The Definitive Guide to Presure Switches: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for presure switches

The global market for pressure switches presents a myriad of challenges for B2B buyers, particularly when it comes to sourcing reliable and efficient devices tailored to specific applications. With the diversity of mechanical and electronic pressure switches available, navigating the intricacies of specifications, performance, and compatibility can be daunting. This guide delves into the various types of pressure switches, their applications across industries, and essential criteria for supplier vetting, enabling buyers to make informed decisions that align with their operational needs.

This comprehensive resource addresses critical considerations such as cost factors, quality standards, and geographical nuances relevant to buyers in regions like Africa, South America, the Middle East, and Europe, including key markets such as Germany and Saudi Arabia. By understanding the operational principles behind pressure switches and the specific requirements of their applications—from HVAC systems to industrial machinery—B2B buyers can enhance their procurement strategies.

Furthermore, the guide emphasizes the importance of selecting the right pressure switch to optimize system performance and reliability, ultimately safeguarding equipment from potential failures. With actionable insights and expert recommendations, this resource is designed to empower international buyers to navigate the global market with confidence, ensuring they select the most suitable pressure switches for their unique business needs.

Understanding presure switches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Pressure Switch | Utilizes a spring and piston mechanism; robust design | HVAC systems, water pumps, industrial machinery | Pros: High voltage tolerance, simple operation. Cons: Less accurate than electronic switches. |

| Electronic Pressure Switch | Incorporates pressure transducers; digital readouts | Automation systems, precision manufacturing, robotics | Pros: High accuracy, long-term stability. Cons: More complex and potentially higher costs. |

| Adjustable Pressure Switch | Allows users to set specific pressure thresholds | Water treatment, pneumatic systems, HVAC | Pros: Customizable settings for varied applications. Cons: May require calibration. |

| Vacuum Pressure Switch | Designed to measure negative pressure; specialized design | Boilers, air compressors, HVAC systems | Pros: Essential for vacuum applications. Cons: Limited to negative pressure scenarios. |

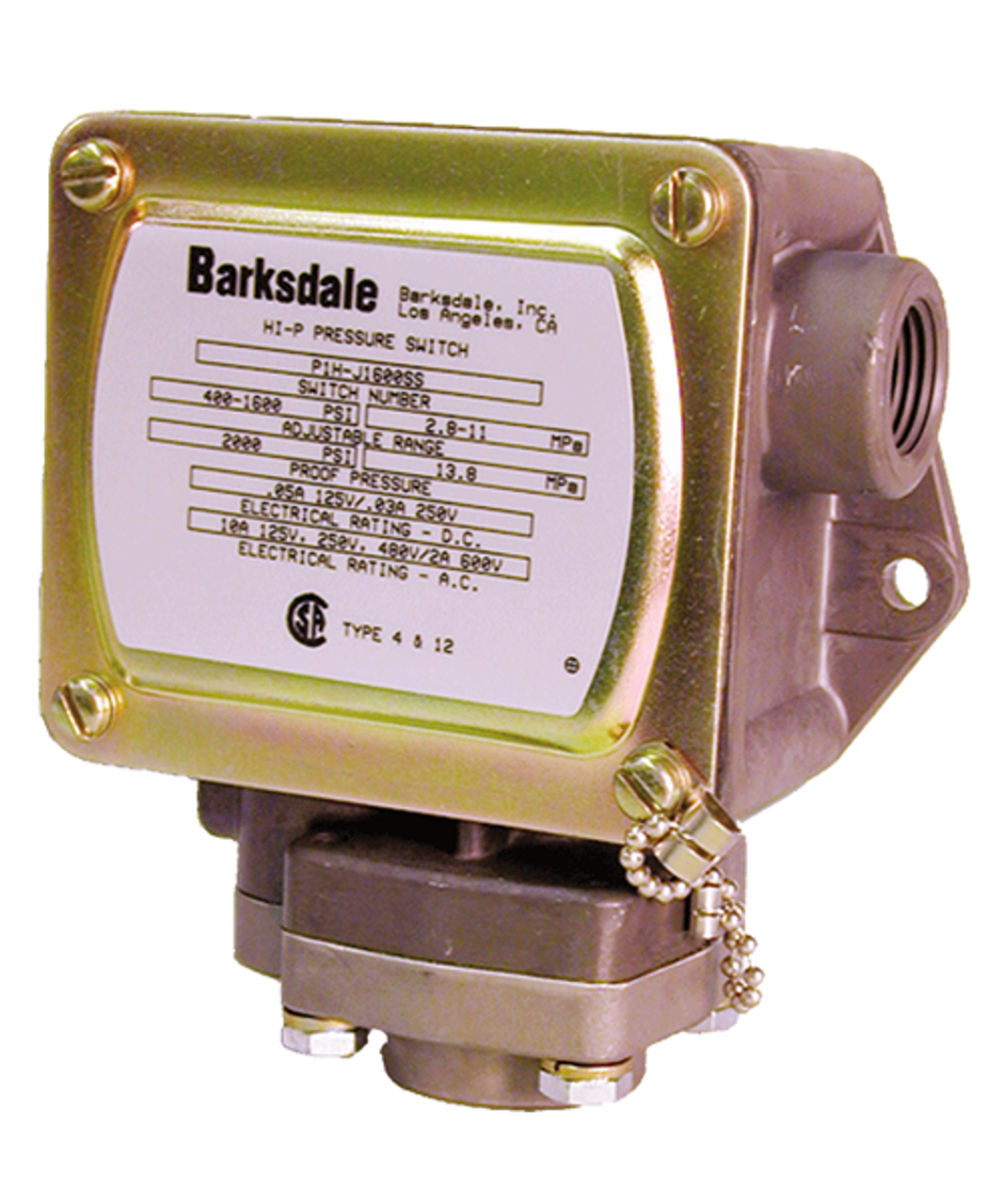

| High-Pressure Switch | Handles high-pressure environments; durable construction | Oil & gas, hydraulic systems, heavy machinery | Pros: Reliable in extreme conditions. Cons: Can be more expensive due to robust materials. |

What Are the Characteristics of Mechanical Pressure Switches?

Mechanical pressure switches are characterized by their simplicity and robustness. They operate using a spring and piston mechanism, which makes them suitable for various applications, including HVAC systems and industrial machinery. B2B buyers should consider their high voltage tolerance and ease of use, although they may sacrifice some accuracy compared to electronic alternatives. These switches are ideal for environments where durability and reliability are paramount.

How Do Electronic Pressure Switches Enhance Precision?

Electronic pressure switches utilize pressure transducers to provide digital readouts and precise measurements. This type is particularly beneficial in automation systems and precision manufacturing, where accuracy is crucial. B2B buyers should weigh the advantages of high accuracy and long-term stability against the potential for higher costs and complexity in setup. These switches are well-suited for applications requiring frequent adjustments and monitoring.

Why Choose Adjustable Pressure Switches for Custom Applications?

Adjustable pressure switches allow users to set specific pressure thresholds, making them versatile for applications like water treatment and pneumatic systems. They offer a customizable solution that can adapt to different operational needs. When purchasing, B2B buyers should consider the need for calibration and potential variations in performance. These switches are valuable for businesses looking for flexibility in their pressure management systems.

What Makes Vacuum Pressure Switches Essential?

Vacuum pressure switches are specifically designed to measure negative pressure, making them crucial in applications like boilers and air compressors. Their specialized design caters to systems requiring vacuum measurements, ensuring safety and efficiency. B2B buyers should recognize their limitations, as they are not suitable for positive pressure scenarios. However, their role in maintaining operational integrity in vacuum environments is invaluable.

How Do High-Pressure Switches Perform in Extreme Conditions?

High-pressure switches are built to withstand extreme pressure environments, making them indispensable in industries such as oil & gas and hydraulic systems. Their durable construction ensures reliability in challenging conditions. For B2B buyers, the investment in high-pressure switches may be higher due to the robust materials used, but the reliability they offer in critical applications justifies the cost. Understanding the specific pressure ratings and operational environments is crucial for making informed purchasing decisions.

Key Industrial Applications of presure switches

| Industry/Sector | Specific Application of Pressure Switches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Oil pressure monitoring in drilling operations | Enhances safety by preventing equipment failure due to low oil pressure. | Compatibility with high-pressure systems and harsh environments. |

| Water & Wastewater Management | Well pump pressure regulation | Ensures consistent water supply, reducing downtime and maintenance costs. | Corrosion-resistant materials for chemical exposure. |

| HVAC Systems | Air compressor pressure control | Improves energy efficiency and system reliability, lowering operational costs. | Adjustable settings to meet varying pressure requirements. |

| Automotive | Engine oil pressure monitoring | Protects engine integrity by preventing damage from low oil pressure. | Sensors that can withstand high temperatures and vibrations. |

| Manufacturing | Pneumatic system pressure regulation | Increases automation efficiency and reduces operational risks. | Must meet specific industry standards for safety and performance. |

How Are Pressure Switches Used in the Oil & Gas Industry?

In the oil and gas sector, pressure switches are crucial for monitoring oil pressure during drilling operations. These devices ensure that oil pressure remains within safe limits, preventing equipment failure that could lead to costly downtime or safety hazards. International buyers, particularly in regions like the Middle East, should consider pressure switches that can withstand extreme pressures and temperatures, as well as those designed for corrosive environments.

What Role Do Pressure Switches Play in Water & Wastewater Management?

Pressure switches are employed in well pump systems to regulate water pressure, ensuring a steady supply for residential and commercial use. By automatically turning the pump on or off based on pressure levels, these switches help maintain optimal performance and reduce the risk of equipment damage. Buyers from Africa and South America should prioritize switches made from corrosion-resistant materials to handle the chemical properties of groundwater.

How Do Pressure Switches Improve HVAC Systems?

In HVAC systems, pressure switches are used to control air compressors, maintaining the necessary pressure for efficient operation. This not only enhances energy efficiency but also prolongs the lifespan of the equipment, leading to lower operational costs. B2B buyers in Europe, especially in energy-conscious markets like Germany, should look for adjustable pressure switches that can adapt to varying system demands, ensuring optimal performance.

Why Are Pressure Switches Essential for Automotive Applications?

In the automotive industry, pressure switches monitor engine oil pressure to safeguard against engine damage. When oil pressure falls below a preset level, the switch triggers an alert or shuts down the engine to prevent catastrophic failure. Buyers in regions with extreme temperatures, such as Saudi Arabia, should focus on switches that are designed to endure high temperatures and vibrations, ensuring reliability in harsh conditions.

How Do Pressure Switches Enhance Manufacturing Operations?

Manufacturing facilities utilize pressure switches to regulate pneumatic systems, which are essential for automation and operational efficiency. By ensuring that pressure levels remain stable, these switches help reduce risks associated with equipment malfunction and enhance overall productivity. Buyers in this sector should seek pressure switches that comply with industry standards for safety and performance, ensuring they can withstand the rigors of continuous operation.

3 Common User Pain Points for ‘presure switches’ & Their Solutions

Scenario 1: Struggling with Inaccurate Pressure Readings

The Problem: In many industrial applications, maintaining precise pressure levels is crucial for operational efficiency and safety. B2B buyers often encounter issues with inaccurate pressure readings from their pressure switches. This can lead to over-pressurization or under-pressurization, resulting in equipment damage, production downtime, and increased operational costs. For instance, a manufacturer may rely on a mechanical pressure switch that has not been calibrated correctly, leading to erroneous readings and potentially hazardous situations.

The Solution: To mitigate inaccuracies, buyers should prioritize sourcing high-quality pressure switches with a proven track record of reliability. Investing in electronic pressure switches can significantly improve accuracy due to their advanced sensing technologies, such as strain gauges. It is essential to conduct regular maintenance and calibration of pressure switches according to the manufacturer’s guidelines. Additionally, buyers should consider integrating pressure monitoring systems that offer real-time data and alerts for any anomalies, allowing for timely interventions. This proactive approach helps in maintaining optimal pressure levels and extends the lifespan of equipment.

Scenario 2: Facing Compatibility Issues with Existing Systems

The Problem: Many B2B buyers face the challenge of integrating new pressure switches into their existing systems. This can be particularly problematic in industries with legacy equipment where specifications may differ significantly from modern devices. For example, a company looking to upgrade their pneumatic systems may find that the new pressure switches are incompatible with the existing wiring or control systems, leading to costly modifications or delays in production.

The Solution: To avoid compatibility issues, it is crucial for buyers to conduct a thorough assessment of their current systems before selecting a pressure switch. They should engage with suppliers who offer customization options to ensure that the pressure switch can be tailored to fit specific operational requirements. Additionally, buyers should seek manufacturers that provide detailed technical support and documentation to facilitate a smooth integration process. Opting for universal pressure switches that can accommodate a range of configurations may also reduce compatibility risks. Establishing a relationship with a knowledgeable supplier can provide insights into the best products for specific applications, minimizing disruption during the transition.

Scenario 3: Dealing with Frequent Failures and Downtime

The Problem: Frequent failures of pressure switches can lead to significant downtime and increased maintenance costs. This is a common pain point for B2B buyers in industries such as manufacturing and oil and gas, where pressure switches are critical for operational safety and efficiency. For instance, a company might experience repeated failures due to environmental factors like high temperatures or corrosive substances, resulting in operational delays and potential safety hazards.

The Solution: To combat frequent failures, buyers should focus on selecting pressure switches that are specifically designed to withstand harsh environmental conditions. This includes evaluating the materials used in the construction of the switches, such as corrosion-resistant alloys or high-temperature plastics. Conducting a thorough analysis of the application environment and selecting pressure switches with appropriate ratings for temperature, pressure range, and chemical resistance is essential. Additionally, implementing a robust maintenance program that includes regular inspections and testing can help identify potential issues before they lead to failures. Establishing a feedback loop with the supplier can also lead to better product recommendations and improvements based on real-world performance data, ensuring long-term reliability and efficiency.

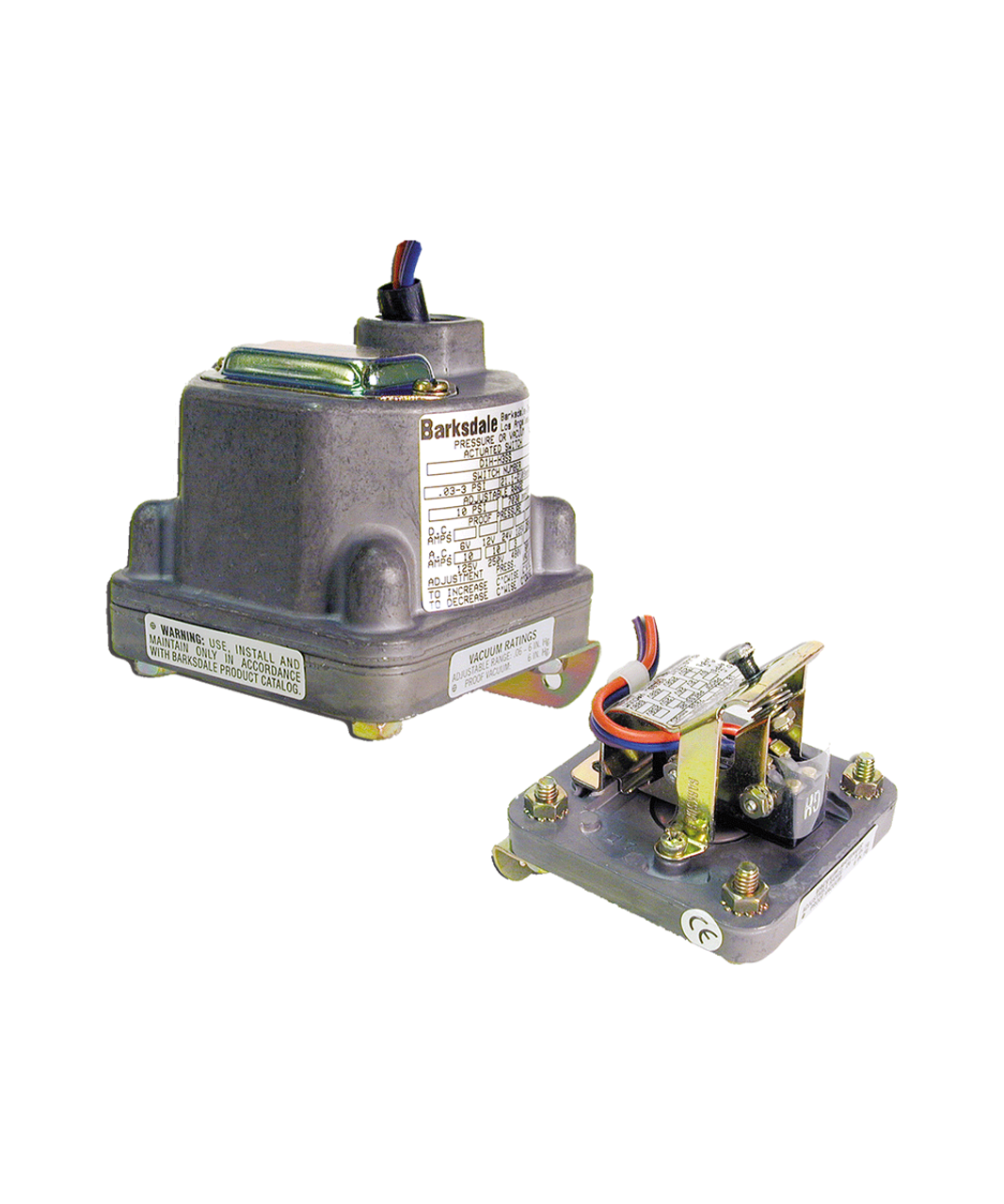

Illustrative image related to presure switches

Strategic Material Selection Guide for presure switches

What Are the Key Materials Used in Pressure Switches?

When selecting pressure switches for industrial applications, the choice of materials is critical for performance, durability, and compliance with regional standards. Here, we analyze four common materials used in the construction of pressure switches, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

How Does Stainless Steel Perform in Pressure Switch Applications?

Key Properties: Stainless steel is known for its high strength and excellent corrosion resistance, making it ideal for applications involving aggressive media. It typically withstands temperatures up to 300°C and pressures exceeding 6000 psi, depending on the specific alloy used.

Pros & Cons: The durability of stainless steel ensures a long lifespan, even in harsh environments. However, it is generally more expensive than other materials, which can impact the overall cost of the pressure switch. Manufacturing complexity can also be higher due to the need for specialized machining processes.

Impact on Application: Stainless steel pressure switches are suitable for a wide range of media, including water, oil, and various chemicals. Their resistance to corrosion makes them particularly valuable in industries like oil and gas, pharmaceuticals, and food processing.

Considerations for International Buyers: Buyers from regions such as Europe and the Middle East should ensure compliance with standards like ASTM and DIN for stainless steel grades. In markets like Africa and South America, the availability of specific grades may vary, impacting lead times and costs.

What Role Does Brass Play in Pressure Switch Manufacturing?

Key Properties: Brass offers good mechanical strength and moderate corrosion resistance, typically rated for temperatures up to 150°C and pressures around 3000 psi.

Pros & Cons: Brass is generally less expensive than stainless steel, making it a cost-effective choice for less demanding applications. However, its corrosion resistance is inferior, particularly in saline or acidic environments, which can lead to premature failure.

Impact on Application: Brass is well-suited for applications involving air and non-corrosive fluids. It is commonly used in HVAC systems and general industrial applications where the media is not overly aggressive.

Illustrative image related to presure switches

Considerations for International Buyers: Buyers should be aware of the potential for brass to corrode in certain environments, particularly in coastal regions. Compliance with local standards regarding lead content in brass is also essential, especially in Europe where regulations are stringent.

How Do Plastic Materials Compare for Pressure Switches?

Key Properties: Plastic materials, such as polycarbonate and nylon, are lightweight and can withstand temperatures up to 100°C and pressures around 1500 psi.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for complex shapes and designs. However, plastics may not be suitable for high-pressure applications or aggressive chemicals, limiting their use.

Illustrative image related to presure switches

Impact on Application: Plastic pressure switches are often used in low-pressure applications, such as in water pumps and HVAC systems. They can be a good choice for applications where weight and cost are significant factors.

Considerations for International Buyers: Buyers must consider the chemical compatibility of the plastic with the media being monitored. Additionally, compliance with international standards for material safety and performance is crucial, especially in regions with strict regulations.

What Are the Benefits of Using Aluminum in Pressure Switches?

Key Properties: Aluminum is lightweight and has good corrosion resistance, with temperature ratings up to 200°C and pressure ratings around 3000 psi.

Pros & Cons: The lightweight nature of aluminum makes it an attractive option for portable applications. However, it is generally less durable than stainless steel and can be more susceptible to wear and tear in harsh environments.

Impact on Application: Aluminum pressure switches are often used in automotive and aerospace applications where weight is a critical factor. Their resistance to corrosion makes them suitable for various fluids, including water and oil.

Considerations for International Buyers: International buyers should ensure that aluminum pressure switches meet local standards for performance and safety. In regions like the Middle East, where temperatures can be extreme, it’s essential to verify that the aluminum alloy used can withstand high heat.

Summary of Material Selection for Pressure Switches

| Material | Typical Use Case for Pressure Switches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, pharmaceuticals | High corrosion resistance | Higher cost | High |

| Brass | HVAC systems, general industrial | Cost-effective | Moderate corrosion resistance | Medium |

| Plastic | Water pumps, HVAC systems | Lightweight, low cost | Limited pressure/chemical resistance | Low |

| Aluminum | Automotive, aerospace | Lightweight | Less durable than steel | Medium |

This guide provides a comprehensive overview of material selection for pressure switches, catering to the specific needs and considerations of international B2B buyers across various regions.

In-depth Look: Manufacturing Processes and Quality Assurance for presure switches

What Are the Main Stages of Manufacturing Pressure Switches?

The manufacturing process of pressure switches involves several key stages, each critical to ensuring the quality and reliability of the final product. The primary phases include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Pressure Switches?

Material preparation is the initial step in manufacturing pressure switches. It involves selecting high-quality raw materials that meet specific application requirements. Common materials include stainless steel, brass, and various polymers, chosen for their resistance to corrosion and ability to withstand varying pressures and temperatures. Suppliers should provide documentation verifying material properties and compliance with relevant standards, which is essential for B2B buyers to assess.

What Forming Techniques Are Used in Pressure Switch Manufacturing?

The forming stage employs techniques such as stamping, machining, and molding. For mechanical pressure switches, components like diaphragms or pistons are often stamped or machined to precise specifications. Electronic pressure switches may require more complex forming processes for their integrated circuits and sensors. Precision in this stage is paramount, as even minor deviations can affect functionality. B2B buyers should inquire about the equipment used and the qualifications of the personnel involved in forming processes to ensure they meet industry standards.

How Are Pressure Switches Assembled?

During the assembly phase, individual components are meticulously brought together. This process often includes the installation of diaphragms, springs, and electrical contacts for mechanical switches, or the integration of sensors and electronic circuitry for electronic switches. Automated assembly lines may be used to enhance consistency, but manual assembly is common for more complex products. Quality assurance checks are typically performed at this stage to ensure that each unit meets the required specifications before moving on to the finishing process.

What Finishing Processes Are Commonly Used for Pressure Switches?

Finishing involves surface treatments such as plating, painting, or coating to enhance durability and corrosion resistance. For pressure switches, the finishing process may also include sealing components to prevent leaks, which is critical for maintaining operational integrity. Proper documentation of finishing processes, including any certifications, should be provided to B2B buyers to ensure compliance with international standards.

What Quality Assurance Standards Are Relevant for Pressure Switches?

Quality assurance is vital in the manufacturing of pressure switches to ensure safety, reliability, and performance. Various international and industry-specific standards apply to this sector.

How Do International Standards Like ISO 9001 Impact Pressure Switch Manufacturing?

ISO 9001 is a globally recognized standard for quality management systems (QMS). Manufacturers of pressure switches often adopt this standard to ensure consistent quality in their processes. Compliance with ISO 9001 demonstrates a commitment to quality and customer satisfaction, making it an important certification for B2B buyers to verify. Suppliers should provide documentation that outlines their QMS and how it aligns with ISO standards.

What Industry-Specific Certifications Should B2B Buyers Look For?

Beyond ISO 9001, other certifications such as CE marking for European markets and API standards for oil and gas applications are crucial. CE marking indicates that the pressure switch complies with EU safety and environmental requirements, while API certifications are essential for equipment used in the petroleum industry. B2B buyers should ensure that suppliers possess relevant certifications that align with their specific industry needs.

What Are the Key Quality Control Checkpoints in Pressure Switch Manufacturing?

Quality control (QC) is integral to the pressure switch manufacturing process, with several checkpoints established to ensure product integrity.

What Are the Initial Quality Control (IQC) Checkpoints?

The IQC phase occurs upon receipt of raw materials and components. Manufacturers conduct inspections to verify that incoming materials meet specified requirements. This step may include visual inspections, dimensional checks, and material property tests. B2B buyers can ask suppliers for IQC reports to confirm that only compliant materials are used in production.

How Is In-Process Quality Control (IPQC) Conducted During Manufacturing?

IPQC occurs during the manufacturing process, where operators perform checks at various stages. This may include monitoring the forming processes and conducting assembly inspections to ensure that tolerances and specifications are met. Regular audits and process evaluations can enhance product quality. B2B buyers should inquire about the frequency of IPQC checks and the methods employed to document findings.

What Final Quality Control (FQC) Measures Are Implemented?

FQC is performed on the completed pressure switches before they are shipped. This includes functional testing, where switches are activated to ensure they operate correctly under specified conditions. Other tests may include pressure testing, electrical continuity checks, and environmental testing. B2B buyers should request FQC documentation to verify that the products meet all operational specifications before delivery.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure the integrity of the products they purchase, B2B buyers must conduct thorough due diligence on potential suppliers.

What Audit Practices Should B2B Buyers Consider?

Conducting audits of suppliers is an effective way to assess their manufacturing processes and quality assurance practices. Buyers can either perform on-site audits or request third-party audit reports. These audits should evaluate compliance with international standards, the effectiveness of the QMS, and the overall manufacturing environment.

How Can Buyers Request Quality Reports and Third-Party Inspections?

Buyers should establish clear communication with suppliers regarding the availability of quality reports. These reports should detail the results of IQC, IPQC, and FQC checks. Additionally, third-party inspection services can provide unbiased assessments of manufacturing practices, offering buyers additional peace of mind.

What Are the Unique Quality Control Considerations for International Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, may face unique challenges in quality control.

How Do Regional Standards Affect Quality Assurance?

Different regions may have specific regulatory requirements that impact product certifications and quality standards. For example, buyers in Europe may prioritize CE marking, while those in the Middle East may require compliance with local regulations. Understanding these regional nuances is crucial for buyers to ensure compliance and avoid potential legal issues.

Illustrative image related to presure switches

What Should Buyers Know About Supply Chain Transparency?

Supply chain transparency is essential for international buyers to ensure that all components meet quality standards. Buyers should request information about the supply chain, including the origin of materials and the quality assurance practices of suppliers. This transparency can help mitigate risks associated with sourcing from diverse regions.

By understanding the manufacturing processes and quality assurance practices associated with pressure switches, B2B buyers can make informed decisions that enhance the reliability and performance of their systems. It is crucial to establish strong partnerships with suppliers who prioritize quality and compliance, ensuring that the products meet the demands of their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘presure switches’

To assist B2B buyers in sourcing pressure switches effectively, this guide outlines a practical checklist that ensures a thorough procurement process. By following these steps, buyers can make informed decisions, thereby enhancing operational efficiency and reducing risks associated with equipment failure.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right pressure switches for your application. Consider factors such as the type of pressure switch (mechanical or electronic), pressure range, and the media involved (e.g., air, water, or chemicals). This will help you filter options and ensure compatibility with your system requirements.

Illustrative image related to presure switches

Step 2: Assess the Application Requirements

Understanding the specific application where the pressure switch will be used is essential. Different applications—such as HVAC systems, water pumps, or industrial machinery—have unique demands. Evaluate the operating temperature, pressure types (positive or negative), and environmental conditions (e.g., humidity, exposure to corrosive materials) to select the most suitable switch.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. Look for established manufacturers with a reputation for quality and reliability. Request company profiles, product catalogs, and case studies, and seek references from buyers in similar industries or regions to gauge their performance and service levels.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you consider comply with relevant industry standards and possess necessary certifications. Certifications like UL approval or ISO standards can indicate a commitment to quality and safety. Verify that the products meet regulatory requirements specific to your region or industry, which is particularly vital in international transactions.

Step 5: Request Samples for Testing

Before finalizing an order, request samples of the pressure switches. Testing samples in your actual application helps confirm compatibility and performance under real-world conditions. This step reduces the risk of costly mistakes and ensures the selected switch meets your operational needs.

Step 6: Discuss Pricing and Warranty Terms

Engage in discussions about pricing, including bulk discounts or OEM pricing options. Ensure that you understand the warranty terms and after-sales support offered by the supplier. A strong warranty can provide peace of mind and protect your investment should any issues arise post-purchase.

Step 7: Finalize Logistics and Delivery Options

Once you’ve selected a supplier, discuss logistics, including delivery timelines, shipping costs, and customs requirements, especially for international orders. Establish clear communication channels for tracking shipments and addressing any potential delays, ensuring you receive your pressure switches in a timely manner for operational continuity.

By following these steps, B2B buyers can streamline their sourcing process for pressure switches, ensuring they choose reliable products that meet their technical requirements while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for presure switches Sourcing

What Are the Key Cost Components in Sourcing Pressure Switches?

When sourcing pressure switches, understanding the cost structure is crucial for international B2B buyers. The primary components that contribute to the overall cost include:

Illustrative image related to presure switches

-

Materials: The choice of materials significantly impacts pricing. High-quality materials, such as stainless steel for wetted parts or specialized plastics for housings, can increase costs. Additionally, materials that meet specific chemical compatibility requirements will also add to the expense.

-

Labor: Labor costs vary by region and manufacturing processes. Skilled labor for assembly and testing can be more expensive, particularly in countries with higher wage standards.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. These expenses are typically distributed across all products manufactured.

-

Tooling: Initial setup costs for molds or specialized tools can be significant, especially for custom or specialized pressure switches. These costs are amortized over the production run, affecting the unit price.

-

Quality Control (QC): Robust QC processes ensure that pressure switches meet safety and performance standards. Enhanced testing protocols can increase costs but are essential for compliance with international certifications.

-

Logistics: Shipping costs can vary widely based on the distance from the manufacturer, the volume of the order, and the choice of shipping method. International buyers must consider customs duties and potential delays in transit.

-

Margin: Suppliers will typically add a margin to cover their business risks and operational costs. This margin can vary based on the supplier’s market positioning and the competitiveness of the industry.

How Do Price Influencers Affect the Sourcing of Pressure Switches?

Several factors influence the pricing of pressure switches, making it essential for buyers to understand these nuances:

-

Volume/MOQ: The minimum order quantity (MOQ) often affects pricing. Larger orders typically result in reduced per-unit costs due to economies of scale. Buyers should consider negotiating bulk purchase agreements to maximize savings.

-

Specifications/Customization: Customized pressure switches, tailored to specific applications, may incur additional costs. Standard products usually offer better pricing, so buyers should weigh the need for customization against budget constraints.

-

Quality and Certifications: Products that meet international quality standards and certifications (like UL, CE) may carry a premium price. However, investing in certified products can reduce risks associated with safety and compliance in various markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more due to their perceived value and customer service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining who bears the risk and costs of shipping. For example, DDP (Delivered Duty Paid) means the seller takes on all responsibility, potentially leading to higher upfront costs, while EXW (Ex Works) places the burden on the buyer.

What Tips Can Help Buyers Optimize Costs When Sourcing Pressure Switches?

B2B buyers can take several strategic approaches to enhance cost efficiency and overall value in sourcing pressure switches:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders or ongoing contracts. Highlighting potential long-term partnerships can lead to better pricing arrangements.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with each pressure switch, including maintenance, operational efficiency, and potential downtime. A slightly higher initial investment might lead to lower TCO in the long run.

-

Stay Informed on Pricing Trends: Monitoring market trends and fluctuations in raw material prices can provide insights for negotiating better deals or timing purchases to align with lower pricing periods.

-

Leverage Local Knowledge: Buyers from Africa, South America, the Middle East, and Europe should utilize local agents or distributors who understand regional dynamics, customs, and logistics, potentially improving both cost and service levels.

-

Request Samples: Before committing to large orders, consider requesting samples to assess quality and suitability for your application. This step can mitigate risks associated with bulk purchases.

Disclaimer on Indicative Prices

The prices for pressure switches can vary significantly based on the factors discussed. The figures presented in various sources may not reflect the final pricing for specific orders or customized solutions. Always consult with suppliers for accurate quotes tailored to your specific requirements.

Alternatives Analysis: Comparing presure switches With Other Solutions

Exploring Alternatives to Pressure Switches: A Comparative Analysis

In industrial applications, pressure switches play a critical role in maintaining operational safety and efficiency. However, B2B buyers should consider various alternatives that may better suit specific needs or applications. Below is a comparative analysis of pressure switches against two alternative solutions: pressure transducers and mechanical pressure gauges. This analysis helps buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to presure switches

| Comparison Aspect | Pressure Switches | Pressure Transducers | Mechanical Pressure Gauges |

|---|---|---|---|

| Performance | Moderate; good for on/off control | High; continuous pressure measurement | Moderate; visual pressure indication |

| Cost | Generally low to moderate | Moderate to high | Low to moderate |

| Ease of Implementation | Simple, often plug-and-play | Requires calibration and integration | Easy; direct installation |

| Maintenance | Low; infrequent calibration | Moderate; regular calibration required | Low; minimal maintenance needed |

| Best Use Case | Safety systems, HVAC, pumps | Precision monitoring, automation | General monitoring, non-critical applications |

What Are the Advantages and Disadvantages of Pressure Transducers?

Pressure transducers convert pressure into an electrical signal, providing continuous monitoring and higher accuracy compared to pressure switches. Their ability to integrate with automation systems makes them suitable for applications requiring real-time data. However, they typically come at a higher cost and require more sophisticated setup and calibration, which may not be ideal for simpler applications. The maintenance of transducers is also more frequent due to their sensitivity and reliance on electronic components.

How Do Mechanical Pressure Gauges Compare?

Mechanical pressure gauges provide a straightforward visual representation of pressure levels without the need for electrical components. They are generally less expensive and easier to install, making them suitable for applications where precise pressure control is not critical. However, they lack the automation capabilities and accuracy of pressure switches and transducers, limiting their use in more complex systems. Mechanical gauges also do not provide on/off control, which can be a significant drawback in safety-critical applications.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right solution for pressure management involves assessing specific operational needs, budget constraints, and the complexity of the application. Pressure switches are ideal for safety mechanisms and straightforward control tasks, while pressure transducers offer superior accuracy and integration for automated systems. Mechanical gauges serve well in less critical environments where cost-effectiveness is paramount. By evaluating these alternatives against their unique requirements, B2B buyers can make informed decisions that enhance efficiency and safety in their operations.

Essential Technical Properties and Trade Terminology for presure switches

What Are the Key Technical Properties of Pressure Switches?

Understanding the essential technical properties of pressure switches is critical for B2B buyers, particularly those involved in industries such as manufacturing, oil and gas, and HVAC systems. Here are some of the most significant specifications to consider:

Illustrative image related to presure switches

1. Material Grade

The material used in pressure switches often dictates their durability and performance. Common materials include stainless steel, brass, and plastic. Stainless steel is favored for its corrosion resistance, making it suitable for harsh environments, while brass is often used for lower-cost applications. For B2B buyers, selecting the right material ensures that the pressure switch can withstand the specific conditions of their application, minimizing the risk of failure.

2. Pressure Range

The pressure range indicates the minimum and maximum pressures the switch can effectively monitor. It’s crucial for buyers to select a pressure switch that fits within the operational parameters of their system. If the switch is rated too low, it may fail to activate; if rated too high, it could lead to equipment damage. A good rule of thumb is to set the operational pressure at 40-60% of the switch’s maximum rating to ensure longevity and reliability.

3. Operating Temperature

The operating temperature defines the environmental conditions in which the pressure switch can function optimally. High temperatures can degrade materials, while low temperatures may hinder performance. B2B buyers must consider the operating environment of their equipment to ensure that the pressure switch can handle temperature fluctuations, thus preventing operational downtime.

4. Electrical Ratings

The electrical ratings specify the voltage and current limits for the pressure switch. This is particularly important for applications that involve high voltages or currents. Buyers need to ensure that the electrical specifications align with their system requirements to avoid electrical failures that could lead to costly repairs.

5. Hysteresis

Hysteresis refers to the difference between the switch’s activation and deactivation points. This specification is essential for maintaining system stability, as it prevents rapid cycling of the switch, which can lead to wear and tear. Understanding hysteresis helps buyers select a pressure switch that provides consistent performance without frequent interruptions.

What Are Common Trade Terms in the Pressure Switch Industry?

Familiarizing oneself with industry-specific terminology can greatly enhance communication and negotiation processes in B2B transactions. Here are some key terms relevant to pressure switches:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of pressure switches, OEMs often provide custom solutions tailored to specific applications. Understanding OEM dynamics can help buyers negotiate better pricing and ensure compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers who may need to balance inventory costs with production needs. Knowing the MOQ helps in planning purchases and managing budgets effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. For pressure switches, issuing an RFQ can help buyers compare different options and select the most cost-effective solution that meets their technical requirements.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms that are widely used in international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth logistics.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For pressure switches, lead times can vary based on customization and manufacturing capabilities. Knowing lead times is critical for project planning and ensuring that equipment is available when needed.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and reduce costs in their pressure switch procurement processes.

Navigating Market Dynamics and Sourcing Trends in the presure switches Sector

What are the Current Market Dynamics and Key Trends in the Pressure Switches Sector?

The pressure switches market is experiencing significant growth driven by industrial automation, increased demand for advanced monitoring systems, and the ongoing transition towards smart manufacturing. Key drivers include the rising need for safety and efficiency in industrial applications, particularly in sectors like oil and gas, water treatment, and HVAC. As industries in Africa, South America, the Middle East, and Europe invest in upgrading their infrastructure, the demand for reliable pressure control solutions continues to surge.

Emerging trends indicate a shift towards electronic pressure switches, which offer superior accuracy and functionality compared to their mechanical counterparts. These advanced devices are increasingly being integrated into automated systems, providing real-time data and enabling predictive maintenance, which is crucial for industries aiming to reduce downtime and operational costs. Additionally, the growth of the Internet of Things (IoT) is influencing the design and application of pressure switches, allowing for enhanced connectivity and data analytics capabilities.

International buyers should be aware of varying regulatory standards across regions, especially in Europe and the Middle East, where compliance with safety and environmental regulations is paramount. Understanding local market nuances and establishing relationships with reliable suppliers will be vital for successful sourcing strategies.

How is Sustainability and Ethical Sourcing Impacting the Pressure Switches Market?

Sustainability has become a pivotal consideration in the sourcing of pressure switches, with increasing pressure on manufacturers to reduce environmental impact. The production of pressure switches involves materials that can have significant ecological footprints, such as metals and plastics. As a result, B2B buyers are urged to prioritize suppliers that demonstrate a commitment to sustainable practices.

Illustrative image related to presure switches

Ethical sourcing is equally important, with many organizations focusing on establishing transparent supply chains. Buyers should look for manufacturers that adhere to recognized sustainability certifications, such as ISO 14001 for environmental management and RoHS compliance for hazardous substances. Additionally, the adoption of ‘green’ materials in the production of pressure switches, such as recyclable metals and eco-friendly plastics, can further enhance a company’s sustainability profile.

Incorporating sustainability into procurement strategies not only mitigates environmental risks but also aligns with the growing consumer demand for responsible business practices. International buyers are encouraged to engage with suppliers who actively participate in sustainability initiatives and who can provide documentation on their environmental impact.

What is the Historical Evolution of Pressure Switches in the B2B Sector?

The evolution of pressure switches dates back to the early industrial era when mechanical devices were primarily utilized to monitor and control pressure levels in various applications. Initially, these switches relied on simple mechanical components, such as bourdon tubes and diaphragms, to activate or deactivate systems based on pressure changes. Their robustness made them ideal for high-voltage and high-amperage tasks, leading to widespread adoption in industries like manufacturing and HVAC.

As technology progressed, the introduction of electronic pressure switches marked a significant turning point. These devices not only improved accuracy but also offered enhanced functionalities, such as programmable settings and digital displays. This shift has allowed for greater integration within automated systems, aligning with modern demands for efficiency and real-time monitoring.

Today, the pressure switches market continues to evolve, driven by advancements in smart technology and IoT integration, reflecting the ongoing transformation in industrial practices worldwide. B2B buyers are encouraged to stay informed about these historical developments to better understand current product offerings and their applications.

Frequently Asked Questions (FAQs) for B2B Buyers of presure switches

-

How do I select the right pressure switch for my application?

Selecting the right pressure switch requires considering several factors: the type of pressure (positive, negative, or compound), the pressure range, the operating temperature, and the chemical compatibility of the process fluid. Mechanical switches are suitable for high voltages, while electronic switches provide greater accuracy and durability. Additionally, assess whether you need features like adjustable setpoints or integrated displays. Consult with suppliers who can provide technical support tailored to your specific requirements. -

What are the key differences between mechanical and electronic pressure switches?

Mechanical pressure switches operate using a physical mechanism, such as springs and diaphragms, making them robust for simpler tasks and high-voltage applications. In contrast, electronic pressure switches utilize sensors and electronics for precise measurements and offer features like programmable outputs and enhanced durability. While mechanical switches are often more cost-effective, electronic switches provide higher accuracy and longer operational life, making them preferable for complex systems. -

What customization options are available for pressure switches?

Many manufacturers offer customization options, including different pressure ranges, electrical connections, and materials for wetted parts to ensure compatibility with specific fluids. You can also request features like adjustable setpoints, integrated displays, or specific mounting configurations. Discuss your requirements with suppliers early in the procurement process to ensure that the final product meets your operational needs. -

What should I consider when evaluating international suppliers of pressure switches?

When evaluating international suppliers, consider their certifications (like ISO or UL), manufacturing capabilities, and experience in your industry. Look for reviews or testimonials from other B2B buyers, and assess their responsiveness and customer service. Additionally, inquire about their quality assurance processes, lead times, and logistics capabilities to ensure they can meet your delivery requirements. -

What are typical minimum order quantities (MOQs) for pressure switches?

Minimum order quantities can vary significantly based on the supplier and the type of pressure switch. Generally, MOQs range from a few units for standard models to larger quantities for custom configurations. It’s essential to discuss your needs with suppliers, as they may offer flexibility on MOQs, especially for long-term partnerships or bulk orders. -

What payment terms should I expect when sourcing pressure switches internationally?

Payment terms can vary widely depending on the supplier and the nature of the order. Common terms include advance payment, net 30, or net 60 days, especially for established relationships. Some suppliers may accept letters of credit or escrow services for larger transactions. Always clarify payment terms upfront to avoid misunderstandings and ensure a smooth transaction process. -

How do I ensure quality assurance for pressure switches from international suppliers?

To ensure quality assurance, request detailed documentation about the supplier’s manufacturing processes, certifications, and testing protocols. Consider asking for samples before placing a large order to evaluate performance. Additionally, you may want to include quality clauses in your purchase agreements and possibly arrange for third-party inspections or audits to verify compliance with your quality standards. -

What logistics considerations should I keep in mind when importing pressure switches?

When importing pressure switches, consider shipping methods, lead times, and customs regulations in your country. Engage with logistics providers familiar with international shipping to help navigate tariffs, duties, and import restrictions. It’s also wise to confirm with your supplier about packaging standards to ensure safe transit and compliance with local regulations, as well as to establish clear communication channels for tracking shipments.

Top 6 Presure Switches Manufacturers & Suppliers List

1. SOR Controls Group – Pressure & Vacuum Switches

Domain: sorinc.com

Registered: 1997 (28 years)

Introduction: Pressure & Vacuum Switches from SOR Controls Group are designed for high performance and customization. Key features include:

– Models: Adjustable Dead Band, Explosion Proof, Hermetically Sealed, Weatherproof, Bourdon Tube, Dual Hi-Lo, among others.

– Ranges: From 5 to 10,000 psi, including vacuum ranges.

– Certifications: CSA, SIL, UL/CSA, ATEX, TestSafe (SAA), INMETRO.

– Warranty: 3 years.

…

2. Honeywell – Pressure Switches

Domain: automation.honeywell.com

Registered: 1988 (37 years)

Introduction: Honeywell pressure switches operate with a variety of materials including air, motor/transmission oils, jet fuels, and other hydrocarbons. They may be factory set from 0.5 psi to 3000 psi. Features include snap action switching with adjustable differential, low contact resistance, and gold-over-silver contacts. Available with or without a dead band.

3. IQS Directory – Pressure Switches

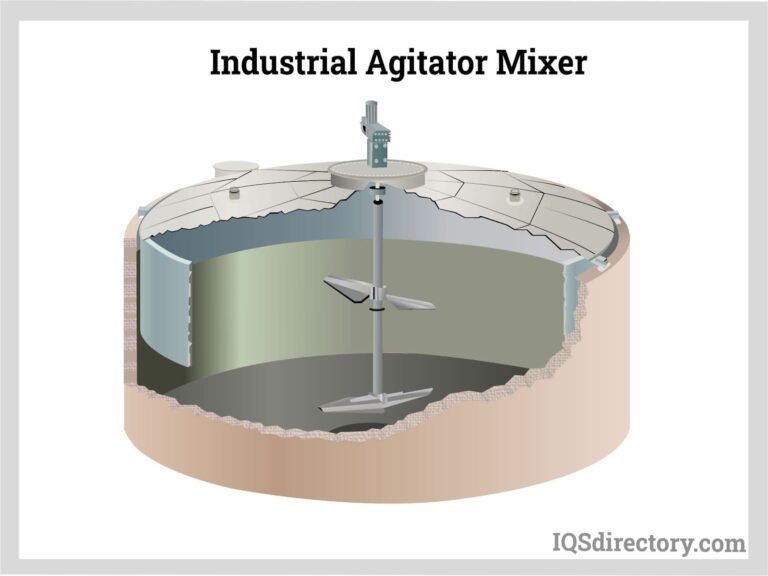

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Pressure switches are devices activated by the pressure of fluids, air, or gases reaching a predetermined level. They consist of components such as bourdon tubes, pistons, diaphragms, or membranes that react to pressure changes. Key parts include: 1. Process (Inlet) Port: Connects the switch to the process unit, allowing fluid entry. Commonly uses NPT threaded fittings. 2. Pressure Sensing Element…

4. WIKA – Pressure Switches

Domain: wika.com

Registered: 1996 (29 years)

Introduction: Pressure switches open or close a corresponding switch contact when a preset pressure is reached. They can have mechanical or electrical switch contacts, with or without displays, and various setting options. Suitable for a variety of industrial and technical processes, WIKA offers a broad selection of pressure switches for different applications. Standard instruments can be ordered easily through…

5. Graybar – Pressure Switches

Domain: graybar.com

Registered: 1995 (30 years)

Introduction: Pressure Switches available from various manufacturers including Telemecanique Sensors, Square D (Schneider Electric), and others. Key specifications include:

– Switch Range: Varied ranges such as 40 to 100 psi, 65 to 200 psi, 70 to 150 psi, and more.

– Rated Current: Options include 10A, 20A, 6A, and others.

– Contact Operation: Types include DPST-DB, 2NC, SPDT, and more.

– NEMA Rating: Options i…

6. McMaster – Adjustable Pressure Switches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Adjustable Pressure Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for presure switches

In the evolving landscape of industrial automation, the strategic sourcing of pressure switches is essential for enhancing operational efficiency and ensuring system reliability. Buyers must prioritize factors such as the type of pressure switch—mechanical or electronic—based on specific application needs. Understanding the nuances of pressure range, operating temperature, and material compatibility can significantly influence procurement decisions.

Moreover, engaging with manufacturers that offer customized solutions can lead to improved functionality and cost-effectiveness. As industries in Africa, South America, the Middle East, and Europe continue to grow, the demand for high-quality pressure switches will only increase. Establishing strong supplier relationships and exploring OEM pricing options can provide a competitive edge in this dynamic market.

Looking ahead, it is imperative for international B2B buyers to stay informed about technological advancements in pressure switch design and application. By leveraging strategic sourcing practices, businesses can not only enhance their operational capabilities but also contribute to sustainable industrial growth. Embrace the opportunity to optimize your sourcing strategy today—connect with trusted suppliers and explore innovative solutions tailored to your specific needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.