The Definitive Guide to Screw Machines: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for screw machines

In the fast-paced world of manufacturing, sourcing the right screw machines can be a daunting challenge for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. With varying demands for precision, volume, and complexity across industries such as automotive, aerospace, and electronics, understanding the nuances of different screw machine types—ranging from multi-spindle to CNC variants—is crucial for optimizing production efficiency and cost-effectiveness.

This comprehensive guide delves into the diverse landscape of screw machines, exploring their applications, advantages, and limitations to equip buyers with the knowledge needed for informed purchasing decisions. From assessing the specific requirements of your production line to evaluating potential suppliers, we provide actionable insights that can streamline your sourcing process.

Navigating the global market for screw machines requires not only an understanding of the technical specifications but also a strategic approach to supplier vetting, cost analysis, and logistical considerations. By leveraging this guide, B2B buyers will gain the confidence to select the right machinery that aligns with their operational goals, ultimately enhancing productivity and driving business growth in competitive markets.

Understanding screw machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Spindle Screw Machines | Versatile, suitable for a wide range of parts | Automotive, electronics, general manufacturing | Pros: Reliable, versatile; Cons: Limited complexity, slower than CNC. |

| Multi-Spindle Screw Machines | Multiple spindles for simultaneous production | High-volume manufacturing in various industries | Pros: High production rates, cost-effective; Cons: High initial cost, limited versatility. |

| CNC Screw Machines | Computer-controlled for precision and flexibility | Aerospace, medical devices, intricate components | Pros: High precision, quick setup; Cons: Higher investment, complex programming. |

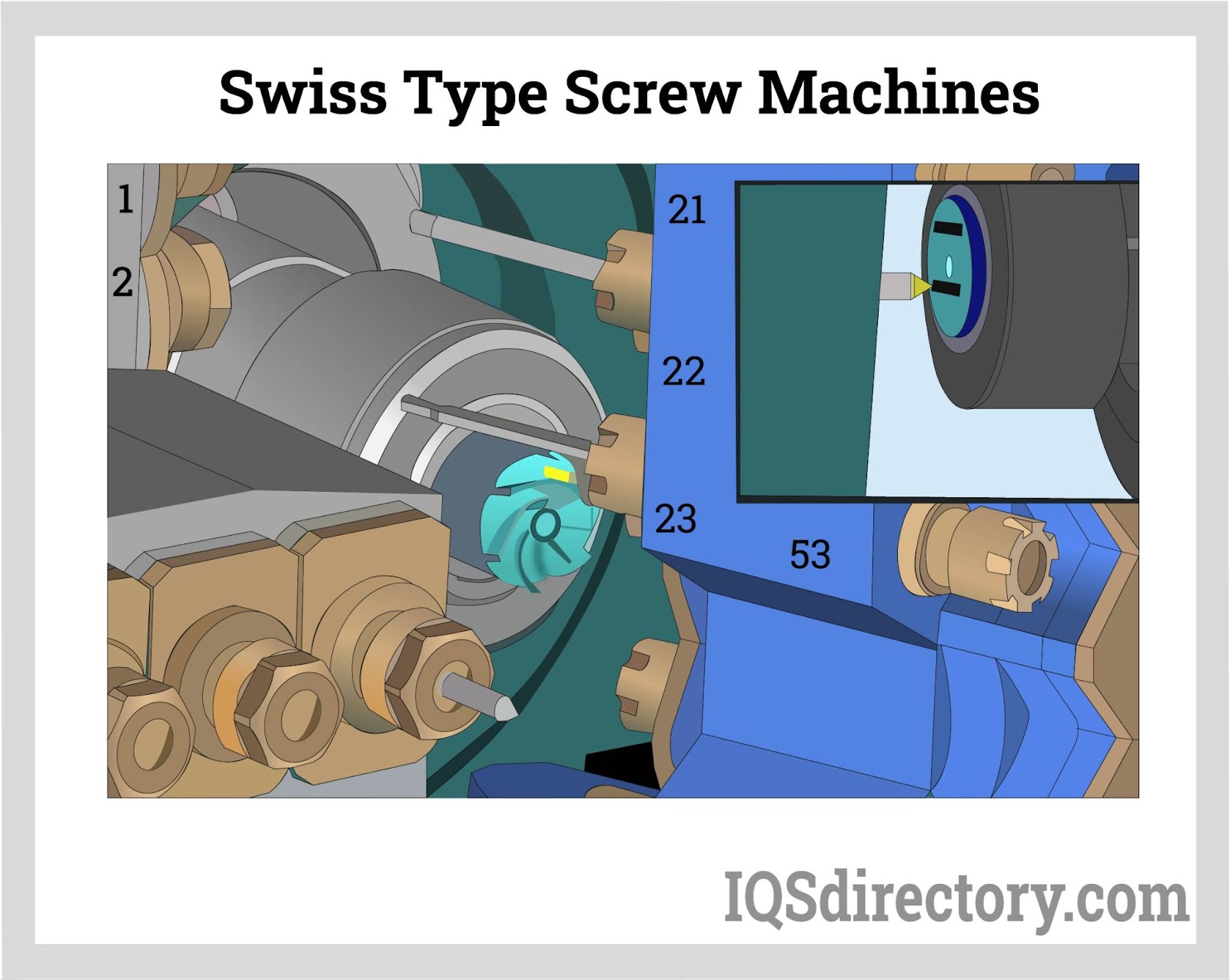

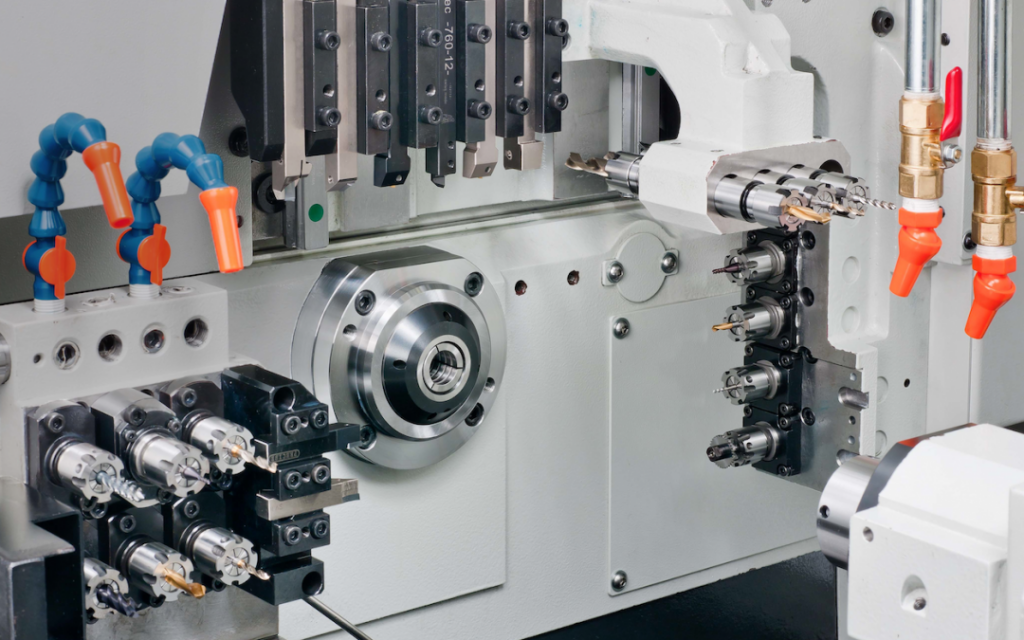

| Swiss-Type Screw Machines | Sliding headstock and guide bushing for small, intricate parts | Electronics, watchmaking, medical devices | Pros: Excellent precision, supports small parts; Cons: High cost, requires skilled operators. |

| Cam-Operated Screw Machines | Controlled by camshafts, ideal for simple parts | High-volume production of screws and bolts | Pros: Fast production, cost-efficient for simple parts; Cons: Limited complexity, reduced adaptability. |

What Are the Key Characteristics of Single-Spindle Screw Machines?

Single-spindle screw machines, such as Brown & Sharpe models, are known for their versatility and reliability. They can produce a wide array of components, making them suitable for various industries, including automotive and electronics. Buyers should consider their production needs, as these machines are slower than CNC options and may not handle complex designs effectively. While they are economical, manufacturers must assess whether their production volume justifies the choice of a single-spindle machine.

Illustrative image related to screw machines

How Do Multi-Spindle Screw Machines Enhance Production Efficiency?

Multi-spindle screw machines are designed for high-volume production, featuring multiple spindles that work on several parts simultaneously. This technology significantly boosts efficiency, making them ideal for industries requiring rapid output, such as automotive and heavy machinery. While they offer cost savings for bulk production, potential buyers should be aware of the high initial investment and the machine’s limitations in versatility compared to CNC options. An evaluation of production volume and part similarity is crucial when considering this type.

Why Are CNC Screw Machines Preferred for Precision Manufacturing?

CNC screw machines utilize computer numerical control to achieve high precision and flexibility in machining operations. They are particularly advantageous for industries like aerospace and medical devices, where tight tolerances are critical. Although the initial investment is higher and programming can be complex, the ability to quickly adapt to different part designs makes CNC machines a valuable asset for manufacturers looking to optimize production and maintain quality. Buyers should weigh the benefits of precision against their budget constraints.

What Makes Swiss-Type Screw Machines Unique?

Swiss-type screw machines are characterized by their sliding headstock and guide bushing, allowing for the production of small, intricate parts with exceptional precision. They are commonly used in industries like electronics and watchmaking. While these machines excel in producing components with tight tolerances, they come with a higher price tag and require skilled operators for effective use. Businesses considering Swiss machines should evaluate their specific needs for precision and complexity to justify the investment.

Illustrative image related to screw machines

What Are the Advantages of Cam-Operated Screw Machines?

Cam-operated screw machines are designed for high-speed production of simpler parts, such as screws and bolts. They are particularly cost-effective for high-volume runs where complexity is minimal. However, their limitations in producing intricate designs and adaptability make them less versatile than CNC machines. Buyers should consider their production requirements, including part complexity and volume, to determine if cam-operated machines align with their operational goals.

Key Industrial Applications of screw machines

| Industry/Sector | Specific Application of screw machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of engine components and fasteners | High-speed production with precision reduces costs | Consider machine precision, cycle time, and material compatibility. |

| Aerospace | Manufacturing of complex aerospace parts | Ensures high accuracy and reliability for safety-critical components | Look for machines that handle exotic materials and offer tight tolerances. |

| Electronics | Creation of small electronic components | Facilitates mass production while maintaining quality standards | Evaluate for flexibility in part design and ease of programming. |

| Medical Devices | Fabrication of surgical instruments | High precision is crucial for functionality and safety | Focus on suppliers with a strong track record in quality assurance. |

| Construction Equipment | Production of bolts, screws, and fittings | Reduces lead times and enhances production efficiency | Assess machine adaptability for various part sizes and materials. |

How Are Screw Machines Utilized in the Automotive Industry?

In the automotive sector, screw machines are vital for producing engine components and fasteners that require high precision and rapid output. These machines enable manufacturers to streamline production processes, significantly reducing costs associated with labor and material waste. International buyers should prioritize sourcing machines that can handle a variety of materials and ensure consistent quality, especially for high-volume production runs.

What Role Do Screw Machines Play in Aerospace Manufacturing?

Screw machines are indispensable in aerospace manufacturing, where the production of complex components demands exceptional accuracy and reliability. These machines are designed to work with advanced materials like titanium and aluminum alloys, critical for ensuring safety in flight. Buyers from regions like Europe and the Middle East must consider suppliers that offer machines capable of achieving tight tolerances and have a proven history of compliance with aerospace standards.

Why Are Screw Machines Important for Electronics Production?

In the electronics industry, screw machines facilitate the mass production of small components such as connectors and housings. The ability to produce these parts at high speeds while maintaining strict quality standards is crucial for meeting market demand. B2B buyers should evaluate the flexibility of machines in accommodating various part designs, as well as their programming capabilities to adapt to evolving industry needs.

How Do Screw Machines Contribute to the Medical Device Sector?

The medical device industry relies on screw machines for the fabrication of surgical instruments and other precision components. High accuracy is essential in this sector, as even minor deviations can impact device performance and patient safety. Buyers should focus on sourcing machines from reputable manufacturers with robust quality assurance processes to ensure compliance with medical regulations and standards.

What Benefits Do Screw Machines Offer for Construction Equipment Manufacturing?

In the construction equipment sector, screw machines are used to produce bolts, screws, and fittings that are essential for assembly. These machines enhance production efficiency by reducing lead times and optimizing manufacturing processes. When sourcing screw machines for this application, businesses should assess the machine’s adaptability to different part sizes and materials, ensuring they can meet the diverse needs of construction projects.

3 Common User Pain Points for ‘screw machines’ & Their Solutions

Scenario 1: High Initial Investment for Screw Machines

The Problem: Many B2B buyers face the challenge of the high initial investment required for screw machines, particularly multi-spindle and CNC models. This financial burden can be daunting for businesses, especially for smaller manufacturers or those in developing markets. The concern is not just about the purchase price; buyers often worry about the long-term return on investment (ROI) and whether the machine will meet their production needs efficiently. This fear can lead to indecision, causing companies to delay upgrades or expansions that are critical for remaining competitive.

The Solution: To navigate this challenge, businesses should conduct a thorough cost-benefit analysis before purchasing. Buyers should evaluate their production volume and specific requirements to determine the most suitable type of screw machine. For high-volume production, investing in multi-spindle machines can yield significant savings over time due to reduced cycle times and increased output. Additionally, exploring financing options or leasing agreements can make the upfront costs more manageable. Manufacturers should also consider the long-term benefits of precision and reduced waste, which can lead to substantial cost savings and improved profitability in the long run. Partnering with reputable suppliers who offer robust post-sale support and training can further maximize the investment, ensuring that operators can utilize the machines to their full potential.

Scenario 2: Complexity of Machine Programming and Operation

The Problem: Another common pain point is the complexity associated with programming and operating advanced screw machines, especially CNC models. Many companies struggle with finding skilled operators who can effectively manage these sophisticated machines. This knowledge gap can lead to production delays, increased scrap rates, and ultimately, lost revenue. For businesses in regions with a limited talent pool, this challenge can be particularly pronounced, hindering growth and efficiency.

The Solution: To overcome this hurdle, companies should invest in comprehensive training programs for their workforce. Collaborating with machine manufacturers that offer training resources can be invaluable. Many suppliers provide workshops, online courses, and on-site training to help operators gain the necessary skills. Additionally, implementing a mentorship program where experienced operators guide newer employees can facilitate knowledge transfer and build a more capable team. Furthermore, leveraging user-friendly software for programming can simplify the process, allowing less experienced operators to perform complex tasks with greater confidence. Regularly scheduled maintenance and operational assessments can also help identify areas for improvement, ensuring that the machines are consistently utilized to their maximum efficiency.

Scenario 3: Limited Flexibility in Production Runs

The Problem: B2B buyers often encounter limitations in flexibility when using screw machines, particularly when production demands fluctuate. Many traditional screw machines are designed for high-volume runs of similar parts, which can be problematic in industries that require adaptability to changing customer needs or rapid prototyping. This lack of flexibility can result in longer lead times, increased costs, and a failure to meet market demands, putting businesses at a competitive disadvantage.

The Solution: To address this issue, buyers should consider investing in hybrid screw machines that combine the benefits of multi-spindle efficiency with CNC flexibility. These machines can handle a variety of part designs while maintaining high production rates, allowing businesses to pivot quickly between different product lines. Additionally, implementing lean manufacturing principles can help streamline operations and reduce waste. This includes optimizing machine setup times and adopting just-in-time production strategies. Engaging with suppliers who offer modular tooling systems can also enhance flexibility, enabling quick changes to accommodate various designs without extensive downtime. By fostering a culture of adaptability and continuous improvement, businesses can better align their production capabilities with market demands, ensuring sustained growth and customer satisfaction.

Strategic Material Selection Guide for screw machines

What Are the Key Properties of Common Materials Used in Screw Machines?

When selecting materials for screw machines, understanding their properties is crucial for optimizing performance and ensuring compatibility with various applications. Below, we analyze four common materials used in screw machine manufacturing: steel, aluminum, brass, and plastic.

How Does Steel Perform in Screw Machine Applications?

Steel is one of the most widely used materials in screw machines due to its strength and durability. Key properties include high tensile strength, excellent wear resistance, and the ability to withstand high temperatures and pressures. Steel can be alloyed with other elements to enhance specific characteristics, such as corrosion resistance or machinability.

Pros and Cons: The advantages of steel include its robustness, making it suitable for high-stress applications. However, it can be heavy and may require additional processing to achieve desired surface finishes. The manufacturing complexity can also increase with certain steel grades, impacting production costs.

Illustrative image related to screw machines

Impact on Application: Steel’s compatibility with various media, including oils and chemicals, makes it a versatile choice for industries such as automotive and aerospace. Buyers should consider the specific steel grade required for their application to ensure optimal performance.

Considerations for International Buyers: Compliance with standards such as ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) is essential. Buyers from regions like Europe and South America often prefer materials that meet these standards for quality assurance.

What Advantages Does Aluminum Offer in Screw Machine Manufacturing?

Aluminum is favored for its lightweight properties and excellent corrosion resistance. It has a lower density compared to steel, which makes it easier to handle and process. Additionally, aluminum has good thermal and electrical conductivity, making it suitable for applications requiring heat dissipation.

Illustrative image related to screw machines

Pros and Cons: The primary advantage of aluminum is its lightweight nature, which can reduce overall machine weight and enhance efficiency. However, aluminum is generally less durable than steel and may not be suitable for high-stress applications. Its cost can also be higher, depending on the alloy used.

Impact on Application: Aluminum is ideal for applications in the electronics and automotive industries where weight savings are critical. Its corrosion resistance allows it to be used in environments where exposure to moisture or chemicals is a concern.

Considerations for International Buyers: Buyers should ensure that aluminum grades comply with international standards such as JIS (Japanese Industrial Standards) or ISO (International Organization for Standardization). This is particularly important for buyers from the Middle East and Africa, where local regulations may dictate material specifications.

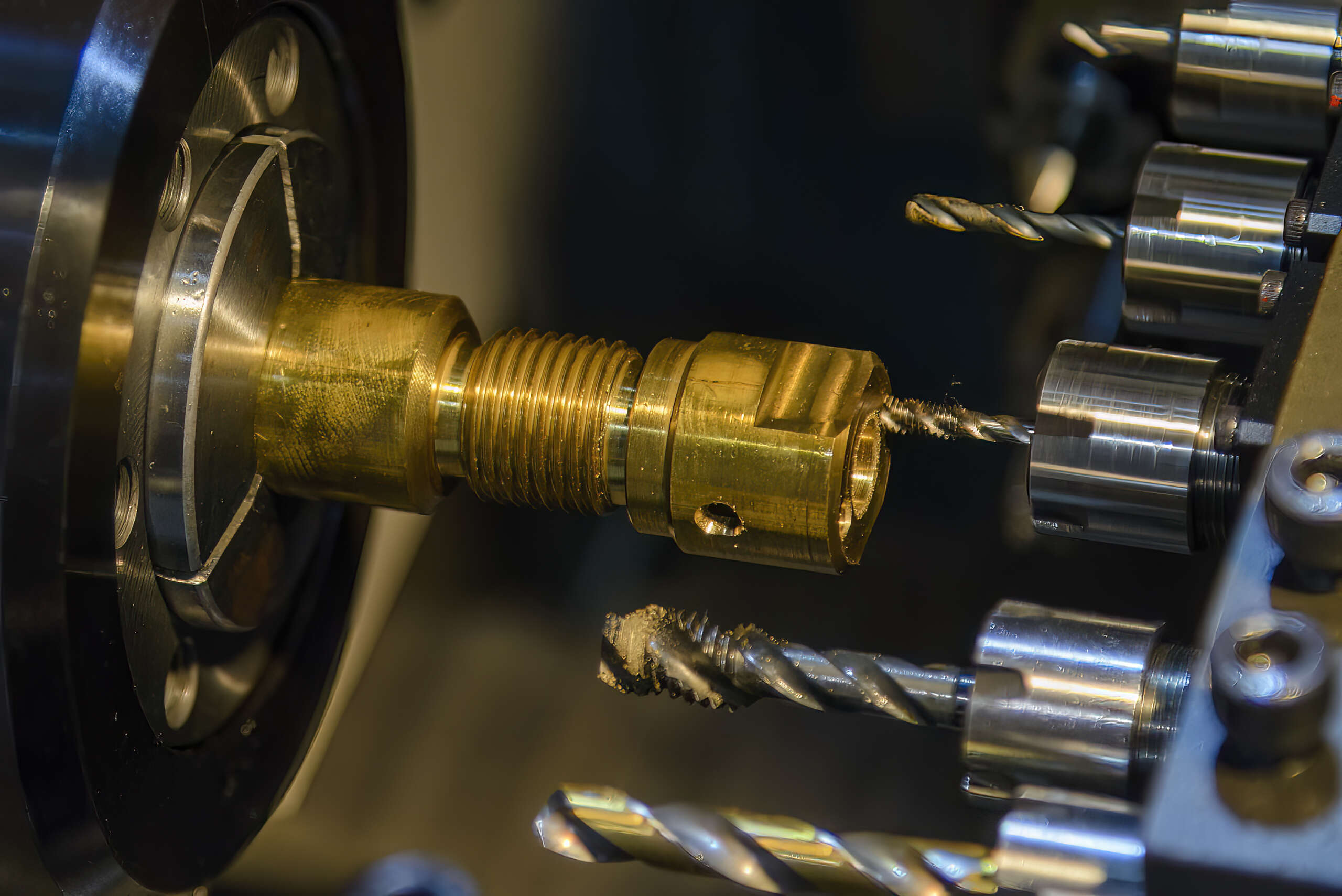

Why Choose Brass for Screw Machine Components?

Brass is an alloy of copper and zinc, known for its excellent machinability and corrosion resistance. It has good thermal and electrical conductivity, making it suitable for precision components such as fittings and fasteners.

Pros and Cons: The advantages of brass include its ease of machining and aesthetic appeal, often used in decorative applications. However, brass can be more expensive than other metals, and its strength is lower than steel, limiting its use in high-stress applications.

Impact on Application: Brass is commonly used in plumbing, electrical, and automotive applications where corrosion resistance is vital. Its compatibility with various fluids makes it a preferred choice for fittings and valves.

Considerations for International Buyers: Compliance with standards like ASTM B16 (Brass Pipe Fittings) is crucial for ensuring quality. Buyers should also consider local sourcing options to mitigate costs and ensure compliance with regional regulations.

How Do Plastics Fit into Screw Machine Manufacturing?

Plastics, such as polycarbonate and nylon, are increasingly used in screw machine applications due to their lightweight properties and resistance to corrosion and chemicals. They can be molded into complex shapes, offering design flexibility.

Illustrative image related to screw machines

Pros and Cons: The main advantage of plastics is their lightweight nature and resistance to corrosion, making them suitable for various applications. However, they may not withstand high temperatures or mechanical stresses as well as metals, limiting their use in certain environments.

Impact on Application: Plastics are ideal for applications in the consumer goods and electronics industries, where weight and corrosion resistance are critical. Their compatibility with various chemicals makes them suitable for use in harsh environments.

Considerations for International Buyers: Buyers should verify that plastic materials meet relevant standards, such as ISO or ASTM, to ensure quality and safety. This is particularly important for industries in Europe and South America, where compliance is strictly monitored.

Summary of Material Selection for Screw Machines

| Material | Typical Use Case for screw machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-stress automotive and aerospace components | High strength and durability | Heavier and more complex to process | High |

| Aluminum | Lightweight automotive and electronics applications | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Brass | Plumbing and electrical fittings | Excellent machinability and aesthetics | More expensive and lower strength | Medium |

| Plastic | Consumer goods and electronics | Lightweight and corrosion-resistant | Limited temperature and stress tolerance | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on material properties, application compatibility, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for screw machines

What Are the Key Stages in the Manufacturing Process of Screw Machines?

The manufacturing process for screw machines involves several critical stages that ensure precision and efficiency in producing high-quality components. Understanding these stages is vital for B2B buyers who seek reliable suppliers capable of meeting their production needs.

1. Material Preparation: How Are Raw Materials Selected and Processed?

Material preparation is the foundational step in the manufacturing process. The choice of raw materials, typically metal or plastic, is crucial as it directly affects the quality and performance of the final product. Common materials include aluminum, brass, stainless steel, and various plastics, each selected based on the specific requirements of the end application.

Before machining, raw materials undergo various treatments such as cutting, deburring, and sometimes heat treatment to enhance their properties. For instance, heat-treated steel can provide increased strength and durability, which is particularly important in high-stress applications like aerospace and automotive parts.

2. Forming: What Techniques Are Used to Shape Components?

Once the materials are prepared, the forming stage begins, where the raw materials are shaped into the desired components. This can be achieved through several techniques, including:

- Turning: The primary method for screw machines, where the material is rotated against a stationary cutting tool to create cylindrical parts.

- Milling: Used for more complex geometries, milling involves rotating a cutting tool to remove material from the workpiece.

- Drilling: This process creates holes in the components, which may be necessary for assembly or function.

- Threading: This is essential for producing screws and bolts, using specialized tools to create helical grooves.

Multi-spindle screw machines, like those from Davenport, enhance production efficiency by performing multiple operations simultaneously, significantly reducing cycle times and increasing throughput.

3. Assembly: How Are Components Brought Together?

After individual components are machined, they may require assembly, particularly in multi-part products. This stage can involve various processes:

- Manual Assembly: Skilled workers often assemble components that require precision or have intricate designs.

- Automated Assembly: For high-volume production, automated systems can efficiently handle assembly tasks, reducing labor costs and increasing consistency.

- Quality Checks During Assembly: Integrating quality control during assembly is crucial. This includes verifying tolerances and ensuring components fit correctly before moving to the next stage.

4. Finishing: What Processes Ensure Quality and Aesthetics?

Finishing processes enhance the appearance and functionality of the components. Common finishing techniques include:

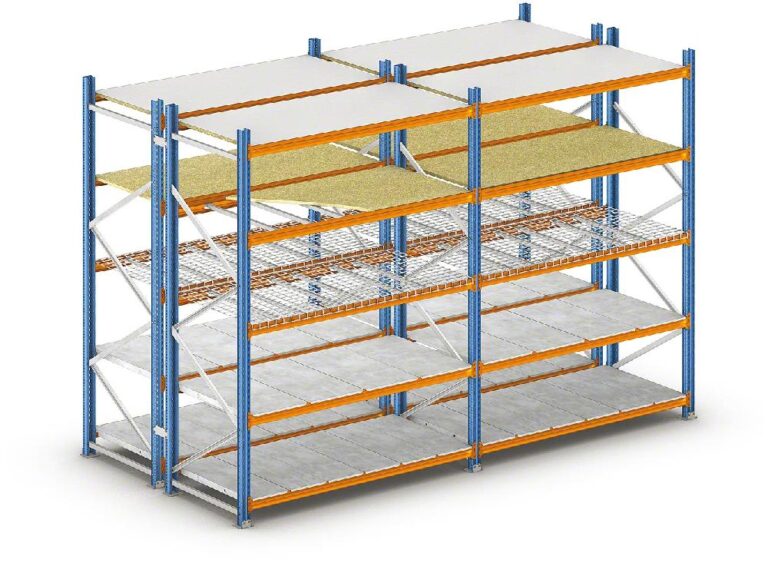

Illustrative image related to screw machines

- Deburring: Removing sharp edges or burrs that can affect performance or safety.

- Polishing: Improving surface finish for aesthetic and functional purposes.

- Coating: Applying finishes such as anodizing or plating to protect against corrosion or enhance surface properties.

Finishing processes are essential not only for aesthetic reasons but also for ensuring that the components meet industry-specific standards for functionality and durability.

How Is Quality Assurance Implemented in Screw Machine Manufacturing?

Quality assurance (QA) is paramount in screw machine manufacturing, especially for international B2B buyers who require consistent quality across different regions and standards.

Relevant International Standards: Which Certifications Should Buyers Look For?

B2B buyers should prioritize suppliers who adhere to internationally recognized quality standards. The ISO 9001 certification is a fundamental standard that outlines quality management principles. It emphasizes customer satisfaction, process approach, and continual improvement.

Illustrative image related to screw machines

In addition to ISO standards, industry-specific certifications may be relevant depending on the application. For example, the CE marking is crucial for products sold in the European market, indicating compliance with health and safety standards. The API certification is important for components used in the oil and gas industry, ensuring they meet stringent performance criteria.

Key Quality Control Checkpoints: What Are the Stages of Quality Assurance?

Quality control (QC) in screw machine manufacturing typically involves several checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various measurements are taken to ensure each component meets design specifications. This includes monitoring tolerances and dimensions during machining.

- Final Quality Control (FQC): After the components are fully assembled and finished, a final inspection occurs to ensure they meet all quality and performance standards before shipping.

Common Testing Methods: How Are Components Tested for Quality?

Several testing methods are employed in the QC process:

- Dimensional Inspection: Using tools such as calipers and micrometers to verify that parts meet specified dimensions.

- Functional Testing: Ensuring that components operate correctly under expected conditions.

- Material Testing: Analyzing material properties to confirm they align with requirements.

These testing methods help maintain high standards of quality and reliability for the final products.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial for ensuring product reliability and performance.

What Should Buyers Look For in Supplier Audits and Reports?

Buyers should conduct supplier audits to assess their quality management systems and manufacturing capabilities. During audits, key areas to evaluate include:

- Documented Procedures: Suppliers should have clear, documented quality control procedures that align with international standards.

- Traceability: The ability to trace materials and processes back to their source is vital for accountability.

- Calibration Records: Ensuring that all measurement and testing equipment is regularly calibrated and maintained is crucial for consistent quality.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide additional assurance. These independent organizations can conduct audits and inspections to validate the supplier’s quality control processes, ensuring impartiality and credibility. This is particularly important when sourcing from regions with varying quality standards.

Illustrative image related to screw machines

Conclusion: What Nuances Should International B2B Buyers Consider?

When sourcing screw machines and components, international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should pay close attention to the manufacturing processes and quality assurance practices of potential suppliers. Understanding these aspects not only helps in making informed purchasing decisions but also ensures that the components meet the necessary quality standards for their intended applications. By prioritizing suppliers with robust quality management systems and relevant certifications, buyers can mitigate risks and enhance their operational efficiencies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘screw machines’

To assist B2B buyers in procuring screw machines effectively, this guide provides a structured checklist to streamline the sourcing process. By following these steps, you can ensure that you select the right machine and supplier for your manufacturing needs, ultimately enhancing productivity and product quality.

Step 1: Define Your Technical Specifications

Begin by identifying the specific requirements for your screw machine. Consider factors such as the types of materials you will be machining, the complexity of the parts, and the production volume.

– Material Compatibility: Ensure the machine can handle the grades of metal or plastic you plan to use.

– Precision Requirements: Determine the tolerances needed for your components, as this will influence the type of machine you select.

Step 2: Identify Your Production Needs

Assess your production goals to determine the appropriate machine type. This involves understanding whether you require high-speed production for large volumes or flexibility for smaller batches.

– Volume vs. Complexity: Multi-spindle machines are ideal for high-volume, less complex parts, while CNC machines are better for intricate designs.

– Future Scalability: Consider if your needs may grow in the future; investing in a more versatile machine may be beneficial.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to ensure reliability and quality. Look for established manufacturers with a solid reputation in the industry.

– Company Profiles: Request detailed profiles and case studies that illustrate their experience and expertise.

– Customer References: Speak to existing customers, particularly those in similar industries, to gauge their satisfaction with the supplier’s machines and support.

Step 4: Verify Supplier Certifications

Ensure that the suppliers meet relevant industry standards and certifications, which can be indicative of their commitment to quality and safety.

– ISO Certifications: Look for ISO 9001 or similar certifications that demonstrate adherence to quality management systems.

– Compliance with Regional Standards: Depending on your location, check for compliance with local regulations and safety standards.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that outline the costs involved. This should include pricing for the machines, installation, training, and ongoing support.

– Breakdown of Costs: Ensure the quotation provides a clear breakdown of each component to avoid hidden fees.

– Warranty and Service Agreements: Clarify the warranty terms and what after-sales support is available, as this can impact long-term operational costs.

Step 6: Assess Machine Technology and Features

Investigate the technological capabilities of the machines offered by suppliers. Modern screw machines often come with advanced features that enhance productivity.

– CNC Capabilities: If precision is critical, consider machines with CNC interfaces for programmable operations.

– Automation Options: Evaluate whether the machines can be integrated with automated loading systems for improved efficiency.

Step 7: Plan for Installation and Training

Finally, ensure that the supplier provides comprehensive installation and training services. This is crucial for maximizing the machine’s capabilities and ensuring your team is well-prepared to operate it.

– On-Site Support: Confirm that the supplier will provide on-site installation assistance.

– Training Programs: Look for detailed training programs that cover both operation and maintenance to ensure your team can effectively use the machine from day one.

By following this checklist, B2B buyers can navigate the complexities of sourcing screw machines, ensuring that they make informed decisions that align with their operational needs and business objectives.

Comprehensive Cost and Pricing Analysis for screw machines Sourcing

What Are the Key Cost Components in Screw Machines Sourcing?

When sourcing screw machines, understanding the cost structure is crucial for international buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials, such as steel or specialized alloys, significantly impacts costs. High-quality materials often lead to better durability and performance but can increase upfront expenses.

-

Labor: Labor costs vary by region and depend on the skill level required for assembly and operation. Countries with lower labor costs may offer a more competitive pricing structure, but consider the potential trade-off in quality and expertise.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. A manufacturer with higher overhead may pass those costs onto buyers, so it’s essential to assess the overall efficiency of the production facility.

-

Tooling: Tooling costs can vary significantly based on the complexity of the screw machine and the specific parts being produced. Custom tooling may be necessary for specialized applications, which can further increase costs.

-

Quality Control: Rigorous QC processes ensure that machines meet specific standards and certifications. While this adds to the cost, it can prevent future expenses related to defects or failures.

-

Logistics: Shipping and handling costs can be substantial, especially for international shipments. Factors such as distance, mode of transport, and insurance should be factored into the total cost.

-

Margin: Suppliers will typically include a margin that reflects their business model, market demand, and competition. Understanding the margin can help buyers evaluate the overall value proposition.

How Do Price Influencers Impact Screw Machine Sourcing?

Several factors influence pricing for screw machines, particularly for international buyers:

-

Volume/MOQ: Larger orders often lead to reduced per-unit costs due to economies of scale. Establishing minimum order quantities (MOQ) with suppliers can also facilitate better pricing negotiations.

-

Specifications and Customization: Custom features or specific tolerances can increase costs. Buyers should clearly define their needs to avoid unexpected expenses during production.

-

Materials and Quality/Certifications: Premium materials and certifications (like ISO standards) can elevate prices but may be necessary for industries like aerospace or automotive where precision and reliability are paramount.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers with a track record of quality may charge higher prices but offer lower risks and better support.

-

Incoterms: Understanding the terms of delivery can affect costs. Incoterms define responsibilities for shipping and insurance, and selecting the right terms can help manage total expenses.

What Negotiation Strategies Can Enhance Cost Efficiency for Buyers?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings:

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing and identify competitive offers. This information can provide leverage during negotiations.

-

Total Cost of Ownership (TCO): Focus on TCO rather than just the upfront price. This includes maintenance, operational efficiency, and potential downtime costs, which can provide a clearer picture of long-term value.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Trust and ongoing communication often yield more favorable conditions.

-

Flexible Specifications: If possible, be flexible with specifications and customization to allow for alternative solutions that can reduce costs.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Obtain multiple proposals to compare pricing, terms, and overall value, which can enhance negotiation power.

What Should Buyers Keep in Mind Regarding Pricing Nuances in International Markets?

When sourcing screw machines internationally, buyers must be aware of pricing nuances:

-

Currency Fluctuations: Be mindful of exchange rates, as they can significantly affect the final cost. Locking in prices when favorable can mitigate risks.

-

Import Duties and Taxes: Factor in any tariffs or taxes that may apply to imported machinery, as these can substantially increase overall costs.

-

Cultural Considerations: Different regions may have unique negotiation styles and expectations. Understanding cultural nuances can facilitate smoother discussions and agreements.

In conclusion, a comprehensive understanding of cost components, pricing influencers, and effective negotiation strategies is essential for B2B buyers in the screw machine market. By considering these factors, buyers can enhance their sourcing decisions and achieve better financial outcomes.

Alternatives Analysis: Comparing screw machines With Other Solutions

In the realm of high-volume manufacturing, selecting the right machining solution is crucial. While screw machines are a popular choice for producing precision components, several alternative technologies may also meet specific production needs. This section will compare screw machines against two viable alternatives: CNC lathes and rotary transfer machines. Each option offers distinct advantages and disadvantages, depending on factors such as performance requirements, cost, and application suitability.

Illustrative image related to screw machines

| Comparison Aspect | Screw Machines | CNC Lathes | Rotary Transfer Machines |

|---|---|---|---|

| Performance | High-speed production of small to medium parts; multiple spindles enhance efficiency. | Excellent for complex geometries; programmable for precision. | Ideal for high-volume, multi-operation tasks; fast cycle times. |

| Cost | Moderate initial investment; cost-effective for high volumes. | Higher initial cost; software and programming can increase expenses. | High upfront costs; generally justified for high production volumes. |

| Ease of Implementation | Requires skilled operators; setup times can vary based on part complexity. | Complex programming needed; initial setup can be time-consuming. | Requires thorough planning for tool changes; less flexible for low volumes. |

| Maintenance | Generally low maintenance; durable machines with a long lifespan. | Higher maintenance due to complexity; requires skilled technicians. | Moderate maintenance; efficiency declines with improper upkeep. |

| Best Use Case | High-volume production of simple to moderately complex parts. | Small to medium batch production of intricate components with tight tolerances. | Large-scale production of complex parts requiring multiple operations. |

What Are the Key Advantages and Disadvantages of CNC Lathes as an Alternative?

CNC lathes stand out for their versatility and precision. They are capable of producing complex geometries and can be programmed to adapt to various designs, making them suitable for both small and medium batch productions. The downside is that they come with a higher initial investment and require skilled operators to manage the programming and setup processes. For manufacturers focusing on precision and flexibility, CNC lathes can be an excellent choice despite their cost.

How Do Rotary Transfer Machines Compare to Screw Machines?

Rotary transfer machines excel in high-volume production environments where multiple operations are needed on a single part. They significantly reduce cycle times by allowing several machining processes to be performed in sequence. However, they often come with high upfront costs and require careful planning to maximize efficiency. While they can be less adaptable for small batch production, they are ideal for manufacturers who need to produce a large quantity of complex parts quickly and efficiently.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the right machining solution involves evaluating specific production requirements, including part complexity, volume, budget, and available workforce skills. Screw machines are a strong choice for high-volume production of less complex parts, while CNC lathes offer flexibility and precision for intricate designs. Rotary transfer machines are best suited for high-volume, multi-operation needs. By understanding the strengths and weaknesses of each alternative, B2B buyers can make informed decisions that align with their operational goals and production demands.

Essential Technical Properties and Trade Terminology for screw machines

What Are the Key Technical Properties of Screw Machines?

When evaluating screw machines for manufacturing, several critical technical specifications are essential for B2B buyers to consider. Understanding these properties not only aids in selecting the right machine but also ensures that production requirements are met efficiently.

What is Material Grade and Why is it Important?

Material grade refers to the quality and composition of the materials that can be processed by screw machines. Common grades include stainless steel, aluminum, and various alloys. The choice of material grade affects the durability, strength, and overall performance of the final product. For manufacturers, selecting the appropriate material grade ensures that the produced components meet industry standards and customer specifications, ultimately influencing product longevity and market competitiveness.

How Does Tolerance Impact Production Quality?

Tolerance indicates the allowable variation in the dimensions of a part. In screw machining, precision tolerances can range from ±0.001 inches to tighter specifications based on the application. High tolerance levels are crucial in industries such as aerospace and automotive, where even minor discrepancies can lead to significant failures. Understanding tolerance requirements helps manufacturers optimize machine settings and processes, ensuring that parts fit correctly and function as intended.

Why is Cycle Time a Critical Metric?

Cycle time is the total time required to produce a part from start to finish. This includes setup time, machining time, and any necessary secondary operations. Shorter cycle times contribute to higher productivity and lower operational costs, making it a key metric for B2B buyers seeking efficient manufacturing solutions. By analyzing cycle times, companies can identify bottlenecks and streamline their production processes, thus enhancing overall efficiency.

What Role Does Setup Time Play in Production Efficiency?

Setup time is the duration required to prepare a screw machine for production, including tooling changes and machine calibrations. Reducing setup time is vital for improving productivity, especially in environments with frequent job changes or small batch sizes. Machines designed for quick setups, such as CNC screw machines, provide manufacturers with the flexibility to adapt to varying production needs without sacrificing efficiency.

How Does the Chucking Mechanism Affect Machining Versatility?

Chucking mechanisms hold the workpiece in place during machining operations. The type of chuck—manual, pneumatic, or hydraulic—can significantly influence machining versatility and ease of operation. For instance, multi-spindle machines equipped with advanced chucking systems can accommodate a range of part sizes and shapes, enhancing operational flexibility. This adaptability is essential for manufacturers aiming to diversify their product offerings while maintaining production efficiency.

What Are Common Trade Terms in the Screw Machine Industry?

Understanding industry jargon can facilitate smoother communication between buyers and suppliers. Here are several key trade terms relevant to screw machines:

What Does OEM Stand For?

OEM, or Original Equipment Manufacturer, refers to a company that produces components or products that are used in another company’s end product. In the context of screw machines, OEMs may provide specialized parts or entire machines, ensuring compatibility and quality standards are maintained. For B2B buyers, partnering with reputable OEMs can enhance product reliability and performance.

What is MOQ and Its Significance in Purchasing?

MOQ stands for Minimum Order Quantity, which is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for manufacturers to manage inventory and cash flow effectively. A higher MOQ can lead to cost savings per unit, but it may also require careful planning to ensure demand aligns with production capabilities.

How is RFQ Used in the Procurement Process?

RFQ, or Request for Quotation, is a standard process in procurement where buyers solicit price quotes from suppliers for specific products or services. In the screw machine industry, issuing an RFQ can help buyers compare offerings, negotiate terms, and make informed purchasing decisions. This process is essential for ensuring competitive pricing and aligning supplier capabilities with project requirements.

What are Incoterms and Why Do They Matter?

Incoterms, short for International Commercial Terms, are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping, insurance, and tariffs. For B2B buyers involved in global sourcing of screw machines, understanding Incoterms is critical for managing logistics and ensuring compliance with international trade regulations.

Illustrative image related to screw machines

By familiarizing themselves with these essential technical properties and trade terminology, B2B buyers can make informed decisions that enhance their manufacturing capabilities and competitive edge in the market.

Navigating Market Dynamics and Sourcing Trends in the screw machines Sector

What are the Key Trends Driving the Screw Machines Market?

The screw machines market is experiencing dynamic growth driven by several global factors. Firstly, the demand for high-precision components in industries such as automotive, aerospace, and electronics is escalating. This has led to a significant shift towards multi-spindle and CNC screw machines, which offer higher efficiency and precision. Additionally, technological advancements are influencing the adoption of hybrid machines that combine traditional mechanics with modern CNC technology, providing both reliability and flexibility.

Emerging trends also indicate an increasing reliance on automation and smart manufacturing practices. International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly seeking machines that integrate with IoT systems for real-time monitoring and data analytics. This not only enhances productivity but also facilitates proactive maintenance, reducing downtime and operational costs.

Furthermore, sustainability is becoming a pivotal factor influencing sourcing decisions. Buyers are prioritizing suppliers that demonstrate commitment to eco-friendly practices and materials, aligning their procurement strategies with broader environmental goals. The global push for green manufacturing is reshaping sourcing dynamics, compelling suppliers to adapt or face obsolescence.

How is Sustainability Shaping Sourcing Trends in the Screw Machines Sector?

The screw machines sector is increasingly recognizing the importance of sustainability and ethical sourcing. Environmental impact considerations are driving buyers to seek suppliers who prioritize sustainable practices, including the use of eco-friendly materials and manufacturing processes. For instance, companies are now exploring the use of recycled metals and bioplastics in their products, which can reduce waste and lower the carbon footprint associated with production.

Moreover, ethical supply chains are becoming a focal point for international buyers. Companies are expected to demonstrate transparency in their sourcing processes, ensuring that materials are sourced responsibly and that labor practices meet ethical standards. Certifications such as ISO 14001 for environmental management systems and Fair Trade certifications are gaining traction, providing buyers with assurance of compliance with sustainability standards.

Investing in suppliers with ‘green’ certifications not only enhances a company’s brand reputation but can also lead to cost savings in the long term through efficient resource use and waste reduction. As the market evolves, the emphasis on sustainability will continue to shape procurement strategies, influencing which suppliers are favored in the competitive landscape.

How Have Screw Machines Evolved Over Time?

The evolution of screw machines dates back to the early 20th century when single-spindle machines dominated the landscape, offering basic capabilities for producing turned parts. Over the decades, innovations led to the introduction of multi-spindle machines, which significantly increased production efficiency by enabling simultaneous machining of multiple components.

The introduction of CNC technology in the late 20th century marked a pivotal shift, allowing for greater precision and flexibility in machining operations. Today, hybrid machines that combine the mechanical reliability of traditional models with advanced CNC controls are gaining popularity. This evolution not only reflects technological advancements but also the growing demand for high-quality, complex parts across various industries, positioning screw machines as essential tools in modern manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of screw machines

-

How do I choose the right screw machine for my production needs?

Selecting the appropriate screw machine hinges on various factors, including the complexity of parts, production volume, and precision requirements. For high-volume runs of simple parts, multi-spindle automatic screw machines are ideal due to their efficiency. Conversely, if precision and versatility for intricate components are priorities, CNC or Swiss-type machines may be better suited. Assess your specific production goals, including the types of materials you’ll be using and the tolerances required, to make an informed decision. -

What are the benefits of investing in CNC screw machines?

CNC screw machines provide several advantages for modern manufacturing, including high precision, flexibility, and reduced setup times. They can produce complex shapes with tight tolerances and can be easily programmed for various part geometries, making them highly adaptable. While the initial investment may be higher than traditional machines, the long-term benefits in terms of efficiency, reduced labor costs, and versatility often justify the expenditure, especially for manufacturers looking to scale operations. -

What is the minimum order quantity (MOQ) for screw machines?

The MOQ for screw machines can vary significantly based on the manufacturer and the specific model. Some suppliers may offer single machines for initial trials, while others might require bulk orders for cost efficiency. It is essential to communicate your production needs with potential suppliers, as many are willing to accommodate smaller orders, especially for custom configurations or when introducing new clients to their products. -

How can I ensure the quality of screw machines from international suppliers?

To guarantee quality when sourcing screw machines internationally, conduct thorough due diligence on potential suppliers. Request certifications, such as ISO or CE, and ask for references from existing clients. Additionally, consider visiting the manufacturing facility if possible, or utilize third-party inspection services to assess the machines before shipment. Establishing clear communication regarding quality standards and expectations is crucial to ensuring a successful partnership. -

What payment terms should I expect when purchasing screw machines?

Payment terms for screw machines can vary widely among suppliers, often influenced by the order size, machine type, and relationship with the buyer. Common arrangements include a deposit upfront with the balance due upon delivery or a letter of credit for larger transactions. Negotiating favorable terms that align with your cash flow and production timelines is vital, so be sure to discuss options early in the negotiation process. -

What are the logistics considerations for importing screw machines?

When importing screw machines, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with handling heavy machinery to navigate these complexities. Additionally, ensure that all necessary documentation, such as commercial invoices and packing lists, is in order to avoid delays at customs. Understanding import duties and taxes applicable in your country is also crucial for accurate budgeting. -

How can I customize screw machines to meet my specific production requirements?

Many suppliers offer customization options for screw machines to cater to unique production needs. This may include modifications to tooling, programming for specific part geometries, or integration with existing production lines. Discuss your requirements with the supplier early in the engagement process to determine the feasibility and associated costs of customization. Ensure that any agreed-upon modifications are documented to avoid misunderstandings during production. -

What after-sales support should I expect from screw machine manufacturers?

After-sales support varies among manufacturers but is a critical aspect of your purchasing decision. Look for suppliers that offer comprehensive services, including installation assistance, training for operators, and ongoing technical support. Additionally, inquire about warranty terms and the availability of spare parts, as these factors can significantly impact machine uptime and overall production efficiency. A strong after-sales relationship can enhance the longevity and performance of your investment.

Top 4 Screw Machines Manufacturers & Suppliers List

1. BCEPI – Precision Screw Machines

Domain: bcepi.com

Registered: 2005 (20 years)

Introduction: Screw machines are automatic lathes used in manufacturing, automotive, and aerospace industries to produce high volumes of precision parts quickly and efficiently. They perform operations such as drilling, tapping, and threading, producing parts with tight tolerances and complex geometries. Types of screw machines include single-spindle, multi-spindle, and Swiss-style machines, each suited for dif…

2. Cox Manufacturing – Acme Gridley Multi-Spindle Screw Machines

Domain: coxmanufacturing.com

Registered: 2003 (22 years)

Introduction: Acme Gridley Multi-Spindle Screw Machines are designed for high volume production runs in the turned parts industry. They are available in four, six, and eight spindle configurations, known for their reliability and productivity. These machines are suitable for materials including brass, aluminum, stainless steels, and titanium. The bar capacity ranges from small 7/16″ models to large 8″ bar machi…

3. Swistek – Swiss Type Automatic Screw Machines

Domain: swistek.com

Registered: 2010 (15 years)

Introduction: New Swiss Type Automatic Screw Machines for sale by Swistek Machinery America. Brands include STAR, TSUGAMI, GANESH, HANWHA, SWISTEK, and CITIZEN. Contact information: 50 Seemans Lane, Milford, CT, 06460, Phone: 203-301-4848, Email: [Email Us].

4. Reddit – Screw Machines Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The text discusses screw machines, specifically Swiss-type automatic lathes and sliding headstock machines. Key points include: 1. Complexity: Screw machines are more complex than CNC or manual mills and lathes, requiring skilled operators. 2. Setup Challenges: Setting up screw machines and designing/manufacturing cams is time-consuming and requires expertise. 3. Productivity: There is a debate on…

Strategic Sourcing Conclusion and Outlook for screw machines

In the evolving landscape of manufacturing, the strategic sourcing of screw machines is paramount for businesses aiming to enhance productivity and reduce operational costs. By understanding the diverse types of screw machines—ranging from multi-spindle systems to CNC models—buyers can make informed decisions tailored to their production needs. The advantages of multi-spindle machines, such as increased efficiency and reduced cycle times, position them as ideal solutions for high-volume production, particularly in industries like automotive and aerospace.

As international B2B buyers from regions including Africa, South America, the Middle East, and Europe seek to optimize their manufacturing processes, the importance of selecting the right screw machine cannot be overstated. Investing in advanced technology not only improves precision but also adapts to changing market demands.

Looking ahead, the integration of smart manufacturing solutions and automation will further revolutionize the capabilities of screw machines. We encourage buyers to explore innovative options and leverage strategic partnerships that can drive growth and operational excellence. Embrace the future of manufacturing—make strategic sourcing your competitive advantage today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to screw machines