The Definitive Guide to Locking Latches: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for locking latches

In an increasingly interconnected world, sourcing reliable locking latches presents a unique challenge for international B2B buyers. The need for secure, high-quality latching mechanisms is paramount across various industries, from construction to transportation and beyond. This comprehensive guide delves into the diverse landscape of locking latches, offering insights into various types, applications, and materials. Whether you are seeking heavy-duty options for industrial use or child safety latches for residential settings, understanding the nuances of locking latches is essential for making informed purchasing decisions.

This guide not only outlines the different types of locking latches available in the market but also provides practical advice on supplier vetting, cost analysis, and compliance with international standards. With a particular focus on the needs of buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Nigeria, we aim to empower you with the knowledge required to navigate this global market effectively. By equipping you with actionable insights and best practices, this resource will help streamline your procurement process, ensuring you select the right locking latches that meet your specific security and operational requirements.

Understanding locking latches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Deadbolt Latches | Requires a key for locking; high security | Commercial doors, residential gates | Pros: Excellent security; durable. Cons: Installation can be complex; may require specific door prep. |

| Slide Bolt Latches | Simple mechanism; slides into a bolt for locking | Gates, sheds, and storage areas | Pros: Easy to install; cost-effective. Cons: Less secure than other types; can be vulnerable to force. |

| Hook Latches | Uses a hook to secure; often adjustable | Fencing, gates, and livestock enclosures | Pros: Versatile; simple design. Cons: May not be suitable for high-security needs; can wear over time. |

| Magnetic Latches | Uses magnets for secure closure; often self-latching | Cabinets, enclosures, and light doors | Pros: Convenient; silent operation. Cons: May not withstand heavy-duty use; limited security. |

| Keyless Entry Latches | Operated via keypad or card; no physical key needed | Modern offices, gates, and secure areas | Pros: Enhanced convenience; eliminates key management. Cons: Dependent on batteries or power; potential for technology failure. |

What Are the Characteristics of Deadbolt Latches and Their Suitability for B2B Buyers?

Deadbolt latches are renowned for their robust security features, requiring a key to unlock, which makes them a preferred choice for commercial and residential applications where security is paramount. They are particularly suitable for external doors and high-risk areas due to their resistance to forced entry. B2B buyers should consider the installation complexity and potential need for specialized door preparation, which may add to overall costs. However, their durability and effectiveness in preventing unauthorized access often justify the investment.

How Do Slide Bolt Latches Work and Where Are They Best Used?

Slide bolt latches operate with a straightforward mechanism that allows a bolt to slide into a fixed position, securing the door or gate. They are ideal for use in gates, sheds, and storage areas where security is necessary but not as critical as in other applications. The ease of installation and cost-effectiveness make them appealing to B2B buyers. However, it is important to note that slide bolt latches may be less secure than other locking mechanisms, and their vulnerability to force could be a concern in high-security environments.

What Advantages Do Hook Latches Offer for Various Applications?

Hook latches utilize a hook mechanism to secure doors or gates and are often adjustable to accommodate different sizes. Their versatility makes them suitable for a wide range of applications, including fencing and livestock enclosures. B2B buyers appreciate their simple design and ease of installation. However, it is crucial to consider that hook latches may not meet the security needs of more demanding environments, as they can wear out over time and may be susceptible to tampering.

In What Situations Are Magnetic Latches Most Effective?

Magnetic latches utilize magnetic forces to secure closures, often featuring a self-latching design that enhances convenience. They are commonly used in cabinets, enclosures, and light doors where silent operation and ease of use are prioritized. B2B buyers may find magnetic latches appealing due to their low maintenance and user-friendly functionality. However, it is essential to recognize that their security capabilities are limited, making them less suitable for heavy-duty use or high-security applications.

Why Are Keyless Entry Latches Gaining Popularity Among B2B Buyers?

Keyless entry latches operate via keypads or cards, eliminating the need for physical keys and enhancing convenience in secure access areas. They are increasingly used in modern offices and secure gates, appealing to B2B buyers looking for efficient access management solutions. The convenience of keyless systems can streamline operations, but buyers should also consider the dependency on batteries or power sources and the potential for technology failures, which could impact security and access.

Key Industrial Applications of locking latches

| Industry/Sector | Specific Application of locking latches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Securing cargo containers and transport vehicles | Enhanced security and theft prevention | Durability, weather resistance, and compatibility with existing systems |

| Construction & Building | Locking gates and access points on job sites | Improved site security and restricted access | Compliance with safety regulations and ease of installation |

| Agriculture & Farming | Locking storage units and equipment sheds | Protection against theft and environmental factors | Resistance to rust and corrosion, especially in humid climates |

| Manufacturing & Warehousing | Securing machinery and storage areas | Safeguarding valuable assets and ensuring safety | Load capacity, material strength, and ease of use |

| Residential & Commercial | Gate latches for fences and doors | Increased property security and aesthetic appeal | Variety of styles, finishes, and keying options available |

How Are Locking Latches Utilized in the Transportation & Logistics Sector?

In the transportation and logistics industry, locking latches are crucial for securing cargo containers and transport vehicles. They provide an essential layer of security against theft and unauthorized access during transit. Buyers in this sector should consider latches that are durable and weather-resistant, ensuring long-term functionality despite exposure to various environmental conditions. Compatibility with existing locking mechanisms is also vital to maintain operational efficiency.

What Role Do Locking Latches Play in Construction & Building Applications?

Locking latches are widely used to secure gates and access points on construction sites, effectively enhancing site security. They prevent unauthorized entry, protecting both personnel and equipment. For buyers in this sector, it is crucial to source latches that comply with safety regulations and can be easily installed. Selecting robust materials that withstand the rigors of a construction environment is also essential to ensure longevity and reliability.

How Do Locking Latches Benefit Agriculture & Farming Operations?

In agriculture, locking latches secure storage units and equipment sheds, safeguarding against theft and environmental damage. Farmers often face challenges related to equipment security and weather exposure, making reliable latching solutions vital. Buyers should prioritize latches that exhibit resistance to rust and corrosion, particularly in humid climates, ensuring that their investments remain protected over time.

Why Are Locking Latches Important in Manufacturing & Warehousing?

Locking latches serve a critical function in manufacturing and warehousing by securing machinery and storage areas. This protection helps prevent unauthorized access and ensures the safety of valuable assets. When sourcing latches for these applications, businesses should focus on load capacity and material strength to withstand frequent use. Additionally, ease of use is important for operational efficiency, allowing quick access when necessary.

How Do Locking Latches Enhance Security in Residential & Commercial Properties?

Locking latches are commonly employed in residential and commercial settings to secure gates, fences, and doors, thereby increasing property security. They not only deter potential intruders but also enhance the aesthetic appeal of properties. Buyers should look for a variety of styles and finishes that fit their specific design needs, as well as options for keying that align with their security protocols.

3 Common User Pain Points for ‘locking latches’ & Their Solutions

Scenario 1: Inconsistent Security Standards Across Regions

The Problem: Many B2B buyers face the challenge of inconsistent security standards for locking latches when operating in international markets. For instance, a company based in Europe may have stringent security regulations, while a counterpart in Africa may have different requirements. This disparity can lead to complications in selecting the appropriate locking latch that meets local regulations, resulting in compliance issues and potential security vulnerabilities. The lack of clarity on material standards, locking mechanisms, and installation guidelines can further exacerbate the problem, leaving buyers unsure about their choices.

The Solution: To address this issue, B2B buyers should conduct thorough market research tailored to each region where they operate. This involves collaborating with local experts or consultants who understand the specific security regulations and standards applicable in that area. Buyers should also evaluate locking latches that are certified by recognized international standards organizations. Engaging with suppliers that offer a range of locking latches compliant with various regional standards can streamline the sourcing process. Additionally, buyers can leverage product data sheets and technical documentation from manufacturers to ensure they have a clear understanding of the specifications required for compliance. This proactive approach not only helps in selecting the right products but also builds trust with local partners and customers.

Scenario 2: Difficulty in Ensuring Compatibility with Existing Systems

The Problem: Another common pain point for B2B buyers is ensuring that new locking latches are compatible with existing gate or door systems. For example, a manufacturing facility may have specific gate designs or materials that require unique latch specifications. If a buyer selects a locking latch that does not fit properly, it can lead to costly modifications, delays in project timelines, and potential security risks if the latch fails to operate as intended.

The Solution: To mitigate compatibility issues, buyers should conduct a comprehensive assessment of their current systems before sourcing locking latches. This involves measuring the dimensions and material types of existing gates or doors and understanding the operational requirements, such as weight and frequency of use. It is advisable to consult with manufacturers or suppliers to obtain samples and test them in the field prior to committing to a bulk purchase. Buyers should also consider latches that offer adjustable features or modular designs to accommodate a range of applications. By prioritizing compatibility in the selection process, B2B buyers can ensure seamless integration and enhance the overall security of their installations.

Scenario 3: Challenges in Long-Term Durability and Maintenance

The Problem: B2B buyers often encounter issues related to the long-term durability and maintenance of locking latches, particularly in harsh environments. For instance, industrial facilities in coastal areas may face corrosion due to salt exposure, while others may deal with extreme temperatures that affect latch functionality. Buyers may find that cheaper options fail prematurely, leading to increased maintenance costs and operational downtime.

The Solution: To combat durability challenges, buyers should invest in high-quality locking latches made from robust materials such as stainless steel or zinc-plated steel that are resistant to corrosion and wear. When sourcing, it is important to inquire about the manufacturer’s testing processes for durability and environmental resistance. Additionally, buyers should establish a regular maintenance schedule to inspect and service locking latches, ensuring they remain functional and secure. Utilizing latches designed for specific environmental conditions, such as weatherproof or UV-resistant options, can also enhance longevity. By focusing on quality and maintenance, buyers can reduce long-term costs and ensure the reliability of their locking mechanisms.

Strategic Material Selection Guide for locking latches

When selecting materials for locking latches, it’s essential to consider the specific properties and performance characteristics that will meet the demands of various applications. Below is an analysis of four common materials used in the manufacture of locking latches, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Steel for Locking Latches?

Steel, particularly stainless steel, is a popular choice for locking latches due to its strength and durability. It typically exhibits excellent tensile strength and can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Stainless steel also offers good corrosion resistance, especially in environments exposed to moisture or chemicals.

Pros: Steel’s strength makes it ideal for high-security applications. It is also relatively cost-effective compared to other metals, and its availability is widespread.

Cons: Although stainless steel is resistant to rust, it can still corrode under certain conditions, particularly if not properly treated. Additionally, manufacturing processes for steel latches can be complex, potentially increasing production costs.

Impact on Application: Steel locking latches are suitable for a variety of media, including industrial settings where exposure to harsh conditions is common.

Considerations for International Buyers: Compliance with standards such as ASTM or DIN is crucial, especially in regions like Europe and the Middle East. Buyers should ensure that the latches meet local regulations regarding safety and durability.

How Does Aluminum Compare as a Material for Locking Latches?

Aluminum is another common material for locking latches, valued for its lightweight properties and resistance to corrosion. It is particularly effective in applications where weight is a concern, such as in automotive or aerospace industries.

Pros: Aluminum is lightweight, making it easier to install and handle. It also has excellent corrosion resistance, which is beneficial in humid or coastal environments.

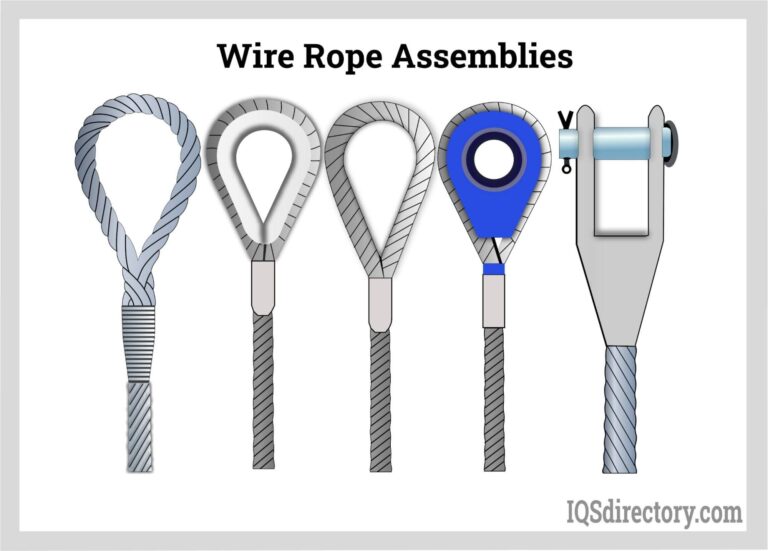

Illustrative image related to locking latches

Cons: While aluminum is durable, it is not as strong as steel, which may limit its use in high-security applications. The cost of aluminum can also be higher than that of steel, depending on the alloy used.

Impact on Application: Aluminum latches are ideal for applications where weight savings are critical, such as in portable equipment or outdoor settings where moisture exposure is frequent.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades and their compliance with international standards, such as JIS in Japan or EN in Europe, to ensure suitability for their applications.

What Role Does Plastic Play in Locking Latch Applications?

Plastic materials, particularly engineering plastics like nylon or polycarbonate, are increasingly used in locking latches due to their versatility and resistance to corrosion.

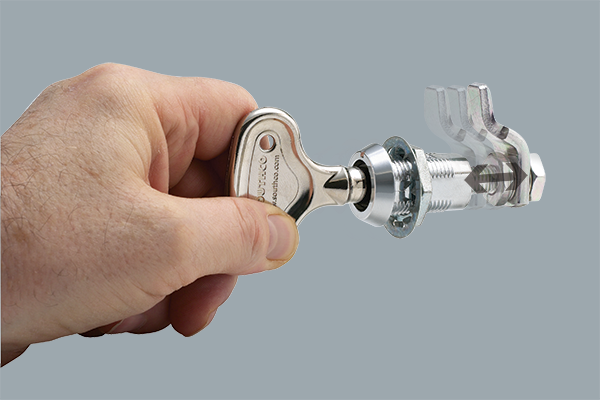

Illustrative image related to locking latches

Pros: Plastic latches are lightweight, non-corrosive, and can be manufactured in various colors and designs, making them aesthetically pleasing. They are also generally less expensive than metal options.

Cons: Plastic latches may not offer the same level of strength or security as metal latches, making them unsuitable for high-security applications. They can also be affected by extreme temperatures, which may limit their use in certain environments.

Impact on Application: Plastic locking latches are suitable for residential applications or light-duty commercial uses where aesthetics and corrosion resistance are prioritized over security.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with relevant safety and environmental regulations, particularly in regions with stringent standards.

How Does Brass Function as a Material for Locking Latches?

Brass, an alloy of copper and zinc, is often used in decorative locking latches due to its attractive appearance and good corrosion resistance.

Pros: Brass latches provide a classic look and are resistant to corrosion, making them suitable for indoor and outdoor applications. They also have antimicrobial properties, which can be beneficial in certain environments.

Cons: Brass is generally more expensive than steel and aluminum, which can be a drawback for budget-conscious buyers. Additionally, brass can be softer than steel, making it less suitable for high-security applications.

Impact on Application: Brass latches are often used in residential settings, particularly for doors and cabinets where aesthetics are important.

Considerations for International Buyers: Buyers should be aware of the specific alloy compositions and ensure compliance with local standards, particularly in regions like Europe where material specifications can be stringent.

Summary Table of Material Selection for Locking Latches

| Material | Typical Use Case for locking latches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-security environments | Excellent strength and durability | Potential for corrosion if untreated | Medium |

| Aluminum | Lightweight applications | Lightweight and corrosion-resistant | Lower strength than steel | Medium to High |

| Plastic | Residential and light-duty use | Lightweight and non-corrosive | Limited strength and temperature sensitivity | Low |

| Brass | Decorative residential applications | Aesthetically pleasing and corrosion-resistant | Higher cost and lower strength | High |

This guide provides a comprehensive overview of material options for locking latches, enabling international B2B buyers to make informed decisions based on their specific needs and compliance requirements.

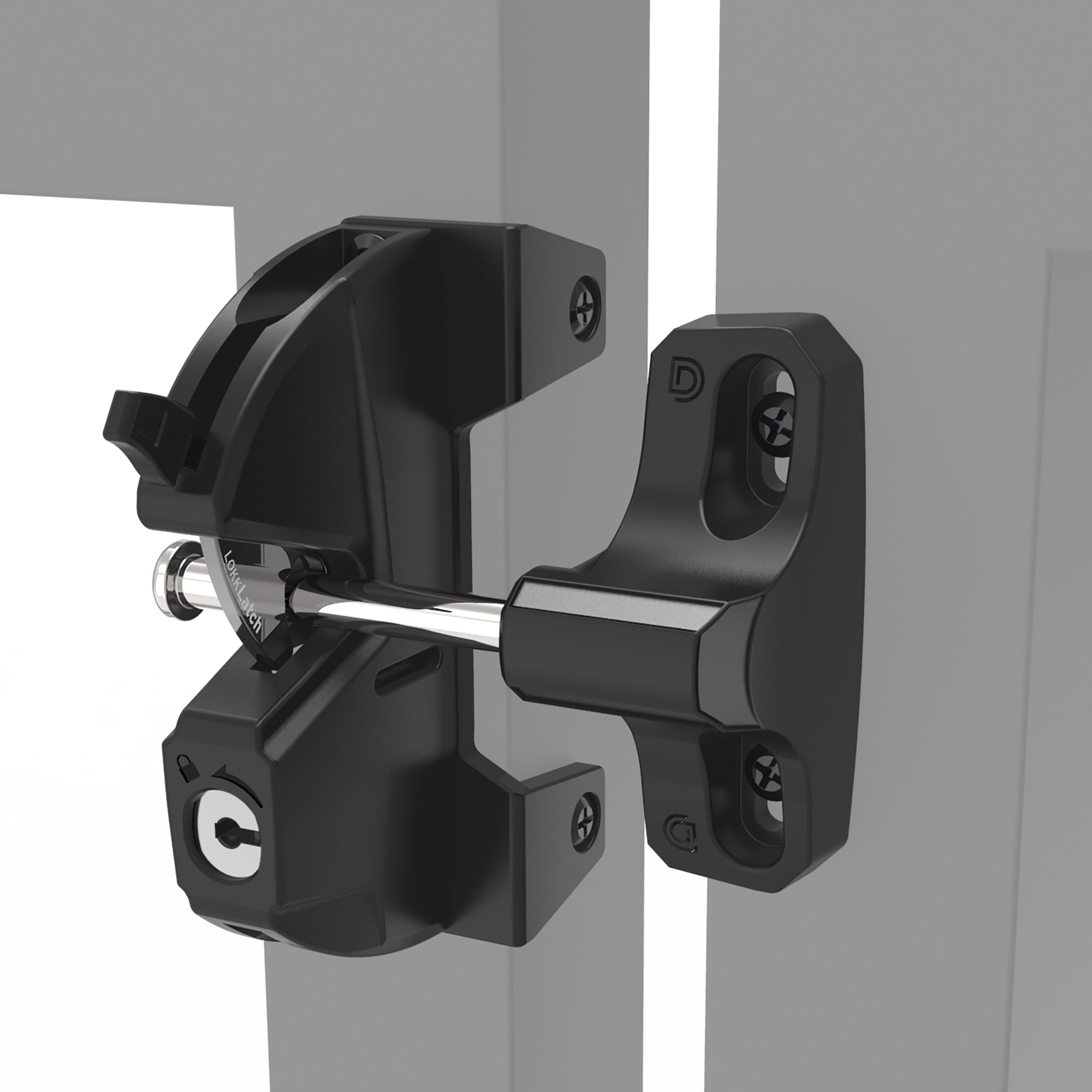

Illustrative image related to locking latches

In-depth Look: Manufacturing Processes and Quality Assurance for locking latches

What Are the Main Stages of Locking Latch Manufacturing Processes?

Manufacturing locking latches involves several critical stages, each designed to ensure that the final product meets the specified performance and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Locking Latch Production?

The manufacturing process begins with the selection of high-quality raw materials. Common materials for locking latches include stainless steel, brass, aluminum, and various plastics. The choice of material significantly influences durability, corrosion resistance, and overall performance. Once selected, materials are cut, shaped, and treated to prepare them for the forming stage. This preparation may include processes like annealing or surface treatment to enhance material properties.

How Are Locking Latches Formed?

Forming is a crucial stage where raw materials are shaped into the components of locking latches. This can involve various techniques, including stamping, forging, and machining.

Illustrative image related to locking latches

- Stamping: This process uses a die to cut or shape materials, creating precise components quickly and efficiently.

- Forging: Involves shaping metal using compressive forces, resulting in stronger components due to improved grain structure.

- Machining: This method involves removing material from a solid block to create intricate designs, which is essential for components requiring high precision.

Each technique has its advantages, and the choice often depends on the design complexity and production volume.

What Is the Assembly Process for Locking Latches?

After forming, components are assembled into finished locking latches. This stage may involve manual or automated assembly processes, including the installation of springs, pins, or locking mechanisms. Quality control checks often occur during assembly to ensure that components fit together correctly and function as intended.

In automated settings, robotic systems can significantly enhance efficiency and consistency, while manual assembly allows for detailed inspection and customization.

Illustrative image related to locking latches

What Finishing Techniques Are Applied to Locking Latches?

The finishing stage is essential for both aesthetics and functionality. Finishing processes can include:

- Coating: Applying a protective layer (e.g., powder coating, electroplating) to prevent corrosion and enhance appearance.

- Polishing: This improves the surface finish and can increase aesthetic appeal.

- Heat Treatment: Strengthens the latch through controlled heating and cooling processes, enhancing durability.

Finishing not only affects the latch’s look but also its resistance to environmental factors, which is crucial for outdoor applications.

What Quality Assurance Standards Are Relevant for Locking Latches?

Quality assurance (QA) is vital in the manufacturing of locking latches, ensuring that products meet international standards and customer specifications. International standards such as ISO 9001 set the framework for quality management systems (QMS) across various industries.

How Do International Standards Impact Quality Control?

ISO 9001 focuses on continuous improvement and customer satisfaction. Compliance with these standards indicates that a manufacturer has a robust QMS in place, which is critical for B2B buyers looking for reliable suppliers.

Other industry-specific certifications may include:

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Spec Q1: Relevant for suppliers in the oil and gas industry, ensuring quality in products like latches used in critical applications.

What Are the Key Quality Control Checkpoints in Locking Latch Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that each component meets quality standards. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during production, this monitoring ensures that manufacturing processes are followed correctly and that any deviations are addressed immediately.

- Final Quality Control (FQC): The final inspection occurs before products are shipped, checking for functionality, aesthetic defects, and compliance with specifications.

What Testing Methods Are Commonly Used for Locking Latches?

Various testing methods are employed to verify the functionality and durability of locking latches. These may include:

- Mechanical Testing: Evaluates strength, flexibility, and fatigue resistance.

- Environmental Testing: Assesses how well latches perform under different environmental conditions, such as humidity, temperature fluctuations, and exposure to corrosive elements.

- Functional Testing: Ensures that latches operate correctly under expected use conditions.

These tests provide essential data that B2B buyers can use to gauge product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are effective strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess a supplier’s manufacturing practices and quality control measures firsthand. This can include reviewing QMS documentation and observing production processes.

- Quality Reports: Requesting detailed quality reports can provide insights into a supplier’s performance over time, including defect rates and corrective actions taken.

- Third-Party Inspections: Engaging independent inspection agencies can provide unbiased assessments of the supplier’s quality control processes and product integrity.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of specific nuances in quality control that may vary by region. For instance, standards like ISO may be universally recognized, but local regulations can also play a significant role in manufacturing practices. Buyers should ensure that suppliers comply with both international standards and any local regulations pertinent to their market.

Illustrative image related to locking latches

Additionally, understanding cultural differences in business practices can aid in establishing effective communication regarding quality expectations. For example, in regions like Germany, a strong emphasis on engineering and precision may lead to different expectations compared to markets in Africa or South America, where adaptability and cost-effectiveness might be prioritized.

Conclusion

Understanding the manufacturing processes and quality assurance mechanisms for locking latches is essential for B2B buyers aiming to make informed procurement decisions. By focusing on critical stages such as material preparation, forming, assembly, and finishing, as well as the importance of rigorous quality control standards and practices, buyers can ensure they partner with suppliers who deliver reliable, high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘locking latches’

This practical sourcing guide aims to provide B2B buyers with a structured approach to procuring locking latches, ensuring that you make informed decisions that meet your security and operational needs. By following this checklist, you can streamline your purchasing process, mitigate risks, and enhance your supply chain efficiency.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s vital to have a clear understanding of your specific requirements. Consider the type of locking latch needed, such as gate latches, door latches, or specialized locks for unique applications. Additionally, specify the materials (e.g., stainless steel, aluminum) and any necessary features, such as weather resistance or child safety mechanisms.

Step 2: Research Market Trends and Standards

Staying abreast of industry standards and market trends can significantly influence your purchasing decisions. Review specifications from relevant industry bodies to ensure compliance with safety and performance standards. Understanding current trends, such as the demand for eco-friendly materials or advanced locking mechanisms, can also guide you in selecting innovative products that enhance security.

Illustrative image related to locking latches

Step 3: Evaluate Potential Suppliers

Thoroughly vetting suppliers is crucial for ensuring quality and reliability. Request detailed company profiles, including years in business, product certifications, and customer testimonials. Look for suppliers with experience in your specific industry and verify their ability to deliver on time and within budget.

- Check for certifications: Ensure suppliers comply with international standards (ISO, ASTM) relevant to locking latches.

- Request case studies: These can provide insights into how the supplier has successfully met similar needs for other clients.

Step 4: Assess Product Quality and Durability

Quality is paramount when it comes to locking latches, as they play a critical role in security. Request samples to evaluate the construction, finish, and functionality of the latches. Pay attention to aspects such as ease of installation, operation, and resistance to wear and tear, especially if they will be used in high-traffic areas.

Step 5: Analyze Pricing and Terms of Sale

A comprehensive cost analysis should go beyond the unit price of locking latches. Consider factors such as bulk purchase discounts, shipping costs, and potential tariffs, especially when sourcing internationally. Clarify payment terms, return policies, and warranty options to avoid any unexpected expenses later on.

Step 6: Verify After-Sales Support and Service

Reliable after-sales support is essential for addressing any issues that may arise post-purchase. Inquire about the supplier’s customer service practices, including their response times and availability of technical support. A supplier that offers robust after-sales service can significantly reduce operational disruptions and ensure long-term satisfaction.

Illustrative image related to locking latches

Step 7: Establish a Long-Term Partnership

Finally, consider the long-term implications of your supplier relationship. Establishing a partnership with a reliable supplier can lead to better pricing, exclusive access to new products, and priority service. Regular communication and feedback can foster a collaborative environment that benefits both parties.

By following these steps, B2B buyers can navigate the complexities of sourcing locking latches effectively, ensuring that their procurement process is efficient and aligns with their operational requirements.

Comprehensive Cost and Pricing Analysis for locking latches Sourcing

What Are the Key Cost Components for Sourcing Locking Latches?

Understanding the cost structure of locking latches is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. Common materials include stainless steel, aluminum, and high-grade plastics. Prices fluctuate based on market demand and availability, particularly for metals.

-

Labor: Labor costs vary widely by region. In countries with lower wage standards, the manufacturing cost may be reduced, but this can also impact quality. For high-quality products, skilled labor is essential, which can drive costs up.

-

Manufacturing Overhead: This encompasses expenses related to factory operations such as utilities, maintenance, and administrative costs. Efficient production processes can help minimize these overheads.

-

Tooling: The initial costs for molds and dies used in the production of locking latches can be substantial. Custom designs or specialized latches will typically incur higher tooling costs.

-

Quality Control (QC): Investing in quality control is crucial to ensure that products meet safety and durability standards. The cost of QC can vary depending on the complexity of the latch design and regulatory requirements.

-

Logistics: Transportation costs, including shipping and handling, are a significant part of the overall cost. International buyers should consider the impact of different shipping methods and distances on pricing.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. This margin can vary based on the supplier’s positioning in the market and their operational efficiency.

How Do Price Influencers Affect Locking Latch Costs?

Several factors influence the pricing of locking latches, especially in a B2B context:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically attract discounts. Buyers should evaluate their needs against potential savings from bulk purchases.

-

Specifications and Customization: Custom latches designed to specific requirements may incur additional costs due to the complexity of manufacturing and tooling. Standard products are generally more cost-effective.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., ISO, CE) can increase costs but are essential for markets with stringent safety regulations. Buyers should weigh these factors against their own quality requirements.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their products due to proven quality and service.

-

Incoterms: The choice of Incoterms affects the overall cost. For instance, DDP (Delivered Duty Paid) may include more initial costs but simplifies logistics for the buyer.

What Are the Best Practices for Negotiating Prices on Locking Latches?

Effective negotiation strategies can help buyers secure better pricing on locking latches:

-

Research and Benchmarking: Conduct thorough market research to understand typical pricing structures. This knowledge equips buyers to negotiate from a position of strength.

-

Discuss Total Cost of Ownership (TCO): Focus on the long-term value rather than just the upfront cost. Highlight potential savings in maintenance, durability, and operational efficiency.

-

Leverage Volume Discounts: If your business model allows, consider consolidating orders or collaborating with other companies to reach higher order quantities for better pricing.

-

Build Relationships with Suppliers: Establishing long-term partnerships can lead to more favorable terms and pricing over time.

What Pricing Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can affect costs significantly. Consider locking in rates or negotiating terms that mitigate this risk.

-

Import Tariffs and Duties: Understand the local regulations regarding tariffs and duties that may apply to imported goods. This can impact the overall cost and pricing strategy.

-

Cultural Sensitivities: Different regions may have varying expectations regarding pricing negotiations and business practices. Tailoring approaches to fit local customs can facilitate smoother transactions.

Conclusion

When sourcing locking latches, understanding the intricate cost structures and pricing influencers is vital for making informed purchasing decisions. By leveraging negotiation strategies and being mindful of the unique challenges of international sourcing, buyers can optimize their procurement processes and achieve better outcomes. Always remember to request indicative pricing, as actual costs may vary based on market conditions and specific supplier agreements.

Alternatives Analysis: Comparing locking latches With Other Solutions

Exploring Alternatives to Locking Latches in Security Solutions

When evaluating security options for commercial applications, it’s vital to consider various alternatives to locking latches. While locking latches provide effective security for gates, doors, and cabinets, other solutions may offer enhanced performance, cost efficiency, or ease of use. This analysis presents a comparison between locking latches and two viable alternatives: electronic locks and padlocks.

Comparison Table

| Comparison Aspect | Locking Latches | Electronic Locks | Padlocks |

|---|---|---|---|

| Performance | Reliable for basic security needs; may be prone to tampering if not robust. | High security with advanced features like keyless entry and audit trails. | Versatile, but can be vulnerable to cutting or picking. |

| Cost | Generally low-cost, varying by material and style. | Higher initial investment; costs can vary widely based on technology. | Affordable, but long-term costs may accrue for replacements. |

| Ease of Implementation | Simple installation; often requires basic tools. | More complex installation; may need professional setup. | Easy to install; requires minimal tools. |

| Maintenance | Low maintenance; occasional lubrication needed. | Regular software updates and battery replacements required. | Minimal maintenance; periodic checks for wear and tear. |

| Best Use Case | Ideal for gates and cabinets where moderate security is sufficient. | Best for high-security areas requiring controlled access. | Suitable for temporary or portable security needs. |

Detailed Breakdown of Alternatives

What are Electronic Locks and their Advantages?

Electronic locks are sophisticated locking mechanisms that use digital technologies, including keypads, biometrics, or mobile applications for access. One of the primary advantages of electronic locks is their ability to provide enhanced security features, such as audit trails and remote access management. Additionally, they eliminate the need for physical keys, reducing the risk of unauthorized duplication. However, the complexity of installation and the higher initial costs can be barriers for some businesses. Regular maintenance, including software updates and battery changes, is also necessary to ensure optimal performance.

How Do Padlocks Compare to Locking Latches?

Padlocks are widely recognized for their versatility, as they can secure various items, from gates to storage units. They are generally more affordable than electronic locks and are easy to install without specialized tools. However, their security level can vary greatly based on the material and design; lower-quality padlocks may be susceptible to cutting or picking. For temporary or portable security needs, padlocks can be an excellent choice, but they might not provide the same level of security as electronic locks or robust locking latches.

Making the Right Choice: How Can B2B Buyers Select the Best Security Solution?

Selecting the right locking mechanism for your business requires careful consideration of your specific security needs and operational context. If you require a simple, cost-effective solution for moderate security, locking latches may suffice. For applications where higher security is paramount, such as data centers or sensitive areas, electronic locks offer advanced protection features. Conversely, if your needs are temporary or you require flexibility, padlocks could be the most suitable option. Ultimately, understanding the performance, cost implications, and ease of implementation of each alternative will empower B2B buyers to make informed decisions that enhance their security posture.

Essential Technical Properties and Trade Terminology for locking latches

What Are the Key Technical Properties of Locking Latches?

When sourcing locking latches, understanding their technical properties is crucial for ensuring compatibility, durability, and security. Below are essential specifications that B2B buyers should consider:

-

Material Grade

The material used in locking latches significantly affects their strength and corrosion resistance. Common materials include stainless steel, zinc-plated steel, and plastic composites. Stainless steel offers high corrosion resistance, making it suitable for outdoor applications, while zinc-plated steel provides a cost-effective option with adequate durability for less demanding environments. -

Load Rating

This specification indicates the maximum weight a latch can securely hold. Load ratings vary widely depending on the latch design and material. Understanding the load rating is vital for applications in heavy-duty environments, such as industrial gates, where failure could lead to safety hazards or security breaches. -

Finish and Coating

The finish of a latch affects both its aesthetic appeal and its resistance to environmental factors. Options include powder coating, chrome plating, or anodizing. A high-quality finish not only enhances the latch’s appearance but also prolongs its lifespan by protecting it from rust and wear, which is especially important in humid or coastal regions. -

Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. Precise tolerances are essential for ensuring that the latch fits correctly and operates smoothly. For B2B buyers, understanding tolerance levels can prevent costly installation issues and ensure that the latch performs reliably in its intended application. -

Locking Mechanism Type

Different locking mechanisms, such as deadbolts, tumbler locks, or electronic locks, provide varying levels of security. B2B buyers must assess the required security level for their application to choose the most appropriate locking mechanism. This choice impacts not only security but also ease of use and maintenance.

What Are Common Trade Terms Related to Locking Latches?

Familiarity with industry jargon is essential for effective communication and negotiation in the locking latch market. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When purchasing locking latches, understanding whether a supplier is an OEM can impact product quality and warranty considerations, as OEMs typically adhere to higher standards. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to manage inventory effectively and ensure they meet supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. It typically includes specifications for the locking latches required. Utilizing RFQs can streamline the procurement process and ensure competitive pricing among suppliers. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps in understanding shipping, liability, and payment responsibilities, which can significantly affect overall costs and risk management. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is essential for effective project planning and inventory management. Long lead times can delay project timelines, impacting business operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing locking latches, ensuring that they meet their operational needs while maintaining security and compliance.

Navigating Market Dynamics and Sourcing Trends in the locking latches Sector

What Are the Current Market Dynamics in the Locking Latches Sector?

The global market for locking latches is experiencing notable growth driven by rising security concerns across various sectors, including residential, commercial, and industrial applications. Key trends include the increasing adoption of smart locking mechanisms, which integrate with IoT technologies, enabling remote access and enhanced security features. B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly seeking products that offer not only security but also ease of installation and maintenance.

Emerging sourcing trends highlight the shift towards local suppliers, as companies aim to reduce lead times and transportation costs. In regions such as Nigeria and Germany, there’s a growing emphasis on sourcing from local manufacturers to support economic development and ensure compliance with regional regulations. Additionally, the demand for customizable locking latches is on the rise, allowing businesses to tailor solutions to specific security needs and aesthetics.

As the market evolves, international buyers must stay informed about technological advancements and industry standards. For instance, the integration of biometric systems into locking latches is becoming more prevalent, appealing to sectors that prioritize advanced security features. The competitive landscape is also shifting, with manufacturers focusing on innovative designs and materials to differentiate their offerings.

How Can Sustainability and Ethical Sourcing Influence Your Locking Latches Procurement?

In today’s business environment, sustainability and ethical sourcing have become paramount considerations for B2B buyers in the locking latches sector. The environmental impact of manufacturing processes and material sourcing is under increasing scrutiny. Buyers are encouraged to seek suppliers who prioritize sustainable practices, such as using recycled materials or reducing waste during production.

Certifications like ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are valuable indicators of a supplier’s commitment to sustainability. Additionally, the use of ‘green’ materials, such as recycled metals or sustainably sourced plastics, not only minimizes environmental footprints but can also enhance the marketability of products in eco-conscious markets.

Illustrative image related to locking latches

For businesses operating in regions like the Middle East and Europe, where regulatory pressures regarding sustainability are intensifying, opting for suppliers with a clear sustainability strategy can be a competitive advantage. This focus not only aligns with consumer preferences for environmentally responsible products but also mitigates risks associated with potential regulatory penalties.

How Has the Locking Latches Sector Evolved Over Time?

The evolution of the locking latches sector reflects broader trends in security and technology. Historically, locking latches were simple mechanical devices, primarily used for securing gates and doors. Over the decades, advancements in materials science have introduced stronger and more durable metals, enhancing the reliability of these products.

The introduction of electronic and smart locking mechanisms marks a significant shift in the industry. These innovations have been propelled by advancements in technology, allowing for features such as remote access, real-time monitoring, and integration with home automation systems. As security needs become more complex, the locking latches sector continues to adapt, offering solutions that meet the demands of modern consumers and businesses alike.

Overall, understanding these dynamics is crucial for international B2B buyers seeking to make informed sourcing decisions in the locking latches market.

Frequently Asked Questions (FAQs) for B2B Buyers of locking latches

-

1. How do I ensure the quality of locking latches before purchasing?

To ensure quality, it’s crucial to conduct thorough supplier vetting. Request samples to evaluate the material, finish, and functionality. Check for certifications and compliance with international standards, such as ISO or ASTM, relevant to your region. Additionally, read reviews or seek references from other B2B buyers. Establishing a quality assurance process, including inspections during production and before shipment, can help mitigate risks associated with poor-quality products. -

2. What is the best locking latch for securing outdoor gates?

For outdoor gates, consider heavy-duty locking latches made from corrosion-resistant materials like stainless steel or aluminum. Look for features such as weatherproofing and ease of installation. Keyed or combination locking mechanisms provide added security against unauthorized access. Brands like D&D Technologies offer specialized latches designed for outdoor use, ensuring durability and functionality in various weather conditions. -

3. How can I customize locking latches to meet my specific needs?

Most manufacturers offer customization options, including size, color, and finish, to suit your specific requirements. Communicate your needs clearly, including any special features such as keyless entry or child safety locks. Be prepared to meet minimum order quantities (MOQs) for customized products, and consider lead times for production. Collaborating closely with your supplier during the design phase can ensure that the final product meets your expectations. -

4. What are the typical minimum order quantities (MOQs) for locking latches?

MOQs for locking latches vary significantly by supplier and product type. Generally, MOQs can range from 100 to several thousand units. Factors influencing MOQs include customization options, production capabilities, and material availability. When sourcing, communicate your volume needs upfront to negotiate terms that work for both parties, especially if you are a smaller business or entering a new market. -

5. What payment terms should I expect when sourcing locking latches internationally?

Payment terms can vary widely among suppliers, but common practices include partial payment upfront (usually 30-50%) and the balance upon shipment or delivery. Some suppliers may accept letters of credit or escrow services for larger orders. Always clarify payment terms before finalizing contracts to avoid misunderstandings. Consider using secure payment methods to mitigate risks associated with international transactions. -

6. How can I efficiently manage logistics when importing locking latches?

Efficient logistics management involves understanding shipping options, customs regulations, and delivery timelines. Work with freight forwarders who specialize in your destination regions to navigate complexities. Ensure all shipping documents are in order, including invoices and packing lists, to facilitate smooth customs clearance. Establishing a reliable communication channel with your supplier can help manage timelines and address any unforeseen delays. -

7. What should I do if I receive defective locking latches?

If you receive defective products, promptly notify your supplier with detailed documentation, including photographs and descriptions of the defects. Most reputable suppliers will have a return policy or warranty that allows for replacements or refunds. It’s essential to maintain a clear line of communication and document all correspondences to ensure a satisfactory resolution. Consider implementing a quality inspection process for future orders to minimize such issues. -

8. How can I assess the reputation of a locking latch supplier?

To assess a supplier’s reputation, research their history in the industry, focusing on reviews and testimonials from previous clients. Utilize platforms like Alibaba or trade associations for insights. Request references and follow up with previous customers to understand their experiences. Additionally, evaluate the supplier’s certifications and any awards they may have received, which can indicate their commitment to quality and customer service.

Top 3 Locking Latches Manufacturers & Suppliers List

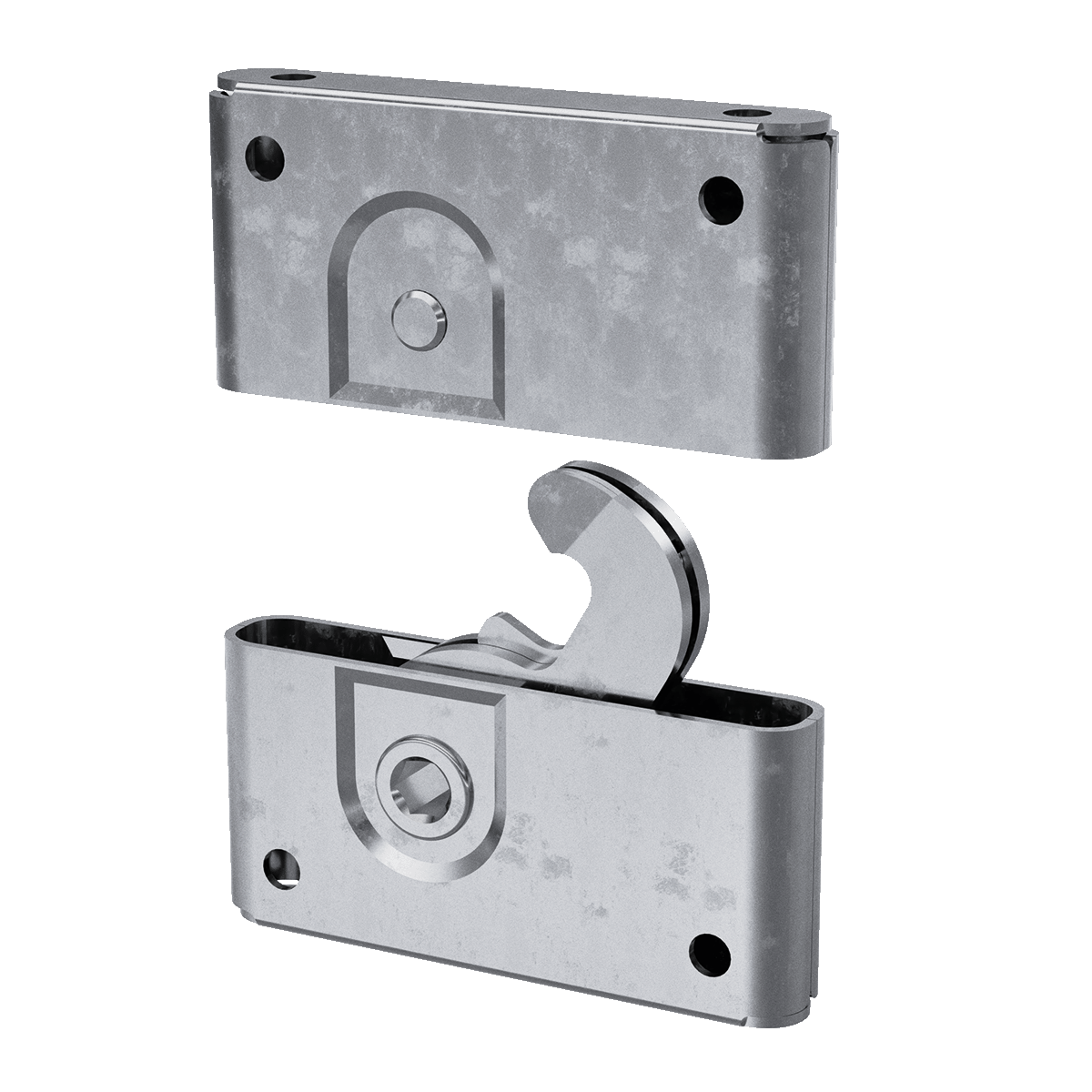

1. KIPP – Latches & Locks

2. National Hardware – Gate Latches and Locks

Domain: national-hardware.com

Registered: 2019 (6 years)

Introduction: Gate Latches and Locks are essential security hardware for gates, available in various finishes, features, and styles. Options include basic latches and padlock versions.

3. Pelican – TSA Locking Latches Set

Domain: colorcase.com

Registered: 1998 (27 years)

Introduction: Pelican Air TSA Locking Latches, Black, Push-Button (Set of 2 with Keys)\n- Price: $54.00\n- Features: 2 Genuine Pelican Medium Black Push-Button TSA Locking Latches, 2 Latch Keys, 2 Medium Latch Pins\n- Case Compatibility: Fits all Air cases except 1745 & 1755; Fits select Protector Cases (1450, 1500, 1520, 1550, 1600, 1620)\n- Made in the USA\n- Easy to open push-button latch design\n- TSA appro…

Strategic Sourcing Conclusion and Outlook for locking latches

In summary, strategic sourcing of locking latches presents a vital opportunity for international B2B buyers to enhance security and operational efficiency. Understanding the diverse range of products available—from gate latches to specialized locking mechanisms—enables businesses to select the right solutions tailored to their unique needs. Prioritizing quality and reliability in these components not only ensures safety but also contributes to long-term cost savings and customer satisfaction.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-quality locking latches is expected to grow. Buyers should actively seek partnerships with reputable suppliers that offer a variety of locking solutions, ensuring compliance with regional standards and preferences.

Looking forward, embracing innovation in locking latch technology will be crucial. As manufacturers introduce advanced features such as smart locking systems and enhanced durability, staying informed will allow businesses to remain competitive. Engage with suppliers, leverage market insights, and invest strategically to position your operations for success in a rapidly changing landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.