The Definitive Guide to Rotary Drum Blender: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for rotary drum blender

Navigating the global market for rotary drum blenders can be a daunting task for B2B buyers, especially when sourcing equipment that meets specific operational needs. The challenge lies in identifying reliable suppliers who offer high-quality, efficient mixing solutions tailored for diverse industries, from agriculture to food processing. This guide aims to demystify the complexities of rotary drum blenders by providing a comprehensive overview of types, applications, and key features, ensuring that international buyers—particularly those in Africa, South America, the Middle East, and Europe, including Brazil and Saudi Arabia—can make informed purchasing decisions.

Within these pages, you will discover insights into various rotary drum blender configurations, their suitability for different materials, and how to assess supplier credentials. We will also explore the financial implications of your investment, outlining essential factors that influence cost-effectiveness and long-term value. By equipping you with the knowledge to evaluate performance, maintenance, and compliance with international standards, this guide empowers you to choose the right rotary drum blender that not only enhances productivity but also aligns with your strategic business goals. Let’s embark on this journey to optimize your mixing processes and drive operational excellence in your organization.

Understanding rotary drum blender Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Drum Mixer | Forward/reverse rotation, angled baffle plates, high discharge rates | Cement, animal feed, spices | Pros: Efficient mixing, easy maintenance. Cons: Limited to free-flowing materials. |

| Mk VII Rollo-Mixer | Enclosed turbine section, Free-Fall Processing®, large volume options | Plastics, petrochemicals, food products | Pros: Gentle blending, high capacity. Cons: Initial investment can be high. |

| Rotary Batch Mini Mixer | Compact design, quick blending, suitable for small scales | Laboratory, pilot plants, small production | Pros: Versatile, easy to clean. Cons: Limited capacity for larger operations. |

| Continuous Rotary Blender | Continuous feed and discharge, high throughput | Large-scale manufacturing, food processing | Pros: High efficiency, consistent output. Cons: Complexity in setup and maintenance. |

| Tumble Blender | Gentle tumbling action, suitable for fragile materials | Pharmaceuticals, food, chemicals | Pros: Preserves material integrity, low shear. Cons: Slower mixing compared to other types. |

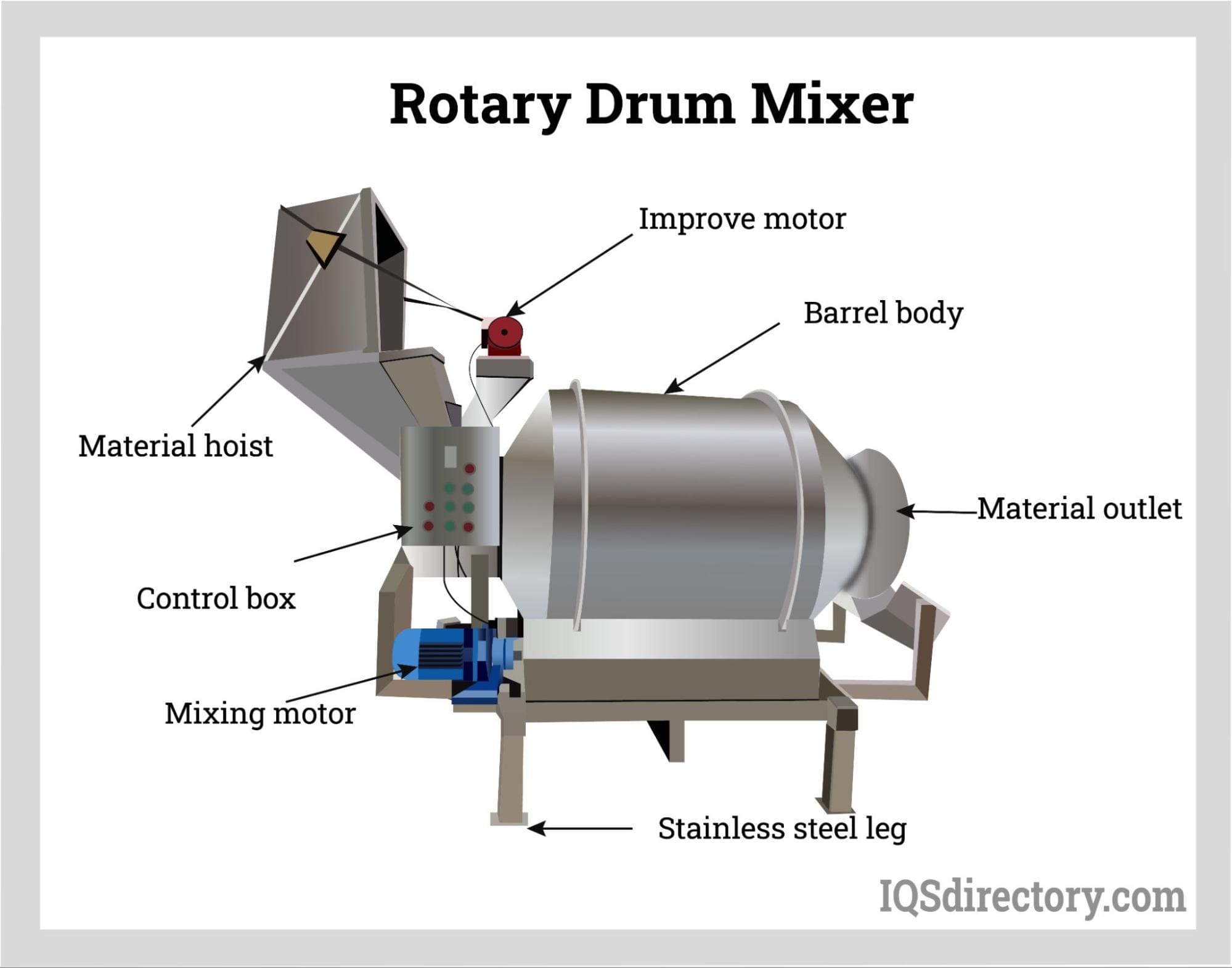

What Are the Characteristics of a Rotary Drum Mixer?

The Rotary Drum Mixer is designed for efficient mixing of heavy, free-flowing materials. Its unique forward and reverse rotation, coupled with angled baffle plates, ensures that materials are thoroughly mixed with virtually 100% product discharge. This type is particularly well-suited for industries such as construction, agriculture, and food processing. Buyers should consider the material compatibility, maintenance ease, and the mixer’s ability to handle the specific weight and flow characteristics of their products.

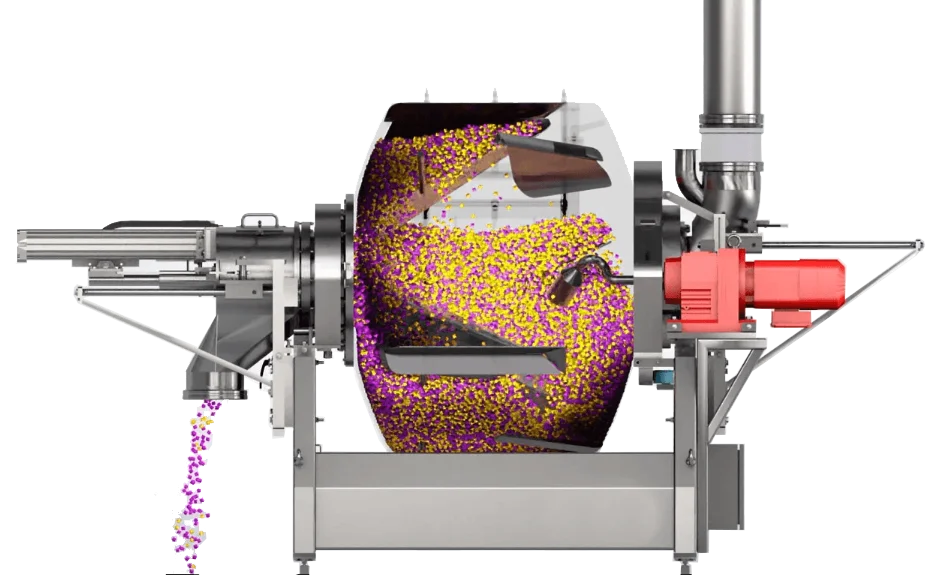

How Does the Mk VII Rollo-Mixer Stand Out?

The Mk VII Rollo-Mixer is noted for its gentle yet effective blending capabilities, making it ideal for handling delicate materials like plastic pellets and food products. Its Free-Fall Processing® technology allows for uniform mixing without damaging the product. With a capacity range from small to over 1,200 cu ft, it is suitable for large-scale applications. B2B buyers should evaluate the initial cost against the long-term benefits of efficiency and product quality, especially in high-demand environments.

Why Choose a Rotary Batch Mini Mixer?

The Rotary Batch Mini Mixer is perfect for smaller operations or laboratory settings, offering capacities from 0.25 to 15 cu ft. Its four-way mixing action ensures a gentle blend, ideal for materials that require careful handling. This type is particularly advantageous for businesses needing to conduct trials or small-scale production runs. Buyers should assess their volume needs and the importance of quick cleaning and setup, as these features can significantly impact operational efficiency.

What Are the Benefits of a Continuous Rotary Blender?

Continuous Rotary Blenders are designed for high-throughput operations, allowing materials to be fed and discharged continuously. This type is especially useful in large-scale manufacturing settings where consistent quality and output are paramount, such as in food processing and chemical production. While they offer significant efficiency, buyers must consider the complexity of setup and maintenance, as well as the initial investment required for such equipment.

In What Scenarios Is a Tumble Blender Preferred?

Tumble Blenders utilize a gentle tumbling action, making them suitable for fragile materials that could be damaged by more aggressive mixing methods. They are widely used in the pharmaceutical and food industries, where product integrity is crucial. When purchasing a Tumble Blender, businesses should weigh the advantages of preserving material quality against the slower mixing times compared to other options, especially if speed is a critical factor in their operations.

Key Industrial Applications of rotary drum blender

| Industry/Sector | Specific Application of rotary drum blender | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Mixing animal feed and premixes | Ensures uniformity in nutrient distribution, improving animal health and productivity | Material compatibility, ease of cleaning, and discharge efficiency |

| Food and Beverage | Blending spices, tea leaves, and coffee beans | Maintains flavor consistency and quality in products, enhancing customer satisfaction | Food-grade materials, contamination prevention, and regulatory compliance |

| Construction Materials | Mixing cement, lime, and plaster | Increases efficiency in material preparation, reducing waste and costs | Durability, maintenance needs, and mixing capacity |

| Plastics and Petrochemicals | Blending plastic pellets and additives | Achieves uniform product quality, essential for downstream processing | Customization options, load size variations, and blending speed |

| Chemical Processing | Mixing industrial detergents and catalysts | Ensures precise formulation and efficiency in chemical reactions | Safety features, material compatibility, and maintenance ease |

How is Rotary Drum Blender Used in Agriculture for Animal Feed?

In the agricultural sector, rotary drum blenders are extensively used to mix animal feed and premixes. These blenders ensure a uniform distribution of nutrients, which is critical for the health and productivity of livestock. With a focus on efficiency, these machines can handle large volumes while minimizing contamination risks. Buyers in regions like Africa and South America should prioritize equipment that offers easy cleaning features and robust construction to withstand harsh operating conditions.

What Role Does Rotary Drum Blender Play in Food and Beverage Industry?

In the food and beverage industry, rotary drum blenders are vital for blending spices, tea leaves, and coffee beans. These blenders help maintain flavor consistency and quality, which are crucial for customer satisfaction and brand loyalty. Buyers, particularly in Europe and the Middle East, must ensure that the equipment meets food-grade standards, is made from materials that prevent contamination, and complies with local food safety regulations.

How Does Rotary Drum Blender Enhance Efficiency in Construction Materials?

For the construction materials industry, rotary drum blenders are employed to mix cement, lime, and plaster. This equipment enhances efficiency by ensuring that materials are uniformly mixed, which reduces waste and optimizes the quality of the final product. Businesses in this sector should consider the durability of the blenders and their maintenance needs, particularly in regions where operational downtime can significantly impact project timelines.

How is Rotary Drum Blender Applied in Plastics and Petrochemicals?

In the plastics and petrochemical industries, rotary drum blenders are used for blending plastic pellets and additives. The ability to achieve uniform product quality is essential, as it impacts downstream processing and the final product’s performance. Sourcing considerations include customization options to meet specific blending requirements, variations in load sizes, and the speed of blending processes, which are particularly important for large-scale manufacturers in South America and the Middle East.

What Benefits Does Rotary Drum Blender Provide in Chemical Processing?

In chemical processing, rotary drum blenders are used to mix industrial detergents and catalysts. These blenders ensure precise formulation and efficiency in chemical reactions, which are critical for product effectiveness. Buyers should focus on safety features, material compatibility with various chemicals, and ease of maintenance to ensure long-term operational success. This is especially relevant for businesses in regions with stringent safety regulations, such as Europe and Saudi Arabia.

3 Common User Pain Points for ‘rotary drum blender’ & Their Solutions

Scenario 1: Inconsistent Mixing Quality Leading to Product Variability

The Problem: One of the primary challenges faced by B2B buyers of rotary drum blenders is achieving consistent mixing quality, especially when dealing with varying batch sizes and material types. For instance, a company producing animal feed might find that the final product’s consistency varies significantly, leading to discrepancies in nutritional value and affecting customer satisfaction. This inconsistency can stem from improper loading techniques, inadequate equipment maintenance, or the selection of inappropriate blender specifications.

The Solution: To address this issue, it’s essential to invest in a rotary drum blender that is specifically designed for the materials you are working with, such as the Mk VII Rollo-Mixer®, which offers gentle and uniform mixing capabilities. Conduct thorough testing of your materials in different mixer configurations to determine the optimal settings for your specific application. Additionally, implement a regular maintenance schedule to ensure that the equipment remains in top condition. Using sensors or monitoring systems to track mixing parameters in real-time can also help in adjusting processes on the fly, ensuring that every batch meets the desired quality standards.

Scenario 2: Difficulty in Cleaning and Preventing Cross-Contamination

The Problem: Another common pain point for buyers is the challenge of cleaning rotary drum blenders effectively, especially in industries where hygiene is critical, such as food processing or pharmaceuticals. Residue left behind from previous batches can lead to cross-contamination, compromising product quality and safety, which can be particularly concerning for businesses in regulated markets.

The Solution: To mitigate this issue, choose a rotary drum blender designed with easy cleaning in mind, such as those with smooth surfaces and accessible discharge ports. Models that offer features like complete cleanout capabilities and removable baffles are ideal as they facilitate thorough cleaning. Establishing a standard operating procedure (SOP) for cleaning that includes the use of suitable cleaning agents and methods tailored to the materials being processed can further enhance hygiene. Additionally, consider investing in blenders with stainless steel construction, which is easier to sanitize compared to carbon steel.

Scenario 3: High Operational Costs Due to Inefficiencies

The Problem: Many businesses find themselves facing high operational costs linked to inefficient mixing processes. This may be due to prolonged mixing times, excessive energy consumption, or frequent breakdowns requiring costly repairs. For instance, a construction materials company using a rotary drum blender for cement mixes might experience delays and increased labor costs due to an inefficient mixing cycle.

The Solution: To reduce operational costs, it’s crucial to select a rotary drum blender that offers efficient mixing capabilities and robust construction. Look for models with features like variable speed controls and optimized mixing patterns that can significantly reduce mixing time while maintaining quality. Additionally, consider investing in energy-efficient motors and automation technologies that can streamline operations. Regular training for operators on best practices can also enhance the efficiency of the mixing process, ensuring that all personnel are aware of how to maximize equipment performance and minimize downtime.

Strategic Material Selection Guide for rotary drum blender

What Are the Key Materials Used in Rotary Drum Blenders?

When selecting a rotary drum blender, the choice of material is critical to ensure optimal performance and longevity. Below are analyses of four common materials used in the construction of rotary drum blenders, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Carbon Steel Perform in Rotary Drum Blenders?

Key Properties: Carbon steel is known for its strength and durability. It typically has a high tensile strength and can withstand moderate temperature and pressure variations. However, it is susceptible to corrosion if not properly coated or maintained.

Pros & Cons: The main advantages of carbon steel include its lower cost compared to stainless steel and its high strength, making it suitable for heavy-duty applications. However, its susceptibility to rust and corrosion limits its use in applications involving moisture or corrosive materials, requiring additional protective coatings.

Impact on Application: Carbon steel is ideal for blending dry, non-corrosive materials such as sand, cement, and animal feed. Its performance may be compromised in humid or acidic environments.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local environmental conditions that may accelerate corrosion. Compliance with local standards such as ASTM for material specifications is essential.

What Benefits Does Stainless Steel Offer for Rotary Drum Blenders?

Key Properties: Stainless steel is highly resistant to corrosion and can withstand extreme temperatures and pressures, making it suitable for a wide range of applications. It is also easy to clean, which is vital in industries like food processing.

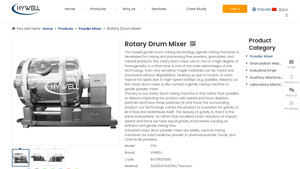

Illustrative image related to rotary drum blender

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of the equipment. However, it is significantly more expensive than carbon steel, which can impact initial investment costs.

Impact on Application: Stainless steel is particularly beneficial for blending food products, pharmaceuticals, and other sensitive materials where hygiene is paramount. Its non-reactive nature ensures that there is no contamination of the product.

Considerations for International Buyers: Buyers in Europe and the Middle East often prefer stainless steel due to stringent hygiene regulations. Compliance with standards such as DIN and JIS is crucial for market acceptance.

How Does Abrasion-Resistant Steel Enhance Rotary Drum Blender Performance?

Key Properties: Abrasion-resistant steel is designed to withstand wear and tear from abrasive materials. It typically features a high hardness rating, which allows it to maintain its structural integrity over time.

Pros & Cons: The key advantage of abrasion-resistant steel is its longevity in applications involving hard or gritty materials, such as aggregates and minerals. However, its higher cost and the complexity of manufacturing can be limiting factors.

Impact on Application: This material is particularly suited for blending heavy, abrasive materials, ensuring that the equipment remains functional and efficient over extended periods.

Considerations for International Buyers: In regions like Brazil, where mining and aggregate industries are prominent, the use of abrasion-resistant steel can enhance operational efficiency. Buyers should ensure compliance with local mining and safety standards.

What Role Does Polypropylene Play in Rotary Drum Blenders?

Key Properties: Polypropylene is a lightweight, corrosion-resistant plastic that can handle a range of temperatures. It is not as strong as metals but offers excellent chemical resistance.

Pros & Cons: The advantages of polypropylene include its low cost and resistance to a variety of chemicals, making it suitable for specific applications. However, it may not be suitable for high-temperature processes or heavy-duty applications due to its lower tensile strength.

Impact on Application: Polypropylene is ideal for blending lightweight materials, such as agricultural chemicals and certain food products, where metal contamination is a concern.

Considerations for International Buyers: Buyers in the Middle East and Africa should consider the chemical compatibility of polypropylene with local materials. Compliance with safety regulations is also essential.

Summary of Material Selection for Rotary Drum Blenders

| Material | Typical Use Case for rotary drum blender | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Blending dry, non-corrosive materials | High strength and durability | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals | Corrosion resistance, easy to clean | Higher initial cost | High |

| Abrasion-Resistant Steel | Heavy, abrasive materials | Long lifespan in tough conditions | Higher cost, complex manufacturing | Med |

| Polypropylene | Lightweight, chemical-sensitive materials | Low cost, chemical resistance | Not suitable for high temperatures | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on their specific application needs and regional considerations.

Illustrative image related to rotary drum blender

In-depth Look: Manufacturing Processes and Quality Assurance for rotary drum blender

What Are the Main Stages in the Manufacturing Process of Rotary Drum Blenders?

The manufacturing process of rotary drum blenders involves several critical stages, each designed to ensure that the final product meets the high standards required by B2B buyers across diverse industries. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is material preparation. Manufacturers typically source high-quality raw materials, such as carbon steel or stainless steel, depending on the intended application of the rotary drum blender. For food-grade applications, stainless steel with specific finishes is often required to meet sanitary standards. The materials undergo thorough inspection to ensure compliance with specifications and industry standards. This stage may also involve cutting and shaping the raw materials into manageable sizes for further processing.

How Is the Forming Process Executed?

The forming stage entails shaping the prepared materials into the components that will make up the rotary drum blender. Techniques such as welding, machining, and bending are commonly employed. For instance, the drum itself is often formed using specialized machinery that ensures precise dimensions and tolerances. Advanced techniques, such as laser cutting, may also be used to enhance accuracy and reduce waste. This stage is critical, as any defects in the components can lead to operational inefficiencies and increased maintenance costs.

Illustrative image related to rotary drum blender

What Does the Assembly Stage Involve?

Once the individual components are formed, the assembly stage begins. This process involves the careful integration of various parts, including the drum, baffle plates, bearings, and seals. Depending on the design, assembly can be a labor-intensive task that requires skilled technicians to ensure that all components fit together seamlessly. Attention to detail during this stage is paramount, as it directly impacts the performance and longevity of the rotary drum blender.

Which Techniques Are Used in the Finishing Process?

The finishing stage involves applying protective coatings and surface treatments to enhance durability and resistance to corrosion. This might include powder coating or polishing to achieve a smooth, easy-to-clean surface. For food-grade applications, additional steps may be necessary to ensure that all surfaces are sanitary and free from contaminants. Quality control checks are often integrated into this stage to verify that the finish meets the required specifications.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is an essential component of the manufacturing process for rotary drum blenders, ensuring that each unit meets stringent performance and safety standards. International standards, such as ISO 9001, guide manufacturers in establishing effective quality management systems. In addition to these, industry-specific certifications like CE and API may be required depending on the application and region.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process to identify and address potential issues early. These checkpoints typically include:

- Incoming Quality Control (IQC): This stage focuses on inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted at various stages to monitor compliance with quality standards. This could include checking tolerances during the forming stage or verifying assembly integrity.

- Final Quality Control (FQC): At the end of the manufacturing process, a comprehensive inspection is performed to ensure the rotary drum blender operates as intended. This might include performance testing, safety checks, and verification of compliance with relevant certifications.

What Testing Methods Are Commonly Used for Rotary Drum Blenders?

Testing methods for rotary drum blenders vary based on their intended application but generally include the following:

- Performance Testing: This assesses the efficiency of the mixer in blending materials, often done using test batches in controlled environments.

- Durability Testing: Manufacturers simulate extended use conditions to evaluate the blender’s longevity and resistance to wear and tear.

- Safety Testing: Compliance with safety standards is verified, ensuring that the equipment is safe for operation in its intended environment.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are some effective strategies:

- Audits: Conducting on-site audits allows buyers to assess the manufacturing process firsthand. This includes evaluating the cleanliness of the facility, the competence of staff, and adherence to safety protocols.

- Quality Reports: Requesting detailed quality reports provides insights into the supplier’s quality management practices. Buyers should look for documented evidence of compliance with international standards and industry-specific regulations.

- Third-Party Inspections: Engaging third-party inspectors can offer an unbiased evaluation of the supplier’s quality control processes. These inspections can validate certifications and ensure that the products meet the required specifications.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate a complex landscape of quality control and certification nuances. Different regions may have varying standards, which can impact the acceptance of products. For instance, CE marking is essential for products sold within the European Union, whereas other regions may have their own certification requirements.

Understanding these nuances is critical for ensuring compliance and facilitating smooth trade. Buyers should actively engage with suppliers to clarify any certification requirements and ensure that all necessary documentation is provided.

Conclusion

The manufacturing processes and quality assurance practices for rotary drum blenders are crucial for ensuring that these machines meet the high standards required by international B2B buyers. By understanding the manufacturing stages, quality control checkpoints, testing methods, and verification strategies, buyers can make informed decisions and select suppliers that align with their operational needs. This knowledge is particularly valuable for businesses operating in diverse markets, including Africa, South America, the Middle East, and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rotary drum blender’

To assist international B2B buyers in sourcing rotary drum blenders effectively, this practical guide outlines essential steps to ensure a smooth procurement process. By following this checklist, buyers can make informed decisions that align with their operational needs and industry standards.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for your rotary drum blender. This includes the desired capacity, mixing speed, and compatibility with the materials you intend to blend. Understanding your operational requirements helps narrow down potential suppliers and ensures you select a machine that meets your specific needs.

- Capacity Considerations: Determine the volume of materials you need to process to select an appropriately sized blender.

- Material Compatibility: Ensure the blender can handle the specific types of materials, whether they are powders, granules, or liquids.

Step 2: Research Supplier Reputation

Investigate potential suppliers to assess their reputation within the industry. Look for established manufacturers with a history of producing reliable and efficient rotary drum blenders. A strong reputation often correlates with product quality and customer service.

- Client Testimonials: Seek feedback from other companies in your sector who have purchased similar equipment.

- Industry Experience: Consider suppliers with extensive experience in your specific industry, as they may better understand your unique requirements.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; engage with them directly to gauge their responsiveness and support capabilities.

- Request Documentation: Ask for product specifications, maintenance records, and warranty information.

- Visit Facilities: If possible, arrange to visit supplier facilities to observe their manufacturing processes and quality control measures.

Step 4: Verify Compliance with Standards

Ensure that the rotary drum blender complies with relevant industry standards and regulations. This is particularly important for sectors such as food and pharmaceuticals, where equipment must meet stringent safety and quality requirements.

- Certifications: Look for certifications such as CE, CSA, or ISO that indicate adherence to international safety and quality standards.

- Local Regulations: Be aware of any specific regulations in your region that the equipment must comply with.

Step 5: Assess Maintenance and Support Services

Evaluate the maintenance requirements of the rotary drum blender and the support services offered by the supplier. A machine that is easy to maintain will minimize downtime and repair costs.

- Maintenance Plans: Inquire about the availability of service contracts or maintenance plans.

- Technical Support: Ensure that the supplier provides adequate technical support, including troubleshooting assistance and parts availability.

Step 6: Compare Pricing and Terms

Once you have narrowed down your options, compare the pricing and terms from different suppliers. Keep in mind that the lowest price isn’t always the best deal; consider the overall value, including quality, support, and warranty.

Illustrative image related to rotary drum blender

- Include Hidden Costs: Factor in shipping, installation, and any potential import duties when comparing costs.

- Negotiate Terms: Don’t hesitate to negotiate payment terms and delivery timelines to align with your financial and operational schedules.

Step 7: Finalize Purchase Agreement

After selecting a supplier, ensure all terms are documented in a formal purchase agreement. This should outline the specifications, pricing, delivery schedule, and warranty details to protect both parties.

- Clear Specifications: Include detailed descriptions of the equipment and any optional features.

- Review Terms: Make sure to review the agreement carefully and clarify any ambiguities before signing.

By following these steps, international B2B buyers can confidently navigate the sourcing process for rotary drum blenders, ensuring they select the right equipment to meet their operational needs.

Comprehensive Cost and Pricing Analysis for rotary drum blender Sourcing

Understanding the cost structure and pricing for rotary drum blenders is crucial for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. This analysis provides insights into the components that drive costs and how various factors influence pricing.

What Are the Key Cost Components in Rotary Drum Blender Manufacturing?

-

Materials: The choice of materials significantly impacts cost. Rotary drum blenders are typically made from carbon steel or stainless steel, with the latter often incurring higher costs due to its corrosion resistance and suitability for food-grade applications. Custom finishes can also add to material costs.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled labor is essential for assembling and testing these machines, particularly when precision is required for high-performance applications.

-

Manufacturing Overhead: This includes expenses related to factory operation, utilities, and equipment maintenance. Effective management of overhead costs can lead to more competitive pricing.

-

Tooling: The initial investment in tooling for rotary drum blenders can be substantial. This cost is amortized over the production run, making it essential for buyers to consider the volume of their orders to ensure cost-effectiveness.

-

Quality Control (QC): Ensuring high standards through rigorous QC processes is essential, especially for applications in sensitive industries like food and pharmaceuticals. The costs associated with QC can vary based on the certifications required (e.g., ISO, CE).

-

Logistics: Transportation and shipping costs can significantly affect the final price, particularly for international buyers. Factors like distance, shipping method, and customs duties must be considered.

-

Margin: Suppliers typically mark up their prices to cover costs and generate profit. Understanding the standard margins in the industry can help buyers negotiate better.

What Influences Pricing for Rotary Drum Blenders?

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes usually lead to better pricing due to economies of scale. Buyers should discuss potential discounts for bulk orders with suppliers.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Quality and Certifications: Higher quality standards and certifications can elevate costs but are often necessary for compliance in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer better warranties and after-sales support, justifying a higher price.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is crucial for calculating the total landed cost. Different Incoterms can shift cost responsibilities between the buyer and supplier, impacting overall pricing.

How Can Buyers Optimize Costs When Sourcing Rotary Drum Blenders?

-

Negotiation: Engage in open discussions with suppliers about pricing, especially when placing large orders. Highlighting the potential for future business can lead to better terms.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. Investing in higher-quality equipment may yield long-term savings.

-

Understand Pricing Nuances for International Markets: Be aware of local economic conditions and currency fluctuations that may affect pricing. Buyers from Africa, South America, the Middle East, and Europe should also consider logistical challenges that may add to costs.

-

Request Quotes from Multiple Suppliers: Gathering quotes from different suppliers can provide insights into competitive pricing and help identify the best value.

Disclaimer on Indicative Prices

Prices for rotary drum blenders can vary widely based on the factors discussed above. It is advisable for buyers to obtain updated quotes from suppliers, as market conditions and production costs are subject to change. Always factor in the total cost of ownership when evaluating potential investments in rotary drum blenders.

Alternatives Analysis: Comparing rotary drum blender With Other Solutions

Understanding Alternatives to Rotary Drum Blenders in Mixing Solutions

When evaluating mixing solutions for industrial applications, it’s crucial to consider various alternatives to rotary drum blenders. Each mixing technology offers unique advantages and limitations based on specific operational needs, materials being processed, and production scales. This analysis will help B2B buyers make informed decisions by comparing rotary drum blenders with other viable mixing solutions.

| Comparison Aspect | Rotary Drum Blender | Continuous Mixer | Horizontal Ribbon Blender |

|---|---|---|---|

| Performance | Efficient for heavy, free-flowing materials; 100% product discharge | High throughput for continuous processes; suitable for viscous materials | Good for dry powders; effective at blending granules and pastes |

| Cost | Moderate initial investment; low maintenance costs | Higher initial cost; ongoing operational costs can be significant | Moderate initial cost; maintenance varies based on design |

| Ease of Implementation | Requires space for installation; simple operation | Requires integration with existing systems; more complex setup | Easier to integrate; requires less space |

| Maintenance | Low maintenance; easy to clean | Moderate maintenance; wear and tear on components | Moderate; needs regular cleaning to avoid cross-contamination |

| Best Use Case | Ideal for batch mixing of granular and powder materials | Suitable for high-volume production where continuous mixing is needed | Best for consistent blending of dry ingredients in smaller batches |

What Are the Advantages and Disadvantages of Continuous Mixers?

Continuous mixers are designed for high-volume applications where materials must be processed without interruption. They excel in blending viscous materials and can handle large quantities efficiently. However, they generally come with a higher initial investment and ongoing operational costs due to the need for continuous operation and maintenance of components. Additionally, their complexity can pose challenges during implementation, especially in systems that require integration with existing equipment.

How Do Horizontal Ribbon Blenders Compare?

Horizontal ribbon blenders are another alternative, particularly favored for their ability to mix dry powders and granules effectively. They utilize a horizontal trough with a ribbon-like agitator that moves materials in a continuous flow, ensuring uniform blending. The initial cost is moderate, and they are relatively easy to integrate into existing operations. However, maintenance can be a concern, particularly if not cleaned regularly, as this can lead to contamination between batches.

Conclusion: How Can B2B Buyers Select the Right Mixing Solution?

Choosing the right mixing solution depends on multiple factors, including the type of materials being processed, production volume, and specific operational requirements. Rotary drum blenders are excellent for batch mixing heavy and free-flowing materials with low maintenance needs. In contrast, continuous mixers are ideal for high-volume, uninterrupted production, while horizontal ribbon blenders offer versatility for dry ingredient blending. B2B buyers should assess their unique needs, including cost constraints, maintenance capabilities, and desired performance levels, to select the most suitable mixing technology for their operations.

Essential Technical Properties and Trade Terminology for rotary drum blender

What Are the Key Technical Properties of a Rotary Drum Blender?

When evaluating rotary drum blenders, several technical properties are crucial for ensuring optimal performance and suitability for specific applications. Understanding these specifications can help B2B buyers make informed decisions.

1. Material Grade

Rotary drum blenders are typically constructed from either carbon steel or stainless steel. Carbon steel is robust and cost-effective, making it suitable for non-corrosive applications. In contrast, stainless steel offers superior resistance to corrosion and is essential for food-grade or pharmaceutical applications. Choosing the right material grade is vital for durability and compliance with industry standards.

2. Capacity and Load Volume

Capacity refers to the amount of material the drum can handle, typically measured in cubic feet (cu ft). Rotary drum blenders come in various sizes, accommodating different batch sizes from small laboratory mixes to large-scale production. Understanding the required capacity is essential for optimizing production efficiency and preventing bottlenecks in manufacturing processes.

3. Mixing Efficiency

Mixing efficiency is determined by the design features of the drum, such as the angle of baffles and the rotation speed. Effective mixing ensures uniformity in the final product, which is critical in industries such as food processing and pharmaceuticals. Buyers should assess the mixing capabilities to meet their quality standards and reduce rework.

4. Discharge Mechanism

The discharge mechanism, which can include swing doors or chutes, affects how easily the blended material is removed from the drum. A complete discharge system minimizes product waste and contamination, ensuring that the entire batch is utilized efficiently. This is particularly important for businesses aiming to reduce costs and improve sustainability.

5. Maintenance Requirements

Ease of maintenance is a critical consideration. Features like accessible bearings and seals, along with designs that prevent contamination, contribute to lower maintenance costs and downtime. For B2B buyers, understanding the maintenance requirements can lead to better operational efficiency and reduced long-term costs.

6. Safety Features

Safety features such as guards over moving parts and emergency stop mechanisms are essential for protecting operators during the mixing process. Compliance with safety regulations not only safeguards personnel but also enhances the company’s reputation and reduces liability risks.

What Are Common Trade Terms Associated with Rotary Drum Blenders?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some essential terms that buyers should know.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another company’s brand. When sourcing rotary drum blenders, understanding OEM relationships can help buyers evaluate the quality and reliability of the equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it can impact inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases effectively.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes specifications and quantities required. For buyers, submitting an RFQ is a strategic way to ensure competitive pricing and clarify expectations with potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping and freight. Understanding these terms is essential for international transactions, ensuring that both parties are clear on who is responsible for shipping costs, insurance, and risks.

5. Lead Time

Lead time is the time taken from placing an order to receiving the product. In the context of rotary drum blenders, understanding lead times helps buyers manage production schedules and avoid delays in their operations.

6. Customization Options

Customization refers to the ability to modify the equipment according to specific needs, such as size, features, or material. Buyers should inquire about customization options to ensure that the rotary drum blender meets their precise operational requirements.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing rotary drum blenders more effectively, leading to better investment decisions and improved operational outcomes.

Illustrative image related to rotary drum blender

Navigating Market Dynamics and Sourcing Trends in the rotary drum blender Sector

What Are the Key Trends Shaping the Rotary Drum Blender Market?

The rotary drum blender market is witnessing significant growth driven by increasing demand for efficient mixing solutions across various industries, including agriculture, food processing, and construction materials. Key trends include the adoption of advanced technologies such as automation and IoT integration, which enhance operational efficiency and provide real-time monitoring capabilities. Additionally, manufacturers are focusing on the development of larger-capacity blenders, such as the Mk VII Rollo-Mixer, which can handle substantial volumes while maintaining uniformity in mixing. This trend is particularly relevant for international B2B buyers in regions like Africa and South America, where industries are scaling up production to meet rising local and export demands.

Emerging sourcing trends reflect a shift towards suppliers that offer customizable solutions tailored to specific industry needs, along with robust after-sales support. B2B buyers are increasingly prioritizing suppliers with proven track records in reliability and maintenance efficiency, particularly in regions with challenging logistics. Furthermore, sustainability is becoming a pivotal consideration, with a growing emphasis on energy-efficient designs and materials that minimize environmental impact. As buyers navigate these dynamics, understanding local market conditions and supplier capabilities is essential for successful sourcing strategies.

How Is Sustainability Influencing B2B Sourcing for Rotary Drum Blenders?

Sustainability is a critical factor influencing the sourcing decisions of B2B buyers in the rotary drum blender sector. The environmental impact of manufacturing processes and the lifecycle of equipment are under scrutiny, prompting companies to seek out suppliers that demonstrate a commitment to green practices. This includes the use of eco-friendly materials, energy-efficient designs, and manufacturing processes that reduce waste and emissions.

Illustrative image related to rotary drum blender

Ethical sourcing is equally important, as buyers are increasingly looking for suppliers who adhere to fair labor practices and have transparent supply chains. Certifications such as ISO 14001 for environmental management systems or materials with recognized green certifications can provide assurances that suppliers are committed to sustainability. This focus on ethical sourcing not only aligns with global environmental goals but also enhances brand reputation and customer loyalty in competitive markets.

As B2B buyers evaluate rotary drum blenders, they should prioritize partnerships with manufacturers who not only meet their operational needs but also share a commitment to sustainability. This approach can lead to long-term cost savings, enhanced brand value, and a positive impact on the environment.

What Is the Historical Context of Rotary Drum Blenders in the B2B Market?

The rotary drum blender has evolved significantly since its inception, reflecting advancements in industrial mixing technology and changing market demands. Initially designed for basic mixing tasks, these machines have transitioned to highly specialized equipment capable of handling a diverse range of materials, from agricultural products to complex chemical formulations. The introduction of features such as automated controls, enhanced safety mechanisms, and improved cleaning processes has transformed rotary drum blenders into indispensable tools for modern manufacturing.

Over the decades, as industries have grown more competitive and focused on efficiency, the rotary drum blender has become synonymous with consistent quality and reliability. This evolution is particularly relevant for B2B buyers seeking to optimize their production processes. Understanding the historical context of these machines can provide valuable insights into their capabilities, helping businesses make informed purchasing decisions that align with their operational goals.

Frequently Asked Questions (FAQs) for B2B Buyers of rotary drum blender

-

How do I choose the right rotary drum blender for my application?

Selecting the right rotary drum blender involves assessing several key factors, including the materials you intend to mix, batch size, and desired mixing efficiency. Consider the physical properties of your materials—are they heavy, fragile, or free-flowing? Additionally, evaluate the mixer’s capacity and features, such as the ability to handle liquids or additives. Consult with manufacturers to understand the specifications and performance metrics of different models, and consider testing options to ensure compatibility with your production needs. -

What is the ideal capacity for a rotary drum blender?

The ideal capacity for a rotary drum blender varies based on your production scale and the volume of materials you need to mix. For smaller operations or batch processes, blenders with capacities ranging from 3.5 to 400 cubic feet are commonly used. Larger industrial applications may require units capable of handling over 1,200 cubic feet. It’s crucial to align the blender’s capacity with your batch sizes to optimize efficiency and minimize downtime during mixing operations. -

What are the common industries that utilize rotary drum blenders?

Rotary drum blenders are widely used across various industries, including agriculture, food production, construction materials, and pharmaceuticals. In agriculture, they mix animal feeds and fertilizers, while in the food industry, they blend spices, coffee, and other ingredients. The construction sector often uses these blenders for cement and aggregate mixing. Understanding the industry-specific requirements and applications will help you identify the most suitable blender for your business. -

What customization options are available for rotary drum blenders?

Many manufacturers offer customization options for rotary drum blenders to meet specific operational needs. Customizations may include adjustments to drum size, materials of construction (such as carbon steel or stainless steel), and enhancements like special baffle configurations or discharge systems. Additional features such as liquid addition ports, temperature controls, or safety enhancements can also be tailored. Discuss your specific requirements with suppliers to explore the available options that best fit your production needs. -

What are the minimum order quantities (MOQ) for rotary drum blenders?

Minimum order quantities for rotary drum blenders vary by manufacturer and model. Some suppliers may have a MOQ of one unit, particularly for custom or specialized blenders, while others may require larger orders for bulk purchases. It’s essential to communicate your needs with potential suppliers to understand their policies and negotiate terms that align with your purchasing strategy. Additionally, consider the impact of MOQ on your cash flow and inventory management. -

What payment terms should I expect when purchasing a rotary drum blender?

Payment terms for purchasing rotary drum blenders can differ significantly among suppliers. Common terms include a percentage deposit upon order confirmation, with the balance due prior to shipping. Some manufacturers may offer financing options or extended payment plans for larger orders. Always clarify payment conditions upfront, including accepted payment methods and any potential discounts for early payment, to avoid misunderstandings and ensure smooth transactions. -

How can I ensure quality assurance (QA) for my rotary drum blender?

To ensure quality assurance for your rotary drum blender, request detailed specifications and certifications from suppliers. Look for manufacturers that adhere to international standards, such as ISO certification, which indicates a commitment to quality management. Additionally, inquire about the testing protocols used during production and whether the equipment can be tested with your materials before purchase. Establishing a robust QA process will help mitigate risks associated with equipment performance and longevity. -

What logistics considerations should I keep in mind for international shipping?

When arranging for international shipping of rotary drum blenders, consider factors such as shipping methods, customs regulations, and import duties. Choose a reliable freight forwarder experienced in handling industrial equipment to ensure compliance with shipping regulations. Additionally, plan for potential delays by allowing extra time for customs clearance and inspection. Understanding the logistics landscape in your destination country, including local infrastructure and transportation options, will help streamline the delivery process and reduce costs.

Top 8 Rotary Drum Blender Manufacturers & Suppliers List

1. Scott Equipment – Rotary Drum Mixer

Domain: scottequipment.com

Registered: 1996 (29 years)

Introduction: Rotary Drum Mixer from Scott Equipment Company is designed for efficient mixing of heavy, free-flowing, or fragile materials. Key features include:

– Drum rotation: forward and backward

– Angled baffle plates and optional swing inlet-discharge door for 100% product discharge

– Manufactured in carbon steel or stainless steel with standard or food grade finishes

– Bearings and seals do not conta…

2. Continental – Mk VII Rollo-Mixer®

Domain: continentalrollomixer.com

Registered: 2001 (24 years)

Introduction: The Mk VII Rollo-Mixer® is a rotary drum blender designed for gentle and uniform mixing of pellets, granules, and powders, particularly in large-scale plastics and petrochemical applications. Key specifications include:

– Working load volume: Up to 1,286 cu ft

– Blending capacity: 65,000 lbs in 3 minutes

– Features Free-Fall Processing® for complete discharge

– Available in 51 sizes ranging fr…

3. Munson Machinery – Rotary Batch Mini Mixers

Domain: munsonmachinery.com

Registered: 1996 (29 years)

Introduction: Rotary Batch Mini Mixers are designed for gently blending dry materials in 2 to 3 minutes, with the ability to add liquids uniformly and discharge without segregation. They are suitable for laboratory, pilot plant, or small-production scale applications, with capacities ranging from 0.25 to 15 cu ft (7 to 425 liters). The mixers utilize a four-way mixing action that tumbles, turns, cuts, and folds…

4. JR Boone – Rotary Drum Mixers

Domain: jrboone.com

Registered: 1997 (28 years)

Introduction: Rotary Drum Mixers are designed for gentle industrial mixing with low speed and no moving parts inside the drum. They are suitable for delicate, friable, or abrasive materials and are commonly used for tea blending with optional spray bars for liquid additions. The mixers feature unique fully welded mixing blades that fluidise the mixture with each revolution, allowing for efficient mixing of powd…

5. Surplus Record – Used Rotary Mixers and Blenders

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: Used Rotary Mixers and Blenders For Sale | Surplus Record

Manufacturers: Burton (10), Munson (3), Con-Tech (1), Doyle (1), Scott (1), Variovak (1)

Locations: California (6), Illinois (4), Michigan (1), New Jersey (2), Ohio (10)

Motor Condition: All Conditions (Used Only: 22, New/Rebuilt Only: 1)

Key Listings:

1. Munson #700-TS-50, 100 cu.ft. rotary mixer, 7-1/2 HP, 1800 RPM, New, Packaging Dir…

6. HYWELL – Rotary Drum Mixer

Domain: hywellco.com

Registered: 2014 (11 years)

Introduction: Product Name: Rotary Drum Mixer

Manufacturer: Hywell Machinery

Model: YYH

Brand: HYWELL

Code: 8479820090

Material: SUS304/SUS316L/Titanium

Application: Food, Pharmaceutical, Chemical

Key Features:

– Gentle mixing technology for fine powders, granulates, and natural products

– High degree of homogeneity in a short time

– Suitable for sensitive and fragile materials without degradation or heating

-…

7. Stainless Steel – Rotary Drum Powder Mixer

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Stainless Steel Rotary Drum Powder Mixer – 84271”, “Condition”: “Used”, “Price”: “$2,695.00 or Best Offer”, “Payment Options”: “As low as $129.38/mo”, “Shipping”: “Freight – Check item description or contact seller for details”, “Location”: “Mexico, Mexico”, “Returns”: “Seller does not accept returns”, “Seller”: {“Name”: “Union Standard Equipment”, “Feedback”: “100% positive”, “I…

8. AGI – Rotary Drum Batch Blending System

Domain: aggrowth.com

Registered: 1998 (27 years)

Introduction: The AGI Rotary Drum Batch Blending System is designed for space and loading efficiency, offering fast, efficient, and safe rotary blending. Key features include:

– Durable construction with heavy gauge stainless steel materials and double welded seams for strength.

– Available capacities: 6-, 8-, 10-, 13-, and 16-ton direct drive systems, with the 13- and 16-ton models being among the highest capa…

Strategic Sourcing Conclusion and Outlook for rotary drum blender

As international markets continue to evolve, the strategic sourcing of rotary drum blenders offers significant advantages for businesses across diverse industries. Key takeaways emphasize the importance of selecting equipment that enhances operational efficiency while minimizing maintenance costs. The versatility of rotary drum blenders in applications ranging from agriculture to food processing underlines their essential role in achieving consistent product quality and maximizing throughput.

Investing in high-quality rotary drum blenders can lead to substantial long-term savings and improved product reliability. Buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Brazil and Saudi Arabia, should prioritize suppliers that provide robust testing facilities and customization options to meet specific operational requirements.

As you move forward in your sourcing strategy, consider the unique needs of your production processes and the potential for innovation in blending technology. The future of manufacturing lies in adopting solutions that not only enhance productivity but also align with sustainability goals. Engage with reputable manufacturers today to explore how rotary drum blenders can transform your operations for competitive advantage in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to rotary drum blender