The Definitive Guide to Magnetic Thermostat Sensor For Zozirushi Electric Rice Cooker:…

Introduction: Navigating the Global Market for magnetic thermostat sensor for zozirushi electric rice cooker

In the ever-evolving landscape of kitchen appliances, sourcing a reliable magnetic thermostat sensor for Zojirushi electric rice cookers presents a unique challenge for B2B buyers across the globe. With varying quality standards and specifications, businesses must navigate a complex market to ensure they select components that guarantee optimal performance and durability. This comprehensive guide aims to empower international buyers, particularly those in Africa, South America, the Middle East, and Europe, including emerging markets like Nigeria and Brazil, with essential insights for informed purchasing decisions.

Throughout this guide, we will delve into the various types of magnetic thermostat sensors available, exploring their applications and the critical role they play in the efficiency of rice cookers. Understanding the specifications and features that differentiate these sensors is vital for businesses looking to enhance product offerings and customer satisfaction. Additionally, we will provide actionable strategies for vetting suppliers, assessing cost implications, and identifying quality assurance practices to ensure a seamless procurement process.

By equipping B2B buyers with the knowledge necessary to navigate the global market for magnetic thermostat sensors, this guide will facilitate smarter sourcing decisions that align with business objectives and consumer needs. Whether you are seeking to enhance product reliability or expand your market presence, understanding the intricacies of these components will be invaluable in driving your business forward.

Understanding magnetic thermostat sensor for zozirushi electric rice cooker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Magnetic Center Thermostat | Round shape, responsive to temperature changes | Electric rice cookers, home appliances | Pros: Reliable performance; Cons: Limited compatibility with non-Zojirushi models. |

| Temperature Limiter Thermostat | Built-in safety features to prevent overheating | Commercial rice cookers, food service | Pros: Enhanced safety; Cons: May require additional installation expertise. |

| Adjustable Magnetic Thermostat | Adjustable temperature settings for versatility | High-end rice cookers, specialty food prep | Pros: Customizable; Cons: Higher initial investment. |

| Dual-Function Magnetic Thermostat | Combines heating control with temperature monitoring | Multi-functional cookers, industrial use | Pros: Efficient energy use; Cons: Complexity may lead to maintenance challenges. |

| Miniature Magnetic Thermostat | Compact size for space-saving designs | Small electric appliances, portable cookers | Pros: Space-efficient; Cons: Limited temperature range. |

What are the Key Characteristics of the Magnetic Center Thermostat?

The Magnetic Center Thermostat is characterized by its round design and high sensitivity to temperature fluctuations. This type is primarily used in electric rice cookers, ensuring that the cooking process is consistent and efficient. B2B buyers should consider its reliability and ease of integration into existing products, although its compatibility is limited to Zojirushi models.

How Does the Temperature Limiter Thermostat Enhance Safety?

The Temperature Limiter Thermostat features built-in safety mechanisms that prevent overheating, making it essential for commercial rice cookers and food service applications. B2B buyers in the food industry should prioritize this type for its safety features, although they should also be aware that installation may require specialized skills.

Why Choose an Adjustable Magnetic Thermostat?

An Adjustable Magnetic Thermostat allows users to customize temperature settings, making it ideal for high-end rice cookers and specialized food preparation. Its versatility appeals to B2B buyers looking for flexibility in cooking applications. However, the initial investment may be higher compared to fixed models, so cost considerations are crucial.

What Benefits Does a Dual-Function Magnetic Thermostat Offer?

The Dual-Function Magnetic Thermostat integrates heating control with temperature monitoring, suitable for multi-functional cookers and industrial applications. This type enhances energy efficiency, which is a significant advantage for B2B buyers focused on reducing operational costs. However, its complexity might lead to maintenance challenges, which should be factored into purchasing decisions.

When is a Miniature Magnetic Thermostat the Right Choice?

The Miniature Magnetic Thermostat is designed for compact appliances and portable cookers, making it an excellent choice for businesses with limited space. B2B buyers should appreciate its space-saving benefits, but they should also consider its limited temperature range, which may not meet the needs of all cooking applications.

Key Industrial Applications of magnetic thermostat sensor for zozirushi electric rice cooker

| Industry/Sector | Specific Application of magnetic thermostat sensor for zozirushi electric rice cooker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Used in commercial rice cookers to maintain optimal cooking temperatures. | Ensures consistent quality and reduces food waste through precise temperature control. | Durability, compliance with food safety standards, and availability of replacement parts. |

| Appliance Manufacturing | Integrated into consumer rice cookers for efficient energy use and safety. | Enhances product reliability and energy efficiency, appealing to eco-conscious consumers. | Certifications for safety, compatibility with existing models, and sourcing from reputable suppliers. |

| Hospitality | Employed in hotel kitchens for bulk rice preparation to streamline operations. | Increases operational efficiency, allowing for large-scale meal preparation without compromising quality. | Volume pricing, lead times for bulk orders, and after-sales support. |

| Home Appliance Retail | Featured in retail rice cookers, enhancing user experience with smart features. | Attracts customers looking for advanced cooking technology, increasing sales potential. | Market trends, consumer preferences, and warranty options. |

| Industrial Food Processing | Utilized in automated rice cooking systems for large-scale food production. | Improves production consistency and safety in high-demand environments. | Technical specifications, integration capabilities, and support for automation systems. |

How is the Magnetic Thermostat Sensor Used in the Food Service Industry?

In the food service sector, magnetic thermostat sensors are crucial for commercial rice cookers, ensuring that rice is cooked at optimal temperatures. This precision helps to maintain the quality and texture of the rice, which is essential for customer satisfaction. For B2B buyers in this industry, it is important to consider the durability of the sensors and their compliance with food safety standards, as these factors directly impact food quality and business reputation.

What Role Does the Magnetic Thermostat Sensor Play in Appliance Manufacturing?

In appliance manufacturing, the magnetic thermostat sensor is integrated into consumer rice cookers to enhance energy efficiency and safety. By providing precise temperature control, these sensors help manufacturers create reliable products that appeal to environmentally conscious consumers. When sourcing these sensors, manufacturers should look for certifications that ensure safety and compatibility with existing models, as well as a supplier’s track record in the industry.

How Can Hospitality Businesses Benefit from Magnetic Thermostat Sensors?

In the hospitality industry, particularly in hotel kitchens, magnetic thermostat sensors are vital for bulk rice preparation. They enable chefs to cook large quantities of rice consistently, which is essential for catering to large groups. For B2B buyers in this sector, considerations such as volume pricing and lead times for bulk orders are critical, as they need to ensure a steady supply for uninterrupted kitchen operations.

Why Are Magnetic Thermostat Sensors Important for Home Appliance Retail?

Retailers of home appliances leverage magnetic thermostat sensors in their rice cookers to enhance user experience with smart cooking features. These features attract consumers looking for advanced technology in their kitchen appliances. B2B buyers in this space should stay informed about market trends and consumer preferences, as well as warranty options that can add value to their product offerings.

How Do Magnetic Thermostat Sensors Support Industrial Food Processing?

In industrial food processing, magnetic thermostat sensors are employed in automated rice cooking systems. They ensure consistent cooking results, which is essential for maintaining quality in high-demand environments. Buyers in this sector should focus on technical specifications and the integration capabilities of these sensors, as well as the level of support provided for automation systems, to ensure seamless operation in their production lines.

3 Common User Pain Points for ‘magnetic thermostat sensor for zozirushi electric rice cooker’ & Their Solutions

Scenario 1: Inconsistent Temperature Regulation in Rice Cookers

The Problem: B2B buyers often face challenges when sourcing magnetic thermostat sensors that do not maintain consistent temperature regulation in Zojirushi electric rice cookers. This inconsistency can lead to overcooked or undercooked rice, affecting product quality and customer satisfaction. As a result, businesses may experience increased returns or complaints, damaging their reputation and profitability. Buyers may struggle to find sensors that are reliable and compatible with their specific models, leading to additional frustration.

The Solution: To overcome this issue, buyers should prioritize sourcing high-quality magnetic thermostat sensors specifically designed for Zojirushi rice cookers. It’s essential to verify compatibility with the exact model before purchasing. Suppliers should provide technical specifications and performance data to ensure that the sensors can regulate temperature accurately. Additionally, conducting thorough quality control checks upon receipt of the sensors can help identify any defects or inconsistencies early in the supply chain. Establishing strong relationships with reputable suppliers can also facilitate better communication and support for any technical issues that arise.

Scenario 2: High Failure Rates of Thermostat Sensors

The Problem: Another pain point for B2B buyers is the high failure rates of magnetic thermostat sensors, which can lead to increased operational costs and downtime. Frequent replacements not only disrupt production but also impact the overall efficiency of rice cooking operations. Buyers may find themselves overwhelmed by the number of options available, leading to poor purchasing decisions that result in unreliable sensors.

The Solution: To mitigate the risk of high failure rates, buyers should focus on sourcing sensors from established manufacturers known for their durability and reliability. Conducting a thorough market analysis to compare product reviews and performance ratings can help identify the best options. It is also advisable to request samples before making bulk purchases, allowing businesses to test the sensors in their operations. Implementing a regular maintenance and inspection schedule for the rice cookers can further reduce the risk of sensor failures by ensuring that any potential issues are detected early.

Scenario 3: Difficulty in Installation and Calibration of Thermostat Sensors

The Problem: B2B buyers often encounter difficulties during the installation and calibration of magnetic thermostat sensors in Zojirushi electric rice cookers. Improper installation can lead to malfunctions, which may cause significant disruptions in cooking processes. This challenge is particularly pronounced for companies with less experienced staff or inadequate training programs, resulting in wasted time and resources.

The Solution: To address installation and calibration challenges, buyers should invest in comprehensive training for their staff on how to install and calibrate magnetic thermostat sensors effectively. This training can be facilitated through workshops or training sessions provided by the supplier. Moreover, sourcing products that come with detailed installation manuals and calibration instructions can streamline the process. Buyers can also consider working with a technical consultant during the initial installation phase to ensure that all sensors are set up correctly, minimizing the likelihood of errors and enhancing operational efficiency.

Strategic Material Selection Guide for magnetic thermostat sensor for zozirushi electric rice cooker

What Are the Key Materials for Magnetic Thermostat Sensors in Zojirushi Electric Rice Cookers?

When selecting materials for magnetic thermostat sensors used in Zojirushi electric rice cookers, it is crucial to consider properties that directly impact performance, durability, and compliance with international standards. Here, we analyze four common materials: stainless steel, thermoplastic, glass, and ceramic. Each material has unique characteristics that influence its suitability for this specific application.

How Does Stainless Steel Perform in Magnetic Thermostat Sensors?

Stainless steel is a popular choice for magnetic thermostat sensors due to its excellent corrosion resistance and ability to withstand high temperatures. Typically rated for temperatures up to 300°C, stainless steel ensures reliable performance in various cooking environments. Its durability makes it suitable for long-term use, especially in regions with high humidity or varying temperatures.

Pros: Stainless steel is highly durable and resistant to rust and corrosion, making it ideal for environments prone to moisture. It also has a relatively low thermal expansion rate, ensuring accurate temperature readings.

Cons: The primary downside is its higher cost compared to other materials, which may impact overall product pricing. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of cooking media, ensuring that the sensor maintains accuracy regardless of the food type being prepared.

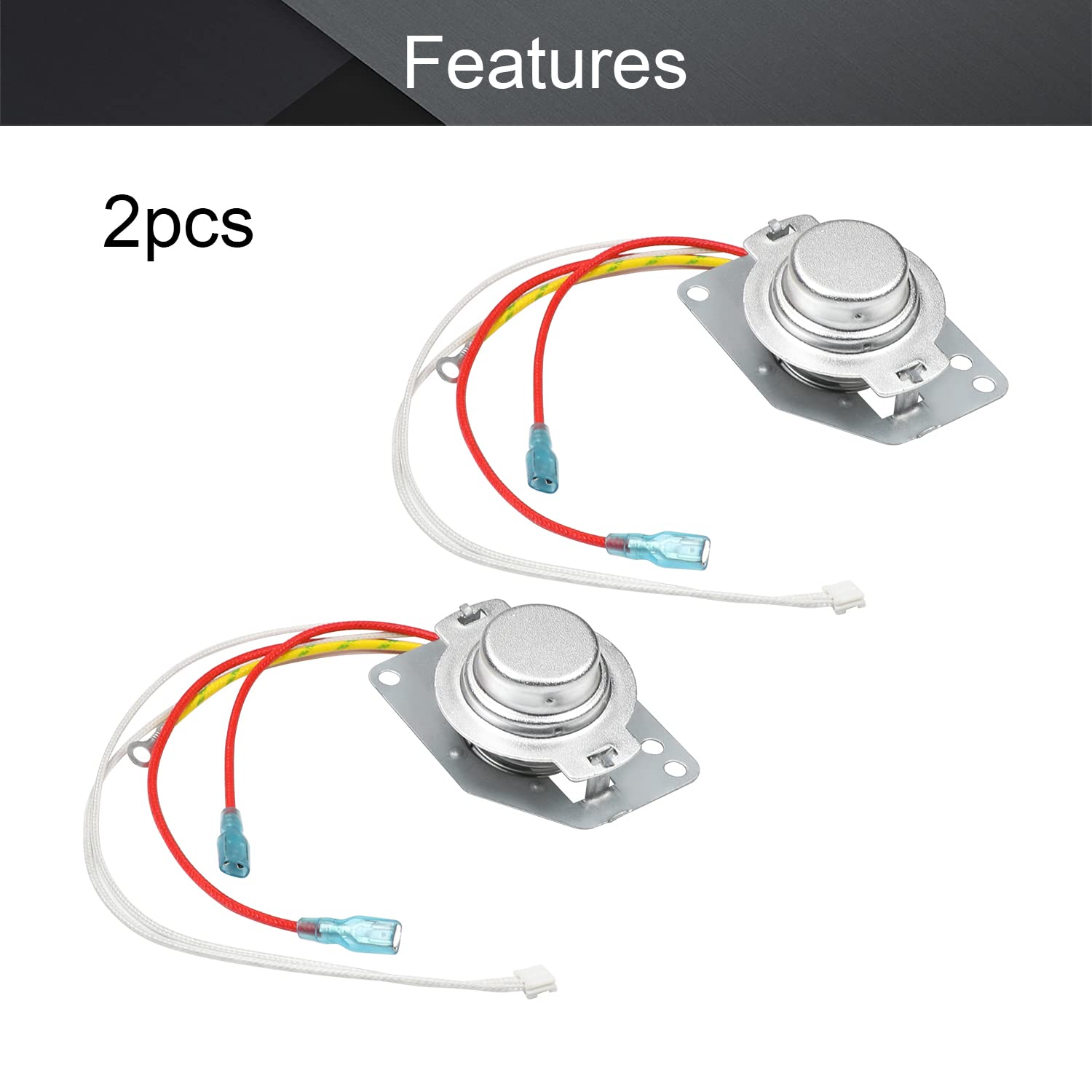

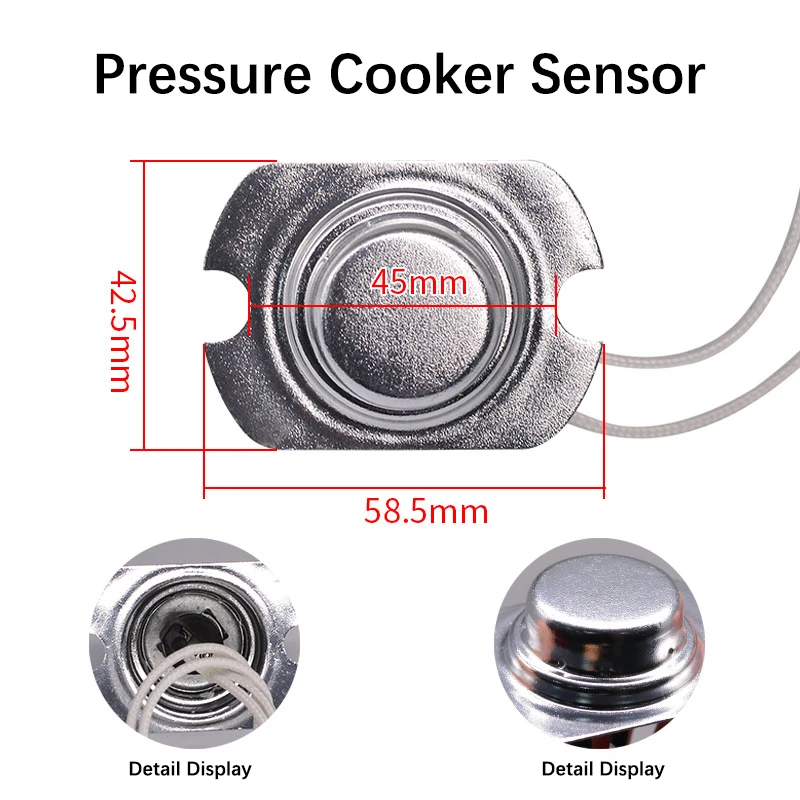

Illustrative image related to magnetic thermostat sensor for zozirushi electric rice cooker

International Considerations: Buyers in Africa, South America, the Middle East, and Europe should ensure compliance with standards such as ASTM and DIN, particularly regarding food safety and material certifications.

What Role Does Thermoplastic Play in Magnetic Thermostat Sensors?

Thermoplastic materials, such as polycarbonate or nylon, are increasingly used in magnetic thermostat sensors due to their lightweight nature and ease of manufacturing. These materials can typically withstand temperatures up to 120°C, which is sufficient for most cooking applications.

Pros: Thermoplastics are cost-effective and easy to mold into intricate shapes, which can simplify the manufacturing process. They also offer good electrical insulation properties.

Illustrative image related to magnetic thermostat sensor for zozirushi electric rice cooker

Cons: However, thermoplastics have lower temperature and pressure ratings compared to metals, which may limit their use in high-performance applications. They can also be less durable over time, especially under constant heat exposure.

Impact on Application: While suitable for many cooking environments, thermoplastics may not be ideal for high-temperature cooking methods, limiting their application in certain rice cooker models.

International Considerations: Buyers should verify that thermoplastics meet relevant compliance standards, particularly in terms of food safety and environmental regulations.

Why Choose Glass for Magnetic Thermostat Sensors?

Glass is another material option for magnetic thermostat sensors, primarily due to its excellent thermal stability and chemical resistance. Glass can handle high temperatures and is often used in applications requiring precise temperature measurement.

Pros: Glass is highly resistant to chemical corrosion, making it suitable for various cooking media. It also provides excellent thermal insulation, ensuring accurate temperature readings.

Cons: The fragility of glass can be a significant drawback, as it is prone to breaking under impact. Additionally, the manufacturing process can be more complex and costly compared to other materials.

Impact on Application: Glass sensors are particularly effective in applications requiring high accuracy, but their fragility may limit their use in environments where physical stress is a concern.

International Considerations: Compliance with safety standards is crucial, especially in regions with strict food safety regulations. Buyers should ensure that glass components are certified for food contact.

What Advantages Does Ceramic Offer in Magnetic Thermostat Sensors?

Ceramic materials are known for their high-temperature resistance and durability. They can withstand temperatures exceeding 1000°C, making them suitable for high-performance applications.

Pros: Ceramics are incredibly durable and resistant to thermal shock, ensuring long-term reliability. They also have excellent electrical insulating properties.

Cons: The primary limitation of ceramics is their cost and brittleness, which can make them less suitable for applications where impact resistance is essential. Manufacturing ceramics can also be complex and time-consuming.

Impact on Application: Ceramics are ideal for high-temperature cooking applications, providing accurate temperature readings even in extreme conditions.

International Considerations: Buyers should ensure that ceramic materials comply with international standards for food safety and thermal performance, particularly in diverse markets.

Summary Table of Material Selection for Magnetic Thermostat Sensors

| Material | Typical Use Case for magnetic thermostat sensor for zojirushi electric rice cooker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-temperature cooking applications | Excellent corrosion resistance and durability | Higher cost and complex manufacturing | High |

| Thermoplastic | General cooking applications with moderate temperature requirements | Cost-effective and easy to mold | Lower temperature ratings and durability | Low |

| Glass | Precise temperature measurement in stable environments | High thermal stability and chemical resistance | Fragility and higher manufacturing costs | Medium |

| Ceramic | High-performance cooking applications requiring extreme temperature resistance | Exceptional durability and thermal shock resistance | Brittle and higher production complexity | High |

This guide provides a comprehensive overview of material considerations for magnetic thermostat sensors in Zojirushi electric rice cookers, aiding international B2B buyers in making informed decisions based on their specific market needs.

Illustrative image related to magnetic thermostat sensor for zozirushi electric rice cooker

In-depth Look: Manufacturing Processes and Quality Assurance for magnetic thermostat sensor for zozirushi electric rice cooker

What Are the Key Stages in the Manufacturing Process of Magnetic Thermostat Sensors for Zojirushi Electric Rice Cookers?

The manufacturing process of magnetic thermostat sensors for Zojirushi electric rice cookers involves several critical stages that ensure the reliability and efficiency of the final product. Understanding these stages is essential for B2B buyers looking to source high-quality components.

-

Material Preparation: The first step in manufacturing involves selecting high-grade materials suitable for thermal regulation. Common materials include thermoplastic polymers, metals, and magnetic alloys. Suppliers must ensure that all raw materials meet industry standards and specifications, as they directly influence the sensor’s performance and durability.

-

Forming: Once materials are prepared, the forming process begins. This stage typically involves methods such as injection molding for plastic components and stamping or machining for metal parts. Precision is crucial here, as any discrepancies can lead to malfunction in the thermostat sensor. Advanced techniques such as CNC machining may be employed to achieve the necessary tolerances.

-

Assembly: After individual components are formed, they undergo assembly. This phase often includes the integration of electronic components and the calibration of magnetic elements to ensure accurate temperature readings. Automated assembly lines are common in this process, enhancing efficiency and consistency in production.

-

Finishing: The final stage of manufacturing involves finishing processes, which may include surface treatment, coating, and quality checks. These processes not only enhance the aesthetic appeal of the thermostat but also improve its resistance to environmental factors such as humidity and temperature fluctuations.

How Is Quality Assurance Implemented in the Manufacturing of Magnetic Thermostat Sensors?

Quality assurance (QA) is a critical aspect of manufacturing, particularly for components used in appliances like rice cookers. The following elements are vital in ensuring that the products meet international standards and customer expectations.

-

Adherence to International Standards: Manufacturers of magnetic thermostat sensors must comply with various international quality standards, including ISO 9001, which emphasizes a quality management system. Certifications such as CE mark and API standards are also relevant, particularly for markets in Europe and the Middle East. These certifications assure buyers that the products meet specific safety and performance criteria.

-

Quality Control Checkpoints: Quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. It ensures that all materials meet the specified standards.

– In-Process Quality Control (IPQC): During the manufacturing process, IPQC monitors production to detect any deviations from quality standards. This may include real-time inspections and testing of components at various stages.

– Final Quality Control (FQC): After assembly, FQC involves comprehensive testing of the finished thermostat sensors. This may include functional tests, endurance tests, and safety evaluations to ensure that the sensors perform reliably under expected conditions. -

Common Testing Methods: Various testing methods are utilized to assess the quality and performance of magnetic thermostat sensors. These include thermal cycling tests, magnetic field tests, and electrical continuity tests. Each method serves to validate the sensor’s functionality and durability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to ensure that their suppliers adhere to stringent quality control measures. Here are some practical approaches:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. Buyers should assess the supplier’s adherence to international standards, their quality management systems, and the capabilities of their facilities.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including data on past performance, defect rates, and compliance with industry standards. These documents can help gauge the reliability and consistency of the supplier’s output.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspections can occur at various stages of production, offering additional assurance regarding the quality of the thermostat sensors.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification that may affect their procurement strategies.

-

Understanding Regional Standards: Different regions may have distinct regulatory requirements. For example, the CE mark is essential for products sold in the European market, while UL certification may be more relevant in North America. B2B buyers should familiarize themselves with the relevant standards in their target markets.

-

Navigating Import Regulations: Import regulations can vary significantly across countries. Buyers must ensure that the products they source comply with local safety and quality standards to avoid potential issues during customs clearance.

-

Language and Communication Barriers: Engaging with suppliers in different regions may present communication challenges. Buyers should ensure that they have clear channels for discussing quality expectations and specifications, potentially utilizing translation services if needed.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance protocols for magnetic thermostat sensors is essential for B2B buyers. By focusing on these areas, buyers can make informed decisions, ensuring they source reliable and high-quality components for Zojirushi electric rice cookers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘magnetic thermostat sensor for zozirushi electric rice cooker’

Introduction

Sourcing a magnetic thermostat sensor for Zojirushi electric rice cookers requires careful consideration and strategic planning. This guide outlines a step-by-step checklist to assist B2B buyers in identifying reliable suppliers, ensuring product quality, and negotiating favorable terms. By following this checklist, you can streamline your procurement process and make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to establish your technical requirements for the magnetic thermostat sensor. This includes dimensions, temperature range, and compatibility with Zojirushi models.

- Identify critical features: Consider if you need features like temperature accuracy or rapid response times.

- Consult with technical teams: Engaging engineers or product managers can help ensure you capture all necessary specifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in magnetic thermostat sensors for electric rice cookers. This step is vital to avoid unreliable vendors.

- Check online directories and trade platforms: Utilize platforms like Alibaba or ThomasNet to find suppliers with a track record in your specific industry.

- Look for industry certifications: Ensure potential suppliers have relevant certifications (e.g., ISO, CE) that demonstrate adherence to quality standards.

Step 3: Evaluate Supplier Experience and Reputation

Assess the experience and reputation of potential suppliers before making a commitment. A supplier’s track record can significantly impact your sourcing outcomes.

- Request company profiles: Ask for details about their history, expertise, and previous projects.

- Seek customer testimonials: Reviews or case studies from other businesses can provide insights into the supplier’s reliability and service quality.

Step 4: Verify Product Quality and Compliance

Quality assurance is paramount when sourcing components like magnetic thermostat sensors. Ensure the products meet both your specifications and industry standards.

- Request samples: Before placing a bulk order, obtain samples to test for quality and compatibility.

- Check compliance documentation: Ensure that the sensors comply with local regulations and safety standards applicable in your target markets.

Step 5: Negotiate Terms and Pricing

Once you’ve selected a supplier, negotiate terms that are favorable for your business. This includes pricing, payment terms, and delivery schedules.

- Discuss volume discounts: If you plan to order large quantities, inquire about bulk pricing options.

- Clarify delivery timelines: Ensure that the supplier can meet your delivery requirements to avoid disruptions in your supply chain.

Step 6: Establish Clear Communication Channels

Effective communication is essential throughout the sourcing process. Establishing clear channels can facilitate smoother transactions and enhance collaboration.

- Set regular check-ins: Schedule updates or meetings to discuss progress, address concerns, and adjust timelines if needed.

- Utilize technology: Consider using project management tools or communication platforms to keep all stakeholders informed.

Step 7: Monitor Supplier Performance Post-Purchase

After procurement, it’s important to monitor the supplier’s performance continuously. This ensures that they meet your expectations and helps build a long-term partnership.

- Evaluate delivery and quality metrics: Track performance against agreed-upon benchmarks.

- Provide feedback: Share your experiences with the supplier to foster improvements and strengthen your business relationship.

By following this checklist, B2B buyers can effectively navigate the sourcing process for magnetic thermostat sensors, ensuring they select the right partners and products for their needs.

Comprehensive Cost and Pricing Analysis for magnetic thermostat sensor for zozirushi electric rice cooker Sourcing

What Are the Key Cost Components for Sourcing Magnetic Thermostat Sensors?

When considering the sourcing of magnetic thermostat sensors for Zojirushi electric rice cookers, it’s essential to break down the cost structure into its core components. The main cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materials: The primary materials involved in the production of magnetic thermostat sensors typically include metals, plastics, and electronic components. The quality and type of materials can significantly impact costs, particularly if sourcing from regions with stringent quality standards.

-

Labor: Labor costs will vary depending on the country of manufacture. In regions with lower labor costs, such as parts of South America and Africa, manufacturers may offer more competitive pricing. However, the trade-off may be in the consistency and quality of the workforce.

-

Manufacturing Overhead: This encompasses costs associated with the facilities, utilities, and equipment used in production. Manufacturers in established industrial zones may have lower overhead due to economies of scale.

-

Tooling: The initial investment in tooling can be significant, especially if the sensors require specialized molds or machinery. Custom tooling for specific designs will add to the upfront costs but can yield long-term savings through increased production efficiency.

-

Quality Control (QC): Ensuring that the sensors meet required specifications is critical, particularly for electrical components. Implementing stringent QC processes can add to costs but is essential to avoid costly returns and reputational damage.

-

Logistics: Transportation costs vary widely depending on the shipping method and destination. International buyers must consider duties, tariffs, and shipping fees when calculating total costs.

-

Margin: Suppliers will add a profit margin to cover their expenses and generate profit. This margin can vary based on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Affect the Cost of Magnetic Thermostat Sensors?

Several factors can influence the pricing of magnetic thermostat sensors, which buyers should consider for effective sourcing:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders often qualify for discounts, making it crucial for buyers to assess their needs accurately.

-

Specifications/Customization: Custom specifications can increase costs due to additional design, tooling, and testing requirements. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials: The choice of materials not only affects the sensor’s performance but also its cost. High-quality materials that meet international standards may incur higher upfront costs but provide better reliability.

-

Quality and Certifications: Sensors that comply with international safety and quality standards may come at a premium. Certifications can be essential for buyers in regulated markets.

-

Supplier Factors: The reputation, reliability, and negotiation flexibility of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while newer suppliers may offer competitive pricing to gain market entry.

-

Incoterms: Understanding the Incoterms agreed upon in the purchase contract is crucial. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can all affect the overall cost.

What Are the Best Buyer Tips for Negotiating Prices on Magnetic Thermostat Sensors?

International B2B buyers should adopt strategic approaches when negotiating prices for magnetic thermostat sensors:

Illustrative image related to magnetic thermostat sensor for zozirushi electric rice cooker

-

Negotiate Volume Discounts: Leverage your purchasing power by negotiating for better pricing on larger orders. Suppliers often prefer bulk orders and may be willing to provide discounts.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront cost but also the long-term implications of sourcing decisions. Factors such as durability, warranty, and after-sales support can significantly affect TCO.

-

Understand Pricing Nuances: Familiarize yourself with the local market conditions in the supplier’s region. Prices may fluctuate based on local economic factors, currency exchange rates, and seasonal demand.

-

Build Relationships: Establishing a good relationship with suppliers can lead to better pricing and favorable terms. Trust and communication can help in negotiating more effectively.

-

Conduct Market Research: Stay informed about market trends and competitor pricing to ensure you are making informed decisions and are not overpaying for your sensors.

By understanding these cost components and price influencers, B2B buyers can make informed decisions when sourcing magnetic thermostat sensors for Zojirushi electric rice cookers, ultimately leading to more cost-effective and efficient procurement strategies.

Alternatives Analysis: Comparing magnetic thermostat sensor for zozirushi electric rice cooker With Other Solutions

Introduction: What Are the Alternatives to Magnetic Thermostat Sensors?

In the world of electric rice cookers, the accuracy and reliability of temperature control are paramount for optimal cooking results. The magnetic thermostat sensor for Zojirushi electric rice cookers has gained popularity for its precision, but it is essential for B2B buyers to consider various alternatives. This section explores other viable solutions that can either complement or serve as substitutes for magnetic thermostat sensors, enabling informed purchasing decisions.

Comparison Table

| Comparison Aspect | Magnetic Thermostat Sensor For Zojirushi Electric Rice Cooker | Thermocouple Sensor | Bimetallic Thermostat |

|---|---|---|---|

| Performance | High accuracy and fast response times | Very high accuracy, but slower response | Good accuracy, but can be less precise |

| Cost | Moderate price point | Higher initial cost | Lower cost |

| Ease of Implementation | Simple installation with existing Zojirushi models | Requires more complex integration | Easy to install, but may need calibration |

| Maintenance | Low maintenance needs | Moderate; needs periodic checks | Low maintenance needs |

| Best Use Case | Ideal for high-end rice cookers requiring precise control | Suitable for industrial applications needing precision | Good for basic home cooking applications |

Detailed Breakdown of Alternatives

Thermocouple Sensor: Pros and Cons

Thermocouples are widely used in various cooking appliances due to their exceptional accuracy and ability to withstand high temperatures. They work by measuring the voltage difference created when two dissimilar metals are joined. The pros of thermocouples include their high accuracy and ability to operate in extreme conditions, making them ideal for industrial settings. However, they come with a higher initial cost and may require more complex integration into existing systems, which could be a barrier for smaller operations.

Bimetallic Thermostat: Pros and Cons

Bimetallic thermostats use two different metals that expand at different rates to regulate temperature. They are straightforward in design and generally less expensive than magnetic sensors or thermocouples. Their ease of installation makes them appealing for less complex cooking applications. However, bimetallic thermostats can sometimes lack the precision of other sensors, resulting in less consistent cooking results. They are best suited for basic home cooking needs rather than high-end rice cookers, where precision is critical.

Conclusion: How to Choose the Right Solution

When selecting a temperature control solution for electric rice cookers, B2B buyers must weigh their specific needs against the characteristics of each option. For high-end applications where precision is crucial, the magnetic thermostat sensor remains the top choice. However, if cost is a significant factor and the application is less demanding, bimetallic thermostats may suffice. For industrial settings where temperature control must be exact, thermocouples could be the best investment despite their higher cost. Understanding the unique requirements of your business will guide you to the most suitable solution, ensuring optimal cooking performance and customer satisfaction.

Essential Technical Properties and Trade Terminology for magnetic thermostat sensor for zozirushi electric rice cooker

Understanding the essential technical properties and industry terminology associated with magnetic thermostat sensors for Zojirushi electric rice cookers is crucial for international B2B buyers. This knowledge not only aids in selecting the right products but also enhances communication with suppliers and manufacturers.

What are the Key Technical Properties of Magnetic Thermostat Sensors?

-

Material Grade

The material grade of a magnetic thermostat sensor typically refers to the quality and composition of the materials used, such as thermoplastic or metal components. High-grade materials ensure durability and reliability under various temperature conditions, which is vital for consistent performance in rice cookers. For B2B buyers, choosing sensors made from superior materials can lead to longer product lifespans and reduced maintenance costs. -

Operating Temperature Range

This specification defines the temperature limits within which the thermostat can function effectively. Magnetic thermostat sensors for rice cookers generally operate within a specific range, often between 0°C to 100°C. Understanding this range is crucial for buyers to ensure that the sensors will perform optimally in different cooking scenarios, particularly in regions with varied climates. -

Tolerance

Tolerance indicates the allowable deviation from the specified temperature reading. A tighter tolerance means more precise temperature control, which is essential for cooking rice perfectly. For B2B buyers, knowing the tolerance levels helps in assessing the quality of the sensor and its suitability for specific cooking applications, ensuring customer satisfaction. -

Response Time

This property measures how quickly the thermostat can react to temperature changes. A faster response time ensures that the rice cooker can adjust heating elements promptly, contributing to better cooking results. For international buyers, understanding response times is critical when evaluating performance, especially in high-demand markets. -

Electrical Specifications

Electrical specifications include voltage ratings and current capacity. Most magnetic thermostat sensors operate at standard voltages, typically between 110V and 240V, depending on regional power standards. Awareness of these specifications is essential for B2B buyers to ensure compatibility with existing appliances and compliance with local electrical standards.

What are Common Trade Terms Related to Magnetic Thermostat Sensors?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. Understanding OEM relationships is essential for B2B buyers when sourcing magnetic thermostat sensors, as it can influence pricing, quality assurance, and lead times. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ helps in budgeting and inventory management, ensuring that they can procure sufficient quantities without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for a specific quantity of products. Utilizing RFQs allows B2B buyers to gather competitive pricing and understand the market better, which is vital for making informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps international buyers navigate logistics and shipping costs, ensuring smoother transactions and fewer misunderstandings. -

Lead Time

Lead time is the period between placing an order and receiving the goods. For B2B buyers, understanding lead times is crucial for inventory planning and meeting customer demands, especially in markets that require quick turnaround times.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing magnetic thermostat sensors for Zojirushi electric rice cookers, ultimately leading to better business outcomes and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the magnetic thermostat sensor for zozirushi electric rice cooker Sector

What Are the Key Market Dynamics and Trends Influencing Magnetic Thermostat Sensors for Zojirushi Electric Rice Cookers?

The market for magnetic thermostat sensors, particularly in the context of Zojirushi electric rice cookers, is experiencing notable growth driven by several global factors. Increasing consumer demand for energy-efficient appliances is a significant driver, pushing manufacturers to innovate and enhance the reliability of their products. The rise of smart home technology is also influencing sourcing trends, as more manufacturers are integrating IoT capabilities into kitchen appliances, including rice cookers. This trend is particularly relevant for international B2B buyers, who must consider sourcing components that are compatible with smart technology.

Regional dynamics play a crucial role in the sourcing landscape. In Africa and South America, the growing middle class is leading to an increase in disposable income, fostering a higher demand for advanced kitchen appliances. Conversely, the Middle East and Europe exhibit a strong preference for high-quality, durable products, which influences sourcing decisions. Moreover, supply chain disruptions due to geopolitical factors and the pandemic have prompted companies to diversify their sourcing strategies, seeking suppliers in more stable regions. Buyers are advised to establish strong relationships with manufacturers who can provide reliable supply chains and quality assurance.

Illustrative image related to magnetic thermostat sensor for zozirushi electric rice cooker

How Important Is Sustainability and Ethical Sourcing for B2B Buyers of Magnetic Thermostat Sensors?

Sustainability is becoming a critical consideration for B2B buyers in the magnetic thermostat sensor market. The environmental impact of manufacturing processes is under scrutiny, with buyers increasingly favoring suppliers who prioritize eco-friendly practices. For instance, sourcing materials that are recyclable or made from sustainable resources can significantly reduce the carbon footprint associated with production.

Ethical sourcing is equally vital, as businesses are held accountable for their supply chains. Buyers should seek manufacturers with transparent practices, ensuring fair labor conditions and compliance with international labor standards. Certifications such as ISO 14001 (environmental management) or Oeko-Tex (sustainable textiles) are indicators of a supplier’s commitment to sustainability. By prioritizing ethical sourcing, B2B buyers not only enhance their brand reputation but also contribute to a more sustainable future.

What Is the Historical Context of Magnetic Thermostat Sensors in Electric Rice Cookers?

The evolution of magnetic thermostat sensors dates back to the early developments in home appliance technology. Initially, these sensors were designed for basic temperature regulation, but advancements in materials science and electronics have transformed their functionality. The introduction of digital technologies has allowed for greater precision and reliability, making these sensors an integral component of modern electric rice cookers.

As consumer preferences shifted towards convenience and efficiency, manufacturers began to adopt more sophisticated thermostat designs, including magnetic sensors, which offer quick response times and enhanced accuracy. Today, these sensors are not only essential for cooking performance but also play a critical role in energy conservation, reflecting the growing trend towards sustainability in appliance manufacturing. Understanding this evolution can help B2B buyers appreciate the technological advancements that enhance product quality and reliability in the magnetic thermostat sensor market.

Illustrative image related to magnetic thermostat sensor for zozirushi electric rice cooker

Frequently Asked Questions (FAQs) for B2B Buyers of magnetic thermostat sensor for zozirushi electric rice cooker

-

How do I solve compatibility issues with magnetic thermostat sensors for Zojirushi electric rice cookers?

To address compatibility concerns, first, confirm the specific model of your Zojirushi rice cooker. Each model may require a unique thermostat sensor, so it’s crucial to reference the manufacturer’s specifications. When sourcing sensors, provide potential suppliers with model details to ensure they can deliver the right part. Additionally, request samples for testing before placing larger orders to verify compatibility, which can save time and resources. -

What is the best magnetic thermostat sensor for Zojirushi electric rice cookers?

The ideal magnetic thermostat sensor depends on the specific model of the Zojirushi rice cooker you are using. It’s advisable to choose sensors that are designed specifically for your model to ensure optimal performance. Look for suppliers that provide detailed product specifications and compatibility information. Reading reviews and seeking recommendations from other B2B buyers can also guide you in selecting the most reliable sensors for your needs. -

What are the typical minimum order quantities (MOQ) for magnetic thermostat sensors?

Minimum order quantities can vary significantly between suppliers. Generally, MOQs for magnetic thermostat sensors might range from 100 to 1000 units, depending on the manufacturer and production capabilities. When negotiating with suppliers, inquire about flexible MOQs, especially if you are testing a new market or product line. Some suppliers may offer lower MOQs for first-time buyers or bulk discounts as you build a long-term relationship. -

How can I ensure quality assurance (QA) when sourcing magnetic thermostat sensors?

To ensure quality, request certifications and testing reports from suppliers. Look for manufacturers that adhere to international quality standards such as ISO 9001. Additionally, consider conducting third-party inspections or audits of the production facility. Establishing clear quality expectations in your contract can help mitigate risks and ensure the products meet your specifications before shipping. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely, but common practices include a 30% deposit upfront and the remaining 70% before shipment. Some suppliers may offer net payment terms based on your relationship and order history. It’s advisable to negotiate terms that align with your cash flow needs while ensuring security, such as using letters of credit for large orders. Always confirm payment methods accepted by the supplier to avoid complications. -

What logistics considerations should I keep in mind when importing magnetic thermostat sensors?

When importing, factor in shipping costs, customs duties, and delivery timelines. Choose a reliable freight forwarder familiar with the regulations in your country to streamline the process. Ensure that the supplier provides all necessary documentation, including invoices and packing lists, to facilitate smooth customs clearance. Additionally, consider the mode of transport (air vs. sea) based on your urgency and budget constraints. -

How can I vet suppliers of magnetic thermostat sensors effectively?

To vet suppliers, research their background, including years in business, customer reviews, and industry reputation. Request references from previous clients and verify their capabilities through site visits or virtual tours if possible. Utilizing platforms like Alibaba or industry-specific trade shows can help you connect with verified suppliers. Assess their communication responsiveness and willingness to provide documentation, which reflects their professionalism. -

What customization options are available for magnetic thermostat sensors?

Many suppliers offer customization options such as size, shape, and temperature range to better fit your Zojirushi rice cooker models. Discuss your specific requirements with potential suppliers early in the negotiation process. It’s crucial to understand any additional costs or changes in lead times associated with custom orders. Request prototypes to evaluate performance before committing to larger quantities.

Top 2 Magnetic Thermostat Sensor For Zozirushi Electric Rice Cooker Manufacturers & Suppliers List

1. ZOJIRUSHI – Thermostat Magnet Bottom Temperature Sensor

Domain: aliexpress.com

Registered: 2006 (19 years)

Introduction: This company, ZOJIRUSHI – Thermostat Magnet Bottom Temperature Sensor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Unbranded – Electric Cooker Thermostat Sensor

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”Rice cooker repair parts Magnetic thermostat Limiter Sensor”,”condition”:”New”,”price”:”$7.87″,”shipping_cost”:”$2.99″,”estimated_delivery”:”Wed, Oct 1 – Wed, Oct 8″,”quantity_available”:5,”brand”:”Unbranded”,”type”:”Electric Cooker Thermostat Sensor”,”description”:”Fit for Electric Cooker. 1 Pcs x Electric Cooker Thermostat”}

Strategic Sourcing Conclusion and Outlook for magnetic thermostat sensor for zozirushi electric rice cooker

In the competitive landscape of electric rice cooker components, the strategic sourcing of magnetic thermostat sensors presents substantial opportunities for international B2B buyers. These sensors are integral to the functionality and reliability of Zojirushi electric rice cookers, ensuring precise temperature control and enhancing product quality. By prioritizing partnerships with suppliers who offer high-quality sensors, businesses can not only improve their product offerings but also bolster customer satisfaction and brand loyalty.

Understanding the regional market dynamics is crucial. For buyers in Africa, South America, the Middle East, and Europe, it is essential to leverage local insights and supplier relationships that align with specific market needs and regulatory standards. Investing in strategic sourcing can lead to significant cost savings and improved supply chain resilience, ultimately driving competitive advantage.

Looking ahead, as consumer preferences evolve towards smart and energy-efficient appliances, there is an increasing demand for innovative components like advanced magnetic thermostat sensors. We encourage B2B buyers to explore partnerships with manufacturers who are committed to technological advancements and sustainability. By doing so, you position your business to meet future market demands and excel in a dynamic industry landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to magnetic thermostat sensor for zozirushi electric rice cooker

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.