The Definitive Guide to Plunger Key: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for plunger key

In an increasingly interconnected global marketplace, sourcing the right plunger key can present unique challenges for international B2B buyers. Whether you are navigating the specific requirements of barrel locks in telecommunications or the precise functionalities of plunger keys for various machinery, the stakes are high. This guide serves as your comprehensive resource, covering essential topics such as types of plunger keys, their diverse applications across industries, and strategies for effective supplier vetting.

Understanding the technical specifications, such as the materials used and compatibility with various locking mechanisms, is critical for making informed purchasing decisions. Additionally, we delve into cost considerations, enabling buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Saudi Arabia and Vietnam—to evaluate their options strategically.

By equipping you with actionable insights and a framework for assessing suppliers, this guide empowers you to make confident decisions that enhance operational efficiency and security. Whether you are a seasoned buyer or new to the procurement process, our aim is to simplify your journey in sourcing high-quality plunger keys, ensuring you meet your business needs with precision and reliability.

Understanding plunger key Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Barrel Lock Plunger Key | Designed for specific barrel locks; made from high carbon steel | CATV installations, telecommunications | Pros: Durable, tamper-resistant; Cons: Limited to specific lock types. |

| Flair 58 Plunger Key | Facilitates optimal plunger orientation; compatible with Flair 58 | Coffee equipment manufacturers | Pros: Enhances equipment performance; Cons: Not compatible with newer models. |

| Single Slot Plunger Key | Simplistic design for straightforward operations | General industrial applications | Pros: Easy to use; Cons: May lack advanced features. |

| Multi-Function Plunger Key | Versatile design for various lock types | Security systems, access control | Pros: High adaptability; Cons: Complexity may lead to misuse. |

| Custom Plunger Key | Tailored designs for specific customer needs | Specialized machinery and equipment | Pros: Exact fit for unique applications; Cons: Higher cost and longer lead times. |

What Are the Characteristics of the Barrel Lock Plunger Key?

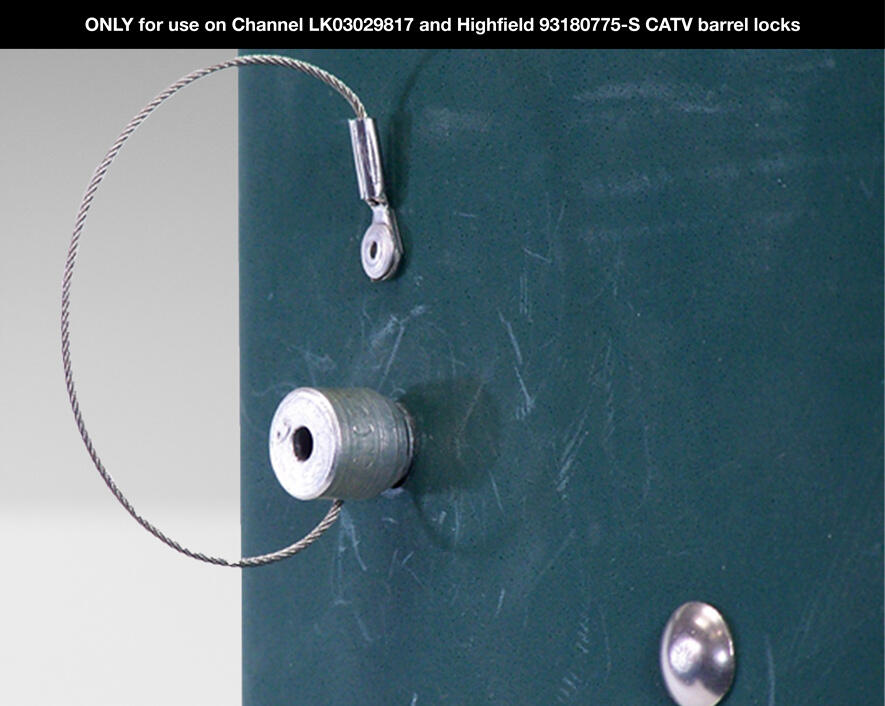

The Barrel Lock Plunger Key is specifically designed to unlock certain barrel locks, such as the Channell LK03029817 and Highfield 93180775-S. Made from high carbon alloy steel, this tool is engineered for heavy-duty use and is particularly valued in CATV installations and telecommunications. Buyers should consider its durability and tamper-resistance, but note that its application is limited to specific locks, which may restrict versatility.

How Does the Flair 58 Plunger Key Enhance Equipment Performance?

The Flair 58 Plunger Key is crafted to optimize the orientation of plungers in coffee equipment, ensuring that the tabs engage effectively when the lever is lifted. This product is particularly relevant for manufacturers in the coffee industry. While it significantly enhances performance, buyers should be aware that it is not compatible with single slot valve plungers purchased after a specific date, making it crucial to confirm compatibility before purchase.

What Are the Advantages of Using a Single Slot Plunger Key?

The Single Slot Plunger Key is characterized by its straightforward design, making it user-friendly for various industrial applications. This key is ideal for businesses looking for a simple solution without the need for complex functionalities. While it offers ease of use, buyers should consider that its lack of advanced features may limit its effectiveness in more specialized environments.

Why Choose a Multi-Function Plunger Key for Security Systems?

The Multi-Function Plunger Key is designed to work with various lock types, making it a versatile choice for security systems and access control applications. Its adaptability is a significant advantage for businesses that require flexibility in their locking mechanisms. However, the complexity of this tool may lead to potential misuse, so training for end-users is essential to maximize its benefits.

What Are the Benefits of Custom Plunger Keys for Specialized Machinery?

Custom Plunger Keys are tailored to meet specific requirements of unique machinery or equipment. This bespoke approach ensures a perfect fit, which is particularly beneficial for specialized manufacturers. While the precision of custom keys can enhance operational efficiency, buyers should be prepared for higher costs and longer lead times compared to off-the-shelf solutions.

Key Industrial Applications of plunger key

| Industry/Sector | Specific Application of plunger key | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Unlocking CATV barrel locks | Ensures timely access to network infrastructure | Compatibility with specific lock types, durability, and security features |

| Manufacturing | Adjusting machinery settings | Enhances operational efficiency and minimizes downtime | Material quality, ease of use, and availability of replacements |

| Food and Beverage | Optimizing espresso machine performance | Improves product consistency and reduces waste | Compatibility with specific machine models, ease of cleaning, and durability |

| Security and Access Control | Keying and unkeying security locks | Provides quick access for maintenance and security checks | Security standards, tamper resistance, and ergonomic design |

| Automotive | Accessing vehicle locking mechanisms | Facilitates efficient repairs and maintenance | Material strength, compatibility with various lock types, and ease of handling |

How is the plunger key utilized in telecommunications and what are the benefits for B2B buyers?

In the telecommunications sector, plunger keys are essential tools for unlocking CATV barrel locks, which secure network infrastructure. This application is critical for ensuring quick access to vital equipment for maintenance and upgrades, thereby minimizing service interruptions. For international B2B buyers, particularly from regions like Africa and the Middle East, sourcing plunger keys that are compatible with specific lock types, such as Channell and Highfield, is paramount. Buyers should prioritize durability and tamper resistance to enhance security and reliability in their operations.

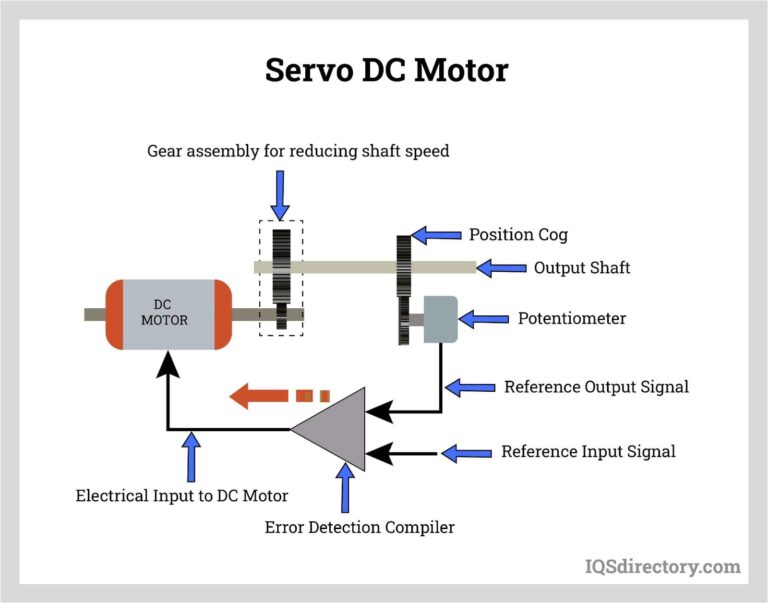

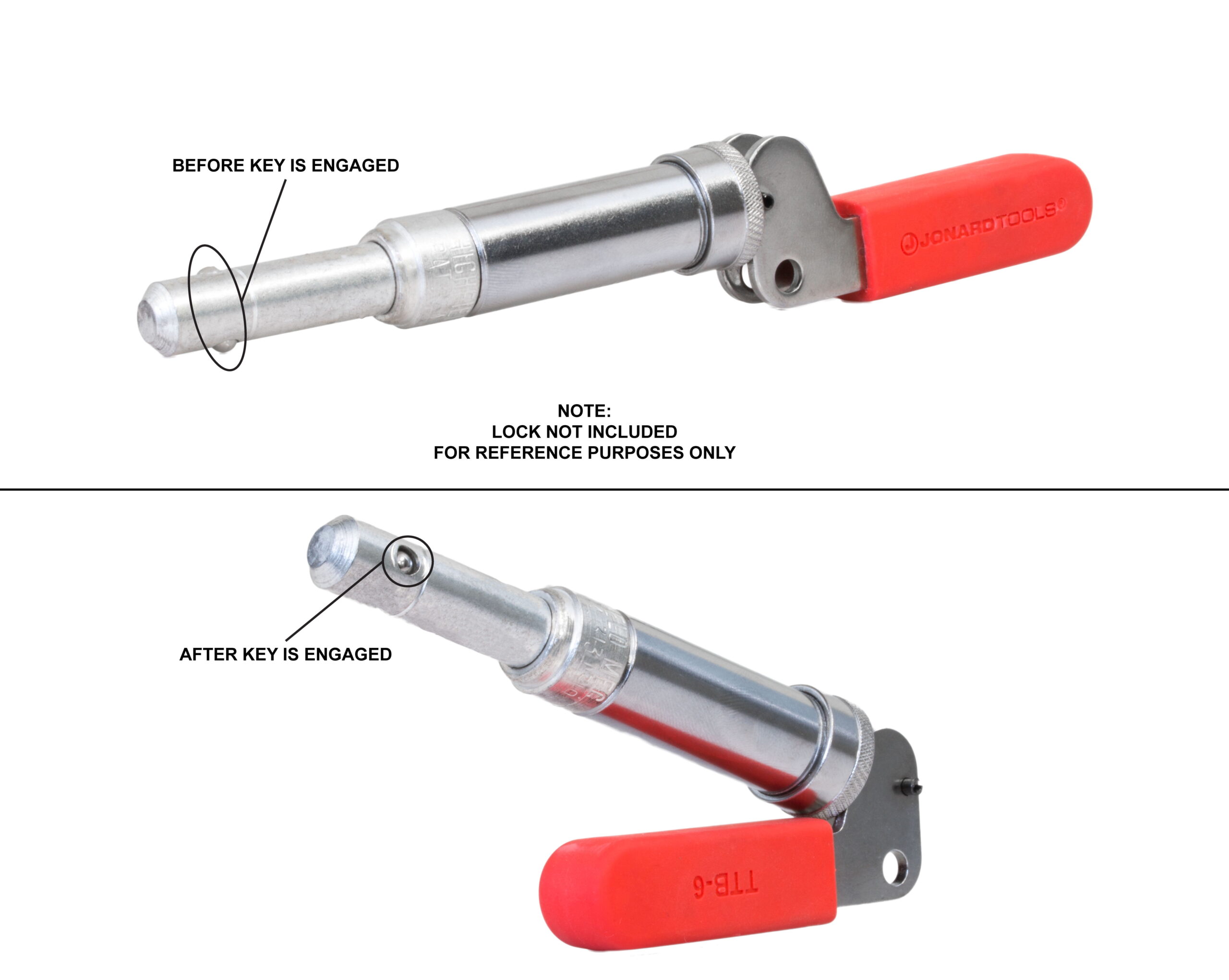

Illustrative image related to plunger key

What role does the plunger key play in manufacturing processes?

In manufacturing, plunger keys are used to adjust machinery settings efficiently. This application is particularly valuable in environments where precision is crucial, as it allows for quick modifications to machinery without extensive downtime. For businesses in South America and Europe, sourcing plunger keys made from high-quality materials is essential to withstand the rigors of industrial use. Buyers must consider the ease of use and the availability of replacement parts to ensure continuous operation and minimize interruptions in production.

How does the plunger key enhance performance in the food and beverage industry?

In the food and beverage industry, plunger keys are instrumental in optimizing the performance of espresso machines. By allowing users to orient the plunger for optimal engagement, these tools ensure consistent extraction and quality of beverages. This application significantly reduces waste and improves customer satisfaction. B2B buyers from regions like Europe and South America should focus on compatibility with specific machine models and the ease of cleaning, as hygiene is a top priority in food service environments.

Why is the plunger key important for security and access control applications?

In security and access control, plunger keys are utilized for keying and unkeying various locks, providing quick access to secure areas for maintenance and inspections. This application is vital for businesses that prioritize security, as it facilitates rapid responses to security breaches or maintenance needs. International buyers should consider sourcing plunger keys that meet specific security standards, ensuring they provide tamper resistance and ergonomic design for ease of use, especially in high-security environments.

Illustrative image related to plunger key

How does the automotive industry benefit from the use of plunger keys?

In the automotive sector, plunger keys enable technicians to access vehicle locking mechanisms efficiently. This application is crucial for performing repairs and maintenance tasks quickly, which can enhance customer satisfaction and operational efficiency. B2B buyers in this industry should prioritize the material strength of plunger keys, ensuring they are compatible with various lock types and easy to handle. This attention to detail can lead to improved service times and better overall vehicle management.

3 Common User Pain Points for ‘plunger key’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Plunger Key for Specific Locks

The Problem: B2B buyers often struggle with sourcing a plunger key that is compatible with specific types of barrel locks. For instance, a telecommunications company may require a plunger key for Channell LK03029817 locks, but many suppliers offer generic tools that do not meet the specifications. This mismatch can lead to operational delays, increased costs, and frustration, as the wrong tools can result in time wasted on returns or exchanges.

The Solution: To avoid compatibility issues, buyers should conduct thorough research before making a purchase. It’s crucial to specify the exact type of barrel lock in need and ensure that the plunger key matches those specifications. Buyers should reach out to manufacturers or suppliers directly, asking for detailed product specifications and compatibility confirmations. Additionally, consider sourcing from reputable brands known for their precision tools, like Jonard Tools, which provide clear descriptions of their products, ensuring you acquire the right key for your specific needs.

Scenario 2: Inconsistent Quality and Durability of Plunger Keys

The Problem: Another common pain point for B2B buyers is the inconsistency in quality and durability of plunger keys. Low-quality keys may fail under heavy use, leading to frequent replacements and higher long-term costs. This is particularly problematic for businesses that rely on these tools for regular maintenance and installation tasks, where downtime can result in significant financial losses.

The Solution: To mitigate this issue, it is vital to invest in high-quality plunger keys made from durable materials, such as high carbon alloy steel. Buyers should prioritize suppliers that offer warranties or guarantees on their products. Additionally, reading customer reviews and case studies can provide insights into the long-term performance of a product. Implementing a standardized evaluation process for tools based on durability and user feedback can significantly enhance the procurement process and ensure long-lasting tool reliability.

Scenario 3: Lack of User Guidance on Proper Usage of Plunger Keys

The Problem: Many B2B buyers encounter challenges due to insufficient guidance on how to effectively use plunger keys. Misuse can lead to damage to both the key and the locking mechanism, resulting in costly repairs. For instance, a technician might not be aware of the correct orientation or technique required to engage the plunger key, which can result in wasted time and resources.

The Solution: To address this issue, suppliers should provide comprehensive user manuals or instructional videos that detail the proper usage of their plunger keys. Buyers can also benefit from seeking training sessions or workshops that focus on the correct handling of these tools. Furthermore, establishing a relationship with the supplier for ongoing technical support can help resolve any operational challenges swiftly. By ensuring that all team members are well-informed about the tools they use, businesses can significantly reduce the risk of misuse and enhance their operational efficiency.

Strategic Material Selection Guide for plunger key

What Are the Key Materials Used in Plunger Key Manufacturing?

When selecting materials for plunger keys, it is essential to consider their properties, performance, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of plunger keys, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Does High Carbon Alloy Steel Perform in Plunger Keys?

High carbon alloy steel is a prevalent choice for plunger keys, particularly for applications requiring strength and durability. This material boasts excellent tensile strength and resistance to wear, making it suitable for heavy-duty use. High carbon alloy steel also provides superior tamper resistance, which is crucial for security applications.

Pros: The high strength-to-weight ratio and durability of this material make it ideal for demanding environments. Additionally, it is relatively cost-effective compared to other high-performance materials.

Cons: However, high carbon alloy steel is susceptible to corrosion if not properly treated, which may limit its longevity in humid or corrosive environments. The manufacturing process can also be complex due to the need for heat treatment.

Impact on Application: This material is particularly effective in applications involving CATV barrel locks, where precision and reliability are paramount.

Considerations for International Buyers: Buyers from regions such as Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, to guarantee material quality and performance.

What Role Does Stainless Steel Play in Plunger Key Applications?

Stainless steel is another popular material for plunger keys, known for its excellent corrosion resistance and aesthetic appeal. It is often used in environments where exposure to moisture or chemicals is a concern.

Pros: The primary advantage of stainless steel is its resistance to rust and corrosion, making it suitable for outdoor and marine applications. It also offers good strength and durability.

Cons: On the downside, stainless steel can be more expensive than other materials, which may affect cost-sensitive projects. Additionally, its manufacturing can be more complex due to the need for specialized machining.

Impact on Application: Stainless steel plunger keys are ideal for applications where hygiene and corrosion resistance are critical, such as in food processing or pharmaceutical industries.

Considerations for International Buyers: Buyers in Europe may prefer stainless steel due to stringent regulations regarding material safety and environmental impact. Compliance with EU standards is essential.

Why Choose Plastic for Plunger Keys?

Plastic materials, such as nylon or polycarbonate, are increasingly being used in the production of plunger keys, especially where weight and cost are significant factors.

Pros: Plastic is lightweight, which reduces shipping costs and makes handling easier. It is also resistant to corrosion and can be manufactured in various colors and designs.

Cons: However, plastic may not offer the same level of strength or durability as metals, making it less suitable for high-stress applications. It can also be affected by temperature extremes, leading to potential failures.

Impact on Application: Plastic plunger keys are often used in low-stress applications or where aesthetics are important, such as in consumer products.

Considerations for International Buyers: Buyers from South America and Africa may find plastic options appealing due to their lower cost and ease of use. However, they should ensure that the material meets local safety standards.

How Do Brass Plunger Keys Compare?

Brass is another material used for plunger keys, particularly in applications requiring good electrical conductivity and corrosion resistance.

Pros: Brass offers excellent corrosion resistance and is less likely to tarnish compared to other metals. It also provides a good balance of strength and weight.

Illustrative image related to plunger key

Cons: The main disadvantage of brass is its relatively high cost compared to other materials like steel or plastic. Additionally, it may not be suitable for high-stress applications.

Impact on Application: Brass plunger keys are often used in electrical applications where conductivity is essential, as well as in decorative applications due to their aesthetic appeal.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider the availability and cost of brass, as well as compliance with relevant standards.

Illustrative image related to plunger key

Summary of Material Selection for Plunger Keys

| Material | Typical Use Case for plunger key | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High Carbon Alloy Steel | CATV barrel locks | High strength and durability | Susceptible to corrosion | Medium |

| Stainless Steel | Outdoor and marine applications | Excellent corrosion resistance | Higher cost and complex machining | High |

| Plastic | Low-stress applications | Lightweight and cost-effective | Lower strength and durability | Low |

| Brass | Electrical and decorative applications | Good corrosion resistance and conductivity | Relatively high cost | Medium |

In conclusion, selecting the right material for plunger keys is crucial for ensuring optimal performance and longevity. By understanding the properties and implications of each material, international B2B buyers can make informed decisions that align with their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for plunger key

What Are the Key Stages in the Manufacturing Process of Plunger Keys?

The manufacturing process of plunger keys involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers assess the capabilities of suppliers and the quality of the products they offer.

Material Preparation: What Materials Are Used in Plunger Key Manufacturing?

The first step in the manufacturing process is material preparation. Most plunger keys are made from high carbon alloy steel, known for its strength and durability. The steel is sourced from reputable suppliers who meet international material standards. Before production begins, the raw material undergoes inspection to ensure it meets specifications, including tensile strength and corrosion resistance.

Forming: How Are Plunger Keys Shaped and Moulded?

The next stage is forming, which typically involves processes like forging or machining. In forging, heated steel is shaped into the desired form using dies, while machining involves cutting the material to precise dimensions. Advanced CNC (Computer Numerical Control) machines are often employed to achieve high precision and reduce material waste. This stage is crucial for ensuring that the plunger key fits its intended lock type accurately.

Assembly: What Assembly Techniques Are Commonly Used?

Following the forming process, the components of the plunger key are assembled. This may include integrating springs or other mechanisms that enhance the key’s functionality. For instance, a smooth plunger and a heavy-duty spring are essential for durability and ease of use. The assembly process is typically automated to ensure consistency, but manual checks may also be performed to maintain quality standards.

Finishing: How Is the Final Product Prepared for Market?

The finishing stage includes surface treatment processes such as polishing, coating, or plating. These treatments not only enhance the aesthetic appeal of the plunger key but also improve its resistance to corrosion and wear. Quality control measures are put in place during this stage to ensure that the final product adheres to specifications, particularly regarding finish quality and functional performance.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical aspect of the manufacturing process for plunger keys, particularly for international B2B buyers. Adhering to recognized standards ensures that the products meet both safety and performance requirements.

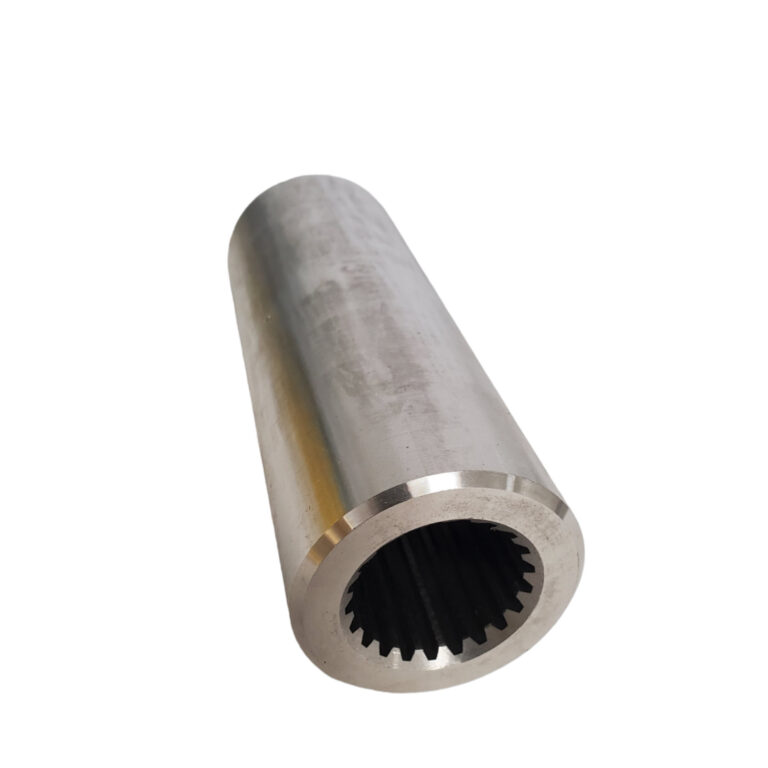

Illustrative image related to plunger key

Which International Standards Apply to Plunger Key Manufacturing?

The ISO 9001 standard is widely recognized in various industries, including hardware manufacturing. This standard focuses on quality management systems and continuous improvement, ensuring that manufacturers maintain high-quality production processes. Compliance with ISO 9001 indicates that a manufacturer has implemented effective quality management practices.

For specific industries, additional certifications may be relevant. For instance, CE marking is essential for products sold in the European market, indicating compliance with EU safety, health, and environmental protection standards. In sectors like oil and gas, API (American Petroleum Institute) standards may apply.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integral to the manufacturing process of plunger keys. Several QC checkpoints are typically established:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components before production begins. Ensuring that only materials meeting specified criteria are used is crucial for the overall quality of the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to monitor production consistency and adherence to specifications. This includes measuring dimensions and testing functionality at various stages.

-

Final Quality Control (FQC): After assembly and finishing, a final inspection is conducted to verify that the plunger keys meet all specifications and quality standards before they are packaged and shipped.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality assurance practices of suppliers is essential. Here are some actionable steps:

Illustrative image related to plunger key

What Auditing and Reporting Methods Can Buyers Use?

Buyers should request documentation of the manufacturer’s quality management system, including ISO certifications and audit reports. Regular audits—either conducted by the buyer or a third-party organization—can provide insights into the supplier’s compliance with quality standards.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection agencies can further validate the quality of the products. These agencies conduct independent assessments of the manufacturing process and final products, ensuring compliance with international standards and specifications. Buyers can request inspection reports prior to shipment, providing an added layer of assurance.

What Are the Unique Quality Control Considerations for International Buyers?

B2B buyers from different regions may face unique challenges regarding quality assurance. For instance:

-

Cultural Differences: Understanding the local manufacturing culture can help buyers navigate quality expectations and communication styles.

-

Regulatory Variances: Different regions may have varying standards and regulations regarding product safety and quality. Buyers must ensure that their suppliers comply with local regulations in their target markets.

-

Logistics and Shipping Risks: Products may be exposed to different conditions during shipping, impacting quality. Buyers should consider how suppliers address these risks, including packaging methods and shipping protocols.

By understanding the manufacturing processes and quality assurance measures in place for plunger keys, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only helps in assessing product quality but also in building stronger partnerships with manufacturers who prioritize excellence and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plunger key’

Introduction

Sourcing a plunger key requires careful consideration of technical specifications, supplier capabilities, and regional compliance. This guide provides a structured checklist to help international B2B buyers navigate the procurement process efficiently, ensuring that they secure the right product for their specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental to sourcing the right plunger key. Consider factors such as compatibility with specific lock types, required material durability, and dimensions. For instance, if you need a plunger key for Channell LK03029817 or Highfield 93180775-S locks, ensure the product matches the required inner diameter and material properties.

- Key Features to Consider:

- Lock compatibility (e.g., barrel locks).

- Material specifications (e.g., high carbon alloy steel for strength).

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in plunger keys. Look for manufacturers with a proven track record in producing high-quality tools, particularly those that have experience in your industry or region. This step helps you build a shortlist of reliable suppliers.

Illustrative image related to plunger key

- What to Look For:

- Established reputation in the industry.

- Positive customer reviews and testimonials.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that your potential suppliers hold the necessary certifications. This is crucial for ensuring product quality and compliance with international standards, especially in regions with strict regulations. Certifications can also indicate a supplier’s commitment to quality assurance.

- Key Certifications to Verify:

- ISO 9001 for quality management.

- Relevant safety certifications for tools.

Step 4: Request Samples for Testing

Always request samples of the plunger key before placing a bulk order. Testing samples allows you to assess the quality, functionality, and compatibility with your existing locks. This step minimizes the risk of costly errors and ensures that you receive a product that meets your specifications.

- Testing Considerations:

- Check for ease of use and reliability.

- Confirm that the sample meets your technical requirements.

Step 5: Assess Pricing and Payment Terms

Evaluate the pricing structures and payment terms offered by your shortlisted suppliers. Competitive pricing is important, but it should not compromise quality. Additionally, understanding payment terms can help you manage cash flow effectively.

- Pricing Factors to Consider:

- Bulk order discounts.

- Shipping and handling fees.

Step 6: Review Logistics and Delivery Options

Logistics play a crucial role in the timely delivery of your plunger keys. Discuss delivery timelines and options with suppliers, especially if you operate in regions with unique logistical challenges. Ensure that the supplier can meet your deadlines without incurring additional costs.

Illustrative image related to plunger key

- Logistics Questions to Ask:

- What shipping methods do they offer?

- Are they familiar with customs regulations in your region?

Step 7: Establish a Long-Term Relationship

Once you have successfully sourced your plunger keys, focus on building a long-term relationship with your supplier. A reliable partnership can lead to better pricing, priority service, and insights into new products or innovations in the market.

- Benefits of a Strong Supplier Relationship:

- Enhanced communication and responsiveness.

- Opportunities for collaboration on future projects.

By following this checklist, B2B buyers can streamline their sourcing process for plunger keys, ensuring they make informed and strategic procurement decisions.

Comprehensive Cost and Pricing Analysis for plunger key Sourcing

What Are the Key Cost Components for Plunger Key Sourcing?

When sourcing plunger keys, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of the material significantly impacts the overall cost. For instance, high carbon alloy steel, commonly used in plunger keys for its durability and tamper resistance, tends to be more expensive than lower-grade alternatives.

-

Labor: The complexity of the manufacturing process can influence labor costs. Skilled labor is often required for precision tooling and assembly, particularly for custom designs.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, equipment maintenance, and factory management. Efficient production processes can help minimize these costs.

-

Tooling: Initial tooling costs can be substantial, especially if a unique design or customization is required. This expense is typically amortized over larger production runs, making it vital to consider the volume of orders.

-

Quality Control (QC): Ensuring that each plunger key meets quality standards is essential, particularly for industries where reliability is critical. Robust QC processes can add to the cost but are necessary for maintaining product integrity.

-

Logistics: Shipping and handling costs vary based on the supplier’s location and the buyer’s destination. International shipping can incur additional fees, including customs duties and taxes.

-

Margin: Suppliers typically add a margin to cover their operational costs and ensure profitability. Understanding the market dynamics can help buyers gauge whether the margins are reasonable.

How Do Price Influencers Affect Plunger Key Costs?

Several factors can influence the pricing of plunger keys:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often results in lower per-unit costs. Buyers should negotiate MOQs to maximize savings, especially when planning for future inventory needs.

-

Specifications and Customization: Custom designs tailored to specific applications can lead to higher costs. Clear specifications help suppliers provide accurate quotes and reduce the likelihood of costly adjustments later.

-

Materials: As previously mentioned, the choice of materials can significantly affect pricing. Buyers should weigh the benefits of premium materials against their budget constraints.

-

Quality and Certifications: Products that meet industry certifications or quality standards may carry a premium. However, these certifications can enhance reliability and reduce long-term risks.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can also affect pricing. Engaging with reputable suppliers who have a track record of quality can lead to better pricing and service.

-

Incoterms: Understanding Incoterms is vital for international buyers. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and delivery timelines. Proper negotiation of these terms can lead to significant savings.

What Tips Can Help Buyers Optimize Plunger Key Sourcing Costs?

To achieve cost-efficiency in sourcing plunger keys, consider the following tips:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for bulk orders. Highlighting potential long-term partnerships can create leverage for better terms.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the total cost of ownership. Consider factors such as maintenance, durability, and potential failure costs when assessing the value of a plunger key.

-

Pricing Nuances for International Buyers: For buyers in regions such as Africa, South America, the Middle East, and Europe, it’s essential to factor in currency fluctuations, import duties, and local market conditions. Understanding these nuances can aid in making more informed purchasing decisions.

-

Market Research: Conduct thorough market research to compare prices and offerings from multiple suppliers. This practice not only aids in negotiation but also helps identify the best value propositions available.

Disclaimer for Indicative Prices

Prices for plunger keys can vary significantly based on the factors outlined above. It is essential for buyers to conduct specific inquiries with suppliers for accurate and updated pricing tailored to their unique requirements.

Alternatives Analysis: Comparing plunger key With Other Solutions

Exploring Alternatives to Plunger Keys for Locking Solutions

When considering locking mechanisms, it’s essential for B2B buyers to explore various solutions that can meet their operational needs effectively. While plunger keys, such as the Jonard TTB-6, are commonly used for specific applications, there are alternative solutions that may offer different advantages depending on the context of use. This analysis will compare plunger keys against other viable alternatives, including traditional key locks and electronic locking systems.

Comparison Table

| Comparison Aspect | Plunger Key | Traditional Key Lock | Electronic Locking System |

|---|---|---|---|

| Performance | High tamper resistance, specific use | General-purpose, moderate security | High security, programmable access |

| Cost | Moderate ($63.99) | Variable, generally lower | Higher initial investment |

| Ease of Implementation | Simple, requires minimal training | Familiar to most users | Requires installation and setup |

| Maintenance | Low maintenance | Moderate, depends on wear | Requires software updates, power |

| Best Use Case | CATV applications, specialized locks | Residential and commercial use | High-security environments |

What Are the Advantages and Disadvantages of Traditional Key Locks?

Traditional key locks are familiar to many users and offer a straightforward approach to securing assets. They are typically less expensive than electronic systems and can be easily replaced. However, their security can be compromised through picking or duplicating keys, and they may not provide the same level of tamper resistance as a plunger key designed for specific locks. Additionally, they require regular maintenance to ensure proper function, especially in high-use environments.

What Makes Electronic Locking Systems a Strong Contender?

Electronic locking systems provide a high level of security and convenience, allowing for programmable access codes, remote control, and tracking capabilities. This makes them ideal for high-security environments such as data centers and restricted areas. However, their higher cost and complexity can be a barrier for some businesses, particularly smaller enterprises. Moreover, they require regular maintenance and updates to ensure security protocols are up to date, as well as a reliable power source, which may not be feasible in all locations.

How Should B2B Buyers Choose the Right Solution?

Choosing the right locking solution hinges on understanding the specific operational needs and security requirements of your business. For companies operating in environments that require high tamper resistance and specialized locking mechanisms, plunger keys may be the most effective choice. Conversely, businesses seeking cost-effective, familiar solutions might lean towards traditional key locks. For those needing advanced security features and management capabilities, electronic locking systems could be the best fit, despite their higher costs and maintenance needs. Evaluating these alternatives based on performance, cost, and maintenance will guide B2B buyers in making informed decisions tailored to their unique circumstances.

Essential Technical Properties and Trade Terminology for plunger key

What Are the Essential Technical Properties of a Plunger Key?

When selecting a plunger key for industrial or commercial applications, understanding its technical specifications is crucial for ensuring compatibility and performance. Here are some of the key properties to consider:

Illustrative image related to plunger key

-

Material Grade

– Plunger keys are often made from high carbon alloy steel, which offers superior strength and durability. This material choice is critical in high-stress environments, as it resists wear and tear while providing tamper resistance. For B2B buyers, selecting a plunger key made from high-grade materials ensures longevity and reliability, reducing the frequency of replacements. -

Lock Compatibility

– A plunger key is typically designed to work with specific lock types, such as barrel locks used in cable television (CATV) applications. For instance, the Jonard TTB-6 is compatible with Channell and Highfield barrel locks. Understanding compatibility is vital for B2B buyers to avoid investing in tools that will not operate effectively with their existing systems. -

Inside Hole Diameter

– The diameter of the hole that the plunger key fits into is a crucial specification. For example, the TTB-6 accommodates locks with an inside diameter ranging from 0.176″ to 0.196″ (4.47 mm to 4.98 mm). Ensuring the correct diameter is essential for effective unlocking; otherwise, the tool may not function properly, leading to operational delays. -

Length and Weight

– The dimensions and weight of the plunger key can influence its ease of use and portability. A standard length, such as 5 inches (approximately 14.55 cm) and a weight of around 0.22 lbs (98.97 g), provides a balance between usability and functionality. B2B buyers should consider these factors to ensure that the tool can be handled easily in various working conditions. -

Finish and Ergonomics

– A polished steel finish not only enhances aesthetics but also contributes to corrosion resistance, important for durability in various environments. Additionally, ergonomic design features, such as a comfortable handle, can improve user experience, which is essential for personnel who may use the tool frequently.

What Are the Common Trade Terms Related to Plunger Keys?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms related to plunger keys:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that are sold under another brand’s name. B2B buyers should consider purchasing from reputable OEMs to ensure product quality and reliability. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to assess their purchasing needs against supplier requirements, especially when sourcing tools like plunger keys. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For B2B buyers, creating an RFQ for plunger keys can help in comparing prices and negotiating better deals. -

Incoterms (International Commercial Terms)

– These are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is critical for B2B buyers, especially when importing or exporting plunger keys, as they clarify shipping responsibilities, costs, and risk management. -

Lead Time

– This refers to the time taken from placing an order to receiving it. Knowing the lead time for plunger keys is crucial for inventory management and project planning, helping businesses avoid operational delays. -

Serialized Tools

– Some plunger keys come with unique serial numbers for tracking and warranty purposes. This feature is significant for B2B buyers as it enhances accountability and facilitates easier replacement or service in case of defects.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding plunger keys, ensuring they select the right tools for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the plunger key Sector

What Are the Current Market Dynamics and Key Trends in the Plunger Key Sector?

The global plunger key market is witnessing significant growth driven by advancements in technology and increasing demand across various industries, including telecommunications, automotive, and security. Key trends influencing this sector include the rise of smart technology integration, which enhances the functionality of plunger keys in security systems. For international B2B buyers, particularly in emerging markets such as Africa, South America, and the Middle East, understanding the nuances of these trends is crucial for making informed sourcing decisions.

One notable trend is the shift towards digital solutions. Many manufacturers are now offering plunger keys equipped with smart features, allowing for remote access and enhanced security measures. As businesses in regions like Saudi Arabia and Vietnam increasingly prioritize security, the demand for technologically advanced plunger keys is expected to rise. Furthermore, the growing emphasis on supply chain resilience has prompted buyers to seek out reliable suppliers who can provide quality products in a timely manner.

Another market dynamic is the increasing focus on customization. B2B buyers are looking for suppliers that can offer tailored solutions to meet specific industry needs. This trend is particularly relevant in sectors such as telecommunications, where plunger keys must be compatible with various locking systems. Suppliers that can demonstrate flexibility and responsiveness to customer needs will likely gain a competitive edge.

How Is Sustainability Influencing Sourcing Trends in the Plunger Key Sector?

Sustainability is becoming a pivotal factor in B2B purchasing decisions, and the plunger key sector is no exception. Buyers are increasingly aware of the environmental impact of their sourcing choices, pushing manufacturers to adopt sustainable practices. This includes utilizing eco-friendly materials in the production of plunger keys and ensuring ethical labor practices throughout the supply chain.

The use of high carbon alloy steel in plunger key manufacturing, while durable, raises concerns about environmental impact. Consequently, buyers are encouraged to seek products certified by recognized ‘green’ standards, which verify that the materials used are sourced responsibly. Suppliers offering transparency regarding their manufacturing processes and sustainability certifications will appeal to conscientious buyers.

Moreover, the importance of ethical supply chains cannot be overstated. Businesses are increasingly prioritizing suppliers that demonstrate social responsibility, including fair labor practices and community engagement. By aligning sourcing strategies with sustainable and ethical principles, B2B buyers not only enhance their corporate reputation but also contribute to broader environmental and social goals.

What Is the Historical Context of Plunger Keys in B2B Markets?

The evolution of plunger keys can be traced back to their early use in basic locking mechanisms, primarily for security purposes. Over the decades, the technology and design of plunger keys have advanced significantly, adapting to the changing needs of various industries. Initially, plunger keys were rudimentary tools, primarily made of simple metals and used in low-security applications.

As industries evolved, so did the complexity of locking systems, leading to the development of specialized plunger keys. For instance, the introduction of barrel locks in telecommunications necessitated the design of specific plunger keys, such as the Jonard TTB-6, which catered to the unique requirements of CATV applications. This specialization has paved the way for increased innovation, resulting in more durable, tamper-resistant, and multifunctional plunger keys that meet the demands of modern security and operational needs.

Today, the plunger key market reflects a blend of historical craftsmanship and contemporary technological advancements, making it essential for B2B buyers to consider both legacy and innovation when sourcing these critical tools.

Frequently Asked Questions (FAQs) for B2B Buyers of plunger key

-

How do I select the right plunger key for my application?

Choosing the right plunger key involves understanding the specific lock type you need to work with. For instance, the Jonard TTB-6 is designed for Channell and Highfield CATV barrel locks with specific inside diameters. Verify the compatibility of the plunger key with your locks, and consider the material and durability for your operational environment. If you have unique requirements, consult with suppliers about customized solutions that meet your specifications. -

What are the key features to look for in a plunger key?

When sourcing a plunger key, prioritize features such as material quality, compatibility with specific lock types, and ease of use. Look for keys made from high carbon alloy steel for enhanced durability and tamper resistance. Additionally, consider the design of the plunger mechanism, as a smooth action and a robust spring can significantly impact performance, especially in high-frequency usage scenarios. -

What is the typical minimum order quantity (MOQ) for plunger keys?

Minimum order quantities can vary widely among suppliers, typically ranging from 100 to 500 units for B2B purchases. Some manufacturers may offer lower MOQs for new clients or specific models. It’s advisable to discuss your needs directly with potential suppliers to negotiate terms that align with your business requirements, especially if you are entering a new market. -

What payment terms are generally offered for international orders?

Payment terms for international orders often depend on the supplier’s policies and your business relationship. Common practices include upfront payment, 30% deposit with the balance before shipping, or net 30/60 terms for established clients. Discuss and agree upon payment methods that best suit your cash flow and risk management preferences, such as letters of credit or escrow services for larger transactions. -

How can I ensure the quality of plunger keys from suppliers?

To guarantee product quality, conduct thorough vetting of potential suppliers. Request samples to assess the plunger key’s build quality and performance. Inquire about their manufacturing processes, quality control measures, and certifications. Establish clear quality assurance protocols in your contract, including specifications for material properties and performance standards to ensure compliance with your expectations. -

What logistics considerations should I be aware of when importing plunger keys?

When importing plunger keys, consider shipping methods, lead times, and customs regulations specific to your country. Choose logistics partners experienced in handling your product type to ensure timely delivery. Additionally, factor in duties and taxes that may apply to your imports, and ensure that your supplier provides the necessary documentation for customs clearance. -

Are there customization options available for plunger keys?

Many suppliers offer customization options for plunger keys, including branding, color, and specific design modifications to suit your operational needs. Discuss your requirements with suppliers to understand the feasibility and costs associated with customization. Customized keys can enhance brand visibility and ensure compatibility with unique lock systems you may be using. -

What are the common applications of plunger keys in various industries?

Plunger keys are widely used in telecommunications for unlocking CATV barrel locks, in security systems, and in various manufacturing processes. Industries such as utilities, telecommunications, and automotive frequently rely on these tools for efficient access to secured areas. Understanding the applications can help you identify potential suppliers who specialize in your industry, ensuring you receive products tailored to your needs.

Top 4 Plunger Key Manufacturers & Suppliers List

1. Budco – Jonard Barrel Lock Plunger Key

2. Highfield – Utility Barrel Lock & Plunger Key System

Domain: highfield-mfg.com

Registered: 1996 (29 years)

Introduction: Utility Barrel Lock & Plunger Key System #5 & #5A

– Unique key and plunger design for increased security for gas utilities

– Cost-effective compared to conventional barrel locks

– #5 and #5A keys are not interchangeable

– Lock styles: #5 series has four styles, #5A series has two styles

– Barrel Lock Series #5: Silver Lock With End Cap (93180106), Silver Lock Without End Cap (93180110)

– Barrel Lo…

3. Flair – Plunger Key

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The Flair 58 Plunger Key is a $2 accessory designed to assist with the alignment of the plunger in the Flair Espresso maker. It addresses issues related to the rotation of the head that may occur after extended use. The product is particularly useful for users with the updated design that includes locking hooks, making it easier to re-align the plunger. The original plunger guide may be discontinu…

4. Jonard – TTB-6 Barrel Lock Plunger Key

Domain: jonard.com

Registered: 1998 (27 years)

Introduction: This company, Jonard – TTB-6 Barrel Lock Plunger Key, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for plunger key

As the global market for plunger keys continues to evolve, strategic sourcing emerges as a critical factor in ensuring businesses can meet the demands of their operations efficiently. By focusing on high-quality materials, such as high carbon alloy steel for durability and tamper resistance, buyers can secure tools that not only enhance operational efficiency but also reduce long-term costs associated with replacements and repairs. Additionally, understanding the specific lock types and compatibility is vital for maximizing the utility of these tools, particularly for specialized applications in various industries.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing practices can lead to enhanced supplier relationships, improved pricing, and better quality assurance. Establishing partnerships with reputable manufacturers can also facilitate access to innovative products that meet diverse market needs.

Looking ahead, businesses are encouraged to stay informed about advancements in plunger key technologies and sourcing strategies. By prioritizing strategic sourcing, companies can not only enhance their operational capabilities but also position themselves competitively in the marketplace. Engage with suppliers today to explore tailored solutions that align with your business objectives and drive success in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.