The Definitive Guide to Outdoor Burn Barrel: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for outdoor burn barrel

Navigating the global market for outdoor burn barrels presents a unique challenge for B2B buyers seeking reliable solutions for waste management and outdoor burning needs. With increasing regulations around waste disposal and a growing emphasis on environmental sustainability, sourcing efficient burn barrels has never been more critical. This guide aims to provide a comprehensive overview of outdoor burn barrels, including various types, applications, and key considerations for supplier vetting and cost evaluation.

International buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Vietnam and Nigeria—will find actionable insights tailored to their specific needs. By examining product features such as material durability, incineration efficiency, and safety mechanisms, this guide empowers businesses to make informed purchasing decisions. Additionally, it highlights the importance of understanding local regulations and market dynamics, ensuring that buyers select products that not only meet their operational requirements but also adhere to compliance standards.

In a competitive landscape, leveraging the insights provided here will enable businesses to optimize their procurement strategies, ultimately leading to enhanced operational efficiency and sustainability in waste management practices.

Understanding outdoor burn barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Steel Barrel | Simple design, typically made from repurposed oil drums | Waste management, agriculture | Pros: Cost-effective; Cons: Less durable, prone to rust. |

| Stainless Steel Incinerator | High-temperature resistance, patented airflow system | Industrial waste disposal, document incineration | Pros: Long-lasting, efficient burn; Cons: Higher initial investment. |

| Burn Cage | Open design for easy access, often portable | Yard waste disposal, landscaping | Pros: Versatile, lightweight; Cons: Less effective in containing smoke. |

| Multi-Use Fire Pit | Dual functionality as a fire pit and burn barrel | Recreational use, outdoor events | Pros: Aesthetic appeal, social use; Cons: Limited waste capacity. |

| Portable Burn Barrel | Compact, lightweight, designed for mobility | Remote site waste management | Pros: Easy transport; Cons: Smaller burn capacity. |

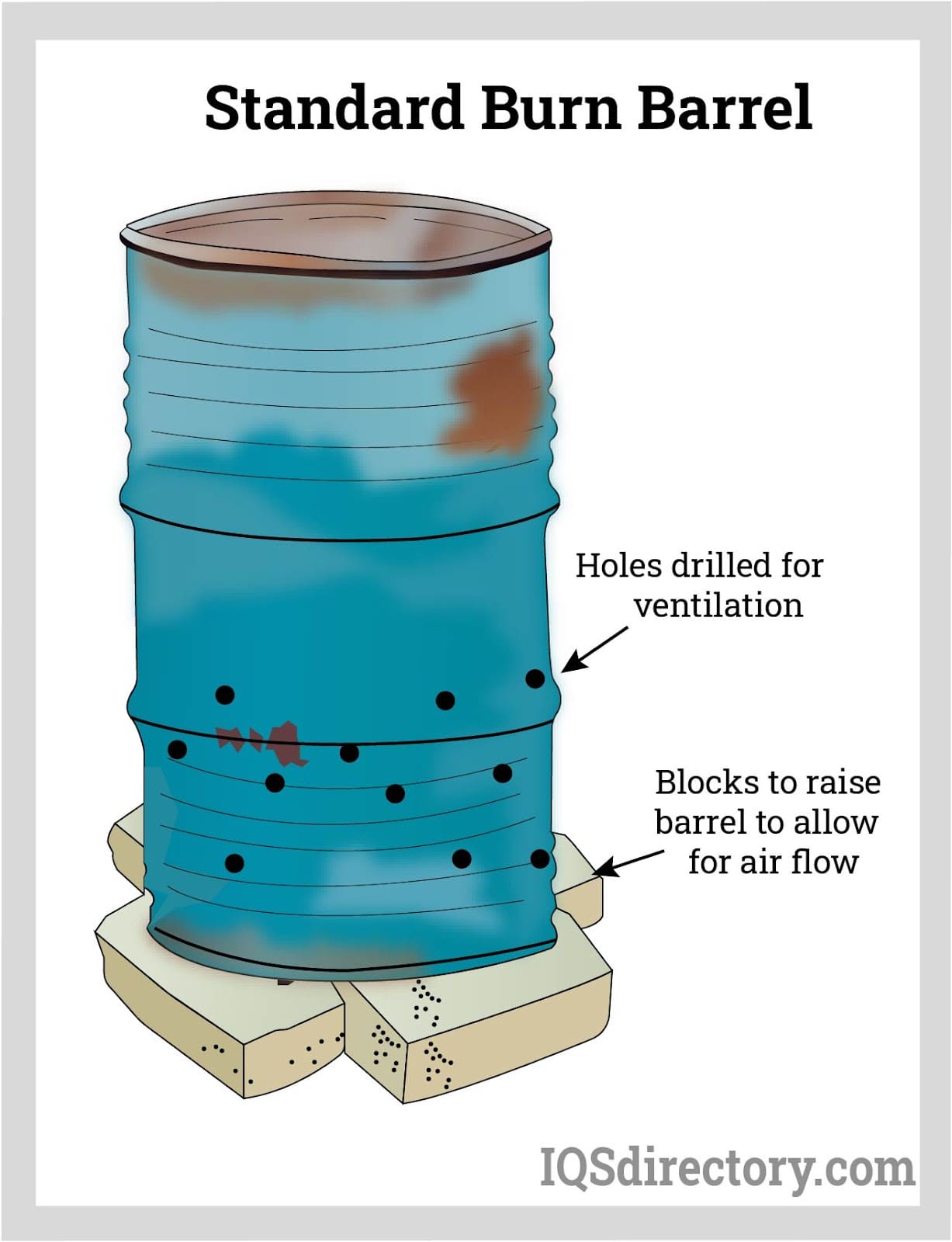

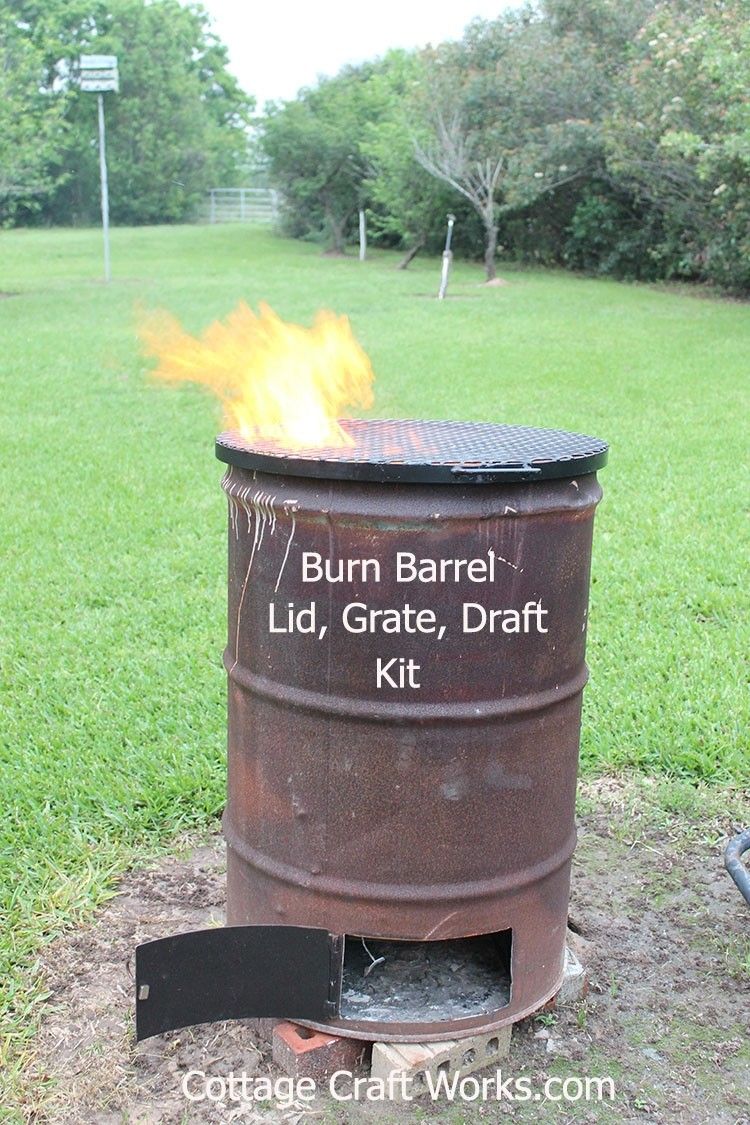

What Are the Characteristics of Traditional Steel Barrels?

Traditional steel barrels are often repurposed oil drums, characterized by their simple cylindrical design. They are widely used in agricultural settings for burning waste materials like leaves and small branches. While they are cost-effective and readily available, their durability is a concern; they can rust and degrade over time, making them less suitable for long-term use. B2B buyers should consider the frequency of use and environmental conditions when opting for this type.

Illustrative image related to outdoor burn barrel

Why Choose a Stainless Steel Incinerator?

Stainless steel incinerators are engineered for high performance, featuring patented airflow systems that facilitate a hotter burn, often exceeding 1800°F. This type is ideal for industrial waste disposal and secure document incineration, ensuring a cleaner and more efficient burning process. Although the initial investment is higher, their longevity and reduced maintenance costs make them a wise choice for businesses looking to manage waste sustainably. Buyers should evaluate their waste volume and incineration needs when considering this option.

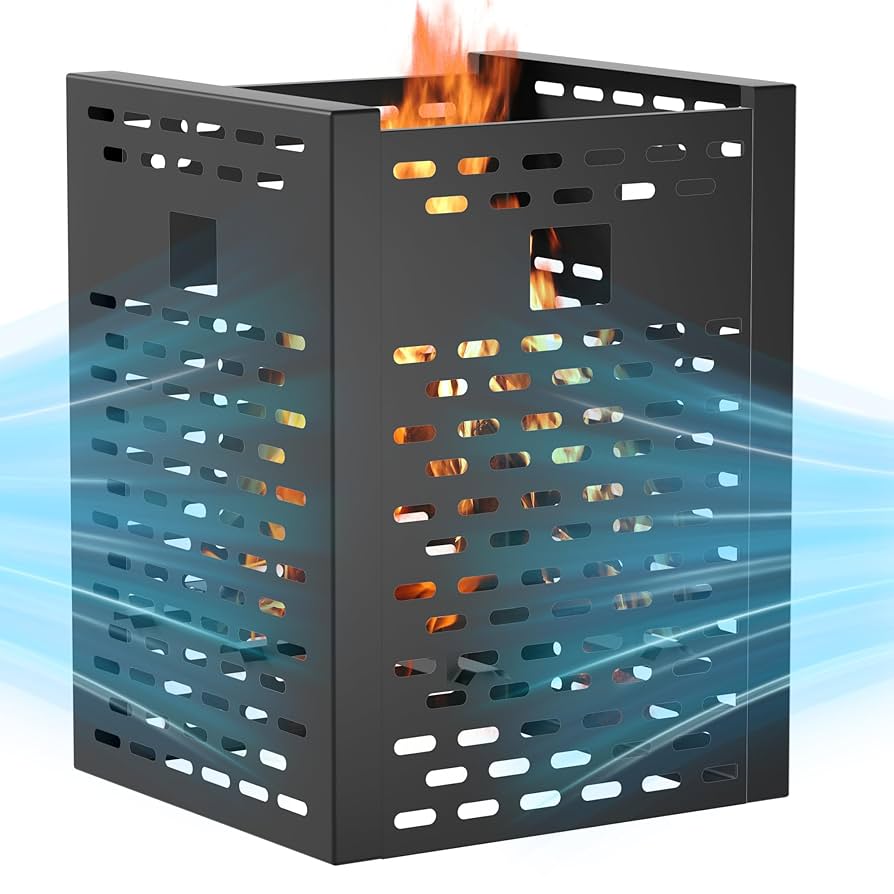

How Do Burn Cages Benefit Landscaping Businesses?

Burn cages are designed with an open structure that allows for easy access and efficient burning of yard waste. Their lightweight and portable nature makes them suitable for landscaping companies and gardening services that need to dispose of debris on-site. While they offer versatility, they may not effectively contain smoke, which could be a concern for businesses operating in urban areas with strict air quality regulations. Buyers should assess the local regulations and specific waste disposal needs before purchasing.

What Are the Advantages of Multi-Use Fire Pits?

Multi-use fire pits serve a dual purpose, functioning both as a burn barrel and a recreational fire pit. This makes them particularly appealing for outdoor event planners and hospitality businesses that want to create a welcoming atmosphere while managing waste. Although they offer aesthetic benefits and can enhance social gatherings, their limited capacity for burning waste may not meet the demands of larger operations. Businesses should consider their primary use case when evaluating this option.

Illustrative image related to outdoor burn barrel

Why Opt for Portable Burn Barrels?

Portable burn barrels are compact and designed for mobility, making them ideal for remote site waste management, such as construction or agricultural projects. Their lightweight design allows for easy transport to various locations, providing flexibility for businesses that operate in multiple areas. However, their smaller burn capacity may be a drawback for larger waste disposal needs. B2B buyers should weigh the convenience of mobility against the volume of waste they typically handle.

Key Industrial Applications of outdoor burn barrel

| Industry/Sector | Specific Application of outdoor burn barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Disposal of agricultural waste | Efficiently manages crop residues and debris, reducing landfill costs. | Durability, capacity, and compliance with local environmental regulations. |

| Construction | Site waste management | Minimizes site clutter and enhances safety by reducing fire hazards. | Size, mobility, and ability to handle specific types of waste materials. |

| Municipal Services | Public waste incineration | Provides a solution for local municipalities to manage waste sustainably. | Cost-effectiveness, capacity, and adherence to community health standards. |

| Forestry | Burning of forest debris and slash | Helps in land clearing and fire prevention, promoting healthier ecosystems. | Resistance to high temperatures, ease of transport, and regulatory compliance. |

| Disaster Relief | Emergency waste disposal during crises | Quickly addresses waste issues in disaster-stricken areas, aiding recovery efforts. | Portability, ease of use, and availability of replacement parts. |

How is the outdoor burn barrel utilized in agriculture for waste management?

In the agricultural sector, outdoor burn barrels serve as a vital tool for the disposal of organic waste, such as crop residues, dead plants, and other debris. By incinerating these materials, farmers can efficiently reduce waste volume and minimize the risk of pests and diseases that thrive in decomposing matter. For international buyers, particularly in regions like Africa and South America, it is essential to ensure that the burn barrels comply with local environmental regulations regarding emissions and waste management practices.

What role do outdoor burn barrels play in construction waste management?

Construction sites often generate significant amounts of waste, including wood scraps, packaging, and other debris. Outdoor burn barrels provide a practical solution for managing this waste on-site, helping to keep the area tidy and reducing fire hazards associated with accumulated materials. When sourcing burn barrels for construction applications, businesses should consider their size and mobility to ensure they meet the specific demands of different job sites, especially in remote areas.

How can municipal services benefit from using outdoor burn barrels?

Municipal services can employ outdoor burn barrels as part of their waste management strategies to incinerate non-recyclable materials safely. This approach not only helps in reducing landfill use but also contributes to cleaner air and a more sustainable environment. For B2B buyers in the public sector, it is crucial to evaluate the cost-effectiveness of these solutions, their capacity, and how well they align with community health standards and regulations.

Illustrative image related to outdoor burn barrel

Why are outdoor burn barrels essential in forestry operations?

In forestry, outdoor burn barrels are commonly used for the controlled burning of slash and other forest debris. This practice aids in land clearing and reduces the risk of uncontrolled wildfires, promoting healthier forest ecosystems. Buyers in the forestry sector should focus on burn barrels that can withstand high temperatures and are compliant with local fire safety regulations, ensuring both efficacy and safety during use.

How do outdoor burn barrels facilitate disaster relief operations?

During disaster relief efforts, outdoor burn barrels become crucial for the rapid disposal of waste generated in affected areas. They provide a quick and efficient means to manage debris, which can otherwise pose health risks and hinder recovery operations. For organizations involved in disaster relief, sourcing portable and user-friendly burn barrels is vital, as is ensuring a ready supply of replacement parts to maintain operational efficiency in challenging environments.

3 Common User Pain Points for ‘outdoor burn barrel’ & Their Solutions

Scenario 1: Ensuring Compliance with Local Regulations

The Problem: In many regions, B2B buyers, especially those in waste management or agricultural sectors, face challenges related to compliance with local environmental regulations governing outdoor burning. Regulations can vary significantly between countries and even regions within a country, creating confusion and potential legal issues. Buyers may struggle to find burn barrels that meet these specific regulations, risking fines and reputational damage.

The Solution: To navigate these regulatory landscapes, B2B buyers should first conduct thorough research on local laws regarding outdoor burning. This can involve consulting government websites, local environmental agencies, or industry associations. When sourcing burn barrels, opt for products that explicitly state compliance with local standards. Look for certifications or approvals that demonstrate adherence to environmental regulations. Additionally, consider engaging with suppliers who offer expert guidance on compliance, ensuring that the chosen burn barrel meets all necessary legal requirements. This proactive approach not only mitigates risk but also positions the buyer as a responsible business leader in their community.

Scenario 2: Managing Smoke and Air Quality Concerns

The Problem: One of the most common complaints about outdoor burn barrels is the excessive smoke they can produce, which can lead to air quality issues and community complaints. B2B buyers in sectors such as landscaping or construction, where waste materials are frequently burned, may find their operations hindered by the need to limit smoke emissions. This not only affects operational efficiency but can also lead to strained relationships with local communities.

Illustrative image related to outdoor burn barrel

The Solution: To tackle smoke and air quality concerns, buyers should invest in burn barrels designed for high-efficiency combustion. Look for models that feature advanced airflow systems, which facilitate a hotter burn and result in less smoke. Suppliers that offer products with this technology can help buyers ensure cleaner burning practices. Additionally, implementing best practices for burning, such as using dry materials and avoiding the burning of plastics or treated wood, can significantly reduce smoke output. By prioritizing cleaner burning solutions, buyers can enhance their operational efficiency while improving their environmental footprint and community relations.

Scenario 3: Durability and Longevity of Burn Barrels

The Problem: Many B2B buyers encounter issues with the durability of standard burn barrels, which can warp or degrade over time, leading to costly replacements and operational downtime. This is particularly problematic for businesses that rely on consistent waste disposal methods, such as those in the agricultural or construction sectors. The need for frequent replacements can disrupt workflows and negatively impact budgets.

The Solution: To overcome durability challenges, B2B buyers should focus on sourcing burn barrels made from high-quality materials, specifically 100% stainless steel, which resists warping and corrosion. When evaluating potential suppliers, request information about the materials used in their products and any warranties or guarantees offered. Additionally, consider suppliers that provide customer testimonials or case studies demonstrating long-term performance. Investing in a more durable burn barrel may involve a higher upfront cost, but the long-term savings from reduced replacements and maintenance can significantly enhance overall profitability. By prioritizing quality, buyers can ensure reliable, long-lasting solutions that support their operational needs.

Strategic Material Selection Guide for outdoor burn barrel

When selecting materials for outdoor burn barrels, it is essential to consider various factors such as durability, temperature resistance, and corrosion resistance. The choice of material directly influences the performance, longevity, and safety of the burn barrel, making it a critical decision for B2B buyers. Here, we analyze four common materials used in the construction of outdoor burn barrels: steel, stainless steel, aluminum, and cast iron.

What are the Key Properties of Steel for Outdoor Burn Barrels?

Steel is one of the most widely used materials for outdoor burn barrels due to its strength and availability. It has a high melting point, typically around 2,500°F (1,370°C), which allows it to withstand intense heat from burning waste. However, standard steel is prone to rust and corrosion when exposed to moisture and the elements.

Pros: Steel is relatively inexpensive and easy to manufacture, making it a cost-effective choice for many manufacturers. It is also readily available and can be easily sourced in various forms.

Cons: The primary drawback of steel is its susceptibility to rust, which can significantly reduce the lifespan of the burn barrel. Additionally, without proper treatment or coatings, steel can warp under high temperatures.

Impact on Application: Steel burn barrels are suitable for general waste burning but may require regular maintenance to prevent corrosion. Buyers in humid climates, such as parts of Africa and South America, should consider this factor seriously.

How Does Stainless Steel Compare for Burn Barrel Applications?

Stainless steel is an upgraded option that offers superior corrosion resistance and durability compared to standard steel. With a melting point similar to that of steel, stainless steel can withstand high temperatures while maintaining its structural integrity.

Illustrative image related to outdoor burn barrel

Pros: The primary advantage of stainless steel is its resistance to rust and corrosion, making it ideal for outdoor use. It also has a sleek appearance and is easier to clean, which can be appealing for buyers focused on aesthetics.

Cons: The main disadvantage is the higher cost associated with stainless steel, which can be a barrier for some buyers. Additionally, the manufacturing process can be more complex, leading to longer lead times.

Impact on Application: Stainless steel burn barrels are suitable for various waste types, including organic materials. International buyers should note compliance with local regulations regarding waste incineration, as stainless steel barrels often meet higher safety standards.

What are the Benefits and Limitations of Aluminum for Burn Barrels?

Aluminum is lightweight and has a good resistance to corrosion, making it a viable option for outdoor burn barrels. Its melting point is lower than that of steel, around 1,220°F (660°C), which may limit its use in high-temperature applications.

Illustrative image related to outdoor burn barrel

Pros: The lightweight nature of aluminum makes it easy to transport and handle. It is also resistant to rust, which can be beneficial in humid environments.

Cons: The lower melting point means that aluminum burn barrels may not be suitable for burning high-temperature materials, limiting their application. Additionally, aluminum can be more expensive than standard steel.

Impact on Application: Aluminum burn barrels are best suited for lighter waste materials. Buyers should consider their specific burning needs and whether the lower temperature tolerance of aluminum aligns with those needs.

Why is Cast Iron a Consideration for Burn Barrels?

Cast iron is known for its exceptional durability and heat retention properties. It can withstand high temperatures, with a melting point around 2,600°F (1,426°C), making it a robust choice for outdoor burn barrels.

Illustrative image related to outdoor burn barrel

Pros: Cast iron is incredibly durable and can last for many years with proper care. It also provides excellent heat retention, which can enhance the efficiency of the burning process.

Cons: The main drawback is the weight of cast iron, which can make transportation and handling more challenging. Additionally, it can be more expensive due to the manufacturing process.

Impact on Application: Cast iron burn barrels are ideal for heavy-duty applications and can handle a wide variety of waste types. Buyers in regions with stringent regulations may find that cast iron barrels meet compliance standards more effectively than lighter materials.

Summary of Material Selection for Outdoor Burn Barrels

| Material | Typical Use Case for outdoor burn barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General waste burning | Cost-effective and widely available | Prone to rust and warping | Low |

| Stainless Steel | Versatile waste incineration | Corrosion-resistant and durable | Higher cost and complex manufacturing | High |

| Aluminum | Lightweight waste disposal | Lightweight and rust-resistant | Lower melting point limits application | Medium |

| Cast Iron | Heavy-duty waste burning | Exceptional durability and heat retention | Heavy and more expensive | High |

This guide provides a comprehensive overview of material options for outdoor burn barrels, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

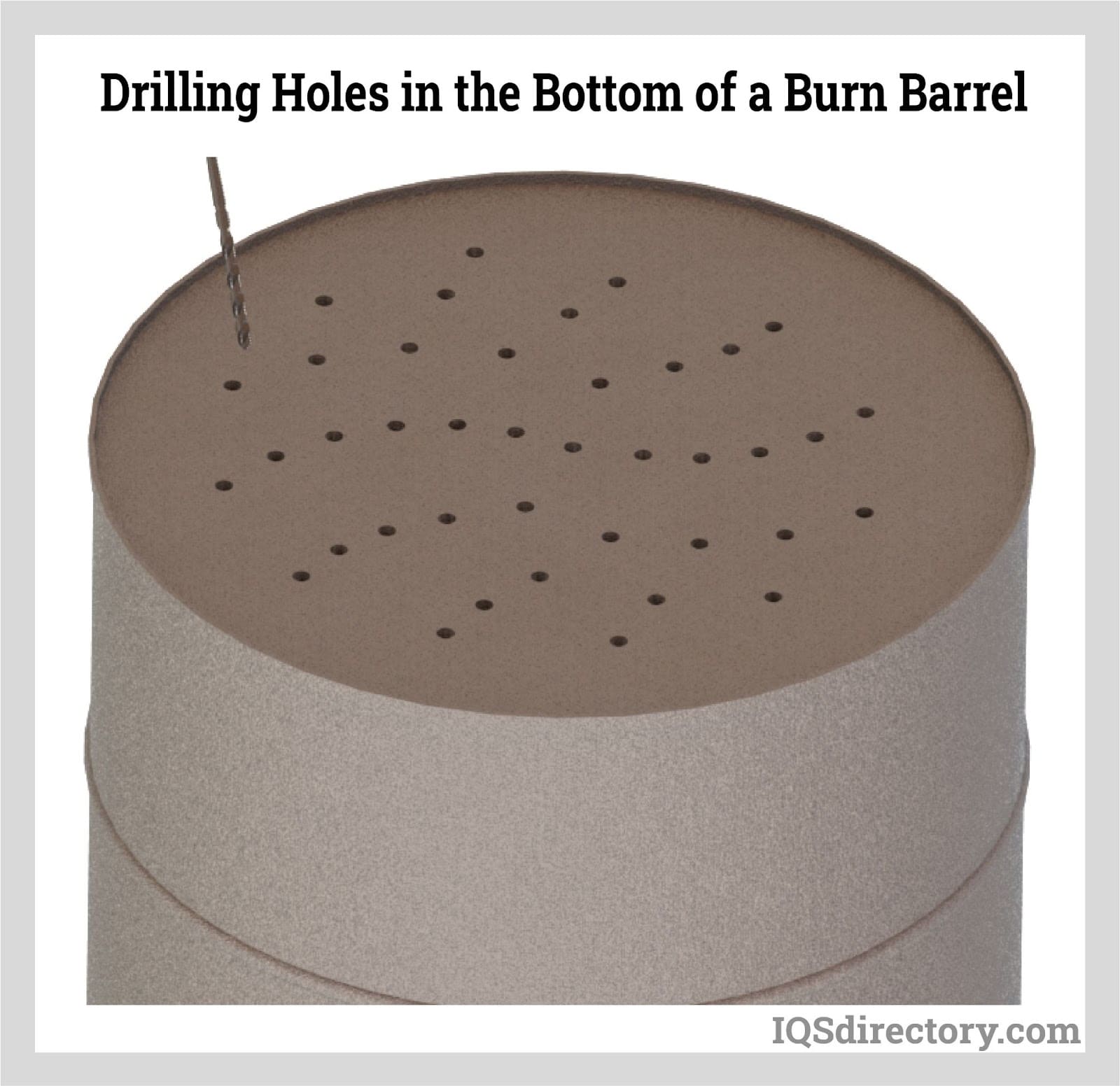

In-depth Look: Manufacturing Processes and Quality Assurance for outdoor burn barrel

What Are the Main Stages in the Manufacturing Process of Outdoor Burn Barrels?

The manufacturing process of outdoor burn barrels typically consists of several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets safety and performance standards.

Illustrative image related to outdoor burn barrel

How Is Material Prepared for Burn Barrel Production?

Material preparation involves selecting the right type of metal, often stainless steel, due to its durability and resistance to warping at high temperatures. Suppliers should ensure that the metal is sourced from reputable manufacturers that comply with international standards. The metal sheets are then cut to size using precision machinery, minimizing waste and ensuring uniformity.

What Techniques Are Used in the Forming Stage of Burn Barrels?

In the forming stage, the cut metal sheets undergo processes such as bending, rolling, and welding to create the barrel’s cylindrical shape. Advanced techniques like laser cutting and CNC machining are commonly employed to achieve high precision. These methods not only enhance the structural integrity of the burn barrel but also contribute to its aesthetic appeal.

How Is the Assembly Process Structured for Burn Barrels?

The assembly process integrates various components, including the barrel body, lid, and any additional features such as airflow systems or ash catchers. Skilled laborers or automated systems typically perform this assembly, ensuring that each part fits correctly and functions as intended. Rigorous checks during assembly help identify any misalignments or defects early in the production line.

What Finishing Techniques Are Commonly Used for Outdoor Burn Barrels?

Finishing involves applying protective coatings or treatments to enhance corrosion resistance and improve the burn barrel’s longevity. This may include powder coating or galvanization, depending on the intended use and environmental conditions. Quality control measures are crucial during this stage to ensure that the finish is uniform and meets all specifications.

What International Standards Should B2B Buyers Consider for Quality Assurance?

Quality assurance in the production of outdoor burn barrels is paramount, especially for international B2B transactions. Buyers should look for compliance with relevant international standards such as ISO 9001, which outlines criteria for a quality management system. This certification indicates that the manufacturer adheres to consistent quality processes.

How Do Industry-Specific Standards Affect Quality Control for Burn Barrels?

In addition to ISO certifications, industry-specific standards like CE marking in Europe and API standards for materials can significantly influence quality assurance practices. CE marking ensures that products meet safety, health, and environmental protection requirements, while API standards are crucial for materials used in combustion applications. Buyers should verify that suppliers hold these certifications.

What Are the Key Quality Control Checkpoints in Burn Barrel Manufacturing?

Quality control checkpoints are vital to maintaining product standards throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Ensures raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): Monitors production processes to detect and correct issues in real time.

- Final Quality Control (FQC): Conducts thorough inspections of the finished product to ensure it meets all specifications and performance standards.

What Testing Methods Are Commonly Used to Ensure Burn Barrel Quality?

Common testing methods for burn barrels include:

- Pressure Testing: Ensures that the structure can withstand high temperatures without compromising safety.

- Thermal Imaging: Evaluates heat distribution during operation to confirm efficient burning.

- Corrosion Resistance Testing: Assesses the longevity of coatings and materials under various environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify a supplier’s quality control processes. This can include:

Illustrative image related to outdoor burn barrel

- Conducting Audits: Regular audits of the manufacturing facility can provide insights into quality management practices.

- Requesting Quality Reports: Suppliers should be able to provide documentation of their quality assurance processes, including test results and compliance certifications.

- Third-Party Inspections: Engaging independent inspectors can help validate that the supplier adheres to international quality standards.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance. Factors such as varying regulations, import/export standards, and local environmental conditions can influence product quality. Buyers should familiarize themselves with local compliance requirements and work closely with suppliers to ensure that products meet both international and regional standards.

How Can Buyers Navigate Certification and Compliance Challenges?

Navigating certification and compliance challenges requires thorough research and collaboration with suppliers who understand both local and international regulations. Buyers may also consider partnering with local representatives or consultants who can provide insights into compliance nuances and facilitate smoother transactions.

Conclusion: Ensuring Quality in Outdoor Burn Barrel Manufacturing

Understanding the manufacturing processes and quality assurance measures for outdoor burn barrels is essential for B2B buyers looking to make informed purchasing decisions. By focusing on rigorous quality control standards, testing methods, and supplier verification practices, businesses can ensure that their investments yield durable and efficient products that meet their operational needs.

Illustrative image related to outdoor burn barrel

Practical Sourcing Guide: A Step-by-Step Checklist for ‘outdoor burn barrel’

This guide aims to provide international B2B buyers with a comprehensive checklist for sourcing outdoor burn barrels. Whether you are looking to procure for municipal waste management, agricultural purposes, or environmental compliance, following these steps will help ensure you make informed decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your burn barrels. Consider factors such as size, material (preferably stainless steel for durability), and combustion efficiency. Understanding your needs will streamline the selection process and ensure that the products meet local regulations and safety standards.

Step 2: Research Market Options

Conduct thorough market research to identify potential suppliers. Utilize online platforms, trade shows, and industry publications to gather information on various manufacturers and their offerings. Pay close attention to brands that are recognized for their quality and innovation, such as those with patented designs that enhance burn efficiency.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a solid reputation for customer service and reliability, as this can significantly impact your procurement process.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you are considering adhere to international quality standards and environmental regulations. Look for certifications such as ISO or CE, which indicate compliance with safety and environmental guidelines. This step not only protects your investment but also ensures that the products are safe for use in your intended application.

Illustrative image related to outdoor burn barrel

Step 5: Request Samples or Demonstrations

Whenever possible, request samples or arrange for demonstrations of the burn barrels you are considering. This will give you firsthand experience with the product’s quality, functionality, and efficiency. Observing the burn process can also help you assess whether the product meets your operational needs.

Step 6: Assess Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare pricing and payment terms. Look beyond the initial purchase price; consider factors such as shipping costs, bulk order discounts, and warranty options. Favor suppliers who offer flexible payment terms, as this can improve cash flow management for your business.

Step 7: Establish a Communication Plan

Finally, establish a clear communication plan with your chosen supplier. Ensure that you have designated points of contact for order tracking, support, and any potential issues that may arise post-purchase. Good communication is essential for a smooth transaction and can foster a long-term partnership.

By following this checklist, B2B buyers can make informed decisions when sourcing outdoor burn barrels, ensuring they select the right products for their specific needs while navigating the complexities of international procurement.

Comprehensive Cost and Pricing Analysis for outdoor burn barrel Sourcing

What Are the Key Cost Components in Outdoor Burn Barrel Production?

Understanding the cost structure for outdoor burn barrels is essential for B2B buyers aiming to negotiate effectively. The main cost components include:

Illustrative image related to outdoor burn barrel

-

Materials: The choice of materials significantly influences the overall cost. For instance, burn barrels made from high-grade stainless steel are more expensive but offer durability and better performance, especially in high-temperature conditions. Conversely, lower-quality materials can reduce initial costs but may lead to higher maintenance and replacement expenses.

-

Labor: Labor costs vary based on the manufacturing location and the complexity of the design. Skilled labor is often required for custom designs or advanced manufacturing processes, impacting the overall pricing.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these costs, but any inefficiencies may be passed on to the buyer.

-

Tooling: The initial investment in tools and molds for production can be significant, especially for custom models. Understanding the tooling costs can help buyers make informed decisions about ordering volumes.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the products meet safety and performance standards. While this incurs additional costs, it is crucial for maintaining brand reputation and minimizing returns.

-

Logistics: Shipping costs can vary widely based on the destination, shipping method, and weight of the barrels. It’s important to account for these when calculating total expenses.

-

Margin: Supplier profit margins will also affect pricing. Buyers should be aware of typical margins in the industry to negotiate effectively.

How Do Price Influencers Impact the Cost of Outdoor Burn Barrels?

Several factors influence the pricing of outdoor burn barrels, particularly in international markets:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Establishing a minimum order quantity (MOQ) with suppliers can help negotiate better pricing.

-

Specifications and Customization: Custom designs or specific features can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as safety and environmental compliance) can elevate prices. Buyers should assess the long-term benefits of investing in certified products versus cheaper alternatives.

-

Supplier Factors: Reputation, reliability, and past performance of suppliers can influence pricing. Established suppliers may charge more due to their experience and quality assurance practices.

-

Incoterms: The terms of trade (Incoterms) will determine who bears the costs and risks during transportation. Buyers should understand these terms to avoid unexpected charges that could inflate the overall cost.

What Are the Best Negotiation Tips for B2B Buyers?

Effective negotiation is key to achieving cost efficiency in purchasing outdoor burn barrels. Here are some actionable tips:

-

Research and Benchmarking: Understand market prices and compare multiple suppliers. This knowledge can empower buyers during negotiations.

-

Long-term Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Suppliers are often more willing to negotiate with repeat customers.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, lifespan, and operational efficiency. Investing in higher-quality products can yield better long-term savings.

-

Flexibility in Specifications: Be open to alternative materials or designs that may lower costs while still meeting functional requirements.

-

Timing Purchases: Take advantage of seasonal sales or supplier promotions. Timing can significantly impact pricing.

What Should International Buyers Consider Regarding Pricing Nuances?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding regional pricing nuances is crucial:

Illustrative image related to outdoor burn barrel

-

Currency Fluctuations: Be aware of exchange rate changes that can affect pricing. Consider pricing in a stable currency when negotiating.

-

Import Duties and Taxes: Research the applicable tariffs and taxes in your country. These can add significantly to the total cost.

-

Shipping and Delivery Times: International shipping can lead to delays. Ensure that suppliers can meet your timeline, as expedited shipping may incur additional costs.

-

Cultural Considerations: Understanding cultural norms in negotiation can enhance communication and foster better relationships with suppliers.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and due diligence when sourcing outdoor burn barrels.

Alternatives Analysis: Comparing outdoor burn barrel With Other Solutions

Exploring Alternative Solutions for Outdoor Waste Management

When considering waste disposal options, especially for outdoor settings, it’s essential to evaluate various methods and technologies available in the market. While outdoor burn barrels have been a traditional choice for incinerating waste, several alternatives offer different benefits and drawbacks. This analysis will compare outdoor burn barrels with incinerators and composting methods to help B2B buyers make informed decisions based on their specific needs.

| Comparison Aspect | Outdoor Burn Barrel | Incinerator | Composting |

|---|---|---|---|

| Performance | Effective for small-scale burning; smoke can be an issue | High-temperature burns reduce emissions; cleaner incineration | Converts organic waste into nutrient-rich compost; slow process |

| Cost | Generally low initial cost; ongoing costs for fuel | Higher upfront cost; low operating costs due to efficiency | Low-cost setup; potential savings on waste disposal |

| Ease of Implementation | Simple to set up; requires minimal space | Requires professional installation; larger footprint | Requires space and time to establish; ongoing management needed |

| Maintenance | Low maintenance; occasional cleaning needed | Low maintenance; periodic checks required | Requires regular turning and monitoring of moisture levels |

| Best Use Case | Ideal for small yards or farms; suitable for dry waste | Suitable for larger operations needing efficient waste disposal | Best for organic waste management in agricultural or garden settings |

What Are the Advantages and Disadvantages of Using an Incinerator?

Incinerators are a robust alternative to outdoor burn barrels, designed to handle a more significant volume of waste with higher efficiency. They operate at extremely high temperatures, which results in a cleaner burn and significantly reduced emissions compared to traditional burning methods. However, the initial investment can be quite high, and these systems often require professional installation. While maintenance is generally low, users must ensure periodic checks to maintain efficiency. Incinerators are best suited for businesses that produce a considerable amount of waste and seek a more environmentally friendly disposal method.

Illustrative image related to outdoor burn barrel

How Does Composting Compare to Burn Barrels?

Composting is another alternative that provides an eco-friendly solution for organic waste disposal. This method involves the biological decomposition of organic matter, resulting in nutrient-rich compost that can be used to enhance soil quality. The primary advantage of composting is its sustainability and cost-effectiveness, as it can turn waste into a valuable resource. However, it requires more time and space to implement and manage effectively. Composting is particularly suitable for agricultural businesses or landscaping companies looking to recycle organic waste while improving soil health.

Conclusion: Which Waste Management Solution is Right for Your Business?

Choosing the right waste management solution depends on various factors, including the type and volume of waste produced, budget constraints, and environmental considerations. Outdoor burn barrels offer a low-cost and straightforward solution for small-scale waste disposal, while incinerators provide a more efficient and cleaner alternative for larger operations. Composting, on the other hand, is ideal for businesses focused on sustainability and organic waste management. By carefully assessing these alternatives, B2B buyers can select the most appropriate method to meet their specific operational needs while adhering to environmental regulations.

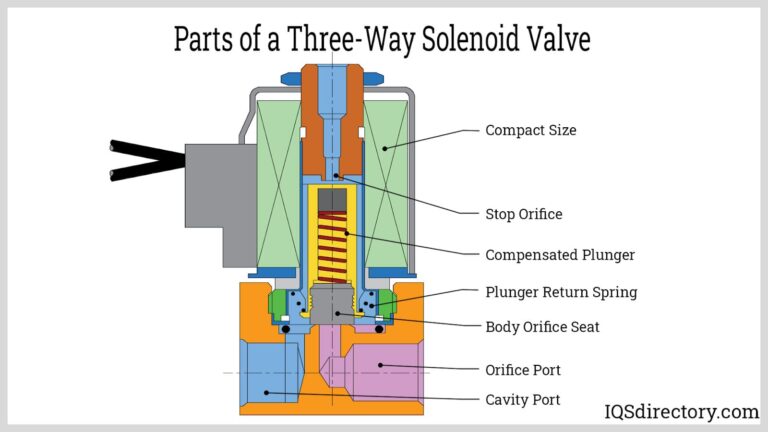

Essential Technical Properties and Trade Terminology for outdoor burn barrel

What Are the Key Technical Properties of an Outdoor Burn Barrel?

When selecting an outdoor burn barrel, several technical specifications are critical for ensuring efficiency, safety, and compliance with local regulations. Here are some essential properties to consider:

-

Material Grade

Burn barrels are typically constructed from various materials, with stainless steel being the most preferred due to its durability and resistance to corrosion. Stainless steel grades like 304 or 316 are often used because they can withstand high temperatures without warping, ensuring longevity. In a B2B context, the choice of material directly impacts maintenance costs and the overall lifespan of the product, making it a vital consideration for suppliers and distributors. -

Burn Temperature

The operational burn temperature of a barrel can significantly affect its efficiency. High-quality burn barrels can reach temperatures exceeding 1800°F, which facilitates complete combustion of waste materials. This is essential not only for reducing smoke emissions but also for compliance with environmental regulations. For B2B buyers, understanding burn temperatures helps in selecting products that meet local air quality standards. -

Airflow Design

The design of the burn barrel’s airflow system is crucial for an efficient burning process. A well-engineered airflow design allows for optimal oxygen intake, which enhances combustion efficiency and minimizes smoke production. This technical property is particularly important for businesses focused on sustainability and environmental responsibility, as it can reduce the carbon footprint associated with waste disposal. -

Capacity and Size

Burn barrels come in various sizes and capacities, typically ranging from small units suitable for residential use to larger models intended for industrial applications. Understanding capacity is essential for B2B buyers, as it dictates the volume of waste that can be processed at one time, influencing operational efficiency and cost-effectiveness. -

Safety Features

Safety is paramount in the design of burn barrels. Features such as flame arrestors, secure lids, and heat-resistant handles contribute to user safety and prevent accidental fires. For B2B buyers, investing in products with robust safety features can reduce liability and enhance customer satisfaction.

What Are Common Trade Terms Related to Outdoor Burn Barrels?

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some common terms you may encounter:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in assessing the quality and reliability of the burn barrels being procured. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B transactions, as it helps buyers understand the financial commitment required for purchasing burn barrels, allowing for better inventory management and budget planning. -

RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers to request pricing and terms for specific products or services. For businesses looking to procure burn barrels, issuing an RFQ can streamline the purchasing process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international trade. Understanding Incoterms is crucial for B2B buyers, as they dictate the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. -

Lead Time

This term refers to the time taken from placing an order to delivery. For B2B buyers, being aware of lead times for burn barrels helps in planning inventory and managing customer expectations effectively.

By understanding these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing outdoor burn barrels, ensuring they meet both operational needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the outdoor burn barrel Sector

What Are the Current Market Dynamics and Key Trends in the Outdoor Burn Barrel Sector?

The outdoor burn barrel market is experiencing significant growth, driven by a combination of environmental regulations, increasing awareness of waste management, and the rise of outdoor recreational activities. As global urbanization accelerates, particularly in regions like Africa, South America, and the Middle East, the demand for effective waste disposal solutions, including burn barrels, is rising. B2B buyers are increasingly seeking products that not only comply with local environmental regulations but also offer enhanced efficiency and safety features.

Emerging trends in the sector include the adoption of advanced materials, such as stainless steel, which provide durability and improved thermal efficiency. Innovations like patented airflow systems that enable hotter burns and reduced smoke emissions are becoming standard features. Additionally, international buyers are showing a preference for manufacturers who offer customization options to cater to local needs and regulations. The integration of technology, such as IoT-enabled burn barrels that monitor temperature and emissions, is also beginning to appear on the market, appealing to tech-savvy buyers.

Illustrative image related to outdoor burn barrel

Furthermore, the shift towards e-commerce platforms for procurement is reshaping the sourcing landscape. B2B buyers are leveraging online marketplaces to access a wider range of products, compare prices, and read customer reviews, facilitating informed purchasing decisions. This trend is particularly evident in regions with developing infrastructure, where traditional retail options may be limited.

How Is Sustainability and Ethical Sourcing Impacting the Outdoor Burn Barrel Market?

Sustainability has become a paramount concern for B2B buyers in the outdoor burn barrel sector. The environmental impact of burning waste, including emissions and potential harm to air quality, has led to increased scrutiny from both consumers and regulatory bodies. Companies that prioritize sustainable manufacturing practices and materials are likely to gain a competitive advantage. For instance, sourcing burn barrels made from recycled or sustainably produced materials can significantly reduce the overall environmental footprint.

Ethical sourcing is closely tied to sustainability, with a growing emphasis on transparency throughout the supply chain. Buyers are increasingly interested in knowing the origins of materials and the labor practices involved in production. Certifications such as ISO 14001 for environmental management and other ‘green’ labels can enhance a manufacturer’s appeal, signaling a commitment to responsible practices.

In addition, incorporating features that promote cleaner burning—such as designs that minimize smoke and maximize heat—aligns with the global shift towards environmentally friendly products. Buyers from regions like Europe and North America are particularly focused on these attributes, as they often face stricter regulations regarding waste management and emissions.

What Is the Historical Context of Outdoor Burn Barrels in B2B Markets?

The history of outdoor burn barrels dates back to the mid-20th century when they were primarily used for agricultural waste disposal and backyard burning. Over the decades, these products evolved from rudimentary designs to more sophisticated incinerators that prioritize efficiency and safety. The introduction of stainless steel and innovative designs, such as those that enhance airflow for hotter burns, marked a significant turning point in the industry.

In recent years, the focus has shifted towards compliance with environmental regulations and the promotion of sustainable practices. As awareness of air quality issues has increased, manufacturers have adapted their designs to meet these challenges, ensuring that modern burn barrels are not only effective but also environmentally responsible. This evolution continues to shape the market, influencing how B2B buyers approach their sourcing decisions today.

Frequently Asked Questions (FAQs) for B2B Buyers of outdoor burn barrel

-

How do I choose the right outdoor burn barrel for my business needs?

Choosing the right outdoor burn barrel involves considering several factors including size, material, and design. Stainless steel barrels offer durability and resistance to warping, making them ideal for long-term use. Assess your specific needs such as the volume of waste to be burned and the frequency of use. Additionally, look for features like efficient airflow systems that enhance combustion, resulting in cleaner emissions. Consulting with suppliers about their product specifications and customer reviews can also help ensure you make an informed decision. -

What are the benefits of using a burn barrel compared to other waste disposal methods?

Burn barrels provide an eco-friendly waste disposal solution by incinerating organic materials, reducing landfill contributions. They can efficiently handle yard debris, paper waste, and other combustible materials, with high burn temperatures ensuring complete incineration. Unlike traditional open burning, burn barrels minimize smoke emissions and contain flames, reducing the risk of wildfires. Furthermore, they can serve dual purposes, such as a backyard fire pit, adding versatility to your investment. -

What customization options are available for outdoor burn barrels?

Many manufacturers offer customization options to meet specific business needs. Customizations can include size adjustments, additional safety features, and unique designs that comply with local regulations. You may also find options for accessories such as ash catchers and cover arrestors that enhance functionality. When discussing customization with suppliers, be clear about your requirements and any regulatory compliance needed in your region to ensure optimal product performance. -

What is the typical minimum order quantity (MOQ) for outdoor burn barrels?

The MOQ for outdoor burn barrels can vary significantly by supplier and region. Typically, manufacturers may require a minimum order ranging from 10 to 50 units for bulk purchases, especially for custom designs. It’s advisable to inquire directly with suppliers about their MOQ policies, as some may offer flexibility for first-time buyers or smaller businesses. Understanding the MOQ can help you plan your inventory and budget accordingly, ensuring you meet your operational needs. -

How can I verify the credibility of a burn barrel supplier?

To verify a burn barrel supplier’s credibility, start by checking their business licenses and certifications. Look for reviews and testimonials from previous clients to gauge product quality and service reliability. Engaging with suppliers through direct communication can also provide insights into their customer service approach. Additionally, attending trade shows or industry conferences can offer opportunities to meet suppliers in person and assess their offerings firsthand, ensuring a trustworthy partnership. -

What are the payment terms commonly offered by burn barrel suppliers?

Payment terms can vary widely among suppliers, but common practices include upfront payment, net 30, or net 60 terms. International transactions may also involve payment methods like letters of credit or escrow services to ensure safety for both parties. It’s important to discuss and negotiate payment terms before finalizing orders, as favorable terms can significantly impact your cash flow and purchasing strategy. Understanding the supplier’s policies can also prevent potential misunderstandings later in the transaction process. -

How do logistics and shipping work for international orders of burn barrels?

When ordering burn barrels internationally, logistics and shipping considerations are crucial. Most suppliers will provide options for freight forwarding, which can include air or sea shipping depending on your urgency and budget. It’s essential to clarify shipping costs, delivery timelines, and potential customs duties before placing an order. Additionally, working with a logistics partner familiar with international trade can streamline the process, ensuring compliance with local regulations and timely delivery. -

What quality assurance measures should I expect from burn barrel manufacturers?

Reputable burn barrel manufacturers typically implement stringent quality assurance (QA) measures to ensure product durability and safety. This includes materials testing, adherence to safety standards, and inspection of finished products before shipping. Ask suppliers about their QA processes, including any certifications they hold, such as ISO standards. Understanding these measures can provide you with confidence in the product’s quality and longevity, ultimately protecting your investment.

Top 2 Outdoor Burn Barrel Manufacturers & Suppliers List

1. Reddit – Burn Barrels

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Burn barrels are used for burning yard waste such as twigs, small branches, and leaves. There are concerns about burning trash that contains plastics and Styrofoam due to health risks associated with inhaling smoke from these materials. The PACT Act of 2022 highlights health issues linked to burn pits, including various types of cancer and respiratory illnesses. Some users mention using burn barre…

2. IQS Directory – Burn Barrels

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Burn barrels are repurposed metal drums used for incinerating combustible waste. They are typically made from old 55-gallon drums and are designed for safety and effectiveness in waste disposal. Key types include: 1. Yard Waste Burn Barrels – Used for incinerating tree trimmings, grass clippings, and untreated wood debris. 2. Galvanized Garden Incinerators – Compact, efficient, and often made from…

Strategic Sourcing Conclusion and Outlook for outdoor burn barrel

As international B2B buyers continue to navigate the evolving landscape of waste management solutions, the strategic sourcing of outdoor burn barrels presents a significant opportunity. Key takeaways emphasize the importance of selecting high-quality, durable products that ensure efficient combustion and minimal environmental impact. Investing in advanced incineration technology, such as stainless steel designs with patented airflow systems, not only enhances operational efficiency but also supports compliance with increasingly stringent environmental regulations.

Illustrative image related to outdoor burn barrel

The value of strategic sourcing cannot be overstated; it allows businesses to leverage competitive pricing, ensure product availability, and foster long-term supplier relationships. By prioritizing suppliers that demonstrate innovation and commitment to sustainability, buyers can position themselves advantageously in the market.

Looking ahead, we encourage B2B buyers from Africa, South America, the Middle East, and Europe to engage with reputable manufacturers and distributors. Collaborating with industry leaders will not only enhance your product offerings but also contribute to a more sustainable future in waste management. Take the next step in optimizing your sourcing strategy and explore the potential of outdoor burn barrels today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.