The Definitive Guide to Retractable Cable Reel Mechanism: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for retractable cable reel mechanism

In the dynamic landscape of international trade, sourcing high-quality retractable cable reel mechanisms presents a unique challenge for B2B buyers. These essential tools are critical for efficient power and data management across various industries, yet navigating the myriad options can be overwhelming. This guide aims to demystify the complexities of the retractable cable reel market, offering insights into different types, applications, and specifications that cater to diverse operational needs.

From manual crank to motorized solutions, our comprehensive exploration covers the full spectrum of retractable cable reels, detailing their suitability for sectors such as construction, telecommunications, and manufacturing. We delve into vital considerations like supplier vetting processes, cost implications, and regulatory compliance, ensuring buyers from regions like Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and established players like Saudi Arabia—can make informed purchasing decisions.

By equipping you with actionable insights and a clear understanding of market trends, this guide empowers international B2B buyers to confidently select the right retractable cable reel mechanism that aligns with their operational demands and budget constraints. Whether you’re looking for custom solutions or standard products, our resource will facilitate a streamlined procurement process, enhancing your business’s efficiency and productivity in a global marketplace.

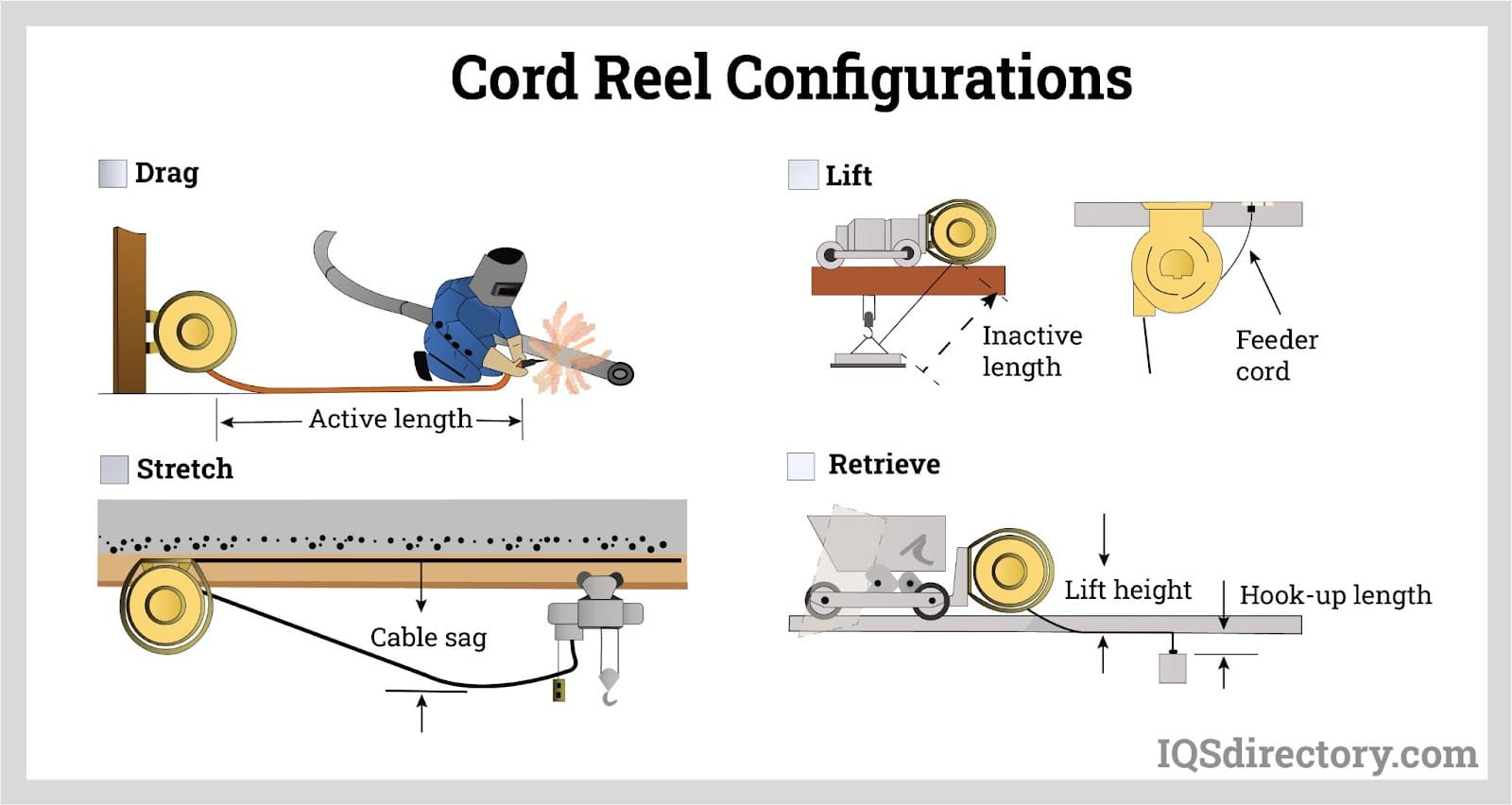

Understanding retractable cable reel mechanism Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spring Retractable Cable Reels | Utilizes a spring mechanism for automatic retraction; lightweight. | Workshops, construction sites, event setups | Pros: Easy to use, minimal maintenance. Cons: Limited length. |

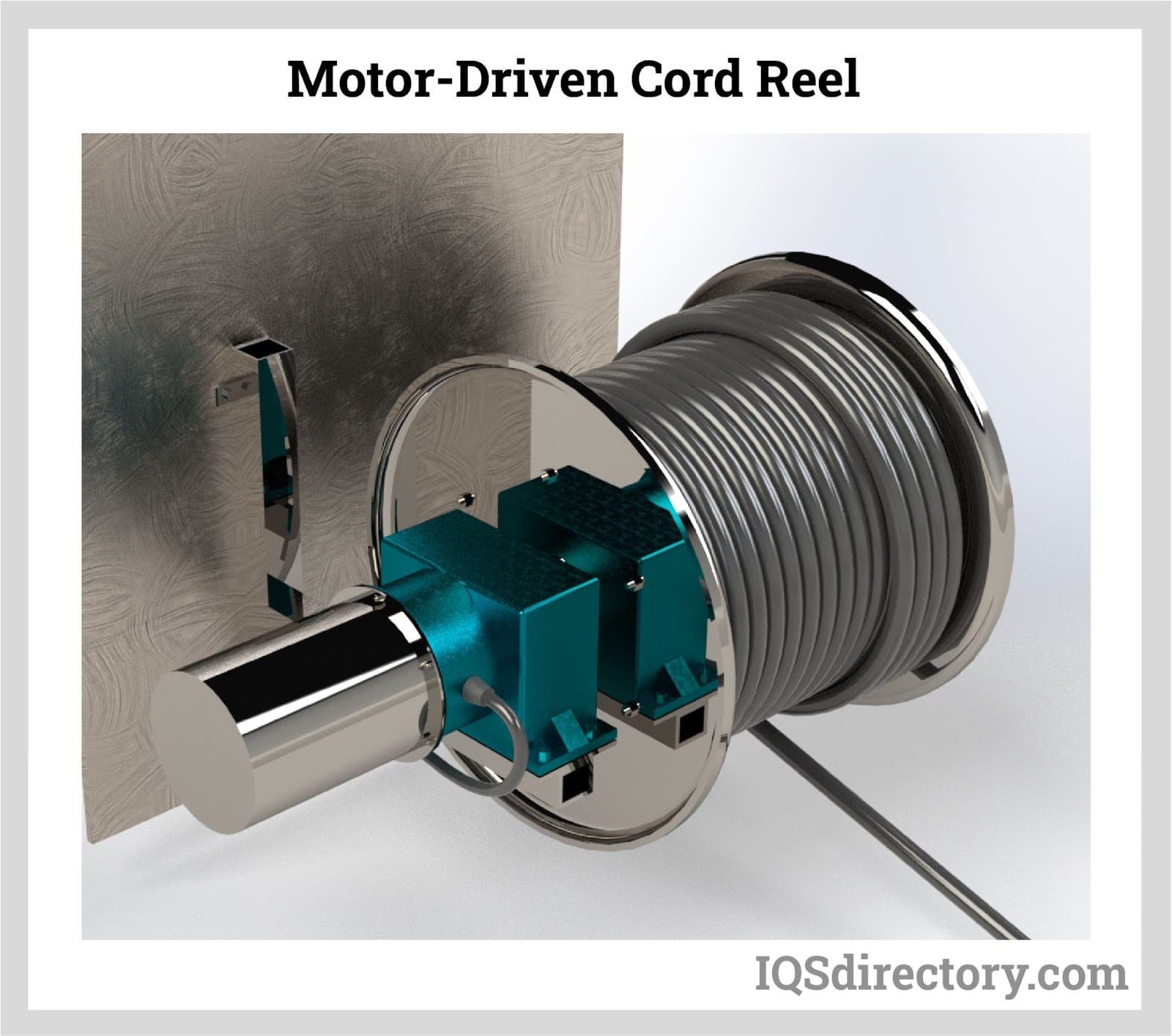

| Electric Cable Reels | Powered by electric motors for automatic winding and unwinding. | Manufacturing, heavy machinery, large events | Pros: High efficiency, can handle longer cables. Cons: Requires power source. |

| Hand Crank Cable Reels | Manual operation with a crank handle; robust and simple design. | Outdoor events, utility services, repairs | Pros: No power required, durable. Cons: Labor-intensive. |

| Combined Hose and Cable Reels | Integrates both hoses and cables in a single unit for versatile use. | Construction, firefighting, industrial sites | Pros: Space-saving, multifunctional. Cons: Potential complexity in design. |

| Custom-Built Cable Reels | Tailored designs to meet specific client needs and specifications. | Specialized industries, custom installations | Pros: Perfect fit for unique applications. Cons: Higher cost, longer lead times. |

What Are the Characteristics of Spring Retractable Cable Reels?

Spring retractable cable reels are designed with a built-in spring mechanism that automatically retracts the cable when not in use. This type is particularly lightweight and easy to operate, making it suitable for environments like workshops and construction sites. B2B buyers should consider the cable length and weight capacity when selecting this type, as these factors can significantly affect usability and efficiency on the job site.

How Do Electric Cable Reels Enhance Efficiency?

Electric cable reels are powered by electric motors, allowing for automatic winding and unwinding of cables. This mechanism is ideal for environments that require frequent use of long cables, such as manufacturing facilities and large events. Buyers should evaluate the power requirements and potential installation costs, as these reels necessitate a reliable power source to function effectively.

Why Choose Hand Crank Cable Reels?

Hand crank cable reels are manually operated and known for their robust design. They are particularly useful in outdoor events or utility services where power access may be limited. While they are durable and require no electricity, the manual operation can be labor-intensive, making them less ideal for high-frequency use. Buyers should assess the physical effort required and the frequency of cable deployment when considering this option.

What Are the Benefits of Combined Hose and Cable Reels?

Combined hose and cable reels offer the unique advantage of integrating both hoses and cables into a single unit, which is particularly beneficial in construction and firefighting applications. This design saves space and simplifies equipment management. However, potential buyers should consider the complexity of the reel’s design and the specific needs of their operations to ensure it meets all requirements effectively.

When Should Businesses Consider Custom-Built Cable Reels?

Custom-built cable reels provide tailored solutions to meet specific industry needs, accommodating unique cable lengths, materials, and operational demands. This option is particularly advantageous for specialized industries or custom installations. While these reels offer a perfect fit for unique applications, they often come with higher costs and longer lead times. B2B buyers should weigh the benefits of customization against their budget and timeline constraints.

Key Industrial Applications of retractable cable reel mechanism

| Industry/Sector | Specific Application of retractable cable reel mechanism | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power supply for machinery and tools | Improved efficiency and safety in operations | Durability, load capacity, and environmental resistance |

| Construction | Temporary power solutions on job sites | Flexibility and reduced trip hazards | Cable length, reel material, and ease of deployment |

| Telecommunications | Cable management for communication networks | Enhanced organization and reduced downtime | Compatibility with various cable types and lengths |

| Automotive | Retractable power sources for workshops | Streamlined operations and reduced clutter | Customization options and voltage requirements |

| Oil & Gas | Power and data cable management in remote locations | Increased safety and operational efficiency | Robustness, weather resistance, and compliance with standards |

How is the retractable cable reel mechanism utilized in manufacturing?

In manufacturing environments, retractable cable reels are essential for providing power to machinery and tools. These reels allow for easy access to electrical connections while minimizing the risk of tripping hazards caused by loose cables. For international buyers, especially from regions like Africa and South America, sourcing durable reels that can withstand harsh conditions and high usage is critical. Considerations such as load capacity and environmental resistance are paramount to ensure safety and longevity in operations.

What role do retractable cable reels play in construction?

In the construction sector, retractable cable reels serve as temporary power solutions, enabling contractors to supply electricity to tools and equipment efficiently on job sites. Their design helps reduce clutter and eliminates the risk of tripping over cables, which is crucial for maintaining safety standards. Buyers in the Middle East and Europe should focus on reels that offer flexibility in cable length and robust materials to withstand outdoor conditions while ensuring ease of deployment and retrieval.

How do retractable cable reels enhance telecommunications?

Telecommunications companies utilize retractable cable reels for effective cable management in communication networks. These reels facilitate organized storage and quick access to cables, thereby minimizing downtime during maintenance or installation. For B2B buyers, particularly in Europe and the Middle East, it’s vital to select reels that accommodate various cable types and lengths, ensuring compatibility with existing infrastructure and enhancing operational efficiency.

In what ways are retractable cable reels beneficial for automotive workshops?

In automotive workshops, retractable cable reels provide streamlined power sources for tools and equipment, reducing workspace clutter and improving workflow. These mechanisms enable technicians to easily access power without the risk of entanglement or damage to cables. When sourcing these reels, international buyers must prioritize customization options to meet specific voltage requirements and ensure compatibility with various automotive tools.

How are retractable cable reels critical in the oil and gas industry?

In the oil and gas sector, retractable cable reels are vital for managing power and data cables in remote locations. They enhance safety by keeping cables organized and out of the way, reducing the risk of accidents. Buyers from regions like Africa and South America should consider reels that are robust and weather-resistant, ensuring compliance with industry standards while effectively supporting operations in challenging environments.

Illustrative image related to retractable cable reel mechanism

3 Common User Pain Points for ‘retractable cable reel mechanism’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Cable Reel for Specific Applications

The Problem: Many B2B buyers struggle with identifying the most suitable retractable cable reel for their unique operational needs. This often arises from the extensive variety of models available—ranging from manual crank to electric, and with varying current capacities and environmental ratings (like IP ratings). For instance, a company in the oil and gas sector may require a high-pressure hose reel that can withstand harsh conditions, while a construction firm may prioritize a model that offers portability and ease of use. This confusion can lead to purchasing the wrong type of reel, resulting in operational inefficiencies and increased costs.

The Solution: To effectively navigate this challenge, buyers should begin by conducting a thorough needs assessment that encompasses their operational requirements, environmental conditions, and frequency of use. They should categorize their needs by defining the specific applications—such as industrial, commercial, or residential—and the environmental factors like moisture, dust, and temperature extremes. Once these parameters are established, buyers can reach out to reputable manufacturers and suppliers, such as SUPERREEL, to discuss their requirements. It’s crucial to inquire about customization options that can meet specific demands, such as reels designed for high-pressure environments or with enhanced durability features. Additionally, requesting product demonstrations or trials can provide practical insights into how well a reel will perform in real-world conditions.

Scenario 2: Frequent Cable Wear and Tear Leading to Increased Maintenance Costs

The Problem: Another prevalent issue among B2B buyers is the rapid wear and tear of cables housed within retractable reels. This problem often arises from suboptimal reel designs that do not adequately protect the cables from abrasion or environmental factors, leading to frequent replacements and increased maintenance costs. For example, in sectors like construction or manufacturing, where cables are often subjected to heavy use and potential damage from machinery, the longevity of the retractable cable reel is critical.

The Solution: To mitigate this issue, buyers should prioritize selecting reels that feature robust design elements aimed at protecting the cables. This includes looking for models that offer protective sheathing or those built with high-quality materials resistant to abrasion and environmental damage. Additionally, implementing a regular maintenance schedule for the cable reels can help extend their lifespan. Buyers should seek guidance from suppliers on the best practices for cable care, such as proper unwinding and rewinding techniques to prevent kinking and tangling. Utilizing reels that allow for easy cable replacement can also minimize downtime and maintenance costs, ensuring operational efficiency.

Illustrative image related to retractable cable reel mechanism

Scenario 3: Complications in Installation and Space Management

The Problem: Many organizations face difficulties during the installation of retractable cable reels, particularly in confined spaces or complex environments. Poor installation can lead to inefficiencies, such as tangled cables or restricted access to power sources. For instance, in industrial settings, the lack of proper spatial planning can result in cables being routed poorly, posing safety hazards and operational disruptions.

The Solution: To avoid installation complications, B2B buyers should engage in detailed spatial planning before purchasing a retractable cable reel. This involves assessing the installation site, considering factors such as available space, ceiling height, and proximity to power sources. Collaborating with installation experts or the reel manufacturer can provide insights on optimal placement and mounting options that maximize efficiency and safety. Buyers should also consider reels with features such as automatic locking mechanisms and swivel mounts, which can enhance usability and adaptability in tight spaces. Lastly, providing training for personnel on proper installation techniques can further mitigate risks associated with improper setup, ensuring that the retractable cable reels function as intended and contribute positively to overall workflow efficiency.

Strategic Material Selection Guide for retractable cable reel mechanism

What Are the Key Materials for Retractable Cable Reel Mechanisms?

When selecting materials for retractable cable reel mechanisms, it is essential to consider the specific requirements of performance, durability, and application compatibility. Here, we analyze four common materials used in the manufacturing of these mechanisms: steel, stainless steel, aluminum, and plastic.

Illustrative image related to retractable cable reel mechanism

How Does Steel Perform in Retractable Cable Reel Mechanisms?

Steel is a traditional choice for retractable cable reels due to its strength and durability. It typically offers excellent tensile strength and can withstand high loads, making it suitable for heavy-duty applications. Steel can handle temperature variations and has a good pressure rating. However, it is prone to corrosion if not properly treated or coated.

Pros: Steel is relatively inexpensive and widely available, making it cost-effective for manufacturers. Its durability ensures a long lifespan, which is appealing to buyers looking for reliable solutions.

Cons: The primary drawback of steel is its susceptibility to rust and corrosion, particularly in humid or coastal environments. This necessitates additional treatments like galvanization or powder coating, which can increase manufacturing complexity and costs.

Impact on Application: Steel reels are suitable for applications involving heavy cables and high-stress environments, but they may not be ideal for corrosive media.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should consider local environmental conditions and compliance with standards such as ASTM or DIN for corrosion resistance.

Illustrative image related to retractable cable reel mechanism

What Advantages Does Stainless Steel Offer for Cable Reels?

Stainless steel is a premium material choice for retractable cable reels, known for its superior corrosion resistance and aesthetic appeal. It can withstand harsh environments, including exposure to chemicals and saltwater, making it suitable for marine and industrial applications.

Pros: The main advantage of stainless steel is its longevity and low maintenance requirements. It does not rust, which is crucial for applications exposed to moisture.

Cons: The downside is that stainless steel is significantly more expensive than regular steel and can be more challenging to machine, which may lead to higher manufacturing costs.

Impact on Application: Stainless steel reels are ideal for applications in corrosive environments, such as chemical plants or coastal areas, where durability is paramount.

Considerations for International Buyers: Buyers should ensure compliance with international standards for safety and quality, especially in regions with stringent regulations.

How Does Aluminum Compare in Terms of Weight and Performance?

Aluminum is favored for its lightweight properties, making it easy to handle and install. It has good corrosion resistance and can be anodized to enhance its protective qualities. Aluminum reels are often used in portable applications where weight is a critical factor.

Pros: The primary advantage of aluminum is its lightweight nature, which reduces transportation costs and makes installation easier. It also offers decent strength-to-weight ratios.

Cons: However, aluminum is generally less strong than steel and may not be suitable for high-load applications. It can also be more expensive than steel, depending on the alloy used.

Impact on Application: Aluminum reels are ideal for portable or temporary applications, such as in construction or events, where ease of movement is essential.

Illustrative image related to retractable cable reel mechanism

Considerations for International Buyers: Buyers should verify that the aluminum used meets international standards for strength and corrosion resistance, particularly in regions with diverse climates.

What Role Does Plastic Play in Cable Reel Mechanisms?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is increasingly used in retractable cable reels due to its lightweight and corrosion-resistant properties. It is non-conductive, making it suitable for electrical applications.

Pros: The main advantage of plastic is its resistance to corrosion and chemicals, making it ideal for various environments. It is also lightweight and cost-effective.

Illustrative image related to retractable cable reel mechanism

Cons: The limitations of plastic include lower strength compared to metals, which may restrict its use in heavy-duty applications. It may also degrade over time when exposed to UV light unless treated.

Impact on Application: Plastic reels are suitable for lighter applications, such as garden or low-voltage electrical cables, where corrosion resistance is more critical than load-bearing capacity.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with relevant safety and quality standards, especially in regions with strict regulations on materials.

Summary Table of Material Selection for Retractable Cable Reel Mechanisms

| Material | Typical Use Case for retractable cable reel mechanism | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications, industrial settings | High strength and durability | Prone to corrosion | Low |

| Stainless Steel | Marine and chemical environments | Superior corrosion resistance | High cost and manufacturing complexity | High |

| Aluminum | Portable and temporary applications | Lightweight and easy to handle | Lower strength than steel | Medium |

| Plastic | Low-voltage and garden applications | Corrosion and chemical resistance | Lower strength and UV degradation | Low |

This strategic material selection guide provides B2B buyers with essential insights for making informed decisions regarding the most suitable materials for retractable cable reel mechanisms, considering performance, cost, and specific regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for retractable cable reel mechanism

What Are the Main Stages of Manufacturing a Retractable Cable Reel Mechanism?

The manufacturing of retractable cable reel mechanisms involves several critical stages, each designed to ensure the final product meets the required specifications for performance and safety. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to retractable cable reel mechanism

Material Preparation

The first stage involves selecting high-quality materials such as stainless steel, aluminum, and durable plastics. The choice of material is crucial as it affects the reel’s strength, weight, and resistance to environmental factors. Suppliers often conduct material inspections to ensure compliance with international standards. For instance, materials may undergo tests for tensile strength and corrosion resistance, ensuring they meet specifications before moving to the next stage.

Forming Processes

Once materials are prepared, forming techniques are employed to create the various components of the retractable cable reel. Common methods include:

- Stamping and Cutting: Used to create metal parts like housings and brackets. Precision is key, as any deviation can impact the assembly and functionality.

- Molding: For plastic components, injection molding is often utilized to achieve complex shapes and designs while maintaining consistency.

- Winding: The cable itself is often wound onto a spool, which requires precision to ensure the cable can retract smoothly without tangling.

These forming processes are often supported by advanced machinery, such as CNC (Computer Numerical Control) machines, which enhance precision and reduce human error.

Assembly Techniques

After forming, the assembly stage brings all components together. This stage may involve:

- Manual Assembly: Skilled workers assemble parts, ensuring that each component fits correctly and functions as intended. This is particularly important for mechanisms that require precise alignment.

- Automated Assembly Lines: In larger operations, automated systems may be used to speed up the process while maintaining quality. Robotics can assist in tasks such as screwing, welding, or fitting parts together.

Quality checks are integrated into the assembly process to catch defects early, reducing waste and ensuring compliance with standards.

Finishing Processes

The final stage involves finishing processes that enhance the durability and appearance of the retractable cable reel. This can include:

- Surface Treatment: Processes such as powder coating or anodizing protect metal surfaces from corrosion and wear while providing an attractive finish.

- Testing and Calibration: Before packaging, each reel is subjected to functional testing to ensure it operates correctly under various conditions. This includes checking the retraction mechanism and electrical connections, if applicable.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is integral to manufacturing processes, especially for products like retractable cable reels, which must meet specific performance and safety requirements. Key international standards include:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, products must meet certain safety, health, and environmental protection standards to gain CE marking. This certification is crucial for B2B buyers in Europe, as it signifies compliance with EU regulations.

- API Standards: For industrial applications, particularly in oil and gas sectors, API (American Petroleum Institute) standards may apply, ensuring that products are safe and reliable under demanding conditions.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is vital at various checkpoints throughout the manufacturing process. Typical QC checkpoints include:

- Incoming Quality Control (IQC): This initial stage checks raw materials and components upon arrival. Materials are inspected for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor the production line’s performance. This includes checking dimensions, assembly accuracy, and functionality.

- Final Quality Control (FQC): Before products are packaged and shipped, they undergo final testing to ensure they meet all functional and safety standards. This may involve stress testing and performance evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers. Here are effective strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing processes, quality control systems, and compliance with international standards. This firsthand evaluation helps identify potential risks.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC stages. These reports offer insights into the consistency and reliability of their production.

- Third-Party Inspections: Engaging third-party inspectors can provide an unbiased evaluation of a supplier’s quality control practices. These inspectors can conduct random checks during production or verify finished products before shipment.

What Are the Specific QC Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate various QC nuances. These include:

- Understanding Local Regulations: Different regions may have specific regulations and standards that need to be adhered to. Buyers must ensure that suppliers comply with local laws in addition to international standards.

- Cultural and Language Differences: Effective communication is essential to understand quality expectations. B2B buyers should consider language barriers and cultural differences that may affect negotiations and quality assurance practices.

- Logistics and Transportation: The quality of products can be compromised during transportation. Buyers should discuss packaging and handling procedures with suppliers to minimize damage risks during shipping.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing retractable cable reels, ensuring they receive products that meet their operational needs and safety standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘retractable cable reel mechanism’

This guide serves as a comprehensive checklist for B2B buyers seeking to procure retractable cable reel mechanisms. By following these steps, you can ensure that you select the right product and supplier to meet your operational needs efficiently.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your retractable cable reel mechanism. Consider factors such as the type of cable to be used, the desired length, and the environment in which the reel will operate.

– Cable Type: Ensure compatibility with electrical standards in your region.

– Length and Capacity: Determine the maximum cable length and weight the reel must support.

Step 2: Identify Application Needs

Understand the application for which the cable reel will be utilized. Different industries may have varying requirements, such as industrial, commercial, or residential use.

– Usage Environment: Consider whether the reel will be used indoors or outdoors, and if it needs to withstand environmental factors like moisture or dust.

– Power Requirements: Assess the electrical load and ensure the reel can handle the necessary current intensity, which may range from 10A to 500A or more.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers before making a commitment. Request detailed company profiles, product catalogs, and case studies to gauge their expertise and reliability.

– References: Ask for references from clients in similar industries to assess their satisfaction with the supplier’s products and services.

– Certifications: Verify if the suppliers have relevant industry certifications, such as ISO standards, which can indicate quality and compliance.

Step 4: Assess Material and Build Quality

Investigate the materials used in the construction of the cable reel. High-quality materials contribute to durability and longevity.

– Material Options: Look for reels made from steel, stainless steel, or aluminum, depending on the application and environment.

– IP Ratings: Consider the ingress protection (IP) ratings, which indicate the level of protection against dust and water.

Step 5: Check Customization Options

Many suppliers offer customization services to tailor the reel to your specific needs. This can be critical for unique applications or branding purposes.

– Design Flexibility: Inquire about the possibility of custom dimensions, color options, or additional features like automatic retraction or integrated safety mechanisms.

– Minimum Order Quantities: Confirm if the supplier has any minimum order requirements, especially for customized products.

Illustrative image related to retractable cable reel mechanism

Step 6: Request Samples and Conduct Testing

Before finalizing your order, request samples to evaluate the product quality firsthand. Testing the reel in real-world conditions can reveal insights into its performance.

– Load Testing: Ensure the reel can handle the intended load without compromising performance.

– Ease of Use: Assess the functionality of retracting mechanisms and any additional features.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate the terms of purchase, including pricing, delivery timelines, and warranty conditions.

– Warranties and Support: Understand the warranty coverage and post-purchase support options available.

– Payment Terms: Discuss payment terms that suit your budget and cash flow needs.

By following this checklist, you can confidently navigate the procurement process for retractable cable reel mechanisms, ensuring that you make informed decisions that align with your operational requirements.

Illustrative image related to retractable cable reel mechanism

Comprehensive Cost and Pricing Analysis for retractable cable reel mechanism Sourcing

What Are the Key Cost Components in Retractable Cable Reel Mechanism Manufacturing?

When sourcing retractable cable reel mechanisms, understanding the underlying cost structure is crucial for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts cost. Common materials such as steel, stainless steel, and aluminum vary in price based on market fluctuations and availability. Custom materials may further increase costs but could provide enhanced durability or specific performance characteristics.

-

Labor: Labor costs can differ based on geographic location and the complexity of the assembly process. Skilled labor is essential for high-quality production, particularly for custom or specialized products. In regions like Europe and the Middle East, labor costs may be higher compared to emerging markets in Africa and South America.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, equipment maintenance, and administrative costs. A well-optimized manufacturing process can help minimize overhead, directly affecting the final price of the product.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are typically amortized over the production run, making high-volume orders more cost-effective in the long run.

-

Quality Control: Implementing stringent QC processes ensures product reliability and compliance with international standards, which can add to the overall cost. However, investing in quality can reduce long-term costs associated with warranty claims and product returns.

-

Logistics: Transportation and shipping costs vary widely depending on the origin and destination, chosen Incoterms, and shipment volume. Efficient logistics management can minimize these costs, particularly for international buyers.

-

Margin: Supplier margins will vary based on factors such as market demand, competition, and product differentiation. Understanding the margin expectations of suppliers can aid in negotiation.

How Do Price Influencers Affect the Sourcing of Retractable Cable Reel Mechanisms?

Several factors influence pricing in the retractable cable reel market, which international buyers should consider to ensure they are making informed purchasing decisions.

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Suppliers often provide discounts for larger orders, making it beneficial for buyers who can commit to higher volumes.

-

Specifications and Customization: Custom designs or specific technical requirements can lead to increased costs. Buyers should evaluate whether customization is necessary or if off-the-shelf products would suffice.

-

Materials: As previously mentioned, the choice of materials plays a critical role in pricing. Buyers should assess the trade-offs between cost and performance to determine the best material for their needs.

-

Quality and Certifications: Products that meet specific quality standards or certifications may command higher prices. However, these certifications can enhance safety and reliability, justifying the investment.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge a premium, but this can be offset by the reduced risk of product failure.

-

Incoterms: The chosen Incoterms will affect the total landed cost of the product. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost estimation.

What Are the Best Negotiation Strategies for International Buyers?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes and cost-efficiency:

-

Total Cost of Ownership (TCO): Focus on TCO rather than just the upfront price. Consider factors such as maintenance, operational efficiency, and potential downtime when evaluating the overall value of the product.

-

Leverage Volume Discounts: If possible, consolidate orders to meet or exceed MOQs for better pricing. Regular purchasing agreements can also strengthen negotiation positions.

-

Evaluate Multiple Suppliers: Request quotes from multiple suppliers to compare pricing, quality, and service levels. This competitive approach can yield favorable terms.

-

Understand Local Market Dynamics: Knowledge of local market conditions, including currency fluctuations and trade tariffs, can provide leverage during negotiations.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, favorable terms, and priority service.

Conclusion: Navigating Pricing Nuances in Global Sourcing

International buyers must navigate a complex landscape of costs and pricing factors when sourcing retractable cable reel mechanisms. By understanding the cost structure, recognizing price influencers, and employing effective negotiation strategies, buyers can optimize their procurement processes and achieve better value. Keep in mind that indicative prices can vary widely based on market conditions and specific project requirements, making ongoing research and supplier engagement critical for successful sourcing.

Alternatives Analysis: Comparing retractable cable reel mechanism With Other Solutions

Introduction: Understanding Alternatives to Retractable Cable Reel Mechanisms

In the quest for efficient cable management solutions, businesses often consider various technologies that fulfill similar roles as retractable cable reel mechanisms. These alternatives can vary significantly in terms of performance, cost, and suitability for specific applications. By analyzing these options, B2B buyers can make informed decisions tailored to their operational needs, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Retractable Cable Reel Mechanism | Manual Cable Management Solutions | Fixed Cable Systems |

|---|---|---|---|

| Performance | High efficiency with automatic retraction | Moderate efficiency, requires manual handling | Consistent performance, limited flexibility |

| Cost | Higher initial investment, long-term savings | Lower initial cost, higher labor costs | Medium cost, variable based on installation |

| Ease of Implementation | Requires some installation expertise | Simple setup, no specialized knowledge needed | Complex installation, often requires professionals |

| Maintenance | Low maintenance, durable designs | Moderate maintenance, wear and tear | Low maintenance, but limited adaptability |

| Best Use Case | Industrial settings, temporary setups | Office environments, small-scale use | Permanent installations in fixed locations |

Detailed Breakdown of Alternatives

Manual Cable Management Solutions

Manual solutions, such as cable ties, clips, and reels, are often employed in smaller settings or less demanding environments. These options are generally more affordable upfront and require minimal technical knowledge for installation. However, they necessitate manual handling, which can lead to inefficiencies and increased labor costs over time. Additionally, manual systems often lack the adaptability and ease of use that retractable systems provide, making them less suitable for dynamic workspaces.

Fixed Cable Systems

Fixed cable systems, which include mounted cable trays or conduits, offer a robust solution for environments where cables need to be securely housed. Their installation can be complex and may require professional services, leading to higher upfront costs. However, they are highly durable and require minimal maintenance once installed. The primary drawback is their lack of flexibility; if reconfiguration or relocation of cables is needed, it can become a cumbersome process. These systems are best suited for environments where cable routes are predictable and not subject to frequent change.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a cable management solution, B2B buyers should assess their specific operational requirements, including the environment, budget constraints, and the need for flexibility. Retractable cable reel mechanisms provide high efficiency and ease of use, making them ideal for industrial applications and temporary setups. Conversely, manual cable management solutions may serve well in smaller, less demanding environments, while fixed cable systems are better suited for permanent installations. By carefully considering these factors, businesses can optimize their cable management strategies to enhance productivity and reduce operational costs.

Essential Technical Properties and Trade Terminology for retractable cable reel mechanism

What Are the Key Technical Properties of Retractable Cable Reel Mechanisms?

Retractable cable reels are essential for managing electrical cords and hoses in various industrial applications. Understanding their technical properties is crucial for B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

-

Material Composition

– Common materials include steel, stainless steel, and aluminum. Stainless steel offers corrosion resistance, making it ideal for outdoor and harsh environments. Aluminum is lightweight, facilitating easier handling. The choice of material directly affects durability and suitability for specific applications, such as in marine or chemical industries. -

Current Rating (Amperage)

– Retractable cable reels can handle a wide range of current ratings, typically from 10A to 500A or more. This specification is vital for ensuring the reel can safely manage the electrical load required by connected devices. B2B buyers must match the current rating of the reel with the needs of their equipment to prevent overheating and potential hazards. -

Ingress Protection (IP) Rating

– The IP rating indicates the level of protection against dust and water ingress. Common ratings include IP44, IP54, IP65, and IP68. A higher IP rating ensures the reel can withstand harsher environmental conditions, which is crucial for industries operating outdoors or in wet environments. Buyers should select reels with appropriate ratings based on their operational environment. -

Rewind Mechanism Type

– The rewind mechanism can be manual (hand crank), spring-driven, or motorized. Each type has its advantages; for example, spring-driven mechanisms offer automatic rewinding, reducing labor costs. Understanding the operational workflow is essential for choosing the right mechanism that enhances efficiency and minimizes downtime. -

Cable Length and Diameter

– The length and diameter of the cable are critical for determining the reel’s suitability for specific applications. Longer cables provide more flexibility in use, while the diameter impacts the reel’s capacity and storage efficiency. Buyers should assess the operational requirements to ensure the selected reel meets their length and capacity needs.

What Are Common Trade Terms Related to Retractable Cable Reels?

In the B2B environment, certain terminology is frequently used when discussing retractable cable reels. Familiarity with these terms can aid in smoother negotiations and transactions:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source high-quality components or custom solutions in retractable cable reels. -

MOQ (Minimum Order Quantity)

– MOQ represents the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers to manage inventory costs and ensure they are purchasing sufficient quantities to meet their operational needs without overcommitting financially. -

RFQ (Request for Quotation)

– An RFQ is a standard business process where buyers invite suppliers to bid on specific products or services. It helps buyers receive competitive pricing and terms from multiple suppliers, ensuring they make cost-effective purchasing decisions. -

Incoterms (International Commercial Terms)

– These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing shipping costs and logistics, especially when sourcing from global suppliers. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. It is a critical factor for buyers to consider, as it impacts project timelines and operational planning. Efficient lead time management can enhance supply chain efficiency and reduce potential downtime.

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions when sourcing retractable cable reel mechanisms tailored to their specific operational requirements.

Navigating Market Dynamics and Sourcing Trends in the retractable cable reel mechanism Sector

What Are the Key Trends Influencing the Retractable Cable Reel Mechanism Market?

The retractable cable reel mechanism sector is witnessing significant growth driven by various global factors. Increasing industrial automation and the demand for efficient power management solutions are primary market drivers. In regions such as Africa, South America, the Middle East, and Europe, the adoption of retractable cable reels is expanding in sectors like construction, manufacturing, and telecommunications. These reels enhance workspace safety by minimizing cable clutter, which is particularly crucial in environments with heavy machinery.

Emerging technologies are reshaping the sourcing landscape, with innovations such as IoT-enabled cable reels gaining traction. These advanced reels offer real-time monitoring and control, appealing to businesses aiming for enhanced operational efficiency. Additionally, manufacturers are focusing on customization to meet specific client requirements, providing options for various drive types, materials, and sizes. This trend is particularly relevant for international buyers who need tailored solutions for diverse applications.

Illustrative image related to retractable cable reel mechanism

Furthermore, the market is seeing a shift towards automation in production processes, which reduces lead times and enhances product quality. Companies are increasingly investing in automation technologies to streamline their operations and meet the growing demand from international markets. This dynamic landscape requires B2B buyers to stay informed about technological advancements and sourcing strategies that optimize their supply chains.

How Is Sustainability and Ethical Sourcing Shaping B2B Practices in This Sector?

Sustainability has become a cornerstone of business operations, influencing purchasing decisions in the retractable cable reel mechanism market. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using recyclable materials and minimizing emissions during production.

Ethical sourcing is equally important, with businesses opting for suppliers that adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and fair trade labels are gaining prominence among B2B buyers. These certifications not only demonstrate a commitment to sustainability but also enhance the brand image, which can be a decisive factor in competitive markets.

Illustrative image related to retractable cable reel mechanism

Moreover, the adoption of ‘green’ materials, such as biodegradable plastics and recycled metals, is becoming more prevalent. Suppliers who can provide eco-friendly options are likely to attract environmentally conscious buyers, especially in regions where regulatory frameworks are tightening around environmental standards. This shift towards sustainable and ethical sourcing is not just a trend; it is becoming a necessity for businesses looking to thrive in a socially responsible marketplace.

What Is the Historical Context of Retractable Cable Reel Mechanisms for B2B Buyers?

The retractable cable reel mechanism has evolved significantly since its inception, driven by technological advancements and changing industrial needs. Initially designed for simple cable storage and management, these mechanisms have transformed into sophisticated devices with multiple functionalities. Early models primarily utilized manual cranking systems, which have now evolved into automatic and motorized options, offering greater convenience and efficiency.

The introduction of materials such as stainless steel and aluminum has improved the durability and performance of these reels, catering to various industrial applications. Additionally, innovations in design have led to the development of compact and lightweight models, making them more suitable for both indoor and outdoor use. As industries continue to evolve, the retractable cable reel mechanism adapts, offering increasingly versatile solutions that align with the demands of modern businesses. This historical context is crucial for B2B buyers who seek to understand the technological lineage and reliability of the products they invest in.

Frequently Asked Questions (FAQs) for B2B Buyers of retractable cable reel mechanism

-

How do I choose the right retractable cable reel mechanism for my business needs?

Selecting the appropriate retractable cable reel mechanism involves assessing several factors, including the application, cable length, and electrical specifications. Determine the type of environment where the reel will be used—industrial, commercial, or residential—as this impacts durability and design. Consider the current intensity requirements, which can range from 10A to over 500A. Additionally, evaluate the drive type (manual, motorized, or spring-driven) that best suits your operations. Customization options may also be available to meet specific operational needs. -

What are the key features to look for in a retractable cable reel?

When sourcing retractable cable reels, prioritize features such as IP rating for dust and water resistance, which can be crucial for outdoor or industrial settings. Look for reels made from durable materials like stainless steel or aluminum, ensuring longevity and resistance to corrosion. Additionally, consider the reel’s winding mechanism, which should operate smoothly and reliably. Safety features, such as automatic locking mechanisms and overload protection, are also essential for preventing accidents and equipment damage. -

What customization options are available for retractable cable reels?

Many manufacturers offer customization options to tailor retractable cable reels to specific operational requirements. This may include variations in size, cable length, material, and color. Some suppliers can integrate unique features, such as specific connectors or power ratings. When discussing your needs with potential suppliers, be clear about your application and any particular standards or certifications required for your industry to ensure the final product meets all necessary specifications. -

What is the minimum order quantity (MOQ) for retractable cable reels?

The minimum order quantity (MOQ) for retractable cable reels can vary significantly between suppliers. Some manufacturers may offer no minimum quantities, allowing you to order as few as one unit, while others may require a minimum of several dozen units. It’s advisable to confirm the MOQ during your initial discussions with suppliers, especially if you are testing a new product line or considering a bulk purchase. Understanding the MOQ can help you plan your budget and inventory accordingly. -

What payment terms should I expect when sourcing retractable cable reels internationally?

Payment terms can vary by supplier and region. Commonly accepted methods include wire transfers, letters of credit, and PayPal. Many suppliers may request a deposit (typically 30% to 50%) upfront, with the balance due before shipping or upon delivery. It’s crucial to clarify payment terms during negotiations, including any options for extended payment plans or discounts for early payment. Ensure that all terms are documented in the purchase agreement to avoid misunderstandings later. -

How do I ensure quality assurance when sourcing retractable cable reels?

To ensure quality assurance when sourcing retractable cable reels, request detailed product specifications and certifications from potential suppliers. Conducting factory audits or requesting samples before placing a larger order can help assess the quality of their products. Additionally, inquire about their quality control processes and any testing procedures they employ to guarantee product reliability and safety. Establishing a clear communication channel for quality concerns can also facilitate smoother transactions and help address issues promptly. -

What logistics considerations should I keep in mind for international shipping of retractable cable reels?

When planning for the international shipping of retractable cable reels, consider factors such as shipping methods, customs regulations, and potential tariffs. Determine the best shipping method for your needs, whether air freight for speed or ocean freight for cost-effectiveness. Familiarize yourself with the import regulations of your country to ensure compliance and avoid delays. Working with a reliable logistics partner can help navigate these complexities and provide support throughout the shipping process. -

How can I vet suppliers of retractable cable reels to ensure reliability?

Vetting suppliers involves a thorough evaluation of their credentials, including certifications, industry experience, and customer reviews. Request references from previous clients and look for case studies that demonstrate their capability in delivering quality products. Additionally, consider their responsiveness and willingness to communicate during the inquiry phase. Engaging in direct discussions about your specific needs can also provide insights into their expertise and reliability, helping you make an informed decision.

Top 7 Retractable Cable Reel Mechanism Manufacturers & Suppliers List

1. Reddit – Retractable Cord Reel Mechanism

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Retractable cord reel mechanism includes a braking system that allows the cable to stay extended and retracts on a second pull. It operates using a combination of a ballpen cam system and a rotating spring, where pulling once engages a tab that prevents rotation, and pulling again disengages the tab, allowing the spring to retract the cable. The reel spins while the wall plug remains stationary, u…

2. Hunter Spring – Mechanical Cable Reels

Domain: hunterspringandreel.com

Registered: 2016 (9 years)

Introduction: Mechanical Cable Reels from Hunter Spring offer a variety of spring powered cable reels with different mounting options, including arbor mounted, base mounted, and bracket mounted reels. The reels range in diameter from 2.0″ to 6.0″ and can provide pull forces from 0.5 lbs to 35.0 lbs, with custom reels available that can provide up to 94 lbs of force. Larger steel reels are used in applications s…

3. SUPERREEL – Retractable Cable Reel

Domain: superreel.com

Registered: 2015 (10 years)

Introduction: {“product_name”:”Retractable Cable Reel”,”manufacturer”:”SUPERREEL”,”drive_types”:[“Manual crank”,”Motorized”,”Spring drive”,”Hand-over-hand”],”current_intensity_range”:”10 to 500A and beyond”,”IP_ratings”:[“IP44″,”IP54″,”IP65″,”IP68″],”materials”:[“Steel”,”Stainless steel”,”Aluminium”],”custom_options”:”Custom built reels”,”minimum_quantities”:”No minimum quantities”}

4. Rita Cruise – Winder Retractable Cord Reel

Domain: ritacruise.com

Registered: 2019 (6 years)

Introduction: Winder retractable cord reel mechanism

5. LinkedIn – Retractable Cord Mechanisms

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: Retractable cord mechanisms are devices used in various applications, including household appliances and industrial equipment. They consist of three main components: a spring mechanism, a cord, and a housing unit. The spring mechanism stores and releases energy to retract the cord, while the cord serves as the medium for force transmission or electrical signals. The housing unit protects and suppo…

6. McMaster – Retractable Reels

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Retractable Reels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Autacusa – Retractable Cable Reels

Domain: autacusa.com

Registered: 1999 (26 years)

Introduction: Retractable cable reels are designed to manage various types of cables including power cords, ethernet cables, audiovisual cables, and hoses. They operate using a coiled spring mechanism that allows the cable to retract smoothly when not in use. Key advantages include space efficiency, organization, safety, mobility, and versatility. When selecting a retractable cable reel, consider factors such a…

Strategic Sourcing Conclusion and Outlook for retractable cable reel mechanism

In summary, the strategic sourcing of retractable cable reel mechanisms presents significant opportunities for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. By focusing on quality, customization, and compatibility with various applications, businesses can enhance operational efficiency and reduce downtime. The ability to source products that meet specific technical requirements—such as varying current capacities and IP ratings—ensures that buyers can optimize their investments and cater to industry-specific needs.

Moreover, leveraging partnerships with reliable manufacturers can lead to better pricing structures, improved supply chain resilience, and access to innovative designs that stay ahead of technological advancements. As demand for retractable cable reels grows, particularly in sectors like construction, manufacturing, and telecommunications, now is the time to align sourcing strategies with future trends.

International buyers are encouraged to engage with suppliers who prioritize sustainability and adaptability, ensuring that their sourcing strategies not only meet current needs but also anticipate future challenges. Embrace the opportunity to enhance your operational capabilities by strategically sourcing retractable cable reel mechanisms that align with your business goals.

Illustrative image related to retractable cable reel mechanism

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.