The Definitive Guide to Plug Point Cover: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for plug point cover

Navigating the global market for plug point covers presents a significant challenge for B2B buyers, particularly those focused on enhancing safety in residential and commercial spaces. With the increasing concern over electrical hazards, sourcing reliable and effective outlet protection solutions is critical. This guide offers a comprehensive exploration of plug point covers, detailing various types, their applications across different environments, and key factors to consider when vetting suppliers.

From child safety in homes to ensuring compliance in commercial settings, the applications of plug point covers are diverse and crucial. Buyers will find valuable insights into the latest trends, including innovative designs that not only prioritize safety but also blend seamlessly with modern aesthetics. Additionally, the guide addresses cost considerations, enabling informed budgeting and procurement strategies.

By empowering international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Brazil and Germany—this resource aims to streamline the purchasing process. With detailed advice on supplier evaluation and selection, buyers can confidently navigate the complexities of the market, ensuring they choose high-quality products that meet their specific safety needs. This strategic approach will ultimately enhance the safety standards in their respective industries, fostering trust and reliability in electrical safety solutions.

Understanding plug point cover Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Outlet Covers | Basic design, fits standard outlets, often plastic | Residential, commercial buildings | Pros: Cost-effective; Cons: Limited safety features. |

| Child Safety Plug Covers | Designed to prevent children from accessing outlets | Childcare facilities, homes with young children | Pros: Enhanced safety; Cons: May be difficult for adults to remove. |

| Dual Fit Plug Covers | Covers both used and unused outlets, allows cord access | Offices, homes with multiple electronic devices | Pros: Versatile usage; Cons: Higher cost than standard covers. |

| Decorative Outlet Covers | Aesthetic design, blends with home décor | High-end residential, hospitality sectors | Pros: Enhances aesthetics; Cons: May lack safety features. |

| Smart Outlet Covers | Integrates technology for remote control and monitoring | Smart homes, tech-savvy environments | Pros: Advanced features; Cons: Expensive and requires setup. |

What Are Standard Outlet Covers and Their Applications?

Standard outlet covers are the most basic type of plug point cover, primarily made from plastic. They are designed to fit standard electrical outlets and provide a simple barrier against dust and accidental contact. These covers are widely used in residential and commercial buildings due to their affordability and ease of installation. However, while they are cost-effective, they do not offer significant safety features, making them less suitable for environments with children or safety concerns.

How Do Child Safety Plug Covers Enhance Safety?

Child safety plug covers are specifically designed to prevent children from accessing electrical outlets, thereby reducing the risk of electrical shocks and accidents. These covers often feature a secure fit that makes it difficult for children to remove them, providing peace of mind for parents and caregivers. They are ideal for childcare facilities and homes with young children. While they enhance safety, one downside is that they can be challenging for adults to remove quickly, which may be a consideration for B2B buyers in environments where adult access is frequently needed.

What Are the Benefits of Dual Fit Plug Covers?

Dual fit plug covers are a versatile solution that accommodates both used and unused outlets. They allow cords to remain plugged in while providing a safety barrier, making them ideal for environments like offices or homes with numerous electronic devices. Their design enables easy access for adults while protecting children from unplugging devices. Although they tend to be more expensive than standard covers, their multifunctionality justifies the investment for businesses looking to enhance safety without sacrificing convenience.

How Do Decorative Outlet Covers Serve High-End Markets?

Decorative outlet covers combine functionality with aesthetics, making them popular in high-end residential and hospitality sectors. These covers are designed to blend seamlessly with various interior designs, enhancing the overall aesthetic of a room. While they provide basic protection against dust and contact, they may lack advanced safety features. B2B buyers in upscale markets should weigh the benefits of aesthetic appeal against the potential need for additional safety measures, especially in family-oriented environments.

What Are Smart Outlet Covers and Their Impact on Modern Spaces?

Smart outlet covers represent the intersection of safety and technology, allowing for remote monitoring and control of plugged-in devices. Ideal for smart homes and tech-savvy environments, these covers can enhance energy efficiency and safety by providing alerts for unusual activity. However, their higher price point and the need for technical setup may deter some buyers. Businesses looking to invest in modern safety solutions should consider the long-term benefits of smart technology against the initial investment costs.

Key Industrial Applications of plug point cover

| Industry/Sector | Specific Application of plug point cover | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Childcare Facilities | Covering electrical outlets in nurseries and daycare centers | Enhances safety for children, reducing liability risks | Compliance with safety standards, durability, ease of installation |

| Hospitality | Protecting outlets in hotels and restaurants | Prevents accidents, enhances guest safety | Aesthetic design, compatibility with various outlet types |

| Residential Construction | Installing in new homes and apartments | Ensures safety for families, increases property value | Energy efficiency, adherence to local regulations |

| Educational Institutions | Outfitting schools and universities | Safeguards students from electrical hazards | Bulk purchasing options, variety in designs and colors |

| Healthcare Facilities | Securing outlets in hospitals and clinics | Prevents electrical accidents, maintains patient safety | Sterilization capabilities, compliance with health regulations |

How Are Plug Point Covers Used in Childcare Facilities?

In childcare facilities, plug point covers are essential for safeguarding electrical outlets from curious little hands. These covers prevent children from inserting objects into sockets, thereby reducing the risk of electrical shocks. Buyers in this sector must ensure that the covers comply with safety regulations and are easy to install and remove for adult access. Additionally, the durability of the materials used is crucial, as these facilities experience high traffic and wear.

What Are the Benefits of Using Plug Point Covers in the Hospitality Industry?

In the hospitality sector, hotels and restaurants utilize plug point covers to enhance guest safety and prevent accidents. By covering outlets, businesses can avoid liability issues related to electrical injuries. Aesthetically pleasing designs that blend with interior decor are important for hotels, while ease of use is vital in restaurants where quick access to outlets is necessary. B2B buyers should prioritize sourcing options that offer both safety and style to meet industry standards.

Why Are Plug Point Covers Important in Residential Construction?

For residential construction, plug point covers are integral in ensuring the safety of new homes and apartments. They protect families from potential electrical hazards, significantly increasing the property’s value by demonstrating a commitment to safety. Buyers in this sector should look for covers that are energy-efficient and comply with local building codes. A variety of designs can also cater to different aesthetic preferences, making them a versatile choice for new builds.

How Do Educational Institutions Benefit from Plug Point Covers?

Educational institutions, including schools and universities, implement plug point covers to create a safe learning environment. By preventing students from tampering with electrical outlets, these covers mitigate the risk of accidents and injuries. When sourcing for this application, institutions should consider bulk purchasing options to meet the needs of multiple classrooms. Additionally, the availability of various colors and designs can help in maintaining an engaging atmosphere conducive to learning.

What Role Do Plug Point Covers Play in Healthcare Facilities?

In healthcare facilities, plug point covers are crucial for ensuring patient safety by preventing electrical accidents. Hospitals and clinics require covers that can withstand rigorous cleaning and sterilization processes. Compliance with health regulations is paramount, making it essential for buyers to source covers that meet these standards. Furthermore, the materials used should be durable to handle frequent use while ensuring a safe environment for patients and staff alike.

3 Common User Pain Points for ‘plug point cover’ & Their Solutions

Scenario 1: Managing Child Safety in Commercial Environments

The Problem: Many businesses, especially those in the childcare and education sectors, face the challenge of ensuring the safety of children in environments filled with electrical outlets. Childproofing these spaces is essential, yet finding effective solutions that do not disrupt the functionality of the space can be daunting. Buyers often struggle to balance safety measures with operational efficiency, as conventional covers may block necessary access to outlets used for various equipment.

The Solution: To address this issue, B2B buyers should consider investing in dual-fit plug point covers designed for commercial use. These covers allow outlets to remain accessible while providing a secure barrier against accidental unplugging or insertion of foreign objects. When sourcing these products, look for options that are easy to install and remove, enabling staff to access outlets quickly without compromising safety. Additionally, consider covers that blend with the decor of the environment to maintain a professional appearance. By selecting high-quality, durable covers that meet safety standards, businesses can create a secure atmosphere without hindering daily operations.

Scenario 2: Addressing Compatibility Issues with Diverse Outlet Types

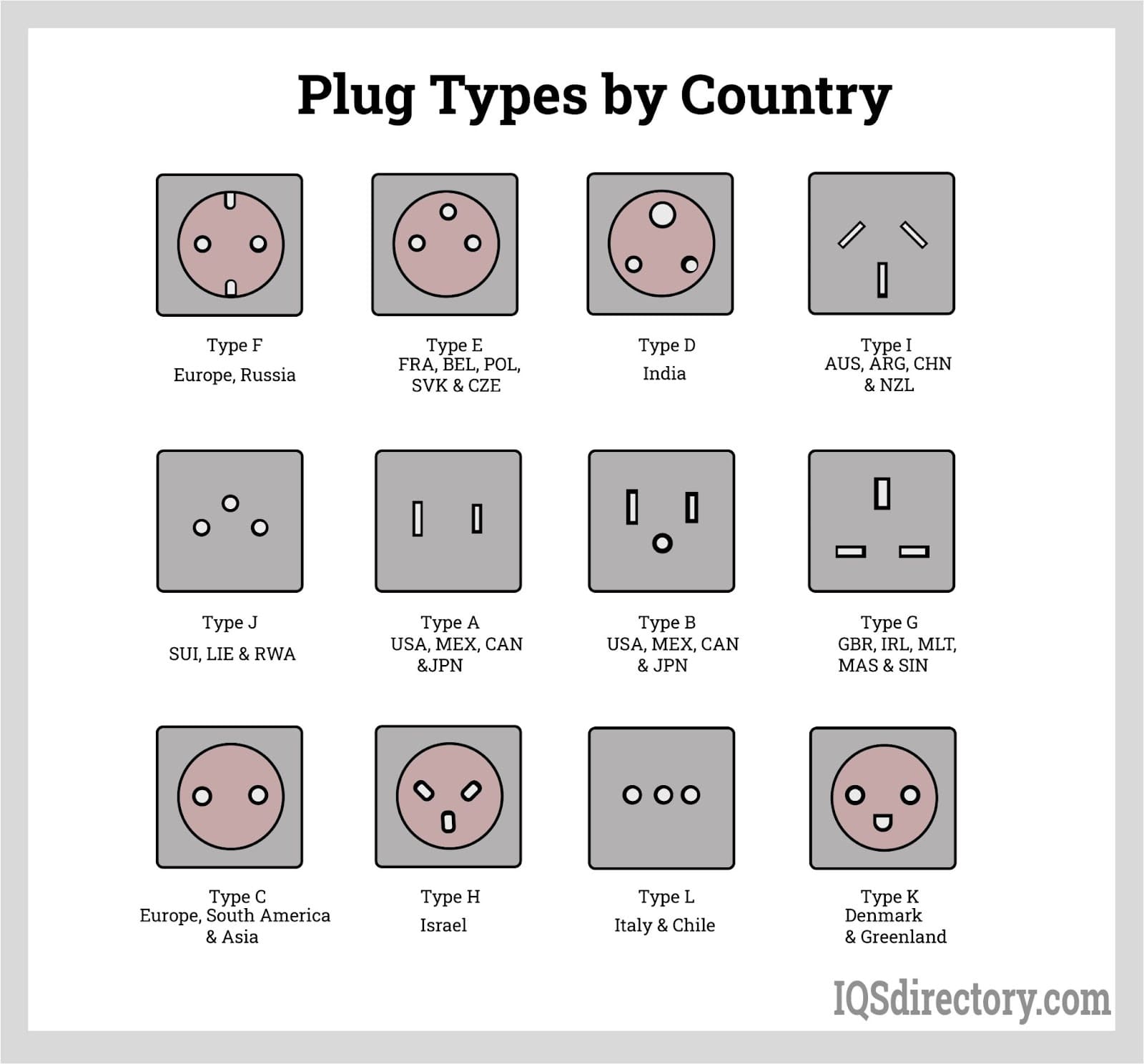

The Problem: In regions with varied electrical standards, B2B buyers often encounter compatibility issues with plug point covers. For instance, outlets in Africa and South America can differ significantly from those in Europe and North America. This discrepancy can lead to frustration when businesses invest in covers that do not fit their existing outlets, resulting in wasted resources and potential safety hazards.

Illustrative image related to plug point cover

The Solution: To overcome this challenge, it is crucial for buyers to conduct thorough research before making purchases. Opt for plug point covers that are labeled as “universal fit” or “dual-fit,” which are designed to accommodate various outlet types. When sourcing these products, inquire about the specifications and compatibility with local electrical standards. Collaborating with reputable suppliers who understand the regional market can also provide valuable insights. Furthermore, consider bulk purchasing to ensure uniformity across multiple locations, reducing the chances of mismatches and enhancing overall safety.

Scenario 3: Reducing Maintenance and Replacement Costs

The Problem: Frequent replacement of plug point covers can become a financial burden for businesses, particularly in high-traffic areas. Covers that wear out quickly or become damaged due to regular use create ongoing maintenance challenges, leading to increased operational costs and potential safety risks. B2B buyers are often looking for solutions that not only ensure safety but also provide long-term durability and cost-effectiveness.

The Solution: Buyers should prioritize sourcing high-quality, robust plug point covers made from durable materials that can withstand wear and tear. Consider investing in covers with reinforced designs or those that feature a child-resistant locking mechanism to extend their lifespan. Additionally, implementing a regular inspection schedule can help identify wear before it becomes a safety issue, allowing for timely replacements without disrupting operations. Engaging with manufacturers that offer warranties can also provide peace of mind and reduce the total cost of ownership. By choosing durable solutions and proactive maintenance strategies, businesses can significantly cut down on replacement costs while ensuring a safe environment for all users.

Strategic Material Selection Guide for plug point cover

When selecting materials for plug point covers, it’s essential to consider various factors that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of plug point covers: plastic, rubber, metal, and silicone.

What are the Key Properties of Plastic for Plug Point Covers?

Plastic is one of the most widely used materials for plug point covers due to its versatility and cost-effectiveness. Key properties include excellent electrical insulation, lightweight nature, and resistance to corrosion. Common types of plastic used include polycarbonate and polypropylene, both of which can withstand a range of temperatures, typically from -20°C to 80°C.

Illustrative image related to plug point cover

Pros: Plastic covers are generally durable, resistant to moisture, and can be produced in various colors and designs, making them suitable for different aesthetic preferences. They are also lightweight, reducing shipping costs.

Cons: However, plastic can be less durable than other materials under extreme conditions, such as high temperatures or heavy impacts. Additionally, some plastics may degrade over time when exposed to UV light.

Impact on Application: Plastic plug covers work well in residential and commercial settings, particularly where electrical safety is paramount. However, buyers should ensure that the selected plastic complies with local safety standards, such as ASTM in the U.S. or DIN in Germany.

How Does Rubber Perform as a Material for Plug Point Covers?

Rubber is another common material, particularly valued for its flexibility and resilience. It offers excellent electrical insulation and is resistant to wear and tear, making it suitable for high-traffic areas.

Pros: Rubber covers are durable and can withstand a wide range of temperatures, typically from -30°C to 90°C. They provide a snug fit, which enhances safety by preventing accidental disconnection of plugged devices.

Cons: On the downside, rubber can be more expensive than plastic and may not be as aesthetically pleasing, which can be a consideration for consumer markets. Additionally, rubber can degrade over time if exposed to certain chemicals or oils.

Impact on Application: Rubber plug covers are ideal for environments where high durability is required, such as industrial settings. International buyers should check for compliance with relevant safety standards, as rubber materials can vary significantly in quality.

What are the Advantages of Metal in Plug Point Covers?

Metal plug point covers, often made from stainless steel or aluminum, are known for their strength and durability. They can withstand significant physical stress and are resistant to corrosion.

Pros: The primary advantage of metal covers is their longevity and ability to provide a robust barrier against physical damage. They also have a sleek, professional appearance that can enhance the aesthetic of high-end installations.

Cons: However, metal covers can be heavier and more expensive than plastic or rubber options. They also require careful handling during installation to avoid damage to the electrical components.

Impact on Application: Metal covers are suitable for commercial and industrial applications where durability is critical. Buyers should ensure that the metal used complies with international standards for electrical safety to avoid potential hazards.

Why is Silicone a Beneficial Material for Plug Point Covers?

Silicone is gaining popularity for plug point covers due to its unique properties. It is highly flexible, resistant to extreme temperatures, and offers excellent electrical insulation.

Pros: Silicone covers can withstand temperatures ranging from -60°C to 200°C, making them ideal for diverse environments. They are also easy to clean and maintain, which is a significant advantage in commercial settings.

Cons: The main drawback of silicone is its higher cost compared to plastic and rubber. Additionally, silicone may not provide the same level of structural integrity as metal covers.

Impact on Application: Silicone plug covers are particularly beneficial in environments where temperature fluctuations are common. International buyers should verify that silicone materials meet local safety and performance standards.

Summary of Material Selection for Plug Point Covers

| Material | Typical Use Case for plug point cover | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Residential and light commercial | Cost-effective and versatile | Less durable under extreme conditions | Low |

| Rubber | Industrial and high-traffic areas | Durable and flexible | More expensive, less aesthetic | Medium |

| Metal | Commercial and industrial | Long-lasting and robust | Heavier and more costly | High |

| Silicone | Environments with temperature fluctuations | High flexibility and easy maintenance | Higher cost, less structural integrity | Medium |

This analysis provides a comprehensive overview of the materials available for plug point covers, enabling international B2B buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for plug point cover

What Are the Key Manufacturing Processes for Plug Point Covers?

The manufacturing of plug point covers involves several critical stages that ensure product quality and safety. Understanding these processes is vital for B2B buyers looking to source reliable products from manufacturers.

What Materials Are Commonly Used in Plug Point Cover Manufacturing?

The primary materials for plug point covers include high-quality plastics such as polycarbonate and PVC. These materials are chosen for their durability, electrical insulation properties, and resistance to heat and chemicals. In some cases, manufacturers may also use materials that are compliant with safety standards, such as flame-retardant plastics to mitigate fire risks. The preparation of these materials includes rigorous quality checks to ensure they meet specified standards before they enter the manufacturing process.

How Are Plug Point Covers Formed?

Forming is a critical stage in the manufacturing process. The key techniques employed include injection molding and extrusion.

Illustrative image related to plug point cover

-

Injection Molding: This is the most common method used for creating intricate shapes and designs in plug point covers. The process involves melting the plastic and injecting it into a mold where it cools and solidifies. This method allows for high precision and repeatability, essential for maintaining quality across large production runs.

-

Extrusion: While less common for plug covers, extrusion can be used for producing simpler shapes or components that may be part of a multi-piece cover. The plastic is forced through a die to create a continuous profile, which is then cut to the desired length.

Both methods require careful temperature control and pressure management to ensure the final product is free from defects.

What Is the Assembly Process for Plug Point Covers?

After forming, the components may undergo an assembly process. This can involve combining different parts, such as attaching a safety lock mechanism or integrating decorative elements. Automated assembly lines are often employed to enhance efficiency, although manual assembly may be used for more complex designs.

Quality control at this stage is crucial, as improper assembly can lead to safety hazards. Manufacturers must ensure that all components fit together securely and function as intended.

Illustrative image related to plug point cover

How Is Finishing Done for Plug Point Covers?

Finishing processes enhance the product’s aesthetic appeal and durability. Common finishing techniques include:

-

Surface Treatment: This may involve polishing, coating, or painting the covers to achieve a desired look or additional protection against wear and tear.

-

Quality Inspection: After finishing, each batch of plug point covers undergoes a thorough inspection to identify any cosmetic defects or functional issues.

What Quality Assurance Measures Are Essential in Plug Point Cover Production?

Quality assurance (QA) in the manufacturing of plug point covers is paramount to ensuring safety and compliance with international standards.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with several international standards that apply to electrical safety products, including:

Illustrative image related to plug point cover

-

ISO 9001: This standard outlines the criteria for a quality management system and is crucial for ensuring consistent product quality across manufacturers.

-

CE Marking: In Europe, plug point covers must comply with the CE marking requirements, indicating that they meet EU safety, health, and environmental protection standards.

-

UL Certification: In North America, UL certification is often sought to demonstrate that products meet rigorous safety standards.

What Are the Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to ensuring that products meet specified standards. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet quality specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to catch defects early and ensure adherence to standards.

-

Final Quality Control (FQC): After production, the finished products are subjected to comprehensive testing. This may include electrical safety tests, durability tests, and visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability and safety.

What Methods Can Be Used for Supplier Audits?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and compliance with international standards firsthand.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s quality management system and any certifications they hold.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s production processes and product quality.

What Are the Common Testing Methods for Plug Point Covers?

To ensure the safety and performance of plug point covers, various testing methods are employed:

-

Electrical Safety Tests: These tests assess the product’s ability to prevent electrical shocks and short circuits.

-

Durability Tests: Products are subjected to stress tests to evaluate their performance under normal and extreme conditions.

-

Environmental Tests: These tests determine how well the covers can withstand environmental factors such as temperature fluctuations and humidity.

What Nuances Should International B2B Buyers Consider Regarding QC and Certification?

International B2B buyers must navigate various nuances when it comes to quality control and certification:

-

Regulatory Compliance: Different regions may have specific regulations governing electrical safety products. Buyers should ensure their suppliers are compliant with local laws in their target markets.

-

Cultural Differences: Understanding cultural attitudes toward quality and safety can influence supplier relationships and expectations.

-

Market-Specific Certifications: Some regions may require additional certifications beyond ISO and CE. Buyers should be aware of local requirements to avoid compliance issues.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for plug point covers empowers B2B buyers to make informed sourcing decisions. By focusing on material selection, manufacturing techniques, and robust quality control systems, buyers can ensure they procure safe and reliable products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plug point cover’

Introduction

This guide is designed to assist B2B buyers in the effective procurement of plug point covers, which are essential for electrical safety, especially in environments with children or where electrical outlets are exposed. The following checklist provides actionable steps to ensure you make informed decisions, optimize your sourcing process, and choose high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications for the plug point covers you need. This includes considering the type of outlets they will cover (standard, decor, etc.), materials (plastic, child-proof), and any specific safety certifications required in your region. Defining these parameters helps streamline your search and ensures compliance with local safety regulations.

Illustrative image related to plug point cover

Step 2: Research Market Trends and Demand

Understanding current market trends and demand for plug point covers in your target regions is crucial. Analyze sales data, customer preferences, and competitor offerings to identify popular features such as ease of installation, aesthetics, and safety features. This research can guide your purchasing decisions and help you select products that are more likely to succeed in your market.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your quality and compliance requirements. Request comprehensive company profiles, including their manufacturing processes, quality control measures, and previous client case studies. Look for suppliers who have a proven track record in your industry and can provide references from other B2B clients, particularly those in similar geographical markets.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers possess the necessary certifications and compliance with international safety standards. Certifications such as CE, UL, or ISO can indicate adherence to quality and safety benchmarks. This step is vital not only for product reliability but also for minimizing liability risks associated with electrical safety.

Step 5: Request Samples for Testing

Before placing a bulk order, request samples of the plug point covers to evaluate their quality and functionality. Testing samples allows you to assess factors such as durability, ease of installation, and overall effectiveness in preventing electrical hazards. This hands-on evaluation is critical for ensuring the products meet your specifications and safety standards.

Step 6: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers and tested samples, engage in negotiations to secure the best pricing and terms. Consider discussing volume discounts, payment terms, and delivery schedules. Establishing favorable terms can significantly impact your overall project budget and cash flow.

Step 7: Plan for Logistics and Distribution

Finally, develop a logistics plan for the distribution of plug point covers to your end customers. This includes considering shipping methods, storage solutions, and inventory management practices. Efficient logistics planning ensures that your products reach customers promptly, enhancing satisfaction and potentially increasing repeat business.

By following these steps, B2B buyers can effectively navigate the procurement process for plug point covers, ensuring they select high-quality products that enhance safety and meet market demands.

Comprehensive Cost and Pricing Analysis for plug point cover Sourcing

What Are the Key Cost Components in Plug Point Cover Sourcing?

When sourcing plug point covers, understanding the cost structure is essential for effective budgeting and pricing negotiations. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials used in manufacturing plug point covers include durable plastics (like PVC or ABS) and, in some cases, fire-retardant materials for added safety. The quality and sourcing of these materials will affect both the price and the safety certifications that can be obtained.

-

Labor: Labor costs can vary greatly depending on the manufacturing location. Countries with lower labor costs, such as those in Southeast Asia or Eastern Europe, might offer more competitive pricing. However, labor quality and expertise in safety product manufacturing should also be considered, as these factors directly influence product reliability.

-

Manufacturing Overhead: This includes costs associated with the manufacturing facility, utilities, and administrative expenses. Factories that implement lean manufacturing practices may have lower overhead, potentially translating to lower prices for buyers.

-

Tooling: Initial setup costs for molds and tooling can be significant, especially for custom designs. This upfront investment is often spread across production runs, so larger orders may benefit from lower per-unit costs.

-

Quality Control (QC): Ensuring that plug point covers meet safety standards is crucial. Implementing rigorous QC processes incurs additional costs but is necessary for compliance with international safety regulations, especially in markets like Europe and North America.

-

Logistics: Shipping costs, including freight and customs duties, can add significantly to the total cost. The choice of Incoterms will influence who is responsible for these costs and can affect pricing negotiations.

-

Margin: Suppliers typically add a margin to cover their operating costs and profit. This margin can vary based on market demand, competition, and the supplier’s pricing strategy.

What Price Influencers Should B2B Buyers Consider?

Several factors can influence the pricing of plug point covers, particularly for international B2B buyers:

Illustrative image related to plug point cover

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing. Suppliers often provide discounts for larger orders, so it’s beneficial to consolidate purchases when possible.

-

Specifications and Customization: Custom designs or specific safety certifications may increase costs. Buyers should weigh the benefits of customization against the price increase.

-

Material Quality and Certifications: Higher-quality materials that meet stringent safety standards (like UL or CE certifications) often come at a premium. Buyers should consider the Total Cost of Ownership (TCO) rather than just the initial purchase price.

-

Supplier Factors: The supplier’s reputation, reliability, and geographical location can influence pricing. Established suppliers may charge higher prices due to their proven track record, while newer suppliers may offer lower prices to gain market entry.

-

Incoterms: Understanding shipping terms is critical. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine the responsibilities of buyers and sellers regarding shipping costs, which can significantly affect the total cost.

What Are the Best Negotiation Tips for B2B Buyers in Different Regions?

-

Research Local Market Conditions: Understanding regional pricing trends and local manufacturing capabilities can provide leverage in negotiations. For instance, manufacturers in Brazil may offer different pricing structures compared to those in Germany due to local economic conditions.

-

Emphasize Long-term Relationships: Suppliers may be more willing to negotiate favorable terms for buyers who commit to long-term partnerships, ensuring stability for both parties.

-

Explore Alternative Suppliers: Diversifying your supplier base can create competitive pressure, leading to better pricing. Engaging suppliers from various regions can also mitigate risks associated with geopolitical factors.

-

Consider Total Cost of Ownership: When evaluating prices, consider all associated costs, including shipping, customs, and potential downtime due to product failures. This holistic view can help justify a higher upfront cost for better-quality products.

-

Be Transparent About Needs: Clearly communicating your requirements and constraints can foster trust and lead to more favorable negotiations. Suppliers appreciate buyers who know what they want and can provide them with the necessary context for pricing decisions.

Conclusion

Navigating the complexities of plug point cover sourcing requires an understanding of the cost structure, price influencers, and effective negotiation strategies. By considering these elements, B2B buyers can make informed decisions that align with their business objectives while ensuring safety and compliance in their product offerings. Always remember that prices can fluctuate based on market dynamics, so it’s advisable to obtain multiple quotes and conduct thorough market research before finalizing any agreements.

Alternatives Analysis: Comparing plug point cover With Other Solutions

Understanding Alternatives to Plug Point Covers

When it comes to safeguarding electrical outlets, plug point covers are a popular choice among consumers and businesses alike. However, there are several alternative solutions that can offer similar protection and functionality. These alternatives may vary in performance, cost, and ease of implementation, making it essential for B2B buyers to explore all options before making a decision.

| Comparison Aspect | Plug Point Cover | Smart Outlet Covers | Electrical Outlet Boxes |

|---|---|---|---|

| Performance | Prevents child access to outlets | Provides remote access control and safety | Fully encloses outlets, offering maximum protection |

| Cost | Low-cost (typically $5-$15) | Moderate cost ($20-$50 each) | Higher upfront cost ($30-$100 each) |

| Ease of Implementation | Easy to install and remove | Requires Wi-Fi setup | Professional installation recommended |

| Maintenance | Minimal maintenance required | Firmware updates may be needed | Low maintenance, but checks needed for wear |

| Best Use Case | Child safety in homes and offices | Smart home integration | High-risk environments, like hospitals or schools |

Exploring Smart Outlet Covers as an Alternative

Smart outlet covers represent a modern alternative that not only protects outlets but also offers remote control capabilities. These devices connect to home automation systems, allowing users to monitor and control power usage. The primary advantage of smart outlet covers is their dual functionality; they enhance safety while integrating seamlessly into smart home ecosystems. However, they come with a higher price point and require a reliable Wi-Fi connection for optimal performance, which may not be feasible in all environments.

Examining Electrical Outlet Boxes for Enhanced Safety

Electrical outlet boxes provide a robust solution for environments where safety is paramount, such as schools, daycare centers, and healthcare facilities. These boxes fully enclose outlets, preventing any accidental access to live wires. Their main benefits include maximum protection and durability. However, they are more costly and often require professional installation, which can lead to increased labor costs. Maintenance is relatively low, but regular checks are necessary to ensure they remain in good condition.

Conclusion: Making the Right Choice for Your Business

When selecting a solution for outlet safety, B2B buyers must consider their specific needs, including the environment, budget, and desired functionality. Plug point covers offer a cost-effective and straightforward solution for basic child safety, while smart outlet covers provide advanced features for tech-savvy environments. For facilities requiring the highest level of safety, electrical outlet boxes are the most effective choice. Ultimately, understanding the pros and cons of each option will help businesses make informed decisions that align with their safety requirements and operational goals.

Essential Technical Properties and Trade Terminology for plug point cover

What Are the Key Technical Properties of Plug Point Covers?

When sourcing plug point covers, understanding the essential technical properties is crucial for ensuring safety, compliance, and durability in various applications. Here are some critical specifications:

-

Material Composition

Plug point covers are commonly made from high-impact plastic or silicone. High-impact plastics offer durability and resistance to wear and tear, making them suitable for high-usage environments. Silicone, on the other hand, provides flexibility and excellent insulation properties. For B2B buyers, selecting the right material is essential to meet safety standards and ensure longevity. -

Electrical Insulation Rating

This rating indicates the cover’s ability to prevent electrical conduction, which is vital for safety. A cover with a higher insulation rating minimizes the risk of electric shock, particularly in environments where children are present. B2B buyers must ensure that the products comply with local electrical safety regulations to avoid liability issues. -

Size and Fit Specifications

Plug point covers come in various sizes to accommodate different outlet types, including standard and decorator outlets. A precise fit is necessary to ensure effectiveness, as poorly fitting covers can be easily removed by children or may not provide adequate protection. Buyers should verify size specifications to align with the outlets used in their target markets. -

Child Safety Features

Many plug point covers incorporate additional features such as locking mechanisms or tamper-resistant designs. These features enhance safety by preventing unauthorized access to electrical outlets. B2B companies focusing on child safety products must prioritize these features to meet consumer expectations and regulatory requirements. -

Environmental Compliance

Products should comply with environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). Compliance ensures that the materials used in plug point covers do not pose risks to health or the environment. B2B buyers should consider suppliers that prioritize sustainability to enhance their brand reputation. -

Durability and Weather Resistance

For outdoor applications, durability against environmental factors like UV rays, moisture, and temperature fluctuations is essential. Selecting covers that are rated for outdoor use ensures they maintain their integrity and functionality over time. B2B buyers operating in diverse climates must assess these properties to avoid frequent replacements.

What Are Common Trade Terms Related to Plug Point Covers?

Familiarity with industry jargon can streamline communication and negotiations in the B2B landscape. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When dealing with plug point covers, understanding OEM relationships helps buyers identify reliable suppliers who can provide custom solutions. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is a critical factor for B2B buyers, as it impacts inventory management and cash flow. Understanding MOQ allows businesses to plan purchases effectively and avoid overstocking. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. For plug point covers, submitting an RFQ can help buyers compare options and negotiate better deals, ensuring they receive competitive pricing. -

Incoterms (International Commercial Terms)

These are pre-defined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for B2B transactions involving plug point covers, as they determine shipping costs, risk, and delivery obligations. -

Lead Time

This refers to the amount of time taken from placing an order to the delivery of the product. For plug point covers, shorter lead times can enhance supply chain efficiency and customer satisfaction. B2B buyers should assess lead times when selecting suppliers to ensure timely project completion. -

Certification Standards

Certifications such as CE marking or UL listing indicate compliance with safety and performance standards. Buyers should prioritize suppliers whose products meet these certifications to ensure quality and safety in their offerings.

By understanding these essential properties and terms, B2B buyers can make informed decisions when sourcing plug point covers, enhancing their safety, compliance, and overall product quality.

Navigating Market Dynamics and Sourcing Trends in the plug point cover Sector

What Are the Current Market Dynamics and Key Trends in the Plug Point Cover Sector?

The global plug point cover market is experiencing notable growth, driven by increasing safety awareness, particularly regarding child safety in residential and commercial environments. In regions like Africa, South America, the Middle East, and Europe, the demand for plug point covers is spurred by urbanization, rising disposable incomes, and stringent safety regulations. For B2B buyers, understanding regional compliance requirements is crucial, as these can vary significantly from one country to another.

Emerging technologies are also influencing sourcing trends. The rise of smart home technologies has led to the development of more advanced plug covers that integrate with home automation systems. Features such as child-proofing, tamper resistance, and the use of transparent materials for aesthetic appeal are gaining traction. Additionally, the shift towards e-commerce platforms has transformed the purchasing landscape, enabling B2B buyers to access a broader range of suppliers and innovative products with ease.

Sourcing strategies are evolving as well, with buyers increasingly favoring direct partnerships with manufacturers to ensure quality control and reliability. This direct engagement can enhance supply chain efficiency, reduce costs, and provide better opportunities for customization. The integration of artificial intelligence and data analytics in supply chain management is also a growing trend, allowing businesses to forecast demand more accurately and streamline their procurement processes.

How Is Sustainability and Ethical Sourcing Impacting the Plug Point Cover Sector?

Sustainability has become a critical consideration in the plug point cover sector, as environmental concerns shape consumer preferences and regulatory standards. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of recyclable materials, reduced carbon footprints, and adherence to eco-friendly manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are now more aware of the social implications of their sourcing decisions, including labor practices and community impact. As a result, certifications such as ISO 14001 (Environmental Management) and Fair Trade are becoming essential criteria for supplier evaluation. These certifications not only enhance brand reputation but also appeal to end consumers who value corporate social responsibility.

Illustrative image related to plug point cover

Moreover, the demand for ‘green’ materials, such as bioplastics and sustainably sourced polymers, is on the rise. These materials are not only environmentally friendly but often offer enhanced durability and performance characteristics. B2B buyers who focus on sustainability can differentiate themselves in the market, attract environmentally conscious clients, and potentially access new funding opportunities aimed at supporting green innovations.

What Is the Brief Evolution and History of Plug Point Covers in a B2B Context?

The evolution of plug point covers can be traced back to the increasing awareness of electrical safety in homes and workplaces. Initially, plug covers were simple plastic caps designed to prevent accidental contact with live electrical outlets, primarily aimed at protecting young children. Over time, these products have evolved into more sophisticated solutions incorporating safety features such as tamper resistance and aesthetic designs that blend seamlessly with modern interiors.

As technological advancements occurred, manufacturers began to introduce innovative designs that cater to the growing smart home market, integrating features that allow for both safety and functionality. Today, plug point covers are not only safety devices but also essential components of contemporary electrical installations, reflecting the dual need for safety and style in residential and commercial spaces.

In summary, the plug point cover sector is positioned at the intersection of safety, technology, and sustainability, presenting significant opportunities for B2B buyers looking to navigate market dynamics effectively. Understanding these trends can empower buyers to make informed sourcing decisions that align with both their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of plug point cover

-

How do I solve the issue of electrical safety in my products?

Ensuring electrical safety is crucial, especially in regions with high electrical hazards. To address this, source high-quality plug point covers designed to prevent accidental shocks and injuries. Look for products that meet international safety standards, such as IEC or UL certifications. Additionally, consider conducting risk assessments on your products and consult with manufacturers who specialize in child-proof or safety-rated outlet covers. Regularly review safety guidelines applicable to your target markets to ensure compliance and enhance your product offerings. -

What is the best plug point cover for international markets?

The best plug point cover for international markets is one that complies with local electrical safety standards and fits standard outlet sizes. For instance, in Europe, look for covers that align with the Schuko standard, while in North America, NEMA configurations are essential. Features like child-proof designs, durability, and ease of installation are also important. Additionally, consider the materials used; options like flame-retardant plastics enhance safety. Researching local preferences and regulations can help tailor your product selection for each market. -

What factors should I consider when vetting suppliers for plug point covers?

When vetting suppliers, prioritize factors such as product quality, compliance with international safety standards, and manufacturing capabilities. Request samples to evaluate the quality of their plug point covers. Assess their certifications, production capacity, and lead times. It’s also beneficial to check their reputation through customer reviews and industry references. Establish clear communication regarding your specifications, and inquire about their experience in exporting to your target regions, ensuring they understand the specific regulations and market needs. -

What are the minimum order quantities (MOQs) for plug point covers?

Minimum order quantities can vary widely among manufacturers, typically ranging from 100 to several thousand units. Factors influencing MOQs include the supplier’s production capabilities, material costs, and customization options. When negotiating, consider your budget and inventory management strategies. Some suppliers may offer flexible MOQs for first-time orders or larger contracts. Always clarify the implications of MOQs on pricing and lead times to ensure your order aligns with your business objectives. -

What payment terms are common in international trade for plug point covers?

Common payment terms in international trade include letters of credit, advance payments, and payment upon delivery. Many suppliers may require a deposit (20-30%) before production begins, with the balance due upon shipment. Negotiating favorable terms is essential, especially for large orders. Familiarize yourself with the payment practices of your target markets, as preferences may vary. Ensure you understand any associated fees, currency exchange rates, and the implications of payment methods on your cash flow and risk management. -

How can I ensure quality assurance (QA) for plug point covers?

To ensure quality assurance, implement a robust QA process that includes supplier audits, product testing, and regular inspections. Specify quality standards in your contracts, and consider third-party inspections before shipment. Establish clear criteria for evaluating the product, including safety certifications, durability, and compliance with industry regulations. Collaborate with suppliers to develop a quality control plan that outlines testing procedures and accountability. This proactive approach minimizes risks and ensures that the products meet your expectations. -

What logistics considerations should I keep in mind when sourcing plug point covers?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling electrical products to navigate international shipping complexities. Understand the import duties and taxes for your target markets, which can impact pricing and profitability. It’s also essential to have a plan for potential delays, especially when dealing with customs clearance. Establish clear communication with suppliers regarding packaging and labeling requirements to ensure compliance with local regulations. -

Can I customize plug point covers to meet specific market needs?

Yes, many manufacturers offer customization options for plug point covers, including color, size, and branding. Customization can enhance your product’s appeal in specific markets and differentiate your brand. When discussing customization, provide detailed specifications and consider the potential impact on lead times and costs. Collaborate with your supplier to ensure that the final product meets safety standards and market preferences. Customization not only adds value but can also strengthen customer loyalty by addressing unique regional requirements.

Top 2 Plug Point Cover Manufacturers & Suppliers List

1. Dreambaby – Dual Fit Plug & Electrical Outlet Covers

Domain: dreambaby.com

Registered: 2001 (24 years)

Introduction: Dual Fit Plug & Electrical Outlet Covers – 2 Pack, SKU: L907, Price: $6.49, In stock, Designed to cover both unused and used outlets, Helps prevent children from pulling plugs out of the wall, Simple installation process, Suitable for all types of outlets (standard and decora), Each package includes 2 covers, Allows parents easy access to outlets while keeping them safe for children.

2. Safety 1st – Plug Socket Covers

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Plug socket covers available in various packs (e.g., 36, 40, 52, 60 packs). Brands include Unbranded, Safety 1st, DreamBaby, and others. Prices range from $2.99 to $23.99. Condition options include new and used. Features include child-proofing and easy installation. Free shipping options available. Listings include auction and buy it now formats.

Strategic Sourcing Conclusion and Outlook for plug point cover

In today’s global marketplace, strategic sourcing of plug point covers presents a unique opportunity for B2B buyers to enhance safety and compliance across various sectors. With increasing awareness around child safety and electrical hazards, investing in quality plug point covers not only meets regulatory standards but also addresses consumer demand for safer environments. Buyers should prioritize suppliers who offer a diverse range of products, including innovative designs that cater to different outlet types and safety needs.

Illustrative image related to plug point cover

Moreover, leveraging strategic sourcing can help businesses optimize costs while ensuring product quality. By establishing strong partnerships with manufacturers, companies can benefit from bulk purchasing, reduced lead times, and improved product availability, particularly in emerging markets across Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for reliable and effective plug point covers is expected to grow, driven by ongoing safety concerns and technological advancements. International B2B buyers are encouraged to assess their sourcing strategies now to capitalize on this trend. Embrace the opportunity to enhance safety standards in your offerings, and position your business as a leader in responsible sourcing and product safety.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.