The Definitive Guide to Rolled Thread Vs Cut Thread: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for rolled thread vs cut thread

Navigating the complexities of sourcing rolled thread versus cut thread fasteners can present significant challenges for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding the key differences between these two threading methods is crucial for making informed purchasing decisions that impact both product performance and overall project success. This comprehensive guide delves into the intricacies of rolled and cut threads, examining their unique characteristics, applications, and suitability for various industries.

Throughout this guide, we will explore the fundamental distinctions between rolled and cut threads, including their manufacturing processes, mechanical properties, and implications for fatigue resistance. We will also provide insights into supplier vetting, cost considerations, and best practices for selecting the right type of threading for your specific applications. By equipping buyers with the necessary knowledge, this resource empowers businesses to enhance their procurement strategies, ensuring they secure high-quality fasteners that meet their operational requirements.

As you navigate the global market for fasteners, let this guide serve as your authoritative resource for understanding rolled thread versus cut thread options, ultimately leading to more strategic and cost-effective sourcing decisions. Whether you are in Saudi Arabia, Brazil, or elsewhere, having the right information at your fingertips can make all the difference in achieving your business objectives.

Understanding rolled thread vs cut thread Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rolled Thread | Formed by displacing material; maintains grain structure; smoother finish | Automotive, construction, aerospace, industrial machinery | Pros: Higher fatigue resistance, greater strength, smoother surface reduces galling. Cons: Typically higher initial cost, limited to specific sizes. |

| Cut Thread | Created by removing material; can be tapped for internal threads | General manufacturing, custom applications | Pros: Versatile for custom sizes, easier to produce fine threads. Cons: Lower fatigue resistance, potential for stress concentration. |

| Unified National Thread (UNC/UNF) | Standardized thread forms; can be rolled or cut | Widely used across various industries | Pros: Compatibility across many applications, readily available. Cons: May not meet specific performance needs in high-stress applications. |

| Fine Thread | Thinner, closely spaced threads; can be rolled or cut | Precision machinery, aerospace, automotive | Pros: Better tension retention, suitable for thin materials. Cons: More challenging to manufacture, may require specialized tools. |

| Metric Thread | Based on metric measurements; can be rolled or cut | International applications, automotive, machinery | Pros: Universally recognized, ideal for global supply chains. Cons: Limited availability in some regions, may require conversion. |

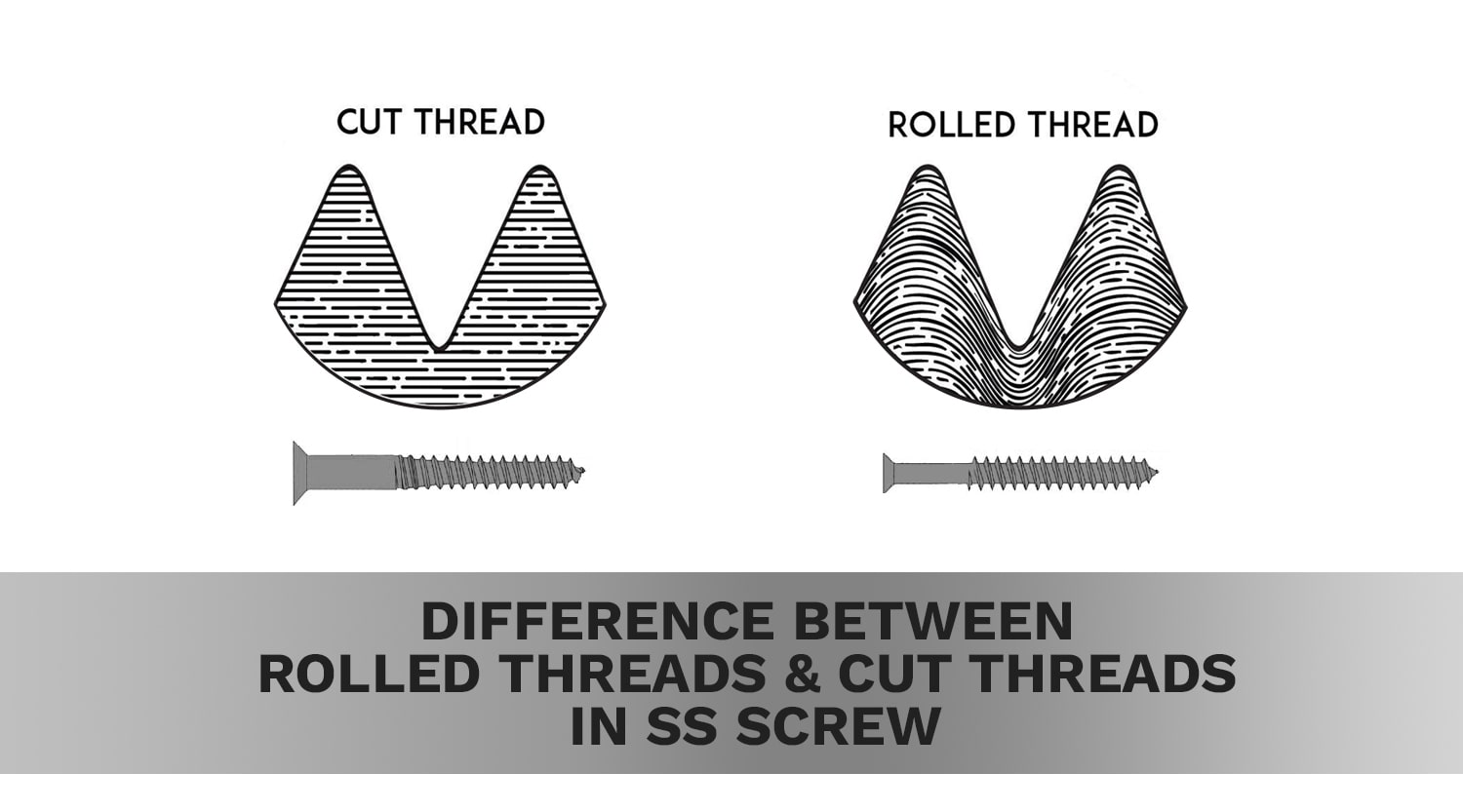

What Are the Key Characteristics of Rolled Threads?

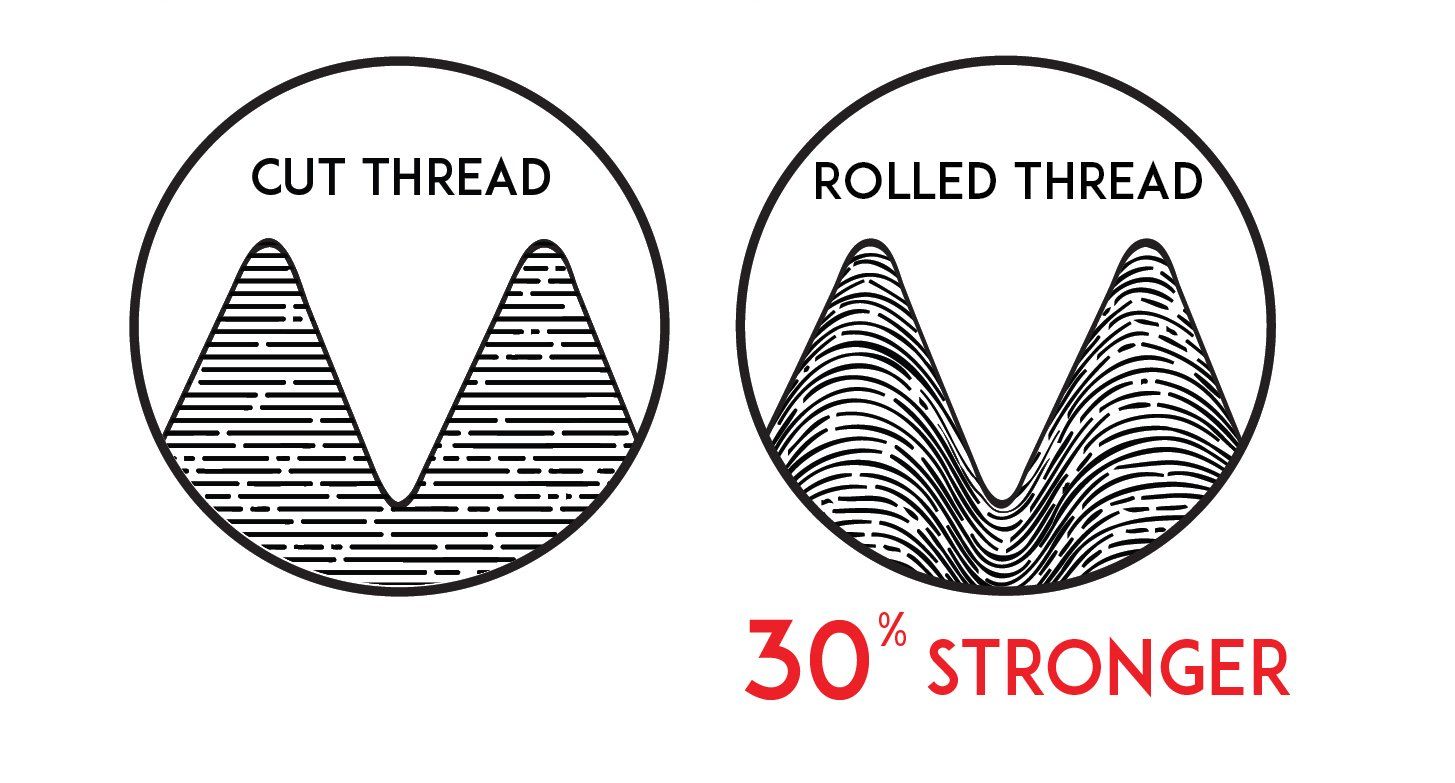

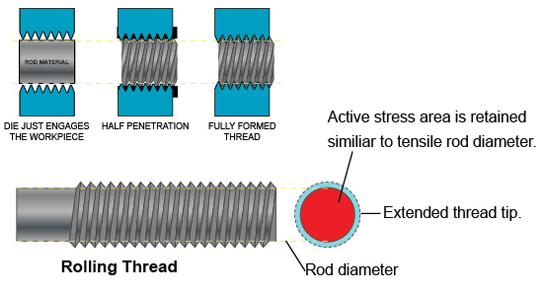

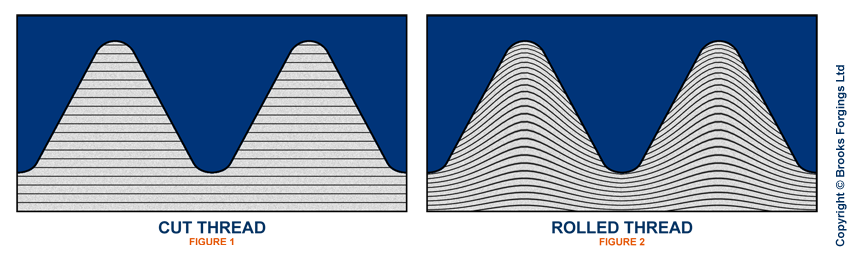

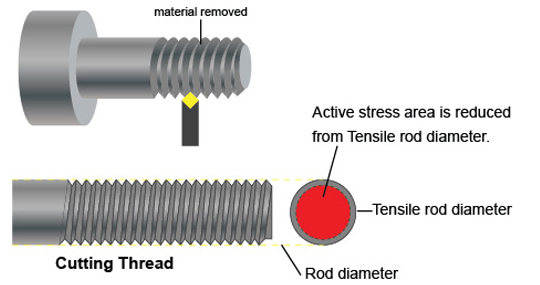

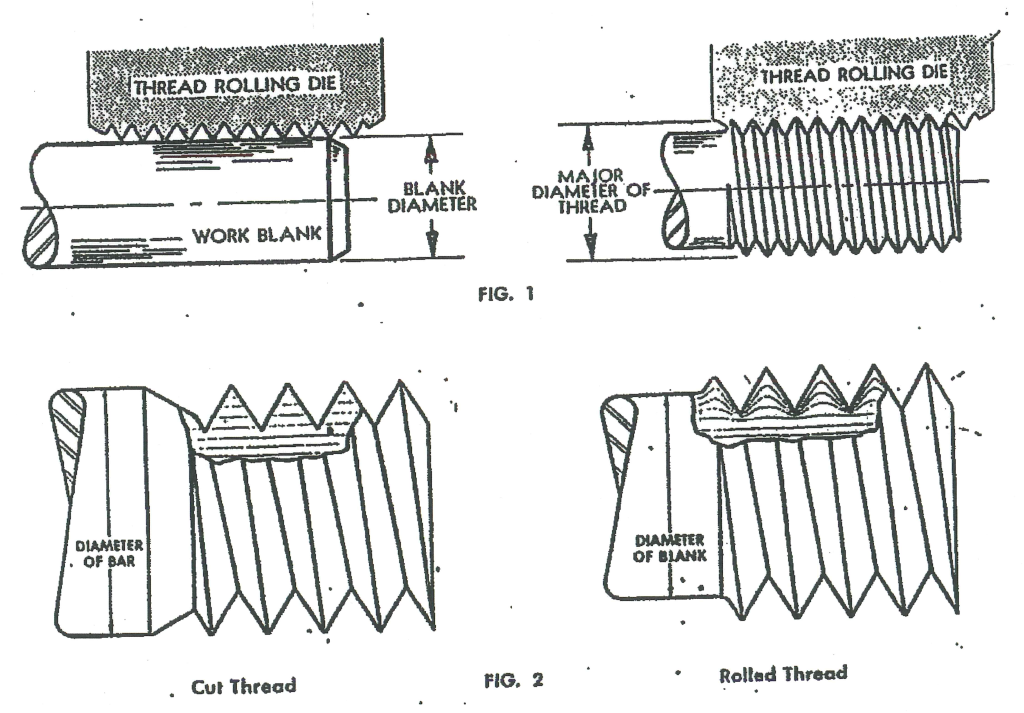

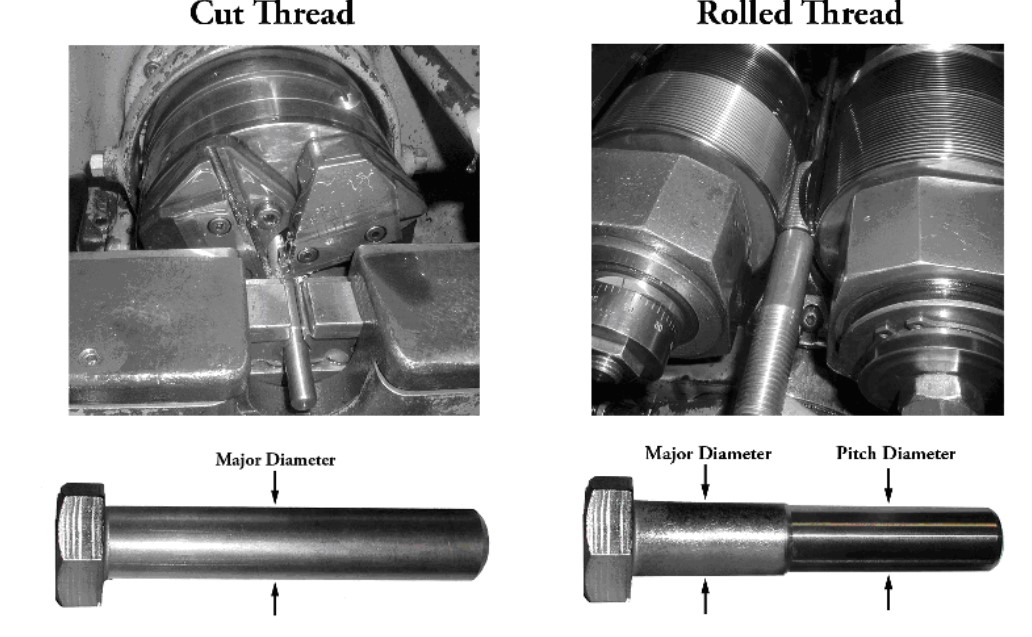

Rolled threads are manufactured by deforming material, which preserves the grain structure and enhances the strength of the final product. This method produces a smoother finish, which can reduce galling and improve performance in applications subjected to fatigue. Rolled threads are particularly advantageous in high-stress environments such as automotive and aerospace, where durability is critical. Buyers should consider the initial investment, as rolled threads can be more expensive due to the manufacturing process and tooling required.

How Do Cut Threads Differ in Suitability?

Cut threads are produced by removing material, allowing for greater flexibility in custom sizes and fine thread applications. This method is commonly used in general manufacturing and situations where specific thread dimensions are needed. However, cut threads may experience stress concentration and reduced fatigue resistance, making them less suitable for high-load applications. B2B buyers should evaluate their specific needs, particularly when considering the operational environment and long-term performance of fasteners.

What Are Unified National Threads and Their Applications?

Unified National Threads (UNC/UNF) represent a standardized thread form that can be either rolled or cut. This standardization ensures compatibility across various applications and industries, making these threads widely available and easy to source. While they are suitable for many general applications, buyers in high-performance sectors should assess whether these threads meet their specific requirements, especially in terms of load-bearing capabilities.

Why Choose Fine Threads for Precision Applications?

Fine threads are characterized by their closely spaced, thinner profile, which offers better tension retention and is ideal for precision machinery and aerospace applications. Although they can be more challenging to manufacture and may require specialized tooling, fine threads provide significant advantages in terms of performance and reliability. B2B buyers should consider the specific requirements of their applications, particularly regarding the materials being used and the expected load conditions.

How Do Metric Threads Benefit Global Supply Chains?

Metric threads are based on standardized metric measurements, making them a preferred choice for international applications. Their universal recognition facilitates smoother transactions in global supply chains, particularly in automotive and machinery sectors. However, buyers should be mindful of potential regional limitations in availability and the need for conversion when dealing with non-metric systems. Understanding the local market dynamics is crucial for effective procurement.

Key Industrial Applications of rolled thread vs cut thread

| Industry/Sector | Specific Application of rolled thread vs cut thread | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine assembly using rolled thread fasteners | Enhanced fatigue resistance improves durability, reducing maintenance costs. | Ensure compliance with automotive standards and specifications for threaded components. |

| Construction | Structural connections with cut thread bolts | Cut threads allow for precise fitting in tight spaces, ensuring structural integrity. | Sourcing should focus on material grade and thread specifications to meet safety regulations. |

| Oil & Gas | Pipeline flanges using rolled threads | Rolled threads provide better sealing and resistance to vibration, preventing leaks. | Evaluate sourcing based on environmental conditions and material compatibility for harsh environments. |

| Aerospace | Fastening components with cut threads | Cut threads allow for tighter tolerances, essential for safety and performance in flight. | Ensure adherence to aerospace standards and certifications for threaded fasteners. |

| Heavy Machinery | Bolts for heavy equipment using rolled threads | Increased strength and fatigue resistance lead to longer equipment lifespan and lower downtime. | Consider sourcing from manufacturers with proven quality control processes and certifications. |

How Are Rolled Threads Used in the Automotive Industry?

In the automotive sector, rolled thread fasteners are commonly employed in engine assembly, where strength and fatigue resistance are critical. The rolling process enhances the material’s grain structure, resulting in superior durability under high-stress conditions. This is particularly important for components that experience repeated tension, such as head bolts. For international B2B buyers in regions like Europe and the Middle East, sourcing rolled threads must comply with stringent automotive standards to ensure reliability and safety.

What Role Do Cut Threads Play in Construction Applications?

Cut thread bolts are frequently used in construction for structural connections, where precise fitting is essential in confined spaces. The ability to cut threads allows for greater customization, which can be crucial when dealing with varying material thicknesses and load requirements. For buyers in South America and Africa, it’s vital to consider local building codes and regulations when sourcing cut thread components to ensure compliance and safety in construction projects.

How Are Rolled Threads Beneficial in the Oil & Gas Sector?

In the oil and gas industry, rolled thread fasteners are preferred for pipeline flanges due to their superior sealing capabilities and resistance to vibration. These characteristics are critical in preventing leaks and ensuring the integrity of high-pressure systems. International buyers in this sector should focus on sourcing rolled threads that meet industry-specific standards and can withstand harsh environmental conditions, particularly in offshore applications.

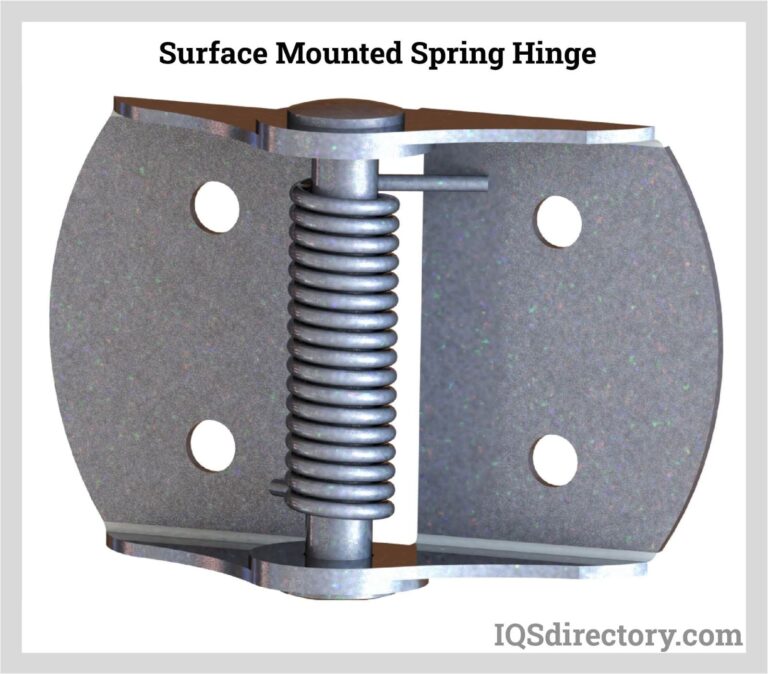

Illustrative image related to rolled thread vs cut thread

Why Are Cut Threads Important in Aerospace Applications?

Cut threads are often utilized in aerospace applications where precision and tight tolerances are paramount. The ability to achieve exact specifications is essential for ensuring the performance and safety of aircraft components. Buyers in the aerospace sector, particularly in regions like Europe, must prioritize sourcing cut thread fasteners from manufacturers who adhere to rigorous aerospace standards and certifications, ensuring reliability during flight.

What Advantages Do Rolled Threads Offer in Heavy Machinery?

In heavy machinery, rolled thread bolts are favored for their increased strength and fatigue resistance, which are vital for components subjected to high loads and operational stress. This leads to a longer lifespan for equipment, reducing the frequency of replacements and minimizing downtime. B2B buyers in Africa and South America should consider sourcing from manufacturers with robust quality control measures to ensure the reliability of rolled thread fasteners in demanding applications.

3 Common User Pain Points for ‘rolled thread vs cut thread’ & Their Solutions

Scenario 1: Thread Strength Concerns in High-Stress Applications

The Problem: B2B buyers often face challenges when specifying fasteners for high-stress applications, such as in construction or automotive industries. They may worry about the fatigue resistance of the threads, especially when dealing with components subjected to constant tension or vibration. The fear of thread failure can lead to costly downtime and safety issues, making it imperative to choose the right threading method.

The Solution: To ensure maximum strength and fatigue resistance, buyers should favor rolled threads over cut threads for high-stress applications. Rolled threads retain the material’s grain structure, enhancing their strength and durability due to the work-hardening process that occurs during rolling. Buyers should consult with manufacturers about the specific fatigue ratings of rolled threads in their application to ensure compliance with safety standards. Additionally, they can request samples or conduct comparative tests on rolled versus cut threads to assess performance under actual operating conditions, enabling informed decision-making.

Scenario 2: Compatibility Issues with Fasteners and Components

The Problem: Compatibility between fasteners and components can be a significant pain point for buyers, especially when sourcing products across international markets. For instance, a buyer may need to match a rolled-threaded bolt with a cut-threaded nut, leading to potential assembly issues and compromised joint integrity. This challenge is particularly relevant in regions like Africa and South America, where standards may vary, and local sourcing can introduce additional complexities.

The Solution: To avoid compatibility issues, buyers should standardize their specifications for both rolled and cut threads based on the relevant industry standards (e.g., ANSI, ISO). They should ensure that both the fasteners and corresponding components are produced to the same thread class and pitch. When sourcing components, buyers should work closely with suppliers to confirm thread compatibility and request detailed technical documentation, including thread tolerances. This proactive approach helps mitigate the risk of assembly failures and ensures that components fit seamlessly together, regardless of their origin.

Scenario 3: Misunderstanding Cost Implications of Threading Methods

The Problem: Many B2B buyers mistakenly perceive cut threads as the more cost-effective option due to lower initial manufacturing costs. However, they often overlook the long-term expenses associated with thread integrity, potential failures, and the need for replacements. This misunderstanding can lead to budget overruns and project delays, particularly in industries with strict timelines and budgets.

The Solution: Buyers should conduct a comprehensive cost analysis that includes both upfront and long-term expenses when choosing between rolled and cut threads. While cut threads may be less expensive initially, the increased durability and fatigue resistance of rolled threads can lead to lower maintenance costs and fewer replacements over time. Buyers can work with suppliers to analyze the total cost of ownership for both threading methods, considering factors such as installation time, longevity, and failure rates. By prioritizing long-term value over initial cost, buyers can make more informed decisions that ultimately enhance project profitability and reliability.

Illustrative image related to rolled thread vs cut thread

Strategic Material Selection Guide for rolled thread vs cut thread

What Are the Key Properties of Common Materials Used in Rolled and Cut Threads?

When selecting materials for rolled and cut threads, several factors must be considered, including mechanical properties, environmental resistance, and manufacturing processes. Here, we analyze four common materials: Carbon Steel, Stainless Steel, Alloy Steel, and Aluminum.

Carbon Steel: A Versatile Choice for Thread Applications

Key Properties: Carbon steel offers excellent tensile strength and hardness, making it suitable for high-stress applications. It typically has a temperature rating up to 400°F (204°C) and can withstand moderate pressure.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and widespread availability. However, it is prone to corrosion if not properly treated, which can limit its use in harsh environments. Additionally, while rolled threads provide better fatigue resistance, cut threads may be easier to produce in custom sizes.

Impact on Application: Carbon steel is compatible with various media, including water and oil, but may not perform well in corrosive environments without protective coatings.

Considerations for International Buyers: Compliance with standards such as ASTM A307 or DIN 933 is crucial. Buyers from regions like South America and the Middle East often prefer carbon steel due to its affordability and adaptability.

Stainless Steel: The Corrosion-Resistant Option

Key Properties: Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance (up to 1500°F or 815°C), and good mechanical properties.

Pros & Cons: Its primary advantage is its durability in corrosive environments, making it ideal for applications in chemical processing and marine industries. However, stainless steel can be more expensive than carbon steel and may require specialized tools for threading.

Impact on Application: Stainless steel is suitable for applications involving water, chemicals, and high humidity. The choice between rolled and cut threads often hinges on the need for strength versus customization.

Considerations for International Buyers: Buyers should ensure compliance with ASTM A193 or JIS standards. In Europe, the preference for stainless steel is rising due to stringent environmental regulations.

Alloy Steel: Enhanced Performance for Heavy-Duty Applications

Key Properties: Alloy steel combines carbon steel with other elements to enhance specific properties, offering high tensile strength and fatigue resistance, suitable for extreme conditions.

Illustrative image related to rolled thread vs cut thread

Pros & Cons: The main advantage of alloy steel is its ability to withstand high stress and temperature, making it ideal for heavy machinery and automotive applications. However, it is generally more expensive and may require more complex manufacturing processes.

Impact on Application: Alloy steel threads are particularly effective in high-load scenarios, such as in automotive and aerospace industries. Rolled threads are preferred for their superior fatigue resistance.

Considerations for International Buyers: Compliance with ASTM A574 or DIN 6912 is essential. Buyers from regions like Africa may find alloy steel increasingly appealing due to the growing demand for durable materials in infrastructure projects.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight, with good corrosion resistance and a temperature rating up to 600°F (316°C). It is not as strong as steel but offers excellent weight-to-strength ratios.

Pros & Cons: The key advantage of aluminum is its low weight, making it ideal for applications where weight savings are critical, such as in aerospace. However, it may not be suitable for high-stress applications due to lower tensile strength.

Impact on Application: Aluminum threads are commonly used in applications involving light loads and corrosive environments, such as marine and automotive sectors. Rolled threads can improve strength, but cut threads are easier to produce for custom designs.

Considerations for International Buyers: Compliance with standards like ASTM B211 is important, especially for buyers in Europe and the Middle East, where lightweight materials are increasingly favored.

Summary Table of Material Selection for Rolled vs. Cut Threads

| Material | Typical Use Case for rolled thread vs cut thread | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General fasteners, structural applications | Cost-effective and widely available | Prone to corrosion | Low |

| Stainless Steel | Chemical processing, marine applications | Excellent corrosion resistance | Higher cost, requires specialized tools | High |

| Alloy Steel | Heavy machinery, automotive applications | High tensile strength and fatigue resistance | More expensive, complex manufacturing | Med |

| Aluminum | Aerospace, lightweight structures | Lightweight and corrosion-resistant | Lower tensile strength | Med |

This strategic material selection guide aims to equip B2B buyers with the necessary insights to make informed decisions when choosing between rolled and cut threads across various materials.

In-depth Look: Manufacturing Processes and Quality Assurance for rolled thread vs cut thread

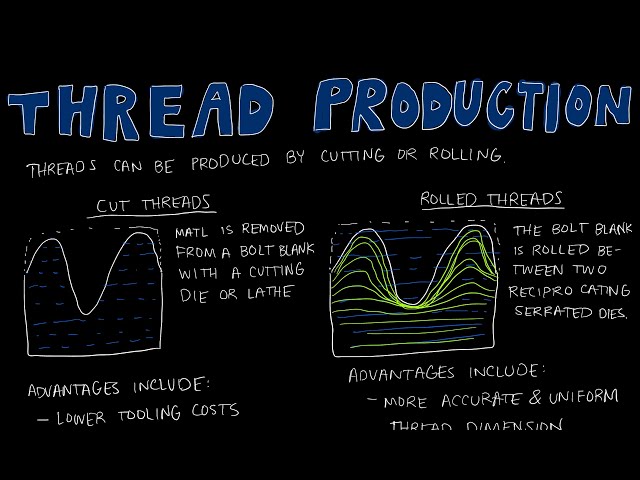

What Are the Key Stages in the Manufacturing Process of Rolled and Cut Threads?

When examining the manufacturing processes for rolled and cut threads, understanding the distinct methodologies is crucial for B2B buyers.

Material Preparation for Rolled vs. Cut Threads

In both processes, the initial step involves selecting the appropriate raw material, typically high-strength steel or alloy. For rolled threads, the material is usually a hot-rolled or cold-drawn bar, which provides the necessary strength and ductility. Conversely, for cut threads, the raw material can also be in the form of bars, but it often undergoes additional treatments like heat treatment to enhance hardness before cutting.

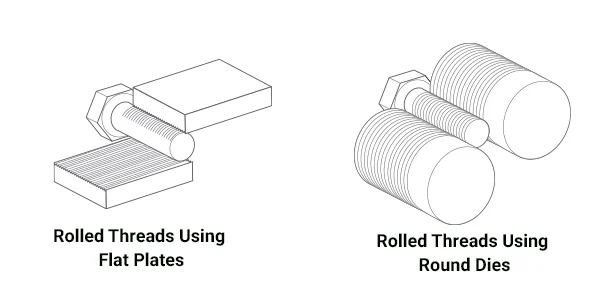

How Are Rolled Threads Formed?

The rolling process involves several key stages:

-

Deformation: The metal is fed into a thread rolling machine, where it is subjected to compressive forces from rotating dies. This action displaces the material to form the desired thread profile while maintaining the integrity of the grain structure, enhancing fatigue resistance.

-

Cooling: Post-rolling, the threads may be cooled to room temperature, ensuring that the material retains its mechanical properties.

-

Finishing: The final steps include surface treatments like shot peening or coating to improve corrosion resistance and surface smoothness.

What Does the Cutting Process Entail?

For cut threads, the process involves:

-

Machining: A threading tap or die cuts the thread into the material. This method removes material, which can lead to stress concentrations and potentially lower fatigue resistance compared to rolled threads.

-

Deburring and Cleaning: After cutting, the threads are deburred and cleaned to remove any metal shavings or contaminants that could affect performance.

-

Heat Treatment: If not done prior to cutting, the threaded component may undergo heat treatment to achieve desired hardness and tensile strength.

What Quality Assurance Measures Are Essential for Thread Manufacturing?

Quality assurance (QA) is critical in ensuring that both rolled and cut threads meet international standards and customer specifications.

Illustrative image related to rolled thread vs cut thread

Which International Standards Should B2B Buyers Consider?

B2B buyers should be well-versed in relevant international quality standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific standards like API for oil and gas applications or CE marking for European markets are important for ensuring compliance.

What Are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials for compliance with specifications, including chemical composition and mechanical properties.

-

In-Process Quality Control (IPQC): During manufacturing, real-time monitoring of critical parameters such as dimensions, thread profiles, and surface finish is essential. Statistical Process Control (SPC) techniques can be employed to track variations.

-

Final Quality Control (FQC): After the manufacturing process, a thorough inspection of the final product is conducted. This may include dimensional checks, tensile testing, and surface quality assessments.

What Testing Methods Are Commonly Used in Thread Quality Assurance?

Testing methods for both rolled and cut threads can vary, but common practices include:

- Dimensional Inspection: Utilizing thread gauges and calipers to ensure compliance with specifications.

- Tensile Testing: Assessing the mechanical properties of the threads under load to ensure they meet strength requirements.

- Fatigue Testing: Particularly relevant for rolled threads, this assesses the ability of the threads to withstand cyclic loading.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes can be challenging yet essential.

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes, quality control measures, and adherence to international standards.

-

Quality Reports: Requesting detailed quality reports, including test results and compliance documentation, can help verify the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product compliance.

What Are the Nuances of Quality Certification for International Buyers?

B2B buyers should be aware of certification nuances when sourcing rolled and cut threads internationally. Different countries have varying standards for quality certification, which can affect product acceptance in local markets. For instance, CE marking is essential for products sold within the European Union, while other regions may have their own compliance requirements.

Understanding these nuances can help buyers make informed decisions and ensure that the products they source meet both their quality expectations and regulatory requirements.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices for rolled and cut threads can empower B2B buyers to make informed sourcing decisions. Prioritizing suppliers that adhere to international standards and robust quality control measures will help ensure the reliability and performance of threaded products in various applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rolled thread vs cut thread’

Introduction

This guide serves as a comprehensive checklist for B2B buyers in the international market looking to procure fasteners featuring either rolled or cut threads. Understanding the distinctions between these two threading methods is crucial for ensuring product performance, reliability, and cost-effectiveness. By following these steps, buyers can make informed decisions that align with their operational needs and quality standards.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes the type of application the threaded fasteners will be used for, the required strength, and any environmental factors that could affect performance.

– Consider the load-bearing requirements: Rolled threads are generally preferred for high-tension applications due to their superior fatigue resistance.

– Specify the material type, diameter, and thread pitch to ensure compatibility with existing components.

Step 2: Evaluate Material Properties

Understanding the material properties of rolled versus cut threads is essential for selecting the right type for your application. Rolled threads are typically stronger due to the work-hardening process they undergo, while cut threads can be more susceptible to stress concentrations.

– Assess the tensile and fatigue strength of both types based on your application needs.

– Review metallurgical aspects, especially if the fasteners will be exposed to harsh conditions or contaminants.

Step 3: Identify Your Supplier Criteria

When sourcing fasteners, identify what criteria are most important for your suppliers. This may include production capabilities, quality assurance processes, and delivery timelines.

– Look for suppliers who specialize in your required thread type, whether rolled or cut, and have a proven track record.

– Ensure they have relevant certifications, such as ISO 9001, that demonstrate their commitment to quality management.

Step 4: Request Samples for Testing

Once you have a shortlist of potential suppliers, request samples of both rolled and cut thread fasteners. Testing samples allows you to evaluate the actual performance of the products in your specific application.

– Conduct stress tests to compare the durability and performance of both threading types under real-world conditions.

– Analyze the ease of installation and compatibility with existing components.

Step 5: Compare Pricing and Lead Times

Cost and delivery time are critical factors in the procurement process. Compare the pricing of rolled versus cut thread fasteners, factoring in the total cost of ownership, including potential replacement costs and installation labor.

– Inquire about bulk purchase discounts and long-term agreements to optimize costs.

– Consider lead times for both types to ensure they align with your project timelines.

Step 6: Evaluate After-Sales Support

After confirming your supplier, assess their after-sales support and warranty policies. Quality support can be invaluable, especially if issues arise post-purchase.

– Check if the supplier provides technical assistance, installation guidance, or troubleshooting.

– Understand the warranty terms for the fasteners to safeguard against defects or performance failures.

Illustrative image related to rolled thread vs cut thread

Step 7: Finalize Your Order with Specifications

Once you’ve selected a supplier and evaluated all factors, finalize your order by clearly stating your specifications. Ensure that all details, such as thread type, material, dimensions, and quantity, are explicitly outlined in the purchase agreement.

– Confirm that the supplier understands the application requirements and quality standards.

– Establish a timeline for delivery and set expectations for communication throughout the process.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing rolled versus cut thread fasteners, ensuring they make the best choice for their operational needs.

Comprehensive Cost and Pricing Analysis for rolled thread vs cut thread Sourcing

What are the Key Cost Components for Rolled Thread vs Cut Thread Sourcing?

When considering the sourcing of rolled thread versus cut thread products, several cost components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of raw materials significantly impacts cost. Rolled threads typically use higher-grade materials that can withstand the deformation process, which may lead to a higher upfront cost compared to cut threads. However, the durability and performance of rolled threads can justify this initial investment over time.

-

Labor: Labor costs vary between the two methods. Rolled threading requires skilled operators to handle the machinery that forms the threads, potentially leading to higher labor costs. In contrast, cut threading may involve simpler processes that can be performed by less skilled workers, reducing labor expenses.

-

Manufacturing Overhead: The overhead associated with rolled thread production can be higher due to the specialized equipment required for rolling. This includes not only the initial investment in machinery but also ongoing maintenance and operational costs.

-

Tooling: Tooling costs for rolled threads can be substantial as it often requires custom dies and rolling tools. For cut threads, the tooling costs might be lower, but the need for frequent replacement due to wear can offset some of these savings.

-

Quality Control: The QC processes for both types of threads ensure compliance with industry standards. Rolled threads often require more rigorous testing due to their application in critical structures, which can increase the overall cost.

-

Logistics: Transportation and handling costs may differ based on the weight and volume of the products. Rolled threads are typically lighter due to reduced body diameters, which can lead to savings in logistics costs.

-

Margin: Suppliers may apply different profit margins based on the complexity and demand for each type of thread. Rolled threads, due to their perceived higher quality, may carry a premium price.

What Influences Pricing for Rolled vs Cut Threads?

Several factors can influence pricing in the B2B marketplace for rolled versus cut threads:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs. Suppliers may offer discounts for larger orders, which is crucial for international buyers looking to optimize their budget.

-

Specifications and Customization: Custom specifications can drive costs up, especially for rolled threads, which may require specialized tooling or production processes. Buyers should ensure that their specifications are clearly communicated to avoid unexpected costs.

-

Materials and Quality Certifications: The choice of material and the presence of quality certifications can significantly impact price. Buyers should consider the total cost of ownership, which includes the longevity and performance of the product, rather than just the initial purchase price.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can also affect pricing. Engaging with established suppliers may lead to better quality and reliability, albeit at a potentially higher cost.

-

Incoterms: Understanding Incoterms is vital for international transactions, as they define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. This can affect the final landed cost of the products.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing Threads?

-

Negotiation Strategies: Leverage volume and long-term contracts to negotiate better pricing. Building a relationship with suppliers can also lead to better terms and potential discounts.

-

Focus on Total Cost of Ownership: Evaluate not just the purchase price but the expected lifespan, maintenance costs, and potential downtime associated with the threads. Rolled threads may be more expensive upfront but can offer savings in the long run due to their durability.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of regional market conditions that may affect pricing. Currency fluctuations, local regulations, and import duties should be factored into the cost analysis.

-

Request Quotations from Multiple Suppliers: Gathering quotes from various suppliers can provide insights into the market rate and help identify the best value.

-

Stay Informed About Market Trends: Understanding market trends and material costs can help buyers anticipate price changes and make informed purchasing decisions.

Disclaimer on Pricing Information

Pricing for rolled and cut threads can vary widely based on multiple factors, including market demand, material costs, and specific supplier pricing strategies. It is advisable for buyers to conduct thorough research and obtain detailed quotes tailored to their specific needs.

Alternatives Analysis: Comparing rolled thread vs cut thread With Other Solutions

Exploring Alternatives to Rolled Thread and Cut Thread Solutions

In the fastener industry, understanding the nuances between rolled threads and cut threads is essential, but it’s equally important to explore alternative methods that can serve similar purposes. This analysis will provide B2B buyers with a comprehensive comparison of these two traditional threading techniques against two viable alternatives: 3D-printed threads and adhesive bonding solutions. Each method has unique advantages and limitations, making it crucial for buyers to assess their specific requirements.

Illustrative image related to rolled thread vs cut thread

| Comparison Aspect | Rolled Thread Vs Cut Thread | 3D-Printed Threads | Adhesive Bonding |

|---|---|---|---|

| Performance | Superior fatigue resistance; maintains grain structure for strength | Moderate; strength varies with material used | High shear strength; can distribute loads evenly |

| Cost | Generally higher due to manufacturing process | Can be lower for small batches; material costs vary | Low initial cost, but long-term reliability can be a concern |

| Ease of Implementation | Requires specialized equipment and skilled labor | Easy for prototyping; requires 3D printing capabilities | Simple to apply; minimal equipment needed |

| Maintenance | Low; durable and reliable under stress | Moderate; depends on material durability | Can require periodic checks for bond integrity |

| Best Use Case | High-stress applications like automotive or aerospace | Prototyping or low-volume production | Applications where welding or threading is impractical |

What Are the Advantages and Disadvantages of 3D-Printed Threads?

3D-printed threads utilize additive manufacturing techniques to create threaded components. The primary advantage is the flexibility it offers in design, enabling rapid prototyping and customization. This method can be cost-effective for small production runs, as it reduces waste and allows for intricate geometries. However, the mechanical properties can vary significantly depending on the material used, which may not provide the same strength and durability as traditional rolled or cut threads. Buyers should consider the application’s stress requirements and whether the 3D-printed material can meet those needs.

How Does Adhesive Bonding Compare to Threading Techniques?

Adhesive bonding is an alternative method for joining components that can eliminate the need for traditional threads altogether. This method provides high shear strength and can distribute loads evenly across surfaces, making it suitable for applications where vibration or movement is present. The simplicity of application and low initial costs are significant advantages. However, the long-term reliability of adhesive bonds can be a concern, particularly in environments subject to extreme temperatures or chemical exposure. Buyers should evaluate the specific conditions of their application to determine if adhesive bonding is a suitable choice.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting between rolled threads, cut threads, and alternative solutions like 3D-printed threads or adhesive bonding, B2B buyers must assess their specific needs, including performance requirements, cost considerations, and application environments. For high-stress applications demanding durability and fatigue resistance, rolled threads are often the best choice. Conversely, for low-volume needs or prototypes, 3D printing may offer advantages. Adhesive bonding provides a unique solution for applications where traditional fastening methods are impractical. By carefully weighing these factors, buyers can make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for rolled thread vs cut thread

What Are the Key Technical Properties of Rolled Threads vs. Cut Threads?

1. Material Grade

The material grade indicates the strength and durability of the threads. Common grades for bolts include ASTM A325 and A490, which define the mechanical properties required for structural applications. For B2B buyers, understanding material grades is crucial as it directly impacts the performance and safety of threaded fasteners in various applications, from construction to manufacturing.

2. Tolerance

Tolerance refers to the permissible limits of variation in dimensions and physical properties of threads. For rolled threads, tolerances are often tighter due to the manufacturing process, which can enhance fit and reduce the risk of loosening under load. B2B buyers should prioritize specific tolerance requirements to ensure compatibility with corresponding nuts and components, ultimately impacting assembly efficiency and reliability.

Illustrative image related to rolled thread vs cut thread

3. Fatigue Resistance

Fatigue resistance is a measure of a material’s ability to withstand cyclic loading over time. Rolled threads typically exhibit superior fatigue resistance compared to cut threads due to the cold working process, which enhances the grain structure. This property is particularly important for applications where repeated stress is expected, such as in automotive or aerospace industries.

4. Surface Finish

Surface finish affects the friction and wear characteristics of threaded fasteners. Rolled threads generally have a smoother surface compared to cut threads, reducing galling and improving assembly ease. Understanding surface finish specifications can help B2B buyers select the right products for applications where surface interaction is critical.

5. Thread Geometry

Thread geometry encompasses the shape and dimensions of the threads, which include pitch, depth, and angle. Despite the differences in manufacturing processes, both rolled and cut threads can conform to standard thread geometries, ensuring compatibility with existing components. B2B buyers must ensure that the selected thread geometry meets the specific requirements of their applications.

Illustrative image related to rolled thread vs cut thread

Which Trade Terminology Is Essential for Understanding Rolled vs. Cut Threads?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rolled vs. cut threads, understanding OEM specifications helps buyers source components that meet industry standards for quality and performance.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest order amount a supplier is willing to accept. This term is particularly relevant in the fastener industry where bulk purchases may be necessary to achieve cost efficiencies. B2B buyers should negotiate MOQs to align with their production needs while optimizing budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. For rolled vs. cut threads, issuing an RFQ can help buyers obtain competitive pricing and ensure they receive the best quality products that meet their technical specifications.

Illustrative image related to rolled thread vs cut thread

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand the logistics of shipping and delivery, which is crucial for timely project execution and cost management.

5. Lead Time

Lead time is the duration between placing an order and receiving the goods. This term is critical in B2B transactions, especially for industries with tight production schedules. Buyers should assess lead times for rolled and cut thread products to ensure they meet project timelines without incurring delays.

By familiarizing themselves with these essential technical properties and trade terminologies, B2B buyers can make informed decisions regarding rolled and cut threads, enhancing their procurement processes and ensuring optimal project outcomes.

Illustrative image related to rolled thread vs cut thread

Navigating Market Dynamics and Sourcing Trends in the rolled thread vs cut thread Sector

What Are the Current Market Dynamics and Key Trends in the Rolled Thread vs. Cut Thread Sector?

The global market for rolled and cut threads is experiencing significant growth, driven by increased demand for high-strength fasteners in various industries, including construction, automotive, and aerospace. Emerging markets in Africa, South America, and the Middle East are witnessing a surge in infrastructure projects, which in turn boosts the need for reliable fastening solutions. In particular, countries like Saudi Arabia and Brazil are investing heavily in construction and manufacturing, creating a ripe environment for international B2B buyers seeking robust sourcing options.

A key trend shaping the market is the technological advancement in manufacturing processes. Innovations in thread rolling technology have led to the production of stronger, more fatigue-resistant fasteners, appealing to buyers focused on durability and performance. Furthermore, the automation of manufacturing processes has improved efficiency and reduced costs, allowing suppliers to offer competitive pricing. Additionally, the integration of digital platforms for sourcing and procurement is transforming how international buyers connect with manufacturers, facilitating smoother transactions and improved transparency.

Another dynamic is the growing preference for rolled threads over cut threads due to their superior mechanical properties. Rolled threads maintain the integrity of the material’s grain structure, leading to enhanced strength and fatigue resistance. This is particularly important for applications subjected to high stress, making rolled threads the preferred choice for critical applications in many sectors.

How Does Sustainability and Ethical Sourcing Impact the Rolled Thread vs. Cut Thread Market?

Sustainability is becoming increasingly important in B2B sourcing decisions, particularly in the rolled thread vs. cut thread sector. The environmental impact of manufacturing processes is under scrutiny, with buyers seeking suppliers that prioritize eco-friendly practices. Rolled thread manufacturing generally has a lower environmental footprint compared to cut thread production, as the rolling process generates less waste and energy consumption.

Moreover, ethical supply chains are gaining prominence among international buyers. Companies are more inclined to partner with manufacturers who demonstrate a commitment to responsible sourcing of raw materials and fair labor practices. Buyers from regions like Europe and the Middle East are particularly focused on suppliers who can provide certifications that verify their adherence to environmental and ethical standards. Green certifications, such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety, are becoming essential for manufacturers looking to attract international clientele.

In addition to compliance with ethical standards, the use of recycled materials in the production of rolled and cut threads is increasingly seen as a competitive advantage. Buyers are actively seeking suppliers that incorporate sustainable practices into their manufacturing processes, thereby aligning their sourcing decisions with their corporate social responsibility goals.

What Is the Brief Evolution and History of Rolled and Cut Threads in the B2B Sector?

The evolution of rolled and cut threads can be traced back to the industrial revolution, when the need for standardized fastening solutions became paramount. Initially, cut threads were the dominant technology due to their simplicity and ease of production. However, as industries progressed, the limitations of cut threads—such as lower fatigue resistance and material wastage—became apparent.

The introduction of thread rolling in the mid-20th century revolutionized the fastener industry. This method allowed for the formation of threads through a process that displaces material rather than removing it, resulting in stronger threads with enhanced mechanical properties. Over time, as technology advanced, the efficiencies of thread rolling became more pronounced, leading to its widespread adoption in critical applications.

Today, the choice between rolled and cut threads hinges on specific application requirements. While cut threads may still be used for low-stress applications due to their cost-effectiveness, rolled threads dominate sectors where strength and reliability are crucial. The ongoing development of materials and manufacturing processes continues to shape the landscape, providing international B2B buyers with an array of options tailored to their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of rolled thread vs cut thread

-

How do I determine whether to use rolled threads or cut threads for my application?

When deciding between rolled and cut threads, consider factors such as strength, fatigue resistance, and application requirements. Rolled threads are generally stronger due to the work-hardening process during manufacturing, making them ideal for high-stress applications. In contrast, cut threads may be suitable for lower-stress environments or when precision is paramount. Evaluate the load conditions, material compatibility, and any industry standards relevant to your application to make an informed decision. -

What is the best thread type for high-stress applications?

For high-stress applications, rolled threads are often the best choice due to their superior fatigue resistance and overall strength. The process of rolling threads compresses the material, enhancing its structural integrity and allowing it to withstand higher loads. Additionally, rolled threads maintain the grain structure of the metal, which contributes to their durability. If your application involves dynamic loading or significant tension, prioritize sourcing rolled thread fasteners. -

How can I ensure the quality of rolled or cut threads from suppliers?

To ensure quality, establish a robust supplier vetting process. Look for manufacturers with certifications such as ISO 9001, which indicates a commitment to quality management. Request samples to conduct thorough inspections using gauges to verify thread dimensions and tolerances. Additionally, inquire about the supplier’s quality assurance processes, including testing methods for fatigue and tensile strength. Regular audits and performance reviews can further ensure consistent quality over time. -

What are the typical lead times for sourcing rolled vs. cut thread products?

Lead times can vary significantly based on the supplier, order quantity, and customization requirements. Rolled threads typically have shorter lead times since they are mass-produced and readily available, while cut threads may require additional machining time. For international shipments, consider logistics factors such as customs clearance and shipping methods. It’s advisable to communicate your timeline expectations clearly with suppliers to avoid delays. -

Are there minimum order quantities (MOQs) for rolled or cut thread fasteners?

Yes, most manufacturers have minimum order quantities that can vary based on the type of thread and customization requirements. Rolled threads, being mass-produced, may have lower MOQs compared to cut threads, which involve more labor-intensive processes. Discuss your specific needs with potential suppliers to understand their MOQs and explore options for smaller orders, especially if you are testing a new product or entering a new market. -

What payment terms should I expect when sourcing thread fasteners internationally?

Payment terms can vary widely among suppliers, but common options include net 30, net 60, or advance payment for first-time orders. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. It’s crucial to establish clear payment terms upfront, including currency, payment method, and any applicable taxes or tariffs to avoid misunderstandings later. -

How do I handle logistics and shipping for international orders of rolled or cut threads?

When managing logistics for international orders, collaborate closely with your supplier to understand shipping options, costs, and timelines. Choose reliable freight forwarders familiar with customs regulations in your destination country. Ensure all documentation, such as commercial invoices and packing lists, is complete to prevent delays at customs. Additionally, consider insurance coverage for valuable shipments to protect against loss or damage during transit. -

What customization options are available for rolled and cut thread fasteners?

Customization options may include variations in thread sizes, lengths, coatings, and materials. Many suppliers offer the ability to produce fasteners that meet specific industry standards or client requirements. Discuss your needs with potential suppliers to explore available options, such as surface treatments for corrosion resistance or specific thread profiles. Be clear about your specifications to ensure the final product meets your expectations and application requirements.

Top 5 Rolled Thread Vs Cut Thread Manufacturers & Suppliers List

1. Portland Bolt – Rolled vs Cut Thread Bolts

Domain: portlandbolt.com

Registered: 1998 (27 years)

Introduction: Rolled vs Cut Thread Bolts: Rolled threads are formed by extruding steel, resulting in a reduced body diameter and a full diameter threaded portion. Advantages include lower costs, lighter weight, and increased resistance to damage. Disadvantages include limitations on maximum diameter (1″) and thread length (8″). Cut threads are formed by removing material from a full diameter body, allowing for …

2. UC Components – Rolled Fastener Threads

Domain: uccomponents.com

Registered: 2001 (24 years)

Introduction: Rolled fastener threads are created by deforming metal between two dies, offering increased strength, fatigue resistance, and improved dimensional accuracy. Commonly used in aerospace, automotive, and construction industries, they are found in bolts, screws, studs, and threaded rods. Cut fastener threads are made by removing material with cutting tools, allowing for flexibility in thread sizes and…

3. Rolled vs. Cut Threads – Strength Comparison

Domain: bbs.homeshopmachinist.net

Registered: 2000 (25 years)

Introduction: The discussion focuses on the comparative strength of rolled versus cut threads in fasteners. Key points include: 1. Rolled threads may be slightly stronger on average, but the difference is not significant. 2. Rolled threads offer advantages in terms of statistical reliability, cost, and uniformity of product due to the chipless machining process. 3. Rolled threads have smoother surfaces and are …

4. Earnest Machine – Cut and Rolled Threads

Domain: earnestmachine.co.uk

Registered: 2014 (11 years)

Introduction: Cut threads (machined threads) are made by cutting away material, while rolled threads are formed by cold forming the steel between dies without removing material. Rolled threads have a rounded root radius, improved fatigue resistance, and increased strength due to the cold working process. For non-heat-treated bolts (grade 2, grade A, low carbon steel), rolled threads are stronger than cut thread…

5. Accu Components – Thread Types Explained

Domain: accu-components.com

Registered: 2020 (5 years)

Introduction: Rolled Thread vs Cut Thread – The Differences And Benefits Of Each Thread Type. Cut Thread: Produced by removing material to create the thread profile using machining tools. Advantages: Neat finish, low tooling costs, fewer limitations on thread diameter and length. Disadvantages: Burrs need removal, higher manufacturing costs, creates swarf. Rolled Thread: Produced by forming material without rem…

Strategic Sourcing Conclusion and Outlook for rolled thread vs cut thread

In evaluating the strategic sourcing of rolled thread versus cut thread fasteners, several key factors emerge that are critical for international buyers. Rolled threads offer enhanced fatigue resistance and durability, making them preferable in applications that demand high strength and longevity, particularly in tension scenarios. The manufacturing process of rolling threads preserves the material’s grain structure, resulting in superior performance characteristics. In contrast, cut threads, while suitable for certain applications, may not provide the same level of strength and reliability, especially in high-stress environments.

For buyers in regions like Africa, South America, the Middle East, and Europe, understanding these distinctions is essential for making informed procurement decisions. Strategic sourcing not only involves selecting the right product but also ensuring that suppliers adhere to quality standards and can meet logistical demands. By prioritizing rolled thread fasteners, organizations can reduce maintenance costs and enhance the overall performance of their assemblies.

Looking ahead, as global industries continue to evolve, the demand for high-performance fasteners will only increase. Buyers are encouraged to engage with suppliers who understand these dynamics and can provide tailored solutions. Embrace the opportunity to leverage advanced fastening technologies to achieve operational excellence in your projects.

Illustrative image related to rolled thread vs cut thread

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to rolled thread vs cut thread