The Definitive Guide to Rotating Latch: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for rotating latch

In the competitive landscape of global manufacturing, sourcing the right components, such as rotating latches, presents a unique challenge for international B2B buyers. These essential fastening devices play a crucial role in a variety of applications, from automotive and aerospace to industrial machinery and furniture. With a wide array of types, materials, and specifications available, selecting the right rotating latch can significantly impact product durability, safety, and operational efficiency.

This comprehensive guide delves into the multifaceted world of rotating latches, addressing key considerations such as types, applications, supplier vetting processes, and cost structures. It aims to equip B2B buyers, especially those from Africa, South America, the Middle East, and Europe—including major markets like Brazil and Germany—with the insights necessary to make informed purchasing decisions. By understanding the nuances of rotating latch specifications and market dynamics, buyers can effectively navigate supplier options and secure the best value for their investment.

Furthermore, this guide highlights best practices in evaluating suppliers, ensuring quality, and optimizing procurement strategies, ultimately empowering businesses to enhance their operational capabilities. Whether you are involved in product design or supply chain management, understanding the intricacies of rotating latches will not only streamline your purchasing process but also contribute to your organization’s long-term success in the global market.

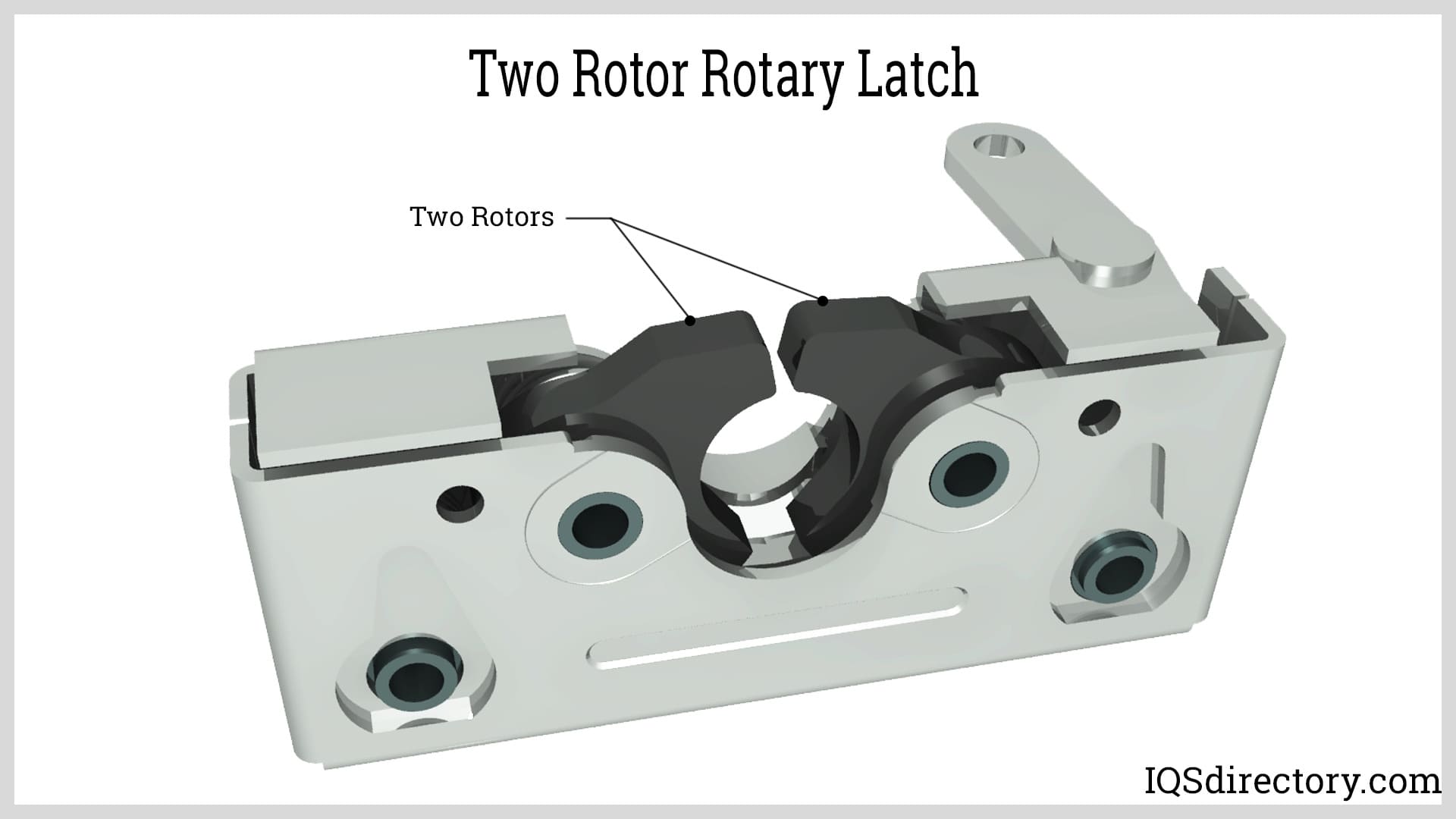

Understanding rotating latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Turn Latch | Spring-loaded mechanism, padlockable | Industrial enclosures, storage solutions | Pros: High security, easy operation. Cons: May require precise installation. |

| Mini-Rotary Latch | Compact design, single-stage operation | Small equipment, portable devices | Pros: Space-efficient, cost-effective. Cons: Limited load capacity. |

| Heavy-Duty Rotary Latch | High tensile strength, waterproof options | Aerospace, heavy machinery | Pros: High durability, suitable for extreme conditions. Cons: Higher cost. |

| Under Panel Mounted Latch | Low-profile design, minimal skin cutouts | Aircraft, automotive applications | Pros: Aerodynamic, easy sealing. Cons: Installation may be complex. |

| Side Mounted Rotary Latch | Versatile installation options, adjustable keepers | Cargo containers, industrial cabinets | Pros: Flexible application, strong locking. Cons: Requires more space for operation. |

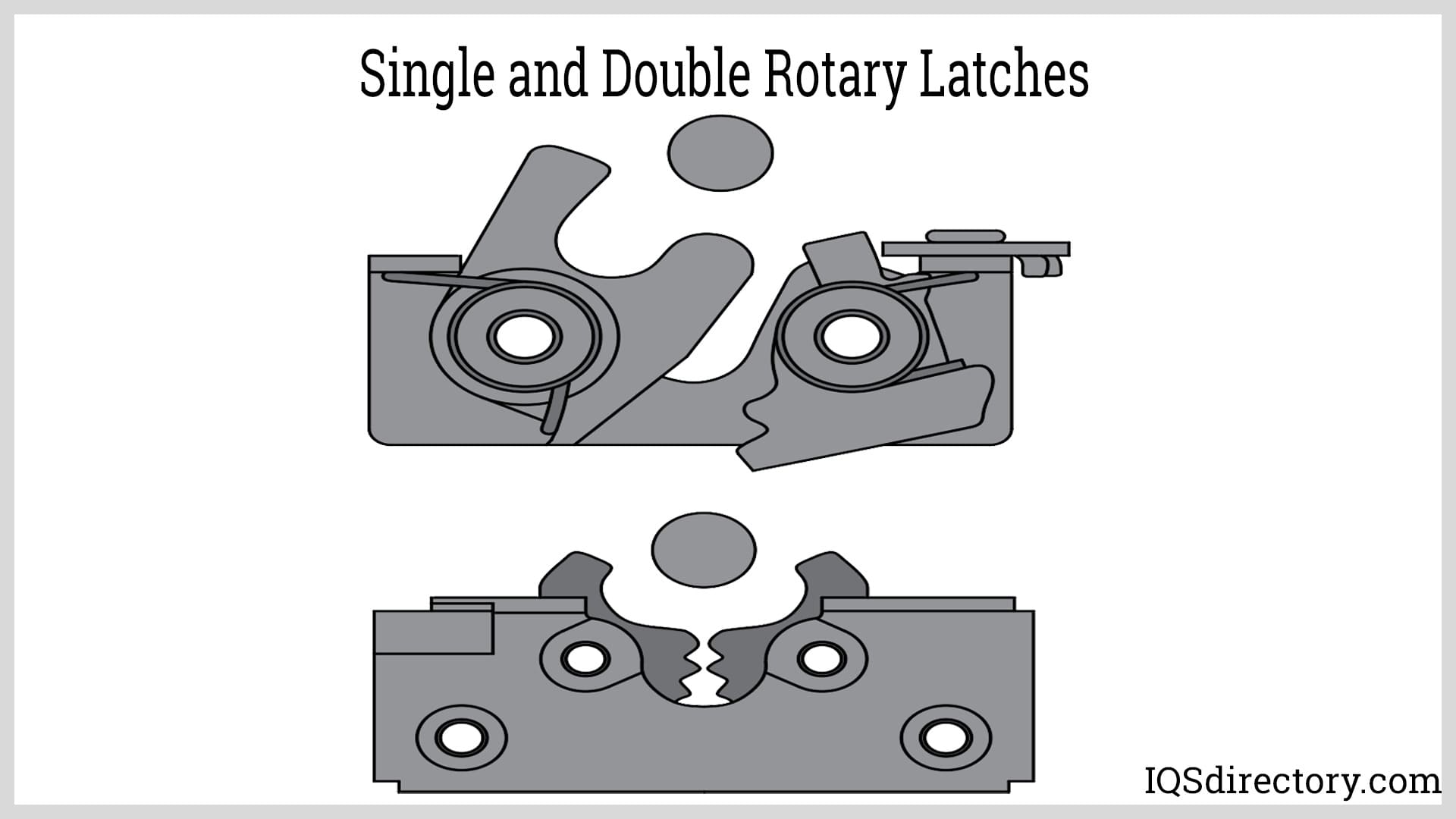

What are the characteristics of Rotary Turn Latches?

Rotary turn latches are designed with a spring-loaded mechanism that allows for secure closure and easy access. They often come with a padlock feature, enhancing security for industrial enclosures and storage solutions. When purchasing, buyers should consider the working load capacity and installation requirements, as precise fitting is crucial for optimal performance. These latches are ideal for environments where security and ease of use are paramount.

Why choose a Mini-Rotary Latch for smaller applications?

The mini-rotary latch is a compact variant perfect for small equipment and portable devices. Its single-stage operation makes it user-friendly while maintaining a low profile. Buyers should assess the load capacity and intended application, as this latch is best for lighter-duty uses. Its cost-effectiveness and space-saving design make it a popular choice in various industries.

How do Heavy-Duty Rotary Latches stand out in demanding environments?

Heavy-duty rotary latches are engineered for high tensile strength and can often withstand harsh environmental conditions, making them suitable for aerospace and heavy machinery applications. These latches may also feature waterproof options for additional durability. Buyers should weigh the benefits of high durability against the higher upfront costs, especially when long-term reliability is critical.

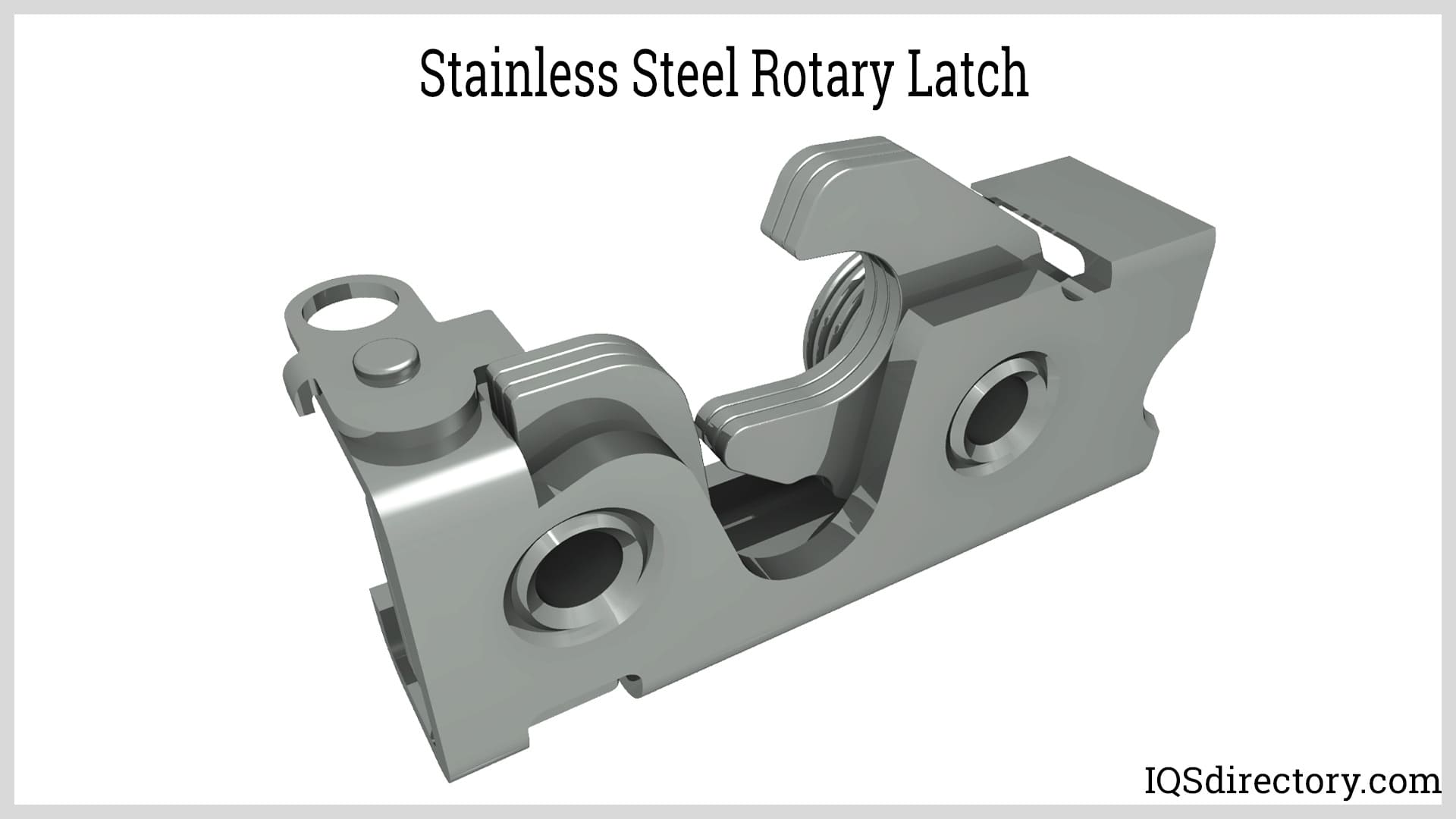

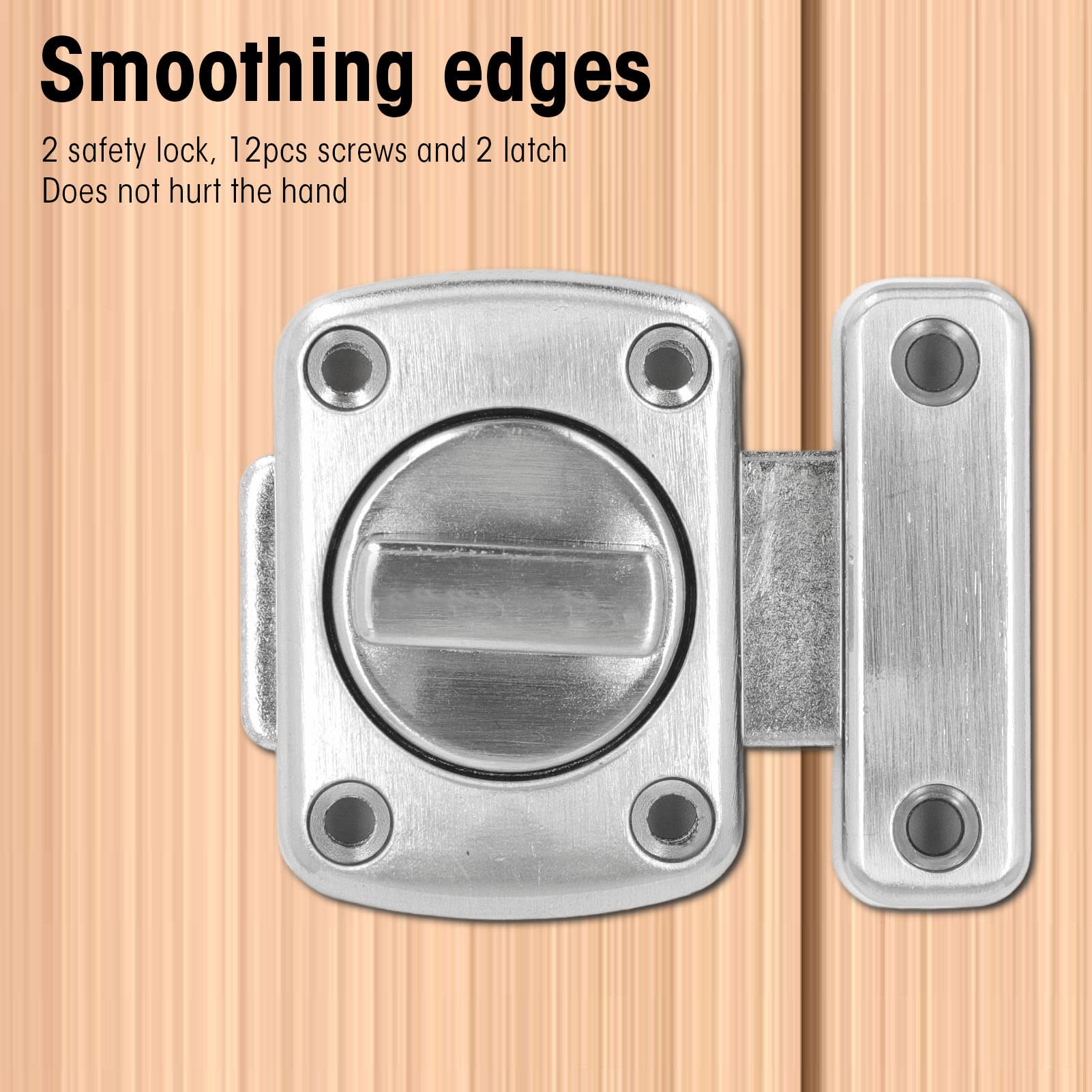

Illustrative image related to rotating latch

What advantages do Under Panel Mounted Latches offer?

Under panel mounted latches feature a low-profile design that minimizes skin cutouts, enhancing aerodynamics in aircraft and automotive applications. They are easily sealed, making them effective for environments requiring weather resistance. Buyers should consider the complexity of installation, as the design may require specialized fitting. Their unique advantages make them ideal for applications where space and aerodynamics are crucial.

In what scenarios are Side Mounted Rotary Latches most effective?

Side mounted rotary latches provide versatile installation options and are often equipped with adjustable keepers, making them suitable for cargo containers and industrial cabinets. Their flexible application allows for strong locking mechanisms, which are essential in securing valuable goods. However, buyers should be mindful of the additional space needed for operation, as this may influence installation plans.

Key Industrial Applications of rotating latch

| Industry/Sector | Specific Application of rotating latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Securing aircraft panels and access doors | Enhances safety and accessibility while minimizing drag | Compliance with aviation standards, weight considerations |

| Automotive | Latching systems for vehicle hoods and trunks | Provides durability and ease of use under variable conditions | Material selection for corrosion resistance, load capacity |

| Industrial Equipment | Locking mechanisms for machinery covers | Protects sensitive components from environmental exposure | Compatibility with existing machinery, ease of installation |

| Marine | Fastening hatches and access points in vessels | Ensures watertight seals and reliability in harsh conditions | Resistance to saltwater corrosion, ease of operation |

| Construction | Securing panels and doors in modular buildings | Improves efficiency and security during transport and use | Strength and durability, customization options available |

How Are Rotating Latches Used in Aerospace Applications?

In the aerospace industry, rotating latches are crucial for securing aircraft panels and access doors. These latches must meet stringent safety regulations while providing a lightweight solution that minimizes aerodynamic drag. International buyers must consider compliance with aviation standards, as well as the latch’s ability to withstand extreme environmental conditions. The use of materials that ensure durability without adding unnecessary weight is essential in this sector.

What Role Do Rotating Latches Play in Automotive Manufacturing?

In automotive applications, rotating latches are commonly used for securing vehicle hoods, trunks, and other access points. Their reliability under variable conditions enhances vehicle safety and operational efficiency. Buyers in this sector should focus on corrosion-resistant materials and ensure that the latches can handle the dynamic loads experienced during vehicle operation. Ease of installation and compatibility with existing vehicle designs are also critical factors for international buyers.

How Are Rotating Latches Applied in Industrial Equipment?

Rotating latches serve as locking mechanisms for machinery covers in various industrial equipment. They provide essential protection for sensitive components against dust, debris, and other environmental factors. For B2B buyers, sourcing latches that are compatible with existing machinery and easy to install is vital. Additionally, understanding the required load capacity and ensuring the latch can withstand operational stresses are crucial considerations.

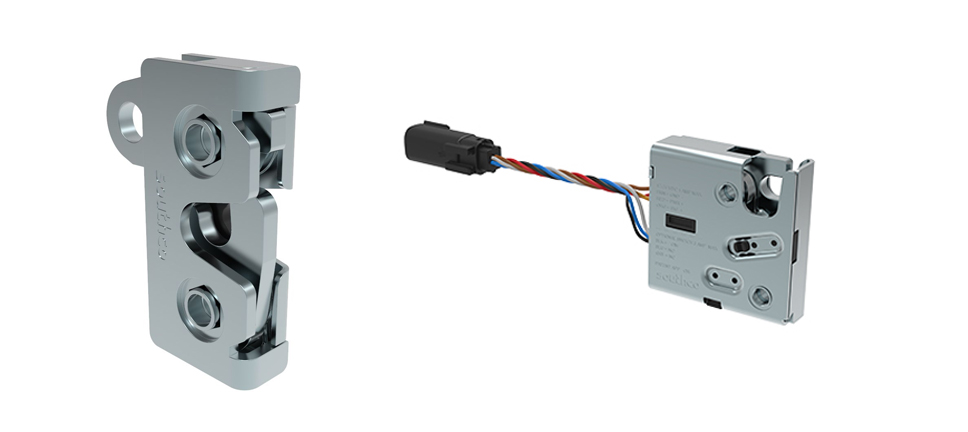

Illustrative image related to rotating latch

Why Are Rotating Latches Important in Marine Applications?

In the marine sector, rotating latches are utilized to fasten hatches and access points on vessels, ensuring watertight seals and reliability in harsh maritime conditions. The latches must be resistant to saltwater corrosion and designed for ease of operation, even in challenging environments. Buyers should prioritize sourcing latches that can endure the rigors of marine life while maintaining operational integrity.

How Do Rotating Latches Enhance Security in Construction?

In construction, rotating latches are employed to secure panels and doors in modular buildings, improving both security and efficiency during transport and use. These latches must be strong and durable to withstand various environmental conditions. Buyers should consider customization options to meet specific project requirements and ensure that the latches can provide the necessary security and functionality throughout the building’s lifecycle.

3 Common User Pain Points for ‘rotating latch’ & Their Solutions

Scenario 1: Ensuring Durability Under Heavy Loads

The Problem: B2B buyers often face challenges when selecting rotating latches that need to withstand substantial loads, particularly in industries such as transportation and heavy machinery. A common issue arises when latches fail under pressure, leading to equipment malfunctions or safety hazards. Buyers may find themselves uncertain about the ultimate tensile strength (UTS) of the latches they are considering, which can lead to costly downtime and repairs if the wrong latch is chosen.

The Solution: To address this challenge, it is essential to conduct thorough research on the specifications of the rotating latches you intend to use. Look for latches with a clearly defined UTS rating that meets or exceeds your application requirements. For instance, a latch with a UTS of 170 Kg should ideally be used at half that capacity for safety, ensuring you are well within the limits. Additionally, consider sourcing latches that feature robust materials, such as stainless steel, which offers high corrosion resistance and longevity. Conducting a load test or consulting with manufacturers can further ensure that the latches will perform reliably under expected conditions.

Scenario 2: Overcoming Installation Complexity

The Problem: Another pain point for buyers is the complexity involved in installing rotating latches, which can lead to increased labor costs and project delays. Many latches require specific installation techniques or tools that are not readily available, resulting in frustration and inefficiencies in the workflow. Buyers may also encounter compatibility issues with existing systems, making it difficult to integrate new latches effectively.

The Solution: To simplify the installation process, it’s crucial to select rotating latches that come with comprehensive installation guides and support. Prioritize latches that are designed for easy integration, such as those with standardized hole sizes or those that can be operated with common tools. Before purchasing, consult technical documentation and reach out to suppliers for clarification on installation requirements. It may also be beneficial to invest in training for your installation team, ensuring they are well-versed in the specific techniques needed for the latches you choose. This proactive approach will minimize installation time and reduce the likelihood of errors.

Scenario 3: Navigating Cost Efficiency and Bulk Purchasing

The Problem: Many B2B buyers struggle with the financial implications of sourcing rotating latches, especially when purchasing in bulk. The challenge lies in balancing quality with cost-effectiveness. Buyers often encounter a wide price range for similar latches, leading to confusion about which products offer the best value. Additionally, they may fear overcommitting to a bulk purchase of a product that may not meet their long-term needs.

The Solution: To navigate this financial landscape, buyers should adopt a strategic approach to sourcing rotating latches. Start by analyzing your projected usage to determine the appropriate quantity needed. Many suppliers offer tiered pricing, where bulk purchases lead to significant discounts—this can dramatically lower the cost per unit. Engage with multiple suppliers to compare not only prices but also quality guarantees and warranties. When possible, request samples or trial orders to assess the latch’s performance before making a large investment. This careful evaluation will help ensure that you secure the best combination of quality and cost-efficiency for your operations.

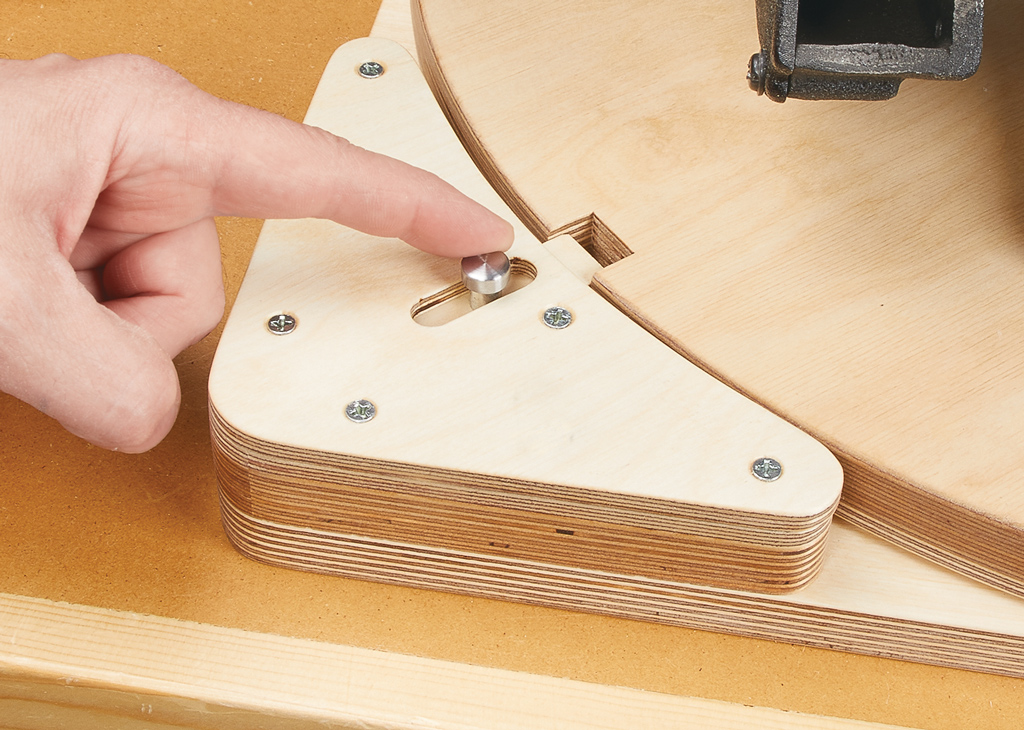

Illustrative image related to rotating latch

Strategic Material Selection Guide for rotating latch

What Are the Key Properties of Common Materials Used in Rotating Latches?

When selecting materials for rotating latches, understanding their properties is crucial for ensuring optimal performance in various applications. Here, we analyze four common materials: stainless steel, mild steel, aluminum, and plastic.

Stainless Steel: The Durable Choice

Stainless steel, particularly type 304, is widely used for rotating latches due to its excellent corrosion resistance and strength. It can withstand high temperatures and is suitable for outdoor applications where exposure to moisture is common. The ultimate tensile strength is around 170 kg, making it robust enough for demanding environments.

Pros: Stainless steel offers exceptional durability and longevity, making it suitable for heavy-duty applications. Its resistance to rust and corrosion is particularly advantageous in humid climates, which is a common concern for buyers in regions like Africa and the Middle East.

Illustrative image related to rotating latch

Cons: The primary drawback is the higher cost compared to other materials. Additionally, its manufacturing complexity can lead to longer lead times, which may not be ideal for urgent projects.

Impact on Application: Stainless steel is compatible with various media, including water and chemicals, making it versatile for different industries, including automotive and aerospace.

Mild Steel: A Cost-Effective Alternative

Mild steel is another popular choice for rotating latches, particularly when cost is a significant factor. Although it does not offer the same level of corrosion resistance as stainless steel, it can be treated with coatings to enhance its durability.

Pros: The primary advantage of mild steel is its lower cost, making it an attractive option for budget-conscious buyers. It is also relatively easy to manufacture and machine, allowing for quicker production times.

Cons: The main limitation is its susceptibility to rust and corrosion, which can reduce its lifespan, especially in humid or corrosive environments. Buyers in regions with high moisture levels should consider additional protective coatings.

Impact on Application: Mild steel latches are suitable for applications where environmental exposure is limited. However, they may not be ideal for outdoor use without proper treatment.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is often chosen for rotating latches due to its lightweight nature and inherent corrosion resistance. It is particularly useful in applications where weight is a critical factor, such as in the aerospace industry.

Pros: The lightweight characteristic of aluminum makes it easier to handle and install, reducing labor costs. Its natural resistance to corrosion also makes it suitable for outdoor applications.

Cons: While aluminum is strong, it does not match the tensile strength of stainless steel, which may limit its use in heavy-duty applications. Additionally, it can be more expensive than mild steel.

Impact on Application: Aluminum latches are ideal for applications requiring weight savings and corrosion resistance, making them popular in industries like transportation and marine.

Illustrative image related to rotating latch

Plastic: The Versatile Option for Lightweight Applications

Plastic rotating latches are gaining popularity due to their lightweight and non-corrosive properties. They are often used in applications where metal latches may not be suitable.

Pros: Plastic latches are typically less expensive and can be manufactured in various colors and designs, offering aesthetic flexibility. They are also resistant to corrosion and chemicals.

Cons: The primary disadvantage is their lower strength compared to metal options, which may limit their use in high-stress applications. Additionally, plastic can degrade over time when exposed to UV light.

Impact on Application: Plastic latches are suitable for indoor applications or environments where exposure to harsh conditions is minimal. They are commonly used in consumer products and lightweight industrial applications.

Summary Table of Material Selection for Rotating Latches

| Material | Typical Use Case for rotating latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty applications, outdoor use | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Mild Steel | Budget-sensitive applications | Cost-effective | Susceptible to rust without treatment | Low |

| Aluminum | Aerospace, transportation | Lightweight and corrosion-resistant | Lower tensile strength than steel | Medium |

| Plastic | Indoor consumer products | Non-corrosive and aesthetic flexibility | Lower strength and UV degradation risk | Low |

This material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on their specific requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rotating latch

What Are the Key Stages in the Manufacturing Process of Rotating Latches?

The manufacturing of rotating latches involves several critical stages that ensure both quality and functionality. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing rotating latches is material selection. Common materials include stainless steel, mild steel, and aluminum, chosen for their strength, durability, and resistance to corrosion. Material preparation involves cutting raw materials to specified dimensions and ensuring they meet the necessary mechanical properties. For instance, stainless steel type 304 is often used for its high corrosion resistance, making it ideal for applications in harsh environments.

Forming Techniques

Once the materials are prepared, forming techniques such as stamping, machining, or bending are employed to shape the components. Stamping is particularly popular for producing the latch body and other intricate shapes, while machining is used for precision parts that require tight tolerances. The use of CNC (Computer Numerical Control) machines enhances accuracy and repeatability, essential for maintaining quality across large production runs.

Assembly Processes

After forming, the next stage is assembly, where various components such as springs, latches, and locking mechanisms are put together. This process can be manual or automated, depending on the production scale. For high-volume manufacturing, automated assembly lines are common, which improve efficiency and reduce labor costs. Key features, such as padlocks or visual indicators, are integrated during this phase, ensuring that the latch functions as intended.

Finishing Touches

The final stage involves finishing processes such as coating, painting, or plating to enhance aesthetics and corrosion resistance. Common finishes include natural stainless steel, zinc plating, or powder coating, each offering different benefits. Quality assurance checks are often integrated into this stage to ensure that the final product meets the specified requirements.

What Are the International Standards and Quality Control Measures for Rotating Latches?

Quality control (QC) is paramount in the manufacturing of rotating latches, particularly for international B2B transactions. Buyers must be aware of relevant international standards and industry-specific certifications to ensure they are sourcing high-quality products.

Understanding ISO 9001 and Other Relevant Standards

ISO 9001 is the most recognized quality management standard globally, focusing on meeting customer requirements and enhancing satisfaction. Manufacturers of rotating latches should comply with this standard to demonstrate their commitment to quality. Additionally, specific industries may require certifications such as CE marking for compliance with European health and safety standards or API specifications for applications in the oil and gas sector.

Quality Control Checkpoints

Effective QC involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial check assesses the quality of raw materials before they enter the production line. It ensures that only compliant materials are used, reducing the risk of defects later in the process.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC monitors processes and outputs to identify any deviations from specifications. This real-time oversight allows for immediate corrective actions, minimizing waste and maintaining product integrity.

-

Final Quality Control (FQC): The final inspection occurs after production but before the product is shipped. This step involves testing the latches for functionality, durability, and compliance with technical specifications. Common testing methods include load testing, corrosion resistance tests, and functional testing to ensure the latch operates correctly under intended conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is essential to mitigate risks associated with product quality.

Conducting Supplier Audits

One effective way to assess a supplier’s QC practices is through regular audits. These can be conducted by the buyer or a third-party inspection agency. During an audit, key areas such as manufacturing processes, quality management systems, and compliance with international standards are evaluated. Audits provide insights into the supplier’s operational capabilities and adherence to quality norms.

Reviewing Quality Control Reports

Buyers should request access to quality control reports, which detail the results of inspections and tests performed during and after production. These reports should include data on defect rates, non-conformities, and corrective actions taken. Consistent positive outcomes in these reports can build trust in the supplier’s quality processes.

Third-Party Inspections

Engaging third-party inspection services can further validate a supplier’s claims regarding their quality control measures. These independent entities can conduct inspections at various stages of the manufacturing process, providing an unbiased assessment of product quality. This service is particularly valuable for international transactions, where buyers may not have the capacity to perform onsite inspections themselves.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions must navigate various nuances when it comes to quality control in rotating latch procurement. Understanding these differences can lead to more informed purchasing decisions.

Cultural and Regulatory Differences

Different regions may have varying standards and expectations regarding quality control. For instance, European buyers might prioritize compliance with CE marking, while buyers in South America may focus on local certifications that ensure products meet regional safety and performance standards. Understanding these nuances can help buyers select suppliers that align with their specific needs.

Risk Management Strategies

International buyers should implement risk management strategies that account for potential quality issues. This can include diversifying the supplier base, maintaining open lines of communication with suppliers, and establishing clear quality expectations in contracts. By proactively addressing potential risks, buyers can enhance their procurement processes and ensure product reliability.

Continuous Improvement and Feedback Loops

Establishing a continuous improvement culture with suppliers can yield long-term benefits. Encouraging feedback and open dialogue about quality issues fosters collaboration and drives innovation in manufacturing processes. This partnership approach can lead to improved product quality and more efficient operations over time.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing rotating latches, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rotating latch’

In the competitive landscape of B2B procurement, sourcing the right rotating latch is crucial for ensuring product reliability and functionality. This guide provides a structured approach to help international buyers effectively navigate the sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of effective sourcing. Determine the specific requirements of the rotating latch, including load capacity, material (e.g., stainless steel versus mild steel), and operational features such as locking mechanisms or waterproof capabilities. This step will ensure that you identify products that meet your operational needs and industry standards.

Step 2: Conduct Market Research

Thorough market research is vital to understand the range of products available and their price points. Explore various suppliers, both local and international, to gauge the offerings and identify potential suppliers that align with your specifications. Pay attention to market trends, such as emerging technologies in latch design or materials, to stay ahead of competitors.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, product catalogs, and references from current clients, particularly those in your region or industry. Look for suppliers with a proven track record of quality and reliability, and consider their ability to provide post-purchase support, such as warranty services or technical assistance.

Illustrative image related to rotating latch

Step 4: Verify Supplier Certifications and Compliance

Ensuring that suppliers adhere to industry standards and certifications is crucial for maintaining product quality and safety. Verify that the suppliers comply with relevant international standards, such as ISO certifications or other industry-specific regulations. This step minimizes the risk of sourcing subpar products and helps maintain compliance with local regulations in your market.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the rotating latches for practical testing. Assess the quality, functionality, and durability of the samples to ensure they meet your specifications. Testing samples can also help identify any potential issues before a larger investment, allowing for adjustments in your order if necessary.

Step 6: Negotiate Pricing and Terms

Once you’ve selected a preferred supplier, engage in negotiations to establish favorable pricing and terms. Discuss bulk order discounts, payment terms, and delivery schedules. A well-negotiated agreement can lead to significant cost savings and ensure a reliable supply chain.

Step 7: Establish a Communication Plan

Maintain open lines of communication with your chosen supplier throughout the sourcing process. Establish a clear communication plan that includes regular updates on order status, shipping timelines, and any potential issues that may arise. Effective communication fosters a strong partnership and can lead to better problem resolution and collaboration in future projects.

By following these steps, B2B buyers can streamline their procurement process for rotating latches, ensuring they select the right products from reliable suppliers while optimizing costs and efficiency.

Comprehensive Cost and Pricing Analysis for rotating latch Sourcing

What Are the Key Cost Components in Rotating Latch Manufacturing?

The cost structure for rotating latches involves several critical components that B2B buyers should consider when sourcing these products. The primary cost elements include:

-

Materials: The choice of material significantly affects cost. Stainless steel, for instance, offers durability and resistance to corrosion, which is often preferred for outdoor or industrial applications. Alternative materials, such as mild steel or zinc-plated options, may reduce costs but could compromise longevity.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Regions with lower labor costs may provide a competitive advantage, but it’s essential to balance this with quality and craftsmanship.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory management. Efficient manufacturing processes can lower overhead, which is particularly important for high-volume production.

-

Tooling: Custom tooling for specific latch designs can be a significant upfront investment. Buyers should evaluate the necessity of customized solutions against standard options to manage costs effectively.

-

Quality Control (QC): Implementing rigorous QC measures ensures that products meet specifications and regulatory standards. While this adds to costs, it ultimately reduces the risk of returns and enhances customer satisfaction.

-

Logistics: Transportation costs can fluctuate based on distance and mode of shipping. International buyers must consider the implications of shipping costs, including potential tariffs and delays.

-

Margin: Suppliers typically add a markup to cover profit margins. Understanding the typical margin in the industry can help buyers negotiate better pricing.

How Do Price Influencers Affect the Cost of Rotating Latches?

Several factors influence the pricing of rotating latches in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often results in significant cost savings. Suppliers frequently offer tiered pricing based on order size, which can lead to lower per-unit costs.

-

Specifications and Customization: Custom latches designed for specific applications may incur additional costs. Buyers should weigh the benefits of customization against the potential for increased expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO standards) enhance product reliability but may increase costs. Buyers should assess whether these factors align with their operational needs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, but they can also offer assurances on quality and delivery times.

-

Incoterms: Understanding the Incoterms governing the shipment can clarify who bears responsibility for shipping costs, insurance, and tariffs. This is particularly relevant for international transactions.

What Are the Best Negotiation Tips for B2B Buyers of Rotating Latches?

To optimize sourcing, international buyers should consider the following strategies:

-

Research and Benchmarking: Understand the market rates for rotating latches by researching multiple suppliers and comparing their offerings. This knowledge will empower buyers during negotiations.

-

Leverage Volume Discounts: If possible, consolidate orders to meet higher MOQ thresholds for better pricing. This approach can be particularly advantageous for businesses anticipating steady demand.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but the TCO, including maintenance, durability, and potential for replacements. Investing in higher-quality latches may yield long-term savings.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better terms and pricing. Regular communication can also facilitate smoother negotiations and future transactions.

-

Understand Local Market Dynamics: For buyers in regions like Africa and South America, being aware of local economic conditions and supply chain challenges can provide leverage in negotiations.

Conclusion: What Should Buyers Keep in Mind About Pricing Nuances in International Markets?

B2B buyers must navigate various pricing nuances when sourcing rotating latches internationally. Currency fluctuations, import/export regulations, and regional market conditions can all impact costs. It’s essential to approach sourcing with a comprehensive understanding of these elements, ensuring informed decisions that align with business objectives.

Disclaimer: Prices mentioned are indicative and may vary based on supplier, market conditions, and order specifics. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing rotating latch With Other Solutions

Introduction to Alternatives in Latching Solutions

In the realm of industrial hardware, selecting the right latching mechanism is crucial for ensuring security and operational efficiency. While rotating latches are popular for their versatility and ease of use, several alternative solutions exist that may better fit specific applications or operational needs. This section explores a few of these alternatives, providing a detailed comparison to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Rotating Latch | Toggle Latch | Hook Latch |

|---|---|---|---|

| Performance | High strength-to-weight ratio; effective in tension loads | Suitable for quick access; reliable locking mechanism | Excellent for heavy-duty applications; strong load-bearing capacity |

| Cost | Moderate pricing ($18.44 – $39.86) | Generally lower cost ($3.00 – $20.00) | Higher cost ($15.00 – $50.00) |

| Ease of Implementation | Requires precise installation; adaptable to various applications | Simple installation; user-friendly | Installation can be complex; may require specialized tools |

| Maintenance | Low maintenance; corrosion-resistant materials available | Low maintenance; occasional lubrication needed | Moderate maintenance; check for wear and tear |

| Best Use Case | Ideal for applications requiring secure closure with minimal intrusion | Best for doors and panels needing frequent access | Suitable for heavy-duty applications, such as trailers and industrial equipment |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Toggle Latches?

Toggle latches are designed for quick engagement and disengagement, making them ideal for applications where frequent access is required. They are generally more cost-effective compared to rotating latches, making them an attractive choice for budget-conscious projects. However, toggle latches may not provide the same level of security as rotating latches, particularly in high-stress environments where load-bearing is critical. Their simple design allows for easy installation and maintenance, but the trade-off is often a compromise in strength and durability.

Illustrative image related to rotating latch

How Do Hook Latches Compare in Terms of Heavy-Duty Applications?

Hook latches excel in heavy-duty applications, offering superior load-bearing capacities and robust locking mechanisms. They are ideal for securing large doors or panels that experience significant tension and shear forces. However, the installation of hook latches can be more complex, often requiring specialized tools and precise alignment to ensure functionality. Additionally, while they provide excellent security, the higher cost of hook latches may deter some buyers who are looking for more economical solutions.

Conclusion: Choosing the Right Latching Solution for Your Needs

When selecting a latching mechanism, B2B buyers must consider various factors such as performance requirements, budget constraints, and the specific use case of the latch. Rotating latches offer a balanced solution for many applications, particularly where security and adaptability are paramount. However, alternatives like toggle and hook latches may serve better in specific scenarios, such as frequent access or heavy-duty applications. By carefully evaluating these factors, businesses can choose the most appropriate latching solution that aligns with their operational needs and cost considerations.

Essential Technical Properties and Trade Terminology for rotating latch

What Are the Essential Technical Properties of a Rotating Latch?

When evaluating rotating latches for various applications, several technical properties are critical for ensuring performance, reliability, and safety. Understanding these specifications helps B2B buyers make informed decisions that align with their operational needs.

Illustrative image related to rotating latch

1. Material Grade

The material used in the construction of a rotating latch significantly impacts its durability and resistance to corrosion. Common materials include stainless steel (e.g., type 304 or 316) and mild steel with zinc plating. Stainless steel offers higher resistance to environmental factors, making it suitable for outdoor or high-humidity applications. Buyers should consider the material grade based on their specific application and environmental conditions.

2. Ultimate Tensile Strength (UTS)

Ultimate tensile strength is a measure of the maximum stress that a material can withstand while being stretched or pulled before breaking. For example, a rotating latch with a UTS of 170 kg can safely operate at approximately half this value, which is crucial for ensuring safety under load. B2B buyers must evaluate UTS to ensure that the latch can handle the required working loads without risk of failure.

3. Working Load Limit (WLL)

Working load limit defines the maximum load that can be safely applied to a latch during regular operations. This value is typically derived from the UTS and provides a safety margin to prevent overloading. Buyers should always select a latch with a WLL that exceeds their operational requirements to account for unexpected forces or loads.

4. Fixing Hole Diameter

The fixing hole diameter is essential for installation compatibility. A standard diameter, such as 5.1 mm, ensures that the latch can be easily mounted onto various surfaces. Buyers need to consider the fixing hole diameter to ensure compatibility with existing hardware and installation processes.

5. Padlockable Feature

A padlockable feature provides an added layer of security, allowing users to secure the latch with a padlock. This is particularly important in applications where unauthorized access needs to be prevented. B2B buyers should assess whether this feature is necessary based on their security requirements.

6. Deflection Limits

Deflection limits indicate how much a latch can compress under load before it reaches its maximum operational capacity. For instance, a latch may have a deflection limit of 6.0 mm at a working load of 110 kg. Understanding these limits helps buyers ensure that the latch will perform effectively without permanent deformation.

What Are Common Trade Terms Used in the Rotating Latch Industry?

Familiarity with industry jargon can streamline communication and facilitate smoother transactions. Here are several key terms relevant to B2B buyers in the rotating latch market.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rotating latches, an OEM might design and manufacture latches that are then sold under different brand names. Understanding OEM relationships helps buyers identify reliable sources for high-quality products.

2. MOQ (Minimum Order Quantity)

Minimum Order Quantity is the smallest number of units a supplier is willing to sell. This term is crucial for buyers, especially those operating on tight budgets or looking to test a new product. Knowing the MOQ can help in planning inventory and managing costs effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price proposals from suppliers for specific products or services. It is a critical step in the procurement process, allowing buyers to compare prices and terms across different suppliers. Utilizing RFQs can lead to more competitive pricing and better terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for international transactions, as they clarify who bears the risk at various stages of the shipping process.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until it is fulfilled. In the context of rotating latches, shorter lead times can be critical for projects with tight deadlines. Buyers should consider lead times when planning their inventory and production schedules.

Illustrative image related to rotating latch

6. Certification Standards

Certification standards, such as ISO or ASTM, indicate that a product meets specific quality and safety requirements. Familiarity with these standards can help buyers ensure that the latches they are sourcing comply with industry regulations and are suitable for their applications.

By understanding these essential technical properties and trade terms, B2B buyers can make more informed decisions regarding rotating latches, ultimately improving their procurement processes and operational efficiencies.

Navigating Market Dynamics and Sourcing Trends in the rotating latch Sector

What are the Key Market Dynamics and Trends Influencing the Rotating Latch Sector?

The global market for rotating latches is driven by several key factors, including the increasing demand for durable and reliable fastening solutions across various industries such as automotive, aerospace, and industrial equipment. The growth of these sectors in emerging markets, particularly in Africa, South America, and the Middle East, is contributing significantly to the demand for high-quality latching systems. Furthermore, advancements in manufacturing technologies, such as automation and precision engineering, have enhanced the quality and reliability of rotating latches, making them more appealing to international buyers.

B2B buyers are increasingly looking for suppliers who leverage digital technologies to streamline their sourcing processes. E-commerce platforms and digital marketplaces are becoming essential tools for buyers to compare products, evaluate pricing models, and check availability. Bulk purchasing options and tiered pricing strategies are particularly attractive, allowing buyers to optimize their procurement budgets. Additionally, there is a growing emphasis on customization, with manufacturers offering tailored solutions to meet specific industry requirements.

How Does Sustainability Impact Sourcing in the Rotating Latch Sector?

Sustainability has become a critical consideration for B2B buyers, influencing their sourcing strategies in the rotating latch sector. The environmental impact of manufacturing processes, particularly in terms of resource consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recyclable materials and reducing emissions during production.

Illustrative image related to rotating latch

Ethical supply chains are also gaining traction, with buyers seeking transparency in the sourcing of materials. Certifications such as ISO 14001 for environmental management and adherence to Fair Trade standards are becoming essential for suppliers aiming to establish credibility. Additionally, the use of ‘green’ materials, such as recycled stainless steel and eco-friendly coatings, can enhance a product’s appeal in the market, aligning with buyers’ sustainability goals.

What is the Historical Context of the Rotating Latch Industry?

The rotating latch has its roots in mechanical engineering, evolving over the decades from simple manual fasteners to sophisticated locking mechanisms used in various applications. Initially designed for industrial use, advancements in materials science and manufacturing techniques have transformed rotating latches into reliable components in sectors such as aerospace and automotive. The integration of features like waterproofing, visual indicators for latch status, and adjustable mechanisms has further expanded their utility.

This evolution reflects a broader trend within the industry, where innovation is driven by the need for enhanced performance, safety, and user convenience. As the demand for high-quality latching solutions continues to rise, the rotating latch sector is poised for further growth, with opportunities for B2B buyers to leverage these advancements for their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of rotating latch

-

1. How do I solve issues with latch durability in harsh environments?

To enhance latch durability in harsh conditions, consider sourcing stainless steel or zinc-plated finishes, which offer superior corrosion resistance. Additionally, look for latches with sealing features, such as O-rings, to prevent moisture ingress. It’s also essential to select latches with high tensile strength ratings, ensuring they can withstand the required loads. Always consult with suppliers about the specific environmental conditions your latches will face, as they may offer tailored solutions or additional protective coatings. -

2. What is the best rotary latch for high-security applications?

For high-security applications, opt for rotary latches designed with mechanical locks and padlockable features. Look for options that provide a robust ultimate tensile strength and are constructed from high-grade materials, such as stainless steel. Additionally, consider latches with visual indicators to confirm the locked status, enhancing operational safety. It’s advisable to evaluate suppliers that specialize in security latching systems and can provide certifications for their products. -

3. How can I ensure the quality of the rotary latches I purchase?

To ensure quality, request certifications from suppliers, such as ISO 9001, which indicates adherence to international quality management standards. Implement a quality assurance (QA) process, including sample testing before bulk purchases. Establish clear specifications regarding materials, strength, and functionality, and seek suppliers who offer warranties or guarantees on their products. Regularly communicate with your supplier to address any potential quality concerns during the production phase. -

4. What factors should I consider when vetting suppliers for rotary latches?

When vetting suppliers, evaluate their experience in the industry, looking for those with a proven track record in manufacturing rotary latches. Check for customer reviews and testimonials to gauge reliability. Assess their production capabilities, lead times, and flexibility in meeting your specific requirements. Additionally, consider their communication practices and responsiveness, as these factors are crucial for a successful long-term partnership. -

5. What are the typical minimum order quantities (MOQs) for rotary latches?

Minimum order quantities (MOQs) for rotary latches can vary significantly based on the supplier and the specific product type. Common MOQs range from 50 to 500 units, depending on the complexity and customization of the latch. Be sure to discuss your needs with potential suppliers, as some may offer lower MOQs for standard products or allow flexibility for larger orders. Consider negotiating terms that align with your inventory management strategies. -

6. What payment terms should I expect when sourcing rotary latches internationally?

Payment terms can vary widely among suppliers, but common practices include a partial upfront payment (30-50%) with the balance due upon delivery or prior to shipping. Some suppliers may offer net 30 or net 60 terms for established customers. Always clarify payment methods accepted, such as wire transfers, letters of credit, or PayPal. Ensure to negotiate terms that provide a balance between cash flow management and supplier confidence. -

7. How do logistics and shipping impact the sourcing of rotary latches?

Logistics play a crucial role in the timely delivery of rotary latches. Factors such as shipping methods (air vs. sea), customs clearance, and local regulations can affect lead times and costs. It is advisable to work with suppliers who have experience in international shipping and can provide insights into potential delays. Consider using freight forwarders to navigate the complexities of international logistics, ensuring smooth transport and delivery of your latches. -

8. Can I customize rotary latches for my specific application?

Yes, many manufacturers offer customization options for rotary latches to meet specific application needs. Customization can include alterations in size, material, finish, and additional features like locking mechanisms or unique mounting configurations. When discussing customization, provide detailed specifications and use cases to ensure the supplier understands your requirements. Be prepared for potential minimum order quantities and lead times that may be longer for customized products.

Top 5 Rotating Latch Manufacturers & Suppliers List

1. Protex – 676LM1SS Rotary Turn Latch

Domain: protex.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “676LM1SS Rotary Turn Latch”, “type”: “Spring Loaded Rotary Latch”, “material”: “Stainless Steel type 304”, “finish”: “Natural”, “weight”: “0.1209 Kg”, “max_working_load”: “110 Kg @ 6.0 mm”, “ultimate_tensile_strength”: “170 Kg”, “safe_working_load”: “Approx. Half UTS”, “fixing_hole_diameter”: “5.1 mm”, “padlockable”: “Yes”, “price”: {“1-19”: “$39.86”, “20-49”: “$33.22”, “50-99”: …

2. Industrilas – Rotary Latching Systems

Domain: industrilas.com

Registered: 1999 (26 years)

Introduction: Rotary latching systems are part of Industrilas’ latching systems product line, which serves various industries including Commercial Vehicles, Door and Window Manufacturers, EV Charging, Food and Pharmaceutical, HVAC, IT and Telecom, Marine, Con-Ag, Off-highway, Power Generation and Distribution, Power Sports, Railway, Recreational Vehicles, Specialty Vehicles, Armoured Vehicles, and Cases. The pr…

3. Hartwell Corp – Rotary Latches

Domain: hartwellcorp.com

Registered: 1997 (28 years)

Introduction: Rotary latches are designed to carry loads in tension only and are used with adjacent shear pins or interlocking faces to react to shear loads. They are operated with a standard mechanic’s tool and are aerodynamically friendly with minimum penetration of the aircraft’s skin. Features include: minimum skin cutouts, high strength-to-weight ratios, mechanical lock incorporated in the latch, reduced e…

4. Industrial Hardware – Rotary Latches

Domain: industrialhwe.com

Registered: 1997 (28 years)

Introduction: Industrial Hardware carries a large inventory of rotary latches including dual stage, single rotor, mini and claw styles. Key features include: 1. Dual Stage Rotary Latches: Available in right hand and left hand versions with threaded, dovetail, and standard mounting styles. 2. Single and Dual Activation Styles: Options for different operational needs. 3. Heavy Duty Rotary Latch: Features various …

5. Southco – R4-25 Rotary Latch

Domain: info.austinhardware.com

Registered: 1996 (29 years)

Introduction: Southco R4-25 Rotary Latch is designed for rugged applications with features including electronic actuation and door status monitoring. It offers reliable push-to-close latching with minimal force, suitable for single or multi-point applications across various industries. Key specifications include a 9000 N load capacity, durable and corrosion-resistant metal construction, compact design for slim …

Strategic Sourcing Conclusion and Outlook for rotating latch

Why Is Strategic Sourcing Essential for Rotating Latch Procurement?

In conclusion, strategic sourcing for rotating latches is paramount for international B2B buyers aiming to optimize their supply chains and ensure product quality. By leveraging quantity discounts and focusing on reliable suppliers, businesses can significantly reduce costs while enhancing their operational efficiency. Understanding the specifications, such as material durability and load capacities, is critical in selecting the right latch for your needs, whether for industrial applications or specialized sectors like aerospace.

What Should International Buyers Consider Moving Forward?

As markets evolve, international buyers from regions like Africa, South America, the Middle East, and Europe must remain agile. Establishing strong relationships with manufacturers can lead to better pricing structures and more innovative solutions tailored to specific needs. Engaging in long-term partnerships can also facilitate access to new technologies and trends, ensuring that your offerings remain competitive.

How Can You Position Your Business for Success?

Looking ahead, the demand for high-quality, reliable rotating latches will continue to grow. Now is the time to evaluate your sourcing strategies, embrace collaboration with suppliers, and invest in quality assurance processes. By taking these proactive steps, you can secure a robust supply chain that not only meets current demands but also positions your business for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to rotating latch

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.