The Definitive Guide to Paracord Vs Shock Cord: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for paracord vs shock cord

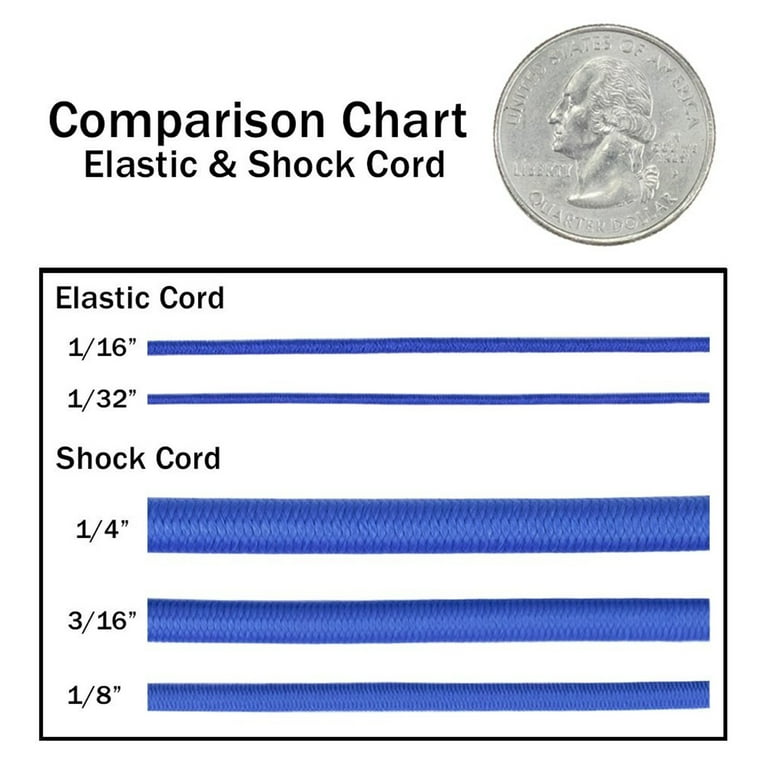

In the increasingly competitive landscape of global sourcing, understanding the nuances between paracord and shock cord is essential for B2B buyers looking to optimize their product offerings. Whether you’re a manufacturer, retailer, or supplier, the challenge lies in selecting the right cord that meets your specific needs and customer expectations. This guide provides an in-depth analysis of paracord versus shock cord, exploring their respective types, applications, and key performance characteristics.

International buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe—including countries like Nigeria and Vietnam—will find invaluable insights into how to vet suppliers, compare costs, and evaluate the durability and versatility of these materials. With detailed comparisons of tensile strength, elasticity, and resistance to environmental factors, this guide aims to empower decision-makers with the knowledge needed to make informed purchasing choices.

Moreover, we will delve into the practical applications of both cords, from outdoor gear and emergency kits to crafting and industrial uses, ensuring that you can match the right product to your specific market demands. Equip yourself with the expertise to navigate the complexities of sourcing paracord and shock cord effectively, ultimately leading to enhanced product performance and customer satisfaction.

Understanding paracord vs shock cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 550 Paracord | High tensile strength (550 lbs), versatile | Outdoor gear, crafting, emergency kits | Pros: Strong, flexible, UV resistant; Cons: Not as elastic as shock cord. |

| Shock Cord | Elastic, absorbs shock, high stretchability | Securing loads, bungee applications, outdoor canopies | Pros: Excellent for tension; Cons: Less durable than paracord in abrasive conditions. |

| Nano Paracord | Lightweight (36 lbs), compact size | Jewelry making, small repairs | Pros: High portability; Cons: Limited strength for heavy-duty applications. |

| 275 Paracord | Stiffer, moderate tensile strength (275 lbs) | Crafting, lanyards, keychains | Pros: Good for small projects; Cons: Less flexible than other types. |

| 1/4” Shock Cord | Strong elastic properties (210 lbs), versatile | Cargo nets, bungee straps, securing items | Pros: High elasticity; Cons: Can wear out faster with heavy use. |

What Are the Key Characteristics of 550 Paracord for B2B Buyers?

550 Paracord is the most popular type due to its balance of strength and flexibility. With a tensile strength of 550 lbs, it is ideal for a variety of applications, including outdoor gear, crafting, and emergency kits. B2B buyers should consider its UV resistance and durability in harsh conditions, which makes it suitable for long-term use. However, its rigidity compared to shock cords means it may not be the best choice for applications requiring significant stretch.

How Does Shock Cord Differ in Application from Paracord?

Shock cord, known for its elasticity, is designed to absorb shock and provide tension. It is commonly used in securing loads, making bungee applications, and creating outdoor canopies. B2B buyers appreciate its ability to stretch without breaking, which is essential for dynamic applications. However, it may not withstand abrasive conditions as well as paracord, making it less suitable for rugged outdoor uses.

Why Choose Nano Paracord for Specialized B2B Needs?

Nano paracord is a lightweight option with a tensile strength of 36 lbs, making it ideal for applications that require compactness, such as jewelry making or small repairs. Its small diameter allows for easy storage and portability, appealing to businesses focused on lightweight products. However, its limited strength restricts its use in heavy-duty scenarios, so buyers must assess their specific needs carefully.

What Advantages Does 275 Paracord Offer for Crafting Projects?

275 paracord strikes a balance between thickness and flexibility, making it great for crafting, lanyards, and keychains. With a tensile strength of 275 lbs, it is suitable for small projects where moderate strength is required. Businesses should consider its stiffness, which can be beneficial for certain applications but may limit flexibility compared to other paracord types.

In What Scenarios is 1/4” Shock Cord the Best Choice?

1/4” shock cord is notable for its strong elastic properties, with a tensile strength of 210 lbs. It is often used in applications such as cargo nets, bungee straps, and for securing items during transport. B2B buyers value its high elasticity, which allows it to handle dynamic forces effectively. However, its lifespan may be shorter under continuous heavy use, so understanding the operational context is essential for procurement decisions.

Key Industrial Applications of paracord vs shock cord

| Industry/Sector | Specific Application of paracord vs shock cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Paracord for camping gear repairs and setups | High tensile strength and versatility for various uses | Durability, UV resistance, and ease of storage |

| Transportation | Shock cord for securing loads in vehicles | Provides shock absorption and flexibility during transport | Tensile strength, elasticity, and weather resistance |

| Manufacturing | Paracord for assembly line applications | Lightweight yet strong for various product assembly | Cost-effectiveness, availability in bulk, and compliance with safety standards |

| Military & Defense | Paracord for tactical gear and survival kits | Essential for emergency situations and gear reliability | Compliance with military specifications and performance standards |

| Crafting & DIY | Shock cord for creative projects and crafts | Versatile for a range of DIY applications | Variety of sizes, colors, and elasticity options available |

How is Paracord Used in Outdoor Recreation and What Benefits Does It Provide?

In the outdoor recreation sector, paracord is widely utilized for camping gear repairs and setups. Its high tensile strength, often exceeding 550 lbs, makes it ideal for lashing tents, repairing backpacks, and creating emergency shelters. B2B buyers in this industry should prioritize sourcing paracord that is UV and rot resistant to ensure durability in various weather conditions. Additionally, its lightweight nature allows for easy transport, making it a staple in emergency kits for adventurers and outdoor enthusiasts.

What Role Does Shock Cord Play in the Transportation Sector?

Shock cord is integral in the transportation industry, particularly for securing loads in vehicles. Its elastic properties allow it to stretch and absorb shock during transport, minimizing the risk of damage to cargo. Businesses involved in logistics and transportation should consider sourcing shock cords with high tensile strength and weather resistance to withstand outdoor elements. The ability to customize lengths and colors can also enhance brand visibility while ensuring that cargo remains secure during transit.

How is Paracord Applied in Manufacturing and What Are the Key Benefits?

In manufacturing, paracord is used for various assembly line applications due to its lightweight yet strong characteristics. It is particularly beneficial in assembling products that require reliable securing without adding significant weight. B2B buyers in this sector should look for cost-effective options that comply with safety standards and are available in bulk. The versatility of paracord enables manufacturers to adapt it for multiple applications, streamlining production processes and reducing downtime associated with equipment failure.

Why is Paracord Essential for Military and Defense Applications?

For military and defense applications, paracord is essential for tactical gear and survival kits. Its reliability in emergency situations, coupled with its ability to withstand harsh conditions, makes it a preferred choice among military personnel. B2B buyers in this sector should prioritize paracord that meets military specifications for strength and durability. Additionally, sourcing from suppliers with a proven track record in defense contracting can ensure compliance with stringent performance standards, providing peace of mind for operational readiness.

What Are the Creative Uses of Shock Cord in Crafting and DIY Projects?

Shock cord is increasingly popular in the crafting and DIY sector, where it is used for a variety of creative projects, including jewelry making and home décor. Its elasticity allows for innovative designs that require flexibility and stretch, such as adjustable straps and decorative elements. B2B buyers should seek suppliers that offer a diverse range of sizes, colors, and elasticity options to meet the needs of various crafting applications. Understanding the specific requirements of the end-use can help in selecting the right type of shock cord for different projects, enhancing both functionality and aesthetics.

3 Common User Pain Points for ‘paracord vs shock cord’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Cord for Specific Applications

The Problem: B2B buyers often find themselves overwhelmed by the variety of options available when choosing between paracord and shock cord. For instance, a company specializing in outdoor gear may require a reliable cord for securing tents and equipment. If they mistakenly opt for shock cord, which has high elasticity but lower tensile strength, they may face issues with stability and security. Conversely, selecting paracord for applications needing high elasticity may result in a rigid setup that does not perform well under dynamic loads.

The Solution: To address this challenge, buyers should first conduct a thorough needs assessment based on the specific applications they intend to use the cord for. For tasks requiring stability and strength—such as securing tents—550 paracord, known for its high tensile strength (up to 550 lbs), is ideal. In contrast, for applications like securing loads on vehicles or for adjustable mechanisms, shock cord with its superior elasticity is more suitable. B2B buyers should consider creating a comparison chart specific to their operational needs, highlighting the strengths and weaknesses of each cord type for various applications. This structured approach will guide them in sourcing the correct cord type that aligns with their use cases.

Scenario 2: Misunderstanding the Material Properties and Durability

The Problem: Many buyers underestimate the importance of material properties when selecting cords. For instance, a manufacturer in the outdoor equipment sector may choose a low-cost shock cord without realizing it is not UV resistant or rot-proof. This oversight can lead to rapid degradation in harsh outdoor conditions, resulting in product failures and increased replacement costs.

Illustrative image related to paracord vs shock cord

The Solution: To mitigate this risk, buyers should prioritize sourcing cords that specify their material properties and certifications. When selecting paracord, look for options that are made from military-grade nylon and offer UV and rot resistance, ensuring long-lasting performance in diverse environmental conditions. Buyers should also request product samples and conduct field tests to assess durability under expected conditions. Establishing relationships with reputable suppliers who provide detailed product specifications and durability testing results will further ensure that the chosen cords meet quality standards and customer expectations.

Scenario 3: Inadequate Knowledge About Cord Maintenance and Longevity

The Problem: A common oversight among B2B buyers is the lack of understanding regarding the maintenance needs of paracord and shock cord. For example, a logistics company may use shock cords extensively for securing cargo but fail to recognize that prolonged exposure to the elements can lead to material fatigue. This lack of awareness can result in unexpected failures during transit, jeopardizing safety and leading to costly damages.

The Solution: Buyers should implement a maintenance schedule for all cords used in their operations. This includes regular inspections for signs of wear, such as fraying or loss of elasticity, and proper storage away from direct sunlight to extend the lifespan of the cords. Additionally, providing training sessions for staff on the proper usage and care of paracord and shock cord can significantly enhance safety and effectiveness. Companies could also consider investing in higher-quality cords that are designed for longevity, which can lead to reduced replacement frequency and overall cost savings in the long run.

Strategic Material Selection Guide for paracord vs shock cord

What Are the Key Materials Used in Paracord and Shock Cord?

When considering the selection of materials for paracord and shock cord, understanding the properties and applications of each material is crucial for B2B buyers. The following analysis focuses on nylon, rubber, polyester, and polypropylene, which are the primary materials used in these cords.

Illustrative image related to paracord vs shock cord

How Does Nylon Affect the Performance of Paracord?

Nylon is the predominant material used in paracord, particularly military-grade variations. It boasts a high tensile strength, typically rated at 550 lbs for standard paracord, making it ideal for applications requiring durability and reliability. Nylon is also resistant to UV light and abrasion, which enhances its longevity in outdoor environments.

Pros: The high strength-to-weight ratio and resistance to environmental factors make nylon an excellent choice for outdoor gear, survival kits, and crafting.

Cons: However, nylon can be more expensive than other materials, and its performance can degrade under prolonged exposure to extreme temperatures.

Illustrative image related to paracord vs shock cord

Impact on Application: Nylon’s compatibility with various outdoor applications, such as camping and hiking gear, makes it a preferred choice among manufacturers.

Considerations for International Buyers: Compliance with standards like ASTM D-2130 for tensile strength can be crucial. Buyers in regions like Africa and South America may need to consider local sourcing of nylon to reduce costs.

What Role Does Rubber Play in Shock Cord Applications?

Rubber is the primary material used in shock cords, often encased in a protective sheath for added durability. It offers excellent elasticity, allowing it to stretch significantly while returning to its original shape, which is essential for applications that involve securing loads or absorbing shock.

Illustrative image related to paracord vs shock cord

Pros: The inherent elasticity of rubber makes it ideal for dynamic applications, such as bungee straps and cargo nets, where movement is expected.

Cons: However, rubber can degrade over time when exposed to UV light and extreme temperatures, limiting its lifespan.

Impact on Application: Shock cords are widely used in transportation and outdoor activities, where their ability to absorb shock is critical.

Considerations for International Buyers: Buyers should be aware of compliance with standards like ISO 9001 for quality management systems. In regions like the Middle East, local suppliers may offer rubber cords that meet specific regional requirements.

How Does Polyester Compare for Durability in Paracord?

Polyester is another material used in some variations of paracord, particularly for applications requiring higher resistance to moisture and UV light. It provides a strong alternative to nylon, with a lower elongation rate, making it suitable for applications where minimal stretch is desired.

Illustrative image related to paracord vs shock cord

Pros: Polyester’s durability and resistance to environmental factors make it ideal for outdoor applications, such as marine use and heavy-duty crafting.

Cons: The cost of polyester can be higher than nylon, and it may not offer the same level of flexibility.

Impact on Application: Polyester is particularly effective in applications requiring dimensional stability and resistance to moisture, making it suitable for outdoor gear.

Considerations for International Buyers: Buyers in Europe may prefer polyester due to its compliance with EU regulations regarding environmental impact and material safety.

Illustrative image related to paracord vs shock cord

What Advantages Does Polypropylene Offer for Cost-Effective Solutions?

Polypropylene is often used in lower-cost paracord and shock cord options. It is lightweight and has a decent tensile strength, making it suitable for less demanding applications.

Pros: The low cost and lightweight nature of polypropylene make it an attractive option for budget-conscious buyers, particularly for non-critical applications.

Cons: However, polypropylene is less durable than nylon or polyester and is more susceptible to UV degradation.

Impact on Application: It is commonly used in crafting and light-duty outdoor activities, where high strength is not a primary concern.

Illustrative image related to paracord vs shock cord

Considerations for International Buyers: Buyers should evaluate the suitability of polypropylene for their specific applications, especially in regions with high UV exposure.

Summary Table of Material Properties

| Material | Typical Use Case for paracord vs shock cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Outdoor gear, survival kits, crafting | High tensile strength and UV resistance | Higher cost and temperature sensitivity | High |

| Rubber | Bungee straps, cargo nets | Excellent elasticity and shock absorption | Degrades under UV exposure and heat | Medium |

| Polyester | Marine use, heavy-duty crafting | Durable and moisture-resistant | Higher cost and less flexibility | Medium |

| Polypropylene | Budget-friendly crafting, light-duty use | Low cost and lightweight | Less durable and UV susceptible | Low |

This detailed analysis provides B2B buyers with actionable insights into material selection for paracord and shock cord, ensuring informed decision-making that aligns with their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for paracord vs shock cord

What Are the Key Manufacturing Processes for Paracord and Shock Cord?

Understanding the manufacturing processes for paracord and shock cord is crucial for B2B buyers seeking reliable and high-quality products. The production of these cords involves multiple stages, each requiring specific techniques to ensure durability and performance.

What Are the Main Stages of Manufacturing Paracord and Shock Cord?

-

Material Preparation

– The primary materials for both paracord and shock cord are nylon and rubber, respectively. For paracord, high-tenacity nylon is preferred for its strength and abrasion resistance, while shock cord typically uses a blend of rubber with a protective sheath, often made from polyester or nylon.

– Quality control begins at this stage, where raw materials are tested for tensile strength, elasticity, and resistance to UV degradation. -

Forming

– The forming process varies between paracord and shock cord. Paracord is typically extruded into a specific diameter (commonly 4 mm for 550 paracord) through a die, ensuring uniformity and strength.

– Shock cords are created by braiding or weaving rubber strands into a tubular form. This process also involves ensuring the elasticity and strength of the final product. -

Assembly

– For paracord, assembly may include integrating inner strands, which enhance strength. The most common types, like 550 paracord, contain seven inner strands that provide additional tensile strength.

– In contrast, shock cords are often assembled with hooks or clips at the ends, which are crucial for their intended use, such as securing loads or creating elastic connections. -

Finishing

– The finishing stage includes treatments to enhance durability, such as UV protection and rot resistance. For paracord, this often involves a coating process, while shock cords may undergo a final inspection to ensure the integrity of their elastic properties.

– Packaging also occurs at this stage, where products are labeled and prepared for shipment, ensuring they meet international shipping regulations.

How Is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) is critical in the manufacturing processes of both paracord and shock cord. Implementing stringent QA measures helps ensure that products meet industry standards and customer expectations.

Illustrative image related to paracord vs shock cord

What International Standards Apply to Paracord and Shock Cord Manufacturing?

-

ISO 9001

– This international standard outlines the criteria for a quality management system. Manufacturers of both paracord and shock cord should be ISO 9001 certified, which demonstrates their commitment to quality and continuous improvement. -

Industry-Specific Standards

– CE Marking: In Europe, products must meet certain safety standards, which is indicated by the CE mark. This is particularly relevant for shock cords used in safety applications.

– API Standards: For shock cords used in industrial applications, adherence to API (American Petroleum Institute) standards may be required, especially in sectors like oil and gas.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are essential for maintaining product integrity throughout the manufacturing process:

-

Incoming Quality Control (IQC)

– This initial checkpoint involves inspecting raw materials for compliance with specifications. Tests may include tensile strength and elasticity measurements, which are crucial for both paracord and shock cord. -

In-Process Quality Control (IPQC)

– During the manufacturing process, continuous monitoring is conducted to ensure that production parameters remain within acceptable limits. This includes checking dimensions and material properties at various stages. -

Final Quality Control (FQC)

– After production, a final inspection is performed on the finished products. This includes stress testing and inspections for defects, such as fraying or inconsistencies in elasticity.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure their suppliers maintain robust quality control practices. Here are several effective strategies:

-

Supplier Audits

– Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This includes reviewing their certifications, production capabilities, and adherence to international standards. -

Requesting Quality Reports

– Buyers should request quality assurance reports that detail the results of tests conducted during production. These reports should include data on tensile strength, elasticity, and compliance with relevant standards. -

Third-Party Inspections

– Engaging third-party inspection services can further validate a supplier’s quality claims. These inspections can include material testing and random sampling of finished products to ensure they meet specified standards.

What Nuances Should International Buyers Consider in Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is essential. Here are some factors to consider:

-

Regional Compliance

– Each region may have specific regulations governing the import and sale of paracord and shock cords. Buyers should familiarize themselves with these regulations to avoid compliance issues. -

Cultural Differences in Quality Expectations

– Quality standards may vary significantly across cultures. Understanding local expectations can help buyers communicate their quality needs effectively and ensure that suppliers are aligned with those expectations. -

Supply Chain Transparency

– Building transparent relationships with suppliers can facilitate better communication regarding quality issues. This is particularly important in regions where supply chains may be less regulated, as it allows for proactive problem-solving.

Conclusion

In-depth knowledge of the manufacturing processes and quality assurance practices for paracord and shock cord is vital for B2B buyers. By understanding each stage of production, relevant international standards, and effective verification methods, buyers can make informed decisions that ensure they source high-quality products. This knowledge not only aids in selecting reliable suppliers but also helps in building strong, compliant partnerships that meet the demands of diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘paracord vs shock cord’

To effectively navigate the procurement of paracord and shock cord, this guide provides a structured checklist for B2B buyers. By following these steps, you can ensure that you make informed decisions that align with your operational needs and budget.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical to sourcing the right type of cord. Determine the required tensile strength, diameter, and material type for your specific applications. For example, paracord typically ranges from 550 lb to over 2,600 lb tensile strength, while shock cord is known for its elastic properties.

- Consider usage scenarios: Will the cord be used for outdoor activities, load securing, or crafting?

- Identify material preferences: Nylon is common for paracord, while shock cord often includes rubber.

Step 2: Understand the Differences Between Paracord and Shock Cord

Before proceeding, ensure you fully understand the differences between these two types of cords. Paracord is known for its strength and versatility, making it suitable for a variety of tasks, from survival gear to crafting. Shock cord, on the other hand, excels in applications requiring elasticity and shock absorption, such as securing cargo.

- Evaluate elasticity needs: If your application requires stretching, shock cord is preferable.

- Assess durability requirements: Paracord is often more abrasion-resistant, making it suitable for outdoor conditions.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in paracord and shock cord. Look for suppliers with a strong reputation in your region, especially if you are sourcing from Africa, South America, the Middle East, or Europe.

Illustrative image related to paracord vs shock cord

- Check industry certifications: Ensure suppliers adhere to quality standards relevant to your industry.

- Review product offerings: Examine their range of products to ensure they meet your specifications.

Step 4: Request Samples for Evaluation

Before making a bulk purchase, request samples from your shortlisted suppliers. This step allows you to physically assess the quality, texture, and performance of the cords.

- Perform strength tests: Assess the tensile strength and elasticity of the samples.

- Evaluate usability: Ensure the cords meet your practical needs in real-world applications.

Step 5: Verify Supplier Certifications

It is crucial to verify that your chosen suppliers hold the necessary certifications to ensure product quality and safety. Look for certifications like ISO or other relevant industry standards that validate their manufacturing processes.

- Assess compliance with regional standards: Different regions may have specific regulations governing cord manufacturing.

- Request documentation: Ensure that the supplier can provide proof of their certifications.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations to finalize pricing, payment terms, and delivery schedules.

- Compare quotes: Evaluate multiple suppliers to ensure you are getting a competitive price.

- Discuss bulk discounts: Inquire about pricing breaks for larger orders, which can significantly impact your budget.

Step 7: Establish a Quality Assurance Process

After placing your order, it’s essential to have a quality assurance process in place. This ensures that the cords delivered meet your predefined specifications and quality standards.

- Plan for inspections: Schedule inspections at various stages of production and upon delivery.

- Set clear return policies: Understand the supplier’s return policies in case the products do not meet your expectations.

By following this checklist, you can streamline your procurement process and ensure that you select the right type of cord for your business needs.

Illustrative image related to paracord vs shock cord

Comprehensive Cost and Pricing Analysis for paracord vs shock cord Sourcing

Understanding the cost structure and pricing dynamics of paracord versus shock cord is essential for international B2B buyers looking to optimize their sourcing strategies. This analysis will break down the key cost components, price influencers, and offer actionable tips for buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Paracord and Shock Cord?

-

Materials: The primary cost driver for both types of cord is the raw materials used in production. Paracord, typically made from nylon, offers high tensile strength and durability, while shock cord is usually rubber or elasticized material, which provides stretchability. The quality of materials directly impacts the final price.

-

Labor: Labor costs can vary significantly based on the region of production. Countries with lower labor costs may offer competitive pricing, but quality and craftsmanship should not be compromised. Skilled labor is particularly crucial for ensuring consistent quality in both paracord and shock cord.

-

Manufacturing Overhead: This includes costs associated with production facilities, equipment maintenance, and utility expenses. Manufacturers with advanced technology may have higher overheads but can achieve better efficiency and product quality.

-

Tooling: Custom tooling for specific cord designs or sizes can add to the initial costs. Buyers seeking unique specifications should factor in these additional costs when negotiating prices.

-

Quality Control (QC): Implementing stringent QC measures can increase costs but is essential for maintaining product quality, especially for buyers in regulated markets. Certifications such as ISO can also affect pricing due to the added costs of compliance.

-

Logistics: Shipping and handling costs play a vital role, especially for international transactions. Factors such as distance, shipping mode, and customs duties can significantly influence the total cost.

-

Margin: Supplier margins can vary based on market demand and competition. Buyers should understand the typical margins within their target region to better negotiate prices.

What Factors Influence Pricing for Paracord and Shock Cord?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Suppliers may offer tiered pricing based on volume, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom specifications, such as color, length, or tensile strength, can lead to higher costs. Buyers should clearly define their needs to avoid unexpected price increases.

-

Material Quality and Certifications: Higher quality materials and certifications can justify higher prices. Buyers should assess the trade-off between cost and quality to ensure they meet their specific application needs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their products due to perceived reliability and customer service.

-

Incoterms: Understanding shipping terms is crucial. Incoterms dictate who is responsible for shipping costs, insurance, and other logistics, influencing the total landed cost of products.

What Are Effective Buyer Tips for Cost-Efficiency?

-

Negotiate Terms: Always negotiate pricing and payment terms. Suppliers may offer discounts for upfront payments or larger orders, which can lower the total cost.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also factors like shipping, handling, and potential quality issues. A lower initial price may not always translate to lower overall costs.

-

Understand Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local market conditions. Buyers from regions such as Africa and South America should also consider the impact of local economic factors on pricing.

-

Conduct Supplier Audits: Before finalizing contracts, conducting audits on potential suppliers can ensure they meet quality and reliability standards. This step can prevent costly mistakes in the supply chain.

Conclusion

In summary, comprehensively analyzing the cost structure and pricing influences of paracord versus shock cord can empower B2B buyers to make informed sourcing decisions. By understanding the key components of cost, negotiating effectively, and considering the total cost of ownership, buyers can optimize their procurement strategies and secure the best value for their investments.

Alternatives Analysis: Comparing paracord vs shock cord With Other Solutions

Exploring Alternatives to Paracord and Shock Cord

In the world of durable cords and ropes, paracord and shock cord stand out due to their strength and versatility. However, various alternatives can offer distinct advantages depending on specific applications, performance requirements, and budget constraints. Understanding these alternatives is crucial for international B2B buyers looking to make informed decisions tailored to their unique needs.

| Comparison Aspect | Paracord Vs Shock Cord | Bungee Cord | Nylon Rope |

|---|---|---|---|

| Performance | High tensile strength, limited stretch | Excellent elasticity and shock absorption | Strong, less elastic but durable |

| Cost | Moderate pricing | Generally lower cost | Varies, often economical |

| Ease of Implementation | Easy to handle and manipulate | Simple to use for quick applications | Requires knots or splicing skills |

| Maintenance | Low maintenance, resistant to UV and rot | Moderate, can degrade over time | Low, but can absorb moisture |

| Best Use Case | Camping, survival gear, crafting | Securing loads, outdoor sports | Heavy-duty applications, marine use |

What Are the Advantages and Disadvantages of Bungee Cords?

Bungee cords are known for their impressive elasticity, which allows them to stretch significantly while absorbing shock. They are ideal for securing loads, especially in transport scenarios where movement is expected. However, their rubber composition can make them less durable over time, particularly when exposed to harsh UV conditions. Bungee cords are typically more affordable than paracord and shock cord, making them an attractive option for temporary or lightweight applications.

How Does Nylon Rope Compare to Paracord and Shock Cord?

Nylon rope is a robust alternative that offers considerable strength and durability. It is particularly suitable for heavy-duty applications such as marine use or construction. Unlike paracord and shock cord, nylon rope generally does not provide much elasticity, making it less suitable for tasks requiring shock absorption. The cost of nylon rope can vary, but it often remains economical, especially for bulk purchases. However, it requires skill in knot tying or splicing for effective use, which may pose a challenge for some users.

Illustrative image related to paracord vs shock cord

Conclusion: How to Choose the Right Cord for Your Needs

When selecting between paracord, shock cord, and their alternatives, B2B buyers must evaluate their specific requirements, including performance expectations, budget limitations, and application contexts. For outdoor enthusiasts and survivalists, paracord’s strength and versatility may be paramount. Conversely, businesses needing to secure loads might prefer the elasticity of bungee cords. Lastly, for heavy-duty applications, nylon rope could be the best fit due to its durability. By understanding the strengths and weaknesses of each option, buyers can make informed decisions that align with their operational needs.

Essential Technical Properties and Trade Terminology for paracord vs shock cord

What Are the Key Technical Properties of Paracord and Shock Cord?

Understanding the essential technical properties of paracord and shock cord is crucial for B2B buyers looking to select the right product for their applications. Here are several critical specifications to consider:

-

Material Composition

Paracord is primarily made from nylon, which provides high tensile strength and durability, making it suitable for various outdoor and survival applications. Shock cord, on the other hand, typically consists of rubber or elastic materials covered with a protective sheath. This composition allows shock cord to stretch significantly, making it ideal for applications requiring elasticity and shock absorption, such as securing loads or creating bungee systems. -

Tensile Strength

Tensile strength is a measure of how much weight a cord can bear before breaking. Paracord is available in various tensile strengths, with the most common being 550 lb (Type III). This makes it suitable for heavy-duty tasks like towing or lashing gear. Shock cords vary in tensile strength as well; for example, a 1/4” shock cord can handle up to 210 lb. Understanding tensile strength is vital for B2B buyers to ensure that the selected cord can handle the intended load without risk of failure. -

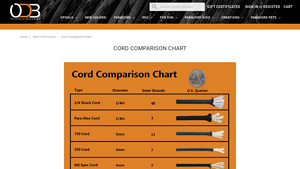

Diameter

The diameter of the cord influences its strength and flexibility. Paracord typically ranges from 1.18 mm to 5 mm, while shock cords can range from 1/32″ to 1/4″. A thicker cord may offer greater strength but can be less flexible, which is a consideration for specific applications like crafting or securing items. Buyers must assess the required diameter based on the intended use to ensure optimal performance. -

Elasticity

Elasticity refers to the ability of a cord to stretch and return to its original shape. Shock cords are designed to stretch significantly, which is essential for applications like bungee cords or cargo nets. In contrast, paracord is less elastic and is better suited for tasks requiring stability and strength, such as constructing shelters. Buyers should choose based on whether they need stretchability or rigidity. -

UV and Abrasion Resistance

Both paracord and shock cord should ideally be resistant to UV light and abrasion, especially for outdoor applications. Paracord is known for its UV resistance, which prolongs its life in harsh conditions. Shock cords may also feature protective sheaths to guard against wear and tear. This resistance is essential for B2B buyers in industries like outdoor gear manufacturing, where product durability is paramount.

What Are Common Trade Terms Associated with Paracord and Shock Cord?

Familiarity with trade terminology is crucial for smooth negotiations and transactions. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of paracord and shock cord, buyers might seek OEM suppliers for customized products tailored to specific applications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for B2B buyers to gauge inventory costs and manage budgets effectively, especially when sourcing materials like paracord or shock cord for large projects. -

RFQ (Request for Quotation)

An RFQ is a document that buyers use to invite suppliers to bid on specific products or services. This is particularly useful when sourcing paracord and shock cord, as it allows buyers to compare prices and terms from multiple suppliers before making a decision. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers involved in importing or exporting paracord and shock cord to ensure clarity on shipping costs, risks, and responsibilities. -

Lead Time

Lead time refers to the time between placing an order and receiving the product. This is a critical factor for B2B buyers, as longer lead times can impact production schedules and project timelines. Buyers should inquire about lead times when sourcing paracord and shock cord to ensure they meet their operational needs. -

Certification

Certification refers to the process of verifying that a product meets specific standards or regulations. For paracord and shock cord, certifications may include safety and quality standards that ensure the product’s reliability and performance. Buyers should prioritize sourcing certified products to ensure compliance and quality assurance in their applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing paracord and shock cord, ensuring that they select the right products for their specific applications and requirements.

Illustrative image related to paracord vs shock cord

Navigating Market Dynamics and Sourcing Trends in the paracord vs shock cord Sector

What are the Current Market Dynamics and Key Trends in the Paracord and Shock Cord Sector?

The global market for paracord and shock cord is experiencing significant growth, driven by increasing outdoor recreational activities, military applications, and DIY crafting trends. The versatility of these cords makes them essential in various sectors, including camping, fishing, and emergency preparedness. Key trends include the rise of e-commerce platforms facilitating international trade, particularly in regions like Africa, South America, the Middle East, and Europe. Buyers are increasingly seeking high-quality materials with specific tensile strengths, such as 550 lb. paracord, known for its durability and flexibility.

Emerging technologies in manufacturing, including advancements in synthetic fibers and eco-friendly production methods, are shaping sourcing strategies. International B2B buyers are prioritizing suppliers who leverage these technologies to enhance product quality while reducing lead times. Additionally, the demand for customization is on the rise, with businesses looking for tailored solutions that fit unique project requirements. This trend is particularly relevant in markets like Nigeria and Vietnam, where local craftsmanship meets global standards.

How is Sustainability and Ethical Sourcing Affecting the Paracord and Shock Cord Market?

Sustainability has become a focal point for B2B buyers in the paracord and shock cord sector. The environmental impact of production processes is under scrutiny, prompting businesses to seek suppliers that adhere to ethical sourcing practices. This includes using recycled materials and ensuring that production methods minimize waste and energy consumption. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® are increasingly important, as they assure buyers of the product’s sustainability credentials.

Ethical supply chains not only enhance brand reputation but also meet the growing consumer demand for environmentally responsible products. As international buyers from regions like South America and Europe increasingly emphasize sustainability, suppliers must adapt their offerings to include ‘green’ materials. For example, paracord made from recycled nylon or shock cord that uses bio-based elastomers can appeal to eco-conscious clients. In this evolving landscape, transparency in the supply chain and the ability to trace the origin of materials will differentiate successful suppliers from their competitors.

What is the Brief Evolution and History of Paracord and Shock Cord in the B2B Context?

The origins of paracord date back to World War II when it was used in military parachutes due to its lightweight and robust design. Its versatility led to its adoption for various civilian applications, including camping and survival gear. Shock cord, or bungee cord, was developed later, primarily for use in securing loads and providing tension in various applications. Over the years, both types of cord have evolved significantly, with advancements in materials and manufacturing processes enhancing their performance and durability.

In the B2B context, the evolution of these cords reflects changing market demands and technological advancements. The rise of outdoor recreational activities and DIY projects has expanded their application, creating new opportunities for suppliers. As international trade continues to grow, understanding the historical context of these products helps buyers appreciate their value and the innovations that drive their current market presence.

Frequently Asked Questions (FAQs) for B2B Buyers of paracord vs shock cord

-

1. How do I choose between paracord and shock cord for my business needs?

When selecting between paracord and shock cord, consider the specific applications you have in mind. Paracord, known for its high tensile strength and minimal stretch, is ideal for tasks requiring durability, such as securing gear or building structures. In contrast, shock cord offers significant elasticity, making it suitable for applications that involve dynamic loads, like bungee systems or securing cargo. Analyze your project’s requirements, including weight capacity, flexibility, and environmental conditions, to make an informed decision. -

2. What is the best paracord type for outdoor survival kits?

For outdoor survival kits, 550 paracord is often regarded as the best option due to its impressive 550 lb. tensile strength and versatility. It can be used for a variety of tasks, including shelter construction, gear repair, and crafting essential items like bracelets or lanyards. Additionally, look for military-grade options that undergo rigorous testing for strength and durability. Evaluate the specific needs of your target market to ensure the selected paracord type meets their expectations for quality and performance. -

3. What are the key factors to consider when sourcing paracord and shock cord internationally?

When sourcing paracord and shock cord, consider factors such as supplier reliability, product quality, and compliance with international standards. Research potential suppliers thoroughly, checking their certifications, customer reviews, and production capabilities. Additionally, assess their ability to provide customization options, minimum order quantities (MOQs), and favorable payment terms. Lastly, understand the logistics involved in shipping to your region, including tariffs, import regulations, and delivery timelines to ensure a smooth procurement process. -

4. How can I verify the quality of paracord and shock cord from suppliers?

To verify the quality of paracord and shock cord, request samples from potential suppliers before making bulk purchases. Conduct tensile strength tests and evaluate the materials used in manufacturing. It’s also beneficial to ask for certifications that demonstrate compliance with industry standards, such as ISO or ASTM. Additionally, consider third-party testing for assurance, especially if your market demands high-quality products for safety-critical applications. -

5. What customization options should I look for when sourcing paracord and shock cord?

When sourcing paracord and shock cord, inquire about customization options such as color, diameter, tensile strength, and packaging. Many suppliers offer the ability to create custom lengths or blend different materials to meet specific application needs. Additionally, consider branding options like custom labels or packaging that can enhance your product’s marketability. Ensure that the supplier can accommodate your requests while maintaining quality and efficiency in production. -

6. What are the typical minimum order quantities (MOQs) for paracord and shock cord?

Minimum order quantities (MOQs) can vary significantly among suppliers based on their production capabilities and the type of cord being ordered. Generally, MOQs for paracord and shock cord can range from 500 to 5,000 meters or units. It is advisable to negotiate with suppliers, especially if you are looking to establish a long-term relationship or if you are placing a first order. Understanding the MOQ will help you manage your inventory and cash flow effectively. -

7. What payment terms are commonly offered by suppliers for paracord and shock cord?

Payment terms for sourcing paracord and shock cord typically range from 30% upfront deposit and 70% upon shipment to full payment in advance. Some suppliers may offer more flexible terms for established customers, including net 30 or net 60 days. It is crucial to discuss payment options during negotiations to ensure they align with your cash flow management. Additionally, consider using secure payment methods to protect your financial transactions. -

8. How can logistics impact my sourcing of paracord and shock cord?

Logistics play a critical role in the timely delivery of paracord and shock cord. Factors such as shipping methods, lead times, customs clearance, and transportation costs can significantly impact your overall procurement process. Ensure that your supplier has a reliable logistics partner and can provide transparent shipping timelines. Also, consider potential disruptions, such as geopolitical issues or natural disasters, that may affect logistics. Planning for these variables will help you maintain a steady supply chain and meet your customers’ demands.

Top 5 Paracord Vs Shock Cord Manufacturers & Suppliers List

1. Bushcraft USA – Cordage Solutions

Domain: bushcraftusa.com

Registered: 2008 (17 years)

Introduction: This company, Bushcraft USA – Cordage Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Reddit – Shock Cord

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Shock cord is a type of elastic cord that resembles paracord but functions similarly to bungee cord. It is commonly used in outdoor gear, such as backpacks and pouches for securing items. Shock cord is smaller in diameter than traditional bungee cord and can often be found in fabric stores under the name ‘elastic cord.’ It is available online and at outdoor retailers like REI. Unlike paracord, whi…

3. Outdoor Bunker – 1/4” Shock Cord

Domain: outdoorbunker.com

Registered: 2007 (18 years)

Introduction: [{‘name’: ‘1/4” Shock Cord’, ‘description’: ‘Dependable, tough and long lasting. Used for bungee straps, cargo nets, hammocks, securing items.’, ‘certification’: ‘Certified Type III Nylon’, ‘tensile_strength’: ‘210-pound’, ‘inner_strands’: ’48’, ‘diameter’: ‘1/4in’, ‘features’: [‘Absorbs Shock’, ‘Rot Resistance’, ‘UV Fading Resistance’, ‘Durable’, ‘Made in the USA’]}, {‘name’: ‘750 Paracord’, ‘des…

4. Stapll – Bungee Cords & Paracord

Domain: stapll.com

Registered: 2021 (4 years)

Introduction: This company, Stapll – Bungee Cords & Paracord, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Paracord Planet – 550 Paracord

Domain: paracordplanet.com

Registered: 2011 (14 years)

Introduction: {“paracords”: [{“name”: “550 Paracord”, “tensile_strength”: “550 lb.”, “diameter”: “4 mm”, “inner_strands”: “7”, “description”: “Most popular variety, great balance of strength and flexibility, used for crafting bracelets, repairing clothing, etc.”}, {“name”: “Nano Paracord”, “tensile_strength”: “36 lb.”, “diameter”: “0.75 mm”, “inner_strands”: “0”, “description”: “Thinnest cord, used for crafting…

Strategic Sourcing Conclusion and Outlook for paracord vs shock cord

How Can Strategic Sourcing Enhance Your Procurement of Paracord and Shock Cord?

In the competitive landscape of international B2B procurement, understanding the nuances between paracord and shock cord can significantly impact your sourcing strategy. Paracord is celebrated for its high tensile strength and versatility, making it an ideal choice for survival kits and outdoor applications. In contrast, shock cord excels in elasticity, making it perfect for securing loads and applications requiring shock absorption.

Strategic sourcing not only involves selecting the right material but also ensuring reliable suppliers who can provide consistent quality and timely delivery. Establishing strong relationships with manufacturers can lead to favorable pricing and terms, critical for maximizing profitability in emerging markets across Africa, South America, the Middle East, and Europe.

Illustrative image related to paracord vs shock cord

Looking ahead, as global demand for durable and multifunctional materials grows, investing in quality paracord and shock cord will be pivotal. Engage with suppliers who understand local market dynamics and can cater to your specific requirements. By leveraging strategic sourcing, you can enhance operational efficiency and drive value for your business. Take the next step in your procurement journey by evaluating your current suppliers and exploring new partnerships that align with your growth objectives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to paracord vs shock cord

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.