The Definitive Guide to Platform Scale: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for platform scale

In today’s competitive global marketplace, sourcing the right platform scale can significantly impact operational efficiency and cost management. B2B buyers often face the challenge of selecting scales that not only meet their specific industrial requirements but also align with international standards and regulations. This comprehensive guide on platform scales addresses this critical need, covering various types of scales, their diverse applications, and practical considerations for supplier vetting and cost analysis.

From high-capacity warehouse pallet scales to specialized models designed for hazardous environments, this guide offers insights tailored to the unique demands of businesses across Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam. It provides actionable strategies for evaluating suppliers, understanding pricing structures, and ensuring compliance with local regulations, empowering buyers to make informed purchasing decisions that enhance their operational capabilities.

By navigating the complexities of the global market for platform scales, this guide not only aids in identifying the right equipment but also fosters long-term supplier relationships that can drive efficiency and profitability. Whether you’re upgrading existing equipment or investing in new technology, our insights will help you streamline your weighing processes and ensure your business remains competitive in an evolving landscape.

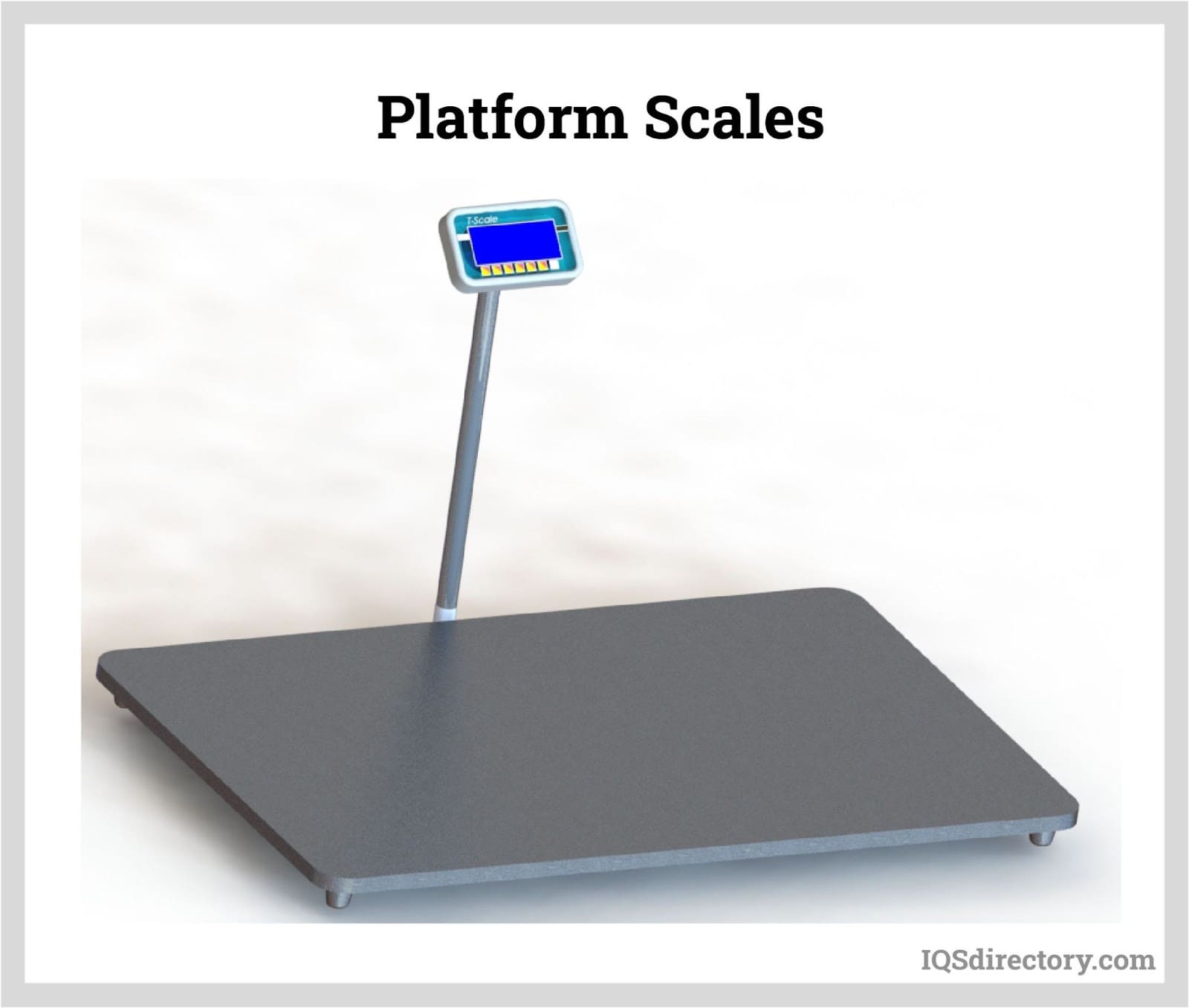

Understanding platform scale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Floor Scales | Heavy-duty steel construction; various capacities; LED display | Warehousing, logistics, manufacturing | Pros: Durable, accurate, versatile. Cons: May require more space. |

| Stainless Steel Scales | Corrosion-resistant; food-safe design; easy to clean | Food processing, pharmaceutical industries | Pros: Hygienic, durable under harsh conditions. Cons: Higher initial investment. |

| Portable Floor Scales | Lightweight; easy to move; battery-operated options | Fieldwork, temporary setups | Pros: Flexibility, ease of transport. Cons: Limited capacity compared to stationary scales. |

| Pit-Mounted Scales | Integrated into the floor; allows for easy loading | Heavy industries, shipping docks | Pros: Space-saving, seamless workflow. Cons: Installation complexity and cost. |

| Hazardous Environment Scales | Intrinsically safe; designed for explosive atmospheres | Chemical, oil and gas sectors | Pros: Safety compliance, reliable in extreme conditions. Cons: Specialized features may increase costs. |

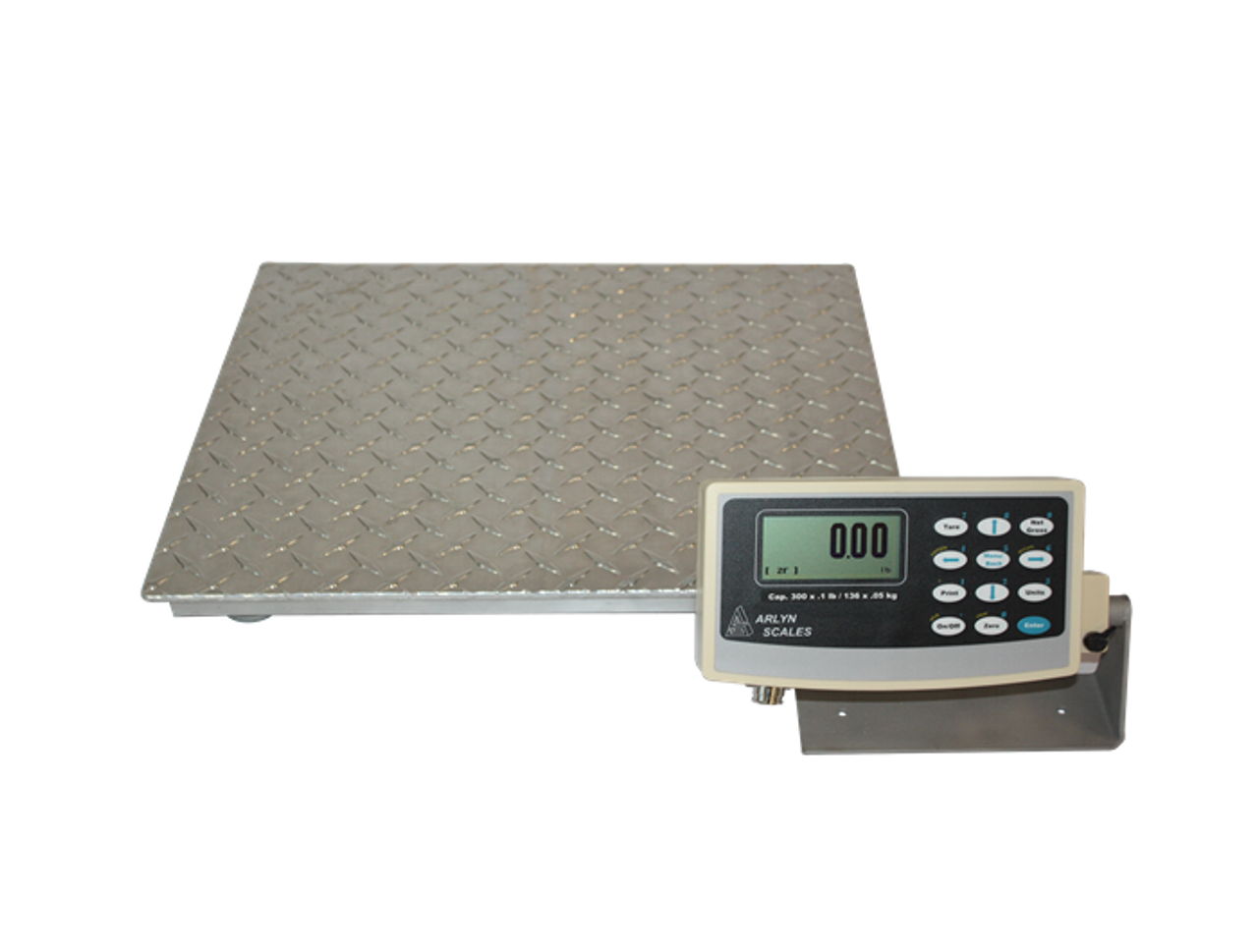

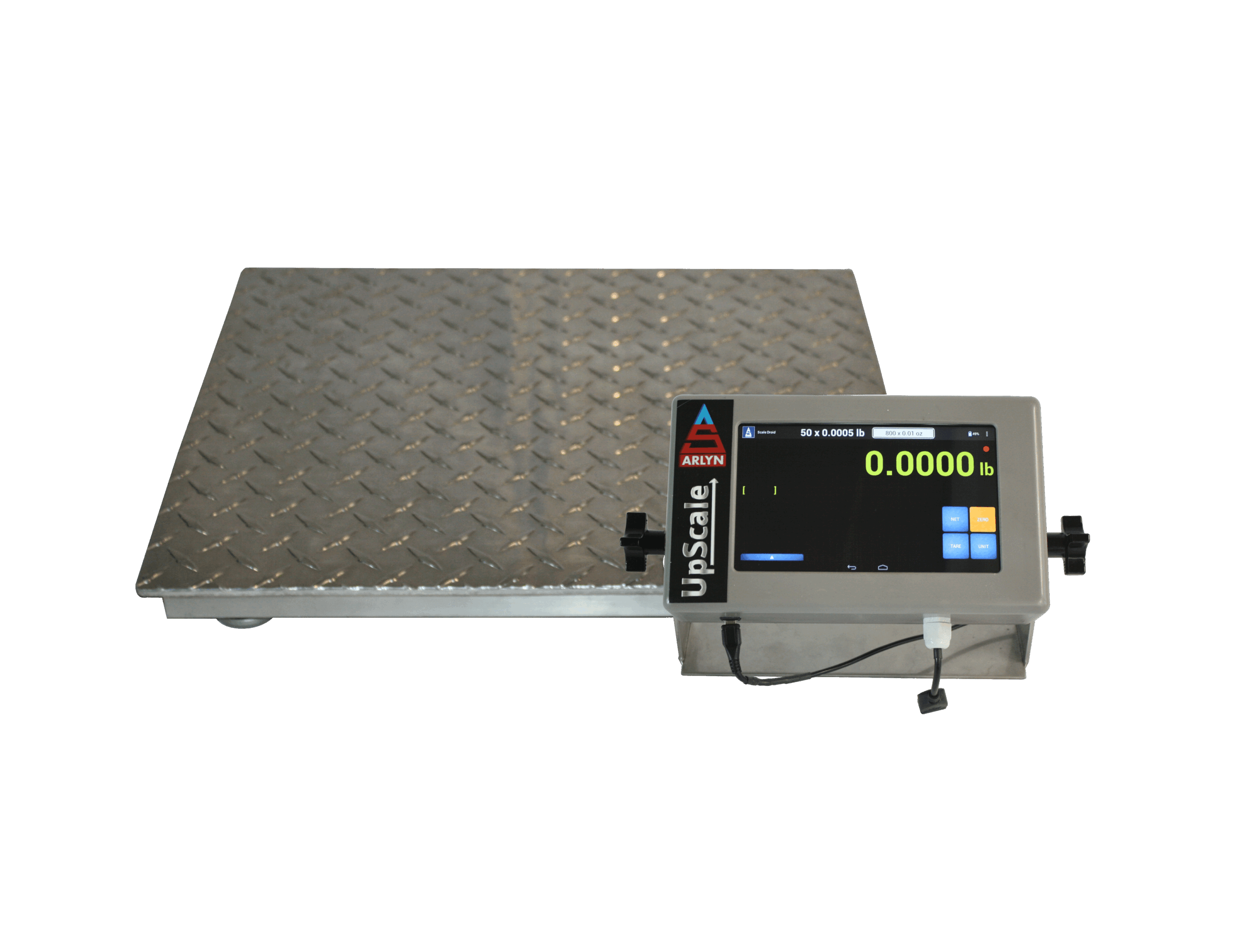

What Are the Characteristics of Standard Floor Scales?

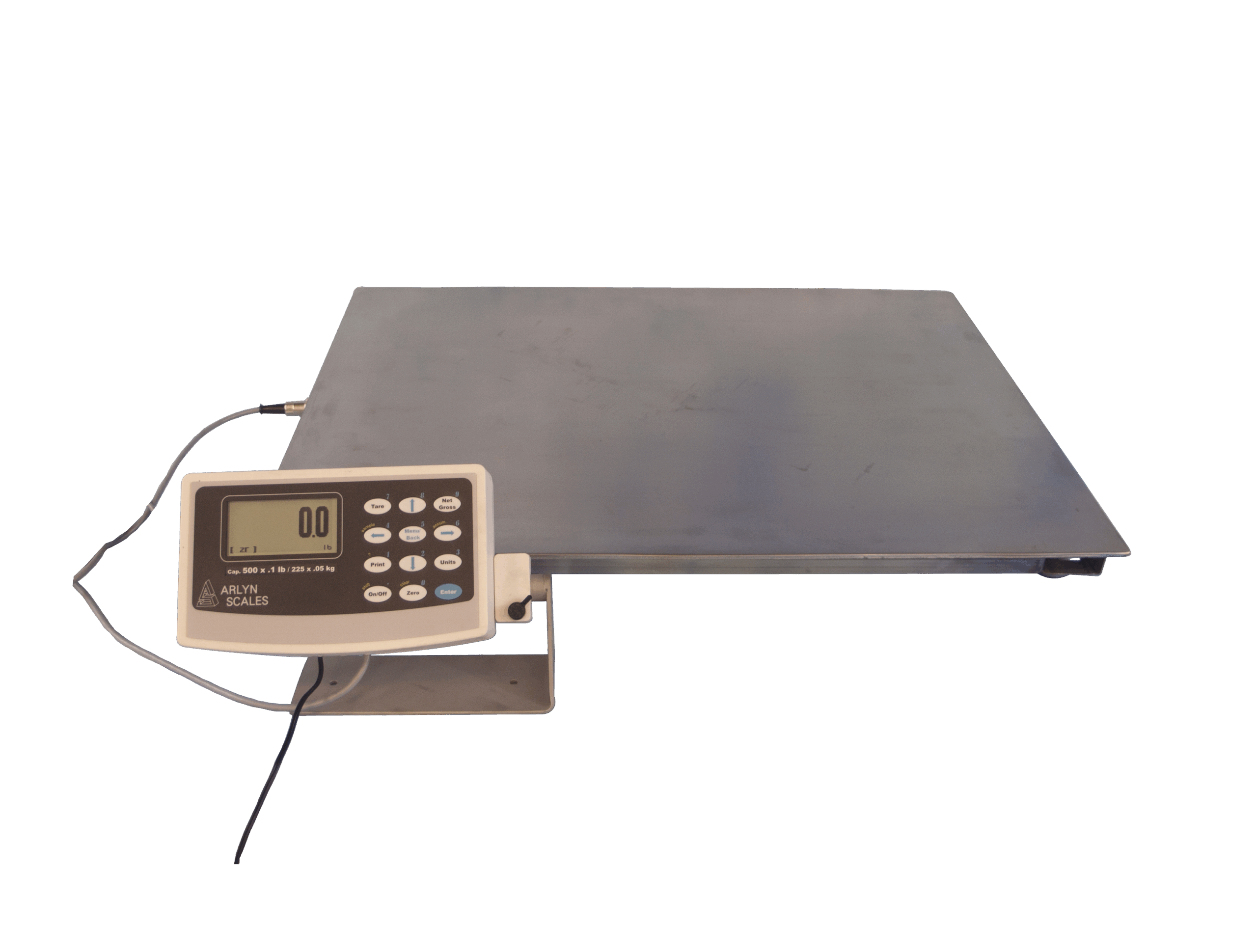

Standard floor scales are characterized by their robust construction, typically made from heavy-duty steel, and are available in various capacities, often ranging from 5,000 to 10,000 pounds. They come equipped with an LED display for easy readability. These scales are ideal for warehousing, logistics, and manufacturing applications where consistent and accurate measurements of heavy loads are essential. Buyers should consider the available space for installation and the scale’s capacity relative to their operational needs.

How Do Stainless Steel Scales Enhance Hygiene in B2B Applications?

Stainless steel scales are specifically designed to meet stringent hygiene standards, making them suitable for industries such as food processing and pharmaceuticals. Their corrosion-resistant properties allow them to endure rigorous cleaning protocols, ensuring compliance with health regulations. While they offer exceptional durability and reliability, buyers should be prepared for a higher initial investment compared to standard scales, which may be justified by their long-term performance in demanding environments.

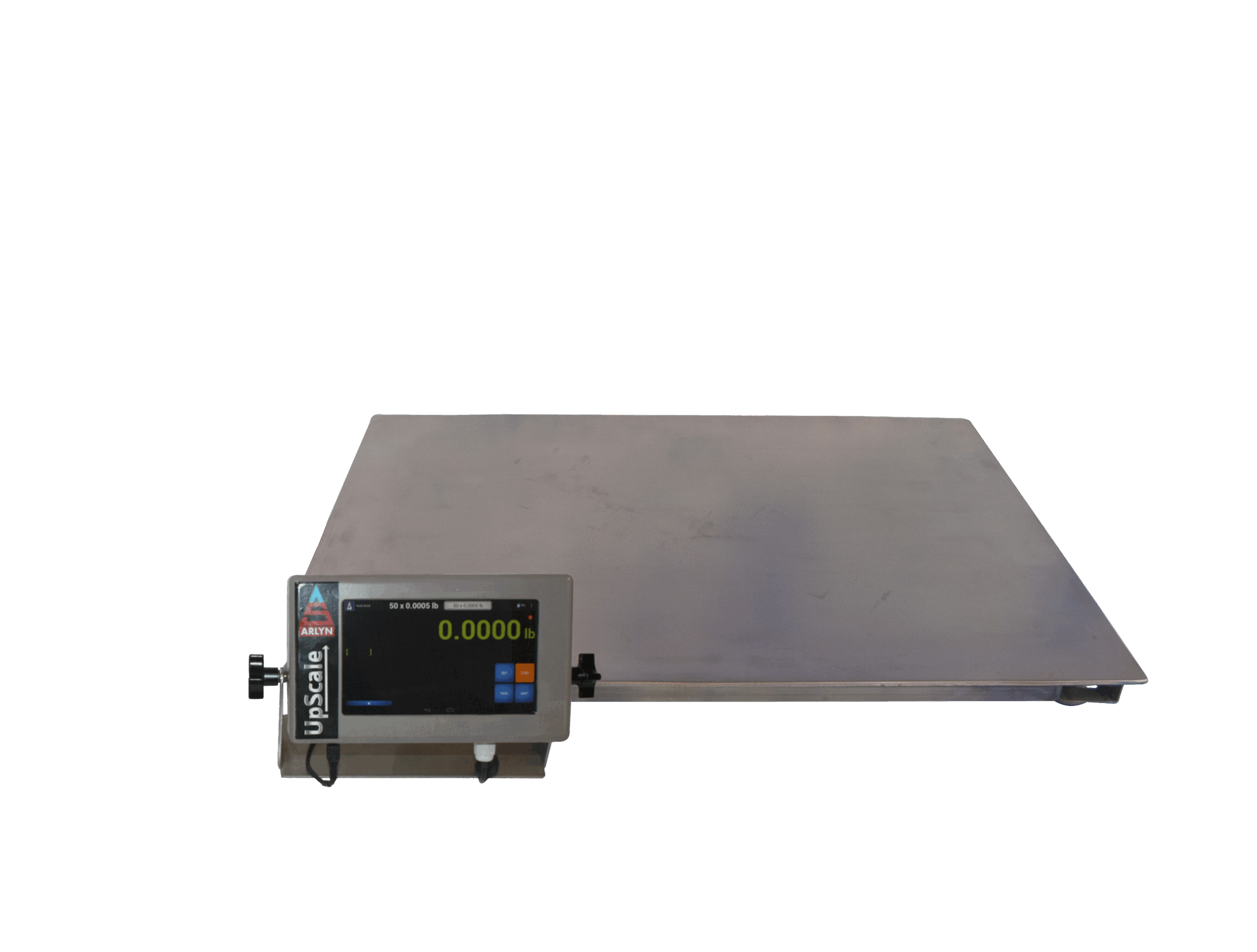

Illustrative image related to platform scale

Why Choose Portable Floor Scales for Flexibility?

Portable floor scales are lightweight and designed for easy mobility, often featuring battery-operated options for fieldwork or temporary setups. Their flexibility makes them ideal for businesses that require weighing equipment in multiple locations or for short-term projects. However, buyers should note that these scales typically have a lower weight capacity compared to stationary models, which may limit their use in heavy-duty applications.

What Advantages Do Pit-Mounted Scales Offer in Industrial Settings?

Pit-mounted scales are integrated into the floor, allowing for seamless loading and unloading of goods without obstructing workflow. This design is particularly beneficial in heavy industries and shipping docks where space is at a premium. While they provide significant efficiency advantages, the complexity and cost of installation can be a consideration for buyers, who must ensure that their facilities can accommodate such a system.

How Do Hazardous Environment Scales Ensure Safety?

Hazardous environment scales are engineered to operate safely in settings where explosive gases, vapors, or dust may be present. These scales comply with stringent safety standards, making them ideal for industries like chemicals and oil and gas. While they provide essential safety features, potential buyers should consider the specialized nature of these scales, which may come with increased costs and require specific maintenance protocols.

Key Industrial Applications of platform scale

| Industry/Sector | Specific Application of platform scale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Warehousing | Pallet Weighing | Streamlines inventory management, reduces shipping costs | Capacity requirements, durability, and space constraints |

| Food Processing | Ingredient Measurement | Ensures consistency in product quality, compliance with regulations | Hygiene standards, material choice (stainless steel), washdown capabilities |

| Manufacturing | Material Handling | Enhances operational efficiency, minimizes downtime | Custom sizes, load capacity, and environmental resistance |

| Chemical and Pharmaceutical | Hazardous Material Weighing | Ensures safety compliance, prevents costly accidents | Intrinsic safety features, material compatibility, and certifications |

| Retail and Distribution | Shipping and Receiving | Improves accuracy in order fulfillment, reduces returns | Legal-for-trade certifications, ease of integration, and support services |

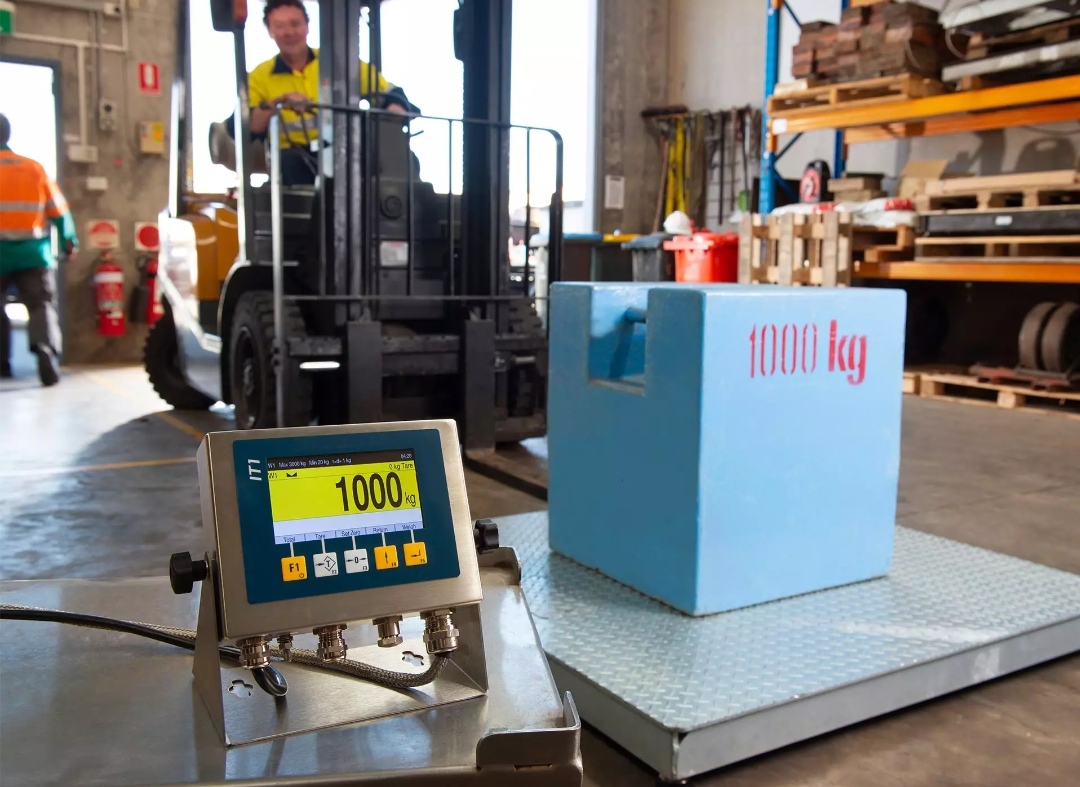

How is Platform Scale Used in Logistics and Warehousing?

In the logistics and warehousing sector, platform scales are essential for pallet weighing. These scales help businesses accurately measure the weight of goods before shipping, ensuring compliance with carrier weight limits and optimizing shipping costs. By providing precise weight data, companies can streamline inventory management and reduce the risk of overloading vehicles, which can lead to fines and operational delays. Buyers in this sector should consider the scale’s capacity and durability, especially in high-volume environments.

What Role Does Platform Scale Play in Food Processing?

In food processing, platform scales are critical for measuring ingredients accurately. This ensures consistency in product quality, which is vital for regulatory compliance and customer satisfaction. Food manufacturers often require scales that meet stringent hygiene standards, such as those made from stainless steel that can withstand high-pressure washdowns. Buyers must prioritize models that are easy to clean and maintain while also offering reliable performance in high-volume production environments.

Illustrative image related to platform scale

How Does Platform Scale Enhance Manufacturing Operations?

Manufacturers utilize platform scales for material handling, particularly in weighing raw materials and components. These scales enhance operational efficiency by minimizing downtime during production, as accurate weight measurements can prevent material shortages or excesses. When sourcing platform scales, manufacturers should look for custom sizes to fit specific workflows and ensure that the scales can withstand the harsh conditions of manufacturing environments.

Why are Platform Scales Important in Chemical and Pharmaceutical Industries?

In the chemical and pharmaceutical industries, platform scales are used for weighing hazardous materials. These scales must meet rigorous safety standards to prevent ignition in explosive atmospheres. By ensuring accurate measurements, businesses can maintain safety compliance and avoid costly accidents. Buyers in these sectors should prioritize scales with intrinsic safety features, durable construction, and compatibility with various materials to ensure reliable performance in demanding environments.

How Do Retail and Distribution Benefit from Platform Scales?

In retail and distribution, platform scales are commonly used for shipping and receiving goods. Accurate weight measurements are essential for order fulfillment, helping to reduce returns due to shipping discrepancies. Buyers should consider scales that are legal-for-trade and easy to integrate into existing workflows, as well as reliable support services to minimize downtime. These features enhance overall operational efficiency and customer satisfaction in the retail sector.

Illustrative image related to platform scale

3 Common User Pain Points for ‘platform scale’ & Their Solutions

Scenario 1: Inefficient Weighing Processes in High-Volume Warehouses

The Problem: In fast-paced warehouse environments, the need for rapid and accurate weighing is paramount. However, many B2B buyers find that traditional weighing methods are cumbersome and time-consuming, leading to bottlenecks during shipping and receiving. For instance, a logistics manager in Nigeria may struggle with outdated scales that require manual adjustments and lengthy calibrations, resulting in delays and increased labor costs. This inefficiency can harm customer satisfaction and overall operational productivity.

The Solution: To overcome these challenges, buyers should invest in digital platform scales designed for high-capacity, high-volume environments. When sourcing these scales, look for features such as quick-connect plug systems and user-friendly interfaces that facilitate rapid setup and operation. Additionally, consider models with built-in data integration capabilities that allow for seamless communication with inventory management systems. This not only streamlines the weighing process but also enhances data accuracy and traceability. Regular training on the proper use and maintenance of these scales can further optimize their functionality, ensuring that warehouse staff can quickly adapt to using them without disruption.

Scenario 2: Space Constraints in Small Facilities

The Problem: Many businesses, particularly in regions with limited real estate, face the challenge of integrating heavy-duty weighing solutions into compact spaces. For example, a manufacturing facility in Vietnam might require a robust floor scale for heavy machinery but struggles with the lack of floor area to accommodate standard-sized equipment. This can lead to inefficient workflows, as teams may have to transport items to and from the scale, wasting time and resources.

The Solution: Buyers should seek out compact, heavy-duty platform scales specifically designed for limited spaces. Look for options such as pit-mounted scales that allow for seamless integration with existing workflows, permitting forklifts and carts to load directly onto the scale without requiring additional space. Scales that feature modular designs or can be customized to fit specific dimensions can also be advantageous. When evaluating potential purchases, ensure that the scales meet the necessary durability and accuracy standards for your specific industry. Implementing these solutions can significantly improve operational efficiency, reduce handling times, and enhance overall productivity.

Scenario 3: Compliance with Industry Regulations

The Problem: B2B buyers in sectors such as food processing or pharmaceuticals often face stringent regulatory requirements regarding weighing accuracy and sanitation. A company in South America might find itself struggling to maintain compliance with health regulations due to the use of outdated, non-hygienic scales, risking fines or even shutdowns during inspections. This scenario not only threatens the business’s operational viability but also its reputation among consumers.

Illustrative image related to platform scale

The Solution: To address compliance issues, invest in stainless steel platform scales that adhere to the highest hygiene and safety standards. These scales should be designed for easy cleaning and maintenance, featuring smooth surfaces and corrosion-resistant materials. Additionally, ensure that the scales are certified for legal trade and meet local regulatory requirements. Conduct regular audits and maintain documentation of calibration and cleaning protocols to reinforce compliance. By prioritizing quality and hygiene in weighing equipment, businesses can safeguard against regulatory penalties and ensure a safer, more reliable operation.

Strategic Material Selection Guide for platform scale

What Are the Key Properties of Common Materials Used in Platform Scales?

When selecting materials for platform scales, it is essential to consider their properties and how they align with the specific requirements of various industries. Here, we analyze four common materials: stainless steel, carbon steel, aluminum, and composite materials.

How Does Stainless Steel Perform in Platform Scales?

Stainless steel is renowned for its corrosion resistance and durability, making it an ideal choice for environments that require high hygiene standards, such as food processing and pharmaceuticals. It can withstand a wide range of temperatures and is less prone to rust, ensuring long-term reliability. However, the manufacturing complexity and higher cost associated with stainless steel can be significant drawbacks. For international buyers, compliance with food safety standards (like FDA regulations) and local certifications (such as ASTM or EN standards) is crucial, especially in regions with stringent health regulations.

What Are the Advantages and Disadvantages of Carbon Steel?

Carbon steel is favored for its strength and cost-effectiveness, making it suitable for heavy-duty applications such as logistics and warehousing. Its high load-bearing capacity is a significant advantage; however, it is susceptible to corrosion, which can limit its lifespan in humid or chemically aggressive environments. Buyers in regions with high moisture levels, such as parts of Africa and South America, should consider protective coatings or regular maintenance to mitigate corrosion risks. Compliance with local industrial standards is also vital to ensure safety and reliability.

Why Choose Aluminum for Platform Scales?

Aluminum is lightweight yet strong, making it an excellent option for portable platform scales. It offers good corrosion resistance, especially when anodized, and is suitable for various applications, including shipping and receiving. However, its lower load-bearing capacity compared to steel can be a limitation for heavy applications. International buyers should consider the specific weight and load requirements of their operations. Additionally, aluminum scales may need to meet specific regional standards, which can vary significantly across different markets.

How Do Composite Materials Enhance Platform Scale Functionality?

Composite materials, often a blend of plastics and metals, provide a unique combination of lightweight properties and resistance to corrosion and chemicals. These materials are particularly useful in specialized applications, such as weighing hazardous materials or in environments where traditional materials may fail. However, the manufacturing complexity and potentially higher costs can be barriers for some buyers. For international markets, understanding the specific chemical compatibility and regulatory requirements of composites is essential, particularly in industries like pharmaceuticals and chemicals.

Illustrative image related to platform scale

Summary Table of Material Selection for Platform Scales

| Material | Typical Use Case for platform scale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | High corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Logistics, warehousing | Strong load-bearing capacity | Susceptible to corrosion | Medium |

| Aluminum | Portable scales, shipping | Lightweight and good corrosion resistance | Lower load capacity | Medium |

| Composite | Hazardous materials, specialized applications | Lightweight and chemical resistant | Higher manufacturing complexity | High |

In conclusion, selecting the right material for platform scales involves balancing performance, cost, and compliance with regional standards. Understanding the specific needs of your application and the environmental conditions will guide you in making an informed decision that aligns with your operational goals.

In-depth Look: Manufacturing Processes and Quality Assurance for platform scale

What Are the Main Stages of the Manufacturing Process for Platform Scales?

The manufacturing process for platform scales is a multi-stage procedure that emphasizes durability, precision, and functionality. Below are the key stages typically involved:

Material Preparation: What Materials Are Used in Platform Scale Manufacturing?

The foundation of any platform scale lies in the quality of materials selected. Common materials include:

- Steel: Heavy-duty steel is often used for its strength and durability, particularly in environments requiring high capacity, such as warehouses and factories.

- Stainless Steel: This material is preferred for applications in food processing or pharmaceutical industries due to its corrosion resistance and hygiene standards.

- Aluminum: Lightweight yet strong, aluminum is chosen for portable scales.

Before fabrication, these materials undergo rigorous quality checks to ensure they meet specific industry standards.

Forming: How Are Platform Scales Shaped and Constructed?

The forming stage involves various techniques such as:

- Cutting and Welding: Sheets of metal are cut to size and welded together to create the platform structure. Laser cutting is often used for precision.

- Casting: In some cases, particularly for load cells, casting techniques might be employed to create complex shapes that are integral to the scale’s functionality.

- Machining: This involves precision machining to ensure that all components fit together seamlessly, enhancing the scale’s overall accuracy.

These methods ensure that the scales can withstand the rigors of industrial use while maintaining accurate measurements.

Assembly: What Are the Key Steps in the Assembly Process?

The assembly stage is crucial for ensuring that all components work together effectively. Key steps include:

- Integration of Load Cells: Load cells are installed and calibrated to ensure they provide accurate readings under various weights.

- Electronics Installation: Digital displays and sensors are integrated into the scales, requiring careful handling to prevent damage.

- Final Assembly: All parts are assembled, including ramps for easy access, and any additional features like mobility options or safety measures.

Attention to detail during assembly is vital, as even minor errors can lead to significant inaccuracies in weighing.

Finishing: How Is the Final Product Prepared for Market?

Finishing processes improve both functionality and aesthetics. Common techniques include:

- Surface Treatment: Powder coating or galvanization may be applied to enhance corrosion resistance and durability.

- Calibration: Each scale is calibrated to ensure precision before being sent to market. This may involve testing the scale with known weights and adjusting accordingly.

- Quality Inspection: A thorough inspection is conducted to ensure that the scale meets both design specifications and industry standards.

The final product should not only look appealing but also be ready to perform reliably in demanding environments.

What Quality Assurance Standards Are Relevant for Platform Scales?

Quality assurance (QA) is critical for ensuring that platform scales meet the necessary performance and safety standards. Key international and industry-specific standards include:

- ISO 9001: This standard outlines criteria for a quality management system, ensuring consistent product quality and customer satisfaction.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For scales used in the oil and gas industry, adherence to API standards ensures that the equipment can operate safely in potentially hazardous conditions.

Adhering to these standards not only guarantees product reliability but also facilitates smoother international transactions.

Illustrative image related to platform scale

What Are the Key Quality Control Checkpoints in Platform Scale Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process to identify defects and ensure compliance with standards. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, various tests are conducted to monitor the quality of components and assembly processes.

- Final Quality Control (FQC): Before products leave the facility, they undergo comprehensive testing to verify accuracy and compliance with standards.

These checkpoints help mitigate risks and ensure that only high-quality products reach the market.

What Common Testing Methods Are Employed to Ensure Platform Scale Accuracy?

Various testing methods are employed to ensure the accuracy and reliability of platform scales:

- Load Testing: Scales are subjected to known weights to ensure that they provide accurate readings. This is often done with calibrated weights.

- Environmental Testing: Scales are tested under different environmental conditions (e.g., humidity, temperature) to ensure they perform reliably in various settings.

- Durability Testing: This involves simulating long-term use to assess how well the scale withstands wear and tear.

These testing methods provide B2B buyers with confidence in the reliability of their investments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence when selecting suppliers to ensure quality standards are met. Effective strategies include:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and compliance with international standards firsthand.

- Quality Assurance Reports: Requesting detailed QA reports can provide insights into the supplier’s processes and any corrective actions taken in the past.

- Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased evaluation of the supplier’s practices and product quality.

These steps are particularly crucial for buyers in regions such as Africa, South America, the Middle East, and Europe, where standards and regulations may vary significantly.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers must navigate various nuances when it comes to quality control:

- Regulatory Differences: Understanding local regulations and standards in both the supplier’s country and the buyer’s country is critical for compliance.

- Cultural Factors: Different cultures may have varying approaches to quality assurance, and understanding these nuances can aid in smoother negotiations and partnerships.

- Logistics and Shipping: Quality assurance doesn’t end at manufacturing. Consider how products are packaged and transported, as these factors can impact the integrity of the scales upon arrival.

By being aware of these nuances, international buyers can make informed decisions that enhance their procurement processes and ensure the quality of their investments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘platform scale’

To assist B2B buyers in procuring platform scales effectively, this guide outlines essential steps to consider during the sourcing process. By following this checklist, you can ensure you make an informed decision that aligns with your operational needs and compliance requirements.

Illustrative image related to platform scale

Step 1: Define Your Technical Specifications

Identifying the precise requirements of your operations is crucial. Consider factors such as the maximum load capacity, dimensions, and material of the platform scale. Additionally, evaluate the environment where the scale will be used—whether in a warehouse, factory, or outdoor setting—as this will influence your choice of materials and features.

- Capacity Needs: Determine the heaviest loads you will need to weigh.

- Material Considerations: Select stainless steel for corrosion resistance in wet environments or aluminum for lightweight portability.

Step 2: Assess Required Features and Functionalities

Different platforms come with various functionalities that can enhance operational efficiency. Look for features such as ramps for easy loading, digital displays for accurate readings, and connectivity options for data integration.

- User-Friendly Design: Ensure that the scale is easy to operate and maintain.

- Integration Capabilities: Consider whether the scale can connect to existing inventory management systems.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from similar industries or regions. It’s important to assess their reputation and reliability.

Illustrative image related to platform scale

- Supplier Reputation: Look for suppliers with a proven track record in your industry.

- Customer Testimonials: Seek feedback from other buyers to gauge satisfaction and performance.

Step 4: Verify Compliance and Certifications

Ensure that the platform scales meet necessary industry standards and regulations. This includes safety certifications and compliance with local laws regarding weighing equipment.

- Regulatory Compliance: Check for certifications like NTEP or OIML, especially if you’re in a legal-for-trade environment.

- Safety Standards: Confirm that the equipment adheres to safety regulations relevant to your industry.

Step 5: Consider After-Sales Support and Warranty

Evaluate the level of after-sales support provided by the supplier. A robust warranty and ongoing support can mitigate future risks related to equipment failure or maintenance.

- Warranty Coverage: Look for warranties that cover both parts and labor.

- Support Availability: Assess whether the supplier offers timely technical support and service options.

Step 6: Request Quotes and Compare Pricing

Once you have narrowed down your options, request detailed quotes from multiple suppliers. Compare pricing not just on the scale itself, but also consider additional costs such as shipping, installation, and maintenance.

- Transparent Pricing: Ensure that quotes break down all costs to avoid hidden charges.

- Value for Money: Balance the cost against the features and reliability of the scales.

Step 7: Finalize Your Purchase and Plan for Implementation

After selecting a supplier and finalizing the purchase, plan for the implementation of the platform scale in your operations. This includes training staff and integrating the scale into existing workflows.

- Training Requirements: Ensure that your team is trained on how to operate and maintain the scale.

- Integration Planning: Develop a strategy for how the new scale will fit into your operational processes.

By adhering to this checklist, you can streamline your sourcing process and make informed decisions that enhance your operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for platform scale Sourcing

What Are the Key Cost Components in Platform Scale Manufacturing?

When evaluating the cost structure for platform scales, several components come into play. The primary cost drivers include materials, labor, manufacturing overhead, tooling, quality control (QC), and logistics.

Illustrative image related to platform scale

-

Materials: The choice of materials—such as stainless steel, aluminum, or carbon steel—affects both durability and price. High-quality materials may increase initial costs but can lead to lower maintenance expenses over time.

-

Labor: Labor costs vary significantly based on geographic location and the complexity of the manufacturing process. Skilled labor in regions with higher wage standards will contribute more to overall costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: This entails the costs of molds, dies, and other equipment necessary for production. Custom tooling for specialized scales will incur higher upfront costs but can yield better efficiency and precision in the long run.

-

Quality Control: Ensuring that scales meet regulatory and industry standards is crucial. Rigorous QC processes can add to costs but are essential for maintaining reliability and customer satisfaction.

-

Logistics: Shipping and handling costs, especially for heavy equipment like platform scales, can be substantial. Factors like distance, mode of transport, and packaging impact logistics expenses.

How Do Price Influencers Impact Platform Scale Sourcing?

Several factors influence the pricing of platform scales, which B2B buyers must consider:

-

Volume/MOQ: Ordering in larger quantities can significantly reduce per-unit costs. Suppliers often provide discounts for bulk purchases, making it an essential consideration for businesses looking to scale.

-

Specifications and Customization: Custom-built scales tailored to specific operational needs will generally cost more than standard models. Buyers should assess their requirements carefully to avoid unnecessary expenses.

-

Materials and Quality Certifications: Scales made from higher-grade materials and those that meet specific certifications (e.g., IP67 for water and dust resistance) will typically command a premium price due to their reliability and durability.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers with a proven track record may charge higher prices but often provide better service and support.

-

Incoterms: Understanding the terms of trade (Incoterms) is crucial. These terms dictate who is responsible for shipping costs, insurance, and tariffs, impacting the total cost of acquisition.

What Are Effective Buyer Tips for Negotiating Platform Scale Prices?

International B2B buyers should employ several strategies to ensure cost-efficiency in their purchasing decisions:

-

Negotiate Terms: Leverage the volume of your order to negotiate better pricing or payment terms. Suppliers may offer more favorable terms for larger commitments or long-term contracts.

-

Assess Total Cost of Ownership (TCO): Consider not just the upfront price but also the long-term costs associated with maintenance, repairs, and potential downtime. A lower initial price may result in higher TCO if the product is less durable.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, import duties, and shipping costs can affect overall pricing. Buyers should factor these elements into their budgeting to avoid unexpected expenses.

-

Research Suppliers Thoroughly: Given the global nature of sourcing, it’s important to vet suppliers based on their reliability, customer service, and history of delivering quality products.

Disclaimer Regarding Indicative Prices

Prices for platform scales can vary significantly based on the factors outlined above. As such, it is advisable for buyers to seek detailed quotes from multiple suppliers and conduct thorough market research to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing platform scale With Other Solutions

Understanding Alternatives to Platform Scales

In the industrial weighing landscape, platform scales are a common choice for businesses needing reliable and accurate weight measurements. However, various alternative solutions can also achieve similar goals, each with distinct advantages and drawbacks. This analysis will explore two viable alternatives to platform scales: Load Cells and Weighbridges. By comparing these options, B2B buyers can make informed decisions based on their specific operational needs.

Illustrative image related to platform scale

Comparison Table

| Comparison Aspect | Platform Scale | Load Cells | Weighbridges |

|---|---|---|---|

| Performance | High accuracy and capacity | Varies based on design; can be precise | Excellent for heavy vehicles |

| Cost | Moderate initial investment | Low to moderate; depends on setup | Higher due to installation costs |

| Ease of Implementation | Generally straightforward | Requires careful integration | Requires significant infrastructure |

| Maintenance | Low; routine checks suffice | Moderate; dependent on environment | High; regular calibration needed |

| Best Use Case | Warehouses, factories, and logistics | Small to medium loads in various settings | Heavy-duty applications like trucking and agriculture |

Pros and Cons of Each Alternative

Load Cells

Load cells are transducers that convert force into an electrical signal, making them a versatile option for many weighing applications.

Pros:

– Flexibility: Load cells can be integrated into various systems, allowing for customized solutions tailored to specific needs.

– Cost-Effective: They generally have a lower initial cost compared to platform scales, especially for smaller operations.

Cons:

– Performance Variability: The accuracy and reliability of load cells depend heavily on their design and installation, which can introduce complexity.

– Integration Challenges: Proper installation requires expertise, and any errors can lead to inaccuracies in weight measurements.

Weighbridges

Weighbridges are large, heavy-duty scales designed for weighing vehicles and their loads. They are commonly used in industries such as transportation, agriculture, and mining.

Pros:

– High Capacity: Weighbridges can handle extremely heavy loads, making them ideal for trucks and other large vehicles.

– Accuracy: They provide precise weight readings, which are critical for compliance in many industries.

Illustrative image related to platform scale

Cons:

– Cost: The initial investment and installation costs can be significant, making weighbridges less accessible for smaller operations.

– Space Requirements: Weighbridges require substantial physical space, which may not be feasible for all businesses.

Making the Right Choice for Your Business

When selecting the best weighing solution for your business, consider the specific requirements of your operations. For companies dealing with smaller loads and requiring flexible integration, load cells may offer a cost-effective and efficient solution. Conversely, businesses that need to weigh heavy vehicles consistently may find that investing in a weighbridge provides the durability and accuracy necessary for their operations.

Ultimately, understanding the unique demands of your industry, alongside the performance, cost, and maintenance implications of each alternative, will guide you in choosing the right weighing technology that aligns with your operational goals.

Essential Technical Properties and Trade Terminology for platform scale

What Are the Essential Technical Properties of Platform Scales?

When selecting a platform scale, understanding its technical properties is crucial for ensuring it meets operational needs. Here are key specifications to consider:

1. Material Grade

The material used in the construction of a platform scale directly affects its durability and performance. Common materials include stainless steel and carbon steel. Stainless steel is often preferred in environments requiring hygiene and corrosion resistance, such as food processing or chemical industries. Carbon steel, while robust, may require additional protective coatings to enhance longevity in harsh conditions. Choosing the right material can minimize maintenance costs and extend the scale’s lifespan.

2. Weighing Capacity

Platform scales come with various weight limits, typically ranging from 1,000 to over 10,000 pounds (or 500 to 5,000 kg). Understanding the required capacity is essential for businesses that handle heavy loads. Overloading a scale can lead to inaccurate readings and potential damage, impacting operational efficiency and safety.

3. Accuracy and Tolerance

Accuracy is fundamental in weighing applications. Most industrial scales offer an accuracy of ±0.1% to ±0.5% of the full scale. Tolerance refers to the allowable deviation from the actual weight. High precision is vital in sectors like pharmaceuticals and logistics, where even minor discrepancies can lead to significant financial losses or compliance issues.

4. IP Rating (Ingress Protection)

The IP rating indicates how well a scale can resist dust and moisture. For example, an IP67 rating means the scale is dust-tight and can withstand immersion in water up to 1 meter. This is particularly important in industries where scales are exposed to harsh environments, ensuring reliable performance and longevity.

5. Size and Footprint

The physical dimensions of a platform scale can significantly impact its usability in confined spaces. Scales are available in various sizes, allowing businesses to select models that fit their operational layout. Compact designs can facilitate easier integration into existing workflows, enhancing efficiency.

What Are Common Trade Terms Related to Platform Scales?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of platform scales, sourcing from reputable OEMs ensures high-quality components and compliance with industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For platform scales, MOQs can vary significantly based on the manufacturer and the scale’s specifications. Knowing the MOQ is essential for budgeting and inventory management, especially for smaller businesses.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing for specific products or services. This is a critical step for B2B buyers to compare costs and terms before making purchasing decisions, ensuring they receive competitive pricing on platform scales.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Familiarity with Incoterms helps businesses mitigate risks and understand their liabilities during the procurement of platform scales.

5. NTEP Certification (National Type Evaluation Program)

NTEP certification indicates that a scale meets specific standards set by the National Conference on Weights and Measures. This certification is crucial for businesses that require legal-for-trade scales, ensuring compliance with local regulations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting platform scales, ultimately enhancing operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the platform scale Sector

What Are the Current Market Dynamics and Key Trends in the Platform Scale Sector?

The global platform scale market is undergoing significant transformation driven by technological advancements and evolving customer needs. Key trends include the increasing demand for high-capacity, durable scales that can withstand harsh industrial environments, particularly in emerging markets like Africa, South America, and the Middle East. The rise of e-commerce and logistics operations has propelled the need for accurate and efficient weighing solutions in warehousing and distribution. Furthermore, the integration of IoT technology is becoming a game-changer, allowing businesses to monitor weight data in real-time, enhancing operational efficiency.

International B2B buyers are particularly focused on sourcing robust platforms that provide high accuracy and durability. For instance, scales with IP67-rated load cells are preferred for their resistance to dust and water, making them ideal for diverse environments. Additionally, the trend toward customized solutions is gaining traction, with manufacturers offering tailored designs to meet specific operational requirements. Buyers are also increasingly interested in suppliers who can provide comprehensive after-sales support and maintenance services, ensuring long-term reliability and performance.

How Does Sustainability Impact Sourcing Decisions in the Platform Scale Sector?

As global awareness of environmental issues rises, sustainability is becoming a crucial factor in B2B sourcing decisions. Buyers are increasingly seeking suppliers that prioritize ethical sourcing practices and environmentally friendly materials. The platform scale sector is no exception; manufacturers are now exploring sustainable materials, such as recycled steel and eco-friendly coatings, to reduce their carbon footprint.

Illustrative image related to platform scale

The importance of ethical supply chains cannot be overstated. Buyers are looking for certifications that demonstrate compliance with environmental standards, such as ISO 14001, which ensures that companies effectively manage their environmental responsibilities. Additionally, platforms that are designed for longevity and durability contribute to sustainability by reducing the frequency of replacements and minimizing waste. This shift towards sustainable practices not only meets regulatory requirements but also resonates with consumers who are increasingly making purchasing decisions based on a company’s environmental impact.

What Is the Historical Context of Platform Scales and Their Evolution?

The evolution of platform scales dates back to the industrial revolution when the need for precise measurement in trade and manufacturing became paramount. Initially, these scales were constructed from simple materials and operated manually, but advancements in technology have led to significant enhancements in both functionality and accuracy.

In the late 20th century, the introduction of electronic scales revolutionized the industry, allowing for greater precision and ease of use. Today, platform scales are equipped with advanced features such as digital displays, connectivity options for data integration, and various capacities tailored to specific industries. This evolution reflects not only technological progress but also the growing demand for efficiency and accuracy in an increasingly competitive global market. As businesses continue to adapt to new challenges, the platform scale sector will likely see further innovations that cater to the needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of platform scale

-

How do I choose the right platform scale for my business needs?

When selecting a platform scale, consider factors such as the weight capacity, size, material, and environmental conditions. Assess whether you need a scale that is portable or fixed, and determine if it needs to withstand harsh conditions like moisture or chemicals. Additionally, think about accessibility features like ramps or pit mounts to facilitate loading. Reviewing specific applications—such as shipping, receiving, or production—will help narrow down your options. Engaging with suppliers who offer customization can also ensure the scale meets your unique operational requirements. -

What is the best platform scale for warehouse operations?

For warehouse operations, a heavy-duty digital platform scale with a capacity of 5,000 to 10,000 pounds is often ideal. Look for features like anti-slip surfaces, durable materials (such as steel or stainless steel), and waterproof load cells, which ensure reliability in demanding environments. Scales that offer easy access for forklifts and customizable sizes can enhance efficiency. Brands known for their robust industrial scales, such as Rice Lake or Avery Weigh-Tronix, often provide solutions tailored for warehouses. -

What are the typical minimum order quantities (MOQs) for platform scales?

Minimum order quantities for platform scales can vary significantly depending on the manufacturer and the specific product line. Generally, MOQs may range from a single unit for standard models to larger quantities for customized or specialized scales. When negotiating with suppliers, inquire about bulk pricing options as well, as many manufacturers offer discounts for larger orders. Always clarify MOQs upfront to avoid any misunderstandings during the procurement process. -

How can I vet suppliers for platform scales in international markets?

To vet suppliers, start by researching their reputation through online reviews, testimonials, and industry references. Verify their compliance with international standards and certifications relevant to your region, such as ISO or CE certifications. Request samples or visit their facilities if possible. Additionally, consider their experience in exporting to your specific market, as this can affect logistics and after-sales support. Engaging with local distributors can also provide valuable insights into supplier reliability. -

What payment terms are common for purchasing platform scales internationally?

Payment terms can vary, but common options include upfront payments, net 30 or net 60 days, and letters of credit. For larger orders, suppliers may require a deposit before production. It’s essential to clarify payment methods acceptable to both parties, including bank transfers or payment platforms. Ensure all terms are detailed in the purchase agreement to protect against any disputes. Building a good relationship with suppliers may also lead to more flexible terms over time. -

What quality assurance measures should I look for when buying platform scales?

Look for suppliers that adhere to rigorous quality assurance protocols, such as ISO 9001 certification. Ensure the scales are tested for accuracy and reliability before shipment. Request documentation of quality checks performed during production, including load cell calibration and performance testing. Additionally, inquire about warranties and after-sales support, as reputable suppliers will stand behind their products and offer assistance if issues arise. -

How can I ensure timely logistics for my platform scale shipment?

To ensure timely logistics, communicate your delivery deadlines clearly with the supplier. Work with suppliers who have established logistics partnerships for international shipping, as they can provide insights into transit times and customs requirements. Consider local shipping regulations and potential delays at customs, especially when importing into regions with strict import controls. Tracking options should also be available to monitor your shipment status throughout the process. -

What are the advantages of customizing a platform scale for my specific needs?

Customizing a platform scale allows you to tailor features such as size, weight capacity, and material to fit your operational requirements. This can enhance efficiency, safety, and accuracy in your weighing processes. Custom scales can also include additional features like integrated software for data management or specific load cell types for unique environments. Investing in a customized solution can lead to long-term savings and improved productivity by ensuring the scale aligns perfectly with your workflow.

Top 3 Platform Scale Manufacturers & Suppliers List

1. ScalesPlus – Heavy Capacity Floor Scales

Domain: scalesplus.com

Registered: 2008 (17 years)

Introduction: Floor scales, also known as platform scales, are designed for heavy-capacity weighing in various settings including industrial, agricultural, and laboratory environments. They come in a wide range of platform sizes and capacities suitable for heavy weighing applications. Common uses include shipping departments, warehouses, food processing facilities, chemical manufacturing, bulk material weighing…

2. Floorscales Online – High-Capacity Digital Platform Scales

Domain: floorscalesonline.com

Registered: 2007 (18 years)

Introduction: Non-NTEP Digital Platform Scales | High-Capacity Warehouse Pallet Scales | Available Sizes: 4′ x 4′, 5′ x 5′ | Weighing Capacities: 5,000 lbs, 10,000 lbs | Features: Plug and Weigh Set Up, Heavy Duty Steel Construction, Heavy Duty Diamond Tread Plate, Two Part Epoxy Paint Finish, Four NTEP Approved Alloy Steel Load Cells, Four Ball and Cup Support Feet for Scale Leveling, Top Access Junction Box |…

3. Fairbanks – Portable Digital Platform Scales

Domain: fairbanks.com

Registered: 1995 (30 years)

Introduction: [{‘name’: ‘Portable Digital Platform Scale – 1200’, ‘capacity’: ‘1,000 lb’, ‘type’: ‘Portable Electro-mechanical’, ‘price’: ‘$2,040.00’}, {‘name’: ‘Portable Digital Platform Scale – 1155’, ‘capacity’: ‘1,000 lb’, ‘type’: ‘Advanced digital weighing – Legal for trade’, ‘price’: ‘$2,350.00’}]

Strategic Sourcing Conclusion and Outlook for platform scale

What Are the Key Takeaways for Strategic Sourcing of Platform Scales?

In the dynamic landscape of international trade, leveraging strategic sourcing for platform scales can significantly enhance operational efficiency and cost-effectiveness. Buyers should prioritize durability, accuracy, and adaptability when selecting scales, ensuring they meet industry-specific requirements while accommodating diverse environmental conditions. The integration of advanced features, such as waterproof load cells and customizable sizes, can streamline operations in industries ranging from logistics to food processing.

How Can Buyers Maximize Value Through Strategic Sourcing?

By establishing strong relationships with reputable suppliers, international buyers can negotiate favorable terms and access innovative technologies that drive productivity. Understanding local regulations and compliance standards is crucial, particularly in regions like Africa, South America, the Middle East, and Europe, where varying requirements may impact sourcing decisions.

What’s Next for Global Buyers of Platform Scales?

As the demand for efficient weighing solutions continues to grow, forward-thinking businesses should embrace the evolving landscape of platform scales. Investing in high-quality equipment not only enhances operational capabilities but also contributes to long-term sustainability. We encourage you to explore reliable suppliers and consider the unique needs of your market to stay ahead in this competitive environment. Your strategic sourcing decisions today will shape the success of your operations tomorrow.

Illustrative image related to platform scale

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.