The Definitive Guide to Replica Footwear: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for replica footwear

In the fast-paced global market, sourcing high-quality replica footwear presents a unique challenge for international B2B buyers. With the rising demand for stylish yet affordable options, particularly in regions like Africa, South America, the Middle East, and Europe, businesses must navigate a complex landscape of suppliers and products. This guide is designed to empower buyers by providing a comprehensive overview of the replica footwear market, covering various types, applications, and essential factors to consider when selecting suppliers.

From understanding the nuances of sizing and design to evaluating the ethical implications of sourcing practices, this guide equips businesses with the knowledge needed to make informed purchasing decisions. It delves into the intricacies of supplier vetting, ensuring that quality and reliability are prioritized, while also addressing cost considerations that can impact the bottom line. With insights tailored specifically for buyers from diverse markets such as Nigeria and Brazil, this resource aims to streamline the process of acquiring replica footwear that meets both aesthetic and economic criteria.

By leveraging this guide, B2B buyers can enhance their competitive edge, ensuring they meet customer demands without compromising on quality or brand reputation. Navigate the complexities of the global replica footwear market with confidence, and discover how strategic sourcing can drive your business success.

Understanding replica footwear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Replica Sneakers | Classic sportswear designs, often inspired by high-end brands | Retailers, online stores, fashion boutiques | Pros: Affordable, trendy; Cons: Quality may vary |

| Custom Replica Footwear | Tailored designs with customizable materials and features | Custom shoe shops, online retailers | Pros: Unique offerings; Cons: Longer production time |

| Fashion Replica Boots | Styles mimicking designer boots, often with varied heel heights | Footwear retailers, e-commerce platforms | Pros: Diverse styles; Cons: May lack durability |

| Replica Casual Shoes | Everyday styles resembling popular casual footwear | Mass-market retailers, discount stores | Pros: High demand; Cons: Less brand recognition |

| Designer-Inspired Sandals | Sandal styles that reflect high-fashion trends | Seasonal retail, online fashion shops | Pros: Seasonal appeal; Cons: Trend-dependent sales |

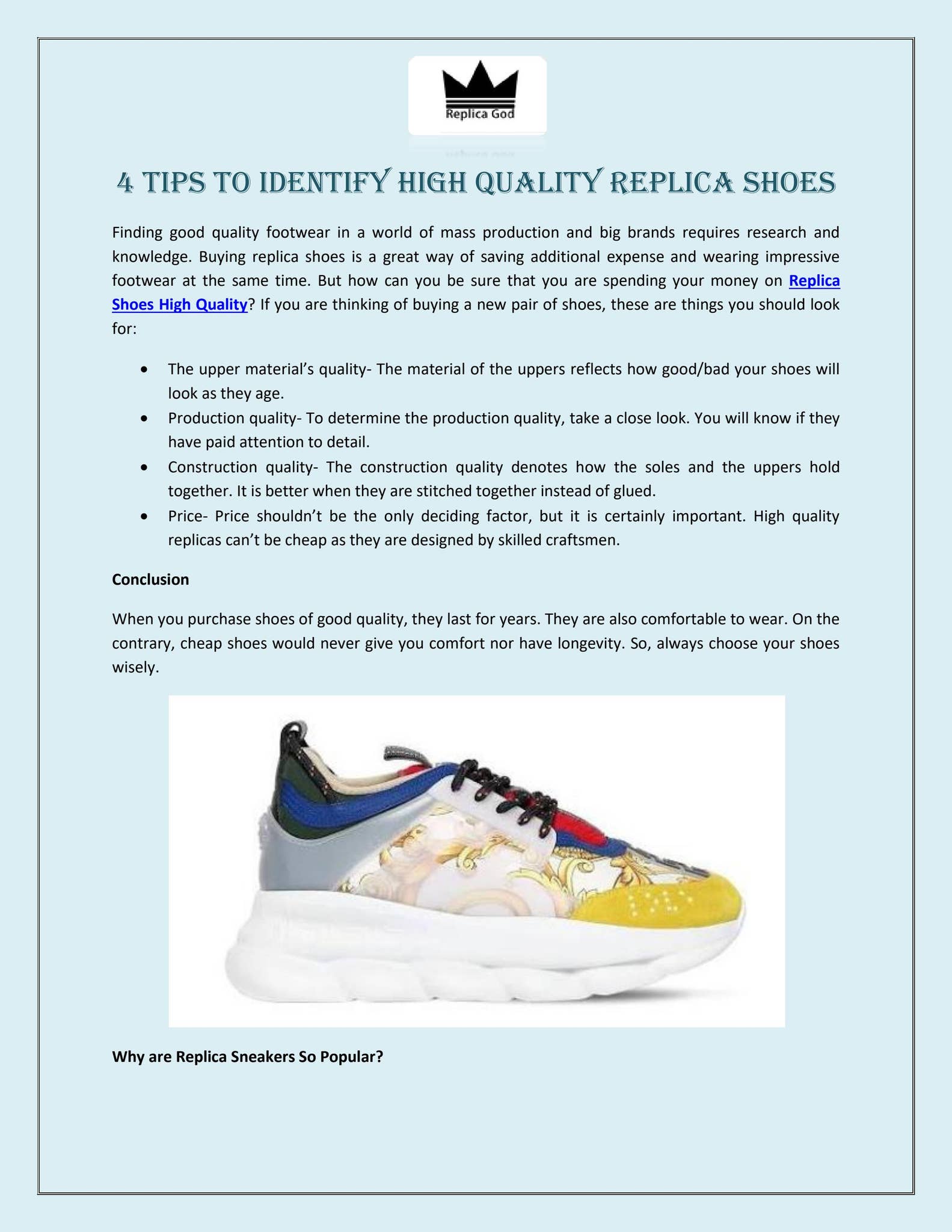

What Are the Key Characteristics of Replica Sneakers?

Replica sneakers are designed to mirror the aesthetics of high-end athletic footwear, often incorporating distinctive elements like colorways and branding. Typically used in retail environments, these shoes cater to a broad audience seeking fashionable yet affordable options. B2B buyers should consider sourcing from reputable manufacturers to ensure product quality, as variations in craftsmanship can impact customer satisfaction and brand reputation.

How Do Custom Replica Footwear Options Work?

Custom replica footwear allows businesses to offer personalized shoe designs, accommodating specific customer preferences in materials and features. This type of footwear is particularly suited for custom shoe shops and online retailers looking to differentiate themselves in a competitive market. Buyers should focus on suppliers who provide reliable customization options and quick turnaround times to meet consumer demands effectively.

What Makes Fashion Replica Boots a Popular Choice?

Fashion replica boots replicate the style of designer footwear, often featuring various heel heights and materials. These boots appeal to retailers looking to attract fashion-conscious consumers, especially during peak seasons. When purchasing, B2B buyers should evaluate the durability and comfort of the boots, as these factors significantly influence repeat purchases and customer loyalty.

Why Are Replica Casual Shoes in High Demand?

Replica casual shoes are designed for everyday wear and often imitate popular brands at lower price points. They are commonly found in mass-market retail environments and are favored by budget-conscious consumers. For B2B buyers, the focus should be on understanding market trends and consumer preferences to ensure the right inventory mix, as these shoes can have a high turnover rate.

How Do Designer-Inspired Sandals Appeal to Seasonal Retail?

Designer-inspired sandals capture current fashion trends, making them a seasonal staple for retailers. These sandals are often marketed during warmer months and can be sold at both online and brick-and-mortar stores. B2B buyers should consider the seasonality of these products and plan their inventory accordingly to maximize sales opportunities, keeping in mind that trends can shift rapidly.

Key Industrial Applications of replica footwear

| Industry/Sector | Specific Application of replica footwear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Offering replica footwear in retail stores | Expands product range while maintaining affordability | Quality assurance, brand alignment, and pricing strategy |

| Sports and Leisure | Replica athletic shoes for training and casual wear | Attracts budget-conscious customers without sacrificing style | Material durability, design accuracy, and comfort |

| Film and Theatre | Costume design incorporating replica footwear | Enhances authenticity of character portrayal | Customization options, historical accuracy, and sizes |

| Event Management | Bulk procurement for promotional events | Cost-effective solution for branded merchandise | Lead times, customization capabilities, and logistics |

| E-commerce Platforms | Online sales of replica footwear | Captures a wider audience through digital channels | SEO optimization, payment processing, and shipping logistics |

How is Replica Footwear Used in Fashion Retail?

In the fashion retail sector, replica footwear serves as an accessible alternative to high-end designer brands. Retailers can offer these products at a lower price point, thus appealing to a broader customer base, especially in regions like Africa and South America, where luxury items may be less attainable. Buyers in this industry must focus on quality assurance to ensure that the replicas meet consumer expectations, while also considering brand alignment to maintain store reputation.

What Role Does Replica Footwear Play in Sports and Leisure?

In the sports and leisure industry, replica athletic shoes are often marketed for training and casual wear, providing a stylish yet affordable option for customers. This approach allows brands to attract budget-conscious consumers who desire the latest trends without the hefty price tag. Buyers should prioritize material durability and design accuracy to ensure customer satisfaction, as well as comfort features that enhance performance during physical activities.

How is Replica Footwear Utilized in Film and Theatre?

Costume designers in the film and theatre industries frequently incorporate replica footwear to enhance the authenticity of character portrayals. By using replicas that accurately reflect specific styles or historical periods, productions can achieve a more believable visual narrative. Buyers in this sector should emphasize customization options, such as unique designs or sizes, to meet specific character requirements and ensure a seamless integration into the overall costume design.

Why is Replica Footwear Important for Event Management?

Event management companies often procure replica footwear in bulk for promotional events, trade shows, or corporate gatherings. This approach provides a cost-effective solution for creating branded merchandise that attendees can use and remember. When sourcing for these applications, considerations such as lead times, customization capabilities, and logistics become critical to ensure timely delivery and brand consistency.

How Can E-commerce Platforms Benefit from Selling Replica Footwear?

E-commerce platforms can significantly benefit from selling replica footwear by capturing a wider audience through digital channels. The online marketplace allows for easy access to diverse styles and price points, appealing to consumers looking for budget-friendly options. Buyers must focus on SEO optimization to drive traffic to their listings, as well as efficient payment processing and shipping logistics to enhance customer experience and satisfaction.

3 Common User Pain Points for ‘replica footwear’ & Their Solutions

Scenario 1: Sizing Issues with Replica Footwear Orders

The Problem: One of the most common challenges B2B buyers face when dealing with replica footwear is inconsistent sizing. Sizing standards can vary significantly between manufacturers and even within the same brand, leading to confusion and potential returns. For buyers in markets like Africa and South America, where footwear sizes may differ from European or American standards, this inconsistency can result in excess inventory, lost sales opportunities, and dissatisfied customers.

The Solution: To mitigate sizing issues, B2B buyers should implement a robust sizing guide that includes detailed measurements for each replica footwear style. Collaborate with manufacturers to standardize sizing charts based on international standards, and ensure that all products come with clear labels indicating their size in both local and international metrics. Additionally, consider offering a sample program where buyers can order a limited range of sizes for testing before committing to larger quantities. This proactive approach allows for better inventory management and increases customer satisfaction by reducing the risk of returns due to sizing errors.

Scenario 2: Quality Assurance Concerns with Replica Footwear

The Problem: Quality assurance is a critical concern for B2B buyers in the replica footwear market. Many buyers may encounter subpar products that do not meet their standards or the expectations of their end customers. Issues can include poor stitching, inferior materials, and overall craftsmanship that undermines brand reputation. This is particularly pertinent in regions where brand loyalty and quality perception are paramount, leading to potential financial losses and damage to business relationships.

The Solution: Establish a comprehensive quality control process that involves direct communication with manufacturers. Buyers should request detailed samples before placing bulk orders and conduct thorough inspections upon receiving shipments. It’s also beneficial to develop a checklist of quality criteria tailored to the specific styles of replica footwear being sourced. Incorporate regular factory audits and consider partnering with third-party inspection services to ensure that quality standards are consistently met. By prioritizing quality assurance, buyers can build trust with their customers and enhance their market positioning.

Scenario 3: Navigating Legal and Ethical Implications of Selling Replica Footwear

The Problem: B2B buyers in the replica footwear industry often face legal and ethical dilemmas regarding the sale of replica products. The line between replicas and counterfeit goods can be thin, and operating in regions with strict intellectual property laws can pose significant risks. Buyers may find themselves in legal disputes, leading to penalties, product seizures, and reputational damage.

The Solution: To navigate these complexities, it is vital for B2B buyers to fully understand the legal frameworks governing replica footwear in their target markets. This involves consulting with legal experts to establish clear guidelines for sourcing and selling replica products. Buyers should ensure that all replica footwear is marketed transparently, clearly distinguishing them from authentic brands. Furthermore, consider sourcing from manufacturers who provide proof of legal compliance, such as licenses to produce replicas. By being proactive in legal compliance and ethical sourcing, businesses can mitigate risks and position themselves as responsible market players, fostering trust with their customers and partners.

Strategic Material Selection Guide for replica footwear

When selecting materials for replica footwear, understanding the properties, advantages, and limitations of various materials is crucial for B2B buyers. This guide analyzes four common materials used in the production of replica footwear, focusing on their performance characteristics, manufacturing complexities, and compliance considerations relevant to international markets.

What are the Key Properties of Leather in Replica Footwear?

Leather is a traditional material in footwear manufacturing, known for its durability and aesthetic appeal. It offers excellent breathability, flexibility, and comfort, making it a preferred choice for high-quality replica sneakers. Leather can withstand a range of temperatures and pressures, providing a good balance between comfort and structural integrity.

Pros: Leather is highly durable and can last for years with proper care. It also provides a premium look and feel, appealing to consumers seeking luxury replicas.

Cons: The cost of high-quality leather can be significant, impacting the overall price point of the footwear. Additionally, leather requires careful handling and maintenance, which can complicate manufacturing processes.

For international buyers, especially in regions like Africa and South America, sourcing ethically produced leather that complies with local and international standards (such as ASTM) is essential.

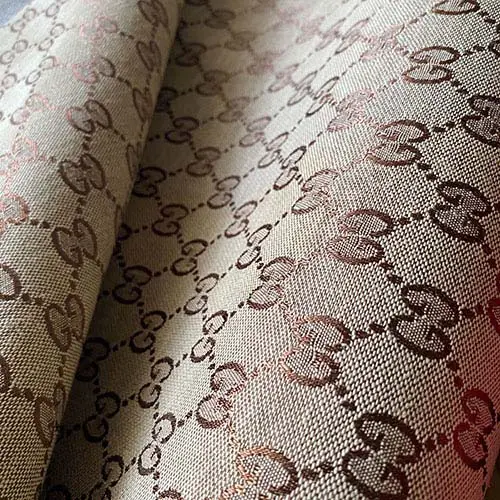

How Does Synthetic Leather Compare for Replica Footwear?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is a popular alternative to natural leather. It mimics the appearance and feel of leather while offering water resistance and easier maintenance.

Pros: Synthetic leather is generally more affordable than natural leather and can be produced in a variety of colors and textures. It is also easier to clean and maintain, making it suitable for casual wear.

Cons: While durable, synthetic leather may not provide the same level of breathability as natural leather, potentially affecting comfort over extended wear. Additionally, it may not appeal to consumers seeking authentic luxury products.

Illustrative image related to replica footwear

For B2B buyers, understanding the environmental impact of synthetic materials is crucial, especially in regions with strict sustainability regulations. Compliance with standards such as REACH in Europe can also influence purchasing decisions.

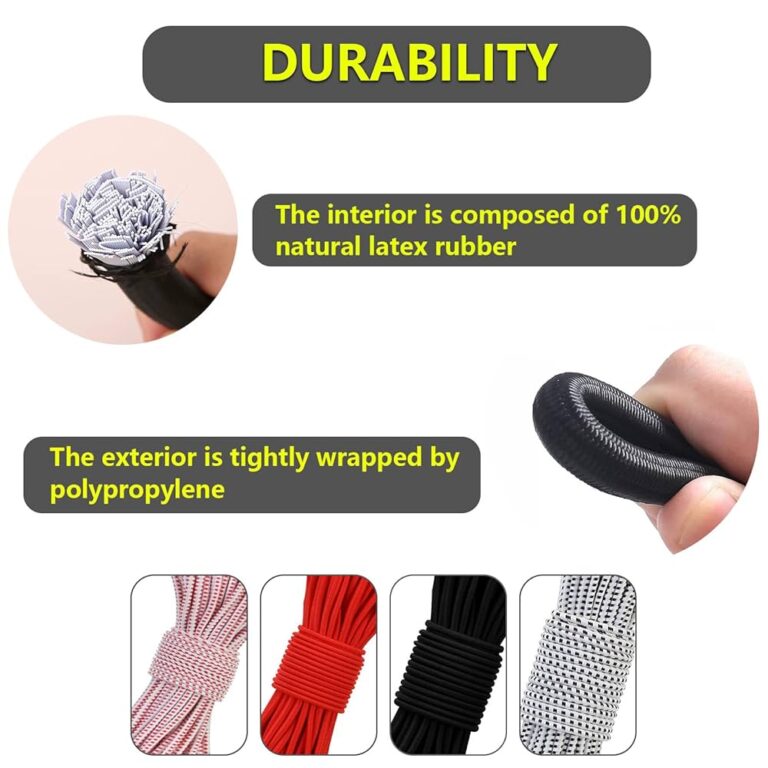

What Role Does Rubber Play in Replica Footwear Production?

Rubber is commonly used for outsoles due to its excellent grip, flexibility, and shock absorption properties. It is particularly effective in providing traction on various surfaces, making it a practical choice for sports and casual footwear.

Pros: Rubber is highly durable and resistant to wear and tear, which enhances the longevity of the footwear. It also offers good insulation against temperature changes.

Cons: The manufacturing process for rubber can be complex, involving multiple steps to ensure quality and performance. Additionally, high-quality rubber can increase production costs.

For international buyers, especially in the Middle East, where extreme temperatures can affect material performance, selecting rubber that meets specific temperature ratings is essential. Compliance with local safety standards can also impact marketability.

How Does Textile Material Influence Replica Footwear Design?

Textiles, including mesh and canvas, are increasingly used in the production of replica footwear for their lightweight and breathable characteristics. They are often utilized in the upper parts of sneakers, providing comfort and style.

Pros: Textiles are generally lightweight and can offer a wide range of designs and colors, appealing to fashion-forward consumers. They are also typically less expensive than leather.

Cons: The durability of textile materials can vary, and they may not provide the same level of support and protection as leather or rubber. Additionally, textiles may require special treatments to improve water resistance.

Illustrative image related to replica footwear

For B2B buyers in Europe, understanding the textile regulations, such as those regarding flame retardancy and chemical treatments, is crucial. Ensuring that textiles meet compliance standards can enhance product credibility in the market.

| Material | Typical Use Case for replica footwear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Uppers and linings | Durable and premium aesthetic | High cost and maintenance complexity | High |

| Synthetic Leather | Uppers and linings | Affordable and easy to maintain | Less breathable than natural leather | Medium |

| Rubber | Outsoles | Excellent grip and shock absorption | Complex manufacturing process | Medium |

| Textile | Uppers and linings | Lightweight and versatile | Varies in durability | Low |

This strategic material selection guide provides B2B buyers with insights into the properties and considerations of various materials used in replica footwear. Understanding these aspects can help in making informed purchasing decisions that align with market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for replica footwear

What Are the Main Stages in the Manufacturing Process of Replica Footwear?

The manufacturing process of replica footwear involves several critical stages, each contributing to the final product’s quality and appeal.

Illustrative image related to replica footwear

Material Preparation

The foundation of any footwear begins with material selection. For replica shoes, manufacturers typically use synthetic materials and lower-cost alternatives to premium leathers. Common materials include polyurethane, rubber, and textile blends that mimic the look and feel of high-end brands. During this stage, materials are sourced from suppliers who meet specific quality criteria, ensuring consistency in production.

Once materials are acquired, they undergo pre-treatment processes such as cleaning, dyeing, and cutting. This step is crucial for ensuring that the materials meet design specifications and quality standards before moving on to the next phase.

Forming the Footwear

After the materials are prepared, the forming process begins. This involves shaping the footwear components, such as the upper, lining, and sole. Advanced machinery, like computer-controlled cutting machines, is often employed to ensure precision in cutting and shaping.

Key techniques include:

- Stitching: Using industrial sewing machines to join various parts of the footwear, ensuring durability and strength.

- Molding: Using heat and pressure to shape soles, ensuring they fit seamlessly with the upper parts of the shoe.

- Lasting: Attaching the upper to the sole using a last, a mold that gives the shoe its final shape.

This stage is critical, as it directly influences the fit and comfort of the final product.

Assembly of the Footwear

The assembly stage sees all components brought together. This includes attaching the upper to the sole, adding insoles, and securing any additional features such as eyelets or decorative elements. Quality control measures are essential during this phase to catch any defects that may arise from improper assembly techniques.

Different assembly techniques can be employed, including:

- Cementing: Using adhesives to bond the sole to the upper.

- Goodyear Welting: A more traditional method where the upper is stitched to a welt, providing enhanced durability.

Each technique has its advantages, and the choice often depends on the desired quality and price point of the replica footwear.

Finishing Touches

Finishing involves adding final details to the footwear, such as polishing, branding, and packaging. The finishing stage can significantly impact the perceived quality of the shoes, as it is the last chance to make an impression on the buyer.

Quality assurance measures at this stage include checking for color consistency, the alignment of logos, and overall aesthetics.

Illustrative image related to replica footwear

How is Quality Assurance Implemented in Replica Footwear Manufacturing?

Quality assurance (QA) is crucial in ensuring that replica footwear meets international standards and customer expectations.

What International Standards Apply to Replica Footwear?

For B2B buyers, understanding the applicable international standards is essential. The most relevant standards include:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- ASTM Standards: In the U.S., various ASTM standards apply to footwear, covering aspects like performance and safety.

Understanding these standards helps B2B buyers assess the credibility and reliability of potential suppliers.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated at various stages of the manufacturing process to ensure product quality. Common checkpoints include:

- Incoming Quality Control (IQC): Conducted on raw materials upon arrival, ensuring they meet specified quality standards before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A comprehensive check once production is complete, assessing overall quality and compliance with standards.

Implementing these checkpoints allows manufacturers to maintain high-quality standards and reduce defects.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of suppliers. Here are some actionable strategies:

Conducting Supplier Audits

Buyers should consider conducting regular audits of suppliers’ facilities. This involves assessing the manufacturing processes, quality control systems, and compliance with international standards. Audits can be performed by the buyers themselves or through third-party inspection services.

Requesting Quality Reports

Suppliers should provide detailed quality reports documenting their QC processes, test results, and any certifications obtained. This transparency allows buyers to make informed decisions based on the supplier’s commitment to quality.

Engaging Third-Party Inspection Services

For added assurance, buyers can engage third-party inspection services that specialize in footwear manufacturing. These services can conduct independent audits and tests, providing an objective assessment of the supplier’s quality control measures.

Illustrative image related to replica footwear

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several nuances exist in quality control processes:

- Cultural Considerations: Different regions may have varying expectations for quality and standards. Buyers should be aware of these differences and communicate their requirements clearly.

- Logistics and Compliance: Import regulations can vary widely, impacting the quality standards that suppliers must meet. Buyers should ensure that their suppliers are compliant with both local and international regulations.

- Language Barriers: Communication can be a challenge when dealing with international suppliers. It’s crucial to ensure that all quality documentation is available in a language understood by all parties involved.

Conclusion

Understanding the manufacturing processes and quality assurance for replica footwear is vital for B2B buyers. By grasping the intricacies of material preparation, forming, assembly, and finishing, along with the implementation of international quality standards, buyers can make informed decisions. Moreover, verifying suppliers through audits, reports, and third-party inspections ensures that the products meet the desired quality benchmarks. By navigating these complexities, international buyers can successfully source high-quality replica footwear that meets their market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘replica footwear’

When sourcing replica footwear, especially in international markets, a structured approach is essential. This guide offers a step-by-step checklist to help B2B buyers navigate the complexities of procurement, ensuring they secure quality products that meet their business needs.

Step 1: Identify Market Demand

Understanding the specific needs of your target market is crucial. Analyze trends in replica footwear within your region, focusing on popular styles, colors, and sizes. This insight will guide your purchasing decisions and help you stock items that are more likely to sell.

- Research Competitors: Look at what similar businesses are offering to identify gaps or opportunities.

- Customer Preferences: Gather feedback from your customer base to understand their preferences and expectations.

Step 2: Define Your Technical Specifications

Clearly outlining what you need in terms of design, materials, and quality standards is vital. This includes specifications like size ranges, color options, and any unique features that differentiate your product offering.

- Quality Standards: Specify the level of quality you expect, including material types (e.g., leather, synthetic) and construction methods.

- Compliance Requirements: Ensure your specifications adhere to any local regulations regarding footwear manufacturing and safety.

Step 3: Research and Evaluate Potential Suppliers

Vetting suppliers is a critical step to ensure you partner with reputable manufacturers. Investigate their background, production capabilities, and past performance.

- Request Documentation: Ask for company profiles, certifications, and references from previous clients.

- Production Capacity: Confirm that the supplier can meet your volume requirements without compromising quality.

Step 4: Assess Sample Products

Before placing a bulk order, always request samples of the footwear you intend to purchase. This allows you to evaluate the quality and craftsmanship firsthand.

- Quality Check: Inspect the materials, stitching, and overall construction of the samples.

- Fit and Comfort: Ensure that the footwear meets the expected comfort levels and fits standard sizing.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, negotiate the terms of your agreement, including pricing, payment terms, and delivery schedules.

- Bulk Discounts: Inquire about pricing tiers for larger orders to maximize your margins.

- Payment Terms: Establish clear payment methods and timelines that suit your cash flow needs.

Step 6: Finalize Logistics and Delivery

Plan the logistics of your order, including shipping methods and timelines. Make sure you understand the import regulations and duties applicable in your country.

- Shipping Options: Compare costs and delivery times between different shipping methods (air, sea, land).

- Customs Regulations: Ensure compliance with local import laws to avoid potential delays or fines.

Step 7: Implement Quality Control Measures

Once the footwear arrives, implement quality control processes to ensure that the products meet your established standards before they reach customers.

- Inspection Protocols: Develop a checklist for inspecting the quality and quantity of the received goods.

- Feedback Loop: Establish a system for gathering feedback from your customers to continuously improve your offerings.

By following these steps, B2B buyers can confidently navigate the sourcing process for replica footwear, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for replica footwear Sourcing

What Are the Key Cost Components in Replica Footwear Sourcing?

When sourcing replica footwear, understanding the cost structure is essential for effective budgeting and pricing strategy. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality synthetic leathers or textiles are often used to replicate the look and feel of genuine products. Depending on the supplier, the cost of materials can vary widely based on their source and quality.

-

Labor: Labor costs can differ based on the manufacturing location. For instance, countries with lower labor costs, such as some regions in Asia, may offer a more competitive pricing structure. However, the skill level required for producing high-quality replicas may necessitate higher wages.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, rent, and equipment maintenance. It’s essential to factor in these costs when calculating the total price of the footwear.

-

Tooling: The initial investment in molds and tools for production can be significant, especially for custom designs. This cost is typically amortized over the production run, making it crucial to consider the minimum order quantity (MOQ) when sourcing.

-

Quality Control (QC): Ensuring the replicas meet quality standards requires a dedicated QC process, which adds to the overall cost. Investing in stringent QC can reduce returns and increase customer satisfaction.

-

Logistics: Shipping and handling costs vary based on the Incoterms agreed upon and the distance from the manufacturer to the buyer. Efficient logistics management can help minimize these expenses.

-

Margin: Suppliers will add a markup to cover their operational costs and profit. Understanding the expected margins can aid in negotiations and pricing strategies.

How Do Price Influencers Affect Replica Footwear Costs?

Several factors can influence the pricing of replica footwear, including volume, specifications, material quality, and supplier conditions.

Illustrative image related to replica footwear

-

Volume/MOQ: Purchasing in larger quantities typically leads to lower unit costs. Buyers should negotiate MOQs that align with their sales forecasts to optimize costs.

-

Specifications and Customization: Custom designs or unique specifications will increase costs due to additional tooling and labor requirements. Clear communication of design needs can help manage these costs.

-

Materials and Certifications: The choice of materials and any required certifications (such as eco-friendly or safety standards) can substantially influence pricing. Buyers should consider the balance between quality and cost.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge a premium for their experience and quality assurance, while newer suppliers might offer lower prices to attract business.

-

Incoterms: Understanding the agreed-upon Incoterms can clarify responsibilities for shipping, insurance, and tariffs, affecting the overall cost structure.

What Are the Best Tips for B2B Buyers in Replica Footwear?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, implementing strategic sourcing practices can lead to significant cost savings.

-

Negotiation: Always negotiate pricing, terms, and conditions. Suppliers may have flexibility in pricing, especially for bulk orders or long-term contracts.

-

Cost Efficiency: Assess the Total Cost of Ownership (TCO), which includes not only the purchase price but also logistics, storage, and potential returns. This holistic view can uncover hidden costs.

-

Pricing Nuances: Be aware of regional pricing differences and market dynamics. For instance, buyers in emerging markets may experience different price sensitivities compared to those in developed regions.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority during production, and improved communication regarding quality and delivery timelines.

Disclaimer on Indicative Prices

Prices for replica footwear can vary widely based on the factors discussed above. It is advisable to obtain multiple quotes and conduct thorough market research before finalizing any agreements. Always consider fluctuations in materials and labor costs when planning your sourcing strategy.

Alternatives Analysis: Comparing replica footwear With Other Solutions

Understanding the Alternatives to Replica Footwear

When considering footwear options, replica footwear serves as a popular choice for buyers looking for stylish designs without the hefty price tag associated with luxury brands. However, it’s essential to evaluate other viable alternatives that may fulfill similar needs while offering distinct advantages. This analysis aims to compare replica footwear against custom-made shoes and branded discount footwear, providing insights for B2B buyers in diverse markets.

Comparison Table

| Comparison Aspect | Replica Footwear | Custom-Made Shoes | Branded Discount Footwear |

|---|---|---|---|

| Performance | Good quality, design fidelity | Excellent fit and customization | Variable quality, brand-dependent |

| Cost | Moderate pricing ($750 – $1,120) | Higher cost ($200 – $1,500) | Lower cost (typically $30 – $150) |

| Ease of Implementation | Readily available online | Requires consultation and lead time | Widely available in stores and online |

| Maintenance | Low maintenance | Varies based on materials used | Generally low maintenance |

| Best Use Case | Fashion-forward consumers | Individuals needing custom fit | Budget-conscious buyers seeking style |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Custom-Made Shoes?

Custom-made shoes offer a personalized experience tailored to the buyer’s specific requirements, including size, style, and materials. The primary advantage is the perfect fit, which can significantly enhance comfort and reduce foot-related issues. However, the downside is the higher price point and longer lead times associated with the customization process. For B2B buyers targeting niche markets, such as orthopedic footwear or luxury custom designs, this option can be appealing despite the cost.

How Does Branded Discount Footwear Compare?

Branded discount footwear represents a cost-effective solution for buyers who prioritize brand recognition and affordability. These shoes are often made by reputable brands that provide a certain level of quality assurance. However, the variability in quality can be a concern, and the styles may not always reflect the latest fashion trends. For B2B buyers in regions where budget constraints are paramount, branded discount footwear can be an attractive alternative that still offers a degree of brand prestige.

Illustrative image related to replica footwear

Conclusion: How to Choose the Right Footwear Solution

Selecting the appropriate footwear solution ultimately depends on the specific needs and goals of the buyer. Replica footwear is ideal for businesses targeting style-savvy consumers who want the latest trends without overspending. Custom-made shoes cater to a niche market that values fit and personalization, while branded discount footwear appeals to budget-conscious buyers seeking reliable quality. By assessing performance, cost, ease of implementation, and maintenance needs, B2B buyers can make informed decisions that align with their market strategy and customer preferences.

Essential Technical Properties and Trade Terminology for replica footwear

What Are the Essential Technical Properties of Replica Footwear?

When considering replica footwear, several technical properties are crucial for ensuring quality and meeting market demands. Understanding these specifications not only aids in product selection but also enhances negotiation and purchasing strategies.

1. Material Grade

Material grade refers to the quality and type of materials used in the construction of replica footwear. Common materials include synthetic leather, canvas, and rubber. Higher-grade materials typically offer better durability, comfort, and aesthetic appeal. For B2B buyers, selecting the right material grade is essential to meet customer expectations and ensure long-term wear.

2. Tolerance Levels

Tolerance levels indicate the acceptable variation in dimensions during manufacturing. For instance, a tolerance of ±0.5mm in shoe length ensures that sizes fit correctly. Tighter tolerances generally equate to higher quality, as they minimize defects. Understanding tolerance is vital for buyers to ensure that the final products meet the required standards and fit specifications.

Illustrative image related to replica footwear

3. Size Range

The size range available for replica footwear often spans various metrics, including European, American, and Asian sizing systems. Offering a comprehensive size range is crucial for capturing a broader market share, especially in diverse regions like Africa and South America. B2B buyers should prioritize suppliers who provide extensive size options to meet local demands.

4. Weight Specifications

Weight specifications relate to the heaviness of the footwear, affecting comfort and wearability. Lighter shoes are generally preferred for casual wear, while heavier options may be more suitable for specific sports or work environments. Buyers need to assess weight specifications to ensure the footwear aligns with the intended use and target audience.

5. Construction Techniques

The methods used in constructing replica footwear, such as stitching, bonding, or molding, significantly impact durability and performance. For example, reinforced stitching can enhance longevity, while glued soles may be more cost-effective but less durable. Understanding construction techniques enables buyers to evaluate the overall quality and value of the footwear.

What Are Common Trade Terms Used in the Replica Footwear Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the replica footwear market. Here are several key terms that B2B buyers should know:

Illustrative image related to replica footwear

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of replica footwear, an OEM might create shoes that are branded under different names. Understanding OEM relationships can help buyers identify potential partners and negotiate better pricing and quality standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it impacts inventory management and financial planning. Knowing the MOQ helps buyers assess whether a supplier can meet their needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. This process is vital for ensuring competitive pricing and assessing multiple suppliers before making purchasing decisions. Effective RFQs can lead to better deals and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are predefined international shipping terms that clarify the responsibilities of buyers and sellers. They dictate who pays for shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to avoid unexpected costs and ensure smooth logistics when importing replica footwear from various regions.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for each distinct product and service that can be purchased. It is essential for inventory management and sales tracking. Buyers should familiarize themselves with SKUs to streamline order processing and ensure accurate inventory levels.

Illustrative image related to replica footwear

By mastering these technical properties and trade terms, B2B buyers can make informed decisions, enhance their purchasing strategies, and ultimately drive success in the replica footwear market.

Navigating Market Dynamics and Sourcing Trends in the replica footwear Sector

What Are the Key Trends Driving the Replica Footwear Market?

The replica footwear sector is experiencing significant growth, driven by several global factors. The increasing demand for affordable luxury items in markets like Africa, South America, the Middle East, and Europe is reshaping consumer preferences. B2B buyers are particularly interested in sourcing products that mimic high-end designs without the hefty price tags. This trend is bolstered by the rise of e-commerce platforms that facilitate easy access to international markets, enabling businesses to meet consumer demands swiftly.

Technological advancements are also influencing sourcing trends. Innovations such as 3D printing and customization capabilities allow manufacturers to create replicas that cater to specific consumer preferences, enhancing product appeal. Moreover, data analytics tools are being utilized to track consumer behavior and optimize inventory management, ensuring that businesses can respond to market fluctuations effectively.

Additionally, the replica footwear market is witnessing a shift toward greater inclusivity in sizing and styles. With brands offering a wider range of sizes and customization options, B2B buyers can cater to diverse consumer bases, particularly in regions with varying body types and fashion preferences. Overall, understanding these market dynamics is crucial for international B2B buyers looking to capitalize on the burgeoning demand for replica footwear.

How Is Sustainability Impacting the Sourcing of Replica Footwear?

As the global focus on sustainability intensifies, B2B buyers in the replica footwear sector must consider the environmental impact of their sourcing decisions. The production of replica footwear often involves materials that may not meet eco-friendly standards, raising concerns about waste and pollution. Therefore, sourcing from suppliers that prioritize sustainable practices is becoming increasingly important.

Illustrative image related to replica footwear

Ethical supply chains are also gaining traction among consumers who are more informed and concerned about the origins of their products. B2B buyers should seek partnerships with manufacturers that use sustainable materials, such as recycled plastics or organic fabrics, and that comply with labor rights and safety standards. Certifications such as Global Organic Textile Standard (GOTS) or the Forest Stewardship Council (FSC) can serve as indicators of a supplier’s commitment to sustainability.

Implementing sustainable sourcing practices not only addresses environmental concerns but also enhances brand reputation and customer loyalty. As consumers are more likely to support brands with ethical practices, B2B buyers who prioritize sustainability will be better positioned to meet the expectations of their clients and consumers.

What Is the Historical Context of the Replica Footwear Market?

The replica footwear market has evolved significantly over the past few decades. Initially, replicas were largely viewed as low-quality imitations, often associated with illegal counterfeiting. However, as consumer attitudes shifted towards value and accessibility, the perception of replica footwear began to change. Brands started to recognize the potential of this market segment, leading to the emergence of high-quality replicas that closely mimic the designs of luxury footwear.

This evolution has been supported by advancements in manufacturing techniques, allowing for greater accuracy in design and materials. Today, the replica footwear market not only caters to cost-conscious consumers but also appeals to a growing audience that appreciates the artistry and design of high-end shoes without the associated costs. This historical context is essential for B2B buyers to understand as they navigate sourcing decisions in a market that continues to grow and evolve.

Frequently Asked Questions (FAQs) for B2B Buyers of replica footwear

-

How do I ensure the quality of replica footwear when sourcing internationally?

To ensure the quality of replica footwear, conduct thorough supplier vetting by requesting samples and assessing their production standards. Look for suppliers with a proven track record in the industry, ideally those who have worked with international brands. Additionally, consider third-party quality assurance services to inspect products before shipment. Establish clear quality benchmarks and specifications in your contracts to hold suppliers accountable for meeting your standards. -

What are the key factors to consider when choosing a supplier for replica footwear?

When choosing a supplier for replica footwear, consider their experience, reputation, and compliance with international standards. Evaluate their production capabilities, including technology and labor practices, to ensure they can meet your demand. It’s essential to verify their ability to customize products according to your specifications, including size, color, and design. Additionally, assess their communication responsiveness and willingness to accommodate your needs. -

What is the minimum order quantity (MOQ) for replica footwear suppliers?

Minimum order quantities (MOQ) for replica footwear can vary widely depending on the supplier and the complexity of the designs. Typically, MOQs range from 50 to 500 pairs per style. It’s advisable to discuss MOQs upfront to avoid surprises. Some suppliers may offer lower MOQs for established relationships or repeat orders, so negotiating based on your business needs can yield better terms. -

What payment terms should I expect when sourcing replica footwear?

Payment terms for sourcing replica footwear often vary by supplier and can include options like upfront payments, letters of credit, or payment upon delivery. Commonly, suppliers may require a 30% deposit before production with the remaining balance due prior to shipping. It’s crucial to clarify these terms in advance and ensure they align with your cash flow needs. Additionally, explore options for payment protection to mitigate risks. -

How can I customize replica footwear to meet my brand’s specifications?

Customizing replica footwear involves collaborating closely with your supplier to define your specifications. Discuss options for materials, colors, sizes, and unique design elements that reflect your brand identity. Many suppliers offer customization services that can accommodate various styles, so be clear about your requirements. Request prototypes to evaluate the designs before final production to ensure they meet your expectations. -

What are the logistics considerations when importing replica footwear?

Logistics considerations for importing replica footwear include selecting reliable shipping methods, understanding customs regulations, and calculating shipping costs. Work with logistics providers experienced in international trade to streamline the process. Ensure all necessary documentation is prepared, such as invoices, packing lists, and any required certificates. Factor in potential delays and customs duties to avoid unexpected expenses. -

How do I handle returns or defective products from my replica footwear supplier?

Establish a clear return policy with your supplier before placing orders. This policy should outline the process for handling defective products, including timelines for reporting issues and the conditions under which returns are accepted. Document all communications regarding defects and keep records of the products in question. A supplier with a solid return policy will facilitate smoother resolutions, protecting your business interests. -

What regulatory considerations should I be aware of when importing replica footwear?

When importing replica footwear, be aware of intellectual property rights and trademark laws that may affect your ability to sell these products legally. Different regions have varying regulations regarding the sale of replica items, so it’s essential to conduct thorough research on the legal implications in your target markets. Consult with legal experts to ensure compliance with all applicable laws and regulations, minimizing the risk of disputes or penalties.

Top 6 Replica Footwear Manufacturers & Suppliers List

1. Maison Margiela – Replica Sneakers

Domain: maisonmargiela.com

Registered: 2008 (17 years)

Introduction: This company, Maison Margiela – Replica Sneakers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Replica Shoes – Key Product

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Key product details include: 1. Categories: Replica Shoes for Women, including various types such as athletic shoes, heels, comfort shoes, and more. 2. Sizes: Available in multiple US shoe sizes, including 6, 7, 8, 9, 10, and half sizes. 3. Colors: A wide range of colors including black, white, beige, blue, brown, gray, pink, yellow, and multicolor options. 4. Brands: Notable brands include Maison…

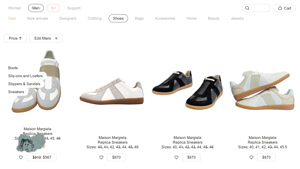

3. Maison Margiela – Replica Sneakers

Domain: sv77.com

Registered: 2011 (14 years)

Introduction: Maison Margiela Replica Sneakers

Sizes: 40, 41, 42, 43, 44, 45, 45.5, 46

Price: $810 (30% OFF) – Now $567

Price: $870 – Sizes available: 40, 41, 42, 43, 44, 45, 46

Price: $805 – Sizes available: 41, 42

Discounts: 30% OFF on select items

4. i The Label – Women’s Fashion Replica Shoes

Domain: ithelabel.com

Registered: 2017 (8 years)

Introduction: Women’s Fashion Replica Chloe Shoes | i The Label | Latest Street Fashion. Price: $249.00 for TVODA Suede And Leather Knee High Boots, $219.00 for LENCU Button Leather Ankle Boots, $229.00 for SVUTO Suede Ankle Boots, $199.00 for VEDFA Diamante Mid Heel Sandals – 7cm, $209.00 for VEDFA Diamante High Heel Sandals – 6.5cm, $209.00 for RAEFU Suede Slippers Slides. Sizes available range from US4 to US…

5. Etsy – Replica Shoes

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Replica Shoes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Sneaker Double – High-Quality Replica Shoes

Domain: sneakerdouble.net

Registered: 2022 (3 years)

Introduction: Sneaker Double Reps Shoes | Best Replica Shoes Website. High-quality replica sneakers at affordable prices. Number 1 rep sneaker site with over 280 5-star reviews. Easy ordering with secure payment options including Credit Card, Cashapp, Apple Cash, or Paypal. QC Photos provided before shipping. Express global shipping with tracking. Offers luxury brand sneakers including Dior, Balenciaga, Louis V…

Strategic Sourcing Conclusion and Outlook for replica footwear

In the rapidly evolving market of replica footwear, strategic sourcing is crucial for B2B buyers aiming to capitalize on consumer demand while navigating the complexities of international trade. Key takeaways emphasize the importance of selecting reliable suppliers who prioritize quality and compliance with local regulations. Buyers from regions such as Africa, South America, the Middle East, and Europe must also consider the diverse preferences of their target markets, ensuring that product offerings align with local tastes and trends.

Investing in strategic sourcing not only mitigates risks associated with counterfeit products but also enhances brand reputation and customer loyalty. By fostering strong relationships with manufacturers and leveraging technology for supply chain management, businesses can improve operational efficiency and responsiveness to market changes.

Looking ahead, the replica footwear market presents significant opportunities for growth. B2B buyers are encouraged to stay informed about emerging trends and consumer preferences, actively seeking partnerships that enable innovation and sustainability. As the market matures, those who embrace strategic sourcing will be well-positioned to thrive in this competitive landscape. Now is the time to evaluate your sourcing strategies and seize the opportunities ahead.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.