The Definitive Guide to Parts Of A Balance Scale: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for parts of a balance scale

In today’s competitive landscape, sourcing the right parts of a balance scale can be a daunting challenge for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. With an array of options available, from mechanical to digital scales, and a variety of components like beams, pans, and load cells, making informed purchasing decisions is crucial for ensuring accuracy and compliance in weighing processes. This comprehensive guide delves into the intricate world of balance scale parts, offering insights into various types, applications across industries, and best practices for supplier vetting.

As businesses increasingly rely on precision and efficiency, understanding the nuances of balance scale components becomes essential. This guide not only outlines the key features and specifications of each part but also explores their applications in sectors such as manufacturing, retail, and scientific research. Furthermore, we will address cost considerations, helping you navigate budgets effectively while ensuring quality and reliability.

Empowering international B2B buyers with the knowledge needed to make informed choices, this guide serves as a valuable resource for those looking to optimize their weighing solutions. By leveraging the insights provided, businesses can enhance operational efficiency, ensure compliance with industry standards, and ultimately drive success in their respective markets.

Understanding parts of a balance scale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Beam Balance Scale | Uses a lever with two pans to measure weight; manual adjustment | Educational, laboratory, industrial | Pros: High precision, no power required. Cons: Requires manual operation; less convenient for high-volume tasks. |

| Digital Balance Scale | Utilizes electronic sensors for weight measurement; digital readout | Retail, laboratories, food industry | Pros: Quick readings, user-friendly, often features tare function. Cons: Requires power source; can be more expensive. |

| Analytical Balance Scale | Extremely precise, often enclosed to minimize environmental impact | Laboratories, pharmaceuticals, chemical research | Pros: High accuracy, suitable for small samples. Cons: Sensitive to vibrations; higher cost. |

| Platform Scale | Large, durable platform for weighing heavy items | Warehousing, shipping, manufacturing | Pros: Handles bulk items, robust design. Cons: Requires significant space; can be costly. |

| Crane Scale | Weighs items suspended from a hook; portable | Construction, shipping, heavy manufacturing | Pros: Ideal for large or irregularly shaped items. Cons: Limited to hanging weights; may require additional equipment. |

What Are the Key Characteristics of Beam Balance Scales?

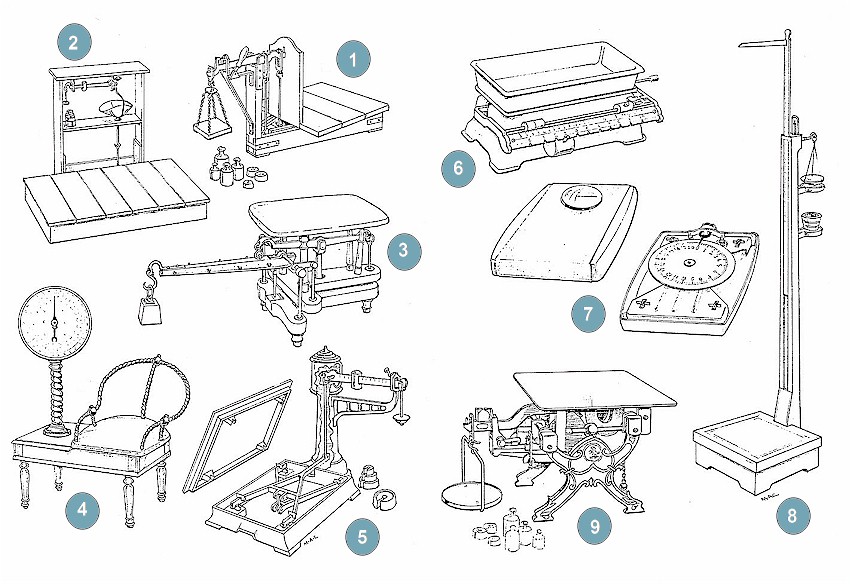

Beam balance scales are mechanical devices that utilize a lever mechanism to measure weight. They consist of two pans suspended from a beam, allowing users to compare the weight of an object against known weights. This type is particularly suitable for educational and laboratory applications, where precise measurements are essential. Buyers should consider the balance’s calibration, ease of use, and the need for manual adjustments, which can be a drawback in high-volume environments.

How Do Digital Balance Scales Improve Measurement Efficiency?

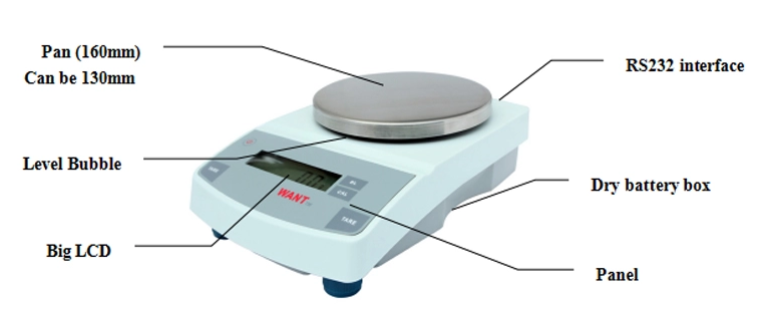

Digital balance scales leverage electronic sensors to provide quick and accurate weight readings, displayed on a digital interface. They are widely used in retail, laboratories, and the food industry due to their user-friendly nature and added features like tare functions. When purchasing, businesses should evaluate the scale’s capacity, accuracy, and the availability of additional functionalities. While digital scales offer convenience, they do require a power source and may come at a higher price point.

Why Are Analytical Balance Scales Essential for Laboratories?

Analytical balance scales are designed for extreme precision, often used in laboratories and pharmaceuticals where minute weight differences can impact results. These scales typically feature enclosed designs to protect against environmental factors. Buyers in scientific fields should prioritize accuracy specifications, capacity, and stability features. While they provide unparalleled precision, they can be sensitive to vibrations and are generally more expensive than other types.

What Advantages Do Platform Scales Offer in Industrial Settings?

Platform scales are built for durability and are ideal for weighing large and heavy items in industrial settings. They feature a spacious platform that accommodates bulk goods, making them indispensable in warehouses and shipping operations. When considering a platform scale, businesses should assess their weight capacity, accuracy, and space requirements. Although they are robust and efficient, the investment can be significant, and they require ample space for operation.

How Do Crane Scales Facilitate Weighing in Challenging Environments?

Crane scales are specialized devices that weigh items suspended from a hook, making them perfect for construction and heavy manufacturing environments. Their portability and ability to handle oversized or irregularly shaped objects are key advantages. Buyers should consider the scale’s maximum weight limit, portability, and the need for additional lifting equipment. While crane scales offer unique benefits, they may limit usage to hanging weights and require careful handling to ensure accurate readings.

Key Industrial Applications of parts of a balance scale

| Industry/Sector | Specific Application of parts of a balance scale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Use of beam balances for quality control in production | Ensures consistent product quality and compliance | Durability and accuracy of components like load cells and beams |

| Retail | Weighing scales for pricing and inventory management | Facilitates accurate pricing and efficient stock management | Calibration standards and ease of integration with POS systems |

| Pharmaceuticals | Analytical balances for precise ingredient measurement | Guarantees formulation accuracy and regulatory compliance | Sensitivity to environmental conditions and precision specifications |

| Education | Beam balances for laboratory experiments | Enhances hands-on learning and scientific accuracy | Robustness and ease of use for students, along with safety features |

| Agriculture | Platform scales for weighing bulk produce | Improves supply chain efficiency and pricing accuracy | Capacity requirements and weather-resistant features for outdoor use |

How Are Parts of a Balance Scale Utilized in Manufacturing?

In the manufacturing sector, beam balances play a crucial role in quality control processes. By accurately measuring raw materials and finished products, manufacturers can ensure that they meet regulatory standards and maintain consistent product quality. This is vital in industries such as food and beverage, where even slight deviations can lead to compliance issues or product recalls. Buyers must consider the durability of components, such as load cells and beams, to withstand the rigors of a production environment.

What Role Do Weighing Scales Play in Retail?

In retail settings, particularly grocery and jewelry stores, weighing scales are indispensable for pricing and inventory management. These scales allow businesses to calculate the total cost of items based on weight, enhancing customer satisfaction and operational efficiency. Retailers need to prioritize calibration standards and the ease of integration with point-of-sale systems to streamline their operations. Accurate scales can significantly affect profit margins by preventing overcharging or undercharging.

Why Are Analytical Balances Important in Pharmaceuticals?

Analytical balances are essential in the pharmaceutical industry for the precise measurement of active ingredients in drug formulation. The accuracy provided by these scales is crucial for ensuring that medications meet safety and efficacy standards, which is vital for regulatory compliance. Buyers in this sector should focus on sourcing balances that are sensitive to environmental conditions, as even minor fluctuations can affect readings. Additionally, the precision specifications must align with the stringent requirements of pharmaceutical applications.

How Do Beam Balances Enhance Learning in Education?

In educational settings, beam balances are often used in laboratory experiments to teach students about mass and weight measurement. These balances provide a hands-on experience that enhances understanding of scientific principles. For educational institutions, sourcing robust and user-friendly scales is essential to ensure safety and ease of use for students. Features that promote safety and durability are particularly important, given the varied experience levels of users in educational environments.

How Are Platform Scales Beneficial in Agriculture?

Platform scales are widely used in agriculture for weighing bulk produce before shipping. Accurate weight measurements are essential for pricing and managing supply chains effectively. They help farmers and distributors ensure that they are receiving fair compensation for their products. When sourcing these scales, considerations such as capacity requirements and weather-resistant features are vital, especially for outdoor use in varying environmental conditions.

3 Common User Pain Points for ‘parts of a balance scale’ & Their Solutions

Scenario 1: Difficulty in Finding Compatible Replacement Parts

The Problem: B2B buyers often face challenges when sourcing replacement parts for balance scales, especially when dealing with older or specialized models. This can be particularly frustrating in industries such as laboratories or manufacturing, where precision is paramount. A buyer might discover that the original manufacturer has discontinued certain parts or that the parts available on the market are not compatible with their existing balance scale model. This lack of compatibility can lead to operational downtime, affecting productivity and revenue.

The Solution: To navigate this issue, buyers should maintain a comprehensive inventory of model specifications and part numbers for their balance scales. When seeking replacements, consider reaching out to specialized suppliers who focus on balance scales and their components. These suppliers often have access to a wider range of parts, including OEM and aftermarket solutions. Additionally, investing in a modular balance scale system can be beneficial. Such systems allow for easy upgrades and part replacements, ensuring compatibility and reducing downtime. Buyers should also establish relationships with manufacturers for direct support and guidance on sourcing parts, which can streamline the process and ensure they receive the correct components.

Scenario 2: Ensuring Accuracy and Compliance in Measurements

The Problem: In industries such as pharmaceuticals and food production, accuracy in measurements is non-negotiable. B2B buyers often struggle with balance scales that drift out of calibration, leading to inaccurate measurements. This can result in non-compliance with industry regulations, product recalls, and ultimately financial losses. A buyer may find that regular calibration of their balance scales is either too frequent or inconsistent, raising concerns about the reliability of their measurements.

The Solution: To ensure measurement accuracy and compliance, buyers should implement a routine calibration schedule for their balance scales. This involves using certified calibration weights that meet the standards of relevant regulatory bodies. It’s advisable to partner with accredited calibration services that can provide traceable certification, ensuring that the scales remain compliant with industry standards. Additionally, investing in high-quality load cells and digital displays can enhance the precision of measurements. Buyers should also consider training staff on the proper use and maintenance of balance scales to minimize user error, which can significantly impact measurement accuracy.

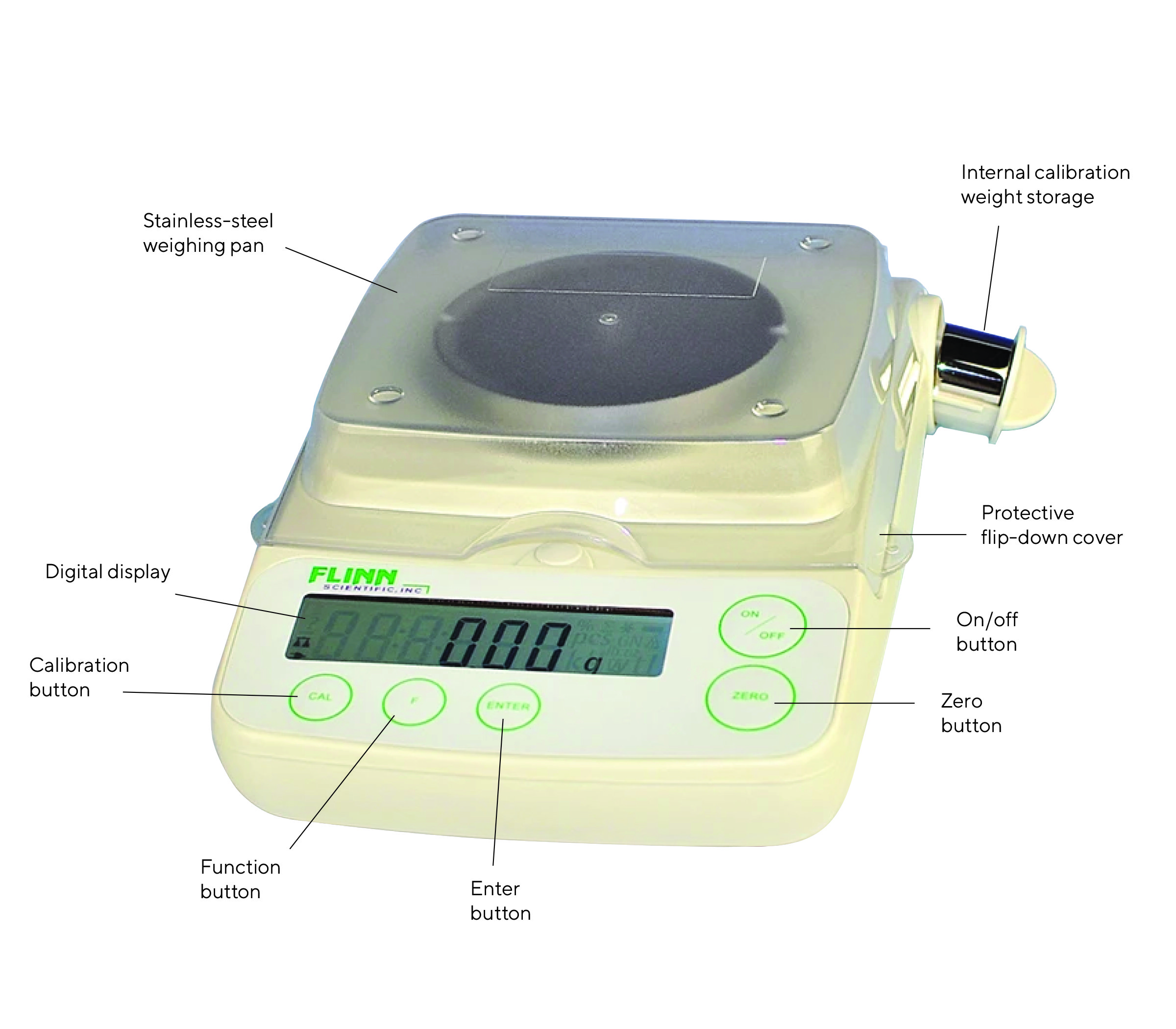

Scenario 3: Understanding Different Types of Balance Scale Parts

The Problem: B2B buyers often encounter confusion regarding the different parts of balance scales and their specific functions, particularly when they are new to this equipment. Understanding the roles of components like the beam, load cells, and pans is essential for effective usage and maintenance. Buyers may purchase parts that do not align with their specific needs, leading to inefficiencies and wasted resources.

The Solution: To address this knowledge gap, buyers should invest time in training and education regarding the parts of balance scales. This can be achieved through workshops, online courses, or direct consultations with industry experts. Suppliers often provide technical documentation and specifications for their products, which can serve as valuable resources. Additionally, creating a reference guide that outlines each part’s function and compatibility with various balance scale models can be a beneficial tool for the purchasing team. Engaging with manufacturers to understand the latest innovations in balance scale technology can also provide insights into which parts enhance performance, ensuring that buyers make informed decisions.

Strategic Material Selection Guide for parts of a balance scale

What Are the Key Properties of Common Materials Used in Balance Scale Parts?

When selecting materials for the components of a balance scale, it is essential to consider their properties, advantages, and limitations. Here, we analyze four common materials: stainless steel, aluminum, plastic, and brass.

How Does Stainless Steel Perform in Balance Scale Applications?

Stainless steel is widely recognized for its strength and corrosion resistance, making it an ideal choice for parts such as the beam and pans of a balance scale. Its ability to withstand high temperatures and pressures enhances its suitability for industrial applications where durability is paramount.

Pros: Stainless steel offers excellent durability and resistance to corrosion, ensuring longevity in various environments. It is also relatively easy to manufacture and can be polished to a high finish, which is beneficial for aesthetic appeal.

Cons: The primary drawback is its cost, which can be higher than other materials. Additionally, while it is robust, it can be heavier, which may not be ideal for portable scales.

Impact on Application: Stainless steel is compatible with a wide range of media, including chemicals and moisture, making it suitable for laboratory and industrial settings.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prioritize compliance with standards such as ASTM and DIN, which often endorse stainless steel for its reliability and safety.

What Advantages Does Aluminum Offer for Balance Scale Parts?

Aluminum is another popular material, especially for components like pans and holders. Its lightweight nature makes it a preferred choice for portable balance scales.

Pros: Aluminum is cost-effective and easy to manufacture, allowing for intricate designs. Its lightweight nature enhances portability, making it suitable for educational and field applications.

Cons: However, aluminum is less durable than stainless steel and can be prone to corrosion if not anodized or treated properly. It may not withstand high temperatures as effectively as stainless steel.

Impact on Application: While suitable for many applications, aluminum may not be ideal for environments involving harsh chemicals or extreme temperatures.

Considerations for International Buyers: Buyers in South America and Africa may find aluminum appealing due to its lower cost, but they should ensure proper treatment for corrosion resistance, particularly in humid climates.

Why Choose Plastic for Balance Scale Components?

Plastic is often utilized for non-load-bearing parts of balance scales, such as housings and buttons. Its versatility and low cost make it an attractive option.

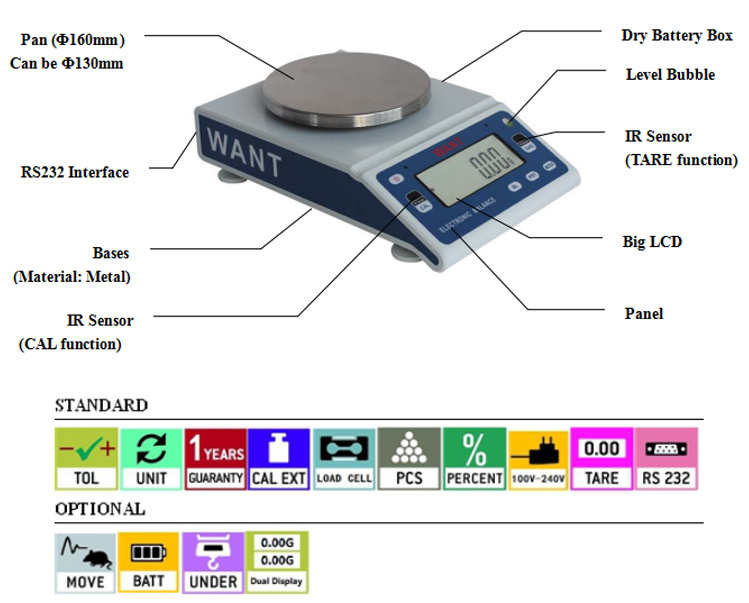

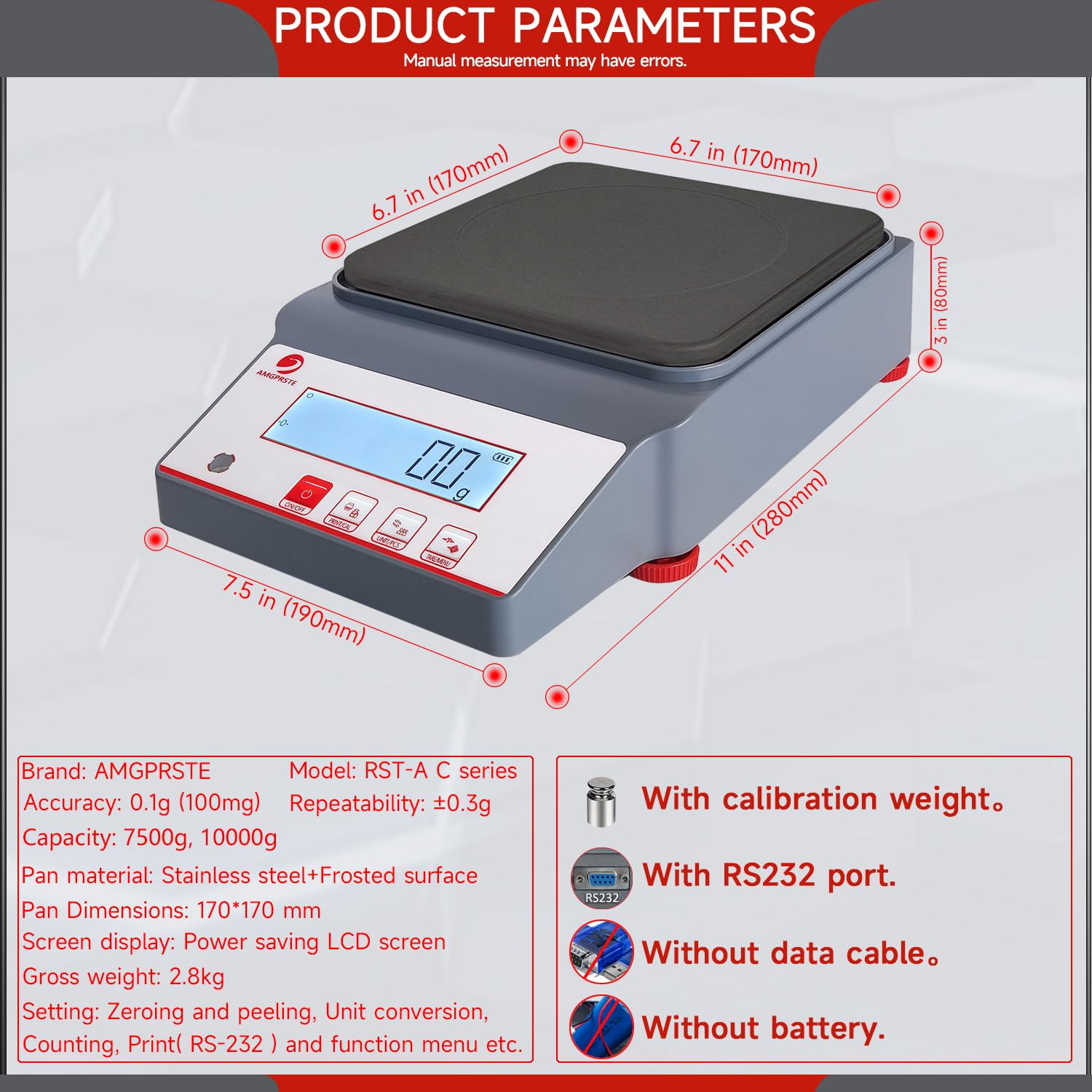

Illustrative image related to parts of a balance scale

Pros: Plastic is lightweight, inexpensive, and can be molded into complex shapes, providing design flexibility. It is also resistant to corrosion and chemicals, making it suitable for various applications.

Cons: The primary limitation is its lower strength and durability compared to metals. It may not perform well under high temperatures or heavy loads.

Impact on Application: Plastic components are ideal for educational scales or low-usage environments but may not be suitable for industrial applications requiring high precision and durability.

Illustrative image related to parts of a balance scale

Considerations for International Buyers: Buyers should consider the specific type of plastic, as not all plastics are created equal. Compliance with safety standards is crucial, especially in regions with strict regulations.

How Does Brass Compare for Balance Scale Parts?

Brass is often used for components like rivets and fittings due to its excellent machinability and aesthetic appeal.

Pros: Brass offers good corrosion resistance and durability, along with a pleasing appearance, making it suitable for decorative components.

Cons: However, brass can be more expensive than other materials and may not be as strong as stainless steel. It is also susceptible to tarnishing over time.

Impact on Application: Brass is suitable for applications where appearance is important, but its mechanical properties may limit its use in high-stress environments.

Considerations for International Buyers: Buyers from Europe may appreciate brass for its aesthetic qualities, but they should be aware of the potential need for maintenance to prevent tarnishing.

Summary of Material Selection for Balance Scale Parts

| Material | Typical Use Case for parts of a balance scale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Beam, pans | High durability and corrosion resistance | Higher cost, heavier weight | High |

| Aluminum | Pans, holders | Lightweight and cost-effective | Less durable, prone to corrosion | Medium |

| Plastic | Housings, buttons | Lightweight and design flexibility | Lower strength, temperature sensitivity | Low |

| Brass | Rivets, fittings | Good machinability and aesthetic appeal | More expensive, tarnishing potential | Medium |

This guide provides B2B buyers with essential insights into material selection for balance scale components, ensuring informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to parts of a balance scale

In-depth Look: Manufacturing Processes and Quality Assurance for parts of a balance scale

What Are the Main Stages in the Manufacturing Process of Balance Scale Parts?

The manufacturing of balance scale parts involves several key stages, each critical to ensuring precision, durability, and quality. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Balance Scale Parts?

Material preparation is foundational in the manufacturing process. Typically, high-quality metals such as stainless steel, aluminum, or specialized alloys are selected for their strength and resistance to corrosion.

- Material Selection: Suppliers should ensure that the materials meet specific standards (e.g., ASTM, ISO) relevant to the intended application of the balance scale.

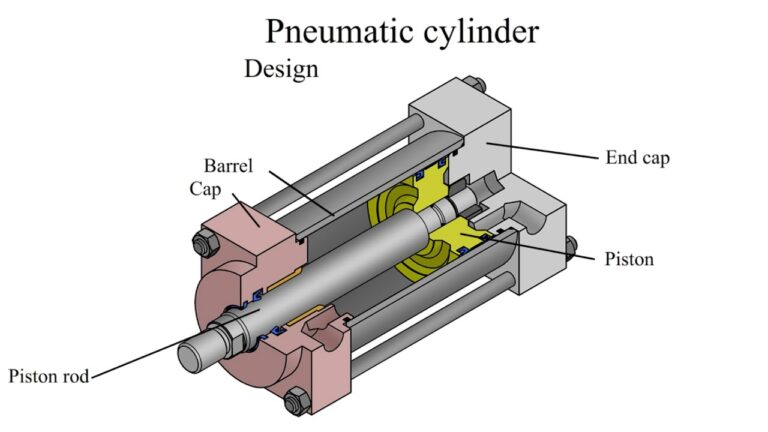

- Cutting and Shaping: Raw materials are cut to size using advanced machinery such as laser cutters or CNC (Computer Numerical Control) machines. This stage ensures that each part, whether it’s the beam, pans, or load cells, is shaped precisely to fit together.

What Techniques Are Used in Forming Balance Scale Parts?

Forming is the next critical stage, where the cut materials are shaped into their final forms.

- Stamping and Molding: For components like pans or the base, stamping or molding techniques are often employed to achieve complex shapes while maintaining uniformity across batches.

- Machining: Precision machining is used for parts like load cells and beams. Techniques such as turning, milling, and drilling are common, allowing for tight tolerances essential for accurate weight measurement.

How Are Balance Scale Parts Assembled?

Assembly is where individual parts come together to form a complete balance scale.

- Sub-Assembly: Components like the beam and pans are first assembled separately. This can involve welding, riveting, or bolting, depending on the design specifications.

- Final Assembly: The sub-assemblies are then integrated into the final product. During this stage, attention to detail is paramount, as misalignment can compromise the scale’s accuracy.

What Finishing Processes Enhance the Quality of Balance Scale Parts?

Finishing processes are crucial for both aesthetic appeal and functional durability.

- Surface Treatment: Parts may undergo treatments such as anodizing or powder coating to enhance corrosion resistance and surface hardness. This is particularly important for parts exposed to harsh environments.

- Calibration: Prior to packaging, scales are calibrated to ensure accuracy. This involves placing known weights on the pans and adjusting the mechanisms until they read correctly.

What Quality Assurance Measures Are Implemented in Manufacturing?

Quality assurance (QA) is integral to the manufacturing of balance scale parts, ensuring that products meet stringent standards and customer expectations.

Which International Standards Guide Quality Assurance for Balance Scales?

International standards such as ISO 9001 play a significant role in guiding quality management systems in manufacturing. Compliance with these standards can enhance customer confidence and facilitate international trade.

- ISO 9001: This standard outlines criteria for a quality management system, emphasizing continuous improvement and customer satisfaction. Manufacturers targeting global markets must adhere to these standards to meet buyer expectations, particularly in Europe and other developed regions.

What Industry-Specific Certifications Should B2B Buyers Look For?

In addition to general quality standards, industry-specific certifications may be necessary. For instance:

- CE Marking: Essential for products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Certification: Relevant for manufacturers producing scales used in industries like oil and gas, ensuring that products meet specific performance criteria.

How Are Quality Control Checkpoints Established?

Quality control (QC) checkpoints are essential throughout the manufacturing process to identify defects and ensure compliance with specifications.

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify that they meet predefined quality criteria.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, random checks and tests are conducted to identify any deviations from quality standards.

- Final Quality Control (FQC): Before shipment, final products undergo rigorous testing, including load testing and calibration checks, to ensure accuracy and reliability.

What Common Testing Methods Are Used for Balance Scales?

Testing methods vary depending on the components but often include:

- Load Testing: Verifying the scale’s accuracy by placing known weights on the pans and assessing the readings.

- Durability Testing: Subjecting the scales to environmental conditions and physical stress to ensure longevity and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

Buyers can take several steps to ensure that suppliers maintain rigorous quality control practices:

- Supplier Audits: Conducting on-site audits of manufacturing facilities can provide insights into quality management practices and adherence to standards.

- Quality Reports: Requesting detailed quality reports that outline testing procedures, results, and compliance with international standards can offer transparency.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices and product reliability.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, must navigate various QC and certification nuances:

- Regional Standards: Understanding specific regional standards and certifications is essential for compliance and market entry. For instance, products sold in the EU must meet CE marking requirements.

- Cultural Considerations: Buyers should be aware of cultural differences that may influence supplier communications and negotiations, particularly in regions with distinct business practices.

- Logistical Challenges: Shipping and handling can impact product integrity. Buyers must ensure that suppliers implement robust packaging and handling procedures to mitigate damage during transit.

In conclusion, the manufacturing processes and quality assurance measures for balance scale parts are intricate and vital for delivering accurate, reliable products. By understanding these processes and the associated quality control measures, B2B buyers can make informed decisions, ensuring they partner with manufacturers that uphold high standards of quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a balance scale’

When sourcing parts for a balance scale, whether for industrial, laboratory, or commercial use, it’s essential to follow a structured approach. This guide provides a step-by-step checklist to ensure you procure the right components efficiently and effectively.

Step 1: Define Your Technical Specifications

Before initiating your search for suppliers, clearly outline your technical requirements. Consider the specific type of balance scale you need—mechanical or digital—as well as the capacity, precision, and environmental conditions in which the scale will operate. Documenting these specifications will help streamline your discussions with suppliers and ensure compatibility with your intended applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in balance scale components. Look for manufacturers with a proven track record in your industry or region. Utilize online directories, trade shows, and industry forums to gather information. Pay attention to their product range, market reputation, and customer reviews to gauge reliability.

Step 3: Evaluate Supplier Certifications

Ensure that your selected suppliers have the necessary certifications and quality standards in place. Common certifications include ISO 9001 for quality management systems and ISO/IEC 17025 for calibration and testing. These certifications indicate that the supplier adheres to industry best practices, which is crucial for ensuring the accuracy and reliability of the balance scale parts.

Step 4: Request Samples and Test Quality

Before finalizing any orders, request samples of the parts you intend to purchase. Testing these samples for quality, durability, and compatibility with your existing systems is vital. This step allows you to assess the performance of components like load cells, beams, and pans, ensuring they meet your operational standards.

Step 5: Confirm Lead Times and Availability

Discuss lead times and product availability with your suppliers. Understanding how quickly they can deliver components is crucial for planning your operations. Inquire about their inventory management practices to ensure they can meet your demands without significant delays, especially if you have tight timelines.

Step 6: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and payment terms. Consider bulk purchasing discounts or long-term contracts if you anticipate ongoing needs. Be clear about your budget constraints while ensuring that the quality of the components is not compromised for cost savings.

Step 7: Establish Communication and Support Channels

Finally, establish clear communication channels with your suppliers. Ensure they provide reliable customer support for any inquiries or issues that may arise post-purchase. A responsive supplier can significantly impact your operational efficiency, especially when dealing with maintenance or replacement parts in the future.

Illustrative image related to parts of a balance scale

By following this checklist, B2B buyers can confidently source the parts needed for balance scales, ensuring both quality and operational efficiency in their respective industries.

Comprehensive Cost and Pricing Analysis for parts of a balance scale Sourcing

When sourcing parts for balance scales, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis breaks down the various cost components involved and highlights the factors that influence pricing in this sector.

What Are the Key Cost Components for Balance Scale Parts?

-

Materials: The cost of raw materials significantly impacts the pricing of balance scale components. Common materials include metals (like aluminum or stainless steel) for durability and plastics for lightweight designs. The choice of materials affects both the performance and longevity of the scale, with higher quality materials commanding a premium.

-

Labor: Labor costs vary by region and impact the overall manufacturing expenses. In countries with higher wage standards, such as those in Europe, labor costs can be substantial, while regions with lower wage expectations, like parts of Africa and South America, may offer cost advantages.

-

Manufacturing Overhead: This includes utilities, rent, and indirect labor associated with the production process. Efficient manufacturing processes can help mitigate overhead costs, but buyers should consider the supplier’s operational efficiency when evaluating pricing.

-

Tooling: The initial investment in tooling for specific parts can be significant, especially for custom components. Tooling costs are typically amortized over production runs, influencing pricing based on order volume.

-

Quality Control (QC): Ensuring that balance scales meet industry standards necessitates quality control measures. The costs associated with QC processes can vary depending on the complexity of the parts and the certifications required, such as ISO or CE markings.

-

Logistics: Shipping costs are a critical factor, especially for international buyers. Factors like distance, mode of transport, and Incoterms can significantly affect the total landed cost. Buyers should account for potential tariffs and duties when importing parts.

-

Margin: Supplier margins also play a role in pricing. A supplier may have different pricing strategies based on their market position, competition, and brand reputation.

How Do Price Influencers Affect the Sourcing of Balance Scale Parts?

-

Volume/MOQ: Suppliers often set minimum order quantities (MOQs) that can affect pricing. Larger orders may reduce per-unit costs, making it advantageous for buyers to consolidate purchases.

-

Specifications and Customization: Customized parts generally incur higher costs due to additional tooling and production complexity. Buyers should clearly define their requirements to avoid unexpected pricing surges.

-

Quality and Certifications: Higher quality standards and required certifications can raise costs. It’s essential for buyers to determine the necessary certifications for their target markets to avoid compliance issues.

-

Supplier Factors: The choice of supplier can significantly influence pricing. Established suppliers with a track record of reliability may charge more, but they often provide better support and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining who bears the costs and risks during shipping. This knowledge can help buyers negotiate better terms and control overall costs.

What Are the Best Practices for Negotiating Costs and Ensuring Cost-Efficiency?

-

Negotiation: Engage suppliers in discussions about pricing and terms. Leverage competitive quotes from multiple suppliers to gain leverage in negotiations.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the total cost of ownership, which includes maintenance, durability, and potential downtime costs. Investing in higher-quality parts may result in lower TCO over time.

-

Pricing Nuances for International Buyers: Buyers in regions such as Africa, South America, the Middle East, and Europe must navigate different economic conditions, currency fluctuations, and import regulations. Establishing relationships with local suppliers or distributors can mitigate some of these challenges.

Conclusion

Navigating the cost structure and pricing of balance scale parts requires careful consideration of various factors. By understanding the cost components, leveraging price influencers, and employing best practices in negotiation, international B2B buyers can make informed decisions that enhance their sourcing strategies. Always remember to account for all variables and engage with suppliers transparently to achieve the best possible outcomes.

Alternatives Analysis: Comparing parts of a balance scale With Other Solutions

Introduction to Alternatives in Weighing Solutions

When it comes to measuring weight or mass, the parts of a balance scale represent a traditional and effective solution. However, as industries evolve, alternative solutions have emerged that may offer enhanced performance, cost savings, or ease of use. Understanding these alternatives is crucial for B2B buyers who seek the most efficient and effective weighing solutions tailored to their specific needs.

Illustrative image related to parts of a balance scale

| Comparison Aspect | Parts Of A Balance Scale | Digital Weighing Scale | Load Cell Scale |

|---|---|---|---|

| Performance | High accuracy for static loads | Very high accuracy, quick readings | Excellent precision, real-time data |

| Cost | Moderate initial investment | Varies widely, generally higher than mechanical | Can be cost-effective for bulk purchases |

| Ease of Implementation | Requires manual adjustment | User-friendly, easy to set up | Requires calibration and integration |

| Maintenance | Low maintenance, durable | Moderate, requires battery changes | Moderate, needs regular calibration |

| Best Use Case | Educational, laboratory settings | Retail, industrial, and laboratory applications | Heavy-duty industrial applications |

Exploring Digital Weighing Scales as an Alternative

Digital weighing scales have become increasingly popular due to their ease of use and advanced features. They provide quick and highly accurate readings, which is essential in fast-paced environments like retail and manufacturing. These scales often come with additional functionalities such as tare weight and unit conversion, making them versatile for various applications. However, they do require a power source, and the initial investment can be higher than traditional balance scales. For businesses needing rapid and precise measurements, digital scales are an attractive option.

Load Cell Scales: A Robust Alternative

Load cell scales utilize load cell technology to convert force into measurable electrical signals, providing precise measurements in real-time. They are especially suitable for heavy-duty applications in industries such as construction and logistics. Load cells can handle larger weights compared to traditional balance scales and are typically more robust. However, they may require a more complex setup and regular calibration to ensure accuracy. Companies looking for high-capacity, precise measurements in industrial settings might find load cell scales to be the best fit.

Conclusion: Choosing the Right Weighing Solution

When selecting a weighing solution, B2B buyers should consider the specific requirements of their operations, including the desired accuracy, budget constraints, and operational environment. While the parts of a balance scale offer reliability and durability, alternatives like digital weighing scales and load cell scales may provide enhanced functionality or efficiency. By evaluating these aspects, businesses can make informed decisions that align with their unique needs and optimize their weighing processes.

Essential Technical Properties and Trade Terminology for parts of a balance scale

What Are the Key Technical Properties of Balance Scale Parts?

When evaluating balance scale components, understanding their technical specifications is crucial for ensuring quality, compliance, and operational efficiency. Here are some essential properties to consider:

1. Material Grade

The material used in balance scale parts—such as stainless steel, aluminum, or plastic—affects durability, weight capacity, and corrosion resistance. For instance, stainless steel is often preferred for its strength and resistance to chemical corrosion, making it ideal for laboratory environments. Selecting the right material grade is essential for optimizing performance and longevity, particularly in industries like pharmaceuticals and food processing.

2. Tolerance Levels

Tolerance refers to the permissible limits of variation in a physical dimension. High precision is critical in balance scales, where even minor deviations can lead to significant errors in measurement. Tolerance levels are especially important for parts like the beam and load cells, where accuracy is paramount. Understanding these specifications can help buyers ensure that the scales meet industry standards and regulatory requirements.

3. Load Capacity

This specification indicates the maximum weight that the balance scale can accurately measure. Different applications—be it laboratory analysis or industrial weighing—require different load capacities. Knowing the load capacity helps buyers select scales that meet their operational demands without risking damage or inaccurate measurements.

4. Calibration Standards

Calibration is vital for ensuring measurement accuracy. Balance scales must adhere to specific calibration standards, such as ISO or ASTM, which define the procedures for verifying the accuracy of measurements. For B2B buyers, understanding these standards is crucial for compliance and for ensuring that the scales are suitable for their specific applications.

5. Environmental Resistance

Certain balance scale parts must withstand various environmental conditions, such as humidity, temperature fluctuations, or exposure to chemicals. Components that are resistant to these factors are essential for industries like pharmaceuticals and food production, where precision and reliability are non-negotiable. Understanding environmental resistance properties can guide buyers in selecting appropriate equipment for their operational settings.

What Are Common Trade Terms Related to Balance Scales?

Familiarity with industry-specific jargon can significantly enhance communication and negotiation processes in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of balance scales, OEMs supply specific components like load cells or pans, which can be integrated into a complete scale. Understanding OEM relationships can help buyers identify quality sources for replacement parts or new equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers when negotiating orders, as it can impact inventory costs and cash flow. Knowing the MOQ helps businesses plan their purchases and manage their budgets effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and other details for specific products or services. For balance scales, an RFQ can include specifications for different parts, allowing suppliers to provide tailored quotes. This process is essential for comparing options and making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms helps B2B buyers navigate logistics and minimize risk in international transactions involving balance scales.

5. Calibration Certificate

A calibration certificate is a document that verifies the accuracy of a balance scale, confirming that it meets specific standards. This certificate is vital for industries where compliance is required. Buyers should always request calibration certificates to ensure that the scales they purchase are reliable and accurate for their applications.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing balance scale components, ensuring they select the right equipment for their specific needs.

Illustrative image related to parts of a balance scale

Navigating Market Dynamics and Sourcing Trends in the parts of a balance scale Sector

What Are the Key Market Dynamics Driving the Parts of a Balance Scale Sector?

The global market for balance scales and their components is experiencing significant growth, driven by an increasing demand for accuracy and precision in various industries. Key drivers include the rise of e-commerce, where precise weight measurements are crucial for shipping logistics, and the expanding manufacturing sectors in Africa, South America, and Asia. Emerging technologies such as IoT-enabled scales are also transforming the landscape by offering real-time data analytics, which enhance operational efficiencies and inventory management.

International B2B buyers are increasingly looking for customizable solutions that cater to specific applications, ranging from laboratory use to industrial weighing. In regions like Europe, particularly Germany, there is a notable trend toward digitalization and automation in manufacturing processes, which influences the demand for advanced weighing solutions. Meanwhile, buyers in developing markets are focusing on affordability and durability, often opting for mechanical balance scales that require no power source.

Another critical trend is the shift towards integrated supply chains. Buyers are seeking suppliers who can provide comprehensive solutions, including not just the parts of balance scales but also the necessary support and maintenance services. This holistic approach allows companies to streamline operations and reduce costs, making it a strategic priority for B2B buyers across the globe.

How Can Sustainability and Ethical Sourcing Impact Your Sourcing Decisions for Balance Scale Parts?

As global awareness of environmental issues rises, sustainability has become a key consideration for B2B buyers in the balance scale sector. Sourcing parts made from eco-friendly materials not only helps mitigate environmental impact but also enhances brand reputation. Buyers are increasingly prioritizing suppliers who adopt sustainable practices, such as using recycled materials for components like the beam, pans, and load cells.

Ethical sourcing is equally important, as it ensures that the supply chain adheres to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. Buyers are advised to conduct thorough due diligence on suppliers to verify their sustainability claims and ensure compliance with international standards.

Illustrative image related to parts of a balance scale

Incorporating sustainability into sourcing strategies can lead to cost savings in the long run. Companies that invest in green technologies and practices often benefit from reduced waste and energy consumption, which can enhance operational efficiency and profitability. By aligning sourcing decisions with sustainability goals, B2B buyers can contribute to a more responsible and environmentally conscious industry.

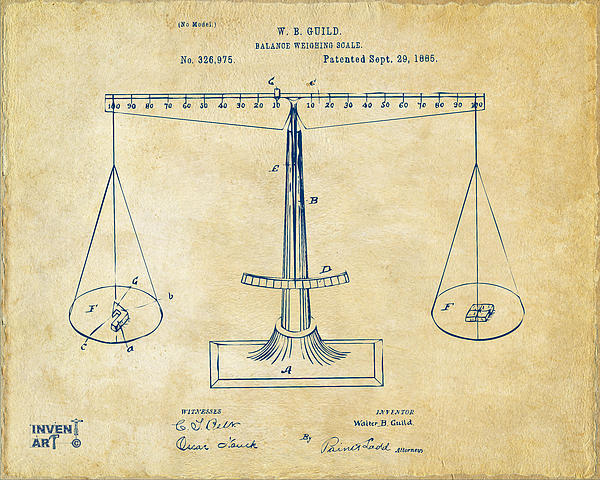

What Is the Historical Context of Balance Scales Relevant to Today’s B2B Market?

The history of balance scales dates back thousands of years, with the earliest known examples used in ancient Egypt for trade and commerce. The fundamental principle of balance scales—measuring weight by comparing two masses—remains unchanged. Over time, technological advancements have led to the development of various types of balance scales, including mechanical, digital, and analytical scales, each designed for specific applications.

In recent decades, the evolution of balance scales has been marked by the integration of digital technology, enabling more precise measurements and enhanced functionalities such as connectivity and data storage. This progression reflects the growing demands of modern industries for accuracy and efficiency. Today, balance scales are essential tools across numerous sectors, including healthcare, manufacturing, and retail, illustrating their enduring relevance in the B2B marketplace.

Illustrative image related to parts of a balance scale

By understanding the historical context and current trends, international buyers can make informed sourcing decisions that align with their operational needs and market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of a balance scale

-

How do I select the right parts for a balance scale?

When selecting parts for a balance scale, consider the specific application and requirements of your industry. Identify the type of scale you need—mechanical, digital, or analytical—and assess the required precision and capacity. Key components include the beam, pans, load cells, and display systems. Additionally, ensure compatibility with existing equipment and confirm that the materials used meet industry standards for durability and accuracy. Consulting with a supplier who specializes in balance scales can provide insights tailored to your needs. -

What are the essential components of a balance scale?

A balance scale typically consists of several key components: the beam (lever), pans (left and right), load cells (for digital scales), a base for stability, and a display screen. The beam balances the weight between the pans, while load cells convert weight into electrical signals for digital displays. Additional parts like rivets and strings may be included for structural integrity. Understanding these components will help you make informed decisions when sourcing parts. -

What customization options are available for balance scale parts?

Many suppliers offer customization options for balance scale parts to meet specific needs. Customizations may include material choices (e.g., stainless steel, plastic), size variations for pans, and specialized load cells for unique weight capacities. Additionally, you can request personalized branding or specific technical features in the display systems. Communicating your requirements clearly to suppliers can facilitate tailored solutions that enhance the functionality of your balance scales. -

What are the minimum order quantities (MOQ) for balance scale parts?

Minimum order quantities for balance scale parts can vary significantly between suppliers. Some may have a low MOQ for standard components, while others might require larger orders for specialized or custom parts. It’s advisable to inquire directly with potential suppliers about their MOQ policies. If you’re a smaller business or just starting, look for suppliers who accommodate smaller orders or consider negotiating terms that suit your purchasing capabilities. -

What payment terms should I expect when sourcing balance scale parts internationally?

Payment terms can vary based on the supplier’s policies and the nature of your order. Common practices include upfront payments, 30% deposits with the balance due upon shipment, or net 30/60 terms for established relationships. Be sure to clarify payment methods accepted (e.g., bank transfer, credit card, letters of credit) and any fees associated with international transactions. Understanding these terms upfront can help avoid misunderstandings and ensure a smooth procurement process. -

How can I ensure quality assurance for balance scale parts?

To ensure quality assurance for balance scale parts, select suppliers who adhere to international quality standards, such as ISO certifications. Request product samples to evaluate quality before placing a larger order. Additionally, inquire about their quality control processes, including testing procedures for accuracy and durability. Establishing clear quality expectations in your purchase agreement can also help maintain high standards throughout the sourcing process. -

What logistics considerations should I take into account when importing balance scale parts?

When importing balance scale parts, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with international shipping to navigate customs clearance efficiently. Be aware of import duties and taxes that may apply to your shipment, and factor these costs into your overall budget. Clear communication with your supplier regarding shipping timelines and packaging can also help ensure that your parts arrive safely and on schedule. -

What are the common challenges faced when sourcing balance scale parts internationally?

Sourcing balance scale parts internationally can pose challenges such as language barriers, cultural differences, and varying quality standards. Time zone differences may complicate communication, and shipping delays can affect project timelines. To mitigate these issues, establish clear lines of communication with suppliers, use detailed specifications to avoid misunderstandings, and build relationships with reputable partners. Conducting thorough research and due diligence can also help identify potential risks and ensure a smoother sourcing experience.

Top 3 Parts Of A Balance Scale Manufacturers & Suppliers List

1. Teach Starter – Balance Scale Poster

Domain: teachstarter.com

Registered: 2012 (13 years)

Introduction: Balance Scale Poster – Diagram with Labels

– Updated: 08 Oct 2019

– Description: A poster containing a diagram with labels showing the key parts of a balance scale.

– Format: Non-Editable PDF

– Pages: 1 Page

– Curriculum: TEKS

– Grades: 3 – 6

– Print Options: Letter-size (for gluing into science journals) and Tabloid (for display in science labs/classrooms).

2. Scale Depot – Balance Scales

Domain: scaledepot.com

Registered: 2013 (12 years)

Introduction: Balance scales are tools used to measure weight by comparing an object’s weight to a known weight. They consist of a beam, a pivot point, and weights. Common types include digital balance scales, analytical balance scales, and precision balance scales. They are used in various settings such as science labs, kitchens, post offices, and grocery stores. Key considerations for accurate readings includ…

3. Scribd – Basic Balance Scale Construction

Domain: scribd.com

Registered: 2006 (19 years)

Introduction: The document describes how to construct a basic balance scale. Key components include a beam with a pivoted center resting on a fulcrum, and pointers to indicate balance. The operation involves placing an object on one pan and calibration weights on the other until balance is achieved, allowing the known weight to equal the unknown object’s weight. It distinguishes between a balance, which measure…

Strategic Sourcing Conclusion and Outlook for parts of a balance scale

In conclusion, the strategic sourcing of parts for balance scales is essential for businesses across various sectors, including manufacturing, retail, and scientific research. By understanding the critical components—such as the apex, beam, pans, and load cells—international B2B buyers can make informed purchasing decisions that enhance operational efficiency and product quality. Investing in high-quality parts not only ensures accuracy and compliance but also supports long-term sustainability in your operations.

As global markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for precision weighing solutions will continue to rise. Buyers should prioritize suppliers who demonstrate reliability, innovation, and the ability to meet diverse industry needs.

Illustrative image related to parts of a balance scale

Moving forward, consider forming strategic partnerships with manufacturers that offer customizable solutions and robust support services. This approach will position your business to adapt to changing market conditions and customer demands. Embrace the opportunity to elevate your sourcing strategy and secure a competitive edge in the marketplace. Now is the time to invest in the future of your weighing solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to parts of a balance scale