The Definitive Guide to Poly Hoses: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for poly hoses

Navigating the global market for poly hoses presents a unique set of challenges for international B2B buyers. As industries increasingly rely on fluid conveyance solutions, sourcing high-quality poly hoses that meet diverse application needs can be daunting. From agricultural irrigation in Africa to industrial manufacturing in Europe, the demand for reliable and versatile hoses is on the rise. This comprehensive guide addresses the various types of poly hoses, their applications across different sectors, and strategies for effective supplier vetting, ensuring buyers can make informed purchasing decisions.

The scope of this guide extends beyond basic product knowledge; it delves into critical factors such as cost considerations, quality assurance processes, and the importance of understanding regional market trends. By equipping B2B buyers from regions like South America, the Middle East, and Germany with actionable insights, this resource empowers them to navigate the complexities of sourcing poly hoses effectively. Whether you are looking to optimize your supply chain or enhance operational efficiency, understanding the nuances of poly hoses will enable you to select the right solutions tailored to your business needs. This guide is your pathway to making confident, informed decisions in the competitive landscape of fluid conveyance solutions.

Understanding poly hoses Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Performance Polymer Hose | High flexibility, resistance to abrasion and chemicals | Agriculture, construction, fluid transfer | Pros: Durable, versatile; Cons: May be more expensive than standard options. |

| Ultra High Pressure (UHP) Hose | Designed for extreme pressure applications, reinforced structure | Oil & gas, hydraulic systems, aerospace | Pros: High strength, safety; Cons: Requires specialized fittings. |

| Lay Flat Poly Hose | Lightweight, easy to transport and store, collapsible design | Irrigation, drainage, construction | Pros: Space-saving, cost-effective; Cons: Limited pressure ratings. |

| Reinforced Polyurethane Hose | Enhanced durability, excellent tensile strength | Automotive, industrial applications | Pros: High performance, chemical resistance; Cons: Can be heavier than alternatives. |

| Composite Hose | Multi-layer construction, resistant to a wide range of chemicals | Chemical transfer, fuel delivery | Pros: Versatile, high chemical resistance; Cons: More complex assembly. |

What are the Key Characteristics of Performance Polymer Hose?

Performance polymer hoses are engineered for high flexibility and resilience against abrasion and chemicals. These hoses are suitable for various applications, particularly in agriculture and construction, where durability and versatility are essential. When purchasing, consider the specific chemical compatibility and pressure ratings required for your operations, as these factors can significantly influence performance and longevity.

Why Choose Ultra High Pressure (UHP) Hose for Your Operations?

Ultra high pressure hoses are specifically designed to withstand extreme pressures, making them ideal for applications in the oil and gas industry, hydraulic systems, and aerospace. Their reinforced structure ensures safety and reliability in demanding environments. B2B buyers should focus on compatibility with existing systems and the availability of specialized fittings when selecting UHP hoses, as these can impact installation and maintenance.

How Does Lay Flat Poly Hose Benefit Your Projects?

Lay flat poly hoses are known for their lightweight and collapsible design, making them easy to transport and store. They are commonly used in irrigation and drainage applications due to their cost-effectiveness and space-saving benefits. When considering lay flat hoses, buyers should evaluate the pressure ratings and ensure they meet the specific requirements of their projects, particularly in high-flow scenarios.

What Makes Reinforced Polyurethane Hose a Good Choice?

Reinforced polyurethane hoses offer enhanced durability and excellent tensile strength, making them suitable for automotive and industrial applications. Their high performance and chemical resistance make them a reliable option for demanding environments. Buyers should assess the weight of these hoses compared to alternatives, as heavier hoses may impact handling and installation processes.

Illustrative image related to poly hoses

Why Consider Composite Hose for Chemical Transfer?

Composite hoses are constructed with multiple layers, providing resistance to a wide range of chemicals, making them ideal for chemical transfer and fuel delivery applications. Their versatility and high chemical resistance are significant advantages for B2B buyers in industries that require safe and efficient fluid handling. However, it is essential to consider the complexity of assembly and ensure that the hose meets all regulatory standards for specific applications.

Key Industrial Applications of poly hoses

| Industry/Sector | Specific Application of Poly Hoses | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation systems | Efficient water delivery, reduced wastage | Durability in harsh weather, compatibility with fittings |

| Construction | Concrete pumping | High-pressure fluid transfer, improved productivity | Pressure ratings, flexibility, and abrasion resistance |

| Automotive | Fuel and fluid transfer | Reliable performance, enhanced safety | Chemical compatibility, temperature resistance |

| Chemical Processing | Transfer of corrosive materials | Safety and efficiency in handling hazardous fluids | Compliance with industry standards, material specifications |

| Life Sciences | Medical and pharmaceutical applications | Sterility and reliability in critical operations | Certification standards, flexibility, and biocompatibility |

How Are Poly Hoses Applied in Agriculture and What Benefits Do They Offer?

In the agriculture sector, poly hoses are essential for irrigation systems, providing a reliable means for water delivery to crops. Their flexibility allows for easy installation and maintenance, while their durability ensures longevity even in harsh weather conditions. International buyers should consider the hoses’ compatibility with existing fittings and the ability to withstand UV exposure. Efficient water delivery through poly hoses minimizes wastage, leading to cost savings and increased crop yield.

What Role Do Poly Hoses Play in the Construction Industry?

Poly hoses are widely used in construction for concrete pumping applications, where high-pressure fluid transfer is crucial. These hoses facilitate the efficient movement of concrete to various job sites, enhancing productivity and reducing downtime. Buyers in this industry need to focus on the pressure ratings and flexibility of the hoses to ensure they can withstand the rigors of construction environments. The abrasion resistance of poly hoses also plays a significant role in maintaining operational efficiency.

Illustrative image related to poly hoses

How Are Poly Hoses Utilized in the Automotive Sector?

In the automotive industry, poly hoses are critical for fuel and fluid transfer applications. Their reliable performance ensures that fluids are transported safely, minimizing the risk of leaks and enhancing overall safety. When sourcing poly hoses for automotive applications, businesses must consider factors such as chemical compatibility and temperature resistance to ensure optimal performance under varying conditions. The use of high-quality poly hoses can lead to improved vehicle reliability and reduced maintenance costs.

What Are the Key Benefits of Poly Hoses in Chemical Processing?

Poly hoses are indispensable in the chemical processing industry, particularly for the transfer of corrosive materials. Their robust construction ensures safe handling of hazardous fluids, which is vital for compliance with safety regulations. Buyers should prioritize sourcing hoses that meet industry standards and specifications, particularly regarding material compatibility and resistance to chemical degradation. The efficiency and safety provided by poly hoses in this sector can significantly reduce operational risks and enhance productivity.

Why Are Poly Hoses Important in Life Sciences?

In the life sciences sector, poly hoses are used for medical and pharmaceutical applications where sterility and reliability are paramount. These hoses facilitate the transfer of fluids in critical operations, ensuring that products meet stringent safety and quality standards. International buyers must consider certification standards and the biocompatibility of the materials used in poly hoses. The use of high-quality poly hoses in this field can lead to improved patient safety and compliance with regulatory requirements.

Illustrative image related to poly hoses

3 Common User Pain Points for ‘poly hoses’ & Their Solutions

Scenario 1: Inconsistent Quality Leading to Downtime

The Problem: B2B buyers often face the challenge of inconsistent quality in poly hoses, leading to unexpected failures and downtime. For instance, a manufacturing plant in Nigeria may procure hoses that do not meet the required specifications or industry standards. This inconsistency can result in leaks, bursts, or general hose degradation, causing production delays and financial losses. The frustration is compounded when buyers are unable to identify the root cause of these failures, often leading to repeated purchases from unreliable suppliers.

The Solution: To overcome this issue, buyers should prioritize sourcing poly hoses from manufacturers with robust quality assurance processes and certifications. When selecting a supplier, it’s essential to request documentation proving compliance with international standards such as ISO 9001. Additionally, engage with suppliers who offer detailed product specifications and testing reports. Establishing a strong relationship with a reputable supplier allows for ongoing communication regarding quality expectations and potential adjustments. Furthermore, consider investing in a small batch of hoses for initial testing before committing to larger orders. This practice not only mitigates risk but also helps in evaluating the hose performance in real-world applications.

Scenario 2: Difficulty in Customization for Specific Applications

The Problem: Many industries, including agriculture and construction, require poly hoses that are tailored to specific operational needs. For example, a South American irrigation company might need hoses that can withstand extreme temperatures and varying chemical compositions. However, generic poly hoses may not meet these specifications, leading to inefficiencies and increased maintenance costs. The lack of customization options can leave buyers feeling frustrated and constrained by their choices.

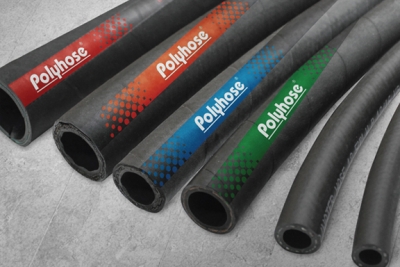

The Solution: Buyers should actively seek suppliers who specialize in custom-engineered solutions. This involves collaborating closely with manufacturers to communicate specific requirements regarding hose diameter, flexibility, chemical resistance, and temperature tolerance. Companies like Polyhose offer custom engineering services where technical teams work directly with clients to design hoses that meet precise application needs. Furthermore, buyers should leverage existing product lines as a base for customization, ensuring that modifications are feasible within the manufacturer’s capabilities. By investing time in the initial design phase, businesses can enhance the durability and performance of their hoses, ultimately leading to long-term cost savings.

Scenario 3: Challenges with Lead Times and Availability

The Problem: In the fast-paced industrial landscape, timely access to poly hoses can be a significant pain point. Buyers often experience delays in delivery, which can halt operations and result in costly downtime. For instance, a construction firm in Europe may find that their preferred hose supplier has long lead times due to stock shortages, impacting project timelines. The inability to quickly source hoses can lead to strained client relationships and financial penalties for missed deadlines.

The Solution: To mitigate lead time issues, buyers should diversify their supplier base and consider suppliers that maintain significant inventory levels. For example, companies like Polyhose have strategically located warehouses that ensure a wide array of products are in stock and ready to ship. When placing orders, buyers should inquire about stock levels and shipping timelines to set realistic expectations. Additionally, establishing a forecasting system that analyzes historical usage patterns can help anticipate future needs, allowing for proactive ordering. Implementing vendor-managed inventory (VMI) systems can also streamline the supply chain, ensuring that critical materials are always available when needed. By prioritizing suppliers with efficient logistics and inventory management, businesses can significantly reduce the risk of operational disruptions.

Illustrative image related to poly hoses

Strategic Material Selection Guide for poly hoses

What Are the Key Materials Used in Poly Hoses?

When selecting poly hoses for various applications, understanding the materials involved is crucial. This guide analyzes four common materials used in poly hoses: Polyethylene (PE), Polyvinyl Chloride (PVC), Polyurethane (PU), and Thermoplastic Elastomer (TPE). Each material has distinct properties, advantages, and limitations that can significantly impact performance and suitability for specific applications.

How Does Polyethylene (PE) Perform in Poly Hose Applications?

Polyethylene is one of the most widely used materials for poly hoses due to its excellent flexibility and resistance to moisture. It typically has a temperature rating of -50°C to 60°C and can handle moderate pressures, making it suitable for irrigation and general fluid transfer.

Pros: PE hoses are lightweight, cost-effective, and resistant to UV radiation and chemicals, which enhances their durability. They are also easy to manufacture, allowing for quick production runs.

Cons: However, PE hoses can be less durable under extreme temperatures and may not withstand high-pressure applications as effectively as other materials.

Impact on Application: PE is compatible with a wide range of media, including water, air, and some chemicals, making it versatile for agricultural and industrial uses.

Considerations for International Buyers: Buyers should ensure compliance with local standards, such as ASTM D1248 for PE, and be aware of the varying quality levels across regions.

Illustrative image related to poly hoses

What Are the Advantages of Polyvinyl Chloride (PVC) in Poly Hoses?

PVC is another popular choice for poly hoses, particularly for applications requiring chemical resistance. It can handle temperatures from -10°C to 60°C and is suitable for low to medium pressure applications.

Pros: PVC hoses are highly durable, resistant to abrasion, and can withstand exposure to various chemicals, making them ideal for industrial settings. They are also available in various colors and sizes, enhancing customization options.

Cons: The rigidity of PVC can limit flexibility, and it may become brittle over time, especially when exposed to UV light.

Impact on Application: PVC hoses are commonly used in construction, irrigation, and chemical transfer, making them suitable for various industries.

Considerations for International Buyers: Compliance with standards like ASTM D1785 and DIN EN 13765 is essential, especially in regions with strict regulations.

How Does Polyurethane (PU) Compare for Poly Hose Use?

Polyurethane hoses are known for their exceptional flexibility and resilience, making them suitable for a range of applications, from pneumatic to hydraulic systems. They can operate effectively in temperatures ranging from -40°C to 80°C.

Pros: PU hoses are lightweight, highly flexible, and resistant to abrasion, which minimizes wear and tear. They also exhibit excellent memory, returning to their original shape after deformation.

Cons: However, PU hoses can be more expensive to produce than PE or PVC and may not be as chemically resistant as PVC.

Impact on Application: PU hoses are ideal for applications requiring high flexibility and durability, such as in robotics or automated machinery.

Considerations for International Buyers: Buyers should check for compliance with relevant standards, such as ISO 9001, and consider the specific chemical compatibility of PU with the intended media.

Illustrative image related to poly hoses

What Role Do Thermoplastic Elastomers (TPE) Play in Poly Hose Selection?

Thermoplastic elastomers combine the properties of rubber and plastic, offering excellent flexibility and durability. TPE hoses typically operate within a temperature range of -40°C to 100°C, making them suitable for various applications.

Pros: TPE hoses are highly flexible, resistant to UV light, and can handle a wide range of chemicals, making them versatile for many industries. Their elasticity allows for easy handling and installation.

Cons: The manufacturing process for TPE can be more complex, leading to higher costs compared to other materials.

Impact on Application: TPE hoses are commonly used in automotive, medical, and food applications due to their versatility and compliance with health regulations.

Illustrative image related to poly hoses

Considerations for International Buyers: Compliance with standards such as FDA regulations for food-grade applications and ASTM D624 is crucial for ensuring safety and quality.

Summary Table of Material Comparisons

| Material | Typical Use Case for poly hoses | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Irrigation, general fluid transfer | Lightweight, cost-effective | Less durable under extreme temperatures | Low |

| Polyvinyl Chloride (PVC) | Construction, chemical transfer | Highly durable, chemical resistant | Limited flexibility, may become brittle | Med |

| Polyurethane (PU) | Pneumatic, hydraulic systems | Exceptional flexibility and resilience | Higher production cost | High |

| Thermoplastic Elastomer (TPE) | Automotive, medical, food applications | High flexibility, UV resistant | Complex manufacturing process | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in poly hoses. Understanding these factors will enable informed decision-making tailored to specific application needs across different international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for poly hoses

What Are the Key Stages in the Manufacturing Process of Poly Hoses?

The manufacturing process for poly hoses involves several critical stages that ensure the final product meets industry standards and customer specifications. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to poly hoses

-

Material Preparation: The process begins with the selection and preparation of raw materials. Polyethylene or polyurethane resins are typically chosen for their durability and flexibility. These materials are subjected to pre-processing, which may involve drying to remove moisture and ensuring uniformity in particle size. This step is crucial, as any inconsistencies can lead to defects in the final product.

-

Forming: During this stage, the prepared materials are transformed into hose shapes. Techniques such as extrusion are commonly employed, where the resin is heated and forced through a die to create a continuous tube. The extrusion process allows for a variety of hose diameters and wall thicknesses, catering to diverse application needs. Additionally, techniques like blow molding may be used for specific designs requiring greater flexibility or specific shapes.

-

Assembly: Once the hose is formed, it undergoes assembly, which involves attaching fittings and connectors. These components are often made of brass, stainless steel, or plastic, depending on the intended use of the hose. The assembly process must ensure a secure fit to prevent leaks and maintain pressure integrity during operation. This stage may also include the application of protective coatings to enhance the hose’s resistance to chemicals and abrasion.

-

Finishing: The final stage includes quality checks, surface treatments, and packaging. This is when the hoses are inspected for any visual defects, cut to specified lengths, and packaged for shipment. Proper finishing is essential to ensure that the hoses are ready for immediate use upon delivery.

Which Quality Assurance Standards Are Relevant for Poly Hose Manufacturing?

Quality assurance in poly hose manufacturing is critical to ensure that products meet both international and industry-specific standards. Key standards include ISO 9001, CE marking, and API specifications.

-

ISO 9001: This international standard focuses on quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established processes to consistently provide products that meet customer and regulatory requirements. This certification is crucial for B2B buyers as it assures them of the supplier’s commitment to quality.

-

CE Marking: For products sold in the European market, CE marking demonstrates compliance with EU safety, health, and environmental protection standards. This is particularly relevant for buyers in Europe, as it is often a legal requirement for certain products.

-

API Standards: The American Petroleum Institute (API) sets standards for products used in the oil and gas industry. For poly hoses used in these applications, adherence to API standards ensures safety and performance under demanding conditions.

What Are the Key Quality Control Checkpoints in Poly Hose Production?

Quality control (QC) checkpoints throughout the manufacturing process help identify and rectify defects early, ensuring that the final products meet required standards. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint focuses on raw materials. Suppliers must provide certificates of conformity, and materials are randomly sampled and tested for compliance with specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted. This may involve monitoring parameters such as temperature, pressure, and dimensional accuracy during extrusion and assembly. Operators are trained to detect anomalies and take corrective actions immediately.

-

Final Quality Control (FQC): After the hoses are completed, they undergo thorough inspection and testing. This includes physical tests (e.g., burst pressure tests) and visual inspections for defects. FQC ensures that only products meeting all specifications are shipped to customers.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers looking to verify supplier QC measures have several options:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality management systems of potential suppliers. This firsthand evaluation can reveal the supplier’s commitment to quality and adherence to standards.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can provide insight into their processes and the results of various inspections. These reports should include data on testing methods, frequency of checks, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality practices. These organizations can conduct comprehensive evaluations and provide certification that the products meet specified standards.

What Testing Methods Are Commonly Used for Poly Hoses?

Several testing methods are employed to ensure the quality and performance of poly hoses:

-

Hydrostatic Testing: This method involves filling the hose with water and pressurizing it to check for leaks and structural integrity. It is a standard test for hoses used in high-pressure applications.

-

Abrasion Resistance Testing: This test assesses the durability of the hose against wear and tear from external factors. Hoses are subjected to controlled abrasion tests to determine their lifespan under typical operating conditions.

-

Chemical Compatibility Testing: Given that poly hoses are often used in industries involving various fluids, testing for chemical compatibility is crucial. This involves exposing the hose material to different chemicals and observing for any degradation or loss of performance.

What Unique Quality Control Nuances Should International Buyers Consider?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, there are specific nuances to consider regarding QC:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers must ensure that their suppliers comply with local regulations, which may differ significantly from those in their home countries.

-

Cultural and Operational Differences: Understanding the cultural context and operational practices of suppliers in different regions can aid in establishing effective communication and expectations regarding quality standards.

-

Logistical Challenges: When sourcing internationally, logistics can impact product quality. Buyers should assess how suppliers manage storage, transportation, and handling to mitigate risks of damage or deterioration during transit.

By understanding these key aspects of manufacturing processes and quality assurance for poly hoses, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Illustrative image related to poly hoses

Practical Sourcing Guide: A Step-by-Step Checklist for ‘poly hoses’

Introduction

Sourcing poly hoses effectively requires a strategic approach to ensure quality, reliability, and suitability for your specific application. This checklist is designed for B2B buyers, particularly those operating in diverse international markets, to streamline the procurement process. By following these steps, you can make informed decisions that align with your operational needs and business goals.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of a successful sourcing strategy. Consider factors such as hose diameter, pressure ratings, material compatibility, and temperature ranges. This clarity will help you communicate effectively with suppliers and ensure that the products meet your operational demands.

- Specific Application Needs: Identify if the hoses will be used for irrigation, industrial applications, or fluid transfer, as different uses require different specifications.

- Regulatory Compliance: Ensure your specifications align with any regional regulations or industry standards pertinent to your application.

Step 2: Conduct Market Research

Understanding the landscape of poly hose suppliers is critical. Research potential vendors who specialize in the type of hoses you require and analyze their market reputation. This step will help you identify key players, emerging companies, and market trends that could influence your purchase decisions.

- Industry Reviews: Look for online reviews, case studies, and testimonials from other businesses in your sector.

- Trade Shows and Expos: Attend industry events to meet suppliers and evaluate their offerings firsthand.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, perform a thorough evaluation. Request detailed company profiles, case studies, and references from existing clients, particularly those in your industry or region. This step is crucial to understanding the supplier’s reliability and product quality.

- Quality Certifications: Verify if the supplier holds relevant certifications such as ISO 9001 or other industry-specific standards.

- Product Range and Customization: Assess whether the supplier can provide a diverse range of products and the ability to customize hoses to meet specific requirements.

Step 4: Request Samples and Test Products

Before finalizing your order, it’s prudent to request samples of the poly hoses you intend to purchase. Testing these samples in real-world conditions allows you to assess their performance and suitability for your needs.

Illustrative image related to poly hoses

- Performance Testing: Evaluate the hoses for durability, flexibility, and resistance to abrasions or chemicals based on your application.

- Compatibility Checks: Ensure that the hoses fit well with existing systems or connectors.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, enter negotiations regarding pricing, delivery terms, and payment conditions. A well-negotiated agreement can save costs and establish a long-term partnership.

- Bulk Order Discounts: Inquire about price breaks for larger orders or long-term commitments.

- Lead Times and Delivery Schedules: Discuss expected lead times and ensure they align with your operational timelines.

Step 6: Verify After-Sales Support and Warranty

Assess the supplier’s commitment to after-sales support and warranty offerings. A reliable supplier should provide robust customer support and warranties that cover defects or performance issues.

- Customer Support Channels: Determine how easily you can reach support representatives for assistance or inquiries.

- Warranty Coverage: Understand the terms of the warranty, including duration and what it covers.

Step 7: Establish a Feedback Loop

After the purchase, create a mechanism for feedback regarding the performance of the poly hoses. This step is vital for ongoing supplier evaluation and ensuring that the products continue to meet your needs.

- Performance Reviews: Regularly assess the hoses’ performance and document any issues or areas for improvement.

- Supplier Communication: Maintain open lines of communication with your supplier to address any concerns or to explore future needs.

By following this structured checklist, B2B buyers can enhance their sourcing strategy for poly hoses, ensuring they make informed and effective procurement decisions.

Illustrative image related to poly hoses

Comprehensive Cost and Pricing Analysis for poly hoses Sourcing

What Are the Key Cost Components in Poly Hose Manufacturing?

When sourcing poly hoses, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used, such as thermoplastic or reinforced polyurethane, significantly impact pricing. Higher-quality materials often lead to improved performance and longevity, justifying a higher initial cost.

-

Labor: Labor costs can vary depending on the manufacturing region. Countries with lower labor costs may offer more competitive pricing, but this can sometimes affect quality.

-

Manufacturing Overhead: This encompasses costs related to facility operations, utilities, and maintenance. Efficient manufacturing processes can help keep these costs in check, allowing suppliers to offer more competitive pricing.

-

Tooling: Specialized tooling for custom hose production can be a significant upfront investment. Buyers should inquire about tooling costs, especially when ordering customized hoses.

-

Quality Control (QC): Rigorous quality assurance processes ensure that products meet industry standards, but they also add to the overall cost. Buyers should assess whether the investment in quality control aligns with their operational needs.

-

Logistics: Shipping costs can vary widely based on the destination, shipping method, and order volume. International buyers should consider the total cost of logistics, including customs duties and taxes.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the margin expectations can assist buyers in negotiating better pricing terms.

How Do Price Influencers Affect Poly Hose Sourcing?

Several factors influence the pricing of poly hoses:

-

Volume/MOQ (Minimum Order Quantity): Larger orders usually result in lower per-unit costs. Buyers should negotiate for volume discounts when possible.

-

Specifications and Customization: Custom hoses tailored to specific applications often come at a premium. Detailed specifications can help suppliers provide accurate quotes, reducing the risk of unexpected costs.

-

Materials and Quality Certifications: Hoses made from high-grade materials and those with certifications (such as ISO or DNV) may command higher prices. Buyers should evaluate the necessity of these certifications based on their industry requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and customer service can impact costs. Established suppliers may charge more due to their proven track record and quality assurance practices.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect pricing. Buyers should understand the implications of terms like FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) to evaluate total costs effectively.

What Are Effective Buyer Tips for Sourcing Poly Hoses?

When sourcing poly hoses, particularly in international markets, consider the following strategies:

-

Negotiate Wisely: Leverage your purchasing volume and long-term relationship potential to negotiate better terms. Suppliers may be more flexible on pricing for committed buyers.

-

Focus on Cost-Efficiency: Calculate the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, replacement frequency, and operational costs. This approach can reveal the true value of investing in higher-quality products.

-

Understand Pricing Nuances in Different Markets: Pricing can differ significantly based on regional economic conditions, currency fluctuations, and local demand. For instance, buyers in Nigeria may face different logistical challenges compared to those in Germany.

-

Request Samples: Before committing to large orders, request samples to assess quality and suitability. This practice can prevent costly mistakes and ensure that the product meets your requirements.

-

Stay Informed on Market Trends: Regularly monitor market conditions, material costs, and new technologies in hose manufacturing. Staying informed can help you anticipate price changes and make better purchasing decisions.

Conclusion

While sourcing poly hoses, a comprehensive understanding of cost components, price influencers, and strategic negotiation techniques is essential. By carefully considering these factors, B2B buyers can make informed decisions that enhance their operational efficiency and profitability. Always remember to verify prices and terms with suppliers, as they can fluctuate based on numerous market dynamics.

Alternatives Analysis: Comparing poly hoses With Other Solutions

Understanding Alternatives to Poly Hoses for Fluid Conveyance

In the dynamic landscape of industrial fluid conveyance solutions, poly hoses have established themselves as a versatile option. However, it’s essential for B2B buyers to consider alternative solutions that might better meet specific operational needs. This section examines two viable alternatives: PVC hoses and stainless steel hoses, highlighting their comparative advantages and disadvantages.

Illustrative image related to poly hoses

| Comparison Aspect | Poly Hoses | PVC Hoses | Stainless Steel Hoses |

|---|---|---|---|

| Performance | Flexible, lightweight, and resistant to abrasion; suitable for various applications. | Good for low-pressure applications; not as durable under high stress. | Excellent durability and pressure resistance; ideal for high-temperature applications. |

| Cost | Generally cost-effective with a wide range of pricing based on specifications. | Lower initial cost, making it attractive for budget-sensitive projects. | Higher upfront cost; long-term investment due to durability. |

| Ease of Implementation | Easy to install and handle; minimal tools required for setup. | Lightweight and easy to install; compatible with standard fittings. | Requires specialized fittings and tools for installation; may need professional assistance. |

| Maintenance | Low maintenance; resistant to wear, but may require periodic inspections. | Moderate maintenance; prone to wear and tear, necessitating replacements. | Minimal maintenance; corrosion-resistant but may need occasional cleaning. |

| Best Use Case | Ideal for agricultural, irrigation, and construction applications. | Best for light-duty applications like garden hoses and low-pressure water transport. | Optimal for industrial applications requiring high pressure and temperature stability. |

In-Depth Analysis of Alternative Solutions

PVC Hoses

PVC hoses are a popular alternative to poly hoses, particularly for lighter-duty applications. Their lower cost makes them an attractive option for businesses operating on tight budgets. PVC hoses are lightweight and easy to handle, which simplifies installation. However, they are generally less durable than poly hoses and may not withstand high pressures or extreme temperatures, leading to more frequent replacements. Their best use case includes garden irrigation and low-pressure water transport, where flexibility and ease of use are prioritized.

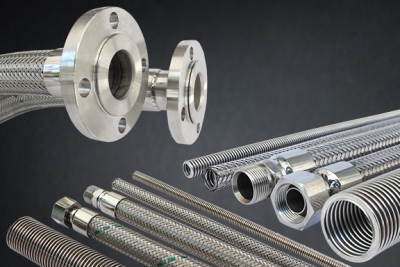

Stainless Steel Hoses

Stainless steel hoses represent a robust alternative, especially in environments where high pressure and temperature resistance are critical. These hoses are exceptionally durable and can handle harsh chemicals, making them suitable for industrial applications. While the initial investment is significantly higher than both poly and PVC hoses, the long-term savings in maintenance and replacement costs can justify the expense. Installation can be more complex and may require specialized fittings and tools, which could deter some buyers. Stainless steel hoses are best suited for industries such as oil and gas, pharmaceuticals, and food processing.

Making the Right Choice: How to Select the Best Hose Solution

When evaluating which hose solution to implement, B2B buyers should carefully consider their operational requirements, budget constraints, and the specific conditions under which the hoses will be used. Poly hoses offer a balanced combination of flexibility, durability, and cost-effectiveness for a wide range of applications. In contrast, PVC hoses might be the right choice for low-pressure, budget-conscious projects, while stainless steel hoses are ideal for high-performance industrial applications. Conducting a thorough needs assessment will enable buyers to select the most suitable solution that aligns with their operational objectives and industry standards.

Essential Technical Properties and Trade Terminology for poly hoses

What Are the Key Technical Properties of Poly Hoses for B2B Buyers?

When evaluating poly hoses for industrial applications, understanding their technical properties is crucial. Here are several key specifications that buyers should consider:

Illustrative image related to poly hoses

-

Material Grade

Poly hoses are often made from materials like polyethylene (PE) or polyurethane (PU). The material grade affects the hose’s flexibility, durability, and resistance to chemicals and UV light. High-grade materials ensure longer service life and lower replacement costs, which is vital for maintaining operational efficiency. -

Working Pressure

This specification indicates the maximum pressure the hose can handle during operation. It is critical for safety and performance; using a hose that cannot withstand the required pressure can lead to failures and hazardous situations. Buyers should select hoses with a working pressure that exceeds their application’s demands to ensure reliability. -

Temperature Resistance

Poly hoses are designed to operate within specific temperature ranges. Understanding the temperature resistance is vital for applications involving hot or cold fluids. Selecting a hose with inadequate temperature tolerance can lead to material degradation and potential system failures. -

Bend Radius

The bend radius is the minimum radius a hose can be bent without compromising its integrity. A smaller bend radius allows for greater flexibility in installation, especially in tight spaces. Buyers should consider this specification to ensure the hose can be routed effectively within their systems. -

Tolerance Levels

Tolerance refers to the permissible limits of variation in dimensions and physical properties of the hose. Tight tolerances are essential for applications that require precision and reliability. For manufacturers and OEMs, maintaining strict tolerance levels is vital to ensure compatibility and performance in high-stakes environments. -

Abrasion Resistance

This property measures the hose’s ability to withstand wear and tear from external factors. Hoses used in rugged environments must have high abrasion resistance to minimize maintenance and replacement costs. This is especially important for industries like construction and mining, where hoses are subjected to harsh conditions.

What Trade Terms Should B2B Buyers Understand When Sourcing Poly Hoses?

Familiarity with industry jargon can greatly streamline the procurement process. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of poly hoses, understanding OEM relationships can help buyers identify reliable suppliers who produce hoses that meet specific industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, especially for businesses looking to maintain cost-effective stock levels without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. Crafting a detailed RFQ helps ensure that buyers receive accurate quotes that reflect their exact needs, enabling better comparison and decision-making. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for understanding shipping costs, insurance, and risk management in international transactions. -

Lead Time

Lead time is the amount of time from placing an order to receiving the product. Understanding lead times helps buyers plan their operations and inventory levels effectively, ensuring that they have the necessary materials when needed. -

Certification Standards

Certification standards, such as ISO or ASTM, indicate that a product meets specific quality and safety benchmarks. Familiarity with these certifications can help buyers evaluate the reliability and performance of poly hoses, ensuring compliance with industry regulations.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing poly hoses, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the poly hoses Sector

What Are the Current Market Dynamics and Key Trends in the Poly Hoses Sector?

The global poly hoses market is experiencing robust growth, driven by increasing demand across various industries, including agriculture, construction, automotive, and manufacturing. Key factors influencing this demand include the rise in infrastructure projects, the expansion of irrigation systems, and the growing need for efficient fluid transfer solutions. Emerging technologies, such as advancements in material science and manufacturing processes, are enabling the production of high-performance hoses that offer improved durability, flexibility, and resistance to environmental factors.

B2B buyers are increasingly leveraging digital platforms for sourcing, leading to enhanced transparency and efficiency in the procurement process. The adoption of data analytics tools allows businesses to make informed purchasing decisions by assessing supplier performance and market trends. Furthermore, the focus on custom-engineered solutions is gaining traction, as businesses look for tailored products that meet specific operational requirements.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of regional market dynamics. For instance, in Africa, the growing agricultural sector is driving demand for poly hoses in irrigation systems. In contrast, European buyers are increasingly prioritizing compliance with stringent quality and safety standards. Understanding these regional nuances is crucial for successful sourcing strategies.

How Is Sustainability Shaping the Sourcing of Poly Hoses in B2B Markets?

Sustainability has become a cornerstone of sourcing strategies in the poly hoses sector. As environmental concerns grow, businesses are prioritizing suppliers that demonstrate a commitment to sustainable practices. The production of poly hoses can have significant environmental impacts, including resource depletion and waste generation. Therefore, B2B buyers must evaluate the ecological footprint of their suppliers, focusing on those who adopt eco-friendly manufacturing processes and materials.

Ethical sourcing is also gaining importance, with buyers increasingly seeking suppliers who uphold fair labor practices and contribute positively to their communities. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ labels serve as indicators of a supplier’s commitment to sustainability. By partnering with certified suppliers, businesses can enhance their reputation and align with consumer expectations for responsible sourcing.

Moreover, the use of recycled or bio-based materials in the production of poly hoses is becoming more prevalent. These innovations not only reduce environmental impact but can also lead to cost savings in the long run. As the market evolves, B2B buyers should prioritize suppliers who are proactive in adopting sustainable practices, ensuring that their sourcing strategies are aligned with global sustainability goals.

What Is the Historical Context of Poly Hoses and Their Evolution in B2B Markets?

The evolution of poly hoses can be traced back to the mid-20th century when advancements in polymer technology began to revolutionize fluid conveyance solutions. Initially, traditional materials like rubber and metal dominated the market, but the introduction of polyvinyl chloride (PVC) and other synthetic materials paved the way for the development of lighter, more flexible hoses.

Over the years, innovations in material science led to the creation of reinforced hoses that can withstand higher pressures and harsh environmental conditions. This evolution has enabled poly hoses to find applications in diverse industries, from agriculture to aerospace. As manufacturers continue to invest in research and development, the poly hoses market is poised for further growth, driven by increasing demand for high-performance and sustainable fluid transfer solutions.

Understanding the historical context of poly hoses helps B2B buyers appreciate the advancements that have shaped the current market and anticipate future trends that could impact their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of poly hoses

-

How do I select the right poly hose for my application?

Choosing the right poly hose depends on several factors, including the type of fluid being transported, pressure requirements, temperature range, and environmental conditions. Consider the specific needs of your application, such as flexibility, chemical resistance, and abrasion resistance. Consult with suppliers who offer custom engineering solutions to ensure you select a hose that meets your operational requirements. It’s also beneficial to review industry standards and certifications relevant to your application to ensure compliance and reliability. -

What are the advantages of using poly hoses over traditional materials?

Poly hoses offer numerous advantages, including lightweight construction, flexibility, and resistance to abrasion and corrosion. They are often more cost-effective than traditional rubber hoses and provide better performance in various applications, such as fluid transfer and irrigation. Additionally, poly hoses can be engineered for specific applications, providing tailored solutions that enhance efficiency and reduce maintenance costs. Their versatility makes them suitable for diverse industries, from agriculture to manufacturing. -

What customization options are available for poly hoses?

Many manufacturers provide extensive customization options for poly hoses, including varying diameters, lengths, colors, and fittings. You can also request hoses with specific performance characteristics, such as higher pressure ratings or enhanced chemical resistance. Engaging with suppliers who specialize in custom solutions can help you design hoses tailored to your unique application needs, ensuring optimal performance and longevity. -

What is the typical minimum order quantity (MOQ) for poly hoses?

Minimum order quantities for poly hoses can vary significantly based on the manufacturer and the specific product. Generally, MOQs can range from a few hundred meters to several thousand, depending on the complexity and customization of the hose. It’s advisable to discuss your requirements directly with suppliers to understand their MOQ policies, which may be flexible for larger orders or specific projects. -

What payment terms should I expect when sourcing poly hoses internationally?

Payment terms can differ widely among suppliers and regions. Common options include advance payment, letter of credit, or payment upon delivery. Many B2B suppliers offer credit terms based on the buyer’s creditworthiness and relationship history. It’s essential to clarify payment terms early in the negotiation process to ensure alignment and prevent misunderstandings. -

How can I ensure the quality of poly hoses from international suppliers?

To ensure quality, it’s crucial to vet potential suppliers thoroughly. Request certifications, such as ISO standards, and inquire about their quality assurance processes. Ask for product samples and conduct performance testing to evaluate their suitability for your application. Additionally, consider suppliers with a strong reputation and positive customer reviews in your industry to mitigate risks associated with international sourcing. -

What logistics considerations should I keep in mind when importing poly hoses?

When importing poly hoses, consider shipping methods, delivery times, and customs regulations. Understand the costs associated with freight, insurance, and potential tariffs. Collaborating with a logistics partner experienced in international trade can help streamline the import process. Additionally, ensure that your supplier can provide the necessary documentation, such as bills of lading and customs declarations, to facilitate smooth customs clearance. -

How do I address potential issues with poly hoses after purchase?

Addressing issues with poly hoses post-purchase involves establishing clear communication with your supplier. Be prepared to provide detailed information about the problem, including usage conditions and any visible defects. Many reputable suppliers offer warranties or service agreements, allowing you to seek replacements or repairs. Documenting issues and maintaining a good relationship with your supplier can facilitate quicker resolutions and future support.

Top 2 Poly Hoses Manufacturers & Suppliers List

1. Rolair – Poly Hose

Domain: rolair.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Poly Hose”, “description”: “The flexible, lightweight polyurethane hose is kink-resistant and capable of performing in all weather conditions. Additionally, it’s field repairable.”, “included_items”: [“Industrial coupler”, “plug”], “available_varieties”: [{“size”: “1/4″ x 50′”, “model”: “1450POLY”}, {“size”: “1/4″ x 100′”, “model”: “14100POLY”}, {“size”: “3/8″ x 50′”, “model”: “3…

2. Poly-Flow – Thermoplastic Hose Solutions

Domain: polyflowhose.com

Registered: 2009 (16 years)

Introduction: Poly-Flow offers a wide range of thermoplastic hose products and fittings, including hydraulic hoses, cleaning and water jetting hoses, and paint spray and specialty hoses. They specialize in bonded thermoplastic hydraulic hoses that provide superior strength, flexibility, and resistance to corrosion and abrasion. Additionally, Poly-Flow manufactures OEM assemblies tailored to the specific require…

Strategic Sourcing Conclusion and Outlook for poly hoses

How Can Strategic Sourcing Enhance Your Poly Hose Procurement?

In conclusion, strategic sourcing of poly hoses represents a crucial opportunity for international B2B buyers aiming to optimize their supply chains. By leveraging the diverse offerings of leading manufacturers, such as Polyhose, businesses can access high-quality products that meet stringent industry standards. The emphasis on customized solutions, technological innovation, and robust customer support can significantly reduce lead times and enhance operational efficiency.

Moreover, understanding the specific needs of various industries—ranging from agriculture to aerospace—allows buyers to make informed decisions that align with their operational goals. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for flexible, durable, and cost-effective poly hoses is set to rise.

Looking ahead, it is essential for B2B buyers to engage actively with suppliers, explore new product innovations, and consider long-term partnerships that foster growth. This proactive approach not only secures a reliable supply chain but also positions businesses to adapt swiftly to changing market dynamics. Embrace the future of fluid conveyance—start your journey in strategic sourcing today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to poly hoses

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.