The Definitive Guide to Size Wire Mesh: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for size wire mesh

In today’s competitive landscape, navigating the global market for size wire mesh can present significant challenges for international B2B buyers. Whether you are seeking durable wire mesh for construction projects or versatile options for architectural applications, understanding the nuances of sourcing this essential material is critical. This comprehensive guide will equip you with the knowledge needed to make informed purchasing decisions by exploring various types of wire mesh, their applications, and key factors to consider when vetting suppliers.

From welded wire mesh to decorative options, the range of products available can be overwhelming. Buyers must consider not only the specific requirements of their projects—such as mesh size, gauge, and material—but also the unique demands of different regions, including Africa, South America, the Middle East, and Europe. By addressing these variables, this guide empowers you to assess cost implications, material suitability, and supplier reliability, ensuring that you select the right wire mesh for your needs.

Additionally, insights into market trends and regional supply chain dynamics will help you stay ahead of the curve in sourcing high-quality wire mesh that meets both functional and aesthetic requirements. With a focus on actionable strategies and expert recommendations, this guide is your go-to resource for optimizing your procurement processes and enhancing your competitive edge in the global market.

Understanding size wire mesh Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Square Wire Mesh | Uniform square openings, commonly available in various gauges | Fencing, reinforcement, architectural design | Pros: Versatile, strong; Cons: Limited flexibility in applications requiring custom shapes. |

| Rectangular Wire Mesh | Rectangular openings, customizable sizes and gauges | Filtration, sifting, and architectural use | Pros: Tailored for specific applications; Cons: May require additional handling for installation. |

| Welded Wire Mesh | Stronger due to welded intersections, available in various sizes | Construction, security fencing, concrete work | Pros: High strength and durability; Cons: Less flexibility in terms of shaping. |

| Decorative Wire Mesh | Aesthetic designs with varied patterns and coatings | Interior design, plant screens, railing infills | Pros: Enhances visual appeal; Cons: May not be suitable for heavy-duty applications. |

| Vinyl Coated Wire Mesh | Galvanized steel with a PVC coating for corrosion resistance | Outdoor fencing, garden applications | Pros: Weather-resistant; Cons: Higher cost compared to standard options. |

What Are the Characteristics and Suitability of Square Wire Mesh?

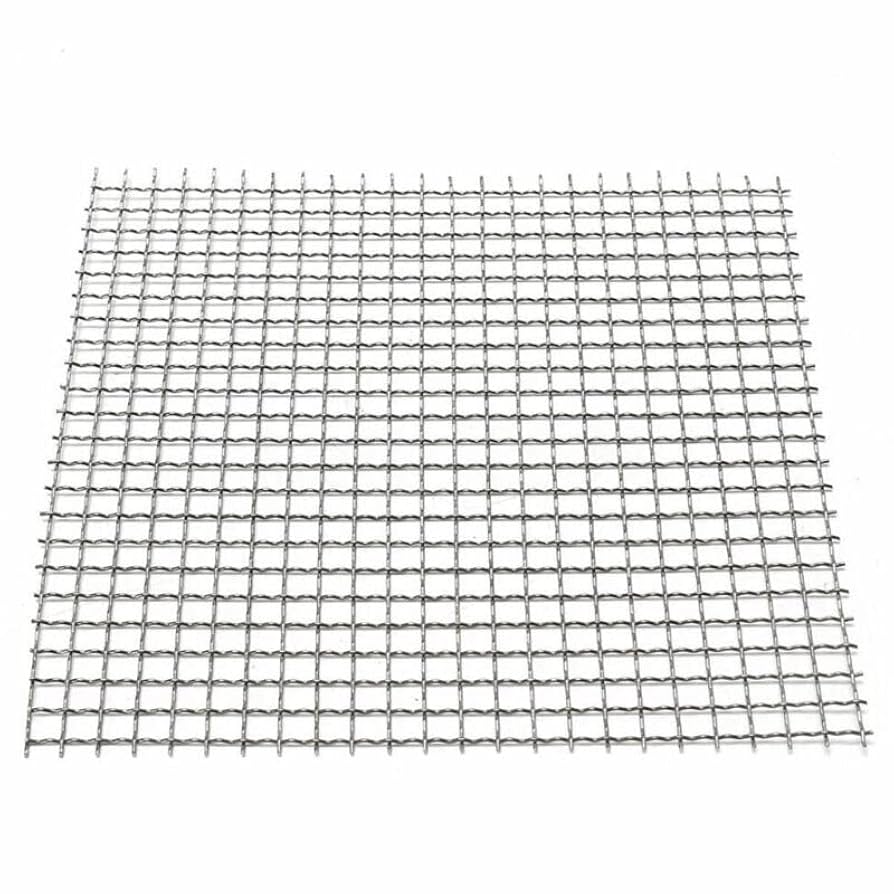

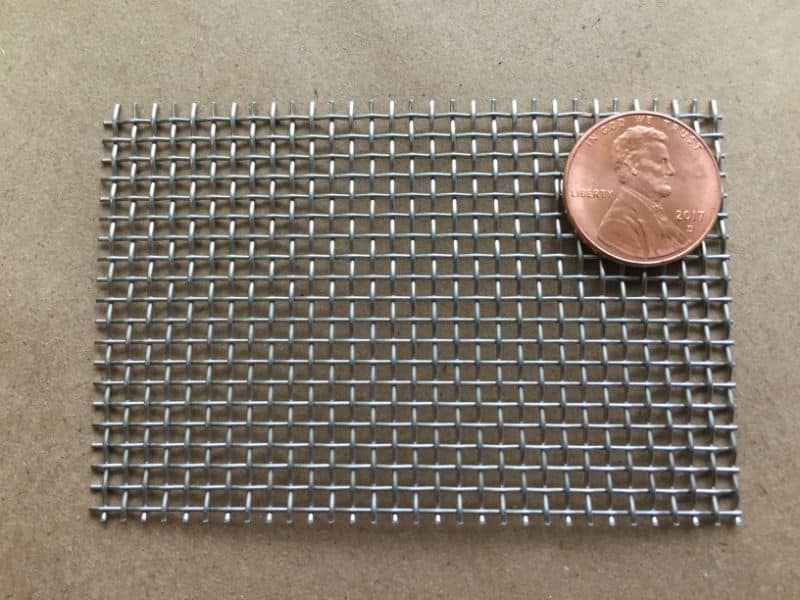

Square wire mesh is characterized by its uniform square openings and is available in a range of gauges, making it suitable for various applications. It is often used in fencing, reinforcement for concrete structures, and architectural designs due to its strength and versatility. When purchasing, buyers should consider the gauge and the material type, as these factors influence durability and application suitability. It is an ideal choice for projects requiring a strong, reliable mesh that can withstand environmental stresses.

How Does Rectangular Wire Mesh Differ in Applications?

Rectangular wire mesh features customizable openings that can be tailored to specific project needs. This type is frequently used in filtration and sifting applications, as well as in architectural settings where unique shapes are required. Buyers should assess the size and gauge needed for their specific application, as the rectangular design can optimize the performance of filtering systems. While it offers flexibility in design, it may require additional handling during installation, which could affect project timelines.

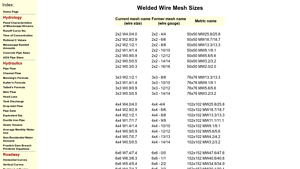

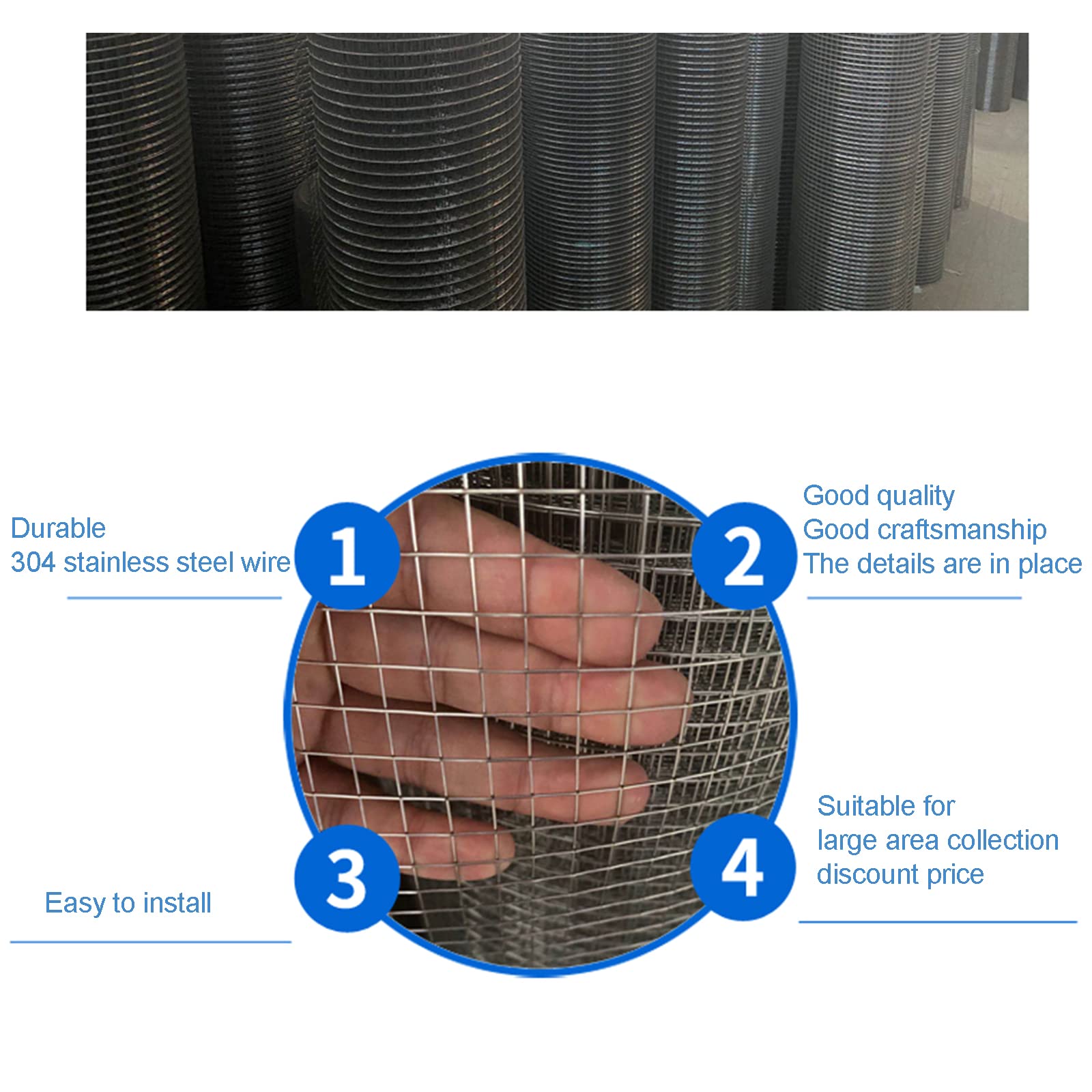

What Makes Welded Wire Mesh a Preferred Choice for Construction?

Welded wire mesh is known for its strength, as the intersections of the wires are welded together, providing a robust structure. This type of mesh is commonly utilized in construction, security fencing, and concrete reinforcement applications. Buyers should evaluate the gauge and size to ensure it meets the load-bearing requirements of their projects. While it offers excellent durability, the rigidity of welded mesh can limit its adaptability for projects that require intricate shapes or adjustments.

How Can Decorative Wire Mesh Enhance Architectural Designs?

Decorative wire mesh is designed with aesthetic appeal in mind, featuring various patterns and coatings that can enhance interior spaces and outdoor environments. It is commonly used in interior design, plant screens, and railing infills. When considering decorative wire mesh, buyers should focus on the design elements and the durability of the material used. Although it provides a unique visual appeal, it may not be suitable for heavy-duty applications, which could limit its use in more demanding environments.

What Are the Benefits of Using Vinyl Coated Wire Mesh?

Vinyl coated wire mesh combines galvanized steel with a protective PVC coating, offering enhanced weather resistance and durability. This type is particularly useful for outdoor fencing and garden applications where exposure to the elements is a concern. Buyers should consider the cost implications of vinyl-coated options compared to standard wire mesh, as they tend to be more expensive. However, the long-term benefits of corrosion resistance can make it a cost-effective choice for projects requiring longevity and minimal maintenance.

Key Industrial Applications of size wire mesh

| Industry/Sector | Specific Application of size wire mesh | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Concrete reinforcement | Enhances structural integrity and load-bearing capacity | Wire gauge, mesh size, and material type |

| Agriculture | Crop protection and fencing | Protects crops from pests and animals | Durability, corrosion resistance, and mesh size |

| Mining and Minerals | Screening and filtration | Efficient separation of materials and contaminants | Mesh size, wire diameter, and tensile strength |

| Architecture and Design | Decorative applications | Aesthetic enhancement while maintaining functionality | Customization options and material selection |

| Oil and Gas | Wellhead protection and filtration | Ensures safety and efficiency in operations | Compliance with industry standards and durability |

How is size wire mesh used in the construction industry?

In the construction sector, size wire mesh is predominantly utilized for concrete reinforcement. This application ensures enhanced structural integrity by providing additional support to concrete structures, which is crucial in regions prone to seismic activity or heavy loads. International buyers should prioritize wire gauge and mesh size, as these factors directly impact the load-bearing capacity and durability of the mesh. Sourcing from reputable suppliers who can provide certifications and compliance with local building codes is essential, especially in developing markets in Africa and South America.

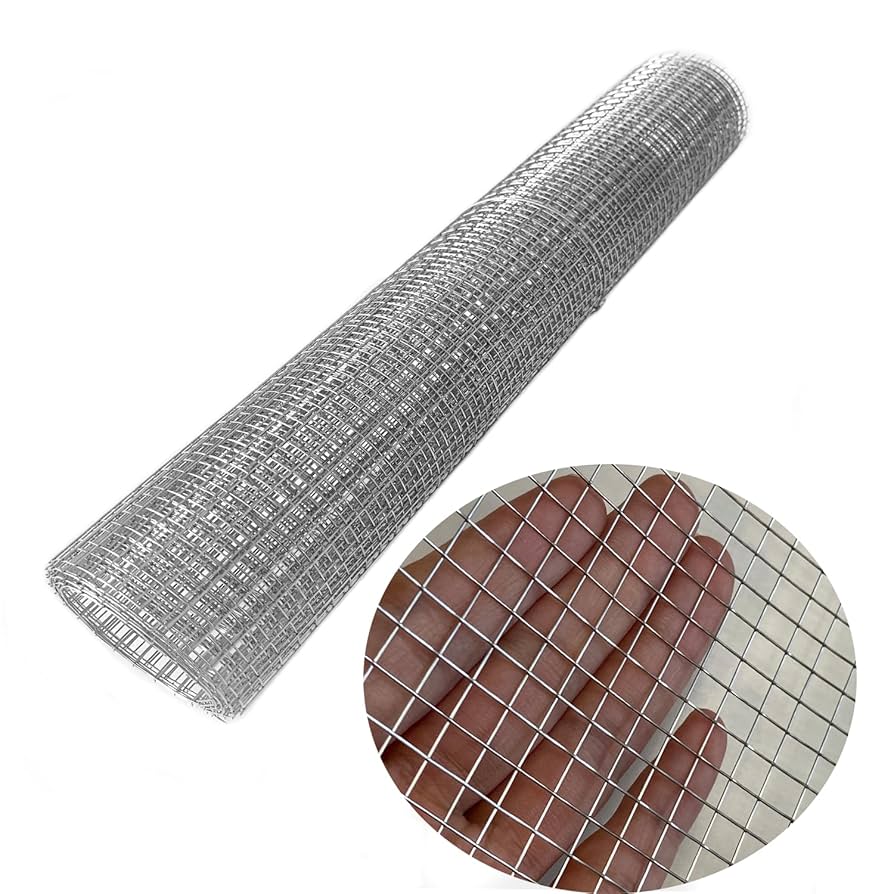

Illustrative image related to size wire mesh

What role does size wire mesh play in agriculture?

In agriculture, size wire mesh is essential for crop protection and fencing. It effectively safeguards crops from pests and animals, promoting healthy growth and higher yields. For B2B buyers, considerations such as durability against environmental factors and corrosion resistance are vital, particularly in regions with harsh climates like the Middle East. Buyers should also evaluate mesh size to ensure it meets specific agricultural needs, balancing protection with airflow and sunlight exposure for the crops.

How is size wire mesh utilized in mining and minerals?

The mining and minerals industry employs size wire mesh for screening and filtration processes. This application facilitates the efficient separation of materials and contaminants, which is crucial for maintaining operational efficiency and product quality. Buyers in this sector must focus on mesh size, wire diameter, and tensile strength, as these attributes determine the effectiveness of separation processes. Additionally, sourcing from suppliers who understand the rigorous demands of the mining industry can provide a competitive edge.

What are the decorative applications of size wire mesh in architecture?

In architecture and design, size wire mesh serves various decorative applications, such as railing infills and cabinet inserts. It offers aesthetic enhancement while maintaining functionality and safety. International buyers should seek customization options to meet specific design requirements, ensuring that the chosen material complements the intended architectural style. Additionally, understanding the local market trends and regulations can aid in sourcing the right products that align with both aesthetic and structural needs.

How is size wire mesh used in the oil and gas sector?

In the oil and gas industry, size wire mesh is critical for wellhead protection and filtration systems. It plays a vital role in ensuring safety and operational efficiency by preventing debris from entering sensitive equipment. Buyers should prioritize compliance with industry standards and focus on the durability of the mesh to withstand extreme conditions. Understanding the specific requirements of wellhead applications and collaborating with suppliers experienced in this sector can significantly enhance project outcomes.

3 Common User Pain Points for ‘size wire mesh’ & Their Solutions

Scenario 1: Sizing Confusion in Custom Projects

The Problem: B2B buyers often encounter difficulties when specifying the right size of wire mesh for their specific applications. This can arise from misunderstandings regarding mesh count, gauge, and the intended use. For instance, a construction company may require a mesh for concrete reinforcement but ends up selecting a size that is too coarse or too fine for the load it must bear. Such mistakes can lead to project delays, increased costs, and potential safety issues, making it critical for buyers to accurately assess their needs.

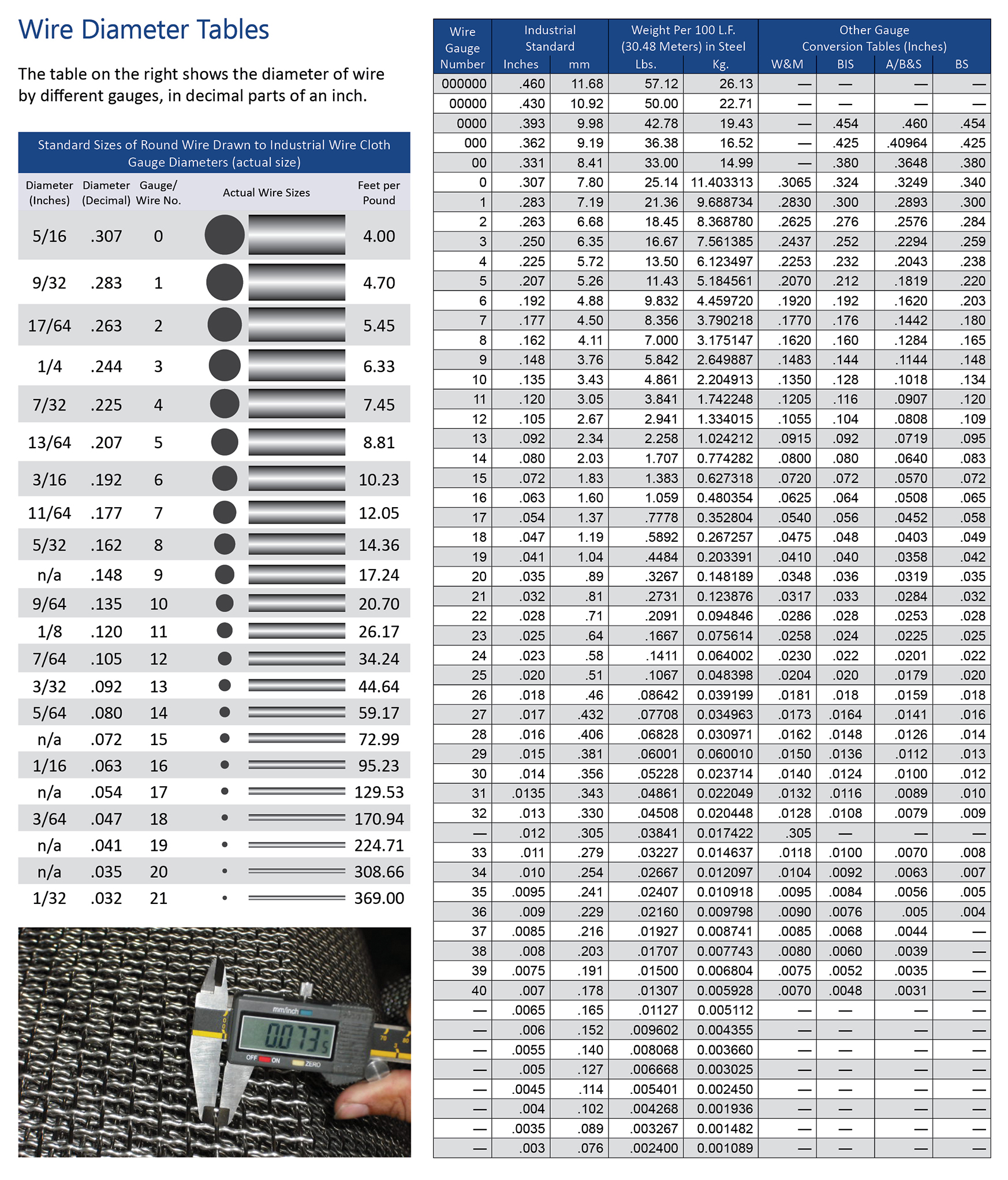

The Solution: To ensure the correct sizing of wire mesh, buyers should conduct a thorough assessment of their project requirements. Start by determining the intended use—whether it’s for construction, filtration, or decorative purposes. Utilize resources such as wire mesh gauge charts to understand the relationship between wire thickness and strength. For concrete applications, consider consulting with structural engineers to define the mesh size and gauge that will provide optimal support. When placing orders, specify both the mesh size and gauge clearly to avoid any miscommunication with suppliers. Furthermore, leveraging samples or prototypes can help verify that the selected mesh meets the project’s needs before committing to larger orders.

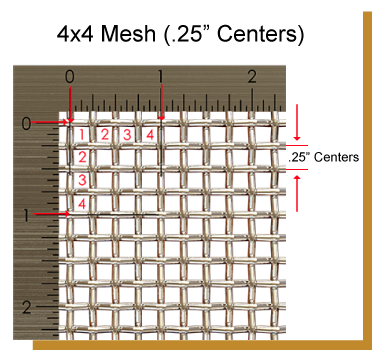

Illustrative image related to size wire mesh

Scenario 2: Quality Assurance and Compliance Challenges

The Problem: B2B buyers often face issues related to quality assurance and compliance with industry standards when sourcing wire mesh. Many regions have specific regulations regarding materials used in construction and manufacturing, particularly concerning safety and environmental impact. Buyers from regions like Africa or South America may find it challenging to ensure that the wire mesh they purchase meets local standards, leading to compliance risks and potential legal repercussions.

The Solution: To mitigate these risks, buyers should prioritize sourcing wire mesh from reputable suppliers who adhere to recognized industry standards, such as ASTM or ISO certifications. Before making a purchase, request documentation that verifies compliance with local regulations. Additionally, establish a strong relationship with suppliers who can provide ongoing support regarding product specifications and updates on industry standards. Consider conducting periodic audits or inspections of received products to ensure they meet quality expectations. Utilizing third-party testing can further validate that the wire mesh performs as required in its intended application, offering peace of mind and safeguarding against compliance issues.

Scenario 3: Supply Chain Disruptions and Lead Time Issues

The Problem: Global supply chain disruptions can significantly impact the availability and delivery timelines of wire mesh. For B2B buyers, especially those in regions such as the Middle East and Europe, delays in receiving orders can halt construction projects and lead to increased costs. The challenge is compounded when specific sizes or custom orders are required, as these may not be readily available in local markets.

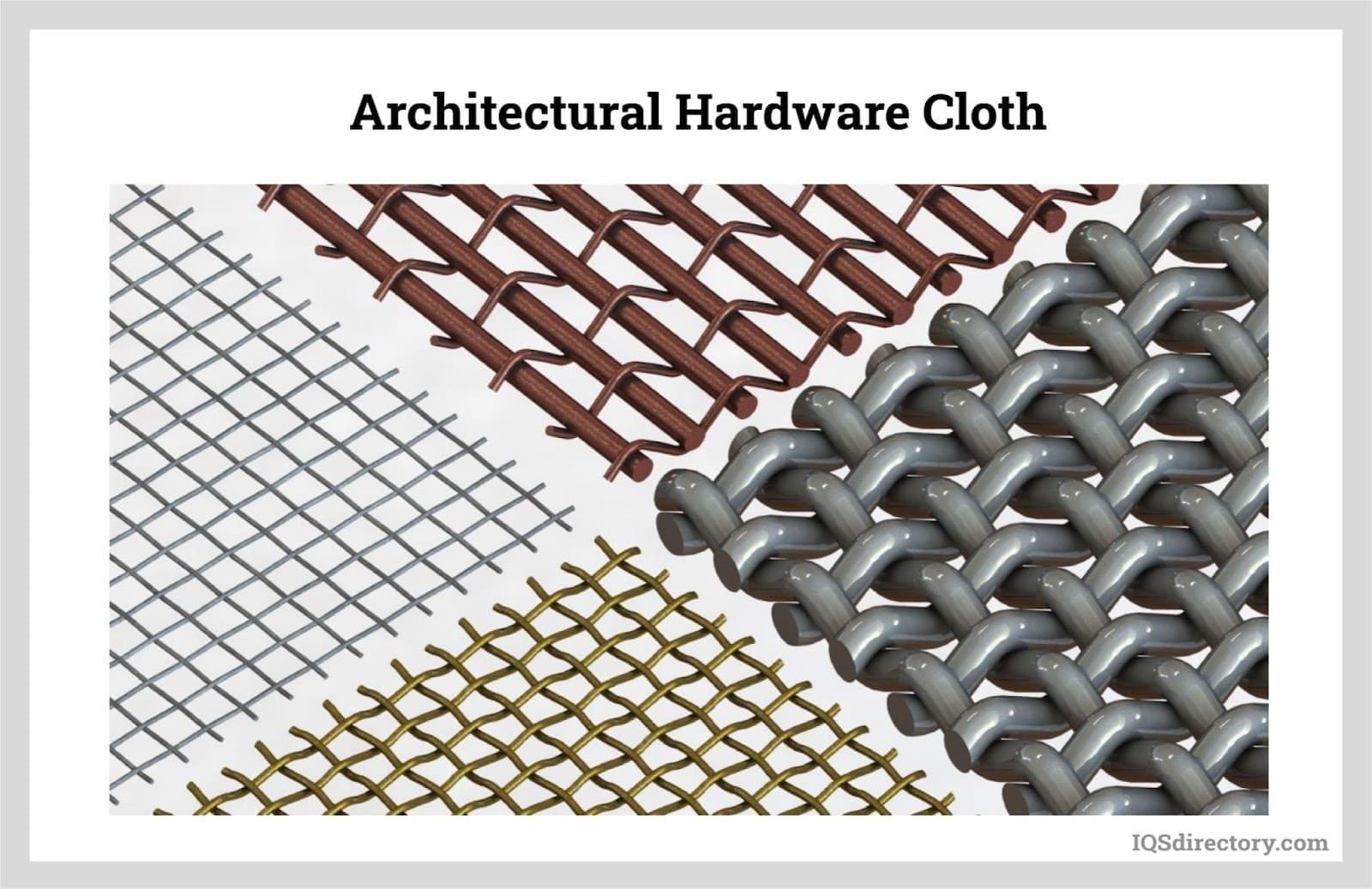

Illustrative image related to size wire mesh

The Solution: To navigate supply chain challenges effectively, buyers should adopt a proactive approach to inventory management. Establishing a strong relationship with multiple suppliers can provide alternative options if one source faces delays. Additionally, consider implementing a just-in-time inventory system that allows for flexibility in ordering sizes of wire mesh based on project timelines. Forecasting demand by analyzing project schedules can help determine when to place orders to avoid last-minute shortages. Furthermore, investing in local suppliers or manufacturers can reduce lead times, providing quicker access to essential materials. Establishing clear communication with suppliers regarding expected delivery times and any potential disruptions can also help in planning around these challenges effectively.

Strategic Material Selection Guide for size wire mesh

What Are the Key Properties of Common Materials Used in Size Wire Mesh?

When selecting wire mesh materials, it is essential to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials used in size wire mesh: Stainless Steel, Carbon Steel, Aluminum, and Copper.

How Does Stainless Steel Perform in Size Wire Mesh Applications?

Stainless steel wire mesh is renowned for its exceptional corrosion resistance, making it ideal for applications exposed to moisture or chemicals. It typically withstands high temperatures, maintaining structural integrity under stress. The material is also non-magnetic and has a high tensile strength, which enhances its durability in demanding environments.

Pros: Stainless steel offers long-lasting performance and is suitable for a wide range of applications, including food processing, pharmaceuticals, and architectural designs. Its aesthetic appeal also makes it a preferred choice for visible installations.

Cons: The primary drawback is its higher cost compared to other materials. Additionally, manufacturing stainless steel mesh can be complex due to the need for specialized equipment.

Illustrative image related to size wire mesh

Impact on Application: Stainless steel is compatible with various media, including liquids and gases, making it versatile for industrial and commercial uses.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial, especially in regions like Europe and the Middle East, where regulations may be stricter. Buyers should also consider the availability of local suppliers to reduce lead times and costs.

What Advantages Does Carbon Steel Offer for Wire Mesh?

Carbon steel is a popular choice for wire mesh due to its strength and affordability. It provides excellent load-bearing capacity and is suitable for applications requiring high durability, such as construction and fencing.

Pros: The cost-effectiveness of carbon steel makes it an attractive option for large-scale projects. Its robustness allows it to withstand significant wear and tear.

Illustrative image related to size wire mesh

Cons: However, carbon steel is prone to corrosion if not properly coated or treated. This limitation restricts its use in environments with high humidity or exposure to chemicals.

Impact on Application: Carbon steel wire mesh is ideal for structural applications but may require protective coatings (like galvanization) to enhance its lifespan.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of local environmental conditions that may affect the performance of carbon steel. Compliance with local standards is also necessary for construction projects.

Illustrative image related to size wire mesh

Why Choose Aluminum for Size Wire Mesh Applications?

Aluminum wire mesh is lightweight and resistant to corrosion, making it suitable for applications where weight is a concern, such as in aerospace or automotive industries. It is also easy to handle and install, which can reduce labor costs.

Pros: The lightweight nature of aluminum allows for easy transportation and installation. It is also non-corrosive, making it ideal for outdoor applications.

Cons: The primary limitation is its lower tensile strength compared to stainless and carbon steel, which may not be suitable for heavy-duty applications.

Illustrative image related to size wire mesh

Impact on Application: Aluminum wire mesh is often used in decorative applications, as well as in environments where corrosion resistance is critical.

Considerations for International Buyers: Buyers should ensure that aluminum products meet international standards for quality and safety, especially in regions with strict regulatory requirements.

What Are the Benefits of Using Copper in Wire Mesh?

Copper wire mesh is known for its excellent conductivity and antimicrobial properties, making it ideal for applications in electronics and healthcare.

Illustrative image related to size wire mesh

Pros: Its unique properties make copper wire mesh suitable for specialized applications, such as in electronic shielding or in environments requiring hygiene.

Cons: Copper is more expensive than other wire mesh materials and can be susceptible to corrosion if not properly maintained.

Impact on Application: Copper wire mesh is particularly effective in applications where conductivity is essential, such as in grounding systems.

Considerations for International Buyers: Buyers should consider the higher cost and potential supply chain issues when sourcing copper wire mesh, especially in regions with limited availability.

Illustrative image related to size wire mesh

Summary Table of Material Selection for Size Wire Mesh

| Material | Typical Use Case for size wire mesh | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, architectural designs | Exceptional corrosion resistance | Higher cost | High |

| Carbon Steel | Construction, fencing | Cost-effective and durable | Prone to corrosion | Low |

| Aluminum | Aerospace, outdoor applications | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Copper | Electronics, healthcare | Excellent conductivity and antimicrobial | Higher cost and corrosion risk | High |

This strategic material selection guide provides valuable insights for B2B buyers, enabling informed decisions based on the specific requirements of their applications.

In-depth Look: Manufacturing Processes and Quality Assurance for size wire mesh

What Are the Key Stages in the Manufacturing Process of Size Wire Mesh?

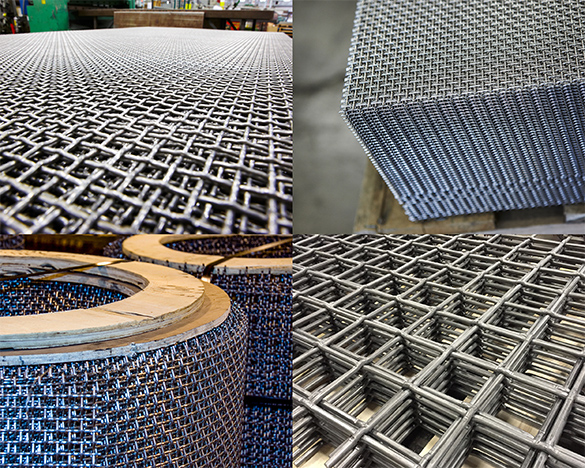

The manufacturing of size wire mesh involves a series of methodical steps designed to ensure precision and quality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting the appropriate wire material, which can vary from stainless steel to galvanized steel, depending on the intended application. The wire is then cut to specified lengths and diameters, ensuring that it meets the desired gauge requirements. Quality raw materials are essential for producing durable wire mesh, as they directly influence the final product’s strength and resistance to corrosion.

-

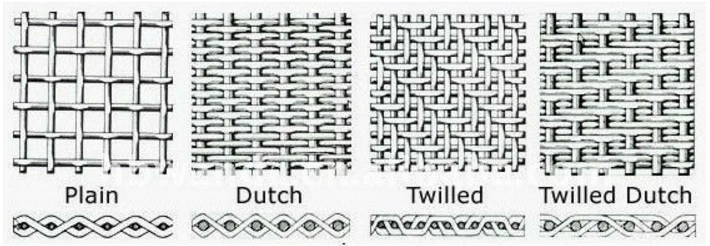

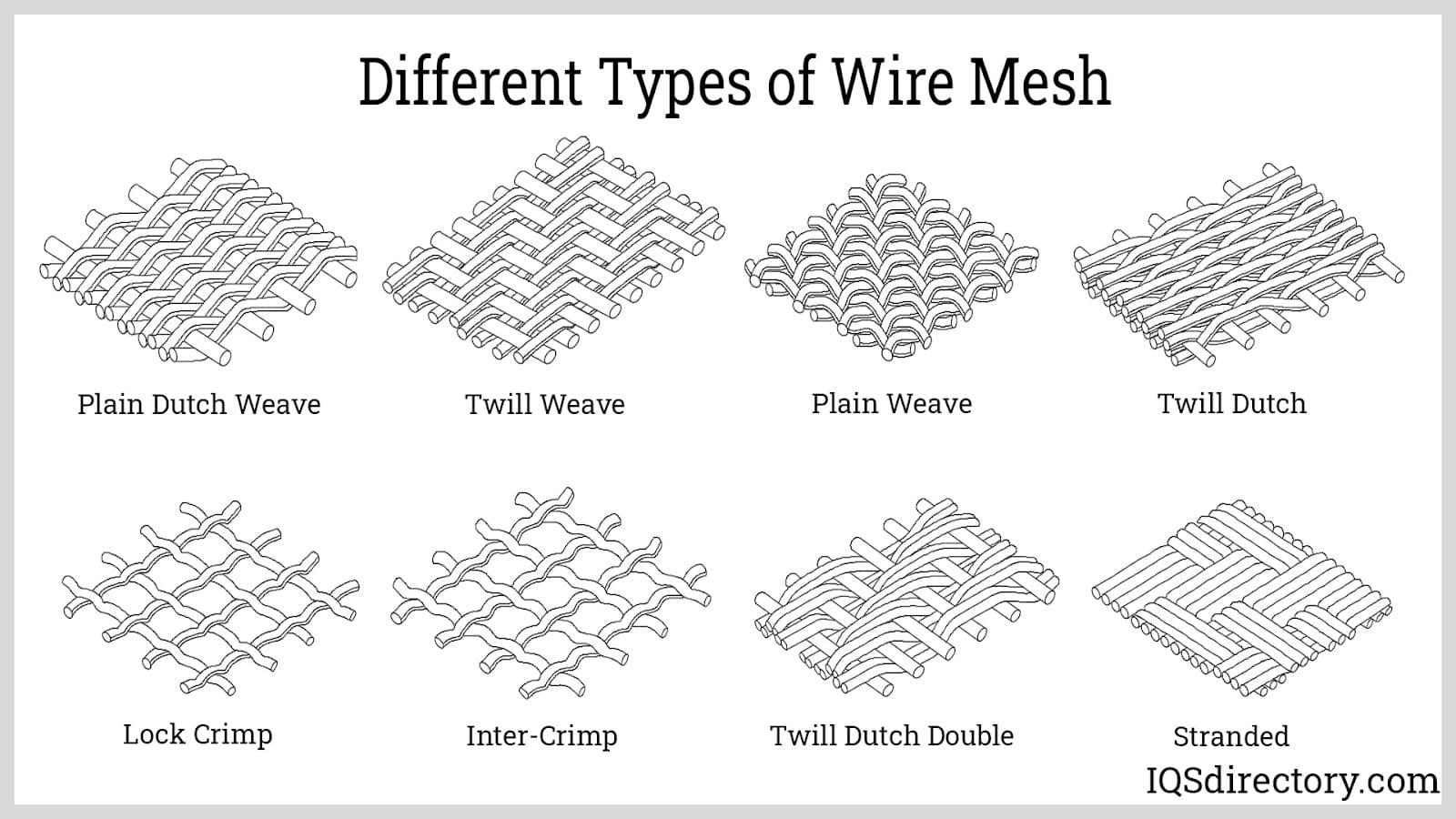

Forming: In this stage, the prepared wires undergo various forming techniques. For welded wire mesh, wires are arranged in a grid pattern, with intersections being welded together using electric resistance welding. For woven wire mesh, the warp and shute wires are interlaced using plain weave or crimping techniques. Advanced machinery, such as rapier looms, is often employed to achieve high precision and efficiency in the weaving process.

-

Assembly: After forming, the mesh panels are assembled to meet specific dimensions and configurations. This may involve cutting larger rolls into sheets or custom sizes, depending on client specifications. Automated systems help streamline this process, ensuring consistency and reducing labor costs.

-

Finishing: The final stage involves surface treatment processes such as coating, galvanizing, or anodizing to enhance corrosion resistance and aesthetic appeal. For instance, PVC coatings are applied to galvanized wire mesh to provide additional protection against the elements. Proper finishing techniques are crucial for ensuring longevity and performance, especially in harsh environments.

How Is Quality Assurance Implemented in Wire Mesh Production?

Quality assurance (QA) is integral to the wire mesh manufacturing process, ensuring that products meet industry standards and customer expectations. The following international and industry-specific standards are often adhered to:

-

ISO 9001: This international standard specifies requirements for a quality management system (QMS) and is crucial for manufacturers seeking to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: In Europe, wire mesh products must comply with certain directives and bear the CE mark, indicating conformity with health, safety, and environmental protection standards.

-

API Standards: For wire mesh used in oil and gas applications, adherence to American Petroleum Institute (API) standards ensures suitability for demanding conditions.

What Are the Key Quality Control Checkpoints in Wire Mesh Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to monitor and validate product quality. Key checkpoints include:

Illustrative image related to size wire mesh

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers must provide material certificates to verify compliance with specified standards.

-

In-Process Quality Control (IPQC): During production, continuous monitoring occurs to ensure that manufacturing processes adhere to established parameters. This includes checking wire gauge, mesh count, and welding integrity. Regular audits and inspections during this phase help identify any deviations early.

-

Final Quality Control (FQC): Once production is complete, the final products undergo rigorous testing. This can include tensile strength tests, corrosion resistance evaluations, and visual inspections for defects or inconsistencies. Ensuring that products meet or exceed specifications at this stage is vital for customer satisfaction.

What Common Testing Methods Are Used to Validate Wire Mesh Quality?

Several testing methods are commonly employed to validate the quality of wire mesh products:

-

Tensile Strength Testing: This measures the maximum stress that the wire mesh can withstand before failure, which is crucial for applications requiring high load-bearing capabilities.

-

Corrosion Resistance Testing: Techniques such as salt spray tests assess how well the wire mesh can resist corrosion, particularly for products intended for outdoor use or harsh environments.

-

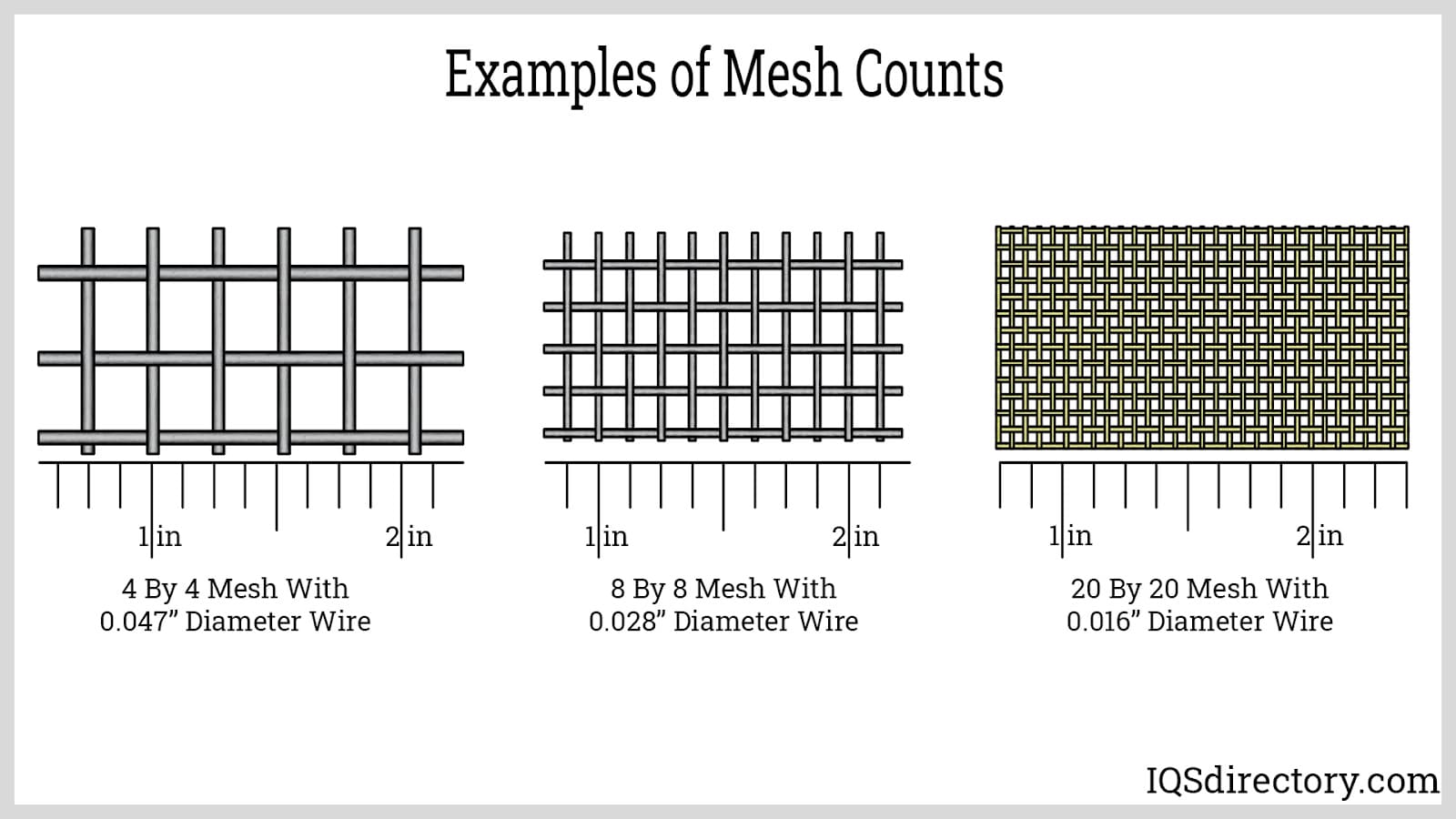

Mesh Count Verification: This involves counting the number of openings per linear inch to ensure conformity with specified mesh sizes, which is critical for applications requiring precise filtration or support.

-

Dimensional Inspection: Regular checks on the dimensions of the finished product ensure that they meet customer specifications and industry standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of wire mesh suppliers:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes, quality control systems, and compliance with international standards. This can be done through on-site visits or by requesting detailed reports.

-

Requesting Quality Control Reports: Suppliers should provide documentation that outlines their quality control procedures, including test results and certifications. This transparency can help buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can perform independent evaluations of the supplier’s products and processes, ensuring compliance with relevant standards.

-

Certifications and Compliance: Buyers should look for suppliers that hold relevant certifications (e.g., ISO 9001, CE marking) and ensure that their products are compliant with local and international regulations, particularly in their regions, such as Africa, South America, the Middle East, and Europe.

What Are the QC Considerations for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, and the Middle East, understanding the nuances of quality control in wire mesh manufacturing is crucial. Factors to consider include:

-

Regional Standards Compliance: Different countries may have specific standards that need to be adhered to. Familiarizing oneself with these standards can aid in selecting suppliers who are compliant.

-

Supply Chain Integrity: Consider the entire supply chain, from raw material sourcing to final delivery, to ensure that quality is maintained at every step.

-

Cultural and Regulatory Differences: Being aware of cultural differences and varying regulatory environments can impact communication and expectations regarding quality assurance.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices related to size wire mesh is essential for B2B buyers. By leveraging the outlined insights, buyers can make informed decisions that ensure the procurement of high-quality wire mesh products suitable for their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘size wire mesh’

The following guide provides a practical step-by-step checklist for B2B buyers looking to procure size wire mesh. This comprehensive checklist is designed to streamline your sourcing process, ensuring that you make informed decisions that align with your specific requirements.

Step 1: Define Your Technical Specifications

Start by clearly defining the technical specifications required for your project. This includes determining the mesh size, wire gauge, and material type (e.g., stainless steel, aluminum, or galvanized steel). Understanding these specifications is crucial as they directly impact the performance, durability, and suitability of the wire mesh for your intended application.

- Mesh Size: Specify the number of openings per linear inch and the clear space between wires.

- Wire Gauge: Choose an appropriate thickness based on strength requirements.

Step 2: Determine Your Application Needs

Identify the specific application for which you need the wire mesh. Different applications, such as fencing, filtration, or architectural design, may require varying mesh types and configurations. This step ensures that you select a product that not only meets your technical specifications but also performs effectively in its intended environment.

- Load-Bearing Requirements: Consider the weight and stress the mesh will endure.

- Environmental Conditions: Assess exposure to elements like moisture, chemicals, or UV light.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in wire mesh. Look for companies with a solid reputation and experience in your industry. This is essential for ensuring reliability in product quality and service delivery.

- Supplier Credentials: Check for certifications, industry experience, and customer reviews.

- Product Range: Ensure the supplier offers a variety of mesh sizes and materials to meet your needs.

Step 4: Request Samples and Specifications

Once you have shortlisted potential suppliers, request samples of the wire mesh that meets your specifications. Evaluating samples allows you to assess the quality, gauge, and weave of the product before making a commitment. This step is vital to ensure the product aligns with your expectations and application requirements.

Illustrative image related to size wire mesh

- Quality Inspection: Look for defects or inconsistencies in the sample.

- Specifications Confirmation: Ensure the sample meets your defined technical specifications.

Step 5: Evaluate Pricing and Terms of Sale

Analyze the pricing structures and terms of sale from each supplier. This includes not only the unit cost of the wire mesh but also shipping costs, payment terms, and any bulk purchase discounts. Understanding the total cost of procurement is essential for budgeting and ensuring cost-effectiveness.

- Cost Comparison: Compare prices based on similar specifications across suppliers.

- Negotiation Opportunities: Explore possibilities for negotiating better terms or pricing.

Step 6: Verify Supplier Certifications and Compliance

Before finalizing your purchase, ensure that the selected supplier meets relevant industry standards and regulations. This may include certifications for quality management systems or compliance with safety standards. Verifying these credentials helps mitigate risks associated with product quality and supplier reliability.

- Quality Assurance: Look for ISO certifications or other relevant industry standards.

- Regulatory Compliance: Ensure the product adheres to local and international regulations.

Step 7: Finalize Your Order and Establish Communication

Once you have verified all aspects, finalize your order with the chosen supplier. Establish clear communication channels for order tracking, delivery timelines, and any post-purchase support. Effective communication is key to addressing any issues that may arise during the procurement process.

- Order Confirmation: Ensure all specifications are documented and confirmed by the supplier.

- Point of Contact: Designate a representative for ongoing communication regarding your order.

By following this checklist, B2B buyers can ensure a streamlined sourcing process that meets their specific needs while minimizing risks associated with procurement.

Illustrative image related to size wire mesh

Comprehensive Cost and Pricing Analysis for size wire mesh Sourcing

What Are the Key Cost Components in Sourcing Size Wire Mesh?

Understanding the cost structure of size wire mesh is essential for B2B buyers, especially those in international markets. The primary cost components include:

-

Materials: The choice of material significantly impacts costs. Common materials include stainless steel, carbon steel, and aluminum, each with varying prices based on market conditions and availability. For instance, stainless steel is generally more expensive due to its corrosion resistance and durability.

-

Labor: Manufacturing wire mesh involves skilled labor for weaving or welding processes. Labor costs can vary based on the location of the manufacturer and local wage standards. For example, sourcing from regions with lower labor costs may offer savings, but consider potential trade-offs in quality.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient production processes can help minimize overhead, impacting the final price.

-

Tooling: Custom sizes or specifications may require specialized tooling, which can increase initial costs. However, these expenses can be amortized over larger production runs, making them more manageable.

-

Quality Control (QC): Ensuring that the wire mesh meets industry standards requires investment in quality control measures. Certifications such as ISO or ASTM can enhance credibility but may add to the overall cost.

-

Logistics: Transportation costs can be significant, particularly for international buyers. Shipping methods, distance, and import duties must be factored into the total cost of ownership.

-

Margin: Suppliers will include a profit margin, which can vary widely based on market competition and perceived value.

How Do Price Influencers Affect Wire Mesh Pricing?

Several factors influence the pricing of size wire mesh in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating favorable terms based on projected volumes can significantly reduce overall expenditure.

-

Specifications and Customization: Custom sizes or unique specifications can increase costs due to the need for specialized production processes. Standard sizes are typically more cost-effective.

-

Material Quality and Certifications: Higher-quality materials and certifications can drive up costs, but they may be necessary for specific applications. Ensure that the benefits align with your project requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can affect pricing. Established suppliers may charge more for their experience and quality assurance.

-

Incoterms: The agreed-upon Incoterms can influence logistics costs and responsibilities. Familiarity with terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can aid in cost calculation.

What Tips Can Help Buyers Negotiate Better Prices for Wire Mesh?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies are vital:

-

Understand Total Cost of Ownership (TCO): Evaluate all cost components, not just the purchase price. Consider logistics, customs duties, and potential delays that could impact project timelines.

-

Leverage Volume Discounts: If possible, consolidate orders to meet or exceed MOQ thresholds. This can lead to significant savings and strengthen your negotiating position.

-

Request Multiple Quotes: Engage multiple suppliers to gain insight into market pricing. This can provide leverage during negotiations and ensure you’re receiving competitive offers.

-

Be Open to Alternatives: If budget constraints exist, consider alternative materials or specifications that can meet your needs without compromising quality.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and potential exclusivity in pricing agreements.

Disclaimer on Indicative Prices

Prices for size wire mesh can fluctuate based on market conditions, material availability, and supplier pricing strategies. It is advisable to conduct thorough market research and obtain current quotes to ensure accurate budgeting.

Alternatives Analysis: Comparing size wire mesh With Other Solutions

Understanding Alternative Solutions to Size Wire Mesh

In the realm of industrial applications, size wire mesh is a versatile solution known for its strength, adaptability, and aesthetic appeal. However, several alternative technologies and materials can also achieve similar objectives, such as filtration, security, and structural support. This analysis will compare size wire mesh against two notable alternatives: perforated metal sheets and expanded metal mesh. Each alternative offers unique benefits and considerations for B2B buyers.

Illustrative image related to size wire mesh

| Comparison Aspect | Size Wire Mesh | Perforated Metal Sheets | Expanded Metal Mesh |

|---|---|---|---|

| Performance | High tensile strength; versatile for various applications | Customizable hole patterns; good airflow | Sturdy; excellent for security and ventilation |

| Cost | Moderate; varies by material and gauge | Generally higher due to custom fabrication | Lower cost due to simpler production |

| Ease of Implementation | Easy to cut and install; lightweight | Installation may require specialized tools | Simple to handle; can be welded or bolted |

| Maintenance | Low; resistant to corrosion (if coated) | Moderate; depends on surface treatment | Low; durable and resistant to wear |

| Best Use Case | Architectural designs, security, filtration | HVAC systems, soundproofing, decorative elements | Fencing, grating, architectural features |

What Are the Advantages and Disadvantages of Perforated Metal Sheets?

Perforated metal sheets are metal panels with a series of holes punched through them. This design allows for airflow and light penetration while maintaining structural integrity. They are often used in HVAC systems, soundproofing applications, and decorative facades.

Pros:

– Highly customizable, allowing for tailored hole sizes and patterns to meet specific project requirements.

– Provides excellent airflow and acoustic properties, making them suitable for ventilation and sound dampening.

Cons:

– Generally more expensive than size wire mesh due to the complexity of the manufacturing process.

– Installation may require specialized tools, which can increase project timelines and costs.

How Does Expanded Metal Mesh Compare to Size Wire Mesh?

Expanded metal mesh is created by cutting and stretching a metal sheet, resulting in a strong, lightweight material with diamond-shaped openings. It is commonly used for security fencing, grating, and architectural applications.

Pros:

– Cost-effective due to the simplicity of its production process.

– Offers superior strength and rigidity, making it an excellent choice for security applications.

Illustrative image related to size wire mesh

Cons:

– Limited flexibility in terms of hole size and shape compared to size wire mesh and perforated sheets.

– May not be suitable for applications requiring fine filtration or aesthetic designs.

How to Choose the Right Solution for Your Needs?

When evaluating the right solution for your specific application, it is essential to consider various factors such as the intended use, environmental conditions, and budget constraints. Size wire mesh excels in versatility and strength, making it a preferred choice for architectural and industrial applications. However, if your project requires specific airflow characteristics or soundproofing capabilities, perforated metal sheets may be more suitable. On the other hand, if cost and security are your primary concerns, expanded metal mesh could provide a practical solution.

In conclusion, understanding the unique benefits and limitations of each alternative will empower B2B buyers to make informed decisions tailored to their project requirements. By carefully assessing performance, cost, and application suitability, businesses can select the most effective material for their needs.

Essential Technical Properties and Trade Terminology for size wire mesh

What Are the Key Technical Properties of Size Wire Mesh for B2B Buyers?

Understanding the essential technical properties of size wire mesh is crucial for B2B buyers looking to make informed decisions. Here are some critical specifications that influence performance and suitability for various applications.

Illustrative image related to size wire mesh

1. Material Grade

Wire mesh is available in multiple material grades, including stainless steel, carbon steel, aluminum, and brass. Each material has unique properties such as corrosion resistance, tensile strength, and thermal conductivity. For instance, stainless steel is preferred in environments prone to moisture, while aluminum is favored for lightweight applications. Selecting the appropriate material grade ensures that the wire mesh will meet the specific demands of the intended application, from industrial use to architectural design.

2. Wire Gauge

Wire gauge indicates the thickness of the wire used in the mesh, typically measured in American Wire Gauge (AWG) or in millimeters. A lower gauge number represents a thicker wire, which generally offers greater strength and load-bearing capacity. Understanding wire gauge is essential for determining whether the mesh can withstand physical stresses in its application, such as in construction or fencing.

3. Mesh Count

Mesh count refers to the number of openings per linear inch, significantly impacting filtration and structural integrity. For example, a higher mesh count provides finer filtration, making it suitable for applications in food processing or pharmaceuticals. Conversely, a lower mesh count offers greater strength and is often used in construction. B2B buyers must match the mesh count to their operational requirements to ensure efficiency and effectiveness.

Illustrative image related to size wire mesh

4. Tolerance

Tolerance refers to the allowable variation in dimensions and characteristics of the wire mesh. It is crucial for ensuring that the mesh fits precisely within the intended application, whether it be for architectural purposes or industrial machinery. Tighter tolerances may be necessary for high-precision applications, while broader tolerances might be acceptable for more general uses. Understanding tolerance helps buyers avoid costly mistakes related to fitting and performance.

5. Coating and Finish

Wire mesh can be coated or finished in various ways, including galvanization, PVC coating, or powder coating. These finishes can enhance properties such as corrosion resistance, aesthetic appeal, and durability. For instance, galvanized wire mesh is widely used in outdoor applications due to its ability to withstand harsh weather conditions. Buyers should consider the environmental factors the wire mesh will encounter to select the appropriate finish.

What Are Common Trade Terms Used in the Wire Mesh Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions involving wire mesh. Here are some common terms that buyers should know.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components or products that are used in another company’s end product. In the wire mesh industry, an OEM may supply mesh to manufacturers of machinery or construction materials. Understanding OEM relationships can help buyers identify reliable suppliers who can meet specific quality and performance standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers to understand, as it can affect pricing and inventory management. Knowing the MOQ helps companies plan their purchases and avoid overstocking or underordering.

Illustrative image related to size wire mesh

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. By issuing an RFQ, buyers can compare offers from multiple vendors, ensuring they receive competitive pricing and favorable terms. This process is essential for strategic sourcing and cost management.

4. Incoterms

Incoterms, or International Commercial Terms, are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as delivery, risk, and transportation costs. Familiarity with Incoterms helps B2B buyers mitigate risks and understand their obligations in cross-border transactions.

5. Lead Time

Lead time is the period from when an order is placed until it is delivered. Understanding lead time is crucial for supply chain management, as it impacts project timelines and inventory levels. Buyers should account for lead times when planning their procurement strategies to ensure timely delivery of wire mesh products.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the size wire mesh Sector

What Are the Key Market Trends Shaping the Size Wire Mesh Sector?

The size wire mesh market is experiencing dynamic shifts driven by several global factors. Increased urbanization and infrastructure development, particularly in regions such as Africa and South America, are propelling demand for wire mesh in construction, landscaping, and industrial applications. Additionally, the rise of automation and digitalization in manufacturing processes is leading to improved production efficiency and quality control, which international buyers should consider when sourcing materials.

Emerging technologies, including advanced mesh production techniques and the integration of AI for predictive analytics, are enhancing inventory management and supply chain transparency. Buyers in the Middle East and Europe, for instance, are increasingly leveraging digital platforms for sourcing, which allows for real-time access to product specifications and availability. Furthermore, customizable mesh sizes and specifications are becoming a standard requirement, as buyers seek tailored solutions to meet specific project needs.

Illustrative image related to size wire mesh

The market dynamics are also influenced by fluctuating raw material prices and trade policies, which can impact cost structures. Buyers should remain vigilant about geopolitical developments and their potential effects on sourcing strategies, especially in regions with complex trade relations.

How Is Sustainability Impacting Sourcing Trends in the Size Wire Mesh Sector?

Sustainability is at the forefront of sourcing decisions in the size wire mesh sector. As environmental concerns grow, businesses are increasingly prioritizing ethical sourcing and the use of sustainable materials. Wire mesh products made from recycled materials or those certified with green standards are gaining traction among B2B buyers who wish to minimize their environmental footprint.

The importance of ethical supply chains cannot be overstated. International buyers must ensure that their suppliers adhere to responsible sourcing practices, which can include fair labor standards and environmentally friendly production methods. Certifications such as ISO 14001 for environmental management systems or the Global Recycled Standard (GRS) can serve as benchmarks for assessing suppliers’ sustainability credentials.

Moreover, the adoption of eco-friendly coatings, like PVC or galvanization processes that reduce corrosion and prolong product life, aligns with sustainability goals. This not only enhances the durability of wire mesh products but also minimizes waste in the long run, offering a compelling case for B2B buyers to invest in sustainable solutions.

How Has the Size Wire Mesh Market Evolved Over Time?

The evolution of the size wire mesh market can be traced back to its foundational role in construction and industrial applications. Initially, wire mesh was primarily utilized for basic fencing and reinforcement in concrete structures. However, as technology advanced, so did the versatility of wire mesh, with applications expanding into architectural designs, landscaping, and decorative elements.

Illustrative image related to size wire mesh

The introduction of various materials, such as stainless steel and aluminum, has further diversified the market, allowing for greater customization and enhanced functionality. Additionally, the shift towards more complex production techniques, including woven and welded mesh, has improved the strength and aesthetic appeal of wire mesh products.

Today, the market is characterized by a demand for high-quality, durable, and sustainable wire mesh solutions that meet the specific needs of international B2B buyers. Understanding this evolution is crucial for buyers looking to make informed sourcing decisions that align with current market trends and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of size wire mesh

-

How do I determine the right wire mesh size for my project?

To determine the right wire mesh size for your project, consider the specific application requirements, such as load-bearing capacity, environmental conditions, and desired aesthetic. Start by assessing the mesh count, which indicates the number of openings per inch, and gauge, which refers to the wire thickness. For structural applications, opt for thicker gauges that provide better strength and durability. Additionally, consult with suppliers who can offer samples or technical specifications tailored to your needs. -

What is the best wire mesh material for outdoor applications?

For outdoor applications, stainless steel wire mesh is often the best choice due to its resistance to corrosion and rust, making it suitable for harsh weather conditions. Galvanized steel mesh is another viable option, offering affordability and decent protection against corrosion. If aesthetics are important, consider PVC-coated wire mesh, which adds an extra layer of protection while enhancing visual appeal. Always evaluate the specific environmental factors before making your selection. -

What are the typical minimum order quantities (MOQs) for wire mesh?

Minimum order quantities for wire mesh can vary significantly depending on the supplier and the specific product. Typically, MOQs range from a few hundred square feet to several thousand, especially for customized sizes or specifications. It is advisable to discuss your requirements with potential suppliers to understand their MOQ policies, as some may offer flexibility for smaller orders, particularly for ongoing partnerships. -

How can I ensure quality assurance when sourcing wire mesh internationally?

To ensure quality assurance when sourcing wire mesh internationally, start by vetting suppliers through reviews, certifications, and their history in the industry. Request samples to assess material quality and workmanship. Additionally, consider setting up third-party inspections during production and before shipment to verify compliance with your specifications. Establish clear quality standards and expectations in your contract to mitigate risks associated with international sourcing. -

What payment terms should I negotiate with wire mesh suppliers?

When negotiating payment terms with wire mesh suppliers, consider factors such as order size, supplier reputation, and your cash flow needs. Common terms include a deposit upfront (usually 30-50%) with the balance due upon delivery or prior to shipment. For larger orders, you may negotiate more favorable terms like extended payment periods or letter of credit arrangements. Always ensure that payment terms are clearly outlined in the contract to avoid misunderstandings. -

What should I consider regarding logistics when importing wire mesh?

When importing wire mesh, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose between air freight for expedited delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Familiarize yourself with import tariffs and duties applicable in your region, as these can impact overall costs. Collaborate with reliable freight forwarders who can manage documentation and ensure compliance with local regulations. -

How can I customize wire mesh to meet specific project needs?

Customization of wire mesh can include adjustments in size, mesh count, wire gauge, and materials. Communicate your specific requirements to suppliers, who can often provide tailored solutions. Some manufacturers offer the ability to create unique patterns or coatings for specialized applications. Be prepared to discuss your project details in-depth to ensure the final product meets all functional and aesthetic needs. -

What are the best practices for maintaining wire mesh in industrial applications?

To maintain wire mesh in industrial applications, regularly inspect for signs of wear, corrosion, or damage. Depending on the material, cleaning may involve removing debris and applying protective coatings. For galvanized and stainless steel meshes, periodic washing can help prevent buildup that may lead to corrosion. Implementing a maintenance schedule can extend the lifespan of the wire mesh, ensuring it continues to perform effectively in demanding environments.

Top 8 Size Wire Mesh Manufacturers & Suppliers List

1. McNichols – Wire Mesh Solutions

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: Product Line: Wire Mesh

Online Order Available: Yes

Mesh Types: Square (226), Rectangular (10), ECO-MESH® (1), Designer Mesh (192)

Construction Types: Woven (357), Welded (71), Standard-Duty Welded (1)

Series Names: ASHLAND™, AURA™, CHATEAU™, CREMONA™, HALO™, HW & IND CLTH, INSECT SCREEN, SHIRE™, TALICA™, TECHNA™, VINYLMESH™

Primary Materials: Aluminum (AL), Brass (BRS), Bronze (BNZ), Bronze/Stain…

2. SD-W – Mesh Wire Specifications

Domain: sd-w.com

Registered: 1999 (26 years)

Introduction: This company, SD-W – Mesh Wire Specifications, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. MCSW – Wire Mesh Gauges

Domain: mcswusa.com

Registered: 2016 (9 years)

Introduction: Wire mesh gauges refer to the thickness of the wire used in the mesh, measured in American Wire Gauge or by diameter in inches or millimeters. Common wire mesh gauges and their diameters include: 6 gauge: 0.192 inches (4.88 mm), 8 gauge: 0.128 inches (3.25 mm), 10 gauge: 0.102 inches (2.59 mm), 12 gauge: 0.080 inches (2.03 mm), 14 gauge: 0.064 inches (1.63 mm), 16 gauge: 0.050 inches (1.27 mm), 18…

4. Darby Wire Mesh – Versatile Wire Mesh Solutions

Domain: darbywiremesh.com

Registered: 2007 (18 years)

Introduction: Wire Mesh Options: Aluminum, Brass, Bronze, Copper, Galvanized, Monel 400, Plain Steel, Stainless Steel (T-304, T-316), Other Alloys. Applications: Fencing, Caging, Infill Panels, Filtration, Building & Construction, Agricultural Use, Window Guards, Fireplace Screens, Decorative Applications, Food Processing, RFI Shielding, Archaeology. Mesh Types: Plain Weave, Plain Crimp, Intermediate Crimp, Loc…

5. Lawrence’s Sintered Metals – Custom Wire Mesh Sizes

Domain: lawrencesinteredmetals.com

Registered: 2008 (17 years)

Introduction: Wire Mesh Sizes: Custom wire mesh available in various sizes and specifications. Key sizes include: 2×2 Mesh (0.047″ wire, 0.453″ opening, 81.2% OA), 3×3 Mesh (0.047″ wire, 0.286″ opening, 73.6% OA), 4×4 Mesh (multiple options: 0.032″ wire, 0.218″ opening, 76.0% OA; 0.047″ wire, 0.203″ opening, 65.9% OA; 0.063″ wire, 0.187″ opening, 56.0% OA), 6×6 Mesh (multiple options: 0.035″ wire, 0.132″ openin…

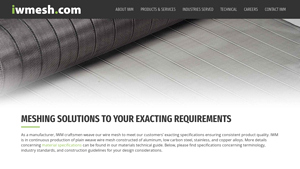

6. IWM – Fine Wire Woven Wire Mesh

Domain: iwmesh.com

Registered: 2015 (10 years)

Introduction: IWM offers fine wire woven wire mesh manufactured from aluminum, low carbon steel, stainless steel, and copper alloys. Key specifications include: 1. Mesh Count: Number of openings per linear inch, designated in both directions (e.g., 10 x 10 mesh). 2. Off-Count Mesh: Different number of openings per inch in each direction (e.g., 10 x 17 mesh). 3. Pitch: Sum of aperture size and wire diameter. 4. …

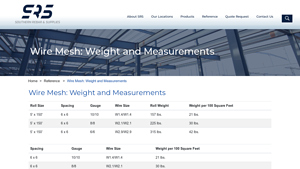

7. Southern Rebar – Welded Wire Fabric

Domain: southernrebar.com

Registered: 2018 (7 years)

Introduction: [{“Roll Size”:”5′ x 150′”,”Spacing”:”6 x 6″,”Gauge”:”10/10″,”Wire Size”:”W1.4/W1.4″,”Roll Weight”:”157 lbs.”,”Weight per 100 Square Feet”:”21 lbs.”},{“Roll Size”:”5′ x 150′”,”Spacing”:”6 x 6″,”Gauge”:”8/8″,”Wire Size”:”W2.1/W2.1″,”Roll Weight”:”225 lbs.”,”Weight per 100 Square Feet”:”30 lbs.”},{“Roll Size”:”5′ x 150′”,”Spacing”:”6 x 6″,”Gauge”:”6/6″,”Wire Size”:”W2.9/W2.9″,”Roll Weight”:”315 lbs.”…

8. Metals Depot – Welded Steel Wire Mesh

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Steel Wire Mesh – Welded & Woven

– Welded Steel Wire Mesh: Grid sheet formed by spot welding steel wires at intersections. Offers greater strength, versatility, and is more economical than woven mesh. Does not fray or unravel, stable and rigid, excellent aesthetic appearance. Suitable for security, cages, screens, fencing, sifting, filtering, machinery guards, enclosures, racking, shelving, and mo…

Strategic Sourcing Conclusion and Outlook for size wire mesh

In the competitive landscape of wire mesh sourcing, strategic procurement is essential for international buyers. Understanding the diverse applications, material types, and mesh specifications—such as gauge, mesh count, and dimensions—enables companies to select the most suitable products for their specific needs. Notably, different regions may have unique requirements; for instance, buyers from Saudi Arabia might prioritize corrosion-resistant options due to the climate, while those in Nigeria may focus on cost-effectiveness and durability.

Strategic sourcing not only enhances product quality but also fosters supplier relationships that can lead to better pricing and availability. As industries evolve, the demand for innovative wire mesh solutions is likely to grow, particularly in construction, agriculture, and manufacturing sectors.

Looking ahead, international buyers should actively engage with suppliers to understand emerging trends and technologies in wire mesh. Collaborating with manufacturers who offer customization options can provide a competitive edge in fulfilling specific project requirements. By prioritizing strategic sourcing now, businesses can position themselves for success in a dynamic market. Reach out to potential suppliers today to explore how tailored wire mesh solutions can drive your operations forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.