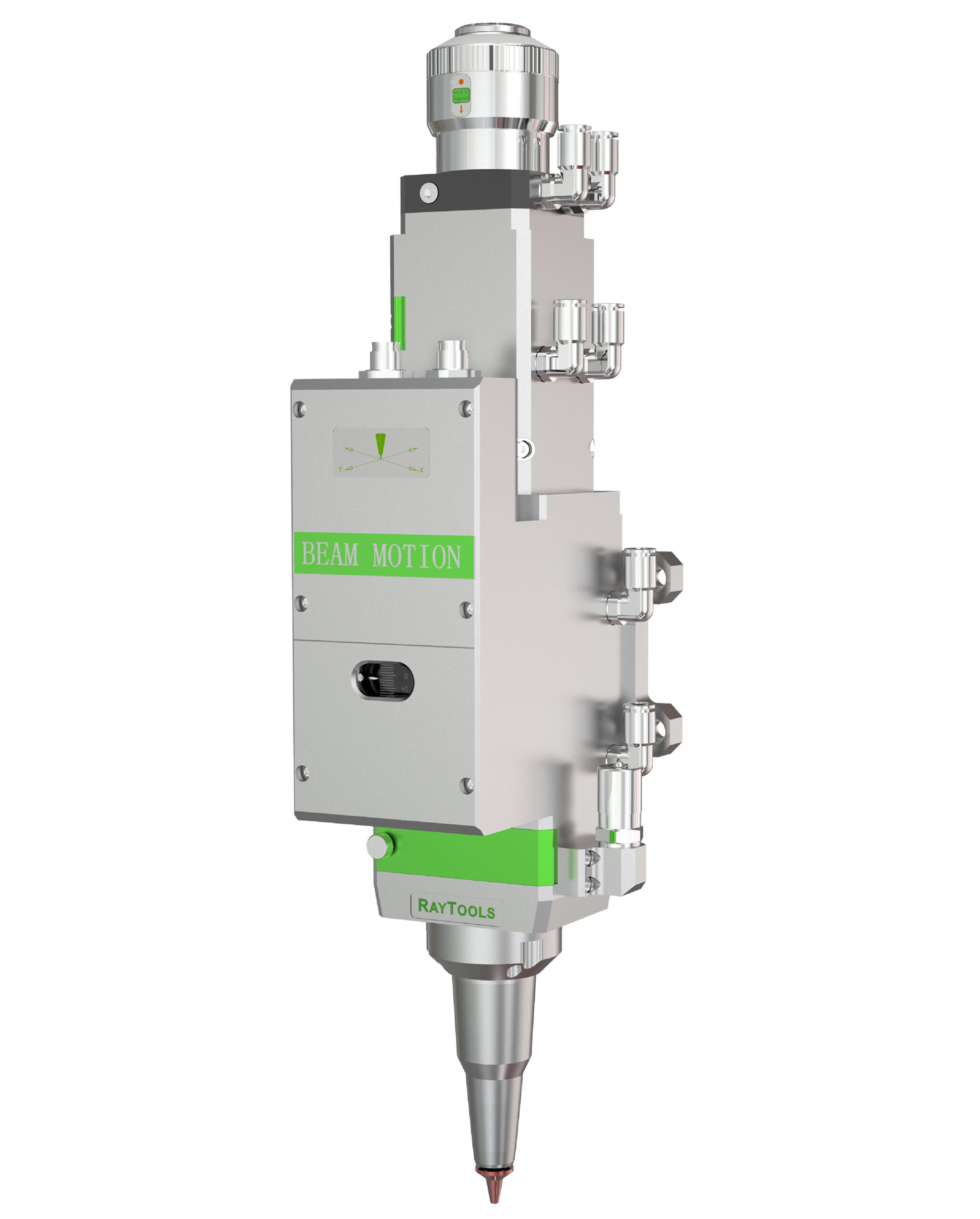

The Definitive Guide to Raytools Bm110保护镜组件: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for raytools bm110保护镜组件

In today’s fast-evolving industrial landscape, sourcing high-quality raytools bm110保护镜组件 poses a significant challenge for international B2B buyers. With the increasing demand for precision in laser cutting applications, companies across Africa, South America, the Middle East, and Europe, including Brazil and Vietnam, require reliable components that enhance operational efficiency. This comprehensive guide addresses the complexities of sourcing these protective mirror components, providing insights into their types, applications, and the critical factors for supplier vetting.

As the global market becomes more competitive, understanding the nuances of the raytools bm110保护镜组件 is essential for making informed purchasing decisions. This guide not only elaborates on the technical specifications and performance benefits of the BM110 series but also delves into cost considerations and potential suppliers across various regions. By equipping B2B buyers with actionable insights, this resource empowers them to navigate the intricacies of the procurement process, ensuring they select components that meet their specific operational needs while optimizing their investment.

Whether you are looking to enhance the performance of your laser cutting machinery or streamline your supply chain, this guide serves as an essential tool for buyers committed to quality and efficiency in their operations.

Understanding raytools bm110保护镜组件 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Protective Lens | Basic design, suitable for general laser cutting operations | General manufacturing, metal fabrication | Pros: Cost-effective, easy to replace Cons: Limited durability under high-intensity use |

| High-Temperature Resistant Lens | Enhanced durability, can withstand higher temperatures | Heavy industry, high-speed cutting applications | Pros: Longer lifespan, better performance Cons: Higher initial cost |

| Multi-Layer Coated Lens | Advanced coatings to minimize reflections and increase clarity | Precision cutting, intricate designs | Pros: Improved cutting quality, reduced glare Cons: More expensive, requires careful handling |

| Drawer-Style Lens Assembly | Quick replacement mechanism, user-friendly design | High-volume production environments | Pros: Fast maintenance, reduced downtime Cons: May require more frequent replacements |

| Ceramic Protective Lens | Made from durable ceramic materials, high resistance to wear | Aerospace, automotive industries | Pros: Superior protection, high thermal stability Cons: Fragile, risk of breakage under impact |

What Are the Characteristics of Each Type of Raytools BM110 Protective Lens?

Standard Protective Lens:

The standard protective lens serves as the baseline option for many businesses engaged in laser cutting. It is designed for general use and is suitable for a variety of materials. B2B buyers often find this lens appealing due to its cost-effectiveness and straightforward replacement process. However, it may not withstand extreme conditions, making it less suitable for high-intensity applications.

High-Temperature Resistant Lens:

This type of lens is engineered to endure elevated temperatures, making it ideal for heavy industrial applications where cutting speed and material thickness can generate significant heat. B2B buyers in sectors such as manufacturing and metal fabrication can benefit from its extended lifespan and reliability. The trade-off is a higher initial investment, which may deter some buyers.

Multi-Layer Coated Lens:

Featuring advanced optical coatings, the multi-layer coated lens reduces reflections and enhances clarity, crucial for precision cutting tasks. Industries requiring intricate designs, such as electronics and jewelry, would find this lens beneficial. While it offers superior performance, the increased cost and careful handling requirements may be a consideration for budget-conscious buyers.

Drawer-Style Lens Assembly:

This innovative design allows for quick and easy replacement of the protective lens, significantly minimizing downtime in high-volume production settings. B2B buyers in environments where efficiency is paramount will appreciate this feature. However, the need for more frequent lens replacements can be a downside, potentially increasing long-term costs.

Ceramic Protective Lens:

Constructed from robust ceramic materials, this lens provides exceptional wear resistance and thermal stability, making it a top choice for industries like aerospace and automotive. B2B buyers looking for long-term durability will find this lens advantageous. However, its fragility poses a risk of breakage, which could be a concern for operations with high physical handling.

Key Industrial Applications of raytools bm110保护镜组件

| Industry/Sector | Specific Application of raytools bm110保护镜组件 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Laser cutting of metal sheets and components | Enhanced cutting precision and reduced material waste | Compatibility with existing laser systems and local support |

| Automotive Manufacturing | Cutting and engraving of automotive parts | Improved production efficiency and part quality | Availability of spare parts and service support in the region |

| Electronics | Precision cutting of circuit boards | Increased accuracy and reduced production costs | Technical specifications and certification for electronic use |

| Aerospace | Fabrication of lightweight components | Weight reduction and improved fuel efficiency | Compliance with industry standards and quality assurance |

| Renewable Energy | Cutting of materials for solar panels | Cost-effective production and sustainability focus | Supplier reliability and delivery timelines for project needs |

How Is the Raytools BM110 Protection Mirror Component Used in Metal Fabrication?

In the metal fabrication industry, the Raytools BM110 protection mirror component is essential for enhancing the laser cutting process. This component protects the laser optics from contamination and damage, ensuring consistent cutting quality. By using this component, businesses can reduce downtime caused by maintenance or replacement of damaged optics. For international buyers, particularly in regions like Africa and South America, sourcing the BM110 requires consideration of compatibility with local laser systems and the availability of technical support.

What Are the Applications in Automotive Manufacturing?

The automotive manufacturing sector utilizes the Raytools BM110 protection mirror component for cutting and engraving various automotive parts. This component helps maintain the integrity of the laser system, leading to improved precision in part production. As a result, manufacturers can achieve tighter tolerances and better fit in assembled vehicles. Buyers from Europe and the Middle East should focus on sourcing components that meet stringent automotive quality standards and ensure timely delivery to meet production schedules.

How Does It Benefit the Electronics Industry?

In electronics, the Raytools BM110 protection mirror component is crucial for the precision cutting of circuit boards. The component safeguards the laser optics from debris and contaminants, which is vital for maintaining the high accuracy required in electronic applications. This leads to lower production costs and higher-quality products. International buyers must verify that the component meets specific technical requirements and has the necessary certifications for electronic manufacturing.

What Role Does It Play in Aerospace Fabrication?

The aerospace industry benefits significantly from the Raytools BM110 protection mirror component, particularly in the fabrication of lightweight components. By protecting the laser optics, this component ensures high-quality cuts that are essential for weight-sensitive applications. The result is improved fuel efficiency and performance in aerospace vehicles. Buyers should ensure that the sourcing of this component aligns with aerospace standards and includes robust quality assurance measures.

How Is It Used in Renewable Energy Applications?

In the renewable energy sector, particularly in the manufacturing of solar panels, the Raytools BM110 protection mirror component plays a vital role in cutting materials efficiently. The component protects the laser system, which is crucial for producing high-quality solar panels at a lower cost. Buyers in this sector, especially in developing regions, should prioritize suppliers that offer reliable delivery and support, ensuring that production timelines are met while maintaining sustainability goals.

3 Common User Pain Points for ‘raytools bm110保护镜组件’ & Their Solutions

Scenario 1: Difficulty in Protecting Critical Components During Operation

The Problem: Many B2B buyers struggle with maintaining the integrity of their laser cutting systems, particularly the critical components like the Raytools BM110 protective mirror assembly. Without proper protection, these components can suffer from contamination and damage due to debris and fumes generated during cutting processes. This leads to increased downtime, higher maintenance costs, and ultimately, reduced productivity. Buyers may also face challenges in identifying the right protective components that offer optimal durability and performance in their specific working environments.

The Solution: To mitigate this issue, it’s essential to invest in high-quality protective mirror assemblies that are specifically designed for the BM110 system. Buyers should ensure that they source original Raytools components, as these are engineered to meet the specific demands of laser cutting applications. Regularly inspect and replace protective mirrors as part of a proactive maintenance schedule, ideally every few weeks, depending on usage intensity. Implementing a routine cleaning protocol can also help maintain the efficiency of the protective mirrors, ensuring they remain clear of contaminants that could impair performance. Training staff on the importance of maintaining these components will foster a culture of care that extends the lifespan of both the mirrors and the laser cutting system.

Scenario 2: Challenges with Quick Replacement of Protective Components

The Problem: In high-volume production environments, the need for rapid replacement of worn or damaged components is critical. Buyers often find themselves facing significant delays when changing out the protective mirror assembly, which can lead to lost production time and increased operational costs. The complexity of the assembly process can deter operators from performing timely replacements, resulting in prolonged periods of compromised equipment performance.

The Solution: To streamline the replacement process, buyers should leverage the Raytools BM110’s drawer-style mirror holder design, which allows for quick and efficient changes. It is advisable to keep an inventory of replacement protective mirrors on hand to minimize downtime. Additionally, training operators on the specific steps for replacing the protective components can significantly enhance efficiency. Providing visual aids or step-by-step guides can further simplify the process, ensuring that replacements are done correctly and swiftly. Investing in a maintenance management system that tracks the usage and replacement schedules of these components can also improve overall operational efficiency.

Scenario 3: Incompatibility with Various Laser Systems

The Problem: International buyers may encounter challenges when attempting to integrate the Raytools BM110 protective mirror assembly with different laser cutting systems, especially when dealing with diverse brands and models. This incompatibility can lead to inefficiencies, as buyers may inadvertently purchase components that do not fit or perform optimally with their existing machinery. This issue is particularly pronounced in regions where laser technologies vary significantly across manufacturers.

The Solution: To address compatibility issues, buyers should thoroughly research the specifications of both their existing laser systems and the Raytools BM110 components. It is crucial to confirm that the protective mirror assembly is compatible with the specific laser interfaces, such as QBH or QD connectors. Collaborating with a knowledgeable supplier who can provide insights on compatibility can also be beneficial. Buyers should consider customizing their purchasing strategy to include consultation with technical experts from Raytools or authorized distributors who can assist in identifying the correct components. Furthermore, documenting the specifications of current systems can facilitate smoother future purchases and integrations, ensuring that all components work seamlessly together.

Strategic Material Selection Guide for raytools bm110保护镜组件

What Are the Key Materials for Raytools BM110 Protective Lens Components?

When selecting materials for the Raytools BM110 protective lens components, it is essential to consider their properties, advantages, and limitations. This analysis will focus on four common materials: Glass, Polycarbonate, Sapphire, and Quartz. Each material has unique characteristics that impact performance, durability, and suitability for various applications.

How Does Glass Perform in Raytools BM110 Protective Lens Components?

Key Properties: Glass is known for its excellent optical clarity and scratch resistance. It typically has a high-temperature rating and is chemically stable, making it resistant to various environmental factors.

Pros & Cons: Glass offers high durability and optical performance, but it can be brittle and prone to shattering upon impact. Its manufacturing process is relatively straightforward, but the cost can be higher than some alternatives, especially for specialty glasses.

Impact on Application: Glass is compatible with a wide range of media and environments, making it suitable for various industrial applications. However, its weight may be a concern in applications requiring lightweight components.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America may need to consider local availability and shipping logistics, as glass can be fragile during transport.

What Are the Advantages of Polycarbonate for Protective Lens Components?

Key Properties: Polycarbonate is a thermoplastic material known for its high impact resistance and lightweight nature. It can withstand high temperatures and has good optical clarity.

Pros & Cons: The primary advantage of polycarbonate is its durability and resistance to shattering, making it ideal for high-impact applications. However, it can be more susceptible to scratching compared to glass, and its optical clarity may not match that of higher-grade glass materials.

Impact on Application: Polycarbonate is suitable for environments where safety and weight are concerns, such as in mobile or portable laser cutting applications.

Considerations for International Buyers: Polycarbonate is often compliant with various international standards, making it a versatile choice. Buyers should ensure that the material meets specific regional regulations, especially in the Middle East and Europe.

How Does Sapphire Compare as a Material for Protective Lens Components?

Key Properties: Sapphire is an extremely hard material with exceptional scratch resistance and thermal stability. It can operate effectively in high-temperature environments.

Pros & Cons: The key advantage of sapphire is its durability and optical performance, making it ideal for high-precision applications. However, it is significantly more expensive and can be challenging to manufacture, leading to higher overall costs.

Impact on Application: Sapphire is particularly suitable for applications requiring high optical clarity and resistance to harsh conditions, such as in aerospace or high-performance industrial settings.

Considerations for International Buyers: Buyers should be aware of the higher costs associated with sapphire and ensure that it meets relevant international standards. This is particularly important for buyers in Europe, where quality control is stringent.

What Role Does Quartz Play in Raytools BM110 Protective Lens Components?

Key Properties: Quartz is renowned for its excellent thermal resistance and optical clarity. It can withstand high temperatures and is chemically inert, making it suitable for various applications.

Pros & Cons: Quartz offers superior performance in terms of thermal stability and optical quality. However, it is heavier than some alternatives and can be more expensive due to its sourcing and manufacturing processes.

Impact on Application: Quartz is ideal for high-temperature applications and environments where chemical exposure is a concern. Its durability makes it suitable for long-term use in demanding industrial settings.

Considerations for International Buyers: Quartz components must meet specific international standards, and buyers should consider the logistics of sourcing and transporting heavier materials, especially in regions like Africa and South America.

Summary Table of Material Selection for Raytools BM110 Protective Lens Components

| Material | Typical Use Case for raytools bm110保护镜组件 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | General industrial applications | High optical clarity | Brittle and prone to shattering | Medium |

| Polycarbonate | Mobile laser cutting applications | High impact resistance | Susceptible to scratching | Low |

| Sapphire | High-precision industrial settings | Exceptional scratch resistance | High cost and manufacturing complexity | High |

| Quartz | High-temperature and chemical exposure | Superior thermal stability | Heavier and more expensive | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, facilitating informed decisions regarding the best materials for Raytools BM110 protective lens components.

In-depth Look: Manufacturing Processes and Quality Assurance for raytools bm110保护镜组件

What Are the Key Stages in the Manufacturing Process of Raytools BM110 Protection Lens Components?

The manufacturing process for Raytools BM110 protection lens components involves several critical stages, each contributing to the overall quality and functionality of the final product. Here are the main stages:

Material Preparation: Ensuring Quality from the Start

The manufacturing process begins with the careful selection of raw materials. High-quality optical glass and durable metal alloys are typically used to ensure the lenses can withstand high temperatures and maintain optical clarity. Suppliers often conduct stringent material inspections to verify that all incoming materials meet predefined specifications before they proceed to the forming stage.

Forming: Shaping Excellence

In the forming stage, the selected materials undergo processes such as cutting, grinding, and polishing. For optical lenses, precision grinding is essential to achieve the desired curvature and thickness. This stage often employs CNC (Computer Numerical Control) machines to ensure high accuracy. Additionally, advanced polishing techniques are used to achieve the required optical quality, minimizing surface imperfections that could affect performance.

Assembly: Bringing Components Together

Once the individual components are prepared, they move to the assembly stage. This stage involves the careful assembly of the protection lens components into the final product. Automated and manual processes are often combined to ensure precision. For instance, the drawer mechanism used for lens replacement in the BM110 is assembled with meticulous attention to ensure smooth operation and reliability. Quality control measures are also implemented at this stage to ensure that all components fit together seamlessly.

Finishing: Final Touches for Quality Assurance

The finishing stage focuses on the final inspections and treatments that enhance the durability and performance of the components. This may include anti-reflective coatings, surface treatments for scratch resistance, and final optical testing to ensure that the lenses meet performance standards. The lenses are then cleaned and packaged, ready for shipment.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the Raytools BM110 protection lens components meet international standards and customer expectations. The following outlines the key QA practices:

What International Standards Guide Quality Assurance for These Components?

Manufacturers of Raytools BM110 components often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards demonstrates a commitment to consistent quality and customer satisfaction. Additionally, industry-specific certifications, such as CE marking, indicate compliance with European health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control is integrated into various stages of the manufacturing process through several checkpoints:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet the necessary specifications. This includes testing for optical clarity and material integrity.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed to monitor the quality of the products. This may include dimensional checks and surface quality inspections at different stages of forming and assembly.

-

Final Quality Control (FQC): The final product undergoes comprehensive testing, including optical performance assessments and functionality tests of the assembly mechanisms. Any components failing to meet the standards are reworked or discarded.

What Common Testing Methods Are Used to Ensure Product Quality?

Several testing methods are employed to ensure that the Raytools BM110 protection lens components meet high-quality standards:

-

Optical Testing: This includes measuring parameters such as transmittance, reflectance, and distortion. These tests ensure that the lenses will perform optimally in their intended applications.

-

Mechanical Testing: Assessments of the durability and strength of the components are conducted, simulating conditions they may face during use.

-

Environmental Testing: Components are subjected to various environmental conditions, such as temperature extremes and humidity, to evaluate their performance under different operational scenarios.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control measures of their suppliers:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is an essential practice for buyers. Audits can be scheduled as part of the procurement process to assess the supplier’s manufacturing capabilities and quality control systems. During these audits, buyers should focus on the following:

-

Review of Quality Management Systems: Understand the supplier’s adherence to international standards such as ISO 9001 and any relevant industry certifications.

-

Inspection of Production Facilities: Evaluate the cleanliness, organization, and technology used in the manufacturing process.

-

Documentation Review: Request access to quality control documentation, including inspection reports and compliance certificates.

How Can Third-party Inspections Enhance Confidence in Supplier Quality?

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies can conduct inspections at different stages of the manufacturing process and provide detailed reports that help buyers make informed decisions.

What Are the Unique Considerations for International B2B Buyers?

International buyers need to navigate various nuances when sourcing components like the Raytools BM110 protection lens:

-

Understanding Regional Compliance: Different regions may have specific regulatory requirements that the products must meet. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Logistics and Supply Chain Management: Considerations such as lead times, shipping methods, and customs regulations can impact the delivery of components. Establishing clear communication with suppliers regarding these factors can mitigate potential delays.

-

Cultural and Language Differences: Effective communication is essential for successful partnerships. Buyers should consider engaging local representatives or using translation services to facilitate smoother interactions.

In conclusion, understanding the manufacturing processes and quality assurance measures for Raytools BM110 protection lens components is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘raytools bm110保护镜组件’

Introduction

This guide is designed to assist B2B buyers in effectively sourcing the Raytools BM110 protection mirror components. By following this step-by-step checklist, you can ensure that your procurement process is thorough, efficient, and tailored to your specific operational needs.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline the technical specifications required for the Raytools BM110 protection mirror components. This includes understanding the optical characteristics, compatibility with existing systems, and specific dimensions. Well-defined specifications will help you communicate your needs effectively and avoid misalignment with suppliers.

Step 2: Research and Identify Reliable Suppliers

Conduct comprehensive research to identify potential suppliers who specialize in laser cutting equipment and components. Utilize industry directories, trade shows, and online platforms. Look for suppliers with a proven track record in providing high-quality products and excellent customer service, as this will significantly reduce the risk of procurement issues.

Step 3: Evaluate Supplier Certifications and Compliance

Confirm that potential suppliers hold relevant certifications and comply with international standards. Certifications such as ISO 9001 or other industry-specific standards ensure that the supplier adheres to quality management practices. This step is crucial in maintaining product quality and reliability, especially when sourcing from international markets.

Step 4: Request Product Samples

Before placing a bulk order, request samples of the Raytools BM110 protection mirror components. This allows you to assess the quality, fit, and compatibility with your existing equipment. Evaluate the samples in real-world conditions to ensure they meet your operational standards and performance expectations.

Step 5: Analyze Pricing and Payment Terms

Gather pricing information from multiple suppliers and compare their offers. Look beyond the initial cost; consider factors such as payment terms, shipping costs, and potential discounts for bulk orders. Understanding the full financial implications will help you make an informed decision that aligns with your budgetary constraints.

Step 6: Assess After-Sales Support and Warranty Options

Inquire about after-sales support and warranty options provided by the supplier. Reliable support is essential for addressing any issues that may arise post-purchase, such as installation guidance or product failures. A solid warranty can also provide peace of mind regarding the longevity and durability of your investment.

Step 7: Finalize and Place Your Order

Once you have evaluated suppliers based on the previous steps, select the one that best meets your needs and place your order. Ensure that all terms are clearly outlined in a purchase agreement, including delivery schedules and return policies. A well-documented agreement will protect both parties and facilitate a smoother transaction process.

By following this checklist, you can navigate the procurement process for Raytools BM110 protection mirror components with confidence, ensuring that you secure the best products for your operational needs.

Comprehensive Cost and Pricing Analysis for raytools bm110保护镜组件 Sourcing

Understanding the cost structure and pricing for the Raytools BM110 protective mirror components is crucial for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. This analysis will cover the essential cost components, price influencers, and provide actionable tips for buyers seeking to optimize their sourcing strategies.

What Are the Key Cost Components for Raytools BM110 Protective Mirror Components?

-

Materials: The primary cost driver for protective mirror components is the quality of materials used. High-grade optical glass and specialized coatings enhance durability and performance, impacting the overall cost. Suppliers may also offer different grades of materials, which can significantly alter pricing.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and quality control. Regions with lower labor costs may provide a competitive edge, but this can also affect quality. It’s essential to balance cost with the expertise required for precision components like the BM110 mirrors.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: The initial investment in molds and tools for production can be substantial. This cost is often amortized over larger production runs, making it crucial for buyers to consider minimum order quantities (MOQs) when negotiating.

-

Quality Control (QC): Rigorous quality assurance processes ensure that each component meets industry standards. This is particularly important for optical components, where precision is paramount. Enhanced QC measures can increase costs but are vital for maintaining product reliability.

-

Logistics: Shipping and handling costs vary widely based on distance, mode of transport, and the terms of delivery (Incoterms). Understanding these factors can help buyers estimate the total landed cost of the components.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on the supplier’s market positioning, brand reputation, and service level.

How Do Price Influencers Impact Sourcing Decisions?

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Buyers should assess their needs carefully to determine if they can commit to larger orders to benefit from economies of scale.

-

Specifications and Customization: Custom features or specific tolerances can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Components that meet specific industry certifications (e.g., ISO, CE) may command higher prices due to the assurance of quality and compliance. Buyers should weigh the importance of certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can significantly influence pricing. Established suppliers may offer premium pricing due to their quality assurance processes and customer service, while emerging suppliers might provide lower prices but with increased risk.

-

Incoterms: Understanding the implications of different Incoterms is essential. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total cost and responsibility for logistics.

What Are the Best Buyer Tips for Cost Efficiency?

-

Negotiation Strategies: Engage suppliers in discussions about pricing, especially if you can offer larger order volumes or long-term contracts. Building relationships can lead to better pricing and terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with quality, reliability, and maintenance. Higher upfront costs may be justified if they lead to lower operational costs.

-

Research and Compare Suppliers: Conduct thorough market research to identify various suppliers and their offerings. Comparing prices, quality, and service levels can lead to more informed purchasing decisions.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and import duties that can affect the final cost of components. Planning for these variables can prevent budget overruns.

Conclusion

In summary, understanding the comprehensive cost structure and pricing dynamics of Raytools BM110 protective mirror components is vital for international B2B buyers. By considering the outlined cost components, price influencers, and practical tips, buyers can make informed sourcing decisions that align with their operational needs and budget constraints. Always remember to seek multiple quotations and assess the total cost implications to ensure a successful procurement process.

Alternatives Analysis: Comparing raytools bm110保护镜组件 With Other Solutions

Introduction: Understanding Alternatives in Laser Cutting Solutions

In the competitive landscape of laser cutting technology, businesses often seek alternatives to enhance their operational efficiency and cost-effectiveness. The Raytools BM110保护镜组件 is a prominent choice for many, but understanding other viable options can empower B2B buyers to make informed decisions tailored to their specific needs. This analysis compares the Raytools BM110保护镜组件 against two alternative solutions: the IPG Photonics Laser Cutting Head and the TRUMPF TruLaser Series, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Raytools BM110保护镜组件 | IPG Photonics Laser Cutting Head | TRUMPF TruLaser Series |

|---|---|---|---|

| Performance | High precision, up to 3.3 kW | Exceptional efficiency, high speeds | Versatile for various materials |

| Cost | Moderate (¥175.00 for components) | High initial investment | Premium pricing, high ROI |

| Ease of Implementation | Simple installation, user-friendly | Requires skilled technicians | Straightforward setup, intuitive controls |

| Maintenance | Low; easy lens replacement | Moderate; specialized service needed | Low; robust design minimizes downtime |

| Best Use Case | Small to medium-scale operations | Large-scale industrial applications | Versatile across industries |

Detailed Breakdown of Alternatives

1. IPG Photonics Laser Cutting Head

The IPG Photonics Laser Cutting Head is renowned for its exceptional efficiency and high cutting speeds, making it ideal for large-scale industrial applications. It offers advanced features such as automated focus adjustment and optimized beam quality. However, the high initial investment can be a barrier for smaller businesses. Additionally, the complexity of the system requires skilled technicians for setup and maintenance, which may increase operational costs.

2. TRUMPF TruLaser Series

The TRUMPF TruLaser Series is a versatile laser cutting solution capable of processing a wide range of materials with precision. It features intuitive controls and a straightforward setup process, making it accessible for various skill levels. While it offers a robust design that minimizes downtime, the premium pricing may deter budget-conscious buyers. However, its high return on investment (ROI) due to efficiency and durability makes it a worthwhile consideration for businesses looking to scale.

Conclusion: Choosing the Right Laser Cutting Solution

Selecting the right laser cutting solution hinges on a business’s specific requirements, budget, and operational scale. The Raytools BM110保护镜组件 is an excellent choice for small to medium-scale operations due to its moderate cost and ease of use. However, for businesses aiming for high efficiency and large-scale production, the IPG Photonics Laser Cutting Head may provide the necessary performance, albeit at a higher price point. Conversely, the TRUMPF TruLaser Series offers versatility and reliability across various applications, making it suitable for diverse industries, despite its premium cost. Ultimately, B2B buyers should assess their unique needs, consider the total cost of ownership, and evaluate the long-term benefits of each solution to make an informed decision.

Essential Technical Properties and Trade Terminology for raytools bm110保护镜组件

What Are the Key Technical Properties of the Raytools BM110保护镜组件?

Understanding the technical properties of the Raytools BM110保护镜组件 (protection lens assembly) is crucial for B2B buyers looking for reliable components for fiber laser cutting applications. Here are some essential specifications:

-

Material Grade

The protection lens is typically made from high-grade optical glass or specialized ceramics. The material choice impacts durability and optical clarity, which are vital for maintaining cutting precision. High-quality materials minimize defects and enhance the lens’s ability to withstand thermal and mechanical stress. -

Optical Coating

This property refers to the thin layers applied to the lens surface to enhance transmission and reduce reflection. Anti-reflective coatings improve light transmission efficiency, which is crucial for maximizing laser performance. In a B2B context, understanding optical coatings can guide buyers in selecting lenses that ensure optimal cutting quality. -

Tolerance Levels

Tolerance indicates the permissible limit of variation in the lens dimensions. A tighter tolerance means a more precise fit in the cutting head assembly, which is essential for maintaining alignment and cutting accuracy. Buyers should prioritize components with tight tolerances to minimize operational disruptions. -

Wavelength Compatibility

Protection lenses must be compatible with specific laser wavelengths (e.g., 1064 nm for fiber lasers). Selecting lenses that match the operational wavelength of the laser ensures effective protection and enhances cutting efficiency. B2B buyers should verify wavelength specifications to avoid costly mismatches. -

Weight

The weight of the lens assembly can affect the overall dynamics of the cutting head. Lighter components can lead to faster movement and reduced wear on the cutting machinery. Buyers should consider the weight specifications when integrating the lens into their existing systems. -

Cleaning and Maintenance Requirements

The ease of cleaning the protection lens is a critical factor. Lenses that require minimal maintenance can reduce downtime and enhance productivity. B2B buyers should inquire about maintenance protocols and the expected lifespan of the lenses.

What Trade Terminology Should B2B Buyers Know for Raytools BM110保护镜组件?

Familiarity with specific industry jargon can facilitate smoother transactions and better decision-making. Here are some common terms relevant to the Raytools BM110保护镜组件:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing high-quality components that meet their standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management. B2B buyers should negotiate MOQs that align with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific product or service. It is a critical step in the procurement process, allowing buyers to compare offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international sales contracts. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers manage risks and costs effectively. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is crucial for planning and ensuring that production schedules are met. Buyers should communicate their timelines clearly to suppliers. -

Warranty Terms

Warranty terms outline the conditions under which a product is guaranteed against defects. Knowing these terms is vital for B2B buyers to ensure they are protected in case of product failures, which can impact production efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding the Raytools BM110保护镜组件, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the raytools bm110保护镜组件 Sector

What Are the Key Market Drivers and Trends for Raytools BM110 Protection Mirror Components?

The raytools bm110保护镜组件 sector is experiencing notable growth driven by advancements in laser technology and the rising demand for precision cutting in various industries. Key drivers include the expansion of manufacturing capabilities in regions like Africa, South America, and the Middle East, where industries such as automotive and metal fabrication are flourishing. As these markets develop, the need for high-quality components that enhance the efficiency and effectiveness of laser cutting systems becomes paramount.

Emerging trends indicate a shift towards automation and digital integration in manufacturing processes. This includes the adoption of smart technologies that improve operational efficiency, such as automated focus adjustments and optimized airflow designs in cutting heads. Additionally, there is an increasing emphasis on compatibility across various laser systems, as seen in the BM110’s ability to connect with multiple fiber interfaces, making it an attractive option for diverse manufacturing setups.

Another significant trend is the growing focus on customization and modularity in sourcing strategies. B2B buyers are increasingly looking for suppliers that can provide tailored solutions, including specific configurations of protection mirror components that meet unique operational requirements. This is particularly relevant for international buyers from regions like Brazil and Vietnam, where local manufacturing demands are evolving rapidly.

How Does Sustainability and Ethical Sourcing Impact the Raytools BM110 Protection Mirror Components Market?

Sustainability and ethical sourcing have become integral considerations in the procurement of raytools bm110保护镜组件. The environmental impact of manufacturing processes, including waste generation and energy consumption, has prompted B2B buyers to prioritize suppliers that adhere to sustainable practices. This includes the use of eco-friendly materials and processes that minimize carbon footprints.

The importance of ethical supply chains cannot be overstated, particularly for international buyers who are increasingly conscious of corporate social responsibility. Companies that demonstrate commitment to ethical sourcing, such as transparent supply chains and fair labor practices, are likely to gain a competitive advantage. Certifications like ISO 14001 for environmental management and ISO 26000 for social responsibility are becoming essential benchmarks for assessing potential suppliers.

Moreover, the demand for ‘green’ materials in the production of protection mirror components is rising. B2B buyers are looking for products that not only meet performance specifications but also align with their sustainability goals. This trend is particularly significant in Europe, where regulatory frameworks are increasingly stringent regarding environmental compliance.

What is the Evolution of the Raytools BM110 Protection Mirror Components Sector?

The raytools bm110保护镜组件 has evolved significantly since its inception, reflecting broader advancements in laser technology and manufacturing processes. Initially designed for basic cutting applications, the BM110 series has undergone multiple iterations, enhancing its functionality and adaptability. The introduction of features such as automatic focus adjustment and advanced optical configurations has significantly improved cutting precision and efficiency.

As global demand for laser cutting technology has increased, so too has the sophistication of the components used within these systems. The BM110’s compatibility with various laser interfaces and its modular design have positioned it as a go-to solution for manufacturers seeking reliability and performance. This evolution mirrors the broader trends in the manufacturing sector, where technological advancements and customer demands continue to shape product development and sourcing strategies.

In conclusion, understanding the market dynamics, sustainability considerations, and historical context of the raytools bm110保护镜组件 is crucial for international B2B buyers. By aligning with current trends and prioritizing ethical sourcing, businesses can position themselves favorably within this rapidly evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of raytools bm110保护镜组件

-

How do I solve issues related to the performance of the Raytools BM110 protective mirror components?

To address performance issues with the Raytools BM110 protective mirror components, start by ensuring they are installed correctly and free from contaminants. Regularly inspect the protective mirrors for signs of wear or damage, as these can significantly impact cutting quality. Additionally, ensure that the optical configuration is optimized for your specific application. If problems persist, consult the product manual for troubleshooting tips or reach out to your supplier for support. -

What is the best way to maintain Raytools BM110 protective mirror components?

To maintain the Raytools BM110 protective mirror components, implement a routine cleaning schedule using appropriate cleaning solutions to avoid scratches or damage. Ensure that the mirrors are stored in a dust-free environment when not in use. Regularly check for signs of wear and replace any damaged components immediately to prevent further issues. Following these practices will help extend the lifespan of your mirrors and maintain optimal cutting performance. -

What are the customization options available for Raytools BM110 protective mirror components?

Customization options for Raytools BM110 protective mirror components can include specific coatings tailored to your material processing needs, as well as varying sizes and configurations to fit different laser cutting setups. Discuss your requirements with your supplier to explore available options that can enhance performance or adapt to unique applications. Custom orders may involve minimum order quantities (MOQs) and additional lead times. -

What is the minimum order quantity (MOQ) for Raytools BM110 protective mirror components?

The minimum order quantity (MOQ) for Raytools BM110 protective mirror components can vary depending on the supplier and the specific configurations or customizations requested. Typically, MOQs range from a few units to larger quantities for bulk orders. It’s advisable to check directly with your supplier for their specific MOQ policies to plan your procurement accordingly. -

What payment terms can I expect when sourcing Raytools BM110 protective mirror components?

Payment terms for sourcing Raytools BM110 protective mirror components will depend on the supplier’s policies. Common terms include partial upfront payments with the balance due upon delivery, net 30 or net 60 days, or full payment in advance. Discussing payment options upfront can help establish a smooth transaction process and may provide opportunities for discounts on larger orders. -

How can I vet suppliers for Raytools BM110 protective mirror components?

To vet suppliers for Raytools BM110 protective mirror components, start by reviewing their reputation through online reviews and testimonials. Check for certifications that demonstrate adherence to industry standards, such as ISO certifications. Additionally, request references from previous clients and inquire about their experience with product quality and customer service. Conducting due diligence will help ensure you partner with a reliable supplier. -

What logistics considerations should I keep in mind when importing Raytools BM110 protective mirror components?

When importing Raytools BM110 protective mirror components, consider logistics factors such as shipping methods, delivery times, and customs clearance processes. Choose a reliable shipping partner familiar with international trade regulations to avoid delays. Additionally, ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate a smooth import process. Understanding these factors can help mitigate potential disruptions. -

What quality assurance measures should I expect for Raytools BM110 protective mirror components?

Quality assurance measures for Raytools BM110 protective mirror components should include thorough inspections at various stages of production, including raw material checks and final product testing. Suppliers should provide certifications and documentation confirming compliance with industry standards. Additionally, inquire about their warranty policies and any post-purchase support they offer to ensure you receive high-quality products that meet your specifications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Raytools Bm110保护镜组件 Manufacturers & Suppliers List

1. Raytools – 激光切割机

Domain: my.world.taobao.com

Registered: 2003 (22 years)

Introduction: Raytools 激光切割机, 价格: ¥ 175.00, 颜色分类: BM110/BM111(下), 用户评价: 5星好评, 类别: 五金/工具 > 机电五金 > 焊接设备 > 激光切割机

2. BM110 – 高性能切割头

Domain: shjiaqiang.cn

Registered: 2023 (2 years)

Introduction: {“product_name”: “BM110切割头”, “power”: “3.3kW”, “features”: {“optical_configuration”: “优化的光学配置”, “airflow_design”: “平滑高效的气流设计”, “automatic_focus”: {“range”: “-12mm~+10mm”, “speed”: “≤170mm/s”, “acceleration”: “≤10m/s²”, “precision”: “0.05mm”}, “fiber_interfaces”: [“QBH”, “QD”, “G5”], “protection”: “多重保护镜片”, “quick_change”: “抽屉式镜座”}, “weight”: “~5.0kg”, “nozzle_specifications”: {“2D”: “D32*M14”, “3D…

3. Levin Laser – 激光陶瓷环与泛塞封

Domain: levinlaser.com

Registered: 2021 (4 years)

Introduction: This company, Levin Laser – 激光陶瓷环与泛塞封, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Raytools – 保护镜组件

Domain: raytools.ch

Introduction: {“product_name”: “保护镜组件”, “product_code”: “120A60200”, “version”: “A”, “price”: “$1.00”, “availability”: “Option not available”, “money_back_guarantee”: “30-day money-back guarantee”, “shipping_info”: “Free Shipping in U.S.”, “description”: “Buy now, get in 2 days”, “applications”: [“Flat Cutting”, “Robot Cutting”, “Tube Cutting”, “Micro Cutting”, “5-Axis 3D Cutting”, “Welding”, “Cladding & Harden…

5. 嘉強 – 聚焦鏡組件

Domain: ruten.com.tw

Registered: 2006 (19 years)

Introduction: 工廠直銷嘉強原裝聚焦鏡組件準直鏡座raytools光纖激光切割頭鏡筒BM111

6. Raytools – D30-F100准直镜筒

Domain: kr.world.taobao.com

Registered: 2003 (22 years)

Introduction: Raytools嘉强 激光切割机 D30—F100准直镜筒(BM111/BM110-新) 价格: ¥190.00 用户评价: 7条评价, 5星好评

7. Raytools – BM110

Domain: veego.com.tw

Registered: 2005 (20 years)

Introduction: {“model”:”BM110″,”brand”:”Raytools”,”features”:[“自動調焦”,”優化的光學配置”,”平滑高效的氣流設計”,”多重保護鏡片”,”抽屜式鏡座”,”高適配性”],”automatic_focus_range”:”-12 mm ~ +10 mm”,”speed”:”≦ 170 mm”,”acceleration”:”≦ 10 m/s²”,”precision”:”0.05 mm”,”aperture”:”28 mm”,”nozzle_specifications”:[“單層”,”雙層”,”非標”],”nozzle_diameters”:[0.8, 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0],”assist_gas_pressure”:”≦ 30bar”,”weight”:”~5 kg”}

Strategic Sourcing Conclusion and Outlook for raytools bm110保护镜组件

In the realm of laser cutting technology, the Raytools BM110 protection mirror component stands out as an essential investment for businesses seeking enhanced cutting quality and operational efficiency. Its innovative design, featuring multiple protective lenses and a user-friendly drawer-style mirror holder, facilitates quick replacements, minimizing downtime. Additionally, the BM110’s compatibility with various laser sources ensures that it can be integrated seamlessly into diverse manufacturing environments, making it a versatile choice for international buyers.

Strategic sourcing of the BM110 protection mirror component can lead to significant cost savings and improved production outcomes. By partnering with reliable suppliers, businesses in Africa, South America, the Middle East, and Europe can secure quality components that enhance their competitive edge in the market.

Looking ahead, the demand for advanced laser cutting solutions is poised to grow. International B2B buyers are encouraged to explore partnerships with manufacturers and distributors that prioritize innovation and quality. Investing in the Raytools BM110 protection mirror component not only optimizes your operations but also positions your business for future success in an evolving industry landscape. Embrace this opportunity to elevate your production capabilities and drive your business forward.