The Definitive Guide to Sch 40 Aluminum Pipe: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for sch 40 aluminum pipe

In the dynamic landscape of international trade, sourcing sch 40 aluminum pipe presents unique challenges for B2B buyers, particularly those operating across diverse markets in Africa, South America, the Middle East, and Europe. With a wide array of applications ranging from structural framing to fluid transportation, navigating the complexities of specifications, supplier reliability, and cost-efficiency can be daunting. This guide aims to demystify the global market for sch 40 aluminum pipe, equipping buyers with essential insights that facilitate informed purchasing decisions.

Within these pages, you will find a comprehensive overview of various types of sch 40 aluminum pipe, including key specifications such as wall thickness, diameter, and alloy composition. We delve into the numerous applications of aluminum pipe across different industries, ensuring you understand where and how to effectively utilize these products. Furthermore, we provide actionable strategies for vetting suppliers, negotiating costs, and ensuring timely delivery, which are crucial for maintaining competitive advantage in your sector.

By synthesizing expert knowledge and market intelligence, this guide empowers you to make strategic choices that align with your business objectives. Whether you’re in Nigeria seeking reliable suppliers or in Germany analyzing cost structures, our insights will help you navigate the global market with confidence and precision.

Understanding sch 40 aluminum pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 6061-T6 Extruded Pipe | High strength, corrosion resistance, and lightweight | Structural applications, framing, fencing | Pros: Excellent mechanical properties, versatile. Cons: Higher cost than standard options. |

| 6063-T52 Pipe | Smooth finish, good for aesthetic applications | Architectural applications, decorative uses | Pros: Better surface finish, easier to work with. Cons: Lower strength compared to 6061-T6. |

| Seamless Aluminum Pipe | No welds, consistent wall thickness | Fluid transport, low-pressure systems | Pros: Higher reliability, less risk of leaks. Cons: Generally more expensive than welded options. |

| Schedule 80 Aluminum Pipe | Thicker walls for higher pressure applications | Industrial plumbing, gas distribution | Pros: Greater strength and durability. Cons: Heavier and more costly than Schedule 40. |

| Custom Extruded Pipe | Tailored dimensions and specifications | Specialized industrial applications | Pros: Meets specific project needs. Cons: Longer lead times and potential for higher costs. |

What Are the Characteristics of 6061-T6 Extruded Pipe?

The 6061-T6 extruded aluminum pipe is known for its high strength and excellent corrosion resistance, making it a popular choice for various structural applications. It is lightweight yet robust, ideal for framing, fencing, and other structural needs in industries such as construction and manufacturing. When purchasing, buyers should consider the specific mechanical properties, including tensile and yield strength, as well as the cost, which is generally higher due to its superior qualities.

How Does 6063-T52 Pipe Differ from Other Types?

The 6063-T52 pipe is characterized by its smooth finish and is often preferred for architectural applications where aesthetics matter. It is easier to work with, making it suitable for decorative uses in buildings and other structures. However, it offers lower strength compared to 6061-T6, which may limit its use in load-bearing applications. Buyers should weigh the visual appeal against the required strength for their specific projects.

Why Choose Seamless Aluminum Pipe for Fluid Transport?

Seamless aluminum pipes are manufactured without welds, ensuring a consistent wall thickness and providing higher reliability, especially for fluid transport in low-pressure systems. This type is less prone to leaks, making it a preferred choice in industries like oil and gas. However, the seamless nature often comes with a higher price tag. Buyers should evaluate the long-term benefits of reliability against initial costs.

What Are the Advantages of Schedule 80 Aluminum Pipe?

Schedule 80 aluminum pipes feature thicker walls designed for higher pressure applications, making them suitable for industrial plumbing and gas distribution systems. Their enhanced strength and durability are significant advantages, especially in demanding environments. However, they are heavier and more costly than Schedule 40 pipes, which may impact shipping and handling costs. Buyers should assess the specific pressure requirements of their applications to determine the best fit.

When Should You Consider Custom Extruded Pipe?

Custom extruded aluminum pipes allow for tailored dimensions and specifications, making them ideal for specialized industrial applications. While they can meet unique project needs, the trade-off often includes longer lead times and potential higher costs. Buyers should carefully evaluate their project requirements and timelines when considering custom options, ensuring that the benefits of customization align with their operational capabilities.

Key Industrial Applications of sch 40 aluminum pipe

| Industry/Sector | Specific Application of sch 40 aluminum pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Used for framing, scaffolding, and structural support. | Lightweight yet strong, reducing labor and transport costs. | Verify compliance with local building codes and standards. |

| Oil & Gas | Employed in low-pressure fluid transport systems. | Corrosion-resistant, ensuring longevity in harsh environments. | Ensure compatibility with specific fluid types and pressure ratings. |

| Water Treatment | Utilized in piping for water filtration systems. | Non-reactive, preventing contamination of treated water. | Confirm material certifications for potable water applications. |

| Automotive | Applied in vehicle frame and exhaust systems. | Reduces overall vehicle weight, improving fuel efficiency. | Assess weight specifications and durability for specific vehicle models. |

| Food & Beverage | Used in food processing and beverage distribution pipes. | Hygienic properties, preventing bacterial growth. | Ensure compliance with food safety regulations and certifications. |

How is sch 40 aluminum pipe utilized in the construction industry?

In the construction sector, sch 40 aluminum pipe is extensively used for framing, scaffolding, and structural support due to its lightweight yet robust nature. This material reduces labor costs and simplifies transportation, making it ideal for large-scale projects. International buyers, especially from regions like Africa and South America, should ensure compliance with local building codes and regulations to avoid project delays.

What role does sch 40 aluminum pipe play in oil and gas applications?

In the oil and gas industry, sch 40 aluminum pipe is critical for low-pressure fluid transport systems. Its corrosion-resistant properties ensure a longer lifespan, even in harsh environments. Buyers should consider the specific fluid types and pressure ratings to ensure the selected pipe meets operational requirements. This is particularly relevant for businesses in the Middle East, where temperature extremes can impact material performance.

Why is sch 40 aluminum pipe essential for water treatment facilities?

Water treatment facilities utilize sch 40 aluminum pipe in their piping systems due to its non-reactive nature, which prevents contamination of treated water. This characteristic is vital for maintaining water quality and safety. Buyers must confirm that the aluminum pipe complies with local regulations for potable water applications, especially in regions like Europe, where stringent standards are enforced.

How is sch 40 aluminum pipe beneficial in the automotive sector?

In the automotive industry, sch 40 aluminum pipe is often used in vehicle frames and exhaust systems. Its lightweight composition helps reduce overall vehicle weight, leading to improved fuel efficiency. When sourcing, businesses should assess the durability and weight specifications to ensure compatibility with various vehicle models. This is particularly important for manufacturers in countries like Germany, where automotive standards are rigorous.

What advantages does sch 40 aluminum pipe offer in food and beverage applications?

In food processing and beverage distribution, sch 40 aluminum pipe is valued for its hygienic properties, which prevent bacterial growth and ensure product safety. This is crucial in maintaining high standards in food quality. Buyers must ensure that the aluminum pipe meets food safety regulations and certifications, particularly when sourcing for operations in regions with strict health guidelines.

3 Common User Pain Points for ‘sch 40 aluminum pipe’ & Their Solutions

Scenario 1: Sourcing Quality and Specifications for Projects

The Problem: B2B buyers often face challenges when sourcing Schedule 40 aluminum pipe that meets specific project requirements. This can stem from a lack of clarity about the specifications needed for their applications, such as tensile strength, wall thickness, and compatibility with existing systems. Additionally, international buyers may experience complications with suppliers who do not fully understand their regional standards or project needs, leading to delays and potential project failures.

The Solution: To effectively navigate this challenge, buyers should start by clearly defining their project requirements, including material specifications, dimensions, and applicable standards such as ASTM B221 or ASTM B429. Engaging with suppliers who have a strong reputation and experience in international markets can help ensure that they understand local regulations and quality expectations. Buyers should request detailed product specifications and certifications from potential suppliers, ensuring that the aluminum pipe meets the necessary mechanical properties, such as a minimum yield strength of 40,000 PSI. Establishing a close relationship with a reliable supplier can also facilitate better communication regarding any unique project needs, ultimately leading to a smoother procurement process.

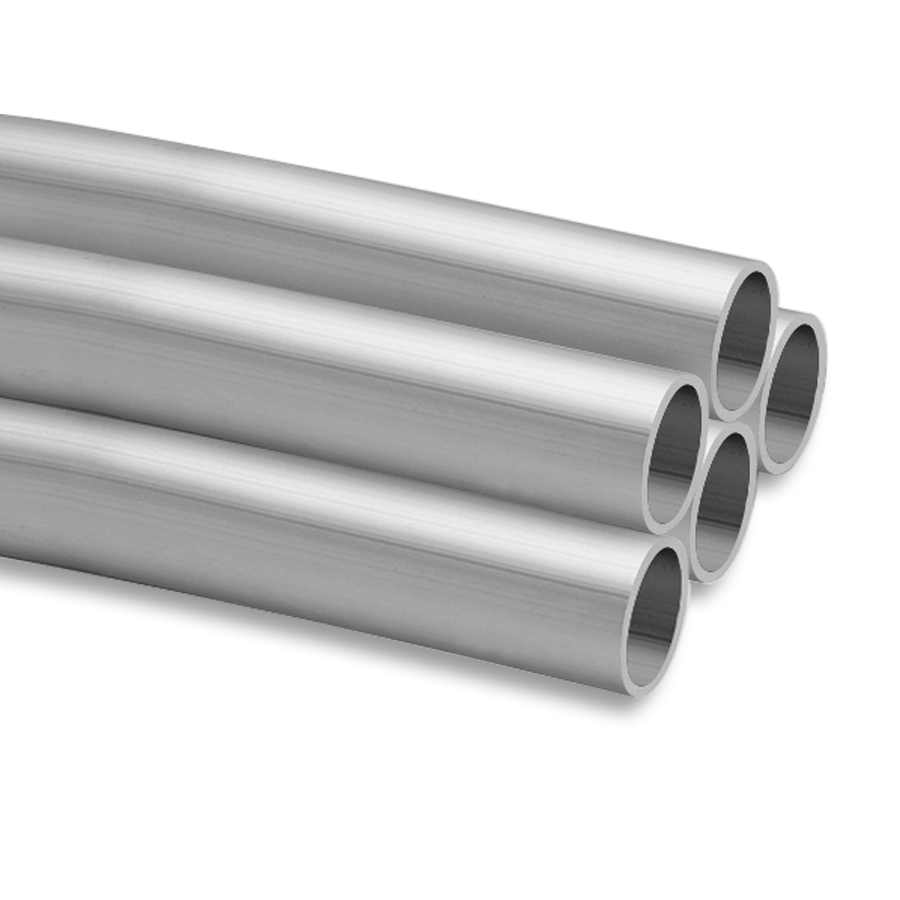

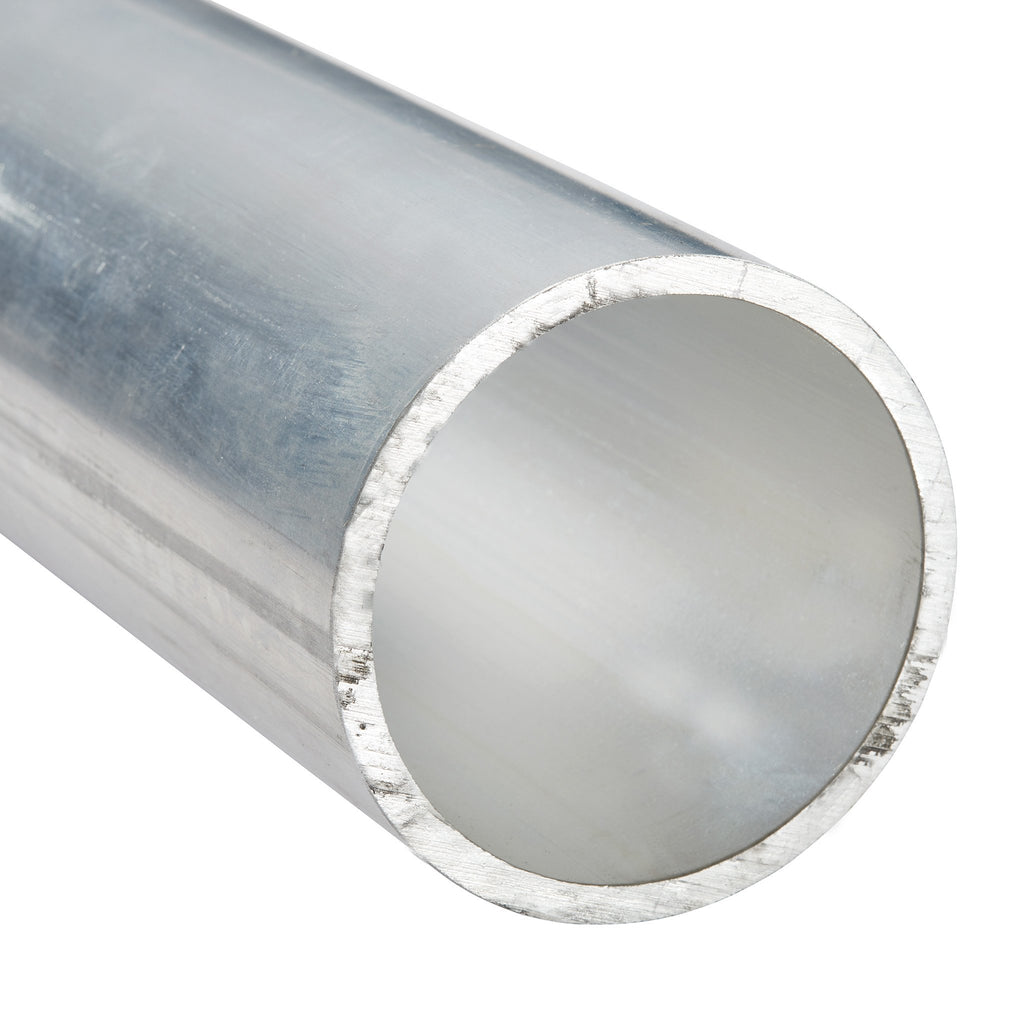

Illustrative image related to sch 40 aluminum pipe

Scenario 2: Managing Lead Times and Delivery Issues

The Problem: Delays in the delivery of Schedule 40 aluminum pipes can significantly impact project timelines and budgets, especially in regions like Africa and South America where logistical challenges are common. B2B buyers often find themselves at the mercy of extended lead times, which can be exacerbated by high demand periods or production capacity issues at manufacturing facilities.

The Solution: To mitigate lead time challenges, buyers should proactively communicate their project timelines to suppliers, allowing for better planning and prioritization of orders. It is beneficial to establish contracts that include clear expectations regarding delivery timelines and penalties for delays. Additionally, maintaining a buffer stock of critical components, including aluminum pipes, can help manage unexpected supply chain disruptions. Buyers should also consider sourcing from multiple suppliers to ensure flexibility and reduce dependency on a single source, which can help smooth out potential delays caused by unforeseen circumstances.

Scenario 3: Understanding the Variability in Product Quality

The Problem: Variability in the quality of Schedule 40 aluminum pipe can create significant headaches for B2B buyers. Inconsistent quality can lead to issues such as pipe failures or incompatibility with existing systems, which can be costly to rectify. Buyers often struggle to identify which suppliers provide reliable quality that adheres to industry standards.

The Solution: To address this issue, buyers should implement a robust quality assurance process that includes thorough evaluation of potential suppliers. This can involve requesting samples for testing, examining third-party certifications, and conducting on-site visits to manufacturing facilities when possible. Establishing quality benchmarks based on recognized industry standards will help ensure that the purchased aluminum pipe is fit for its intended application. Regularly monitoring product performance and maintaining open lines of communication with suppliers can also help in identifying and resolving any quality issues quickly. Additionally, joining industry associations or forums can provide valuable insights into supplier reputations and product quality benchmarks, aiding in better decision-making.

Strategic Material Selection Guide for sch 40 aluminum pipe

What Are the Key Properties of Common Materials for Schedule 40 Aluminum Pipe?

When selecting materials for Schedule 40 aluminum pipe, several alloys stand out due to their unique properties and applications. The most common aluminum alloys used in this context are 6061-T6, 6063-T52, and 6082-T6. Each alloy presents distinct advantages and considerations that can impact performance and cost-effectiveness in various applications.

How Does Aluminum Alloy 6061-T6 Perform in Schedule 40 Applications?

6061-T6 is a widely used aluminum alloy known for its excellent mechanical properties and corrosion resistance. It offers a tensile strength of approximately 45,000 PSI and a yield strength of 40,000 PSI, making it suitable for structural applications. Its ability to withstand temperatures up to 200°F (93°C) without significant loss of strength adds to its versatility.

Pros: The alloy’s strength and lightweight nature make it ideal for applications in construction, automotive, and aerospace sectors. Its weldability and machinability further enhance its appeal for custom projects.

Cons: While 6061-T6 is durable, it can be more expensive than other alloys, and its performance may degrade in highly acidic environments.

Impact on Application: This alloy is particularly effective for transporting fluids under moderate pressure, making it suitable for piping systems in various industries.

Considerations for International Buyers: Compliance with ASTM standards, particularly ASTM B221, is crucial. Buyers from regions like Germany may also need to consider DIN standards for compatibility.

What Advantages Does Aluminum Alloy 6063-T52 Offer?

6063-T52 is another popular choice for Schedule 40 aluminum pipe, especially in architectural applications. It has a lower tensile strength than 6061-T6 but offers superior extrudability, making it easier to shape into complex profiles.

Illustrative image related to sch 40 aluminum pipe

Pros: The alloy is highly resistant to corrosion and is aesthetically pleasing, making it suitable for visible structures like railings and decorative elements.

Cons: Its lower strength limits its application in high-stress environments compared to 6061-T6, which may necessitate thicker walls for certain applications.

Impact on Application: 6063-T52 is ideal for low-pressure fluid transport and architectural applications, where appearance and corrosion resistance are prioritized.

Illustrative image related to sch 40 aluminum pipe

Considerations for International Buyers: Buyers should ensure compliance with ASTM B221 and consider local standards like JIS in Japan or EN in Europe for specific applications.

How Does Aluminum Alloy 6082-T6 Compare for Schedule 40 Pipes?

6082-T6 is a medium-strength alloy that combines good corrosion resistance with excellent weldability. It is often used in structural applications where strength and weight are critical factors.

Pros: This alloy has a good balance of strength and workability, making it suitable for various applications, including marine environments.

Cons: While it offers good mechanical properties, it may not perform as well as 6061-T6 in high-temperature applications.

Illustrative image related to sch 40 aluminum pipe

Impact on Application: 6082-T6 is effective for structural piping in both industrial and commercial settings, particularly where moderate pressure and corrosion resistance are required.

Considerations for International Buyers: Compliance with ASTM and other international standards is essential, especially for projects in regions with stringent regulations.

Summary Table of Material Selection for Schedule 40 Aluminum Pipe

| Material | Typical Use Case for sch 40 aluminum pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061-T6 | Structural applications, fluid transport | High strength and corrosion resistance | Higher cost, less effective in acidic environments | High |

| 6063-T52 | Architectural features, low-pressure systems | Excellent extrudability and aesthetics | Lower strength, may require thicker walls | Medium |

| 6082-T6 | Marine and structural applications | Good balance of strength and workability | Not ideal for high-temperature applications | Medium |

This guide serves as a valuable resource for international B2B buyers, helping them make informed decisions based on material properties, applications, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for sch 40 aluminum pipe

What Are the Main Stages in the Manufacturing Process of Schedule 40 Aluminum Pipe?

The production of Schedule 40 aluminum pipe involves several critical stages, ensuring that the final product meets the required specifications and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with sourcing high-quality aluminum alloy, commonly 6061-T6, known for its excellent mechanical properties and corrosion resistance. The aluminum is then cut into manageable sizes for further processing. Advanced methods like laser cutting may be employed to ensure precision and minimize waste.

Forming Techniques

Forming is a pivotal stage where the aluminum is transformed into pipe shape. Two primary techniques are used: extrusion and seamless forming. In extrusion, aluminum is heated and forced through a die to create a continuous length of pipe. This method is efficient for producing pipes with consistent dimensions. For seamless pipes, the aluminum is shaped without welds, enhancing strength and reducing the risk of leaks in fluid-carrying applications.

Assembly

While most Schedule 40 aluminum pipes do not require extensive assembly, some configurations may involve fittings and connectors. These components must be compatible in terms of size and material to maintain structural integrity.

Finishing

The finishing stage involves surface treatments that enhance durability and appearance. Processes such as anodizing can increase corrosion resistance, while mechanical polishing may improve surface finish. Quality checks are conducted throughout this stage to ensure compliance with specifications.

Illustrative image related to sch 40 aluminum pipe

How Is Quality Assurance Implemented in the Manufacturing of Schedule 40 Aluminum Pipe?

Quality assurance is a fundamental aspect of the manufacturing process for Schedule 40 aluminum pipes, ensuring that products meet international standards and customer expectations. The key components of quality assurance include adherence to international standards, systematic quality checkpoints, and robust testing methods.

Relevant International Standards

Manufacturers of Schedule 40 aluminum pipes typically adhere to several international quality standards, including ISO 9001, which outlines the requirements for a quality management system. Additionally, regional standards such as the CE marking in Europe and API (American Petroleum Institute) standards for oil and gas applications may also apply, depending on the intended use of the pipe.

Quality Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage focuses on the quality of raw materials. Suppliers must provide certification and documentation to verify that the aluminum meets specified grades and standards.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor critical parameters such as dimensions, wall thickness, and structural integrity. Any deviations are addressed immediately to prevent defects in the final product.

-

Final Quality Control (FQC): Once the pipes are finished, a comprehensive inspection is performed. This includes visual inspections and measurements to ensure compliance with specifications. Non-destructive testing methods, such as ultrasonic testing, may be employed to detect internal flaws without damaging the pipe.

What Testing Methods Are Commonly Used in Quality Assurance for Schedule 40 Aluminum Pipe?

Testing is a crucial element of quality assurance in the production of Schedule 40 aluminum pipes. Various methods are employed to validate the mechanical properties, dimensional accuracy, and overall integrity of the pipes.

Common Testing Methods

– Tensile Testing: This method evaluates the pipe’s strength and ductility by measuring how much it can be stretched before breaking. It provides critical information on yield strength, tensile strength, and elongation.

-

Hydrostatic Testing: For pipes intended for fluid transport, hydrostatic testing is essential. It involves filling the pipe with water and pressurizing it to check for leaks and ensure that it can withstand the operating pressures.

-

Dimensional Inspection: Using calipers and gauges, manufacturers verify that the pipes conform to specified dimensions, including outer diameter, inner diameter, and wall thickness. This ensures compatibility with fittings and systems.

-

Corrosion Resistance Testing: For applications in corrosive environments, salt spray tests may be conducted to assess the aluminum’s resistance to corrosion over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with local regulations.

Conducting Audits

Buyers can perform supplier audits to assess the manufacturing processes and quality control systems in place. This can include reviewing documentation of quality management certifications, inspection reports, and testing results.

Illustrative image related to sch 40 aluminum pipe

Requesting Quality Reports

Regularly requesting quality reports from suppliers can provide insights into their QC practices. These reports should detail findings from IQC, IPQC, and FQC stages, as well as results from any testing performed.

Third-Party Inspections

Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can conduct independent audits and testing, providing unbiased evaluations of the supplier’s processes and products.

What Are the Quality Control and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certification is critical for international buyers. Different regions may have varying expectations and regulations regarding quality standards.

Regional Compliance Requirements

For example, in Europe, the CE marking signifies compliance with health, safety, and environmental protection standards. Buyers should ensure that suppliers are compliant with these regulations, which may include additional testing and documentation. In contrast, buyers in the Middle East may prioritize compliance with local standards specific to their industries, such as oil and gas.

Documentation and Traceability

Buyers should also emphasize the importance of documentation and traceability in their supply chain. Suppliers should be able to provide detailed records of material certifications, test results, and compliance with international standards. This documentation is essential for audits and regulatory inspections.

By understanding these manufacturing processes, quality assurance practices, and the necessary verification steps, B2B buyers can make informed decisions when sourcing Schedule 40 aluminum pipes. This knowledge not only enhances procurement efficiency but also ensures that the products meet the required standards for their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sch 40 aluminum pipe’

To successfully procure Schedule 40 aluminum pipe, it’s essential to follow a structured approach that ensures you meet your project requirements while minimizing risks. This checklist serves as a practical guide for B2B buyers navigating the complexities of sourcing aluminum pipe, particularly in international markets.

Step 1: Define Your Technical Specifications

Before initiating any sourcing activities, clearly outline the technical specifications of the Schedule 40 aluminum pipe you require. This includes dimensions, alloy types (commonly 6061-T6 or 6063-T52), and any specific industry standards that must be met, such as ASTM B221 or ASTM B429. Having precise specifications helps avoid miscommunication with suppliers and ensures that the materials received will meet your project needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in aluminum products. Look for companies with a proven track record and positive reviews from previous clients. Utilize industry-specific directories, trade shows, and online platforms to compile a list of potential suppliers. This initial research is critical to ensuring you are dealing with reliable sources.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 for quality management systems or other industry-specific certifications. These certifications indicate a commitment to quality and compliance with international standards. Request documentation to confirm these certifications and assess their validity.

Step 4: Request Samples and Specifications

Before placing a bulk order, request samples of the Schedule 40 aluminum pipe. This allows you to assess the quality, dimensions, and overall suitability for your application. Additionally, ask for the supplier’s product specifications and material certifications to ensure they match your defined criteria.

Step 5: Compare Pricing and Payment Terms

Obtain detailed quotations from multiple suppliers, including all associated costs such as shipping, taxes, and duties. Compare these prices alongside the quality and certifications offered by each supplier. Pay attention to payment terms; negotiating favorable conditions can significantly affect your cash flow and project budget.

Step 6: Confirm Lead Times and Availability

Discuss lead times with your shortlisted suppliers to ensure they can meet your project deadlines. Understanding their production capacity and availability of stock is essential, especially if you are working on a tight schedule. Confirming these details upfront helps prevent delays and ensures timely delivery.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful sourcing process. Establish clear lines of communication with your chosen supplier, including contact persons and preferred methods of communication. Regular updates and open dialogue will help address any issues that may arise and facilitate a smoother transaction process.

Illustrative image related to sch 40 aluminum pipe

By following these steps, B2B buyers can navigate the complexities of sourcing Schedule 40 aluminum pipe effectively, ensuring they select the right suppliers while meeting their project specifications.

Comprehensive Cost and Pricing Analysis for sch 40 aluminum pipe Sourcing

What Are the Key Cost Components in Sourcing Schedule 40 Aluminum Pipe?

When sourcing Schedule 40 aluminum pipe, understanding the cost structure is crucial for B2B buyers. Key cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials typically account for a significant portion of the total cost. The price of aluminum fluctuates based on market demand, geopolitical factors, and currency exchange rates, which can be particularly impactful for international buyers. Labor costs vary by region and can be influenced by local wage standards and skill availability. Manufacturing overhead includes expenses such as utilities, equipment maintenance, and facility costs, which should be factored into the total cost.

Illustrative image related to sch 40 aluminum pipe

Tooling costs can also be considerable, especially if custom pipe sizes or specifications are required. Efficient tooling processes can help reduce costs. Quality control measures are essential to ensure product integrity, particularly for applications in industries like aerospace and construction, where compliance with standards such as ASTM is mandatory. Finally, logistics costs, including shipping, customs duties, and insurance, can vary significantly depending on the destination and chosen Incoterms.

How Do Price Influencers Affect Schedule 40 Aluminum Pipe Costs?

Several factors influence the pricing of Schedule 40 aluminum pipe. Volume and Minimum Order Quantity (MOQ) play a significant role; larger orders often lead to reduced per-unit pricing due to economies of scale. Specifications and customization can also affect costs. Pipes with unique dimensions or additional features may incur higher production costs.

Material quality and certifications are critical in determining price. Pipes that meet higher-grade specifications or come with certifications from recognized bodies typically command higher prices. Additionally, supplier factors such as reputation, reliability, and production capacity can influence pricing. Suppliers with a strong track record may charge a premium but can also provide better service and quality assurance.

Incoterms determine the responsibilities of buyers and sellers in terms of shipping and handling, impacting overall costs. For instance, choosing a Cost, Insurance, and Freight (CIF) term may lead to higher upfront costs but lower risks in case of damage during transit.

Illustrative image related to sch 40 aluminum pipe

What Are Effective Buyer Tips for Negotiating Costs?

B2B buyers should approach negotiations with a clear understanding of their Total Cost of Ownership (TCO). This includes not only the purchase price but also ongoing costs such as maintenance, durability, and potential failure rates. Buyers should ask suppliers for detailed breakdowns of costs to identify areas for potential savings.

When negotiating, consider leveraging volume discounts by consolidating orders or exploring long-term contracts, which can secure lower pricing. Additionally, be open to discussing alternative materials or specifications that may meet your needs at a lower cost.

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, it’s essential to account for currency fluctuations and trade tariffs. Engaging in forward contracts or hedging strategies can mitigate risks associated with currency exchange rates.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It is important to note that indicative prices for Schedule 40 aluminum pipe can vary widely based on the aforementioned factors. Always request updated quotes and consider that market conditions can change rapidly. Ensure that you have a clear understanding of all terms and conditions before finalizing any agreements.

By being well-informed about the cost structure, price influencers, and effective negotiation strategies, B2B buyers can make more informed decisions and optimize their sourcing process for Schedule 40 aluminum pipe.

Alternatives Analysis: Comparing sch 40 aluminum pipe With Other Solutions

When evaluating options for piping solutions in various industrial applications, it’s essential to consider alternatives to Schedule 40 (sch 40) aluminum pipes. This section compares sch 40 aluminum pipes with two viable alternatives: Schedule 80 aluminum pipes and carbon steel pipes. The comparison will focus on critical aspects including performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Sch 40 Aluminum Pipe | Schedule 80 Aluminum Pipe | Carbon Steel Pipe |

|---|---|---|---|

| Performance | Good corrosion resistance; lightweight; suitable for low to medium pressure applications. | Higher strength; better suited for high-pressure applications. | Strong and durable; good for high-pressure and high-temperature applications. |

| Cost | Generally lower cost than alternatives. | Higher cost due to increased wall thickness. | Often less expensive than aluminum but prices can vary based on market conditions. |

| Ease of Implementation | Easy to install; lightweight facilitates handling. | Slightly more challenging due to added weight and thickness. | Requires more robust handling and installation techniques. |

| Maintenance | Low maintenance; corrosion-resistant. | Similar low maintenance but can be more prone to corrosion if not treated. | Requires regular maintenance to prevent rust and corrosion. |

| Best Use Case | Ideal for fluid transport in low-pressure environments (e.g., irrigation, HVAC). | Best for applications requiring higher pressure and structural integrity (e.g., structural frameworks). | Suitable for heavy-duty industrial applications (e.g., oil and gas, construction). |

What are the Advantages and Disadvantages of Schedule 80 Aluminum Pipes?

Schedule 80 aluminum pipes offer a thicker wall compared to sch 40 pipes, providing increased strength and pressure handling capabilities. This makes them ideal for applications where higher pressure is a concern, such as in certain structural frameworks. However, the trade-off is a higher cost and slightly more challenging installation due to their weight. For industries that require robust and reliable piping solutions, the added cost may justify the enhanced performance.

Illustrative image related to sch 40 aluminum pipe

How Do Carbon Steel Pipes Compare to Aluminum Options?

Carbon steel pipes are known for their strength and durability, making them an excellent choice for high-pressure and high-temperature applications. They are typically less expensive than aluminum options, which can be appealing for budget-conscious projects. However, they are also heavier and require regular maintenance to prevent rust and corrosion. This maintenance can lead to increased long-term costs. For applications in harsh environments, carbon steel may require additional protective coatings, which can add to the complexity of installation and maintenance.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When deciding between sch 40 aluminum pipes, Schedule 80 aluminum pipes, and carbon steel pipes, B2B buyers should assess their specific needs, including the operating environment, pressure requirements, and budget constraints. For low-pressure applications where weight is a concern, sch 40 aluminum may be the best choice. In contrast, for high-pressure applications, Schedule 80 aluminum or carbon steel may be more suitable despite their higher costs and maintenance needs. Ultimately, understanding the unique requirements of the project will guide buyers in selecting the most appropriate piping solution.

Essential Technical Properties and Trade Terminology for sch 40 aluminum pipe

Understanding the essential technical properties and trade terminology associated with Schedule 40 aluminum pipe is crucial for B2B buyers, especially in industries that rely on precision materials. This section outlines key specifications and commonly used terms to facilitate informed purchasing decisions.

What Are the Key Technical Properties of Schedule 40 Aluminum Pipe?

Material Grade

Schedule 40 aluminum pipe is typically made from alloys such as 6061-T6 or 6063-T52. The choice of alloy impacts the pipe’s strength, corrosion resistance, and suitability for various applications. For instance, 6061-T6 is known for its excellent mechanical properties, making it ideal for structural applications, while 6063-T52 is often preferred for architectural purposes due to its aesthetic finish.

Wall Thickness

The wall thickness of Schedule 40 aluminum pipe varies depending on the nominal size. Common wall thicknesses range from 0.068 inches for smaller diameters to 0.322 inches for larger sizes. This specification is critical as it directly influences the pipe’s pressure rating and load-bearing capacity, which are essential for ensuring safety and performance in applications such as fluid transport and structural support.

Outside Diameter (OD) and Inside Diameter (ID)

Schedule 40 aluminum pipes have standardized outside and inside diameters that facilitate compatibility with fittings and connectors. For example, a 1-inch nominal size typically has an OD of 1.315 inches and an ID of approximately 1.049 inches. Accurate measurements are vital for ensuring proper installation and functionality in piping systems.

Tensile and Yield Strength

The tensile strength of Schedule 40 aluminum pipe is generally around 45,000 PSI, while the yield strength is approximately 40,000 PSI. These mechanical properties indicate the material’s ability to withstand forces without permanent deformation. Understanding these values helps buyers assess whether the pipe can meet the demands of specific applications, such as high-pressure environments.

Chemical Composition

The chemical composition of aluminum alloys used in Schedule 40 pipes, such as copper, silicon, magnesium, and iron, can affect properties like corrosion resistance and weldability. Buyers should consider these elements when selecting a pipe for environments that may expose it to corrosive substances or require welding during installation.

What Are Common Trade Terms Related to Schedule 40 Aluminum Pipe?

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed under another company’s brand. In the context of aluminum pipes, OEMs might supply components for various industries, including construction and manufacturing, making it essential to identify reliable OEMs for quality assurance.

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory costs and ensure they meet supplier requirements while securing favorable pricing on bulk orders.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This document often includes specifications for the aluminum pipe, such as dimensions and material grades. Engaging in this process allows buyers to compare offers and negotiate better terms.

Illustrative image related to sch 40 aluminum pipe

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs and responsibilities, particularly for international buyers.

ASTM (American Society for Testing and Materials)

ASTM standards specify the quality and performance criteria for materials, including aluminum pipes. Knowing relevant ASTM specifications helps buyers ensure compliance with industry standards and regulations, thus enhancing product reliability.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing Schedule 40 aluminum pipes, ensuring they select the right products for their specific applications and operational needs.

Illustrative image related to sch 40 aluminum pipe

Navigating Market Dynamics and Sourcing Trends in the sch 40 aluminum pipe Sector

What Are the Key Market Drivers for Schedule 40 Aluminum Pipe?

The global market for Schedule 40 aluminum pipe is influenced by several key drivers. Primarily, the demand for lightweight yet durable materials in construction and manufacturing sectors propels the use of aluminum pipes. Industries such as automotive, aerospace, and construction increasingly favor aluminum due to its corrosion resistance and strength-to-weight ratio. Additionally, technological advancements in manufacturing processes, including extrusion and seamless pipe production, enhance the quality and availability of Schedule 40 aluminum pipes, making them more accessible to international buyers.

Emerging trends in digital sourcing and e-commerce platforms are reshaping the way businesses procure materials. B2B buyers from regions like Africa, South America, the Middle East, and Europe can now source aluminum pipes online with relative ease, allowing for greater price transparency and competitive comparisons. The use of data analytics to forecast demand and manage inventory is becoming more prevalent, enabling suppliers to offer customized solutions to meet buyer specifications more efficiently.

How Is Sustainability Influencing the Sourcing of Schedule 40 Aluminum Pipe?

Sustainability is a crucial factor influencing the sourcing of Schedule 40 aluminum pipe. As global awareness of environmental issues increases, businesses are under pressure to adopt more sustainable practices. The aluminum industry, known for its significant energy consumption, is actively pursuing innovations to reduce its carbon footprint. This includes increasing the use of recycled aluminum, which not only minimizes waste but also lowers energy usage compared to primary aluminum production.

Ethical sourcing is becoming essential for B2B buyers, who are increasingly prioritizing suppliers that demonstrate commitment to sustainable practices. Certifications such as ISO 14001 (Environmental Management Systems) and LEED (Leadership in Energy and Environmental Design) are now critical indicators of a supplier’s dedication to sustainability. Buyers in emerging markets, particularly in Africa and South America, are recognizing the value of aligning with suppliers who can provide ‘green’ certifications, which can enhance their market reputation and comply with international standards.

How Has the Schedule 40 Aluminum Pipe Market Evolved Over Time?

The Schedule 40 aluminum pipe market has undergone significant evolution over the years. Initially dominated by heavier steel pipes, the industry began to shift towards aluminum in the mid-20th century due to its favorable properties, including lightweight and corrosion resistance. The introduction of advanced aluminum alloys, particularly 6061-T6, has further enhanced the strength and durability of aluminum pipes, making them suitable for a wider range of applications, from structural to fluid transport.

The globalization of trade has also facilitated the widespread adoption of aluminum pipes across various regions. International standards, such as ASTM B221, have standardized specifications, allowing buyers worldwide to confidently source quality products. Today, the market is characterized by a diverse array of suppliers and manufacturers, offering competitive pricing and customization options, making it easier for B2B buyers to meet their specific needs.

In conclusion, understanding the dynamics of the Schedule 40 aluminum pipe market is crucial for international B2B buyers. Staying informed about market trends, prioritizing sustainability, and recognizing the historical context of aluminum sourcing can enhance procurement strategies and foster stronger supplier relationships.

Frequently Asked Questions (FAQs) for B2B Buyers of sch 40 aluminum pipe

1. How do I determine the right size of sch 40 aluminum pipe for my project?

Selecting the appropriate size of sch 40 aluminum pipe involves understanding your project’s specific requirements, including the intended application and the fluid or material to be transported. Measure the inner diameter (ID) and wall thickness to ensure compatibility with your fittings and connections. It’s crucial to consult technical specifications or industry standards, such as ASTM B221, to guide your choice. Engaging with a knowledgeable supplier can also provide insights into common sizes used in your industry, helping you make an informed decision.

2. What is the best grade of aluminum for sch 40 pipe applications?

The most commonly used grade for sch 40 aluminum pipe is 6061-T6, known for its excellent mechanical properties, corrosion resistance, and weldability. This alloy is ideal for structural applications, including framing and fluid transport. Depending on your specific application, you might also consider 6063-T52 for architectural uses or other grades tailored for high-stress environments. Always consult with your supplier to determine the best alloy suited to your operational conditions and regulatory requirements.

3. What are the typical lead times for ordering sch 40 aluminum pipe?

Lead times can vary significantly based on factors such as order volume, customization, and supplier capabilities. Generally, standard orders may take anywhere from a few days to several weeks. For custom cuts or specific grades, expect longer lead times, potentially up to several weeks. It is advisable to communicate your deadlines clearly with suppliers and inquire about their current production schedules to avoid delays in your project timelines.

4. How do I vet international suppliers of sch 40 aluminum pipe?

To effectively vet international suppliers, start by reviewing their certifications, such as ISO 9001, which indicates a commitment to quality management. Request references from past clients and check for reviews or testimonials. Assess their experience in your specific industry and inquire about their production processes and quality assurance measures. Additionally, visiting their facilities, if feasible, or conducting virtual meetings can provide deeper insights into their operations and reliability.

5. What are common payment terms in international B2B transactions for sch 40 aluminum pipe?

Payment terms can vary widely, but common practices include letters of credit, advance payments, or net payment terms (e.g., 30, 60, or 90 days). It’s essential to negotiate terms that align with both parties’ cash flow needs while ensuring security against potential risks. Consider utilizing escrow services for larger transactions to mitigate risks. Always clarify the payment currency and any additional fees that may apply, especially with international transactions.

6. Can I customize the length and specifications of sch 40 aluminum pipe?

Yes, many suppliers offer customization options for length, diameter, and wall thickness of sch 40 aluminum pipe to meet specific project requirements. Custom orders may incur additional costs and longer lead times. It’s crucial to provide precise measurements and specifications when placing your order. Engaging with your supplier early in the process can help ensure that your requirements are met without compromising quality or delivery timelines.

7. What are the quality assurance measures to consider when sourcing sch 40 aluminum pipe?

Quality assurance measures should include checking for compliance with relevant industry standards, such as ASTM specifications. Request mill test reports that detail the material properties and chemical composition. Suppliers should also have quality control processes in place, including inspections and testing for dimensional accuracy and structural integrity. Inquire about their return policy and procedures for addressing defective products to ensure your investment is protected.

8. What logistics considerations should I keep in mind when importing sch 40 aluminum pipe?

When importing sch 40 aluminum pipe, consider shipping methods, customs regulations, and potential tariffs that may affect your total cost. Collaborate with a logistics partner experienced in international shipping to navigate customs clearance and ensure timely delivery. Proper packaging is essential to prevent damage during transit. Additionally, establish clear communication with your supplier regarding shipping schedules and documentation to facilitate a smooth import process.

Top 3 Sch 40 Aluminum Pipe Manufacturers & Suppliers List

1. Fast Metals – 1-1/2 X SCH 40 Pipe 6061-T6

Domain: fastmetals.com

Registered: 2013 (12 years)

Introduction: 1-1/2″ X SCH 40 (1.900″ OD X .145W) PIPE 6061-T6 EXTRUDED STRUCTURAL

2. McMaster – Aluminum Pipe & Fittings

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Aluminum Pipe & Fittings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Eastern Metal – Aluminum Pipe

Domain: easternmetal.com

Registered: 1996 (29 years)

Introduction: Aluminum Pipe available in standard sizes and alloys such as 6061 and 6063. Pipe sizes up to 12″ SCH 40 are in stock for immediate shipment. High quality anodized marine grade pipe with polished or brushed finish in 6463 alloy. Custom sizes, lengths, alloys, and finishes available. Products include: 1/4″ x 12′ 6063 T52 M/F SCH 40 PIPE, 3/8″ x 20′ 6063 T52 M/F SCH 40 PIPE, 1/2″ x 20′ 6063 T52 M/F S…

Strategic Sourcing Conclusion and Outlook for sch 40 aluminum pipe

In the competitive landscape of global trade, strategic sourcing of Schedule 40 aluminum pipe presents significant opportunities for businesses in Africa, South America, the Middle East, and Europe. Understanding the specifications and applications of this versatile material is crucial for optimizing supply chains and ensuring product quality. Key takeaways include the importance of selecting reliable suppliers who can provide consistent quality and timely delivery, as well as the need to assess local market conditions and regulatory compliance.

The value of strategic sourcing lies in its ability to enhance operational efficiency and reduce costs. By leveraging strong supplier relationships and exploring alternative sourcing options, businesses can mitigate risks and adapt to market fluctuations effectively. Additionally, staying informed about technological advancements in aluminum processing can lead to innovative applications and increased competitiveness.

Looking ahead, international B2B buyers are encouraged to engage in proactive sourcing strategies that align with their specific market needs. By fostering collaboration and embracing sustainability in sourcing practices, companies can not only secure high-quality aluminum pipe but also contribute to a more resilient and environmentally responsible supply chain. The future of your procurement strategy begins today—invest in strategic sourcing to drive growth and success in your business endeavors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.