The Definitive Guide to Merry Go Round For Sale: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for merry go round for sale

In the competitive landscape of playground equipment, sourcing high-quality merry-go-rounds for sale can pose significant challenges for international B2B buyers. Whether you’re a park manager in Africa, an educational institution in South America, or an amusement park operator in Europe, finding the right supplier requires a deep understanding of product specifications, safety standards, and pricing structures. This comprehensive guide is designed to navigate these complexities by providing insights into various types of merry-go-rounds, their applications, and essential considerations for selecting the right model for your needs.

From classic playground merry-go-rounds that encourage cooperative play among children to larger, themed carousel rides suitable for amusement parks, this guide covers a wide range of options. We delve into the nuances of supplier vetting, ensuring that you can identify manufacturers who meet international safety standards and offer durable products. Additionally, we explore cost factors, including pricing trends and budgeting tips, to help you make informed purchasing decisions.

By equipping you with the knowledge to assess quality, safety, and value, this guide empowers B2B buyers from diverse regions—such as Vietnam and Germany—to enhance their offerings with engaging and safe merry-go-rounds that cater to their specific market demands.

Understanding merry go round for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

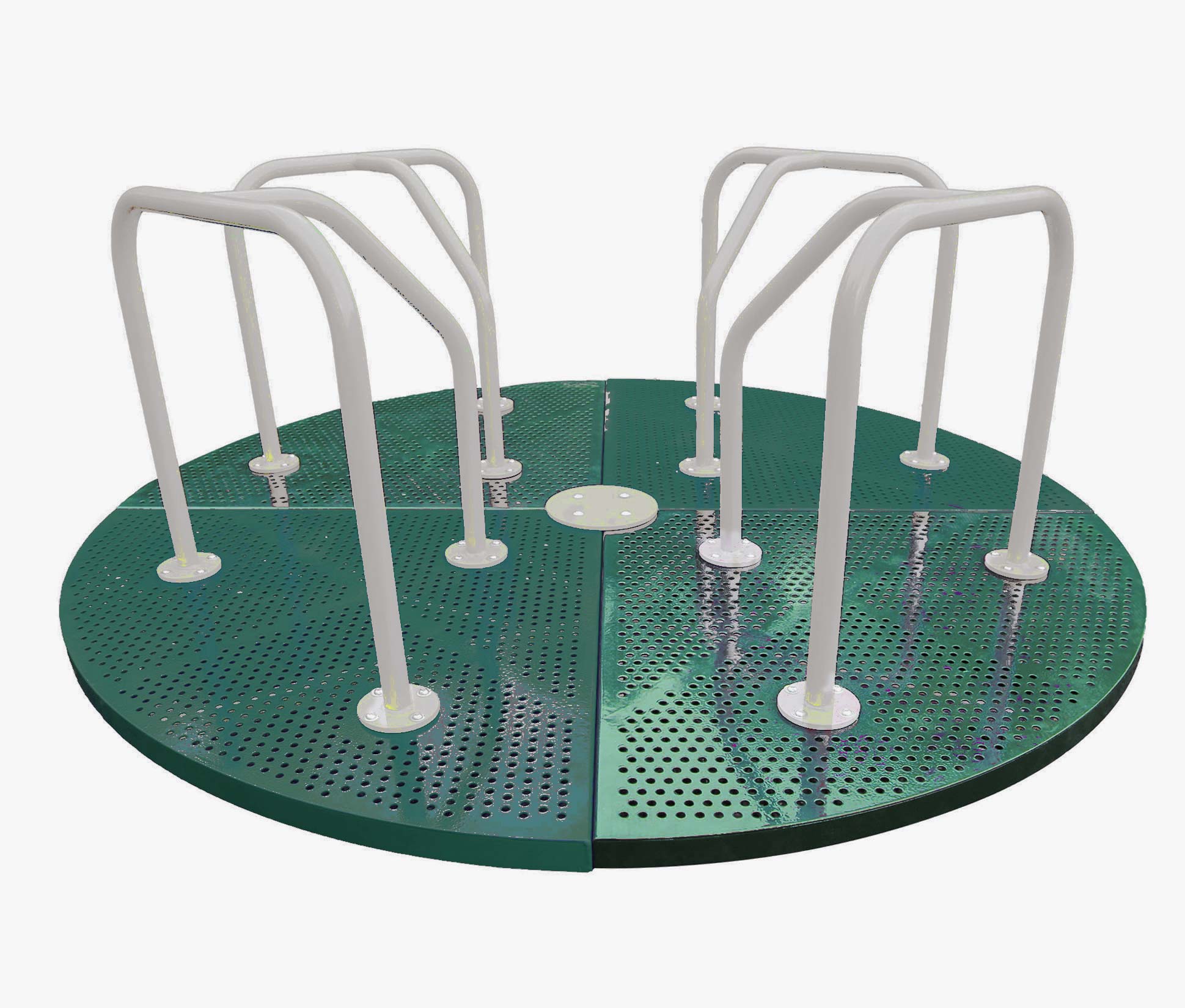

| Traditional Merry-Go-Round | Circular platform, typically for 6-10 children, manual operation | Schools, parks, daycare centers | Pros: Affordable, promotes cooperative play. Cons: Requires physical effort to spin. |

| Wheelchair Accessible Merry-Go-Round | Inclusive design for children with disabilities, sturdy construction | Inclusive playgrounds, community parks | Pros: Promotes inclusivity, meets ADA standards. Cons: Generally higher cost due to specialized design. |

| Themed Merry-Go-Round | Unique designs (e.g., animals, fairy tales), bright colors | Amusement parks, themed attractions | Pros: Attracts visitors, enhances park aesthetics. Cons: Higher maintenance costs, initial investment. |

| Mini Merry-Go-Round | Smaller size, designed for younger children, portable | Daycare centers, small playgrounds | Pros: Space-efficient, affordable. Cons: Limited capacity, not suitable for older children. |

| Double-Decker Merry-Go-Round | Two levels for seating, larger capacity, electric operation | Large amusement parks, fairs | Pros: High capacity, exciting experience. Cons: Requires more space and higher operational costs. |

What Are the Key Characteristics of Traditional Merry-Go-Rounds?

Traditional merry-go-rounds are classic playground staples, typically featuring a circular platform that accommodates 6 to 10 children. They are manually operated, requiring kids to run and push to gain speed before jumping on. These units are suitable for schools and parks where cooperative play is encouraged. When purchasing, consider the playground’s space requirements and ensure the equipment meets safety standards.

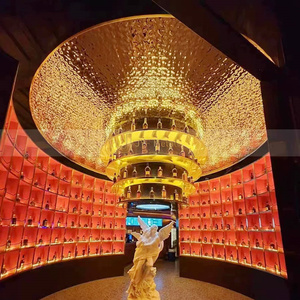

Illustrative image related to merry go round for sale

How Do Wheelchair Accessible Merry-Go-Rounds Promote Inclusivity?

Wheelchair accessible merry-go-rounds are specifically designed to accommodate children with disabilities, ensuring they can participate in play alongside their peers. These units often feature a low profile and sturdy construction, making them safe and easy to access. B2B buyers should prioritize these options for community parks and inclusive playgrounds, as they fulfill ADA requirements and foster an inclusive environment.

What Makes Themed Merry-Go-Rounds Attractive for Amusement Parks?

Themed merry-go-rounds feature unique designs, such as animal characters or fairy tale motifs, making them visually appealing and engaging for children. These rides are ideal for amusement parks and themed attractions as they enhance the overall experience and draw in visitors. Buyers should assess the durability of materials and maintenance costs, as these rides often require more upkeep due to their intricate designs.

Why Choose Mini Merry-Go-Rounds for Smaller Play Areas?

Mini merry-go-rounds are compact and designed specifically for younger children, making them a perfect fit for daycare centers and small playgrounds. Their smaller size allows for easy installation and portability. However, buyers should note their limited capacity, which may not be ideal for larger groups or older children. Cost-effectiveness and safety features are key considerations for B2B buyers in this category.

What Are the Benefits of Double-Decker Merry-Go-Rounds?

Double-decker merry-go-rounds offer a thrilling experience with two levels of seating and a larger capacity, making them suitable for large amusement parks and fairs. These rides are typically electrically operated, providing a smoother experience for users. However, B2B buyers should consider the space required for installation and the higher operational costs associated with maintenance and staffing for such rides.

Key Industrial Applications of merry go round for sale

| Industry/Sector | Specific Application of merry go round for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Installation in school playgrounds | Enhances physical activity and social interaction among students | Consider safety standards, age-appropriate designs, and durability for heavy use |

| Public Parks | Community playgrounds and recreational areas | Attracts families, encourages community engagement, and promotes healthy lifestyles | Evaluate space requirements, maintenance needs, and weather resistance of materials |

| Amusement Parks | Theme park attractions | Drives foot traffic and enhances the overall visitor experience | Focus on capacity, safety certifications, and customization options for branding |

| Childcare Facilities | Play equipment for daycare centers | Provides safe, engaging play options that foster development | Ensure compliance with safety regulations and accessibility features for inclusivity |

| Event Planning | Temporary installations for festivals and fairs | Offers entertainment options that draw crowds and enhance visitor satisfaction | Look for quick installation, transportability, and rental options for flexibility |

How Are Merry-Go-Rounds Used in Educational Settings?

In educational environments, merry-go-rounds are installed in school playgrounds to promote physical activity and social interaction among students. These installations encourage cooperative play, helping children develop teamwork skills while enjoying outdoor activities. For international buyers, especially in regions like Africa and South America, sourcing merry-go-rounds that meet local safety standards and cater to varying age groups is crucial. Durability is also a key consideration, as playground equipment must withstand frequent use.

What Role Do Merry-Go-Rounds Play in Public Parks?

In public parks, merry-go-rounds serve as focal points for community engagement and recreation. They attract families looking for safe, enjoyable activities for their children, thus promoting a healthy lifestyle. Buyers from Europe and the Middle East should consider the space requirements and maintenance needs of these installations. Additionally, selecting materials that are weather-resistant ensures longevity and reduces the need for frequent replacements.

Why Are Merry-Go-Rounds Essential for Amusement Parks?

Amusement parks utilize merry-go-rounds as essential attractions that enhance the overall visitor experience. These rides not only drive foot traffic but also provide entertainment that appeals to a wide audience, including families and children. For B2B buyers in this sector, it’s important to focus on the capacity of the rides, ensuring they can accommodate large groups. Safety certifications and customization options for branding purposes are also vital factors to consider during the sourcing process.

How Do Childcare Facilities Benefit from Merry-Go-Rounds?

Childcare facilities incorporate merry-go-rounds to provide safe and engaging play options that foster child development. These installations encourage physical activity and social interaction among young children, making them a valuable addition to any daycare center. For international buyers, compliance with safety regulations and the inclusion of accessibility features are key considerations. Additionally, ensuring that the equipment is designed for different age groups will enhance the play experience for all children.

What Are the Advantages of Using Merry-Go-Rounds in Event Planning?

In event planning, merry-go-rounds can be temporarily installed at festivals and fairs to provide entertainment options that draw crowds and enhance visitor satisfaction. This not only adds value to the event but also creates memorable experiences for attendees. Buyers should look for options that are easy to transport and set up, as well as those that offer rental possibilities for flexibility. Ensuring the rides are safe and engaging will also contribute to the overall success of the event.

3 Common User Pain Points for ‘merry go round for sale’ & Their Solutions

Scenario 1: Sizing Challenges for Diverse Playground Needs

The Problem: Many B2B buyers, particularly those in education or community development sectors, struggle with choosing the correct size of merry-go-round for their playground projects. With various age groups and play styles to accommodate, selecting a merry-go-round that fits the intended user demographics can be daunting. For instance, a community park may need to cater to both younger children and older kids, leading to uncertainty about whether to invest in a smaller, age-appropriate model or a larger, more versatile option.

The Solution: To effectively address this challenge, buyers should conduct a thorough needs assessment before making a purchase. This includes analyzing the age range of children who will use the playground, the available space, and the expected foot traffic. For instance, if a park primarily serves younger children, a smaller merry-go-round designed for toddlers would be more appropriate. Conversely, for schools where older children are prevalent, a larger model that can handle more users and higher speeds might be necessary. Consulting with manufacturers about the specifications and use cases of different models can provide additional insights. Furthermore, consider requesting demonstration units or visiting existing installations to observe how various sizes perform in real-world settings.

Scenario 2: Safety Compliance and Accessibility Concerns

The Problem: Ensuring safety and accessibility is paramount for playground equipment, yet many buyers feel overwhelmed by the myriad of safety standards and regulations. This is especially true for international buyers who may be unfamiliar with local safety compliance guidelines. A common concern is selecting a merry-go-round that not only meets safety standards but also accommodates children with disabilities, ensuring an inclusive play environment.

The Solution: To navigate safety compliance, buyers should familiarize themselves with local regulations and international safety standards (like ASTM and EN standards) relevant to playground equipment. Partnering with reputable manufacturers who can provide certification and compliance documentation is crucial. Moreover, investing in wheelchair-accessible merry-go-round models can significantly enhance inclusivity. These models typically feature lower platforms and secure harnessing systems, allowing all children to participate in group play. Before finalizing a purchase, request detailed safety reports and installation guidance from the supplier, ensuring that safety surfacing and surrounding space meet required safety zones.

Scenario 3: Budget Constraints and Cost-Effective Sourcing

The Problem: Budget limitations pose a significant barrier for many organizations looking to purchase playground equipment like merry-go-rounds. Buyers often face the dilemma of balancing quality with affordability, leading to concerns about sourcing cost-effective options without compromising safety and durability. This is particularly pertinent for buyers in regions with lower purchasing power, where maximizing every dollar spent is crucial.

The Solution: To overcome budget constraints, buyers should explore multiple sourcing strategies. First, consider bulk purchasing or forming partnerships with other local entities to negotiate better rates from manufacturers. Additionally, seeking out vendors that offer financing options or leasing arrangements can alleviate upfront cost pressures. Conducting market research to compare prices across various suppliers and exploring international shipping options may also reveal more affordable choices. Furthermore, investing in high-quality materials, even if initially more expensive, can lead to long-term savings by reducing maintenance costs and extending the lifespan of the equipment. Buyers should also inquire about warranties and post-purchase support, as these can significantly add value to the investment.

Strategic Material Selection Guide for merry go round for sale

What Are the Common Materials Used in Merry-Go-Rounds for Sale?

When it comes to selecting materials for merry-go-rounds, several options stand out due to their unique properties and suitability for various applications. Understanding these materials is crucial for international B2B buyers, especially when considering factors such as durability, cost, and compliance with local standards.

How Does Steel Perform as a Material for Merry-Go-Rounds?

Steel is one of the most common materials used in the construction of merry-go-rounds. It boasts high tensile strength and excellent durability, making it suitable for heavy loads and dynamic movements. Steel components can withstand significant wear and tear, which is essential for playground equipment.

Pros: Steel is highly durable and resistant to deformation under stress. It can be coated to enhance corrosion resistance, making it suitable for various climates, including humid or coastal environments.

Illustrative image related to merry go round for sale

Cons: The primary drawback of steel is its susceptibility to rust if not properly treated. Additionally, it can be heavier and more expensive than alternative materials, which may affect manufacturing complexity and shipping costs.

Impact on Application: Steel merry-go-rounds are ideal for high-traffic areas such as parks and schools, where they must endure continuous use.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure that the steel used complies with local safety standards and regulations, such as ASTM or EN standards.

What Role Does Plastic Play in Merry-Go-Round Construction?

Plastic, particularly high-density polyethylene (HDPE), is increasingly used in merry-go-rounds due to its lightweight and corrosion-resistant properties. It is often used for seats and other components.

Pros: Plastic is resistant to moisture, UV rays, and chemicals, making it an excellent choice for outdoor use. It is also lightweight, which simplifies installation and reduces transportation costs.

Illustrative image related to merry go round for sale

Cons: While plastic is durable, it may not withstand as much weight or impact as steel. Over time, exposure to harsh weather can lead to fading or brittleness.

Impact on Application: Plastic merry-go-rounds are suitable for younger children and daycare settings, where safety and ease of use are paramount.

Considerations for International Buyers: Buyers should verify that the plastic materials meet safety certifications relevant to their region, such as JIS in Japan or EN in Europe.

How Does Fiberglass Compare for Merry-Go-Round Applications?

Fiberglass is another material option, particularly for decorative elements and structural components. It offers a unique combination of strength and aesthetic appeal.

Illustrative image related to merry go round for sale

Pros: Fiberglass is lightweight yet strong, resistant to corrosion, and can be molded into various shapes and designs. Its aesthetic versatility makes it attractive for theme parks.

Cons: The manufacturing process for fiberglass can be complex and costly. Additionally, it may require specialized knowledge for repairs and maintenance.

Impact on Application: Fiberglass is often used in themed merry-go-rounds where design is a priority, making it suitable for amusement parks.

Illustrative image related to merry go round for sale

Considerations for International Buyers: Buyers should ensure that the fiberglass used complies with fire safety standards and other relevant regulations in their respective countries.

What About Composite Materials for Merry-Go-Rounds?

Composite materials, which combine various substances to enhance performance, are also gaining traction in merry-go-round construction. These materials can offer improved durability and reduced weight.

Pros: Composites can be engineered for specific performance characteristics, such as enhanced impact resistance and lower maintenance needs. They are also resistant to moisture and UV damage.

Cons: The cost of composite materials can be higher than traditional options, and they may not be as readily available in some regions.

Impact on Application: Composites are suitable for high-end installations where performance and aesthetics are critical.

Considerations for International Buyers: Buyers should check for compliance with international safety standards and consider the availability of composite materials in their local markets.

Summary of Material Selection for Merry-Go-Rounds

| Material | Typical Use Case for merry go round for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-traffic parks and schools | High durability and strength | Susceptible to rust without treatment | High |

| Plastic | Daycare centers and playgrounds | Lightweight and corrosion-resistant | May fade or become brittle over time | Medium |

| Fiberglass | Themed amusement parks | Aesthetic versatility and strength | Complex manufacturing process | High |

| Composite | High-end installations | Customizable performance features | Higher cost and availability issues | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in merry-go-rounds, helping them make informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for merry go round for sale

What Are the Key Stages in the Manufacturing Process of Merry-Go-Rounds?

The manufacturing process of merry-go-rounds involves several critical stages, each designed to ensure durability, safety, and aesthetic appeal. Understanding these stages can help B2B buyers make informed decisions when sourcing playground equipment.

Illustrative image related to merry go round for sale

Material Preparation: What Materials Are Used for Merry-Go-Round Manufacturing?

The first step in the manufacturing process is the preparation of materials. High-quality merry-go-rounds are typically constructed from robust materials such as high-grade steel, fiberglass, and durable plastic. Steel is often used for the frame due to its strength and resistance to weather conditions, while fiberglass offers a lightweight yet sturdy option for decorative elements and seating.

Before fabrication, materials undergo rigorous quality checks to ensure they meet industry standards. Suppliers often source materials from certified vendors, ensuring compliance with international standards. This step is crucial for establishing a foundation of quality that will support the entire manufacturing process.

How Are Merry-Go-Rounds Formed and Assembled?

Once materials are prepared, the next step is forming. This involves cutting, welding, and shaping the steel components. Advanced techniques such as CNC machining may be employed for precision cutting, ensuring that each piece fits perfectly. The forming stage is critical; any inconsistencies can lead to safety concerns or premature wear.

Following forming, the assembly stage begins. Components are meticulously put together, often with a focus on modular design, allowing for easier maintenance and repair. Quality control checks are performed at this stage to ensure that all parts are securely fastened and aligned correctly. This is where manufacturers can incorporate custom designs or features, such as wheelchair-accessible options, which are increasingly in demand.

What Finishing Techniques Are Commonly Used in Merry-Go-Round Manufacturing?

The finishing stage of manufacturing is vital for both aesthetics and protection. Merry-go-rounds undergo processes such as powder coating or painting to enhance durability and prevent rust. These finishes not only improve the visual appeal but also provide an additional layer of safety by reducing sharp edges and surfaces.

Manufacturers often utilize environmentally friendly paints and coatings to comply with international regulations, making the products safer for children and the environment. This is particularly important for B2B buyers in regions with stringent safety regulations, such as Europe.

What International Standards and Quality Assurance Protocols Apply to Merry-Go-Round Manufacturing?

Quality assurance is a non-negotiable aspect of the merry-go-round manufacturing process. To meet international standards, many manufacturers adhere to ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards signifies that a company is committed to quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE marking (European Conformity) and API (American Petroleum Institute) standards may apply, especially for materials and components used in merry-go-rounds. These certifications ensure that the products meet safety and performance requirements set by regulatory bodies.

What Are the Key Quality Control Checkpoints in Merry-Go-Round Manufacturing?

Quality control checkpoints are integral to ensuring the final product is safe and reliable. These checkpoints typically include:

Illustrative image related to merry go round for sale

-

Incoming Quality Control (IQC): This initial checkpoint involves testing raw materials for compliance with specifications before they enter the production line. Ensuring high-quality materials can significantly reduce defects later in the process.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to verify that the assembly and finishing processes adhere to predefined standards. This stage helps catch any discrepancies early, allowing for immediate corrective actions.

-

Final Quality Control (FQC): Once assembly is complete, the final product undergoes comprehensive testing, including load tests and safety inspections, to ensure it meets all required standards. This step is crucial for B2B buyers who need assurance that the equipment can withstand rigorous use.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must ensure that their suppliers maintain stringent quality control measures. Here are effective ways to verify these practices:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a manufacturer’s processes, including their quality control systems and adherence to safety standards. This direct assessment can help you identify any potential risks associated with the supplier.

-

Quality Assurance Reports: Requesting detailed QA reports can give buyers a clearer picture of a manufacturer’s commitment to quality. These reports typically outline testing methods, results, and any corrective actions taken.

-

Third-Party Inspections: Utilizing third-party inspection services can offer an impartial evaluation of a manufacturer’s compliance with international standards. Such inspections can provide an additional layer of assurance, especially for buyers in regions with less stringent regulatory environments.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate specific nuances in quality control. Different regions may have varying standards and regulations, requiring buyers to do their due diligence.

-

Understanding Local Regulations: Each country may have its own set of safety standards and regulations for playground equipment. Familiarizing yourself with these can help ensure compliance and avoid costly penalties.

-

Cultural Considerations: When dealing with international suppliers, understanding cultural differences in business practices can facilitate smoother negotiations and partnerships. Establishing clear communication regarding quality expectations is essential.

-

Adaptability to Market Needs: Manufacturers that can customize their products to meet local demands and preferences can provide a competitive edge. Buyers should seek suppliers who demonstrate flexibility and an understanding of regional market trends.

In conclusion, the manufacturing processes and quality assurance for merry-go-rounds involve a comprehensive approach that emphasizes safety, durability, and compliance with international standards. For B2B buyers, understanding these aspects is crucial in making informed purchasing decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘merry go round for sale’

To assist B2B buyers in sourcing merry-go-rounds effectively, this guide provides a structured checklist. It will help ensure that your procurement process is thorough and aligned with your organizational needs.

Step 1: Define Your Requirements

Begin by clearly outlining your specific requirements for the merry-go-round. Consider factors such as size, capacity, age appropriateness, and safety features. This clarity helps in selecting the right model that meets your playground’s needs and complies with local regulations.

Illustrative image related to merry go round for sale

- Capacity Considerations: Determine the number of children the equipment should accommodate, ranging from small, child-friendly models to larger versions for schools and parks.

- Safety Features: Look for options that include wheelchair accessibility and safety surfacing to ensure inclusivity and compliance with safety standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Consider their industry reputation, experience, and product offerings. This step is crucial to find reliable manufacturers that can meet your specifications.

- Supplier Credentials: Check for certifications and compliance with international safety standards.

- Market Presence: Look for suppliers with a strong track record in your target region, such as Africa, South America, the Middle East, or Europe.

Step 3: Evaluate Product Quality

Assess the quality of the merry-go-round models offered by suppliers. Request samples or detailed specifications to ensure that the materials used are durable and safe for children.

- Material Standards: Verify that the merry-go-rounds are made from high-grade materials, such as steel and fiberglass, to withstand outdoor conditions.

- Safety Testing: Ensure the products have undergone rigorous safety testing and meet industry standards.

Step 4: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request quotes for the merry-go-rounds you are interested in. Compare pricing, but also consider the value offered, including warranty and after-sales support.

- Detailed Quotes: Ensure quotes include all costs, such as shipping, installation, and any additional accessories.

- Long-term Value: Look beyond initial costs and consider the total cost of ownership, including maintenance and durability.

Step 5: Verify References and Past Projects

Ask for references from previous clients who have purchased similar merry-go-rounds. This step helps gauge the supplier’s reliability and customer service.

- Client Feedback: Inquire about the client’s experience regarding product performance and supplier responsiveness.

- Case Studies: Request case studies that highlight successful installations in similar environments or regions.

Step 6: Negotiate Terms and Finalize the Purchase

Once you have selected a supplier, engage in negotiations to finalize the terms of purchase. Clarify payment terms, delivery schedules, and warranty conditions.

Illustrative image related to merry go round for sale

- Contract Clarity: Ensure that all agreements are documented in a formal contract to protect both parties.

- Delivery Expectations: Confirm delivery timelines and installation services to ensure a smooth procurement process.

Step 7: Plan for Installation and Safety Checks

After procurement, develop a plan for the installation and conduct thorough safety checks. This step is vital to ensure that the merry-go-round is safely integrated into your playground.

- Installation Guidelines: Follow the manufacturer’s installation guidelines to ensure compliance with safety standards.

- Post-Installation Inspection: Conduct a safety inspection after installation to verify that everything is functioning correctly and safely for use.

By following these steps, B2B buyers can ensure a successful procurement process for merry-go-rounds, ultimately providing a safe and enjoyable play experience for children.

Comprehensive Cost and Pricing Analysis for merry go round for sale Sourcing

What Are the Key Cost Components for Merry-Go-Round Manufacturing?

When sourcing merry-go-rounds, understanding the cost structure is crucial for international B2B buyers. The primary components influencing pricing include:

-

Materials: The quality and type of materials used, such as high-grade steel, fiberglass, and durable plastics, significantly affect the cost. Premium materials enhance safety and longevity but may raise initial expenses.

-

Labor: Manufacturing labor costs can vary widely based on geographic location. Regions with lower labor costs, such as certain areas in Asia, can offer competitive pricing, while European manufacturers may have higher labor rates due to stricter labor laws and standards.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient production processes and modern machinery can help reduce overhead.

-

Tooling: Custom designs may require specialized tooling, which can increase upfront costs. Buyers should consider whether they need standard models or if customization is essential for their market.

-

Quality Control (QC): Implementing stringent QC processes ensures safety and compliance with international standards. The costs associated with QC can vary depending on the level of scrutiny applied.

-

Logistics: Shipping and handling costs are vital, particularly for international buyers. Factors such as distance, mode of transport, and shipping method (air, sea, or land) play a significant role in total logistics costs.

-

Margin: Manufacturers typically apply a profit margin to cover risks and ensure sustainability. This margin can vary based on competition and the specific market conditions.

How Do Pricing Influencers Affect Merry-Go-Round Costs?

Several factors can significantly influence the pricing of merry-go-rounds:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in discounts, as suppliers can spread production and logistics costs over a greater number of units. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom designs or specific safety features can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Products that meet international safety standards may carry a premium price. Ensuring that the merry-go-rounds are certified for safety can justify higher costs, especially in markets with stringent regulations.

-

Supplier Factors: Establishing a relationship with reliable suppliers can influence pricing. Long-term partnerships may lead to better rates and priority service.

-

Incoterms: Understanding shipping terms is crucial for calculating total costs. Different Incoterms (e.g., FOB, CIF) can impact pricing and responsibilities for logistics, insurance, and customs duties.

What Buyer Tips Can Help with Cost-Efficiency in Merry-Go-Round Sourcing?

B2B buyers should consider the following strategies to enhance cost-efficiency when sourcing merry-go-rounds:

-

Negotiation: Engage in open discussions with suppliers about pricing and terms. Leverage volume commitments or long-term contracts to secure better rates.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, durability, and safety features when evaluating the overall cost. A higher upfront investment in quality may lead to lower long-term costs.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and local market conditions that can impact pricing. It’s beneficial to establish payment terms that mitigate risks associated with currency volatility.

-

Research Local Regulations: Different regions may have specific requirements for playground equipment. Understanding these regulations can prevent costly compliance issues down the line.

Disclaimer on Indicative Prices

Prices for merry-go-rounds can vary widely based on specifications, supplier, and market conditions. The figures referenced in this analysis are indicative and may not reflect current market prices. Always consult with suppliers for precise quotes tailored to your specific needs and location.

Illustrative image related to merry go round for sale

Alternatives Analysis: Comparing merry go round for sale With Other Solutions

Introduction to Alternative Solutions for Playground Equipment

When considering playground equipment, particularly merry-go-rounds, it is essential to explore various alternatives that can provide similar benefits while catering to different operational needs and budget constraints. Merry-go-rounds encourage cooperative play and physical activity among children, but other solutions may also fulfill these objectives. This analysis will compare traditional merry-go-rounds with two alternative options: spinning plates and interactive play panels.

Comparison Table

| Comparison Aspect | Merry Go Round For Sale | Spinning Plates | Interactive Play Panels |

|---|---|---|---|

| Performance | High engagement; requires multiple users to operate effectively. | Good for individual play; easy to use. | Engaging for solitary or group play; promotes cognitive skills. |

| Cost | Ranges from $1,800 to $13,500 depending on size and features. | Typically lower cost, around $500 to $2,000. | Moderate cost, generally between $1,000 and $5,000. |

| Ease of Implementation | Requires significant space and safety surfacing. | Easier to install; minimal space needed. | Can be installed in smaller areas; often requires less ground preparation. |

| Maintenance | Moderate; needs regular safety checks and surface upkeep. | Low; generally durable with minimal upkeep. | Low; typically constructed with weather-resistant materials. |

| Best Use Case | Ideal for larger parks and schools that accommodate many children. | Suitable for smaller playgrounds and residential areas. | Excellent for educational environments or parks with limited space. |

Detailed Breakdown of Alternatives

Spinning Plates

Spinning plates serve as a compact alternative to traditional merry-go-rounds, allowing children to rotate and spin individually. They are particularly advantageous for smaller playgrounds or residential areas where space is limited. The cost is lower compared to merry-go-rounds, making them an attractive option for budget-conscious buyers. However, the engagement level may not match that of a merry-go-round, as they primarily cater to solitary play rather than group interaction.

Interactive Play Panels

Interactive play panels offer a different type of engagement by focusing on cognitive and sensory development. These panels can include games, puzzles, and tactile elements that encourage children to explore and learn. While the installation may be simpler and require less space than a merry-go-round, the initial cost can vary based on the complexity of the design. Although they foster individual or small group play, they lack the physical activity component that merry-go-rounds provide, which may be a drawback for buyers prioritizing active play.

Conclusion: Choosing the Right Solution for Your Needs

When selecting playground equipment, B2B buyers must consider various factors, including the target audience, space availability, and budget. Merry-go-rounds remain a classic choice for promoting physical activity and group play, making them ideal for larger parks and schools. However, spinning plates and interactive play panels can serve as effective alternatives in smaller spaces or when budget constraints exist. Ultimately, understanding the specific needs of the playground environment will guide buyers in making the most appropriate decision for their projects.

Essential Technical Properties and Trade Terminology for merry go round for sale

What Are the Key Technical Properties of Merry-Go-Rounds for Sale?

When considering the purchase of merry-go-rounds for commercial use, understanding their technical specifications is crucial for ensuring safety, durability, and compliance with regulations. Here are some essential technical properties to consider:

-

Material Grade

Merry-go-rounds are typically constructed from high-grade materials such as stainless steel, fiberglass, and durable plastics. Stainless steel is favored for its resistance to rust and corrosion, while fiberglass offers lightweight yet sturdy support. The choice of material directly impacts the lifespan of the equipment, maintenance costs, and safety. For B2B buyers, selecting high-quality materials can translate into lower long-term costs and enhanced user satisfaction. -

Capacity

This specification refers to the maximum number of children that can safely use the merry-go-round at one time. It’s essential to match the capacity with the intended user demographic, such as schools or parks. A merry-go-round with a higher capacity can accommodate larger groups, promoting social interaction and cooperative play. Understanding capacity helps buyers choose equipment that meets their needs without compromising safety. -

Size and Dimensions

Merry-go-rounds come in various sizes, typically measured by diameter. Common diameters range from 6 to 10 feet for smaller models, while larger models can exceed 12 feet. The size affects the space required in the play area and the number of children that can use it simultaneously. B2B buyers should ensure that the chosen merry-go-round fits within their designated play area while providing adequate safety zones as per industry standards. -

Safety Standards and Certifications

Compliance with local and international safety standards (like ASTM or EN1176) is critical. This ensures that the equipment has been tested for safety and durability. Buyers should look for certifications indicating that the merry-go-round meets these standards, as this affects insurance, liability, and the overall safety of the playground environment. -

Speed and Power Requirements

For powered merry-go-rounds, understanding the required power specifications is vital. This includes the motor’s power rating (measured in kW) and the operational speed (in RPM). These factors affect both the user experience and the power consumption of the equipment. B2B buyers should consider the electrical infrastructure of their facility to ensure compatibility.

What Are Common Trade Terms Related to Merry-Go-Rounds for Sale?

Navigating the B2B marketplace requires familiarity with specific jargon and trade terms. Here are some commonly used terms relevant to merry-go-round purchases:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of merry-go-rounds, understanding OEM relationships can help buyers identify trusted manufacturers and ensure product quality. -

MOQ (Minimum Order Quantity)

This term refers to the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and planning inventory, particularly for large-scale projects or public installations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process is crucial for B2B buyers looking to compare prices, specifications, and delivery terms from multiple suppliers before making a purchasing decision. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers clarify shipping responsibilities, insurance, and risk, ensuring smoother international trade. -

Lead Time

This term refers to the total time it takes from placing an order to receiving the product. For B2B buyers, knowing the lead time is vital for project planning and ensuring timely installation of playground equipment.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when purchasing merry-go-rounds, ensuring they meet safety standards and fulfill their operational needs.

Navigating Market Dynamics and Sourcing Trends in the merry go round for sale Sector

What Are the Key Trends in the Merry-Go-Round Market for B2B Buyers?

The global merry-go-round market is witnessing dynamic growth, driven by increasing investments in public parks and recreational areas, especially in emerging economies across Africa, South America, the Middle East, and Europe. As urbanization intensifies, municipalities are prioritizing the development of safe, engaging play environments for children, which has led to a surge in demand for traditional playground equipment. B2B buyers are increasingly looking for suppliers who can offer a diverse range of products, from classic merry-go-rounds to innovative designs that incorporate modern safety features and accessibility options.

Emerging technologies are influencing sourcing strategies as well. The integration of digital platforms for procurement is becoming common, allowing for streamlined processes and enhanced communication between manufacturers and buyers. Additionally, buyers are increasingly seeking products that offer customization options, as they aim to cater to specific demographic needs in their regions. For instance, the availability of wheelchair-accessible merry-go-rounds is becoming a vital consideration in many markets, reflecting a growing emphasis on inclusivity.

Furthermore, the competitive landscape is evolving, with manufacturers emphasizing quality and safety certifications to distinguish their offerings. International buyers are advised to scrutinize suppliers for compliance with safety standards, particularly when sourcing from regions with varying regulatory practices.

How Important Is Sustainability and Ethical Sourcing in the Merry-Go-Round Industry?

Sustainability and ethical sourcing are paramount considerations for B2B buyers in the merry-go-round sector. The environmental impact of playground equipment, particularly regarding material sourcing and manufacturing processes, has garnered increased scrutiny. Buyers are now favoring manufacturers who utilize sustainable materials, such as recycled plastics and sustainably sourced wood, thereby reducing their carbon footprint.

Moreover, ethical supply chains are critical in ensuring that products are manufactured under fair labor conditions. Buyers are encouraged to seek suppliers who hold certifications indicating adherence to ethical labor practices, as this not only aligns with corporate social responsibility goals but also enhances brand reputation in the market.

Another trend is the demand for ‘green’ certifications, which assure buyers that the products meet environmental standards. These certifications can serve as a unique selling proposition for suppliers, making their offerings more attractive to socially-conscious buyers looking to invest in environmentally friendly playground equipment.

What Is the Historical Context of Merry-Go-Round Development Relevant to Today’s Market?

The merry-go-round has a rich history dating back to the Middle Ages, originally designed as a form of equestrian training. Over the centuries, it has evolved into a staple of playgrounds worldwide, symbolizing childhood joy and cooperative play. In the 20th century, the introduction of standardized safety regulations transformed the design and manufacturing of merry-go-rounds, making them safer and more durable for public use.

Illustrative image related to merry go round for sale

This evolution reflects broader trends in the playground equipment industry, where safety and inclusivity have become key focal points. As B2B buyers navigate today’s market, understanding this historical context can enhance their appreciation of the innovations in design and safety that define modern merry-go-rounds. Recognizing the importance of historical design philosophies can also guide buyers in selecting products that not only meet contemporary safety standards but also resonate with the cultural significance of playground play.

In summary, the merry-go-round market is characterized by evolving dynamics influenced by technological advancements, sustainability considerations, and historical context, all of which are crucial for B2B buyers seeking to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of merry go round for sale

-

1. How do I choose the right merry-go-round for my playground project?

Selecting the appropriate merry-go-round involves considering several factors, including the age group of users, space availability, and safety requirements. Full-sized models are suited for older children, while smaller versions work well for toddlers. Additionally, ensure that the equipment meets safety standards and includes features like wheelchair accessibility to promote inclusive play. Lastly, evaluate your project budget and compare various suppliers to find competitive pricing and quality. -

2. What are the safety standards for commercial merry-go-rounds?

Safety standards for commercial merry-go-rounds vary by region but generally include compliance with ASTM International and CPSC guidelines in the U.S. or EN1176 in Europe. These standards address construction materials, load limits, and installation requirements to ensure safe use. Before purchasing, confirm that the manufacturer provides certifications and safety testing records. Regular inspections and maintenance are also essential to uphold safety over time. -

3. What customization options are available for merry-go-rounds?

Many manufacturers offer customization options, allowing you to tailor the size, color, and design of merry-go-rounds to fit your project’s theme and specifications. Popular options include themed decorations, varying seating capacities, and additional safety features. When discussing customization, ensure to communicate your specific requirements clearly to the supplier and ask for visual mock-ups or prototypes, if possible. -

4. What is the minimum order quantity (MOQ) for merry-go-rounds?

The MOQ for merry-go-rounds varies by supplier and can depend on factors such as production capacity and material availability. Many manufacturers may have a MOQ ranging from 1 to several units, particularly for custom designs. Always inquire about the MOQ upfront, as it can affect your purchasing decisions and overall project budget. Some suppliers may offer flexibility based on your needs, especially for repeat customers. -

5. What payment terms should I expect when purchasing merry-go-rounds?

Payment terms can differ significantly among suppliers. Common practices include a deposit upfront (typically 30-50%) with the balance due prior to shipping. Some suppliers may offer financing options or payment plans for larger orders. Always clarify payment terms, including accepted methods and currencies, to avoid misunderstandings. Ensure that you also receive a formal invoice outlining all terms before finalizing your order. -

6. How do I vet suppliers for international purchases of merry-go-rounds?

To effectively vet suppliers, start by checking their industry reputation through reviews and testimonials from previous clients. Request references and inquire about their experience with international shipping and compliance with safety standards. Additionally, verify their certifications and inspect their production facilities, if possible. Engaging in direct communication can also provide insights into their customer service and responsiveness. -

7. What logistics considerations should I keep in mind when importing merry-go-rounds?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling playground equipment to navigate international regulations. Ensure you understand the associated costs, such as duties and tariffs, which can affect your overall budget. Additionally, discuss packaging with the supplier to minimize the risk of damage during transit. -

8. What quality assurance practices should I look for in merry-go-round manufacturing?

Quality assurance practices are vital to ensure the durability and safety of merry-go-rounds. Look for manufacturers that implement strict quality control measures, including regular inspections and testing during production. Certifications from recognized bodies can also indicate adherence to safety and quality standards. Before finalizing your order, request documentation that outlines their quality assurance processes and warranties for the products.

Top 5 Merry Go Round For Sale Manufacturers & Suppliers List

1. Playground Outfitters – Merry-Go-Rounds

Domain: playgroundoutfitters.com

Registered: 2016 (9 years)

Introduction: Merry-go-rounds are available in several color combinations and diameters to fit project needs. Sizes range from 6 to 10 feet in diameter. Options include wheelchair accessible merry-go-rounds. Key brands include Action Play Systems, Infinity Playgrounds LLC, NetPlay, SportsPlay, and UltraPlay. Prices range from $1,790.00 to $13,500.00 depending on the model.

2. Bluegrass Playgrounds – Merry Go Rounds

Domain: bluegrassplaygrounds.com

Registered: 2003 (22 years)

Introduction: Merry Go Rounds from Bluegrass Playgrounds, Inc. are safe, ADA compliant, and made in the USA. They feature a mechanical speed control device called a ‘governor’ and are available in various sizes: 4′, 6′, 8′, 10′, 12′, and 16′. The merry-go-rounds come in two standard color options: red base with yellow handrails or green base with tan handrails, with custom colors available at an additional cost…

3. Sinorides – Merry Go Round Ride

Domain: sinorides.com

Registered: 2011 (14 years)

Introduction: Merry Go Round Ride – Manufacturer: Sinorides, Experience: 28 years, Safety: Internationally certified, Capacity options: 6, 8, 12, 14, 16, 21, 24, 36, 56 seats, Power: Ranges from 1.1kW to 11kW, Size: Varies from D2m*H2.5m to D9.6m*H12.6m, Speed: Ranges from 3rpm to 5rpm, Materials: High-grade steel, fiberglass, durable fiber-reinforced plastic, Customization: Available for length, color, and run…

4. Technical Park – Merry Go Round

Domain: technicalpark.com

Registered: 2002 (23 years)

Introduction: Merry Go Round – Single Decker by Technical Park. Features include: nice finishing details, wooden floor, illumination, and decorated panels. Available in sizes with plate diameters ranging from 4 to approximately 11 meters. Floor structure is suspended with tie-bars, and the surface consists of clear coated solid hard-wood panels. Driving unit includes an AC self-braking gear-motor, electronicall…

5. Playground Expedition – Merry-Go-Rounds for Sale

Domain: playgroundexpedition.com

Registered: 2020 (5 years)

Introduction: Merry-Go-Rounds for Sale include the following products: 1. 5-Seat Merry Go Cycle – $2,556.00 2. Radical Rotator – $3,916.00 3. Galaxy Disc – $4,460.00 4. Kings Carousel – $4,696.00 5. Mauritius – $7,416.00 6. One Capacity Wheelchair Accessible Merry Go Round – $15,428.00. The merry-go-rounds are designed for fun and safety, incorporating design principles, safety standards, and material science. …

Strategic Sourcing Conclusion and Outlook for merry go round for sale

In the competitive landscape of playground equipment, particularly merry-go-rounds, strategic sourcing is essential for international B2B buyers. By carefully evaluating suppliers based on quality, safety certifications, and customization options, buyers can ensure they acquire products that not only meet safety standards but also resonate with local cultural preferences. Key considerations include the age and capacity requirements of your target market, as well as the importance of inclusive designs, such as wheelchair-accessible options.

Investing in high-quality merry-go-rounds can foster community engagement and enhance the appeal of parks and recreational facilities, ultimately driving foot traffic and boosting revenue. As you navigate your sourcing journey, leverage the insights gained from industry leaders and manufacturers who offer extensive support and tailored solutions to meet your specific needs.

Illustrative image related to merry go round for sale

Looking ahead, the demand for innovative and safe playground equipment is expected to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Seize this opportunity to elevate your offerings and establish your brand as a leader in the playground equipment sector. Start your sourcing process today and build partnerships that will enrich the play experiences of children worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to merry go round for sale

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.