware of any tariffs or import duties that could affect your total cost. Collaborating with a freight forwarder can help streamline the logistics process and ensure compliance with international shipping regulations. -

What are common applications for slam latches in various industries?

Slam latches are versatile and used across multiple industries, including transportation, agriculture, and construction. In transportation, they secure truck and trailer doors, providing quick access and safety. In agricultural settings, they are commonly found on equipment like trailers and storage units. Additionally, slam latches are utilized in manufacturing for securing drawers and cabinets. Understanding the specific requirements of your industry will help you select the right latch type and features for optimal performance.

Top 6 Slam Latch Manufacturers & Suppliers List

1. Norelem – Slam Latches

Domain: norelemusa.com

Registered: 2024 (1 years)

Introduction: {“productId”:”agid.32555″,”price”:58.08,”name”:”Slam latches”,”material”:”Die cast aluminum with plastic end caps”,”version”:”Black or alu-tone powder coated”,”cover_caps”:”Black or alu-tone”,”description”:”For the simple and safe locking of doors and hatches. Installed from the front without mechanical processing using M6 cylinder-head or cheese-head screws. Secured to prevent removal when locked…

2. Kipp USA – Latches & Locks

3. Eberhard – Slam Latches

Domain: eberhard.com

Registered: 1996 (29 years)

Introduction: Slam Latches from Eberhard include various types such as Non-Locking Pull Ring Latch, Key-Locking Pull Ring Latch, Non-Locking Push Release Latch, Key-Locking Push Release Latch, Non-Locking Paddle Latch, Key-Locking Paddle Latch, Non-FMVSS Rated Slam Latch, FMVSS Rated Slam Latch, Rear Door Lock, Sliding Door Lock, and Sliding Partition Door Lock. Materials used include Zinc Die-Cast, Carbon Stee…

4. Ulrich Manufacturing – Gate Slam Latch

Domain: ulrichmanufacturing.com

Registered: 2019 (6 years)

Introduction: Gate Slam Latch

– Price: $150.00

– Available Styles:

1. Heavy-Duty • Complete – $150.00

2. Lite-Duty • Complete – $50.00

3. Heavy-Duty • Strike Plate ONLY – $90.00

4. Lite-Duty • Strike Plate ONLY – $23.00

5. Heavy-Duty • Pull/Plunge ONLY – $60.00

6. Lite-Duty • Pull/Plunge ONLY – $38.00

7. Heavy-Duty • Pull Latch ONLY – Price not specified.

5. Whitecap – Compression Handles & Slam Latches

Domain: whitecapmarineproducts.com

Registered: 2020 (5 years)

Introduction: Compression Handles and Slam Latches Collection includes 70 products such as: Locking and Non-Locking D-Style Compression Handles (2″, 2-1/2″, 3″, 2-5/8″), Locking and Non-Locking Ring Slam Latches (2″, Stainless Steel), Locking and Non-Locking Lever Pull Slam Latches (2″), Non-Locking Curved Handle Lever Pull Slam Latch, and T-Style Compression Handles (Locking and Non-Locking). Materials include…

6. Latch Manufacturers – Slam Latches

Domain: latchmanufacturers.com

Registered: 2015 (10 years)

Introduction: Slam latches are spring-activated mechanical devices used for securely closing cabinets, drawers, and doors without manual engagement. They are ideal for sliding doors and utility boxes, offering durability and high cycle performance. Key features include automatic locking upon closure, high cycle life, vibration resistance, and various actuation methods (levers, knobs, push buttons). Types of sla…

Strategic Sourcing Conclusion and Outlook for slam latch

What Are the Key Benefits of Strategic Sourcing for Slam Latches?

In the dynamic landscape of manufacturing and logistics, strategic sourcing of slam latches is paramount for B2B buyers. By engaging with multiple suppliers, businesses can negotiate better prices, ensure high-quality materials, and gain access to innovative designs tailored to specific applications. This approach not only enhances supply chain resilience but also fosters long-term partnerships that drive mutual growth.

How Can International Buyers Leverage Market Trends?

As the demand for slam latches grows across diverse industries—from automotive to agriculture—international buyers, particularly in Africa, South America, the Middle East, and Europe, should stay attuned to market trends. Investing in custom solutions can differentiate your offerings in competitive markets. Additionally, understanding regional preferences and compliance standards will streamline procurement processes and mitigate risks.

What Does the Future Hold for Slam Latch Suppliers?

Looking ahead, the integration of smart technologies into slam latch designs presents an exciting opportunity for suppliers and buyers alike. Embracing these advancements can enhance functionality and security, meeting evolving customer expectations. As you consider your sourcing strategies, prioritize suppliers who are committed to innovation and sustainability.

How Should You Move Forward in Your Sourcing Strategy?

Now is the time to act. Evaluate your current suppliers and explore new partnerships that align with your strategic goals. By focusing on quality, efficiency, and innovation, you can position your business for success in an increasingly competitive landscape. Engage with suppliers who understand your unique needs and are eager to collaborate on future projects.

Illustrative image related to slam latch

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to slam latch