The Definitive Guide to Second Hand Car Wash Equipment: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for second hand car wash equipment

In today’s competitive landscape, sourcing second-hand car wash equipment presents both opportunities and challenges for international B2B buyers. With the growing demand for cost-effective solutions, businesses from Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Nigeria, are increasingly turning to pre-owned equipment to enhance their service offerings. However, navigating this global market can be daunting, especially when it comes to ensuring quality, compliance with local regulations, and obtaining reliable suppliers.

This comprehensive guide is designed to empower B2B buyers by delving into the intricacies of the second-hand car wash equipment market. It covers a wide array of topics, including the types of equipment available, their specific applications, supplier vetting processes, and cost considerations. By providing actionable insights and expert recommendations, this guide helps businesses make informed purchasing decisions that align with their operational needs and budgetary constraints.

Whether you’re seeking automatic systems, self-serve options, or specialized tools, understanding the nuances of the second-hand market is crucial. This guide serves as your roadmap to successfully navigate the complexities of sourcing used car wash equipment, ensuring that you can capitalize on opportunities while mitigating risks. With the right knowledge, you can enhance your business operations, improve customer satisfaction, and ultimately drive growth in your market.

Understanding second hand car wash equipment Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Car Wash Systems | Fully automated washing processes; includes drying and waxing options | High-traffic commercial car washes | Pros: Efficient and consistent; Cons: Higher initial cost and maintenance complexity. |

| Self-Serve Car Wash Equipment | Manual operation; customers control the wash process; typically lower investment | Small to medium-sized car wash businesses | Pros: Lower operational costs; Cons: Labor-intensive and variable service quality. |

| Touchless Wash Systems | High-pressure water jets and detergents; no physical brushes used | Urban areas with space constraints | Pros: Reduced risk of damage to vehicles; Cons: May require more water and chemicals. |

| Portable Car Wash Equipment | Compact units; often mobile; suitable for on-site services | Car detailing businesses and fleets | Pros: Versatile and easy to transport; Cons: Limited capacity compared to larger systems. |

| Tunnel Car Wash Systems | Continuous conveyor system; multiple wash stages; high capacity | Large-scale car wash operations | Pros: Fast processing and high throughput; Cons: Significant space and investment required. |

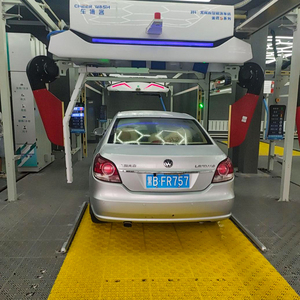

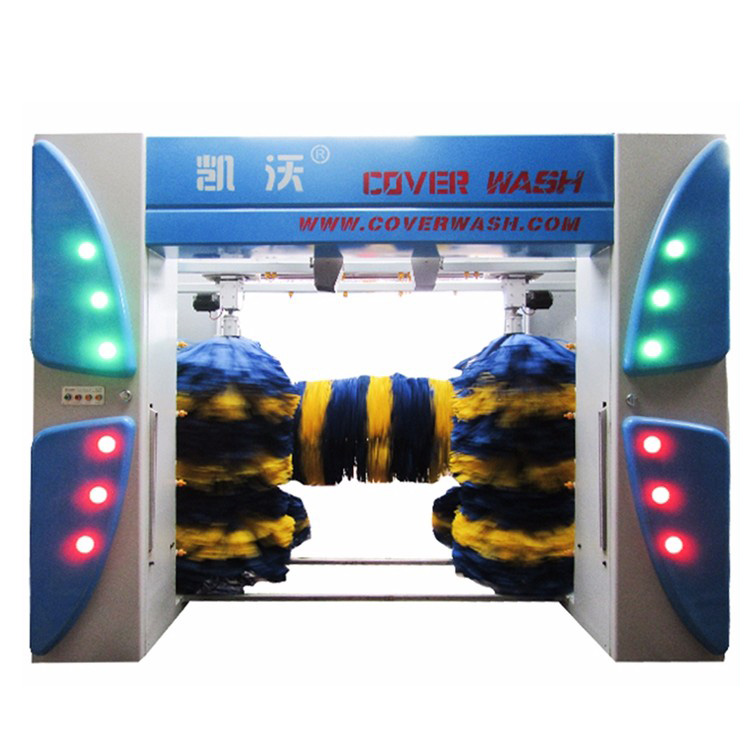

What are the characteristics of Automatic Car Wash Systems?

Automatic car wash systems are designed for high-volume operations, providing a fully automated wash experience that often includes drying, waxing, and additional detailing options. These systems are particularly suitable for commercial car washes in urban and suburban areas where efficiency is paramount. When considering an automatic system, B2B buyers should evaluate the equipment’s reliability, ease of maintenance, and available warranty options to ensure long-term profitability.

Illustrative image related to second hand car wash equipment

How does Self-Serve Car Wash Equipment benefit small businesses?

Self-serve car wash equipment allows customers to wash their vehicles independently, offering a cost-effective solution for small to medium-sized car wash businesses. This type of equipment typically requires a lower initial investment and operational costs compared to automatic systems. B2B buyers should assess the location’s traffic patterns and customer demographics, as well as the potential for upselling services like detailing or vacuuming to enhance revenue.

What makes Touchless Wash Systems unique?

Touchless wash systems utilize high-pressure water jets and specialized detergents to clean vehicles without physical contact. This feature minimizes the risk of scratches and damage, making it ideal for high-end vehicles. B2B buyers should consider the system’s water and chemical usage, as well as its effectiveness in various weather conditions. Understanding customer preferences in their target market can also guide purchasing decisions.

Why choose Portable Car Wash Equipment for on-site services?

Portable car wash equipment offers flexibility and convenience, allowing businesses to provide services at various locations, such as residential areas or corporate fleets. This mobility is particularly advantageous for detailing businesses that want to reach customers directly. Buyers should evaluate the equipment’s ease of transport, setup time, and capacity to ensure it meets their operational needs.

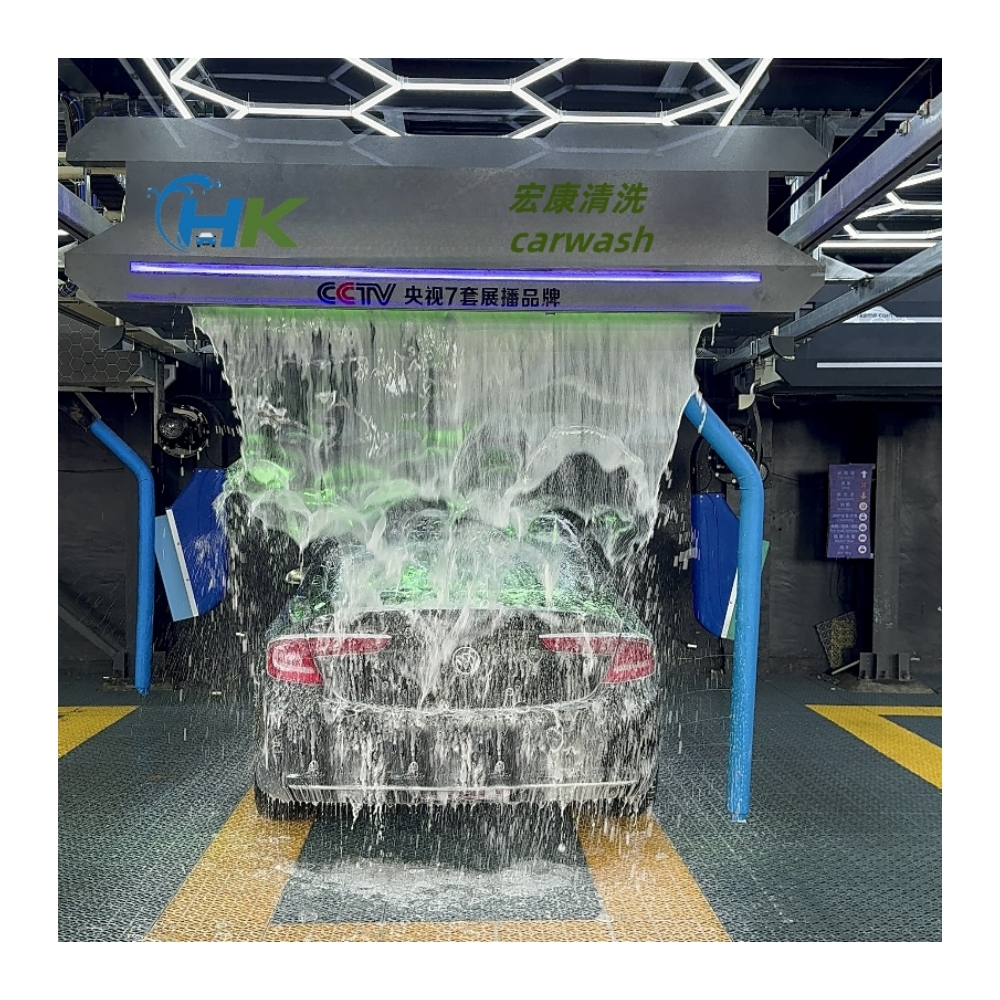

What are the advantages of Tunnel Car Wash Systems?

Tunnel car wash systems are designed for high throughput, allowing multiple vehicles to be washed simultaneously through a conveyor belt. This efficiency makes them suitable for large-scale operations that cater to high traffic volumes. B2B buyers must consider the significant investment required for installation and maintenance, as well as the space needed to accommodate the system. Understanding local market demand can help justify the investment.

Illustrative image related to second hand car wash equipment

Key Industrial Applications of second hand car wash equipment

| Industry/Sector | Specific Application of second hand car wash equipment | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Dealerships | In-house car wash facilities using used equipment | Enhances customer satisfaction and retention | Equipment condition, compatibility with existing systems |

| Fleet Management Companies | High-volume washing solutions for commercial fleets | Reduces operational costs and improves fleet appearance | Reliability, maintenance history, parts availability |

| Car Rental Services | Automated car wash stations for quick turnarounds | Increases efficiency and reduces labor costs | Speed of service, ease of installation, training needs |

| Roadside Service Stations | Self-service wash bays for travelers | Attracts customers and generates additional revenue | Location suitability, space requirements, local demand |

| Car Wash Franchises | Expansion of service offerings with cost-effective options | Diversifies service portfolio and appeals to more customers | Brand reputation, warranty options, resale value |

How Can Automotive Dealerships Benefit from Second Hand Car Wash Equipment?

Automotive dealerships can significantly enhance their customer experience by integrating second hand car wash equipment into their service offerings. This equipment allows dealerships to provide complimentary car washes, improving customer satisfaction and loyalty. When sourcing, dealerships should focus on the condition of the equipment and its compatibility with existing systems to ensure seamless integration into their operations.

What Advantages Do Fleet Management Companies Gain from Used Car Wash Equipment?

Fleet management companies often face the challenge of maintaining a clean and presentable fleet while controlling costs. Utilizing second hand car wash equipment enables these companies to implement high-volume washing solutions that can reduce labor and operational costs. Buyers should prioritize the reliability and maintenance history of the equipment, ensuring it can withstand the demands of frequent use.

How Do Car Rental Services Benefit from Automated Wash Stations?

Car rental services can greatly improve operational efficiency by installing automated car wash stations. Second hand equipment provides a cost-effective way to ensure vehicles are cleaned quickly between rentals, enhancing customer satisfaction. When sourcing, companies must consider the speed of service offered by the equipment and any necessary training for staff to operate it effectively.

Illustrative image related to second hand car wash equipment

What Value Do Roadside Service Stations Find in Self-Service Wash Bays?

Roadside service stations can attract more customers by offering self-service wash bays equipped with second hand car wash equipment. This not only generates additional revenue but also enhances the overall customer experience. Key considerations for sourcing include the suitability of the equipment for the location and the space available for installation, ensuring it meets local demand.

How Can Car Wash Franchises Expand Their Services with Second Hand Equipment?

Car wash franchises looking to diversify their service offerings can benefit from incorporating second hand car wash equipment. This approach allows them to expand their capabilities without the high costs associated with new machinery. When sourcing, franchises should evaluate the brand reputation of the equipment and consider warranty options to protect their investment while maximizing potential resale value.

3 Common User Pain Points for ‘second hand car wash equipment’ & Their Solutions

Scenario 1: Difficulty in Assessing Equipment Condition Before Purchase

The Problem: One of the primary challenges faced by B2B buyers of second-hand car wash equipment is accurately assessing the condition of the equipment before making a purchase. Buyers may encounter discrepancies between the seller’s descriptions and the actual state of the machinery, leading to unexpected repair costs or operational inefficiencies. This issue is particularly pronounced in international transactions, where buyers cannot physically inspect the equipment, making them reliant on photos and descriptions that may not convey the full picture.

The Solution: To mitigate this risk, buyers should insist on comprehensive documentation and third-party evaluations. Before finalizing a purchase, request detailed maintenance records, operational history, and a list of any repairs performed. Additionally, consider hiring a local expert to conduct an inspection if feasible. For international buyers, utilizing video calls to have sellers demonstrate the equipment in real-time can provide an added layer of assurance. Employing a standardized checklist during these evaluations can help ensure that all essential components are assessed, such as pumps, motors, and electrical systems. By being proactive in verification, buyers can significantly reduce the likelihood of purchasing equipment that requires extensive repairs or is not fit for purpose.

Scenario 2: Navigating Limited Warranty and Support Options

The Problem: Another common pain point for B2B buyers in the second-hand car wash equipment market is the lack of warranty and after-sale support. Unlike new equipment, which typically comes with robust warranties and manufacturer support, second-hand purchases often have limited or no warranty coverage. This situation can lead to significant financial strain if the equipment fails shortly after purchase, leaving buyers with little recourse for repair or replacement.

The Solution: To navigate this challenge, buyers should prioritize sourcing equipment from reputable dealers who offer at least a limited warranty or guarantee on their products. Additionally, it is advisable to negotiate the terms of the sale to include some form of after-sale support, such as access to technical assistance or discounted parts. Buyers can also join industry groups or forums where they can connect with other car wash operators who can recommend trustworthy suppliers. By establishing relationships with equipment dealers and service providers, buyers can create a support network that may help mitigate risks associated with warranty and service issues.

Illustrative image related to second hand car wash equipment

Scenario 3: Integrating Used Equipment with Existing Systems

The Problem: B2B buyers often face compatibility issues when integrating second-hand car wash equipment with their existing systems. Different brands and models may have unique specifications, making it challenging to ensure seamless operation without significant modifications. This challenge can lead to extended downtime and increased costs associated with retrofitting or acquiring additional components.

The Solution: To address this problem, buyers should conduct thorough compatibility assessments before purchasing second-hand equipment. This involves reviewing the technical specifications of both the existing systems and the prospective equipment to identify any potential conflicts. It is crucial to consult with technical experts who can provide insights into the integration process. Additionally, buyers should consider investing in modular equipment that allows for easier upgrades or replacements of individual components rather than entire systems. Establishing a clear plan for integration, including timelines and budget considerations, can help streamline the process and minimize operational disruptions. By taking these proactive steps, buyers can enhance their chances of successfully integrating second-hand equipment into their car wash operations.

Strategic Material Selection Guide for second hand car wash equipment

When selecting second-hand car wash equipment, the choice of materials plays a crucial role in determining the longevity, efficiency, and overall performance of the equipment. Here, we analyze four common materials used in car wash equipment, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to second hand car wash equipment

What are the Key Properties of Stainless Steel in Car Wash Equipment?

Stainless steel is a popular choice for various components in car wash systems due to its exceptional corrosion resistance and durability. It can withstand high-pressure applications and extreme temperatures, making it suitable for both hot water and chemical exposure. Stainless steel is also easy to clean and maintain, which is essential in a car wash environment where hygiene is paramount.

Pros & Cons: The primary advantage of stainless steel is its long lifespan, which can significantly reduce replacement costs over time. However, it is more expensive than other materials like plastic or mild steel, which may deter budget-conscious buyers. Additionally, the manufacturing complexity can increase the initial costs.

Impact on Application: Stainless steel’s compatibility with various cleaning agents ensures that it does not degrade over time, maintaining the performance of the equipment. For international buyers, compliance with standards such as ASTM and DIN is essential, particularly in regions with stringent regulations regarding material safety and environmental impact.

How Does Polypropylene Benefit Car Wash Equipment?

Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and lightweight properties. It is often used in components such as water tanks, hoses, and fittings within car wash systems. Polypropylene can handle a range of temperatures and is resistant to various cleaning chemicals, making it suitable for diverse applications.

Pros & Cons: The main advantage of polypropylene is its lower cost compared to metals, making it an attractive option for budget-sensitive buyers. However, its durability is less than that of stainless steel, and it may become brittle over time when exposed to UV light, which can be a concern in sunny regions like Africa and South America.

Impact on Application: Polypropylene is compatible with most cleaning agents, but buyers should ensure that the specific chemicals used do not exceed the material’s temperature and pressure ratings. International buyers should be aware of local regulations regarding plastic materials, as some regions may have restrictions on certain types of plastics.

What are the Advantages of Aluminum in Car Wash Equipment?

Aluminum is another material frequently used in car wash equipment, particularly for structural components and frames. It is lightweight yet strong, allowing for easy installation and maintenance. Aluminum also exhibits good corrosion resistance, especially when anodized.

Illustrative image related to second hand car wash equipment

Pros & Cons: The key advantage of aluminum is its weight, which can reduce shipping costs and make installation easier. However, it is generally less durable than stainless steel and may require more frequent replacements in harsh environments, increasing long-term costs.

Impact on Application: Aluminum’s compatibility with various cleaning agents is generally good, but care should be taken with acidic or alkaline solutions that may cause corrosion over time. For international buyers, understanding the local climate and its impact on aluminum’s performance is crucial, especially in regions with high humidity or saline conditions.

Why is Rubber Important in Car Wash Equipment?

Rubber is commonly used in seals, hoses, and gaskets within car wash systems. Its flexibility and resilience make it an ideal material for components that require a tight seal to prevent leaks and maintain pressure.

Illustrative image related to second hand car wash equipment

Pros & Cons: The primary advantage of rubber is its ability to withstand a range of temperatures and pressures while providing excellent sealing capabilities. However, rubber can degrade over time due to exposure to UV light and certain chemicals, necessitating regular inspections and replacements.

Impact on Application: Rubber’s compatibility with various cleaning agents is generally favorable, but buyers should confirm that the specific rubber compounds used are suitable for the chemicals in their cleaning processes. International buyers should also consider the availability of replacement parts in their region, as sourcing specific rubber components can be challenging in some markets.

Summary Table of Material Selection for Second-Hand Car Wash Equipment

| Material | Typical Use Case for second hand car wash equipment | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, tanks, and frames | Exceptional durability and corrosion resistance | Higher initial cost | High |

| Polypropylene | Water tanks, hoses, and fittings | Cost-effective and lightweight | Less durable, can become brittle | Low |

| Aluminum | Frames and structural components | Lightweight and easy to install | Less durable than stainless steel | Medium |

| Rubber | Seals, hoses, and gaskets | Excellent sealing capabilities | Degrades over time with exposure | Low |

This guide aims to assist B2B buyers in making informed decisions regarding material selection for second-hand car wash equipment, ensuring optimal performance and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for second hand car wash equipment

What Are the Key Stages in the Manufacturing Process of Second Hand Car Wash Equipment?

The manufacturing process for second hand car wash equipment involves several critical stages that ensure the equipment is reliable and performs efficiently. Understanding these stages is essential for B2B buyers looking to purchase used equipment, as it helps assess the quality and longevity of the machinery.

-

Material Preparation: This initial stage involves sourcing high-quality materials such as stainless steel, plastics, and other durable components. Suppliers often work with certified vendors to ensure that the materials meet industry standards. A thorough inspection of incoming materials is crucial, as it sets the foundation for the entire manufacturing process.

-

Forming: Once materials are prepared, they undergo various forming techniques such as bending, cutting, and stamping. For car wash equipment, this may include shaping metal frames for the washing bays, manufacturing spray arms, and creating structural components. Advanced techniques like laser cutting and CNC machining are frequently used to achieve precision and reduce waste.

-

Assembly: The assembly stage brings together all components into a functional unit. This process typically involves multiple workers or automated systems that fit parts together, ensuring that each component aligns correctly. Quality checks are often integrated into this stage to catch any discrepancies early.

-

Finishing: After assembly, the equipment undergoes finishing processes such as painting, coating, or polishing to enhance aesthetics and protect against corrosion. For example, many car wash systems are coated with a protective layer to withstand harsh chemicals and environmental conditions. This stage is vital, especially for used equipment, as it can significantly affect the machine’s lifespan and performance.

What International Standards Should B2B Buyers Consider for Quality Assurance?

When purchasing second hand car wash equipment, international quality standards and certifications play a crucial role in ensuring reliability and safety. Some key standards include:

-

ISO 9001: This is a globally recognized standard for quality management systems (QMS). It ensures that manufacturers consistently meet customer and regulatory requirements, providing a framework for continuous improvement. Buyers should verify that the manufacturer is ISO 9001 certified, as this indicates a commitment to quality.

-

CE Marking: In the European market, products must comply with CE marking requirements to demonstrate conformity with health, safety, and environmental protection standards. Equipment bearing this mark signifies that it meets European Union regulations, which is particularly important for buyers in Europe.

-

API Standards: For specific equipment types, particularly those involving pumps and fluid management, the American Petroleum Institute (API) provides standards that ensure quality and reliability. Equipment meeting API standards is often more trusted, especially in regions with stringent regulatory frameworks.

How Are Quality Control Checkpoints Implemented in Manufacturing?

Quality control (QC) is integral to the manufacturing process of second hand car wash equipment. Several checkpoints are typically employed:

-

Incoming Quality Control (IQC): This checkpoint occurs upon the arrival of raw materials. Inspectors assess materials against specifications to ensure they meet required standards before production begins. This is essential for preventing defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves monitoring production activities. This can include checks at various stages, such as verifying the accuracy of machine settings during the forming phase and ensuring proper assembly techniques are followed. Regular monitoring helps identify issues before they escalate.

-

Final Quality Control (FQC): After assembly and finishing, FQC involves a comprehensive inspection of the entire equipment. This may include performance tests, safety checks, and visual inspections. Equipment must meet all functional requirements before being deemed ready for sale.

What Common Testing Methods Are Used to Ensure Equipment Reliability?

Testing methods for car wash equipment can vary based on the specific components involved. Common testing procedures include:

-

Performance Testing: This evaluates how well the equipment operates under normal conditions. For instance, automatic washers may be tested for water pressure, spray patterns, and drying capabilities.

-

Durability Testing: Used to assess the longevity of equipment, this testing simulates long-term usage to identify potential failure points. It often includes running the equipment through cycles that mimic real-world usage.

-

Safety Testing: Ensures that all safety features function correctly. This may involve checking electrical systems, emergency shut-off mechanisms, and other critical safety components.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure they are sourcing high-quality second hand car wash equipment, B2B buyers should take several steps to verify supplier QC practices:

-

Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should request to see audit reports or certifications that demonstrate compliance with international standards.

-

Quality Reports: Suppliers should provide documentation detailing their quality control processes, including the frequency of inspections and testing methods employed. Buyers can use this information to gauge the reliability of the equipment they are considering.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the equipment’s condition and the manufacturer’s quality practices. This is especially important for international buyers who may not be able to visit the manufacturing site.

What QC and Certification Nuances Should International Buyers Be Aware Of?

International B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should consider several nuances regarding QC and certification:

Illustrative image related to second hand car wash equipment

-

Regional Regulations: Different regions have specific regulations that may affect the certification process. For example, equipment sold in the EU must comply with CE standards, while buyers in Africa may need to consider local compliance certifications.

-

Import Standards: When importing used equipment, understanding the import regulations of the destination country is vital. Some countries may have restrictions on the age or condition of used machinery, affecting what can be legally imported.

-

Documentation Requirements: Ensure that all necessary documentation, including proof of certification and inspection reports, accompanies the equipment. This not only facilitates smoother customs clearance but also serves as evidence of quality assurance.

By understanding the manufacturing processes and quality assurance standards associated with second hand car wash equipment, B2B buyers can make informed decisions that enhance their operational efficiency and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘second hand car wash equipment’

To facilitate a successful procurement process for second-hand car wash equipment, this guide provides a structured checklist. Following these steps will help B2B buyers make informed decisions, minimize risks, and ensure they acquire equipment that meets their operational needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing equipment, it’s essential to outline your specific requirements. Determine the type of car wash system you need—whether it’s automatic, self-serve, or a combination of both. Consider the volume of cars you expect to wash and the features that are critical for your operations, such as water recycling capabilities, payment systems, and the types of wash options available.

Illustrative image related to second hand car wash equipment

Step 2: Research Available Equipment

Utilize reputable online marketplaces and forums dedicated to car wash equipment to identify available options. Websites like Car Wash Consignment and specialized Facebook groups are valuable resources. Pay attention to product details, including age, condition, and any service history provided by sellers, which can give insight into the equipment’s reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet potential suppliers thoroughly. Request company profiles, case studies, and references from previous buyers who have purchased similar equipment. Ensure the supplier has a solid reputation and experience in the car wash industry to mitigate risks associated with equipment quality and support.

Step 4: Inspect Equipment Thoroughly

Whenever possible, arrange for an on-site inspection of the equipment. Look for signs of wear and tear, and verify that all components are functioning correctly. Check for any missing parts or damage that could affect the performance. If an on-site visit isn’t feasible, request detailed photos and videos demonstrating the equipment in operation.

Step 5: Assess Warranty and After-Sales Support

Inquire about warranty options and the availability of after-sales support. A good warranty can provide peace of mind, covering potential repairs or replacements. Additionally, understanding the supplier’s customer service responsiveness will help you gauge how well they support their products post-sale.

Step 6: Negotiate Pricing and Terms

Once you have identified the right equipment and supplier, engage in negotiation regarding pricing and payment terms. Be clear about your budget and seek a deal that reflects the equipment’s value and condition. Consider including terms for delivery and installation, which can significantly affect your overall cost.

Step 7: Finalize the Purchase and Logistics

After reaching an agreement, ensure all terms are documented in a formal contract. Review the logistics of the equipment transfer, including shipping methods and timelines. Confirm that the supplier is responsible for any necessary transportation arrangements and discuss how the equipment will be unpacked and set up at your location.

By following this checklist, B2B buyers can navigate the complexities of sourcing second-hand car wash equipment more effectively, ensuring they make informed decisions that align with their operational goals.

Comprehensive Cost and Pricing Analysis for second hand car wash equipment Sourcing

When sourcing second-hand car wash equipment, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will help you navigate the complexities of procurement, especially in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Second-Hand Car Wash Equipment?

The cost of second-hand car wash equipment can be dissected into several core components:

-

Materials: The base materials of the equipment, such as stainless steel and plastics, significantly influence pricing. Equipment made from durable materials often commands higher prices due to longevity and resistance to wear.

-

Labor: Labor costs associated with refurbishment or maintenance can impact the final price. Equipment that has been professionally serviced will typically be priced higher than units that show signs of neglect.

-

Manufacturing Overhead: This includes the costs incurred in the production of the equipment, which can vary widely based on the brand and the technology used. Established brands with advanced technology may carry a premium.

-

Tooling and Quality Control (QC): The investment in tooling for production and the rigorous QC processes can also add to the cost. Equipment from brands known for stringent QC standards often reflects this in the pricing.

-

Logistics: Shipping and handling costs can be significant, particularly for international buyers. Factors like distance, shipping method, and the need for specialized transport can all affect overall expenses.

-

Margin: The profit margin set by sellers can vary based on market demand and the condition of the equipment. Sellers may adjust their margins based on how quickly they want to sell.

What Influences the Pricing of Second-Hand Car Wash Equipment?

Pricing is not static and can be influenced by various factors:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases may allow buyers to negotiate better pricing. Suppliers often offer discounts for larger orders, which can be beneficial for businesses looking to expand.

-

Specifications and Customization: Equipment with advanced features or customizations typically carries a higher price tag. Buyers should assess their needs to avoid overpaying for unnecessary features.

-

Quality and Certifications: Equipment that comes with certifications or has been validated for compliance with industry standards may justify higher prices. Buyers should consider the long-term benefits of investing in certified equipment.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers with positive reviews may charge a premium, but they often provide better customer support and warranties.

-

Incoterms: Understanding shipping terms can help avoid unexpected costs. Buyers should clarify who is responsible for shipping costs, insurance, and duties to better estimate total expenses.

What Are the Best Negotiation Tips for International B2B Buyers?

Effective negotiation strategies can lead to significant savings:

-

Do Your Research: Gather information on market prices for similar equipment to have a baseline for negotiation. Websites like Car Wash Consignment can provide insights into current market trends.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and potential downtime. A cheaper machine might end up costing more in the long run.

-

Be Open to Compromise: Negotiation can involve give-and-take. Being flexible on payment terms or delivery times may help you secure a better price.

-

Leverage Currency Fluctuations: For international transactions, being aware of currency trends can assist in timing your purchase to maximize savings.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers should be mindful of specific pricing nuances:

-

Local Market Conditions: Prices may vary significantly based on local demand and economic conditions. Understanding regional market trends can provide leverage in negotiations.

-

Import Duties and Taxes: Be aware of potential import duties and taxes that can add to the overall cost. Researching these aspects beforehand can prevent surprises during the purchasing process.

-

Cultural Considerations: Different regions may have varying expectations regarding negotiation styles and pricing practices. Understanding these cultural nuances can enhance buyer-supplier relationships.

Disclaimer on Indicative Prices

The prices mentioned in various listings are indicative and subject to change based on market dynamics, equipment condition, and seller discretion. It’s advisable to confirm current prices and availability directly with the seller before making any commitments.

Illustrative image related to second hand car wash equipment

Alternatives Analysis: Comparing second hand car wash equipment With Other Solutions

In the competitive landscape of car wash solutions, businesses often explore various options to meet their operational needs effectively. While second-hand car wash equipment can be a cost-efficient choice, several alternative technologies and methods are also available. This analysis compares second-hand equipment against two viable alternatives: mobile car wash services and fully automated car wash systems.

| Comparison Aspect | Second Hand Car Wash Equipment | Mobile Car Wash Services | Fully Automated Car Wash Systems |

|---|---|---|---|

| Performance | Varies by model and condition | Good, but depends on staff skill | Consistent high-quality wash |

| Cost | Lower initial investment | Variable, often higher due to labor costs | Higher upfront costs, but lower long-term operational costs |

| Ease of Implementation | Requires installation and setup | Minimal setup required, service-oriented | Requires infrastructure setup and maintenance |

| Maintenance | Can be higher due to age | Low, as the provider handles maintenance | Moderate, with regular servicing needed |

| Best Use Case | Established businesses looking to save costs | Flexible options for new businesses or mobile operations | High-traffic locations needing efficiency and volume |

What Are the Benefits and Drawbacks of Mobile Car Wash Services?

Mobile car wash services present a flexible alternative to traditional car wash methods. These services typically operate with a smaller footprint and can be deployed in various locations, allowing businesses to reach clients directly. One of the main advantages is the reduced need for physical infrastructure, which can lower initial investment costs. However, the reliance on skilled labor may lead to inconsistent performance, and the costs can accumulate over time, especially in high-demand areas.

How Do Fully Automated Car Wash Systems Compare?

Fully automated car wash systems provide a cutting-edge solution for businesses looking to streamline operations. These systems offer consistent, high-quality washes with minimal human intervention, significantly improving efficiency and customer satisfaction. While the initial investment can be considerable, the long-term operational costs often balance out due to lower labor expenses. However, these systems require substantial space and infrastructure, which may not be feasible for all businesses, especially startups or those in less developed markets.

Conclusion: Which Car Wash Solution Is Right for Your Business?

When choosing between second-hand car wash equipment, mobile car wash services, and fully automated systems, B2B buyers should consider their specific needs, budget constraints, and operational capacity. For those with limited capital and existing infrastructure, second-hand equipment can provide a practical entry point. Conversely, businesses aiming for flexibility and customer reach may benefit more from mobile services, while high-volume operators might find fully automated systems to be the most efficient long-term solution. Ultimately, evaluating these alternatives through the lens of performance, cost, ease of implementation, maintenance, and best use case will enable buyers to make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for second hand car wash equipment

What Are the Key Technical Properties of Second Hand Car Wash Equipment?

When purchasing second-hand car wash equipment, understanding its technical specifications is crucial for making informed decisions. Here are some essential technical properties to consider:

-

Material Grade

The material grade refers to the quality of materials used in the construction of car wash equipment. Common materials include stainless steel, aluminum, and high-density polyethylene (HDPE). Higher-grade materials often provide better durability and resistance to corrosion, which is vital for equipment exposed to water and cleaning chemicals. This is particularly important in regions with high humidity or saline environments, like coastal areas in Africa and South America. -

Operating Pressure

Operating pressure is a critical specification that indicates the force at which water is delivered through the system. It is typically measured in pounds per square inch (PSI). For instance, a pressure of 1500-3000 PSI is common for effective vehicle cleaning. Understanding the operating pressure helps buyers ensure that the equipment meets their cleaning requirements and can handle the demands of their customer base. -

Flow Rate

The flow rate refers to the volume of water the equipment can process in a given time, usually measured in gallons per minute (GPM). A higher flow rate results in quicker wash cycles, which can lead to increased throughput and revenue. For B2B buyers, evaluating the flow rate is essential for assessing the operational efficiency of the car wash equipment. -

Wash Cycle Time

This property specifies the duration of the entire washing process. It varies depending on the type of equipment, with automatic systems generally providing faster wash cycles compared to manual setups. A shorter wash cycle can enhance customer satisfaction and allow for more vehicles to be washed in less time, which is a significant factor for profitability. -

Maintenance History

The maintenance history of second-hand equipment is crucial for evaluating its reliability and longevity. Equipment that has been well-maintained typically has a longer lifespan and requires fewer repairs. Buyers should request documentation of past maintenance, including any parts replaced and service logs, to understand the equipment’s condition better.

What Are Common Trade Terms in the Second Hand Car Wash Equipment Industry?

Understanding industry jargon is equally important for navigating the purchase of second-hand car wash equipment. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to the original manufacturer of a product or its parts. In the context of car wash equipment, knowing whether a component is OEM or aftermarket can impact the quality and compatibility of repairs or replacements. OEM parts are often preferred for their guaranteed fit and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the context of equipment parts or consumables, understanding MOQ helps buyers plan their purchasing strategy and manage inventory efficiently. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for a specific quantity of goods or services. For B2B buyers, issuing an RFQ can help compare offers from multiple suppliers, ensuring competitive pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international shipping terms that clarify the responsibilities of buyers and sellers. Familiarity with Incoterms like CIF (Cost, Insurance, and Freight) or FOB (Free on Board) helps buyers understand shipping costs and logistics, which is critical when importing equipment from different regions. -

Refurbished Equipment

This term refers to pre-owned equipment that has been restored to a working condition, often through repairs and updates. Buyers should inquire about the extent of refurbishment to ensure that the equipment meets their operational standards. -

Turnkey Solution

A turnkey solution refers to equipment or a system that is fully operational upon installation. This is particularly appealing for B2B buyers who want to minimize setup time and start operations quickly.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when purchasing second-hand car wash equipment, ensuring they invest in reliable and efficient solutions for their business needs.

Navigating Market Dynamics and Sourcing Trends in the second hand car wash equipment Sector

What are the Key Trends Shaping the Second-Hand Car Wash Equipment Market?

The second-hand car wash equipment market is experiencing a dynamic shift driven by several global factors. Increasing environmental awareness and the push for sustainability have prompted car wash businesses to seek more cost-effective and eco-friendly solutions. In regions such as Africa and South America, where capital for new equipment may be limited, the demand for second-hand machinery is on the rise. Furthermore, as new technologies emerge, businesses are looking to upgrade their services without the financial burden of purchasing brand-new equipment. This has led to a flourishing online marketplace, where platforms specializing in used car wash equipment offer a wide range of options from automatic systems to ancillary components.

International B2B buyers are also witnessing a trend towards digital sourcing platforms. Buyers from the Middle East and Europe are increasingly utilizing online consignment websites and social media marketplaces to find high-quality used equipment at competitive prices. Additionally, the integration of advanced features, such as RFID payment systems and automated wash processes, is becoming common even in second-hand offerings, enhancing operational efficiency and customer satisfaction.

Illustrative image related to second hand car wash equipment

How is Sustainability Influencing the Sourcing of Second-Hand Car Wash Equipment?

Sustainability has become a cornerstone of business practices, impacting sourcing decisions in the second-hand car wash equipment sector. As environmental regulations tighten globally, the focus on reducing waste and extending the lifecycle of equipment has gained traction. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability, looking for equipment that incorporates eco-friendly technologies and materials.

The importance of ethical sourcing cannot be overstated. International buyers are now more conscious of the environmental impact of their purchases, opting for equipment that is not only cost-effective but also contributes to their sustainability goals. Certifications like ISO 14001 for environmental management systems are becoming key considerations during the procurement process. Furthermore, businesses are encouraged to conduct due diligence to ensure that their suppliers uphold ethical standards, thereby promoting a responsible supply chain that minimizes environmental harm.

What is the Historical Context of Second-Hand Car Wash Equipment in B2B Markets?

The evolution of the second-hand car wash equipment market can be traced back to the early days of the car wash industry when businesses relied heavily on manual systems. As technology advanced, the introduction of automated washing systems revolutionized the market, leading to a surge in demand for both new and used equipment. Over the years, the market has matured, with a growing recognition of the value of refurbished equipment that meets modern standards without the hefty price tag.

In recent years, the rise of online marketplaces has transformed how B2B buyers interact with sellers, facilitating easier access to used equipment across geographical boundaries. This shift not only enhances the purchasing experience but also contributes to a more sustainable approach by encouraging the reuse and recycling of machinery. As the market continues to evolve, the interplay between technology, sustainability, and cost-effectiveness will remain central to the sourcing strategies of international buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of second hand car wash equipment

-

1. How do I ensure the quality of second hand car wash equipment before purchasing?

To ensure the quality of second hand car wash equipment, it is vital to request detailed maintenance records and inspection reports from the seller. Conduct a thorough physical inspection, ideally with a qualified technician, to assess the condition of the equipment. Additionally, ask for operational videos or demonstrations to see the equipment in action. Verify the seller’s reputation through reviews or testimonials from previous buyers to mitigate risks associated with the purchase. -

2. What is the best platform for sourcing second hand car wash equipment internationally?

The best platforms for sourcing second hand car wash equipment include specialized websites like Car Wash Consignment and forums such as Car Wash Forum. Additionally, Facebook Marketplace and dedicated groups like TalkCarwash offer a wide range of listings. Evaluate each platform’s credibility by checking seller ratings and feedback, and consider using platforms that provide buyer protection or escrow services for added security. -

3. How can I customize second hand car wash equipment to meet my specific needs?

Customization options for second hand car wash equipment depend on the type of equipment and the seller’s flexibility. Communicate your specific requirements to the seller and inquire about the possibility of modifications, such as upgrades to software or changes in configuration. Some suppliers may also offer retrofitting services or assist in sourcing additional components to tailor the equipment to your operational needs. -

4. What are the typical minimum order quantities (MOQs) for second hand car wash equipment?

Minimum order quantities (MOQs) for second hand car wash equipment can vary significantly based on the supplier and the type of equipment. Generally, individual pieces of equipment may not have an MOQ, while bulk purchases may be encouraged with discounts. Always clarify MOQs with the supplier upfront and negotiate terms that suit your purchasing capabilities, especially when sourcing internationally. -

5. What payment terms should I expect when buying second hand car wash equipment?

Payment terms for second hand car wash equipment can vary widely. Common practices include full payment upfront, a deposit with the balance due upon delivery, or payment via letters of credit for international transactions. Always negotiate payment terms that protect your interests, and consider using secure payment methods or escrow services to mitigate risks, especially when dealing with unfamiliar suppliers. -

6. How do I handle logistics and shipping for international purchases of car wash equipment?

Handling logistics for international purchases involves coordinating with freight forwarders who specialize in heavy equipment transport. Confirm shipping costs, delivery timelines, and insurance coverage with the seller. Ensure all necessary customs documentation is prepared to avoid delays at border crossings. It’s advisable to track shipments closely and communicate with logistics partners to address any issues that may arise during transit. -

7. What should I include in my supplier vetting process for second hand car wash equipment?

A thorough supplier vetting process should include verifying the supplier’s business credentials, checking for industry certifications, and assessing their experience in the car wash equipment market. Request references from previous clients and evaluate their responsiveness and professionalism in communication. Additionally, consider visiting the supplier’s facility if possible to inspect equipment and confirm their operational standards. -

8. Are there warranties or guarantees available for second hand car wash equipment?

Warranties or guarantees for second hand car wash equipment can vary by seller. Some may offer limited warranties on specific components, while others may provide “as-is” sales without any guarantees. Always inquire about warranty terms before purchasing, and consider negotiating warranty coverage as part of the deal to protect your investment. Understanding the warranty policy will help you manage potential repair costs and equipment reliability.

Top 6 Second Hand Car Wash Equipment Manufacturers & Suppliers List

1. Car Wash Consignment – Key Products

Domain: carwashconsignment.com

Registered: 2000 (25 years)

Introduction: Key products for sale include: 1. Super Wash – 3 Bay Self Serve Pumps & 2 Automatic pumps, priced at $12,000 (Product # 5713). 2. McNeil Tunnel with Sonny’s Dryers – 2021, priced at $9,000 (Product # 5657). 3. Complete McNeil Tunnel 2021 Sonny’s Dryer System, includes various McNeil components. 4. DRB – Unitec Portal TI+ – 2025, priced at $29,760 (Product # 5653), brand new, includes RFID and paym…

2. Facebook – Used Car Wash Equipment Marketplace

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Used Car Wash Equipment Marketplace, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. eBay – Car Wash Equipment

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Car Wash Equipment available on eBay includes various items such as:

– High Pressure Washer Jet Water Wash Cleaner Gun (360 l/h) – Brand New, $76.46, Free delivery

– DOCA Car Wash Equipment with options like Mop and 30 Ft Car Wash Brush – Brand New, $14.92, Free delivery

– High Pressure Side Blaster with Blastec Hydraflex nozzles – Brand New, $1,495.00 or Best Offer, +$67.35 delivery

– Car Wash Br…

4. IQS Directory – Used Car Wash Equipment

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Used car wash equipment includes a variety of systems and components such as:

– Touchless car washing systems

– Hand car wash equipment

– Mobile car wash equipment

– Tunnel systems and conveyorized setups

– Drying units

– Chemical applicators

– Finishing solutions

– Blowers

– Vacuums

– Motors

– Air compressors

– Light bars

– Pressure sprayers

– Cloth brushes

– Sensory digital control systems

– Tra…

5. Oasis – Pre-Owned Refurbished Car Wash Equipment

Domain: oasiscarwashsystems.com

Registered: 1998 (27 years)

Introduction: Pre-Owned Factory Refurbished Equipment from Oasis Car Wash Systems includes units that are refurbished to be ‘good as new’ and come with a factory warranty. These units are available at a lower cost compared to new ones and are updated frequently for availability. Interested customers are encouraged to contact Curtis Wade for more details.

6. Car Wash Forum – Used Equipment Marketplace

Domain: carwashforum.com

Registered: 1996 (29 years)

Introduction: Best sites to buy used car wash equipment include Car Wash Consignment, Facebook Marketplace, TalkCarwash Marketplace, and Car Wash Equipment – Buy*Sell*Trade. TalkCarwash Marketplace has 5,100 members, while Car Wash Equipment – Buy*Sell*Trade has 7,300 members. Users are encouraged to check multiple platforms, including forums and eBay, for specific equipment.

Strategic Sourcing Conclusion and Outlook for second hand car wash equipment

In the competitive landscape of car wash services, sourcing second-hand equipment can provide substantial cost savings and operational advantages. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize strategic sourcing to ensure they acquire reliable, well-maintained equipment that meets their specific operational needs. Engaging with platforms like Car Wash Consignment and leveraging social media groups can enhance visibility into available options, facilitating informed purchasing decisions.

When evaluating second-hand equipment, it’s essential to consider the equipment’s maintenance history, operational efficiency, and compatibility with existing systems. By focusing on these criteria, B2B buyers can mitigate risks and maximize their investment. Additionally, establishing relationships with reputable sellers can lead to ongoing support and access to future opportunities.

As the market for second-hand car wash equipment continues to grow, international buyers are encouraged to remain proactive in their sourcing strategies. By staying informed about market trends and utilizing diverse sourcing channels, businesses can position themselves for success in a rapidly evolving industry. Embrace the potential of second-hand equipment today to enhance your car wash operations and drive profitability into the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.