The Definitive Guide to Ruber Tubes: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for ruber tubes

In today’s fast-paced global market, sourcing high-quality rubber tubes can pose significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The diverse applications of rubber tubes—from industrial manufacturing to medical uses—require a deep understanding of the various types available, including latex, silicone, and specialty compounds. This guide aims to equip international buyers with the knowledge they need to navigate the complexities of sourcing rubber tubes, ensuring they can make informed purchasing decisions that meet their specific needs.

Throughout this comprehensive resource, we will explore the different types of rubber tubes, their applications across various industries, and essential criteria for vetting suppliers. Additionally, we will delve into cost considerations and provide insights on negotiating favorable terms, enabling buyers to maximize value while minimizing risk. Understanding these key factors is crucial for businesses looking to enhance their operational efficiency and product quality.

By empowering B2B buyers with actionable insights and a clear roadmap for sourcing rubber tubes, this guide serves as an invaluable tool in fostering successful partnerships and driving growth in a competitive landscape. Whether you are in Nigeria, Brazil, or any other emerging market, this resource will help streamline your procurement process, ensuring you have the right materials to support your business objectives.

Understanding ruber tubes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Latex Rubber Tubing | Highly elastic, stretches up to three times its length | Tool handles, eye splices | Pros: Excellent elasticity; Cons: Not suitable for high-temperature applications. |

| Neoprene Rubber Tubing | Resistant to oil, ozone, and weathering | Automotive, marine, and industrial | Pros: Durable and versatile; Cons: Higher cost compared to other materials. |

| Silicone Rubber Tubing | High-temperature resistance and flexibility | Medical, food processing, and HVAC | Pros: Biocompatible and food-safe; Cons: Can be less chemically resistant than other rubbers. |

| Nitrile Rubber Tubing | Excellent oil and fuel resistance | Automotive and industrial applications | Pros: Great for fuel transfer; Cons: Limited temperature range. |

| EPDM Rubber Tubing | Good weather resistance and flexibility | Outdoor applications, roofing | Pros: Durable against UV exposure; Cons: Not suitable for petroleum-based products. |

What are the characteristics of Latex Rubber Tubing for B2B buyers?

Latex rubber tubing is renowned for its exceptional elasticity, allowing it to stretch up to three times its original length. This feature makes it ideal for various applications such as tool handles and eye splices, where flexibility is crucial. For B2B buyers, particularly in sectors like manufacturing and logistics, the ability to customize lengths sold by the foot can be a significant advantage. However, it’s essential to consider that latex may not perform well in high-temperature environments, limiting its application scope.

How does Neoprene Rubber Tubing stand out in industrial applications?

Neoprene rubber tubing is distinguished by its resistance to oil, ozone, and weathering, making it a preferred choice in automotive and marine applications. Its durability and versatility enable it to withstand harsh conditions, which is a critical consideration for B2B buyers in industries requiring reliable materials. While the initial investment may be higher compared to other rubber types, the long-term cost-effectiveness and reduced need for replacements can justify the expense.

Why is Silicone Rubber Tubing essential for specific industries?

Silicone rubber tubing is characterized by its ability to withstand high temperatures and its flexibility, making it suitable for sensitive applications in medical and food processing sectors. Its biocompatibility and food-safe properties are particularly appealing to B2B buyers in these industries. However, while it offers significant advantages, buyers should be aware that silicone may have limitations regarding chemical resistance compared to other rubber types, which could affect its suitability for certain applications.

What are the benefits of using Nitrile Rubber Tubing?

Nitrile rubber tubing is specifically designed for environments where oil and fuel resistance are paramount, making it an excellent choice for automotive and industrial applications. Its robust construction allows for safe fuel transfer, a vital consideration for B2B buyers in these sectors. However, it’s important to note that nitrile tubing has a more limited temperature range, which may restrict its use in high-temperature applications, warranting careful consideration during procurement.

How does EPDM Rubber Tubing perform in outdoor applications?

EPDM rubber tubing is known for its excellent weather resistance and flexibility, making it ideal for outdoor applications, including roofing and automotive uses. Its durability against UV exposure ensures longevity, which is a critical factor for B2B buyers seeking reliable materials for outdoor installations. However, EPDM is not suitable for petroleum-based products, so buyers must evaluate their specific needs to ensure compatibility.

Key Industrial Applications of ruber tubes

| Industry/Sector | Specific Application of ruber tubes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation systems and water distribution | Enhanced crop yield through efficient water management | Durability in various weather conditions, flexibility in diameter options |

| Food & Beverage | Transfer of liquids and gases in processing plants | Compliance with safety standards, reduced contamination risk | FDA-approved materials, temperature resistance |

| Pharmaceuticals | Medical tubing for drug delivery systems | Precision in dosage delivery, enhanced patient safety | Sterilization capabilities, biocompatibility |

| Automotive | Fuel and coolant transfer systems | Improved vehicle performance, reduced leakage risks | Resistance to temperature fluctuations, compatibility with various fluids |

| Construction | Sealant for joints and gaps in structures | Improved structural integrity, enhanced insulation | Weather resistance, flexibility, and ease of installation |

How Are Rubber Tubes Used in Agriculture and What Problems Do They Solve?

In agriculture, rubber tubes are essential for irrigation systems, allowing for efficient water distribution directly to crops. They help mitigate issues related to water scarcity and ensure that plants receive adequate moisture, which is vital for maximizing yield. Buyers in this sector should prioritize tubes that can withstand various weather conditions and offer a range of diameters to suit different irrigation setups.

What Role Do Rubber Tubes Play in the Food and Beverage Industry?

Rubber tubes are critical in the food and beverage industry for transferring liquids and gases during processing. They help ensure compliance with safety standards, significantly reducing the risk of contamination. International buyers should focus on sourcing tubes made from FDA-approved materials that can handle extreme temperature fluctuations, ensuring both safety and efficiency in food processing operations.

How Are Rubber Tubes Used in Pharmaceuticals and What Are the Key Requirements?

In the pharmaceutical industry, rubber tubes are utilized in drug delivery systems, providing a precise method for administering medications. This application addresses the need for accuracy in dosage and enhances patient safety. Buyers should look for tubes that offer sterilization capabilities and are biocompatible, ensuring they meet stringent health regulations and standards.

What Benefits Do Rubber Tubes Provide in the Automotive Sector?

Rubber tubes are used in automotive applications for transferring fuel and coolant, which is essential for vehicle performance. They mitigate risks associated with leaks and ensure optimal functioning of the engine. Buyers should consider sourcing tubes that are resistant to temperature fluctuations and compatible with various automotive fluids to enhance longevity and reliability.

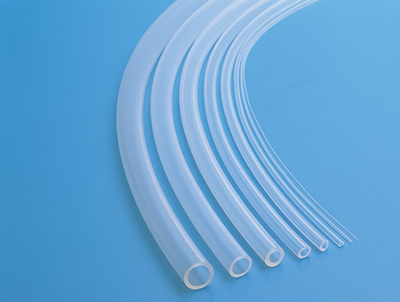

Illustrative image related to ruber tubes

How Do Rubber Tubes Enhance Construction Projects?

In construction, rubber tubes serve as sealants for joints and gaps, improving structural integrity and providing insulation. This application is crucial for maintaining energy efficiency and preventing moisture ingress. Buyers should prioritize tubes that are weather-resistant and flexible, allowing for easy installation and adaptability to various construction environments.

3 Common User Pain Points for ‘ruber tubes’ & Their Solutions

Scenario 1: Sourcing High-Quality Rubber Tubes for Diverse Applications

The Problem: Many B2B buyers face the challenge of sourcing high-quality rubber tubes that meet specific industry standards and requirements. In regions like Africa and South America, where local suppliers may not always provide consistent quality, buyers often struggle with variations in material durability and performance. This inconsistency can lead to product failures, downtime, and increased operational costs, as inferior tubes can rupture or degrade quickly under stress or adverse environmental conditions.

The Solution: To overcome this issue, buyers should prioritize sourcing rubber tubes from reputable manufacturers with proven quality control processes. It’s essential to request certification for the rubber materials used, such as compliance with ASTM, ISO, or other relevant standards. Buyers should also consider engaging in direct communication with suppliers to discuss specific application needs—be it for temperature extremes, chemical exposure, or flexibility requirements. Utilizing samples for testing before placing bulk orders can further mitigate risks associated with quality inconsistencies. Establishing a long-term relationship with reliable suppliers can also ensure a steady supply of high-quality products tailored to the buyer’s exact specifications.

Scenario 2: Ensuring Compatibility with Existing Equipment

The Problem: A common pain point for B2B buyers is ensuring that the rubber tubes they purchase are compatible with their existing equipment and systems. Mismatched sizes, materials, or fittings can lead to inefficiencies and costly modifications. This issue is particularly prevalent in industries like manufacturing or agriculture, where equipment upgrades or changes in production processes may not align with previously sourced tubing.

The Solution: Buyers should conduct a thorough analysis of their current systems before sourcing rubber tubes. This includes measuring existing fittings, understanding pressure and flow requirements, and considering the chemical compatibility of the tube material with the substances being transported. Buyers can create a detailed specification sheet that outlines these requirements, which can then be shared with potential suppliers. Engaging with suppliers that offer customization options can also be beneficial; they can provide tailored solutions that fit specific dimensions and performance criteria. Additionally, leveraging technology such as CAD (Computer-Aided Design) tools can help visualize and confirm compatibility before purchasing.

Scenario 3: Navigating Regulatory Compliance Challenges

The Problem: Regulatory compliance is a significant concern for B2B buyers, especially in industries such as food and beverage, pharmaceuticals, and chemicals. Buyers must ensure that the rubber tubes they use meet stringent health and safety regulations, which can vary significantly across regions like Europe and the Middle East. Failure to comply with these regulations can result in fines, product recalls, or damage to reputation, making it imperative for buyers to navigate these complexities effectively.

The Solution: Buyers should familiarize themselves with the specific regulatory requirements applicable to their industry and region. This includes understanding standards such as FDA regulations for food-grade rubber tubes or REACH compliance in Europe. It’s advisable to work closely with suppliers who are transparent about their compliance certifications and can provide documentation upon request. Buyers can also benefit from conducting regular audits of their suppliers to ensure ongoing compliance. Additionally, seeking legal counsel or consulting with industry experts can provide further insights into navigating regulatory landscapes and avoiding potential pitfalls. By prioritizing compliance from the outset, buyers can protect their operations and maintain a competitive edge in their respective markets.

Strategic Material Selection Guide for ruber tubes

What Are the Key Properties of Common Materials Used for Rubber Tubes?

When selecting rubber tubes for various applications, understanding the properties of different materials is crucial. Here, we analyze four common materials: Natural Rubber, Neoprene, EPDM, and Silicone. Each material has unique characteristics that affect performance and suitability for specific applications.

How Does Natural Rubber Perform in Rubber Tubing Applications?

Natural rubber is known for its excellent elasticity and tensile strength. It can withstand temperatures ranging from -60°C to +80°C, making it suitable for a variety of environments. However, natural rubber is less resistant to ozone and UV exposure, which can lead to degradation over time.

Pros: Natural rubber is cost-effective and provides superior flexibility, making it ideal for applications requiring frequent movement or bending.

Cons: Its susceptibility to environmental factors like ozone and UV light limits its outdoor applications. Additionally, it may not be suitable for chemical exposure, particularly with oils and solvents.

Impact on Application: Natural rubber is best used in applications where flexibility and cost are prioritized, such as in automotive or general industrial settings.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN, particularly for applications in regions like Africa and South America, where environmental conditions may vary significantly.

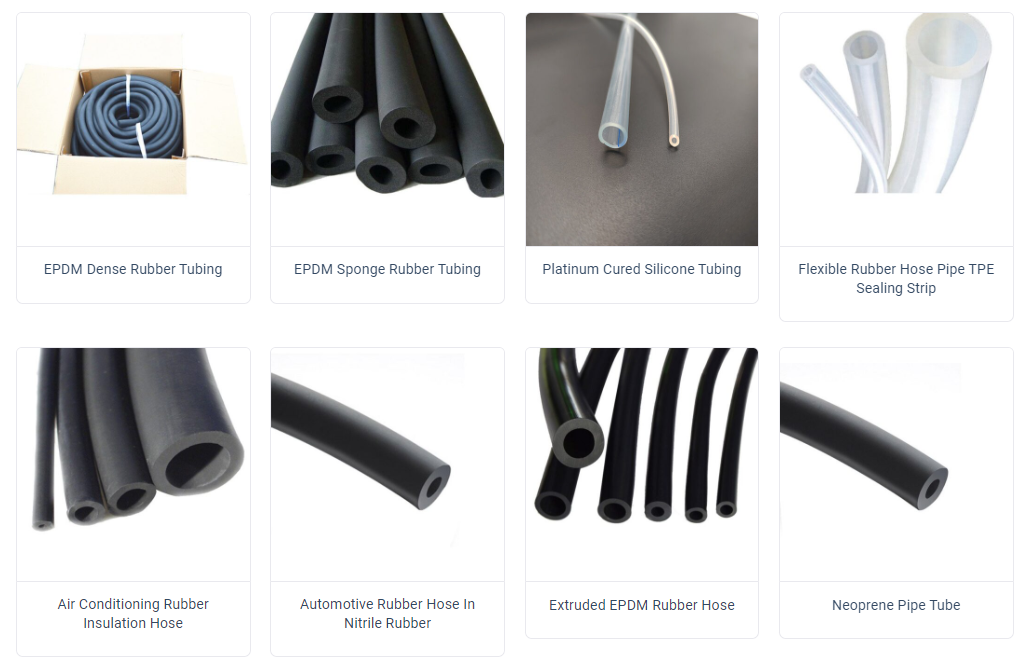

Illustrative image related to ruber tubes

What Advantages Does Neoprene Offer for Rubber Tubing?

Neoprene is a synthetic rubber that exhibits excellent resistance to oil, chemicals, and weathering. It operates effectively in temperatures ranging from -40°C to +120°C, making it versatile for various applications.

Pros: Neoprene’s durability and resistance to environmental factors make it suitable for outdoor and industrial applications. It is also flame-retardant, adding an extra layer of safety.

Cons: The manufacturing process of neoprene can be more complex and costly compared to natural rubber, which may increase the overall price of the final product.

Impact on Application: Neoprene is ideal for applications involving exposure to oils and chemicals, such as in automotive fuel lines or industrial machinery.

Considerations for International Buyers: Compliance with international standards is critical, especially in regions like the Middle East, where high temperatures and exposure to chemicals are common.

How Does EPDM Compare as a Material for Rubber Tubing?

EPDM (Ethylene Propylene Diene Monomer) is known for its outstanding weather resistance and thermal stability. It can operate in a temperature range of -50°C to +150°C, making it highly versatile.

Pros: EPDM is excellent for outdoor applications due to its resistance to UV rays, ozone, and extreme temperatures. It is also compatible with a wide range of chemicals, enhancing its usability.

Cons: While EPDM is durable, its flexibility is not as high as that of natural rubber, which may limit its application in scenarios requiring significant bending.

Illustrative image related to ruber tubes

Impact on Application: EPDM is particularly suitable for applications in the automotive and construction industries, where exposure to harsh weather conditions is common.

Considerations for International Buyers: Buyers should verify compliance with local standards, particularly in Europe, where stringent regulations may apply to automotive and construction materials.

What Makes Silicone a Preferred Choice for Certain Rubber Tubes?

Silicone rubber offers exceptional temperature resistance, functioning effectively from -60°C to +230°C. Its inherent flexibility and chemical resistance make it ideal for a variety of specialized applications.

Pros: Silicone is non-toxic and has excellent thermal stability, making it suitable for food and medical applications. Its flexibility also allows for easy installation.

Cons: Silicone tends to be more expensive than other rubber materials, which can be a limiting factor for budget-conscious buyers.

Impact on Application: Silicone is often used in applications requiring high-temperature resistance, such as in food processing or medical devices.

Considerations for International Buyers: Buyers must ensure silicone products meet relevant health and safety standards, particularly in regions like Europe, where food safety regulations are stringent.

Summary Table of Rubber Tube Materials

| Material | Typical Use Case for ruber tubes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Automotive hoses, industrial use | Excellent flexibility and cost | Poor ozone and UV resistance | Low |

| Neoprene | Fuel lines, industrial machinery | Strong chemical and weather resistance | Higher manufacturing complexity | Medium |

| EPDM | Automotive seals, construction | Outstanding weather resistance | Less flexible than natural rubber | Medium |

| Silicone | Medical devices, food processing | High-temperature and chemical resistance | Higher cost | High |

This strategic material selection guide provides insights into the properties, advantages, and considerations of various rubber tube materials, enabling B2B buyers to make informed decisions tailored to their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for ruber tubes

What Are the Main Stages in the Manufacturing Process of Rubber Tubes?

The manufacturing of rubber tubes involves several critical stages that ensure the final product meets the required specifications and quality standards. Understanding these stages is crucial for B2B buyers who prioritize reliability and performance in their supply chains.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in the manufacturing process involves selecting high-quality raw materials, primarily rubber compounds that can include natural rubber, synthetic rubber, or a blend of both. Manufacturers often utilize compounds that have been specifically formulated to meet industry standards, ensuring durability and flexibility.

Once the materials are selected, they undergo processing, which includes mixing with additives like vulcanizing agents, colorants, and stabilizers. This step is essential for enhancing the rubber’s properties, such as heat resistance, tensile strength, and elasticity. The mixing process typically occurs in a controlled environment to ensure consistency and quality.

Forming: What Techniques Are Used to Shape Rubber Tubes?

The forming stage involves shaping the processed rubber into tubes. This is primarily achieved through extrusion, a common method where the rubber mixture is forced through a die to create continuous lengths of tubing. Extrusion allows for precise control over the dimensions of the tubes, making it an ideal choice for producing items with specific inner and outer diameters.

In some cases, manufacturers may also employ molding techniques, particularly for specialized rubber tubes that require complex shapes or features. Molding can involve compression or injection processes, allowing for the incorporation of additional components like fittings or connectors directly into the tube.

Assembly: How Are Different Components Integrated into Rubber Tubes?

For applications that require additional features, the assembly stage integrates various components into the rubber tubes. This may include attaching fittings, clamps, or other hardware necessary for the tube’s intended use. The assembly process is usually performed in accordance with strict guidelines to ensure that all components are securely attached and aligned.

This stage may also involve additional curing processes, where the assembled tubes are subjected to heat or pressure to enhance their durability. Proper assembly is critical, especially in industries such as automotive or pharmaceuticals, where the performance of rubber tubes can significantly affect operational efficiency.

Illustrative image related to ruber tubes

Finishing: What Processes Ensure Rubber Tubes Meet Quality Standards?

The finishing stage involves applying surface treatments, such as coatings or texturing, to enhance the rubber tubes’ performance characteristics. This may include improving resistance to wear, UV exposure, or chemical degradation. Manufacturers may also conduct a final inspection to ensure that the tubes meet the specified tolerances and quality standards.

What International Quality Assurance Standards Apply to Rubber Tubes?

Quality assurance is a vital aspect of the rubber tube manufacturing process, particularly for B2B buyers who require compliance with international standards. Understanding these standards can help buyers make informed decisions when selecting suppliers.

Which International Standards Should B2B Buyers Be Aware Of?

Several international standards govern the quality of rubber tubes. ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer has established processes to consistently provide products that meet customer and regulatory requirements.

In addition to ISO 9001, other industry-specific certifications may apply, such as CE marking for products sold in the European Economic Area (EEA) or API standards for oil and gas applications. These certifications often require rigorous testing and documentation, ensuring that the rubber tubes are safe and effective for their intended use.

Illustrative image related to ruber tubes

What Are the Key Quality Control Checkpoints in Rubber Tube Manufacturing?

Quality control (QC) plays a pivotal role in ensuring that the rubber tubes produced meet the necessary specifications and standards. B2B buyers should understand the key checkpoints in the QC process to assess supplier reliability.

What Are the Common QC Checkpoints?

-

Incoming Quality Control (IQC): This initial checkpoint focuses on the raw materials received from suppliers. It involves testing the materials for compliance with specified quality standards before they are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are implemented at various stages to monitor production consistency. This may include dimensional checks, visual inspections, and testing for physical properties.

-

Final Quality Control (FQC): After production, FQC ensures that the finished rubber tubes meet all specifications. This includes extensive testing for factors such as flexibility, tensile strength, and resistance to environmental factors.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s QC processes is essential for ensuring product quality and reliability. Here are several methods to assess supplier quality:

What Strategies Can Buyers Use to Confirm Supplier QC?

-

Supplier Audits: Conducting on-site audits can provide direct insight into a manufacturer’s QC processes, allowing buyers to evaluate compliance with international standards and internal practices.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC measures taken throughout the manufacturing process. This may include test results, failure rates, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing capabilities and QC processes. This is particularly beneficial for buyers in regions where they cannot easily perform on-site evaluations.

What Nuances Should International Buyers Consider Regarding QC Certifications?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in QC certifications. Different regions may have varying regulatory requirements and standards for rubber products.

Understanding local market needs and compliance requirements is crucial for successful international trade. Buyers should also consider the potential impact of trade tariffs and shipping regulations on their procurement processes, which may affect the overall cost and reliability of supply chains.

By prioritizing rigorous manufacturing processes and comprehensive quality assurance practices, B2B buyers can ensure they partner with reliable suppliers of rubber tubes that meet their operational needs and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ruber tubes’

To assist B2B buyers in navigating the procurement of rubber tubes, this guide provides a structured checklist. Each step ensures that you make informed decisions, fostering successful supplier relationships and high-quality product acquisition.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the first critical step. Identify factors such as the type of rubber (e.g., latex, neoprene), inner and outer diameters, length, and intended application. This clarity helps in communicating effectively with suppliers and ensures you receive the right product for your needs.

Step 2: Research Supplier Credentials

Not all suppliers are created equal. Investigate their certifications, industry reputation, and years of experience. Look for international certifications like ISO 9001, which indicates a commitment to quality management standards, and check for testimonials or reviews from previous clients.

Step 3: Evaluate Material Quality

The quality of rubber tubes can significantly impact performance. Request samples to assess their elasticity, tensile strength, and resistance to temperature and chemicals. Make sure the materials meet industry standards relevant to your application, especially if they will be used in sensitive environments.

Step 4: Understand Pricing Structures

Pricing can vary widely based on factors like material type, manufacturing processes, and order quantities. Request detailed quotations that break down costs and consider any additional fees for shipping or handling. Compare these with industry benchmarks to ensure competitiveness without compromising quality.

Step 5: Confirm Production Capabilities

It’s essential to verify that your chosen supplier can meet your order volume and delivery timelines. Discuss their production capacity and ask about lead times, especially for large or custom orders. Understanding their capabilities ensures that they can scale with your needs as your business grows.

Step 6: Assess Customer Support and After-Sales Service

Strong customer support is vital for resolving any issues that may arise post-purchase. Evaluate the supplier’s responsiveness and willingness to assist with technical queries or complaints. A supplier with robust after-sales service can provide peace of mind and foster a long-term partnership.

Step 7: Negotiate Terms and Conditions

Before finalizing your order, negotiate terms that protect your interests. Discuss payment terms, return policies, and warranties. Clear agreements on these aspects can prevent misunderstandings and ensure a smoother transaction process.

By following this checklist, B2B buyers can ensure a more streamlined and effective sourcing process for rubber tubes, resulting in high-quality procurement and fruitful supplier relationships.

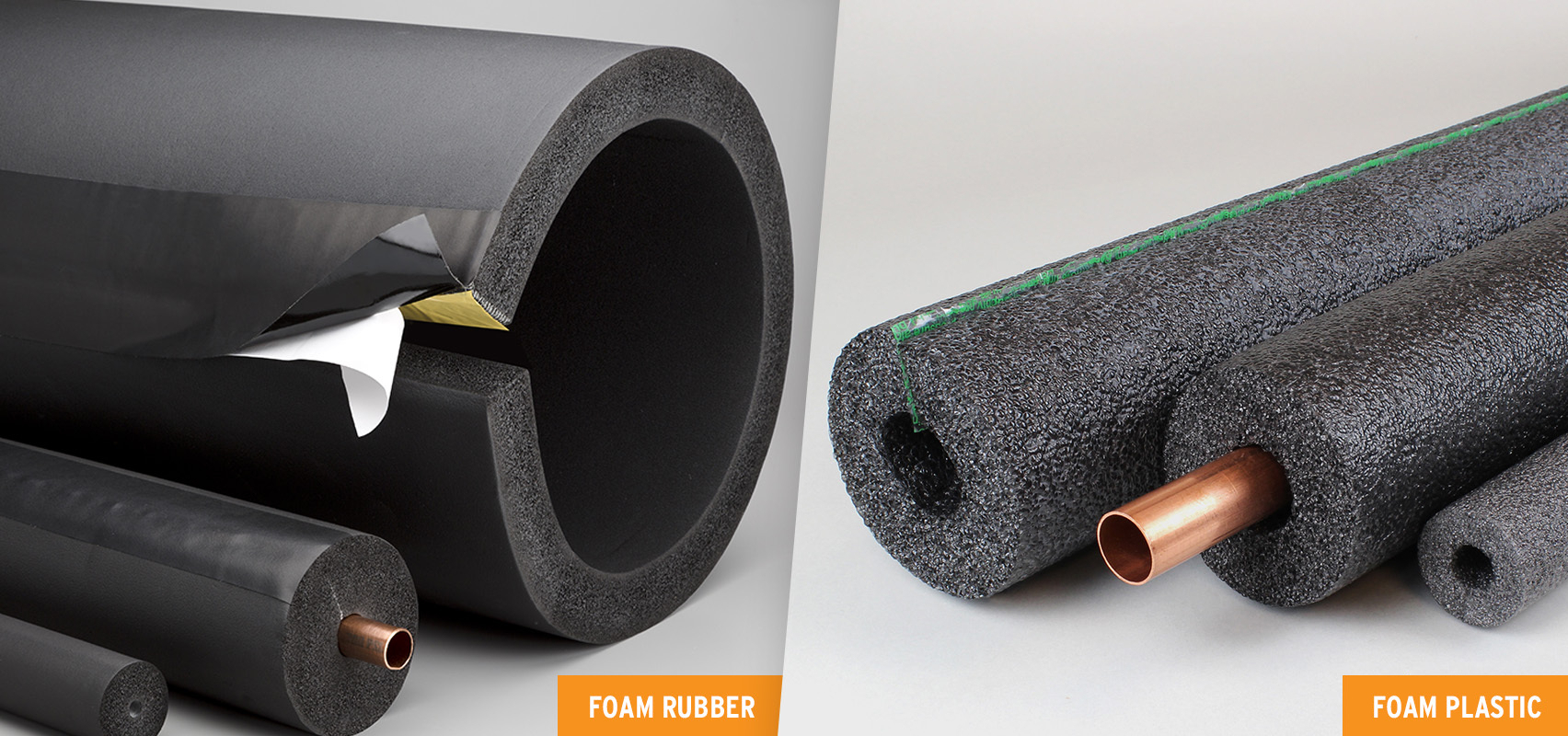

Illustrative image related to ruber tubes

Comprehensive Cost and Pricing Analysis for ruber tubes Sourcing

Understanding the cost structure and pricing dynamics for rubber tubes is crucial for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, price influencers, and strategic tips for international buyers.

What are the Key Cost Components in Rubber Tube Manufacturing?

The cost structure for rubber tubes encompasses several fundamental components:

-

Materials: The primary cost driver in rubber tube manufacturing is the raw materials, which typically include natural rubber, synthetic rubber, and various additives. The price of these materials can fluctuate based on market demand and sourcing locations.

-

Labor: Labor costs vary significantly by region. In developing markets, labor may be less expensive, which can lower the overall manufacturing cost. However, skilled labor is often required for specialized manufacturing processes, which can increase costs.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, facility maintenance, and indirect labor. Overhead can vary based on the efficiency of the manufacturing process and the scale of operations.

-

Tooling: Initial investments in tooling and molds are critical, especially for custom specifications. The costs can be substantial but are generally amortized over larger production runs.

-

Quality Control (QC): Ensuring product quality involves additional costs, including testing and compliance with international standards. Certifications may be required for specific industries, adding to QC expenses.

-

Logistics: Shipping costs can significantly impact the final pricing of rubber tubes, especially for international buyers. Factors such as distance, freight rates, and import duties must be considered.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary widely based on market conditions and competitive pressures.

How Do Price Influencers Affect Rubber Tube Costs?

Several factors can influence the pricing of rubber tubes:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that suit their needs while leveraging volume discounts.

-

Specifications and Customization: Customized products often incur higher costs due to the complexities of manufacturing and additional tooling. Standard products typically have lower prices and shorter lead times.

-

Material Choices: The type and quality of rubber used will impact pricing. High-performance materials may come at a premium but offer enhanced durability and resistance.

-

Quality Certifications: Products that meet specific industry standards or certifications (e.g., ISO, FDA) may be priced higher due to the additional costs associated with compliance.

-

Supplier Factors: The reputation, reliability, and geographical location of the supplier can influence pricing. Suppliers in regions with lower production costs may offer more competitive prices.

-

Incoterms: The chosen Incoterms can significantly affect total landed costs. Buyers should be aware of who is responsible for shipping, insurance, and duties to avoid unexpected expenses.

What Tips Can Help B2B Buyers Optimize Costs?

For international B2B buyers, particularly from regions like Nigeria and Brazil, understanding and negotiating effectively can lead to significant cost savings:

-

Leverage Negotiation: Always engage in negotiations with suppliers. Discussing terms and exploring options for discounts based on volume or long-term partnerships can lead to better pricing.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, assess the long-term costs associated with maintenance, durability, and replacement. A higher upfront cost may be justified by lower operational costs over time.

-

Research Market Prices: Familiarize yourself with market prices to ensure you are getting competitive offers. Engage with multiple suppliers to compare quotes and terms.

-

Stay Informed About Global Trends: Understanding global supply chain dynamics can help buyers anticipate price changes due to fluctuations in raw material costs or shipping rates.

Conclusion

Navigating the complexities of rubber tube sourcing requires a keen understanding of cost structures and pricing dynamics. By considering the outlined components and influencers, B2B buyers can make informed decisions that enhance their procurement strategies. Always remember that prices may vary widely based on numerous factors, and it is prudent to seek multiple quotes and conduct thorough due diligence before finalizing any agreements.

Alternatives Analysis: Comparing ruber tubes With Other Solutions

Exploring Alternative Solutions to Ruber Tubes

In the realm of industrial applications, selecting the right materials for specific tasks is critical. While ruber tubes offer unique benefits, there are alternative solutions that can also fulfill similar roles. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their operational needs.

| Comparison Aspect | Ruber Tubes | Silicone Tubing | PVC Tubing |

|---|---|---|---|

| Performance | Excellent elasticity and durability; withstands high temperatures | High resistance to temperature and chemicals; flexible | Good for low-pressure applications; less durable under heat |

| Cost | Moderate cost, varies by diameter and length | Higher upfront cost but longer lifespan | Generally lower cost, widely available |

| Ease of Implementation | Easy to cut and customize; requires minimal tools | Can be more complex to install due to flexibility | Simple installation, often requires standard fittings |

| Maintenance | Low maintenance; resistant to wear | Low maintenance; resistant to chemicals | Higher maintenance; can degrade over time |

| Best Use Case | Ideal for applications requiring stretch and resilience, such as in medical or automotive sectors | Best for food, pharmaceutical, or high-temperature applications | Suitable for general-purpose plumbing and drainage |

What are the Advantages and Disadvantages of Silicone Tubing Compared to Ruber Tubes?

Silicone tubing presents a viable alternative to ruber tubes, especially in environments where chemical resistance and flexibility are paramount. It performs well under extreme temperatures, making it suitable for high-heat applications such as food processing and pharmaceuticals. However, silicone tubing comes at a higher initial cost, which may be a deterrent for budget-conscious buyers. Additionally, while its flexibility offers advantages in certain applications, it can complicate installation processes that require rigid connections.

How Does PVC Tubing Stack Up Against Ruber Tubes?

PVC tubing is a widely used alternative that excels in affordability and ease of access. It is particularly suitable for low-pressure applications, such as drainage and general plumbing. However, PVC’s performance lags behind ruber tubes in terms of durability and temperature resistance. Over time, PVC can become brittle and degrade, necessitating more frequent replacements and maintenance. This trade-off in longevity and resilience makes it less ideal for high-demand applications.

Making the Right Choice: How Can B2B Buyers Select the Best Option?

When considering the right solution, B2B buyers should assess their specific operational requirements. Ruber tubes offer excellent performance in demanding environments, especially where elasticity and resilience are necessary. In contrast, silicone tubing is better suited for applications requiring chemical resistance and flexibility, albeit at a higher cost. PVC tubing, while budget-friendly, may not offer the longevity required for more rigorous applications.

Ultimately, the decision should be guided by factors such as performance needs, budget constraints, and the specific environment in which the tubing will be utilized. By thoroughly evaluating these alternatives, buyers can ensure they select the most effective solution for their business needs.

Essential Technical Properties and Trade Terminology for ruber tubes

What Are the Key Technical Properties of Rubber Tubes?

When sourcing rubber tubes for industrial applications, understanding their technical properties is crucial for ensuring performance, durability, and compliance with specific industry standards. Here are some essential specifications to consider:

-

Material Grade

Rubber tubes are manufactured from various materials, including natural rubber, neoprene, EPDM, and silicone. Each material has distinct properties like temperature resistance, flexibility, and chemical compatibility. For instance, EPDM rubber is ideal for outdoor applications due to its excellent weather resistance, while silicone is preferred for high-temperature applications. Selecting the right material ensures that the rubber tube meets the operational demands of your specific application. -

Inner and Outer Diameter (ID/OD)

The inner and outer diameter of rubber tubes dictate their flow capacity and compatibility with fittings and connectors. Accurate measurements are essential to ensure a proper fit and prevent leaks or performance issues. Buyers must specify these dimensions clearly when placing orders, as variations can lead to operational inefficiencies. -

Tensile Strength

This property measures the maximum amount of tensile (stretching) stress that the rubber can withstand before breaking. High tensile strength is crucial for applications that involve high pressure or mechanical stress. It reflects the durability and longevity of the product, making it a key consideration for B2B buyers looking for reliable solutions. -

Temperature Resistance

Rubber tubes can be exposed to a wide range of temperatures, from cryogenic conditions to high-heat environments. Understanding the temperature resistance of a particular rubber compound helps in selecting a tube that will maintain its integrity and performance under expected conditions. This is particularly important in industries such as automotive, aerospace, and food processing. -

Chemical Resistance

Different rubber materials have varying levels of resistance to chemicals, oils, and solvents. For applications involving the transport of hazardous or corrosive substances, it is vital to choose rubber tubes that can withstand exposure without degrading. Buyers should consult technical data sheets to ensure compatibility with specific chemicals. -

Wall Thickness

The wall thickness of rubber tubes affects their flexibility, strength, and pressure rating. Thicker walls provide better durability and resistance to punctures, while thinner walls may offer greater flexibility for tight bends. Buyers must assess the operational needs to determine the optimal wall thickness.

What Are Common Trade Terms in the Rubber Tube Industry?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

Illustrative image related to ruber tubes

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of rubber tubes, OEMs often require custom solutions that fit specific equipment designs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for buyers to understand as it affects inventory management and overall cost. Knowing the MOQ helps businesses plan their purchasing strategy effectively. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit pricing and terms for specific products. It typically includes details such as quantity, specifications, and delivery timelines. Sending an RFQ ensures that buyers receive competitive quotes from multiple suppliers. -

Incoterms

International Commercial Terms (Incoterms) are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand shipping costs and liabilities. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for supply chain management, especially in industries where timely delivery is critical to operations. -

Certification Standards

These refer to the quality and safety certifications that rubber tubes may need to meet, such as ISO or FDA standards. Certification ensures that the products comply with industry regulations, which is vital for maintaining quality and safety in applications like food processing or medical use.

By grasping these properties and terms, B2B buyers can make informed decisions when sourcing rubber tubes, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the ruber tubes Sector

What Are the Current Market Dynamics and Key Trends in the Rubber Tubes Sector?

The rubber tubes market is experiencing significant growth, driven by several global factors. The increasing demand for flexible and durable materials in various sectors such as automotive, healthcare, and industrial manufacturing is a primary driver. Emerging markets in Africa, South America, the Middle East, and Europe are particularly active, with countries like Nigeria and Brazil witnessing robust investments in infrastructure and industrial expansion. This has led to a rising demand for high-quality rubber tubing solutions that cater to diverse applications.

Current trends indicate a shift towards digitalization in the sourcing process. B2B buyers are increasingly relying on e-commerce platforms and digital marketplaces to streamline procurement. This trend is complemented by advancements in supply chain technologies, such as blockchain and IoT, which enhance transparency and traceability in sourcing rubber tubes. Furthermore, customization is becoming a key selling point, with manufacturers offering tailored solutions to meet specific client needs, thereby increasing the competitive edge.

As international buyers navigate these dynamics, understanding regional variations in demand and supply is crucial. For instance, the Middle East’s focus on oil and gas industries contrasts with South America’s agricultural needs, necessitating a differentiated approach to sourcing rubber tubes.

How Is Sustainability Influencing Sourcing Decisions in the Rubber Tubes Sector?

Sustainability is becoming an essential consideration for B2B buyers in the rubber tubes sector. The environmental impact of rubber production, including deforestation and carbon emissions, has prompted companies to seek sustainable sourcing solutions. Buyers are increasingly looking for manufacturers who prioritize ethical supply chains and utilize eco-friendly materials in their rubber tube production.

Certifications such as ISO 14001 (Environmental Management) and the Global Organic Textile Standard (GOTS) are becoming important benchmarks for assessing a supplier’s commitment to sustainability. Additionally, the use of recycled rubber and bio-based materials is gaining traction, as companies strive to minimize their ecological footprint. This trend not only supports environmental goals but also appeals to a growing consumer base that values sustainability, thereby enhancing brand reputation and marketability.

As international buyers, particularly from environmentally conscious regions, prioritize ethical sourcing, establishing partnerships with suppliers who adhere to sustainable practices will be key to maintaining competitive advantage and fulfilling corporate social responsibility objectives.

What Is the Historical Context of Rubber Tubes in the B2B Market?

The evolution of rubber tubes dates back to the 19th century, with the advent of rubber vulcanization by Charles Goodyear, which revolutionized the material’s properties and applications. Initially used in the automotive industry, rubber tubes found their way into various sectors, including healthcare and construction, due to their flexibility, durability, and resistance to various chemicals.

Over the years, advancements in manufacturing processes and material science have led to the development of specialized rubber compounds that enhance performance in extreme conditions. This historical context is essential for B2B buyers, as it highlights the continuous innovation within the sector and the importance of selecting suppliers that are at the forefront of technological advancements. Understanding this evolution can aid in making informed sourcing decisions that align with both current market trends and future demands.

Frequently Asked Questions (FAQs) for B2B Buyers of ruber tubes

-

How do I select the right rubber tubing for my application?

Choosing the right rubber tubing depends on various factors including the type of fluid or gas being transported, temperature ranges, and required flexibility. Consider the chemical compatibility of the rubber material with the substances it will encounter. For instance, neoprene and nitrile are excellent for oils, while silicone is ideal for high-temperature applications. Additionally, evaluate the inner and outer diameter sizes needed for your specific fittings and ensure the tubing meets any relevant industry standards. -

What are the advantages of using rubber tubing over plastic tubing?

Rubber tubing offers several advantages over plastic alternatives, including superior flexibility, durability, and resistance to temperature extremes. Rubber can maintain its integrity under a wider range of temperatures, from -65°C to +70°C, and is less likely to degrade when exposed to chemicals. Furthermore, rubber tubing typically exhibits better tensile strength and tear resistance, making it suitable for demanding industrial applications. -

What customization options are available for rubber tubing?

Many suppliers offer customization options for rubber tubing, including variations in diameter, length, and rubber composition. You can request specific colors, hardness levels, and even additional features like reinforcement layers for enhanced strength. It’s advisable to communicate your exact requirements to potential suppliers early in the process to ensure they can meet your specifications effectively. -

What is the minimum order quantity (MOQ) for rubber tubing?

The minimum order quantity for rubber tubing can vary significantly by supplier and product type. Typically, MOQs can range from a few meters to several hundred meters. It is essential to clarify this with your supplier, especially if you are testing a new application or product. Some suppliers may offer lower MOQs for standard products, while custom items may require larger orders. -

How can I ensure the quality of the rubber tubing I purchase?

To ensure quality, request certifications such as ISO or ASTM compliance from your supplier. Ask for samples before placing a larger order to evaluate the material’s properties and performance. Additionally, inquire about the supplier’s quality assurance processes, including testing methods and batch traceability, to verify that the tubing meets your standards consistently. -

What payment terms should I expect when ordering rubber tubing internationally?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, deposits, or net terms (e.g., 30 or 60 days after delivery). Ensure to discuss payment methods that are secure and convenient for both parties, such as letters of credit or escrow services. It’s also wise to clarify currency exchange rates and any additional fees that may apply. -

What are the logistics considerations for importing rubber tubing?

When importing rubber tubing, consider shipping methods (air freight vs. sea freight), as they affect cost and delivery time. Factor in customs clearance processes and potential tariffs, which may vary based on your country of import. Collaborating with a logistics provider familiar with international trade regulations can facilitate a smoother process and ensure compliance with local laws. -

How do I vet suppliers for rubber tubing in international markets?

To vet suppliers effectively, conduct thorough research on their reputation, including reviews and testimonials from other B2B buyers. Request references and check their manufacturing capabilities, certifications, and compliance with international standards. Participating in trade shows or industry conferences can also provide insights into potential suppliers. Finally, consider visiting their facilities if feasible, to assess their operations firsthand.

Top 5 Ruber Tubes Manufacturers & Suppliers List

1. Filcoflex – Seamless Rubber Tubing

Domain: filcoflex.com

Registered: 2006 (19 years)

Introduction: Seamless Rubber Tubing features a smooth inside surface and a wrapped, light textured outside finish. It is made from gum rubber, EPDM, or nitrile and is available in standardized diameters. The tubing can be cut to length in two standard long lengths and comes in various thicknesses. Applications include flexible sleeves, bulk bag filling bladders, connecting sleeves, gum rubber sleeves, load out…

2. McMaster – Rubber Tubing

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Rubber Tubing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. The Rubber Company – Rubber Tubing

Domain: therubbercompany.com

Registered: 2013 (12 years)

Introduction: Rubber tubing is available in various rubber compounds and a wide selection of inner and outer diameter sizes. It is used for the safe transfer of solids, liquids, and gases due to its high resistance. The tubing can withstand temperatures ranging from -65°C to +70°C and offers superior tensile strength and tear resistance compared to plastic and solid tubing, making it suitable for a variety of a…

4. AeroRubber – Custom Rubber Tubing

Domain: aerorubber.com

Registered: 1997 (28 years)

Introduction: Custom rubber tubing available in a wide range of ID/OD sizes based on extrusion and mandrel made manufacturing processes. Options include solid and closed cell sponge materials. Features include conjoined tubing, cut-to-length, slit tubing, extended lengths, and custom packaging. Material grade options include Economy, Commercial, High-Grade, and Spec-Grade formulations, with compounds such as cl…

5. Fisher Scientific – Rubber and Silicone Tubing

Domain: fishersci.com

Registered: 1995 (30 years)

Introduction: This company, Fisher Scientific – Rubber and Silicone Tubing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for ruber tubes

In conclusion, the strategic sourcing of rubber tubes presents a myriad of opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The versatility of rubber tubing—ranging from its use in industrial applications to its adaptability for niche markets—positions it as a crucial component for a variety of sectors, including manufacturing, agriculture, and healthcare. Buyers should prioritize sourcing high-quality materials that offer durability, temperature resistance, and the ability to handle diverse substances safely.

As you navigate the complexities of global supply chains, it is essential to build relationships with reputable suppliers who can provide reliable products tailored to your specific needs. Engaging in strategic sourcing not only enhances operational efficiency but also mitigates risks associated with supply disruptions.

Looking ahead, the demand for innovative rubber tubing solutions will only grow, driven by advancements in technology and increasing sustainability standards. Take proactive steps now to secure your supply chain, explore new suppliers, and stay ahead of industry trends. Embrace the potential of rubber tubes to elevate your business operations and drive success in your markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.