The Definitive Guide to Plate And Frame Heat Exchanger Diagram: Cost, Materials & Top…

Introduction: Navigating the Global Market for plate and frame heat exchanger diagram

In today’s competitive global marketplace, sourcing the right plate and frame heat exchanger diagram can be a critical challenge for international B2B buyers. With increasing demands for energy efficiency and sustainability, businesses must navigate various options to find the most effective solutions for their heat transfer needs. This guide is designed to equip you with comprehensive insights into the different types of plate heat exchangers, their applications across various industries, and the essential factors to consider when selecting the right model for your operations.

From gasketed to brazed and welded designs, each type of heat exchanger offers unique advantages and potential drawbacks. Understanding these differences is crucial for making informed purchasing decisions that align with your operational requirements and environmental goals. Additionally, this guide will cover vital aspects such as supplier vetting, cost analysis, and maintenance considerations, ensuring you have all the necessary tools to optimize your procurement process.

Whether you are based in Nigeria, Saudi Arabia, or any other region in Africa, South America, or Europe, this resource empowers you to make strategic decisions that enhance your operational efficiency while contributing to sustainable practices. By leveraging the insights provided here, you can confidently navigate the complexities of the plate and frame heat exchanger market, ultimately driving better outcomes for your business.

Understanding plate and frame heat exchanger diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gasketed Plate Heat Exchanger | Removable plates sealed with gaskets; easy maintenance | Food processing, HVAC, chemical industries | Pros: Easy to clean; customizable. Cons: Potential for leakage due to gasket wear. |

| Brazed Plate Heat Exchanger | Plates are brazed together, compact design | Refrigeration, HVAC, and oil industries | Pros: High efficiency; space-saving. Cons: Difficult to clean; limited to certain fluids. |

| Welded Plate Heat Exchanger | Plates are welded, suitable for high temperature and pressure | Petrochemical, power generation | Pros: Durable; ideal for corrosive fluids. Cons: Not cleanable; higher initial cost. |

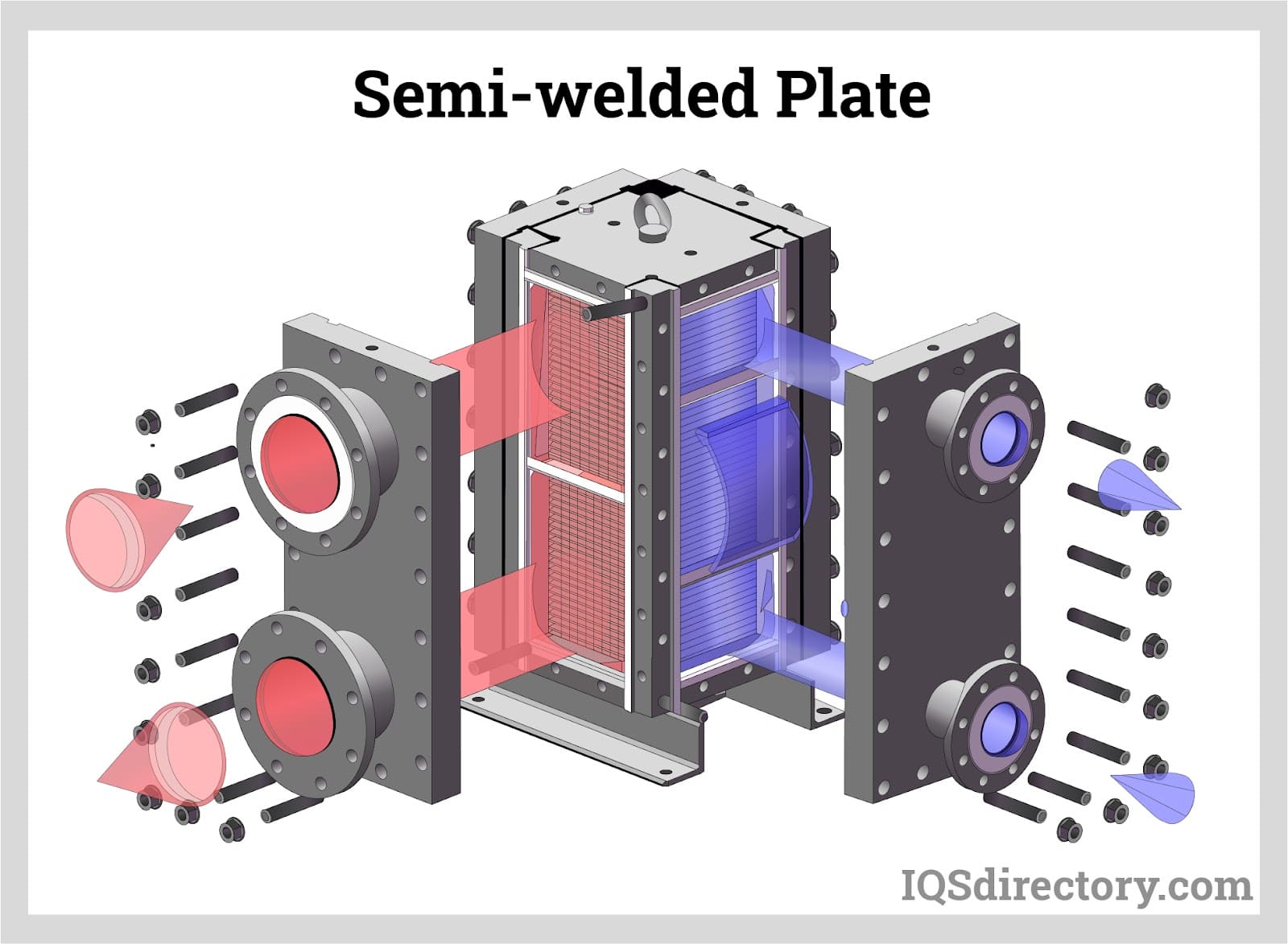

| Semi-Welded Plate Heat Exchanger | Combination of welded and gasketed plates; versatile | Pharmaceutical, specialty chemical | Pros: Reduced risk of leakage; easy to service. Cons: More complex design may increase costs. |

| Compact Plate Heat Exchanger | Smaller footprint with high thermal efficiency | Process industries, district heating | Pros: Saves space; high performance. Cons: May have higher pressure drops; specific design needs. |

What are Gasketed Plate Heat Exchangers and Their Suitability for B2B Buyers?

Gasketed plate heat exchangers feature removable plates sealed with gaskets, allowing for easy maintenance and cleaning. They are widely used in industries such as food processing and HVAC, where hygiene and efficiency are paramount. For B2B buyers, the key consideration is the balance between maintenance ease and the risk of leakage as gaskets age. Choosing high-quality gaskets can mitigate some of these concerns, making them a reliable choice for many applications.

How Do Brazed Plate Heat Exchangers Stand Out in B2B Applications?

Brazed plate heat exchangers are characterized by their compact design, where plates are permanently bonded together using a brazing process. They are ideal for refrigeration and HVAC applications due to their high efficiency and space-saving benefits. Buyers should consider the limitations in cleaning and the types of fluids used, as these exchangers are not suitable for all applications. Their economic advantages often outweigh the potential downsides, particularly in high-performance environments.

What Makes Welded Plate Heat Exchangers a Durable Option for Industrial Use?

Welded plate heat exchangers are designed with plates that are welded together, making them exceptionally durable and suitable for high-temperature and high-pressure applications. Commonly used in petrochemical and power generation sectors, they excel in handling corrosive fluids. B2B buyers must weigh the higher initial costs against the long-term benefits of durability and efficiency. The inability to clean these exchangers may be a drawback for some, but their robustness can justify this limitation.

Why Choose Semi-Welded Plate Heat Exchangers for Versatile Applications?

Semi-welded plate heat exchangers combine the benefits of welded and gasketed designs, allowing for versatility in applications like pharmaceuticals and specialty chemicals. They reduce the risk of leakage while maintaining ease of service. B2B buyers should focus on the specific requirements of their processes, as these exchangers can handle a variety of fluids effectively. The complexity of their design may lead to higher costs, but the advantages in fluid management often make them a worthwhile investment.

What Advantages Do Compact Plate Heat Exchangers Offer for Space-Constrained Environments?

Compact plate heat exchangers are designed to deliver high thermal efficiency within a smaller footprint, making them ideal for process industries and district heating applications. Their ability to perform well in limited spaces is a significant advantage for B2B buyers looking to optimize plant layouts. However, potential challenges include higher pressure drops and specific design needs that must be addressed during the purchasing process. Understanding these factors is crucial for ensuring the right fit for operational requirements.

Key Industrial Applications of plate and frame heat exchanger diagram

| Industry/Sector | Specific Application of plate and frame heat exchanger diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Pasteurization processes for dairy and juice production | Enhances product safety and quality while maximizing energy efficiency | Compliance with health regulations, material compatibility, and ease of maintenance |

| Chemical Processing | Cooling and heating of chemical reactions | Improves process efficiency and reduces operational costs | Resistance to corrosion, temperature tolerance, and customization options |

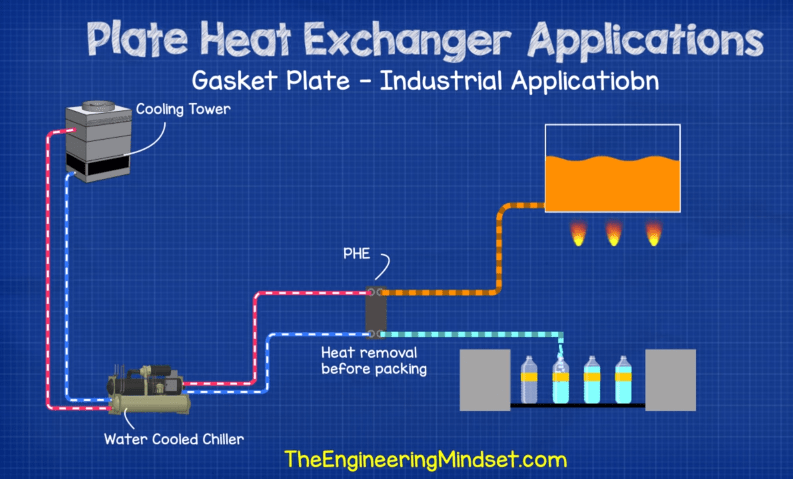

| HVAC Systems | Chilled water systems for commercial buildings | Increases energy efficiency and reduces utility costs | Size adaptability, pressure rating, and installation requirements |

| Pharmaceutical Manufacturing | Temperature control in drug formulation | Ensures product integrity and compliance with industry standards | Certification for pharmaceutical use, cleaning protocols, and scalability |

| Renewable Energy | Heat recovery in biomass and geothermal systems | Enhances energy recovery and sustainability | Efficiency ratings, material durability, and integration capabilities |

How is the plate and frame heat exchanger diagram utilized in the food and beverage industry?

In the food and beverage sector, plate and frame heat exchangers are vital for pasteurization processes, particularly in dairy and juice production. These systems facilitate the efficient transfer of heat, ensuring that products are heated to safe temperatures without compromising quality. For international buyers, especially from regions like Africa and South America, sourcing heat exchangers that comply with local health regulations is critical. Additionally, considerations around material compatibility with food products and ease of maintenance can significantly impact operational efficiency.

What role does the plate and frame heat exchanger diagram play in chemical processing?

In chemical processing, plate and frame heat exchangers are employed for the cooling and heating of chemical reactions, enhancing process efficiency and reducing operational costs. These exchangers are designed to handle a variety of corrosive materials and extreme temperatures, making them essential for maintaining product quality and process safety. Buyers from the Middle East and Europe should prioritize sourcing options that offer resistance to corrosion and customization capabilities to meet specific process requirements.

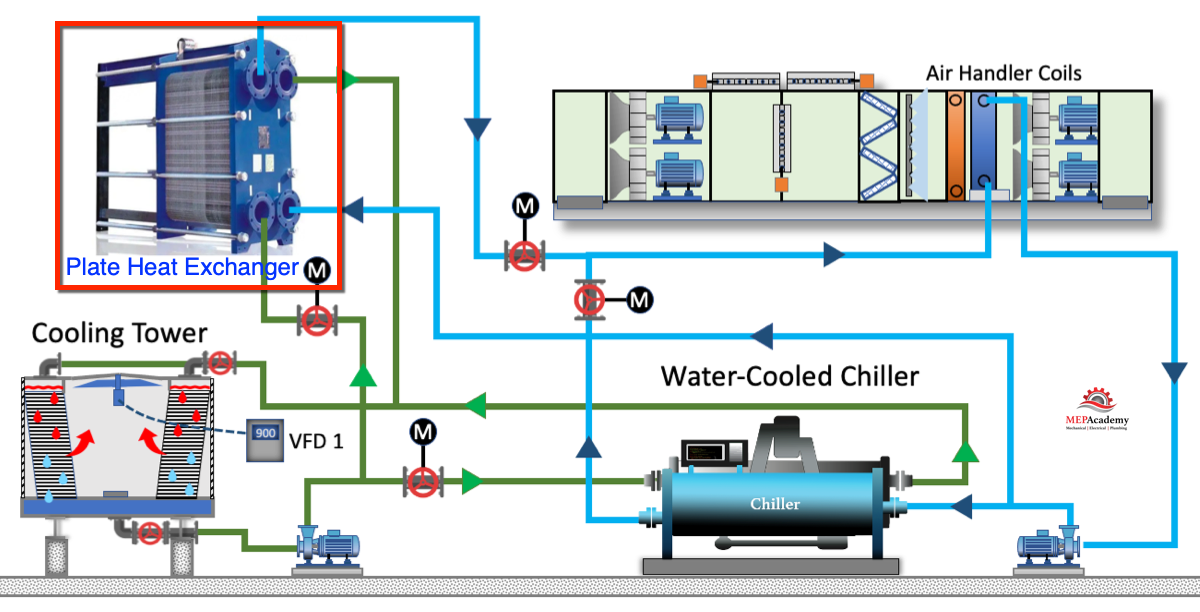

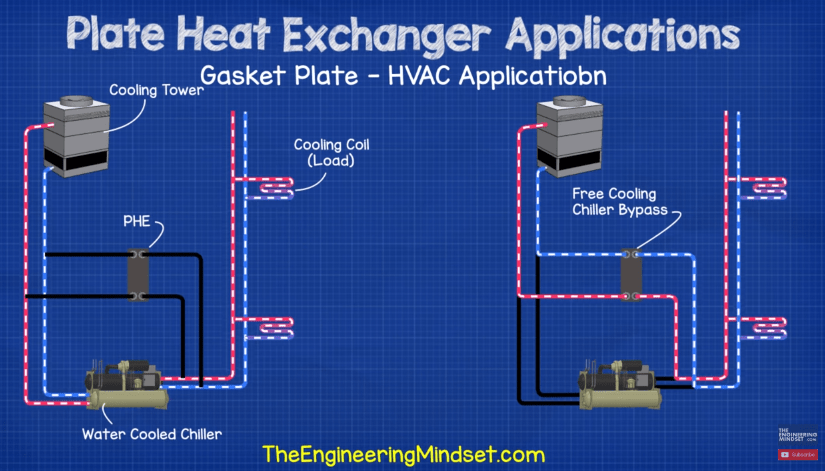

How do plate and frame heat exchangers enhance HVAC systems?

Within HVAC systems, plate and frame heat exchangers are integral to chilled water systems used in commercial buildings. They maximize energy efficiency by facilitating effective heat transfer, thereby reducing utility costs. For international buyers, particularly in regions with varying climate conditions, it is essential to consider the size adaptability and pressure ratings of these exchangers to ensure optimal performance in diverse environments.

Why are plate and frame heat exchangers important in pharmaceutical manufacturing?

In pharmaceutical manufacturing, plate and frame heat exchangers are crucial for maintaining temperature control during drug formulation. This ensures product integrity and compliance with stringent industry standards. Buyers, especially from Europe and the Middle East, must focus on sourcing exchangers that meet specific certifications for pharmaceutical use, as well as those that offer reliable cleaning protocols and scalability to adapt to production demands.

How can plate and frame heat exchangers contribute to renewable energy initiatives?

In renewable energy applications, such as biomass and geothermal systems, plate and frame heat exchangers play a significant role in heat recovery. They enhance energy recovery processes, contributing to sustainability efforts. For international buyers, particularly in Africa and South America, it is vital to assess efficiency ratings and material durability to ensure that the heat exchangers can withstand the operational demands of renewable energy systems while integrating seamlessly with existing infrastructure.

3 Common User Pain Points for ‘plate and frame heat exchanger diagram’ & Their Solutions

Scenario 1: Difficulty Understanding System Compatibility

The Problem: Many B2B buyers struggle with identifying whether a specific plate and frame heat exchanger diagram aligns with their operational needs. This challenge often arises from varying specifications across different industries, such as food processing or chemical manufacturing, where thermal efficiency and fluid compatibility are critical. Without a clear understanding of how the diagram translates to real-world applications, buyers may inadvertently invest in equipment that does not integrate well with their existing systems or meet their process requirements, leading to costly downtime and inefficiencies.

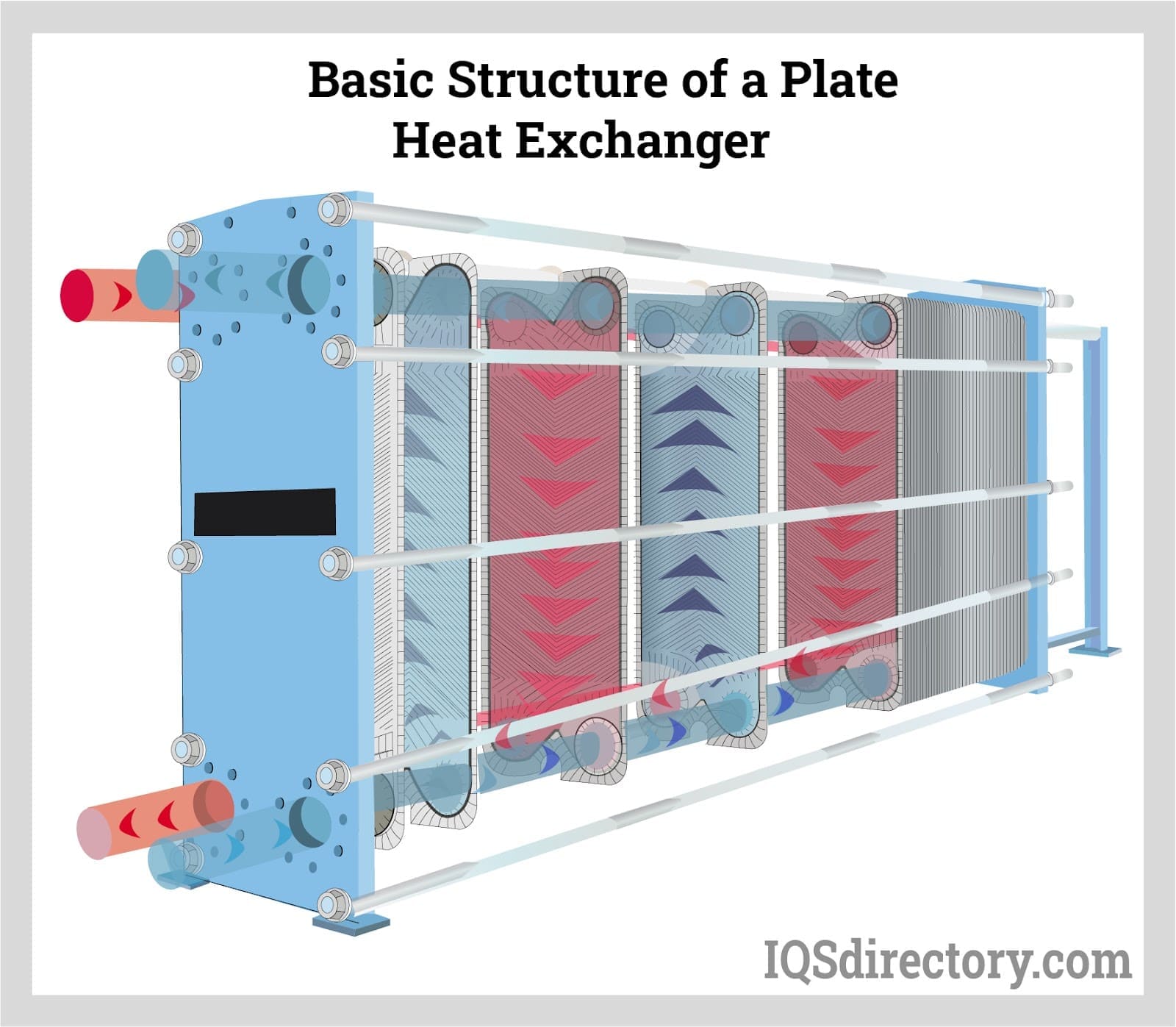

Illustrative image related to plate and frame heat exchanger diagram

The Solution: To mitigate this issue, buyers should conduct a thorough needs assessment that includes a detailed analysis of their current systems and operational parameters. Engaging with manufacturers or suppliers who offer customized solutions can provide valuable insights. Requesting technical consultations where the supplier reviews the specific plate and frame heat exchanger diagram in relation to your existing setup can help clarify compatibility. Furthermore, utilizing simulation software to visualize how the heat exchanger will function within your system can offer a clearer perspective, ensuring that the selected model aligns with thermal performance goals and fluid dynamics.

Scenario 2: Concerns About Maintenance and Longevity

The Problem: Another common pain point is the concern regarding the maintenance requirements and lifespan of plate and frame heat exchangers. B2B buyers often fear that inadequate maintenance could lead to leaks or decreased efficiency, especially in harsh operating environments typical in regions like Africa and the Middle East. The perception that these systems might require frequent, costly interventions can deter potential buyers, leading to hesitancy in adoption despite their efficiency benefits.

The Solution: To address these concerns, it’s essential to emphasize the importance of a well-structured maintenance plan. Buyers should consider investing in training for their staff on the specific maintenance protocols outlined in the heat exchanger’s documentation. Additionally, sourcing equipment from suppliers who provide robust after-sales support, including training and routine check-ups, can alleviate fears about maintenance. Implementing a predictive maintenance program that leverages IoT technology can also help in monitoring the system’s performance in real-time, allowing for timely interventions before any significant issues arise.

Illustrative image related to plate and frame heat exchanger diagram

Scenario 3: High Energy Costs Due to Inefficient Heat Transfer

The Problem: Many businesses face escalating energy costs, which can be exacerbated by inefficient heat transfer in their existing systems. B2B buyers may find themselves at a crossroads, unsure whether to invest in a new plate and frame heat exchanger or attempt to optimize their current setup. The dilemma often stems from a lack of clarity about how to accurately evaluate the energy efficiency of their existing equipment against potential new investments.

The Solution: To tackle this challenge, buyers should conduct an energy audit to assess the efficiency of their current heat exchange processes. This audit can reveal inefficiencies and help quantify potential savings from implementing a new plate and frame heat exchanger. Collaborating with energy consultants can provide tailored recommendations based on the audit findings. Furthermore, when reviewing heat exchanger diagrams, buyers should look for models that emphasize high thermal efficiency ratings and low pressure drops, as these factors directly influence energy consumption. Requesting case studies from suppliers that demonstrate energy savings achieved by other clients can also provide the necessary confidence to make a well-informed investment decision.

Strategic Material Selection Guide for plate and frame heat exchanger diagram

What Are the Key Materials for Plate and Frame Heat Exchangers?

When selecting materials for plate and frame heat exchangers, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials: stainless steel, titanium, carbon steel, and nickel alloys.

How Does Stainless Steel Perform in Plate and Frame Heat Exchangers?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance (up to 800°F or 427°C), and good mechanical strength. It typically has a pressure rating that accommodates a wide range of industrial applications.

Pros & Cons: The durability of stainless steel makes it suitable for various media, including aggressive chemicals and high-temperature fluids. However, its higher cost compared to other materials can be a limiting factor for budget-conscious projects. Manufacturing complexity is moderate, as it requires specialized welding techniques.

Illustrative image related to plate and frame heat exchanger diagram

Impact on Application: Stainless steel is particularly effective in food processing, pharmaceuticals, and chemical industries due to its hygienic properties and ability to withstand cleaning processes.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is crucial. Buyers from regions such as Africa and the Middle East should ensure that the selected grade of stainless steel meets local regulations for corrosion resistance and mechanical properties.

What Are the Advantages of Using Titanium in Heat Exchangers?

Key Properties: Titanium offers exceptional corrosion resistance, especially in seawater and acidic environments, with a temperature rating of about 1,000°F (538°C). Its lightweight nature contributes to lower structural loads.

Pros & Cons: The primary advantage of titanium is its longevity and resistance to pitting and crevice corrosion. However, titanium is significantly more expensive than stainless steel and requires specialized manufacturing techniques, which can increase lead times.

Impact on Application: Titanium is ideal for applications involving seawater or highly corrosive chemicals, making it a preferred choice in marine and chemical processing industries.

Considerations for International Buyers: Buyers should consider the availability of titanium and its alloys in their region, as well as the compliance with international standards. In Europe, for instance, specific grades may be preferred for marine applications.

Why Choose Carbon Steel for Plate and Frame Heat Exchangers?

Key Properties: Carbon steel is known for its high strength and ability to withstand high pressures and temperatures, typically rated up to 1,200°F (649°C). However, it is less resistant to corrosion compared to stainless steel and titanium.

Pros & Cons: The cost-effectiveness of carbon steel makes it an attractive option for large-scale applications. However, its susceptibility to rust and corrosion requires additional protective coatings or treatments, which can complicate maintenance.

Impact on Application: Carbon steel is well-suited for applications involving water and steam, commonly used in power generation and HVAC systems.

Considerations for International Buyers: Buyers must ensure that carbon steel grades comply with local standards and regulations, particularly in regions like South America, where varying environmental conditions may affect material performance.

What Are the Benefits of Nickel Alloys in Heat Exchangers?

Key Properties: Nickel alloys exhibit excellent resistance to corrosion and oxidation, with temperature ratings often exceeding 1,500°F (815°C). They are particularly effective in extreme environments.

Pros & Cons: The primary advantage of nickel alloys is their durability in harsh conditions, making them suitable for chemical processing and oil and gas applications. However, they are among the most expensive options and can be challenging to machine and fabricate.

Illustrative image related to plate and frame heat exchanger diagram

Impact on Application: Nickel alloys are ideal for applications involving high temperatures and corrosive environments, such as petrochemical and aerospace industries.

Considerations for International Buyers: Buyers should be aware of the specific nickel alloy grades available in their region and ensure compliance with international standards, particularly in the Middle East where oil and gas applications are prevalent.

Summary Table of Material Selection for Plate and Frame Heat Exchangers

| Material | Typical Use Case for plate and frame heat exchanger diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals, chemical industries | Excellent corrosion resistance | Higher cost compared to other materials | High |

| Titanium | Marine applications, chemical processing | Exceptional corrosion resistance | Significantly higher cost | High |

| Carbon Steel | Power generation, HVAC systems | Cost-effective for large applications | Susceptible to rust and corrosion | Medium |

| Nickel Alloys | Petrochemical, aerospace industries | Durability in extreme environments | Expensive and challenging to fabricate | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their plate and frame heat exchanger applications while considering factors such as cost, performance, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for plate and frame heat exchanger diagram

What Are the Key Stages in the Manufacturing Process of Plate and Frame Heat Exchangers?

The manufacturing of plate and frame heat exchangers involves several critical stages that ensure the final product meets the required efficiency and durability standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used?

The first stage of manufacturing involves selecting appropriate materials. Plates are typically made from stainless steel, due to its excellent corrosion resistance and thermal conductivity. In some cases, titanium may be used for highly corrosive environments, while carbon steel may be selected for cost-sensitive projects.

Illustrative image related to plate and frame heat exchanger diagram

Once the materials are chosen, they are cut to size using laser cutting or water jet cutting techniques. This precision ensures that each plate meets the specific design requirements and tolerances necessary for optimal heat transfer efficiency.

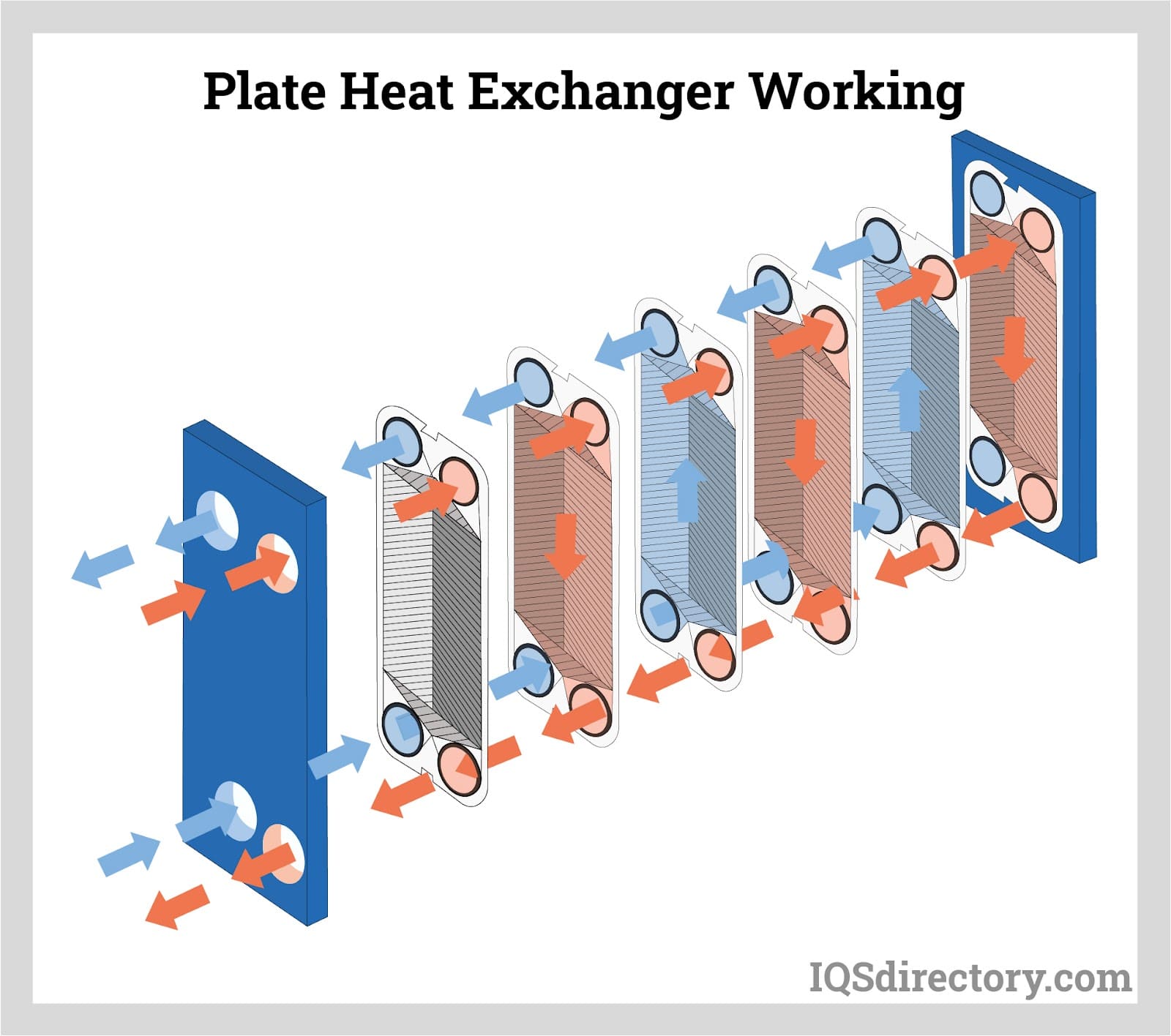

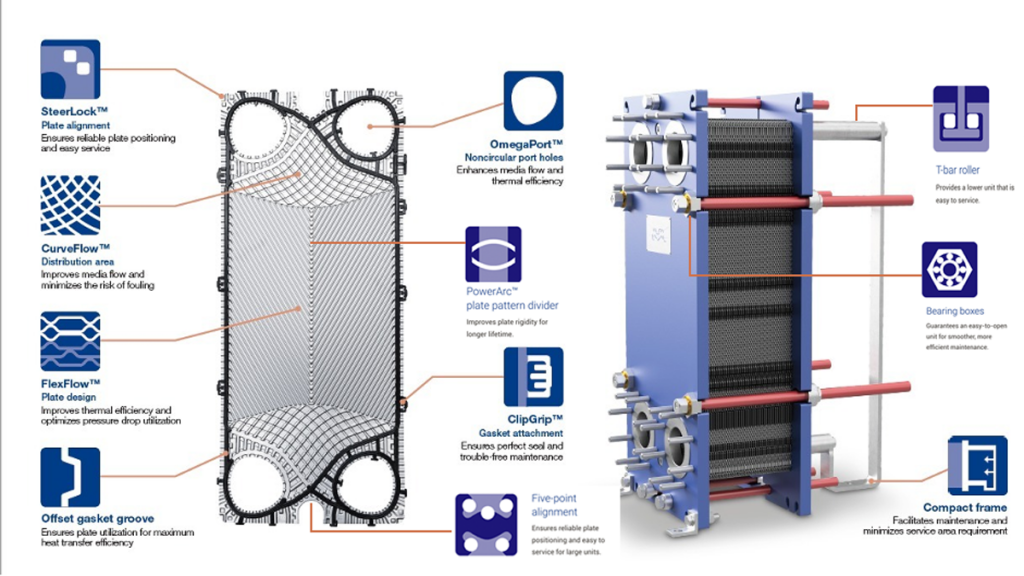

Forming: How Are Plates Shaped?

After cutting, the plates undergo a forming process. This typically involves creating the characteristic corrugated shape that enhances turbulence and heat transfer efficiency. Techniques like stamping or pressing are commonly used to achieve the desired plate geometry. The corrugated pattern also improves the fouling resistance, making the heat exchanger more effective and easier to maintain.

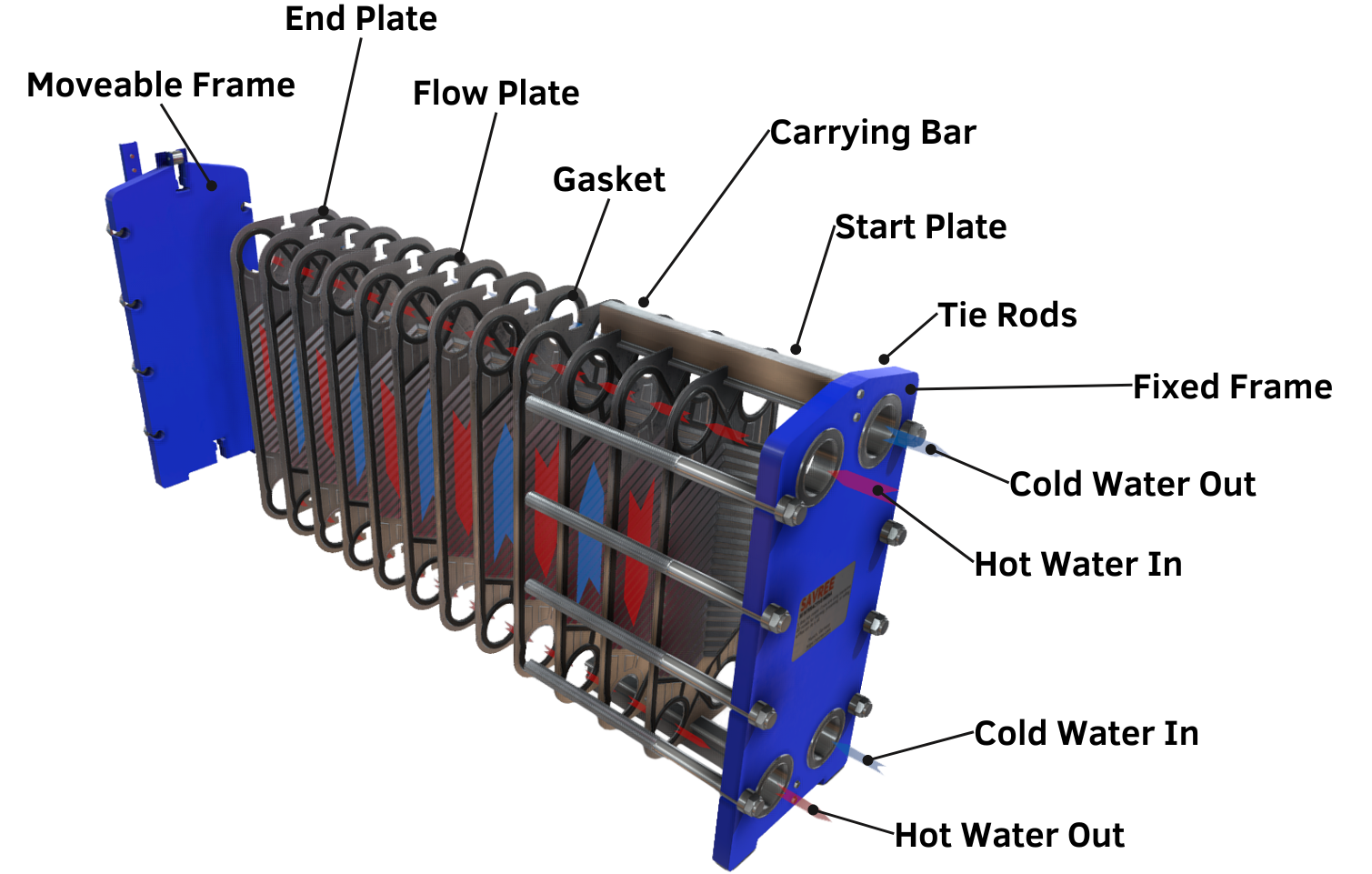

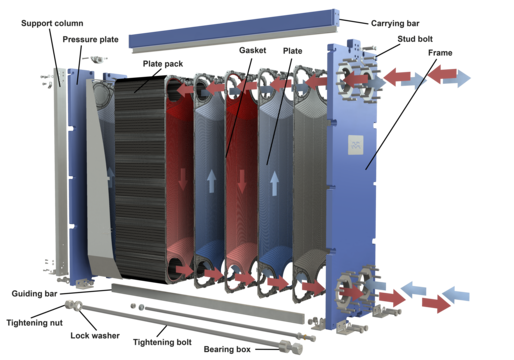

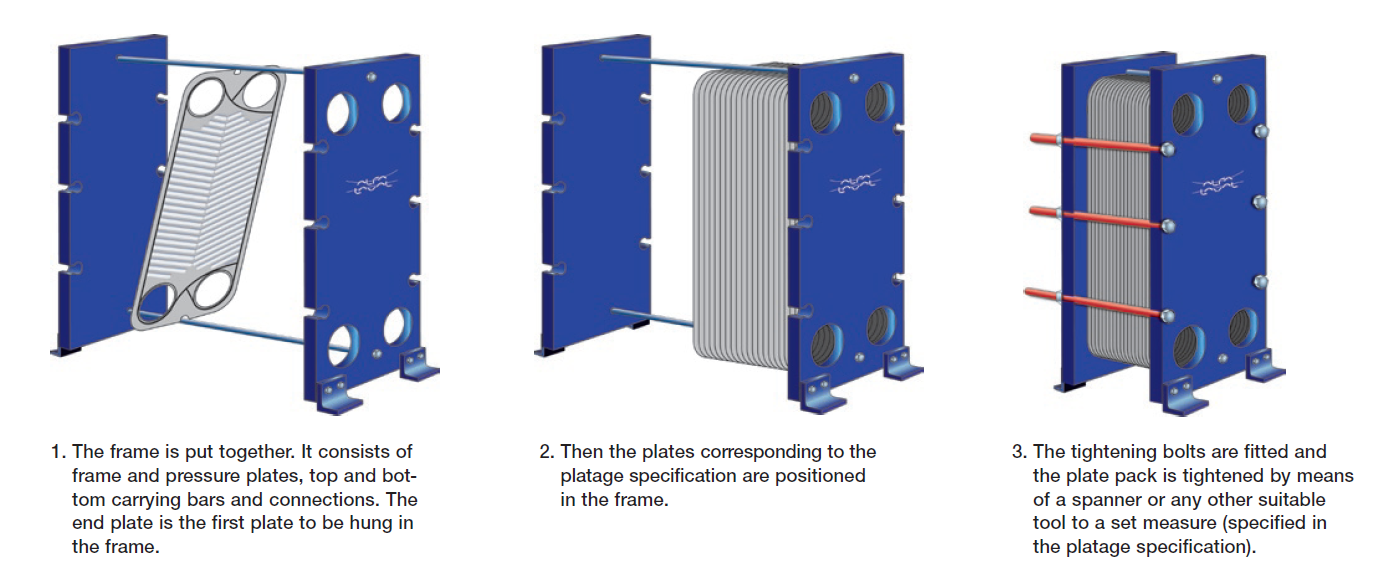

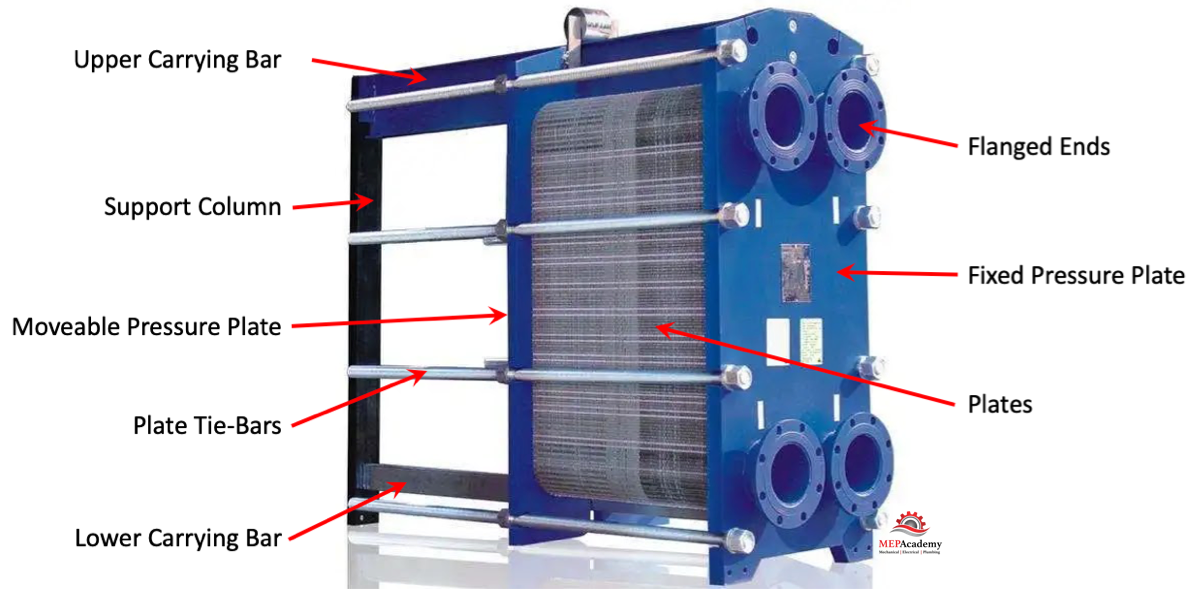

Assembly: What Does the Assembly Process Involve?

The assembly stage is crucial for ensuring that the heat exchanger functions correctly. Plates are stacked in alternating directions and secured in place by a frame. Gaskets are inserted between the plates to create seals that prevent leaks. Depending on the type of heat exchanger, gaskets may be made from rubber, silicone, or other materials that can withstand the operating conditions.

During assembly, attention is paid to alignment and spacing to ensure optimal flow paths for the fluids. After assembly, the unit is often subjected to initial pressure tests to verify that there are no leaks before moving on to the finishing processes.

Illustrative image related to plate and frame heat exchanger diagram

Finishing: What Are the Final Touches?

The finishing stage may include various treatments such as surface polishing, coating, or passivation to enhance corrosion resistance. These processes can improve the longevity and performance of the heat exchanger. For some applications, additional surface treatments may be necessary to meet specific industry standards.

How Is Quality Assurance Implemented in Plate and Frame Heat Exchanger Manufacturing?

Quality assurance (QA) is vital in the manufacturing of plate and frame heat exchangers to ensure reliability and compliance with international standards. Buyers should be aware of the QA processes in place to mitigate risks associated with poor-quality products.

What International Standards Govern Heat Exchanger Manufacturing?

Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, other certifications may be relevant based on industry applications. For instance, CE marking may be required for products sold within the European Union, while API (American Petroleum Institute) certifications may apply for heat exchangers used in the oil and gas sector.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected upon arrival. Materials must meet specified standards and tolerances before they can be processed.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed to ensure that each stage meets quality standards. This may include dimensional checks and visual inspections of plates and assemblies.

-

Final Quality Control (FQC): Once the heat exchanger is fully assembled, it undergoes rigorous testing. This includes pressure testing, leak testing, and performance evaluations to ensure it meets the designed specifications.

What Testing Methods Are Commonly Used?

Different testing methods are employed to validate the quality and performance of plate and frame heat exchangers:

-

Hydrostatic Testing: This test checks for leaks by filling the exchanger with water at a pressure higher than its operating conditions.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or dye penetrant testing are used to identify any structural flaws without damaging the components.

-

Performance Testing: This includes measuring the heat transfer efficiency and pressure drop across the heat exchanger to ensure it operates as designed.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers:

-

Audits: Conducting on-site audits of manufacturing facilities can provide insight into the processes and quality management systems in place.

-

Quality Reports: Requesting detailed quality reports and certifications from suppliers can help buyers assess compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and final products.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of additional nuances in quality control:

-

Regulatory Compliance: Different regions may have specific regulations regarding materials, manufacturing processes, and safety standards. It’s essential to ensure that the supplier complies with the local regulations in the buyer’s country.

-

Cultural and Language Barriers: Understanding the supplier’s quality assurance practices may be affected by cultural differences and language barriers. Establishing clear communication channels is critical.

-

Logistical Considerations: The logistics of shipping and handling can impact the integrity of the product. Buyers should discuss packaging and transport methods with suppliers to minimize risks.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they select suppliers who deliver reliable, high-quality plate and frame heat exchangers that meet their operational needs.

Illustrative image related to plate and frame heat exchanger diagram

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plate and frame heat exchanger diagram’

To assist international B2B buyers in procuring a plate and frame heat exchanger, this practical sourcing guide offers a structured checklist. By following these steps, you can ensure that you make informed decisions that align with your operational needs and sustainability goals.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your plate and frame heat exchanger. Consider factors such as the types of fluids involved, operating temperatures, pressure ranges, and desired heat transfer efficiency. This step is crucial because precise specifications will help you identify the right model and avoid costly mistakes later in the procurement process.

Step 2: Research Available Types and Configurations

Understand the different types of plate heat exchangers available in the market, including gasketed, brazed, welded, and semi-welded designs. Each type has unique advantages and limitations in terms of maintenance, durability, and efficiency. Knowing these distinctions will enable you to select a design that best meets your operational and environmental requirements.

Step 3: Evaluate Potential Suppliers

Before making a purchasing decision, conduct thorough evaluations of potential suppliers. Request company profiles, product catalogs, and references from businesses in similar industries or regions. Look for suppliers with a proven track record in delivering high-quality products and responsive customer service, as these factors are critical for ensuring reliable operation.

Step 4: Verify Compliance with Industry Standards

Ensure that the suppliers you consider comply with relevant industry standards and certifications. This could include ISO certifications, compliance with local regulations, or adherence to international safety standards. Compliance not only guarantees product quality but also mitigates risks associated with safety and environmental impacts.

Illustrative image related to plate and frame heat exchanger diagram

Step 5: Assess Maintenance and Support Services

Inquire about the maintenance requirements and support services offered by the supplier. A supplier that provides comprehensive maintenance services can save you time and reduce operational downtime. Additionally, check if they offer training for your personnel on proper operation and maintenance of the heat exchangers.

Step 6: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, lead times, and terms of service. Compare these quotes not just on price but also on the value offered, including warranties, after-sales support, and potential discounts for bulk purchases. This will help you ensure you are making a cost-effective choice.

Step 7: Finalize Your Decision and Place the Order

After thorough evaluation and comparison, finalize your decision based on the best alignment of quality, price, and service. Place your order with clear communication regarding delivery timelines and installation support. Ensure that all contractual obligations are clearly defined to prevent misunderstandings in the future.

By following this checklist, B2B buyers can confidently navigate the procurement process for plate and frame heat exchangers, ensuring that they select the most suitable products for their specific applications while supporting their sustainability initiatives.

Comprehensive Cost and Pricing Analysis for plate and frame heat exchanger diagram Sourcing

What Are the Key Cost Components for Plate and Frame Heat Exchanger Diagrams?

When sourcing plate and frame heat exchangers, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and margin.

-

Materials: The choice of materials significantly impacts costs. Common materials used in plate heat exchangers include stainless steel, titanium, and various alloys. Stainless steel offers a balance of cost and corrosion resistance, making it a popular choice. However, if corrosion resistance is paramount, titanium may be preferred, albeit at a higher cost.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Skilled labor is required for tasks such as welding and assembly, especially when producing customized units. Regions with lower labor costs can provide competitive pricing, but this may also affect quality.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and salaries of non-production staff. Efficient manufacturing processes can help minimize overhead, thereby reducing overall costs.

-

Tooling: The initial setup for production, including molds and jigs, contributes to upfront costs. Custom designs may require specialized tooling, which can increase expenses. Standardized designs often have lower tooling costs.

-

Quality Control (QC): Ensuring that the heat exchangers meet industry standards is crucial. QC processes involve inspections and testing, adding to the cost but ultimately ensuring reliability and performance.

-

Logistics: Transportation costs can vary significantly depending on the distance and mode of transport. Buyers should consider the impact of logistics on total costs, especially when sourcing from overseas suppliers.

-

Margin: Suppliers typically add a margin to their costs to ensure profitability. This margin can vary based on market conditions, competition, and the supplier’s business model.

How Do Price Influencers Affect Plate and Frame Heat Exchanger Costs?

Several factors influence the pricing of plate and frame heat exchangers, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Suppliers often provide discounts based on the volume of orders. Minimum Order Quantities (MOQs) can also dictate pricing, as larger orders spread costs over more units, reducing per-unit pricing.

-

Specifications/Customization: Custom designs tailored to specific applications can increase costs. Buyers should weigh the benefits of customization against the potential for higher pricing and longer lead times.

-

Materials: As mentioned earlier, the choice of materials impacts pricing. High-performance materials can command premium prices but may lead to cost savings in terms of durability and maintenance.

-

Quality/Certifications: Certifications such as ISO, ASME, or other industry standards can influence costs. Suppliers with higher quality certifications may charge more due to the investment in quality assurance processes.

-

Supplier Factors: The supplier’s reputation, location, and experience can affect pricing. Established suppliers may offer higher-quality products but at a premium price.

-

Incoterms: The chosen Incoterms determine who bears the costs and risks during shipping. This can affect the total landed cost, so buyers should clarify terms to avoid unexpected charges.

What Buyer Tips Should B2B Buyers Consider When Sourcing Heat Exchangers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to enhance cost-efficiency:

-

Negotiate Pricing: Leverage volume orders and long-term relationships to negotiate better pricing. Suppliers may be willing to offer discounts for bulk purchases or repeated business.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, operational costs, and potential downtime. A lower initial price may lead to higher costs down the line if quality is compromised.

-

Understand Pricing Nuances: Familiarize yourself with local market conditions and pricing structures. Factors such as tariffs, import duties, and currency fluctuations can affect overall costs.

-

Research Suppliers: Conduct thorough research on potential suppliers. Request samples or visit manufacturing facilities if possible. This can help ensure that the supplier meets your quality and cost expectations.

-

Consult Experts: Engaging with industry experts or consultants can provide insights into best practices for sourcing heat exchangers, helping you make informed decisions.

Disclaimer on Indicative Prices

It is important to note that prices for plate and frame heat exchangers can vary widely based on the aforementioned factors. This analysis provides a framework for understanding potential costs but should not be considered a definitive pricing guide. Always obtain quotes from multiple suppliers to ensure competitive pricing tailored to your specific needs.

Alternatives Analysis: Comparing plate and frame heat exchanger diagram With Other Solutions

Introduction: Understanding Alternative Solutions in Heat Exchange

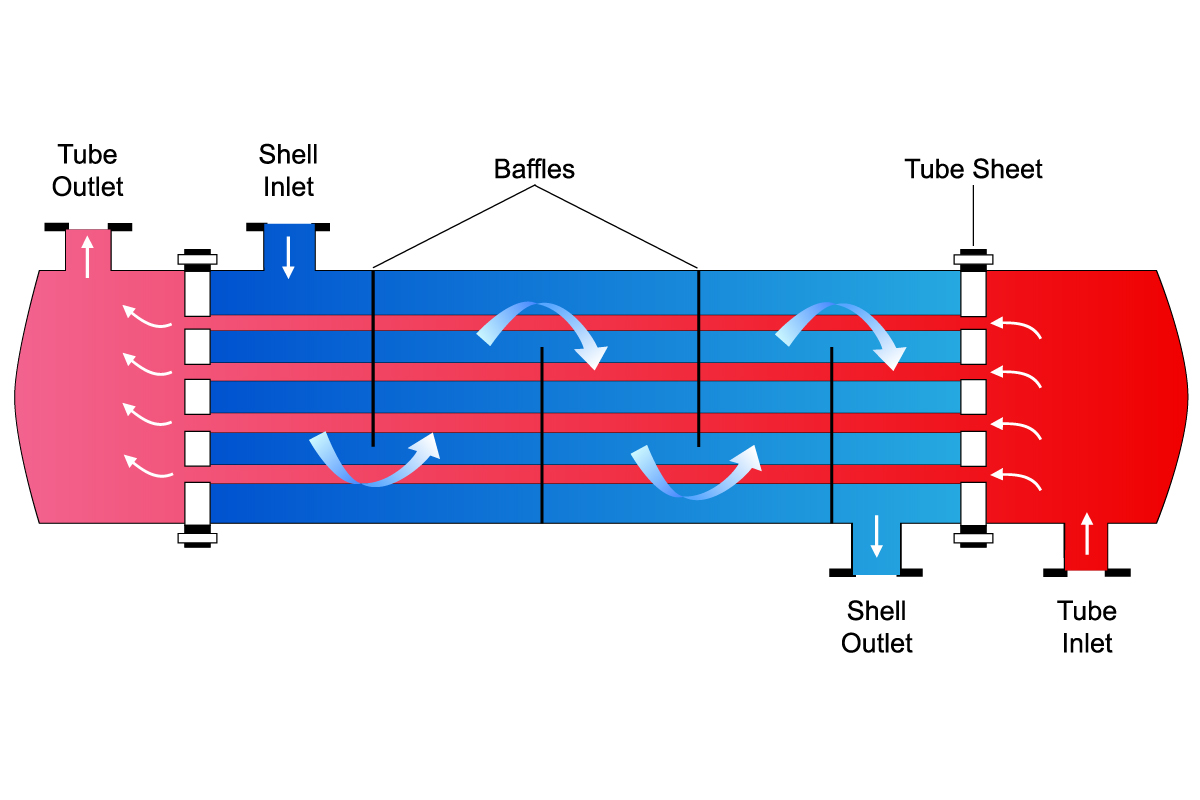

In the realm of thermal management, choosing the right heat exchanger is crucial for optimizing performance and efficiency. While the plate and frame heat exchanger diagram illustrates a popular and effective solution for transferring heat between fluids, various alternatives can also meet specific operational requirements. This section will compare the plate and frame heat exchanger with two viable alternatives: shell and tube heat exchangers and air-cooled heat exchangers. Each option has unique characteristics that can influence decision-making for B2B buyers in industries across Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Plate And Frame Heat Exchanger Diagram | Shell And Tube Heat Exchanger | Air-Cooled Heat Exchanger |

|---|---|---|---|

| Performance | High heat transfer efficiency, compact design | Good for large temperature differences | Effective for ambient cooling |

| Cost | Moderate initial investment, low maintenance costs | Higher initial investment, but durable | Generally lower initial cost, depends on ambient conditions |

| Ease of Implementation | Requires careful installation and setup | More complex installation | Simple installation, requires space |

| Maintenance | Easy to disassemble and clean | Requires more effort to maintain | Minimal maintenance required |

| Best Use Case | Ideal for applications with close temperature control | Suitable for large industrial processes | Best for cooling in outdoor settings |

Detailed Breakdown of Alternatives

Shell and Tube Heat Exchangers

Shell and tube heat exchangers are among the most widely used types in industrial applications, especially where large temperature differences exist between fluids. They consist of a series of tubes, with one fluid flowing through the tubes and another fluid circulating around them within a shell.

Pros: These systems can handle high pressures and temperatures, making them suitable for heavy-duty applications. They are also durable and have a long service life.

Cons: However, the initial investment is higher than that of plate heat exchangers, and maintenance can be more complex due to their design. Additionally, they occupy more space, which can be a limitation in smaller facilities.

Air-Cooled Heat Exchangers

Air-cooled heat exchangers utilize ambient air to remove heat from a fluid. They are typically used in outdoor settings and can be an economical choice for cooling applications.

Pros: These exchangers are relatively simple to install and require minimal maintenance. They do not depend on water sources, which is beneficial in arid regions.

Illustrative image related to plate and frame heat exchanger diagram

Cons: Their performance is highly dependent on environmental conditions; in hotter climates, efficiency may decline. They may also require more space compared to other solutions, making them less suitable for confined areas.

Conclusion: Making the Right Choice for Your Heat Exchange Needs

When selecting the right heat exchanger for your operations, it is essential to consider not only the performance and cost but also the specific application requirements and environmental conditions. Plate and frame heat exchangers offer excellent efficiency and easy maintenance, making them ideal for precise temperature control scenarios. Conversely, shell and tube heat exchangers may be better suited for high-pressure applications, while air-cooled systems can provide cost-effective cooling in outdoor environments. By carefully evaluating these factors, B2B buyers can make informed decisions that align with their operational goals and sustainability initiatives.

Essential Technical Properties and Trade Terminology for plate and frame heat exchanger diagram

What Are the Critical Technical Properties of a Plate and Frame Heat Exchanger?

Understanding the essential technical properties of plate and frame heat exchangers is vital for B2B buyers, as these specifications can directly impact efficiency, durability, and overall system performance. Here are some key specifications to consider:

1. Material Grade

The material grade used in the construction of the plates significantly influences the heat exchanger’s resistance to corrosion and thermal conductivity. Common materials include stainless steel, titanium, and nickel alloys. Selecting the right material is crucial, especially in industries where fluids may be corrosive or where hygiene is paramount, such as in food processing or pharmaceuticals.

Illustrative image related to plate and frame heat exchanger diagram

2. Plate Thickness

Plate thickness affects the exchanger’s ability to withstand pressure and temperature variations. Thicker plates can handle higher pressures but may reduce heat transfer efficiency due to increased thermal resistance. Buyers should balance the need for durability with the required heat transfer efficiency, particularly in high-pressure applications.

3. Heat Transfer Area

The total heat transfer area is a key specification that determines the efficiency of the heat exchanger. A larger surface area typically results in better heat transfer performance. B2B buyers should consider their specific application needs to ensure they select a heat exchanger that provides adequate heat transfer without being oversized, which can lead to unnecessary costs.

4. Design Pressure and Temperature Ratings

Each plate and frame heat exchanger comes with specific design pressure and temperature ratings, which indicate the maximum operational limits. Understanding these ratings is critical to avoid equipment failure and ensure safety in high-temperature or high-pressure applications. Buyers must assess their operational conditions to select a suitable exchanger.

5. Flow Arrangement

The flow arrangement—counterflow, parallel flow, or crossflow—affects the efficiency of heat transfer. Counterflow arrangements typically provide the highest thermal efficiency, while parallel flow is less effective but easier to maintain. Buyers should consider their application requirements and maintenance capabilities when evaluating flow arrangements.

What Are Common Trade Terms Related to Plate and Frame Heat Exchangers?

Familiarity with industry terminology can enhance communication with suppliers and facilitate smoother transactions. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of heat exchangers, understanding if a supplier is an OEM can indicate the level of quality and reliability in the products offered.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and cost efficiency. Understanding MOQ can help businesses plan their purchasing strategies effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other details for a specific quantity of goods. For heat exchangers, providing detailed specifications in an RFQ ensures that suppliers can offer accurate quotes, making it easier to compare options.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers for the delivery of goods. Familiarity with these terms can help B2B buyers understand shipping costs, risks, and responsibilities, which is crucial for international transactions.

5. Fouling Resistance

Fouling resistance refers to the ability of a heat exchanger to resist the buildup of unwanted materials on its surface. This property is essential for maintaining efficiency and reducing maintenance costs. B2B buyers should inquire about fouling resistance when selecting a heat exchanger for specific applications.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they select the right plate and frame heat exchanger for their operational needs while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the plate and frame heat exchanger diagram Sector

What Are the Current Market Dynamics for Plate and Frame Heat Exchanger Diagrams?

The plate and frame heat exchanger market is witnessing a robust growth trajectory, primarily driven by the increasing demand for energy-efficient solutions across various industries. As global industries seek to optimize their energy consumption, the efficiency of plate heat exchangers makes them a preferred choice for applications in food and beverage, pharmaceuticals, and HVAC systems. Emerging technologies such as IoT integration for real-time monitoring and predictive maintenance are reshaping sourcing strategies, enabling buyers to make informed decisions based on performance data.

In regions like Africa, South America, and the Middle East, the rising focus on industrialization and infrastructure development is further catalyzing market growth. For instance, countries like Nigeria and Saudi Arabia are investing heavily in energy projects, which creates a substantial demand for advanced heat exchanger systems. Additionally, the ongoing shift towards renewable energy sources is influencing buyers to consider heat exchangers that facilitate efficient thermal management in solar and geothermal applications.

Illustrative image related to plate and frame heat exchanger diagram

Moreover, international trade dynamics are affecting sourcing trends. Buyers are increasingly looking for manufacturers that can provide customized solutions and adhere to local regulations. This trend is encouraging partnerships between local suppliers and international manufacturers, ensuring that the products meet regional compliance standards while enhancing supply chain resilience.

How Is Sustainability Influencing Sourcing Trends in the Plate and Frame Heat Exchanger Sector?

Sustainability is becoming a cornerstone of sourcing strategies for plate and frame heat exchangers. Buyers are increasingly concerned about the environmental impact of their procurement choices, leading to a preference for manufacturers that prioritize eco-friendly practices. This includes sourcing materials that are recyclable or made from sustainable resources, thus minimizing the carbon footprint associated with production.

Ethical supply chains are gaining importance as well. Businesses are not only focused on the end product but also on the processes involved in its creation. Suppliers that can demonstrate transparency in their sourcing and manufacturing processes, such as obtaining green certifications (e.g., ISO 14001), are more likely to attract international buyers. Certifications serve as a benchmark for environmental responsibility, assuring buyers that the products they are investing in align with their sustainability goals.

Furthermore, the emphasis on energy efficiency in heat exchangers contributes to long-term operational savings, making them a favorable option for companies looking to reduce their overall environmental impact. As global regulations tighten around emissions and energy usage, sourcing from sustainable manufacturers will not only meet compliance but also position businesses as leaders in corporate social responsibility.

What Is the Evolution of Plate and Frame Heat Exchanger Technology?

The evolution of plate and frame heat exchangers can be traced back to the early 20th century when the need for more efficient heat transfer systems became apparent. Initially, these systems were limited in design and application, primarily serving the needs of industrial processes. However, with advancements in materials and manufacturing techniques, the design evolved to incorporate corrugated plates, which significantly enhanced heat transfer efficiency.

Illustrative image related to plate and frame heat exchanger diagram

The introduction of gasketed, brazed, and semi-welded designs allowed for greater versatility in applications, catering to a wide range of industries. The transition towards automation and the integration of digital technologies have further transformed the sector, allowing for real-time monitoring and control of heat transfer processes. This evolution not only improved performance but also opened new avenues for energy conservation and sustainability, making plate and frame heat exchangers a vital component in modern industrial applications.

As the market continues to innovate, buyers can expect even more sophisticated solutions that address both efficiency and environmental concerns, further solidifying the role of plate and frame heat exchangers in global industries.

Frequently Asked Questions (FAQs) for B2B Buyers of plate and frame heat exchanger diagram

-

How do I solve compatibility issues with my plate and frame heat exchanger?

To address compatibility issues, start by thoroughly understanding the specifications of your existing systems, including fluid types, temperatures, and pressures. Consult with manufacturers or suppliers who can provide detailed diagrams and material compatibility data. Additionally, consider using heat exchangers that allow for easy modification or customization, ensuring they can adapt to your operational requirements. Regular maintenance and checks can also prevent potential compatibility problems over time. -

What is the best type of plate and frame heat exchanger for high-temperature applications?

For high-temperature applications, welded plate heat exchangers are often the best choice. They are constructed without gaskets, allowing them to withstand higher pressures and temperatures compared to gasketed models. This makes them ideal for industries such as petrochemicals or power generation, where fluid temperatures can be extreme. Always evaluate the specific needs of your application and consult with industry experts to ensure optimal selection. -

What factors should I consider when sourcing plate and frame heat exchangers internationally?

When sourcing internationally, consider factors such as the supplier’s reputation, manufacturing capabilities, and compliance with international standards. Assess their experience in your specific industry and request references from previous clients. Additionally, evaluate their logistics capabilities, including shipping times and costs, to ensure timely delivery. It’s also beneficial to understand the after-sales support they provide, including maintenance and troubleshooting assistance. -

How can I ensure the quality of plate and frame heat exchangers I purchase?

To ensure quality, verify that your supplier adheres to recognized international quality standards, such as ISO 9001. Request detailed documentation of their manufacturing processes, including certifications and testing protocols. Conduct audits or inspections if possible, and look for suppliers who offer warranty and service agreements. Additionally, consider requesting samples or visiting their facilities to assess their production quality firsthand. -

What are the typical payment terms for purchasing plate and frame heat exchangers?

Payment terms can vary significantly based on the supplier and the size of the order. Common terms include a percentage upfront (often 30-50%) with the balance due upon delivery or after installation. For larger orders, suppliers may offer more flexible terms, including installment payments. Always clarify payment terms before finalizing the contract and consider negotiating terms that suit your cash flow needs, particularly in international transactions. -

What are the minimum order quantities (MOQ) for plate and frame heat exchangers?

Minimum order quantities can vary widely among manufacturers. Some suppliers may have MOQs as low as one unit for standard models, while others may require larger quantities for custom designs or specialized applications. It’s essential to discuss your specific needs with potential suppliers and inquire about any flexibility in MOQs, especially if you are testing a new product or entering a new market. -

What customization options are available for plate and frame heat exchangers?

Customization options often include adjustments in size, plate configuration, and materials used, tailored to specific operational needs. Suppliers may also offer modifications for different fluid types and temperature ranges, as well as additional features like enhanced corrosion resistance or improved cleaning access. Engage with suppliers early in the design process to explore available options and ensure that your requirements are fully understood and met. -

How do I handle logistics and shipping for international orders of heat exchangers?

Handling logistics for international orders involves several key steps. First, work closely with your supplier to understand shipping options, costs, and timelines. Ensure that you have all necessary documentation for customs clearance, including commercial invoices and packing lists. Consider partnering with a freight forwarder experienced in handling industrial equipment to streamline the process. Additionally, factor in potential delays and plan for contingencies to ensure timely project execution.

Top 3 Plate And Frame Heat Exchanger Diagram Manufacturers & Suppliers List

1. Chere Resources – Plate and Frame Heat Exchangers

Domain: cheresources.com

Registered: 1998 (27 years)

Introduction: Plate and frame heat exchangers are typically used for liquid-liquid exchange at low to medium pressures. Gasket-free versions can operate at high temperatures (up to 550°C) and pressures (up to 780 psi). They offer flexibility with adjustable gaps between plates to accommodate fouling. The counter-current flow allows approach temperatures as low as 1 to 2°F. Advantages include requiring less spac…

2. Thermopedia – Plate and Frame Heat Exchangers

Domain: thermopedia.com

Registered: 2007 (18 years)

Introduction: Plate and Frame Heat Exchangers are designed with closely spaced metal plates clamped between a head and follower, featuring corner ports sealed by gaskets. They can operate at pressures from 1 to 25 atmospheres. Plates are made from materials like stainless steel, titanium, and Hastelloy, with thicknesses between 0.5 and 1.2 mm and effective heat transfer areas ranging from 0.03 to 3.5 m². Up to …

3. Reddit – Plate Heat Exchangers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Plate heat exchangers are designed to provide a large surface area for heat transfer while maintaining low flow restrictions. They can be equipped with rubber seals, which may be glued or clip-on. Some types are bolted together with gaskets for sealing, while others are brazed together for industrial applications. They are effective but can become clogged with dirty processes, making cleaning a ch…

Strategic Sourcing Conclusion and Outlook for plate and frame heat exchanger diagram

In the evolving landscape of industrial applications, plate and frame heat exchangers emerge as a pivotal solution for enhancing energy efficiency and sustainability. By strategically sourcing these advanced heat exchangers, businesses can significantly reduce operational costs while optimizing thermal performance across various sectors. Key considerations for international buyers include understanding the distinct types of plate heat exchangers—gasketed, brazed, welded, and semi-welded—and how each variant aligns with specific operational requirements, such as temperature and pressure conditions.

Investing in high-quality plate heat exchangers not only facilitates superior heat transfer but also supports broader environmental goals by minimizing energy waste. For B2B buyers in Africa, South America, the Middle East, and Europe, the emphasis on reliable, efficient equipment is paramount. As industries increasingly prioritize sustainable practices, the demand for innovative heat exchange solutions will only grow.

Looking ahead, now is the time for businesses to evaluate their heat exchange needs and explore strategic partnerships with reputable suppliers. By doing so, companies can position themselves for future success while contributing to a more sustainable industrial ecosystem. Engage with industry experts today to ensure your operations are not only efficient but also environmentally responsible.

Illustrative image related to plate and frame heat exchanger diagram

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.