The Definitive Guide to Linear Screw Actuator: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for linear screw actuator

In the rapidly evolving landscape of industrial automation, sourcing the right linear screw actuator can be a daunting challenge for B2B buyers, especially in emerging markets like Nigeria and Brazil. These precision-engineered devices are pivotal in facilitating smooth linear motion in various applications, from robotics to medical devices. However, with a plethora of options available, understanding the nuances of different actuator types, such as rotating screws and rotating nuts, becomes essential for making informed purchasing decisions.

This comprehensive guide delves into the critical aspects of linear screw actuators, offering insights into their diverse configurations and applications. We will explore how to effectively vet suppliers, assess cost implications, and align your project requirements with the right actuator technology. By providing a thorough analysis of the market landscape, potential buyers will gain the knowledge needed to navigate the complexities of sourcing linear screw actuators tailored to their specific needs.

For international B2B buyers from Africa, South America, the Middle East, and Europe, this guide serves as a vital resource to empower your procurement strategy. With actionable insights and expert recommendations, you can streamline your sourcing process, minimize risks, and ultimately enhance the efficiency and reliability of your operations. Embrace the future of motion control with confidence, armed with the information necessary to make sound purchasing decisions in a global market.

Understanding linear screw actuator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotating Screw (MLS) | Motor rotates a lead screw to translate a load via a lead nut | CNC Machines, Robotics, Medical Devices | Pros: High precision, compact design; Cons: Requires external guidance for optimal performance. |

| Rotating Nut (MLN) | Nut rotates within the motor body, translating a load on a fixed lead screw | 3D Printing, Automated Assembly, HVAC | Pros: Simplified design, flexible configurations; Cons: May have limited load capacity compared to other types. |

| Motorized Lead Screw Actuator (MLA) | Integrated motor and lead screw in a closed assembly | Industrial Automation, Packaging Equipment | Pros: Reduces assembly complexity, efficient space usage; Cons: Less customizable than modular configurations. |

| Non-Captive Lead Screw Actuator | Motor and lead screw are separate; load is moved by the lead screw | Material Handling, Laboratory Automation | Pros: Versatile in application, ideal for long travel distances; Cons: Requires more space for installation. |

| Stepper Motor Linear Actuator | Combines hybrid stepper motor with precision lead screw | Medical Devices, X-Y Stages, Pipetting Devices | Pros: High torque density, customizable; Cons: Complexity in integration may require expert knowledge. |

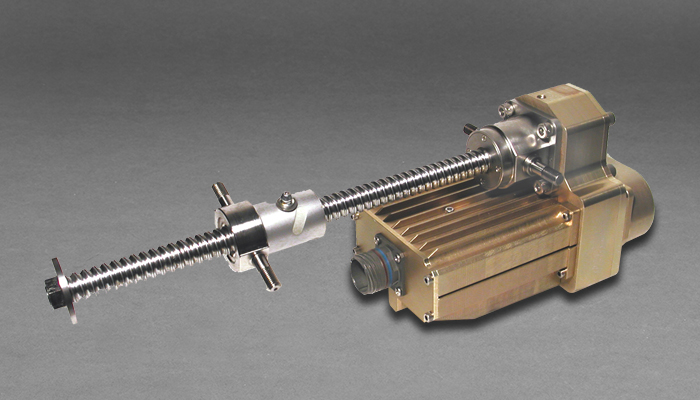

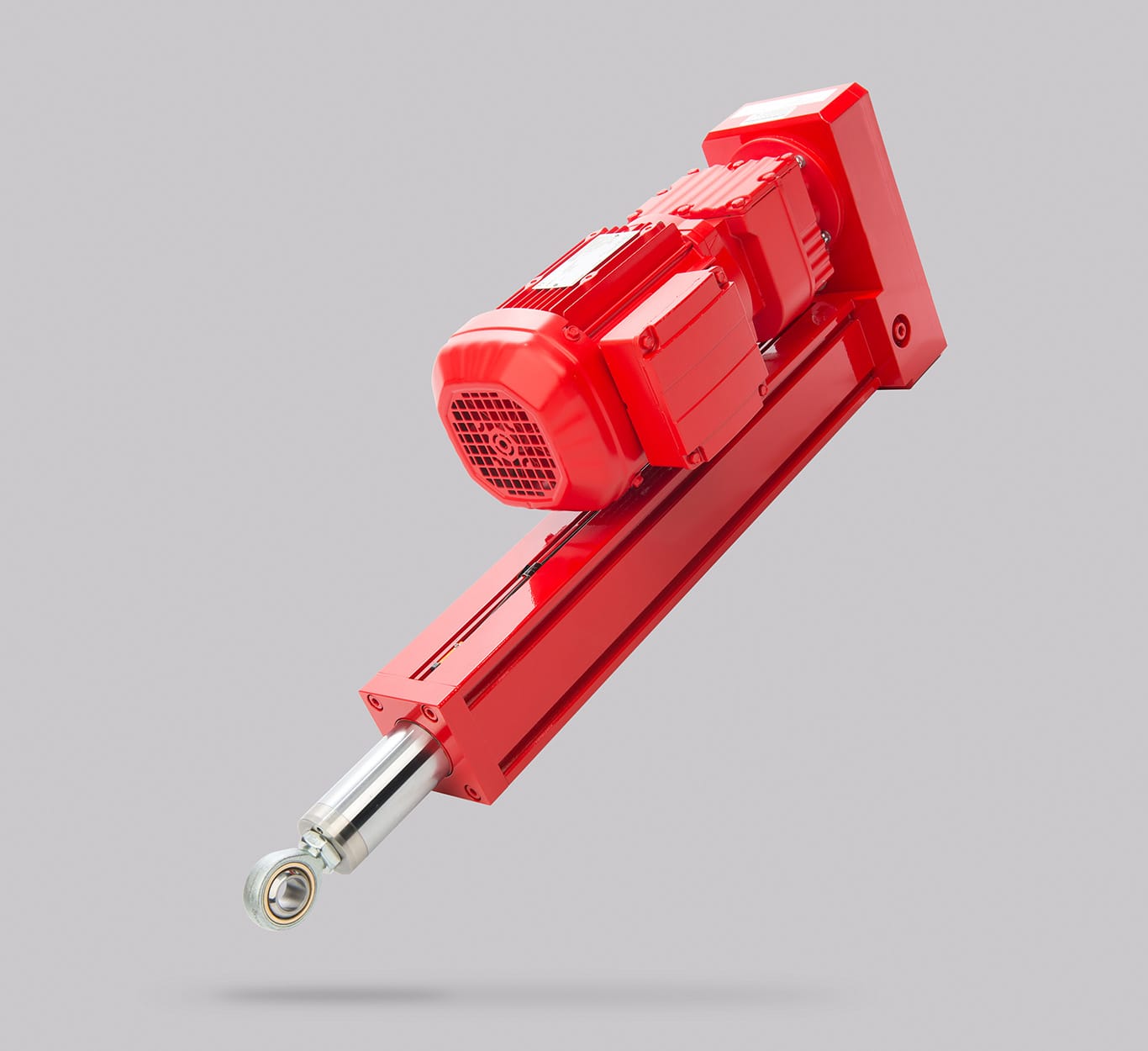

What are the Characteristics of Rotating Screw (MLS) Actuators?

Rotating Screw (MLS) actuators utilize a stepper motor to rotate a lead screw, translating a load attached to the lead nut. This design is ideal for applications requiring high precision, such as CNC machines and robotics. Buyers should consider the need for external guidance systems, as MLS actuators often require this for optimal performance. Their compact design allows for efficient use of space, making them suitable for tight installations.

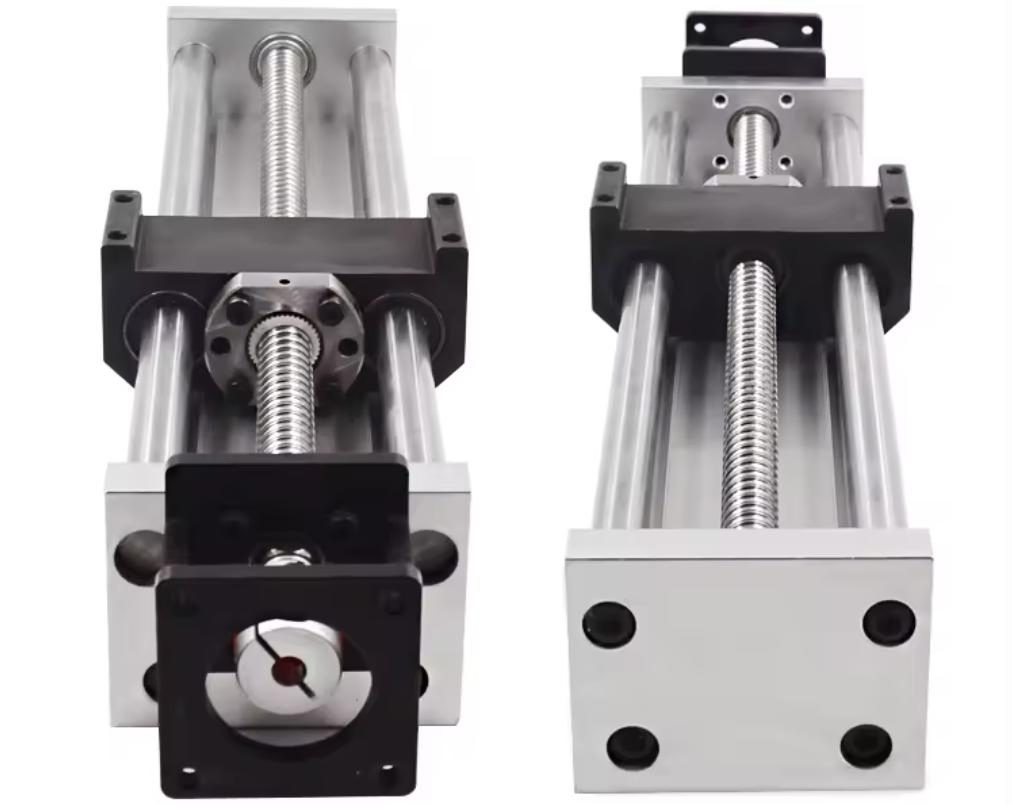

How Do Rotating Nut (MLN) Actuators Differ?

Rotating Nut (MLN) actuators feature a nut that rotates within the motor body, translating a load attached to a fixed lead screw. This configuration is particularly beneficial for applications like 3D printing and automated assembly, where design flexibility is crucial. While MLN actuators simplify the design by eliminating the need for external guidance, potential buyers should be aware of their limited load capacity compared to other actuator types.

What Makes Motorized Lead Screw Actuators (MLA) Efficient?

Motorized Lead Screw Actuators (MLA) combine a motor and lead screw into a single closed assembly. This integration reduces assembly complexity and is highly efficient for industrial automation and packaging applications. Buyers should appreciate the space-saving design but note that MLAs may offer less customization than modular systems, which could be a limiting factor for specific applications.

When Should Non-Captive Lead Screw Actuators Be Used?

Non-Captive Lead Screw Actuators separate the motor and lead screw, allowing for longer travel distances. They are well-suited for material handling and laboratory automation applications. Buyers should consider the installation space required for these actuators, as they can be bulkier than their captive counterparts. Their versatility and ability to handle extended travel make them a solid choice for various industrial applications.

Why Choose Stepper Motor Linear Actuators?

Stepper Motor Linear Actuators combine a hybrid stepper motor with a precision lead screw, offering high torque density and customizable options. They are ideal for medical devices and X-Y stages where precise control is essential. However, the complexity of integration can be a challenge, necessitating a deeper understanding of the technology for effective implementation. Buyers should weigh the benefits of customization against the potential need for expert installation.

Illustrative image related to linear screw actuator

Key Industrial Applications of linear screw actuator

| Industry/Sector | Specific Application of linear screw actuator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Automated surgical tables | Enhances precision and efficiency in surgeries | Ensure compliance with medical regulations and high load capacities. |

| Manufacturing | CNC machining centers | Improves accuracy and speed in production | Look for high durability and customizable specifications. |

| Robotics | Robotic arms for assembly lines | Increases automation and reduces labor costs | Consider integration capabilities with existing systems. |

| HVAC Systems | Actuation of control valves | Optimizes energy efficiency and system reliability | Evaluate environmental conditions and required torque specifications. |

| Aerospace | Positioning systems for flight simulators | Enhances training accuracy and user experience | Ensure lightweight materials and high reliability under stress. |

How Are Linear Screw Actuators Used in Medical Devices?

In the medical sector, linear screw actuators are integral to the operation of automated surgical tables. These actuators provide precise positioning and movement, which are critical during surgeries where accuracy is paramount. By automating the adjustment of the table, hospitals can improve surgical outcomes while minimizing the risk of human error. International buyers should prioritize sourcing actuators that meet stringent medical device regulations and can handle significant load capacities, ensuring reliability in high-stakes environments.

What Role Do Linear Screw Actuators Play in Manufacturing?

In manufacturing, particularly in CNC machining centers, linear screw actuators are used to control the movement of tools and materials with exceptional precision. This capability allows manufacturers to produce high-quality components at faster rates, significantly improving operational efficiency. When sourcing these actuators, businesses should focus on durability and the ability to customize specifications to fit their specific machining requirements, which can vary across different regions, including Africa and South America.

How Are Linear Screw Actuators Applied in Robotics?

Linear screw actuators are commonly used in robotic arms for assembly lines, where they facilitate precise movements required for assembling components. This automation not only increases production speed but also reduces labor costs by minimizing the need for manual intervention. Buyers should consider the integration capabilities of these actuators with existing robotic systems, ensuring seamless operation and enhanced productivity.

Illustrative image related to linear screw actuator

Why Are Linear Screw Actuators Important for HVAC Systems?

In HVAC systems, linear screw actuators are essential for the actuation of control valves, which regulate airflow and temperature. By optimizing these functions, businesses can achieve greater energy efficiency and reliability in their HVAC systems. When sourcing actuators for this application, it is crucial to evaluate the specific environmental conditions they will operate in and the torque specifications required to ensure effective performance.

How Do Linear Screw Actuators Enhance Aerospace Applications?

In the aerospace industry, linear screw actuators are used in positioning systems for flight simulators, enhancing the accuracy of training environments for pilots. These actuators allow for precise adjustments that replicate real-world conditions, providing a better training experience. Buyers in this sector should focus on sourcing lightweight materials that do not compromise on reliability, especially under the stress of frequent use and varying operational conditions.

3 Common User Pain Points for ‘linear screw actuator’ & Their Solutions

Scenario 1: Difficulty in Achieving Precise Motion Control

The Problem: Many B2B buyers struggle with achieving the desired level of precision in applications that require linear motion. This is particularly true in sectors like robotics and automation, where even minor inaccuracies can lead to significant operational inefficiencies and costly errors. Buyers often find that standard linear screw actuators do not meet their specific precision requirements, which can result in increased downtime and the need for expensive re-engineering.

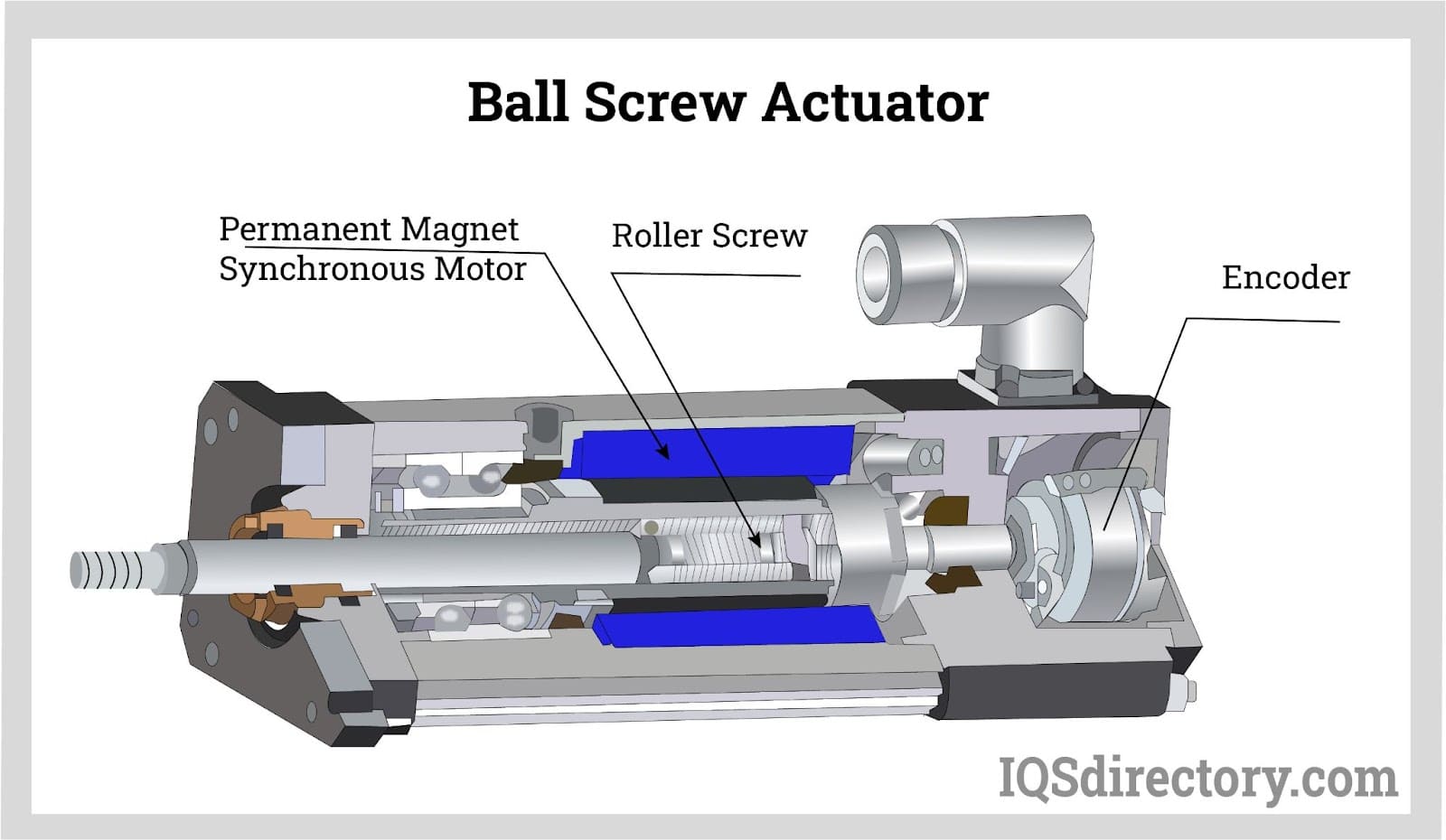

The Solution: To overcome this challenge, B2B buyers should prioritize sourcing linear screw actuators that come with built-in feedback mechanisms such as rotary encoders. These encoders provide real-time data on position and speed, allowing for more accurate control of the actuator’s movements. Additionally, buyers should consider customizing the actuator by specifying the lead screw pitch and diameter that best fit their application. Engaging with suppliers who offer tailored solutions can lead to better alignment of the actuator’s capabilities with operational needs. Buyers can also invest in simulation tools to model the actuator’s performance before implementation, ensuring the chosen actuator will deliver the required precision.

Scenario 2: Integration Issues with Existing Systems

The Problem: A common pain point for B2B buyers is the difficulty in integrating new linear screw actuators into existing machinery or systems. This can arise from compatibility issues with current components, leading to delays in project timelines and increased costs. Buyers may find themselves facing unexpected challenges in adapting their systems to accommodate new technology, which can disrupt workflow and affect overall productivity.

Illustrative image related to linear screw actuator

The Solution: To mitigate integration challenges, buyers should conduct a thorough compatibility assessment before selecting a linear screw actuator. This involves closely examining the specifications of both the actuator and the existing system, including dimensions, load capacities, and operational requirements. Buyers should also engage with manufacturers who provide comprehensive technical support and documentation, including CAD models and integration guidelines. Furthermore, implementing a phased approach to integration can help identify potential issues early in the process, allowing for adjustments without significant disruptions to operations.

Scenario 3: High Maintenance and Downtime Costs

The Problem: Maintenance and operational costs associated with linear screw actuators can be a significant concern for B2B buyers, particularly in environments where equipment is subjected to harsh conditions. Frequent breakdowns or performance degradation not only lead to increased maintenance expenses but also result in extended downtime, impacting productivity and profitability.

The Solution: To reduce maintenance requirements and extend the lifespan of linear screw actuators, buyers should consider selecting models designed for durability and ease of maintenance. Features such as sealed housing can protect internal components from dust and moisture, while lubrication systems that require less frequent servicing can minimize maintenance efforts. Additionally, buyers should invest in training for their technical staff to ensure they understand proper maintenance protocols and can troubleshoot issues effectively. Establishing a proactive maintenance schedule, including regular inspections and timely replacements of wear parts, will help keep actuators in optimal condition and reduce unexpected downtime.

Strategic Material Selection Guide for linear screw actuator

What Are the Key Materials Used in Linear Screw Actuators?

When selecting materials for linear screw actuators, it is crucial to consider their properties, advantages, and limitations. The choice of material directly impacts the actuator’s performance, durability, and suitability for specific applications. Below are analyses of four common materials used in linear screw actuators.

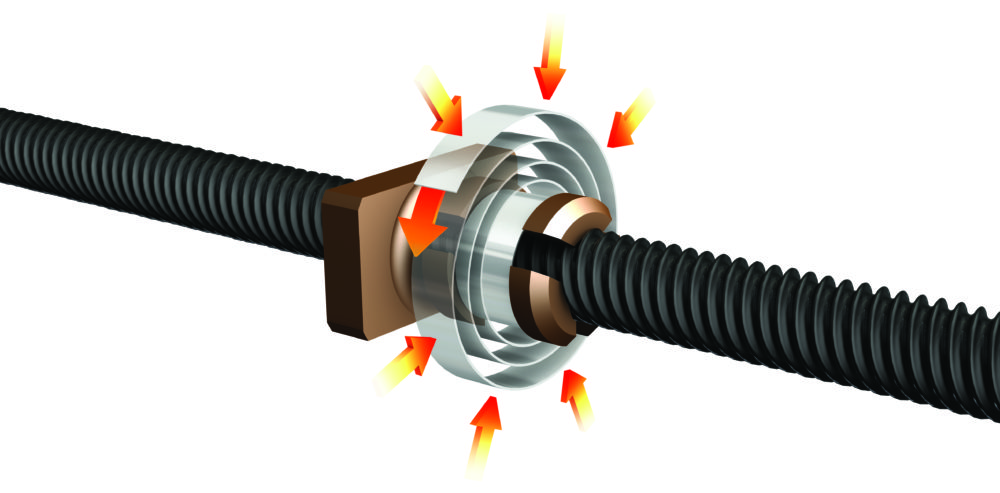

How Does Steel Perform in Linear Screw Actuators?

Steel is a widely used material in linear screw actuators due to its strength and durability. Key properties include high tensile strength and excellent wear resistance, making it suitable for heavy-duty applications. Steel can withstand high temperatures and pressures, which is beneficial for demanding environments. However, it is susceptible to corrosion unless properly treated or coated.

Pros: Steel’s high strength-to-weight ratio and durability make it ideal for applications requiring heavy loads. It is also relatively cost-effective compared to other materials.

Cons: The susceptibility to rust and corrosion can lead to increased maintenance costs. Additionally, the manufacturing complexity can be higher due to the need for treatments or coatings.

Illustrative image related to linear screw actuator

For international buyers, particularly in regions like Africa and South America, compliance with local standards (like ASTM) is essential to ensure quality and reliability in harsh environments.

What Advantages Does Aluminum Offer for Linear Screw Actuators?

Aluminum is another popular choice for linear screw actuators, known for its lightweight and corrosion-resistant properties. It offers good thermal conductivity and is easier to machine compared to steel. Aluminum can operate effectively in moderate temperature ranges, making it suitable for various applications.

Pros: The lightweight nature of aluminum allows for easier handling and installation, reducing overall system weight. Its natural resistance to corrosion minimizes maintenance needs.

Cons: Aluminum has a lower tensile strength than steel, which may limit its use in high-load applications. Additionally, it can be more expensive depending on the alloy used.

International buyers should consider the specific aluminum grades that meet regional standards, ensuring compatibility with local manufacturing practices.

How Does Plastic Compare in Linear Screw Actuators?

Plastics, particularly engineered polymers, are increasingly used in linear screw actuators for their low weight and resistance to corrosion. Commonly used plastics include nylon and polycarbonate, which can handle moderate loads and provide good wear resistance.

Pros: Plastics are lightweight, resistant to chemicals, and can be molded into complex shapes, allowing for design flexibility. They also tend to be quieter in operation compared to metal counterparts.

Cons: The primary limitation is their lower load-bearing capacity and temperature resistance compared to metals. Plastics may also degrade over time under UV exposure or extreme temperatures.

For international buyers, understanding the specific chemical compatibility of plastics is crucial, particularly in industries like food processing or pharmaceuticals.

What Role Does Stainless Steel Play in Linear Screw Actuators?

Stainless steel is an excellent choice for linear screw actuators, particularly in applications where corrosion resistance is critical, such as in marine or medical environments. It combines the strength of steel with enhanced corrosion resistance, making it suitable for harsh conditions.

Pros: Stainless steel offers excellent durability and is less prone to rust and corrosion, making it ideal for applications requiring hygiene and longevity.

Cons: It is generally more expensive than regular steel and can be heavier, which may affect the actuator’s overall weight and cost.

International buyers should ensure that the stainless steel grades used comply with local standards, particularly in industries with strict regulatory requirements.

Summary Table of Material Selection for Linear Screw Actuators

| Material | Typical Use Case for linear screw actuator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight applications | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Plastic | Consumer products, medical devices | Design flexibility and low weight | Limited load capacity | Low |

| Stainless Steel | Marine, medical, and food processing | Excellent corrosion resistance | Higher cost and weight | High |

This strategic material selection guide provides B2B buyers with a comprehensive understanding of the materials used in linear screw actuators, enabling informed decisions that align with their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for linear screw actuator

What Are the Main Stages of Manufacturing Linear Screw Actuators?

The manufacturing process for linear screw actuators involves several critical stages, each designed to ensure precision and quality. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Linear Screw Actuators?

The first step in the manufacturing process is material preparation. This involves selecting high-quality raw materials, such as stainless steel or aluminum, that meet the necessary strength and durability requirements for actuator applications. After selection, the materials undergo treatments like annealing to relieve stress and improve machinability. Furthermore, components are often cut to size using techniques like laser cutting or CNC machining, ensuring that they adhere to precise dimensions.

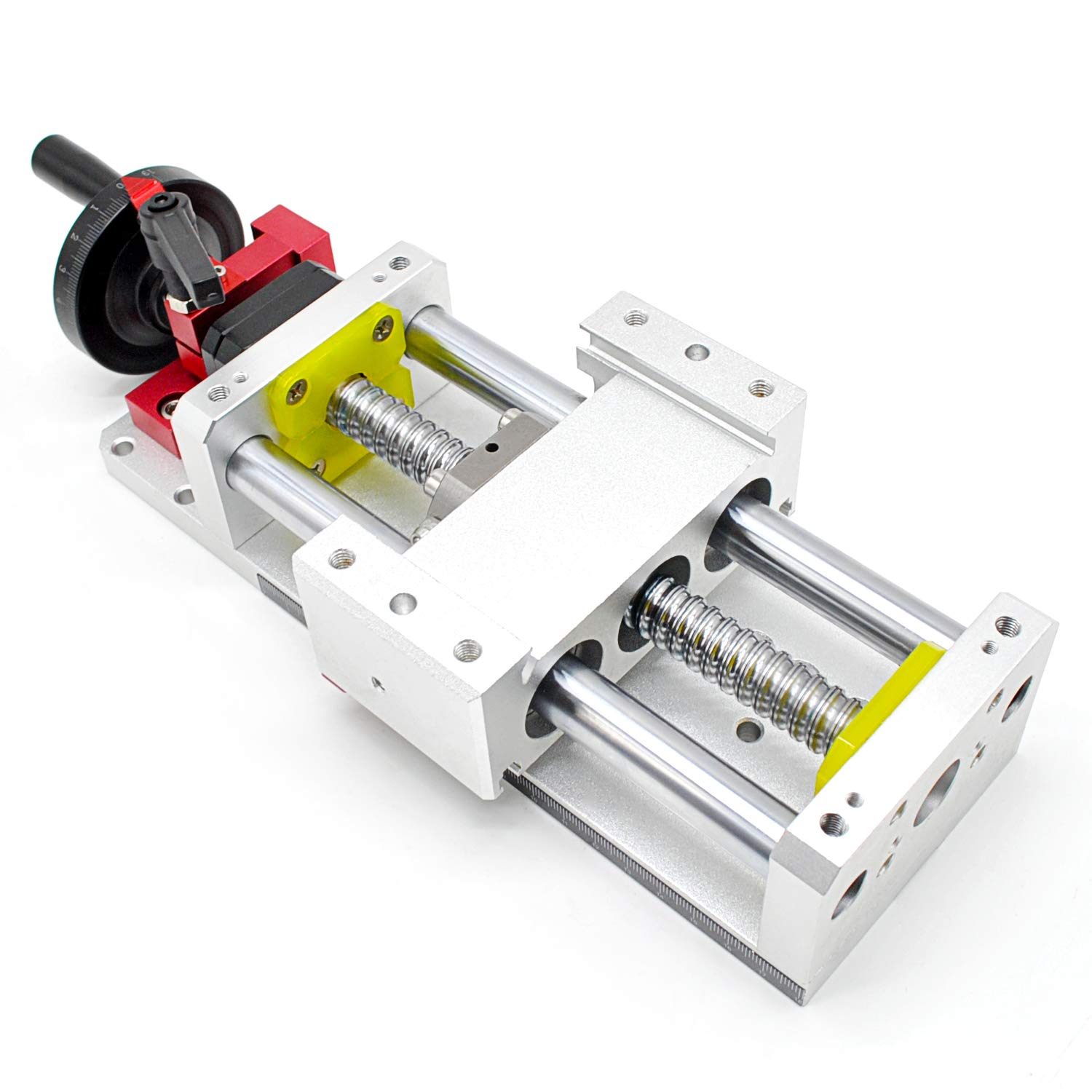

What Forming Techniques Are Used in Linear Screw Actuator Production?

Once the materials are prepared, the next phase is forming. This may involve processes such as machining, where components like lead screws and nuts are turned and milled to achieve the required thread profile and surface finish. Techniques such as rolling or forging may also be employed to create robust components with superior mechanical properties. The choice of forming technique significantly impacts the actuator’s performance, particularly in terms of load-bearing capacity and wear resistance.

How Are Linear Screw Actuators Assembled?

The assembly stage involves integrating various components, including the motor, lead screw, and nut. Depending on the actuator configuration—such as rotating screw or rotating nut—this stage may require precise alignment to ensure optimal functionality. Assembly often employs methods like press fitting or adhesive bonding to secure components, followed by torque verification to ensure that all fasteners are tightened to specified standards. Automated assembly lines are increasingly common, enhancing efficiency and consistency in production.

What Finishing Processes Are Essential for Linear Screw Actuators?

Finishing processes are crucial for enhancing the performance and longevity of linear screw actuators. These processes typically include surface treatments such as anodizing, coating, or polishing to improve corrosion resistance and reduce friction. Testing for surface hardness and finish quality is common at this stage to ensure that the components can withstand operational wear. Additionally, the actuators may undergo cleaning processes to remove any contaminants before packaging.

What Quality Assurance Standards Are Relevant for Linear Screw Actuators?

Quality assurance is vital in the manufacturing of linear screw actuators to ensure that products meet both customer expectations and regulatory requirements. International standards like ISO 9001 provide a framework for quality management systems, focusing on continuous improvement and customer satisfaction. In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications may also apply, depending on the actuator’s intended use.

How Are Quality Control Checkpoints Structured in Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints established to monitor quality at different stages.

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components as they arrive at the facility. Suppliers must provide documentation, such as material certifications and test results, to verify compliance with specifications.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves monitoring the production process through random inspections and measurements. This ensures that any deviations from specifications are identified and corrected promptly.

-

Final Quality Control (FQC): Once assembly is complete, FQC involves comprehensive testing of the finished linear screw actuators. Common testing methods include load testing, cycle testing, and functional testing to confirm that the actuators perform as intended under operational conditions.

What Common Testing Methods Are Used for Linear Screw Actuators?

Testing methods play a critical role in validating the performance and reliability of linear screw actuators. Common tests include:

- Load Testing: Evaluates the actuator’s capacity to handle specified loads without failure.

- Cycle Testing: Assesses the actuator’s durability by simulating extended use over its expected lifespan.

- Functional Testing: Verifies that the actuator operates correctly within its designated parameters, including speed, accuracy, and response time.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some effective strategies:

-

Supplier Audits: Conducting audits of potential suppliers helps assess their manufacturing capabilities and adherence to quality standards. This process provides insights into their quality management practices and operational efficiency.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including results from IQC, IPQC, and FQC. These documents should outline any non-conformances and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality processes. These organizations can conduct inspections at various stages of production, ensuring compliance with international standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers must navigate various quality control and certification nuances when sourcing linear screw actuators. Understanding local regulations, import requirements, and certification processes is essential. Buyers should also consider the reputation of the supplier in their respective markets, as this can impact product acceptance and regulatory compliance.

Additionally, buyers should be aware of potential barriers related to language and cultural differences, which may affect communication regarding quality expectations. Establishing clear contracts and specifications upfront can help mitigate these challenges.

Conclusion

The manufacturing processes and quality assurance measures for linear screw actuators are complex yet essential for delivering high-performance products. By understanding these processes and implementing robust QC practices, B2B buyers can ensure they source reliable actuators that meet their operational needs. Engaging in thorough supplier evaluations and maintaining open lines of communication will further enhance the procurement experience, particularly in diverse international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘linear screw actuator’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure linear screw actuators. Given the diverse applications and critical specifications associated with these devices, following a structured approach will help ensure that you select the right product for your needs. From defining technical requirements to assessing suppliers, this checklist will facilitate a streamlined procurement process.

Illustrative image related to linear screw actuator

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the cornerstone of a successful procurement process. Specify key parameters such as load capacity, speed, travel length, and environmental conditions where the actuator will operate. For instance, consider whether you need a rotating screw or nut configuration based on your application needs.

- Load Capacity: Determine the maximum weight the actuator will need to handle.

- Speed and Precision: Define the speed at which the actuator must operate and the level of precision required for your application.

Step 2: Identify Application Requirements

Different applications may necessitate specific features in a linear screw actuator. Assess whether your project requires additional functionalities such as integrated encoders for feedback or anti-rotational guidance systems for improved precision. Understanding these requirements upfront will guide you toward the most suitable actuator configuration.

- Feedback Mechanisms: Decide if real-time position and speed feedback is crucial for your operation.

- Environmental Factors: Consider factors such as temperature, humidity, and exposure to contaminants that might affect actuator performance.

Step 3: Evaluate Potential Suppliers

Before making a purchase, it’s essential to vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This step helps ensure that the supplier has a proven track record and can meet your technical needs.

Illustrative image related to linear screw actuator

- Certifications and Compliance: Check for industry certifications that validate the supplier’s quality assurance processes.

- Customer Testimonials: Look for reviews or testimonials from past clients to gauge reliability and service quality.

Step 4: Request Customization Options

Engaging with suppliers about customization can lead to a solution that perfectly fits your application. Many suppliers offer the ability to tailor actuators to specific performance needs, including size, lead screw pitch, and material choices. Custom solutions can enhance efficiency and reduce installation complexity.

- Material Selection: Inquire about different materials used for lead screws and nuts to ensure durability and performance.

- Size and Configuration: Discuss the possibility of adjusting dimensions to fit your machinery or application space.

Step 5: Assess Pricing and Total Cost of Ownership

While initial pricing is important, it is crucial to consider the total cost of ownership, which includes installation, maintenance, and energy consumption over the actuator’s lifespan. Request detailed quotes that break down all costs, and compare these against the expected performance and longevity of the actuators.

- Long-Term Savings: Evaluate how energy-efficient options may lead to lower operational costs.

- Maintenance Requirements: Understand the maintenance needs and potential costs involved in keeping the actuator operational.

Step 6: Verify Warranty and Support Services

A robust warranty and reliable support services are indicators of a trustworthy supplier. Ensure that the supplier offers a clear warranty policy that covers defects and performance issues. Additionally, inquire about technical support availability, especially if your application requires ongoing assistance.

- Warranty Terms: Look for warranties that cover parts and labor for a reasonable duration.

- Technical Support: Check if the supplier provides ongoing support via phone, email, or onsite assistance.

Step 7: Finalize Your Purchase and Confirm Logistics

Once you have selected a supplier and finalized your specifications, confirm the logistics of your order. Discuss lead times, shipping options, and any necessary documentation for international shipping, especially if you are sourcing from overseas suppliers.

- Shipping Arrangements: Clarify shipping methods and delivery times to ensure timely project execution.

- Documentation: Ensure all necessary documentation, including customs paperwork, is prepared for a smooth transaction.

By following these steps, B2B buyers can enhance their procurement process for linear screw actuators, ensuring they select the best solutions for their specific needs.

Illustrative image related to linear screw actuator

Comprehensive Cost and Pricing Analysis for linear screw actuator Sourcing

What Are the Key Cost Components in Linear Screw Actuator Manufacturing?

When sourcing linear screw actuators, it is essential to understand the breakdown of costs that contribute to the overall price. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly influences the cost. High-grade alloys and specialized plastics may increase the price but enhance durability and performance. For instance, stainless steel is often preferred for its corrosion resistance, particularly in harsh environments.

-

Labor: Labor costs vary depending on the region of production. Countries with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and equipment maintenance. Efficient production processes can help minimize these costs, impacting the final price positively.

-

Tooling: Custom tooling for specific actuator designs can be a significant upfront investment. While this may raise initial costs, it often leads to better long-term pricing for larger orders.

-

Quality Control: Rigorous QC processes ensure that the actuators meet specified standards. However, these processes also add to the overall cost. Certifications such as ISO can further elevate pricing but provide assurance of quality.

-

Logistics: Shipping costs can vary greatly based on distance, shipping methods, and Incoterms. For international buyers, understanding these costs is crucial to avoid unexpected expenses.

-

Margin: Suppliers typically add a profit margin on top of their costs. This margin can vary based on market competition and the perceived value of the actuator.

How Do Price Influencers Impact Linear Screw Actuator Costs?

Several factors can influence the pricing of linear screw actuators, and understanding them can provide buyers with negotiation leverage.

-

Volume/MOQ: Suppliers often have a minimum order quantity (MOQ) that can affect pricing. Ordering in bulk may lead to significant discounts, making it economically viable for larger projects.

-

Specifications and Customization: Custom specifications can lead to increased costs due to the need for specialized production processes or materials. Buyers should evaluate whether standard products can meet their needs before opting for custom solutions.

-

Materials: The choice of materials not only impacts the performance but also the cost. For example, actuators made with advanced composites may cost more initially but offer long-term savings through reduced maintenance.

-

Quality and Certifications: Products with recognized certifications may come at a premium, but they often guarantee reliability and performance, crucial in industries such as medical or aerospace.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital, as they dictate who bears the risk and cost at each stage of transportation. Buyers should choose terms that align with their logistics capabilities and risk tolerance.

What Negotiation Strategies Can Enhance Cost-Efficiency for International Buyers?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can help optimize costs when sourcing linear screw actuators.

-

Leverage Volume: If possible, consolidate orders across multiple projects to meet MOQ thresholds, thus benefiting from bulk pricing.

-

Explore Local Suppliers: Consider sourcing from local manufacturers to reduce shipping costs and lead times. This can also minimize complexities related to customs and tariffs.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price and consider factors like maintenance, energy consumption, and lifespan. A higher upfront cost may be justified if the actuator offers lower operational costs over time.

-

Negotiate Terms: Engage suppliers in discussions about payment terms, delivery schedules, and warranty conditions. Flexibility in these areas can lead to better overall pricing.

What Should International Buyers Keep in Mind About Pricing Nuances?

International buyers should be aware of specific nuances that can affect pricing. Currency fluctuations can impact costs, especially in long-term contracts. Additionally, tariffs and import duties may apply, which can significantly alter the final cost of sourcing actuators from different countries.

Understanding local market conditions and supplier dynamics can also provide insights into potential price variations. Always request detailed quotations to ensure that all costs are transparent and accounted for, minimizing the risk of unexpected expenses upon delivery.

Disclaimer on Indicative Prices

Prices for linear screw actuators can vary widely based on numerous factors, including specifications, order volume, and supplier. As such, the figures provided in this analysis are indicative and should be confirmed through direct supplier engagement to ensure accuracy for specific purchasing scenarios.

Alternatives Analysis: Comparing linear screw actuator With Other Solutions

Understanding Alternative Solutions to Linear Screw Actuators

In the realm of linear motion control, linear screw actuators are a popular choice due to their precision and reliability. However, various alternatives can achieve similar objectives, each with its unique advantages and drawbacks. This analysis compares linear screw actuators with two viable alternatives: pneumatic cylinders and electric linear actuators, helping B2B buyers make informed decisions tailored to their operational needs.

Illustrative image related to linear screw actuator

| Comparison Aspect | Linear Screw Actuator | Pneumatic Cylinder | Electric Linear Actuator |

|---|---|---|---|

| Performance | High precision, moderate speed | High speed, less precise | Moderate precision, high speed |

| Cost | Moderate to high initial investment | Generally lower initial cost | Moderate initial investment, higher long-term costs |

| Ease of Implementation | Requires precise installation and setup | Easier to install, but needs compressed air supply | Relatively simple setup with electrical connections |

| Maintenance | Low maintenance; lubrication required | Moderate; requires periodic checks and air supply maintenance | Low; minimal upkeep needed |

| Best Use Case | Applications needing precise control | Fast, high-force applications like packaging | Applications needing flexibility and integration with control systems |

In-Depth Look at Alternative Solutions

Pneumatic Cylinders: What Are Their Strengths and Weaknesses?

Pneumatic cylinders utilize compressed air to create motion, making them an effective solution for applications requiring rapid actuation. Their primary advantage is speed; they can move quickly and handle large loads with ease. However, they are not as precise as linear screw actuators, which can be a significant drawback in applications demanding high accuracy. Additionally, pneumatic systems require a continuous supply of compressed air, which can lead to increased operational costs and complexity in maintenance. This makes them ideal for environments like assembly lines, where speed is prioritized over precision.

Electric Linear Actuators: Are They a Viable Alternative?

Electric linear actuators offer a blend of speed and precision, making them suitable for various applications. They are known for their ease of integration with existing control systems, allowing for sophisticated automation solutions. However, electric actuators can come with higher long-term operating costs due to energy consumption and potential wear on electrical components. Their maintenance is relatively low, but they require careful attention to the power supply and electrical connections. Electric actuators excel in scenarios where programmable motion control is necessary, such as in robotics and automated machinery.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate actuator solution hinges on understanding the specific requirements of your application. If precision and reliability are your top priorities, linear screw actuators are likely the best choice. For operations emphasizing speed and less stringent accuracy, pneumatic cylinders may be more suitable. Conversely, electric linear actuators provide a balance of flexibility and control, making them ideal for automated environments. By evaluating the performance, cost, ease of implementation, maintenance needs, and best use cases of each option, B2B buyers can make well-informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for linear screw actuator

What Are the Key Technical Properties of Linear Screw Actuators?

When selecting a linear screw actuator, understanding critical technical properties is essential for ensuring optimal performance and compatibility with your application. Below are some key specifications to consider:

Illustrative image related to linear screw actuator

1. Load Capacity

The load capacity indicates the maximum weight the actuator can handle without failure. This specification is crucial for B2B buyers as it directly affects the actuator’s suitability for specific applications, such as robotics or industrial machinery. Selecting an actuator with an appropriate load capacity ensures operational efficiency and safety.

2. Lead and Pitch

The lead refers to the distance the nut moves with one complete screw rotation, while the pitch is the distance between adjacent threads. A higher lead allows for faster linear movement but may reduce precision. Understanding these terms helps buyers balance speed and accuracy in applications like CNC machines or 3D printers, where both factors are critical.

3. Material Grade

The material from which the actuator is made (e.g., stainless steel, aluminum) affects its durability, corrosion resistance, and overall performance. Buyers in industries such as food processing or pharmaceuticals should prioritize materials that meet specific regulatory standards to ensure longevity and safety in their applications.

4. Tolerance

Tolerance indicates the allowable deviation from specified dimensions and is vital for ensuring precision in applications. High-tolerance specifications are essential in sectors like medical devices, where even minor inaccuracies can lead to significant issues. Understanding tolerance helps buyers assess the actuator’s suitability for high-precision tasks.

5. Duty Cycle

The duty cycle specifies the ratio of operational time to idle time, which is critical for applications requiring continuous operation. For example, an actuator with a high duty cycle is preferable in manufacturing settings, as it ensures reliability and reduces downtime.

6. Motor Type

The type of motor used (stepper, servo, or DC) influences the actuator’s performance characteristics, including speed, torque, and control capabilities. B2B buyers must consider the motor type to align with their control systems and operational requirements effectively.

What Are Common Trade Terms Associated with Linear Screw Actuators?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of linear screw actuators, OEMs often provide customized solutions tailored to specific applications, making them crucial partners for businesses looking for specialized components.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers as it impacts inventory management and upfront costs. Negotiating favorable MOQs can lead to better pricing and flexibility in procurement.

3. RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers. This term is essential for B2B buyers looking to compare prices and terms from multiple vendors. A well-prepared RFQ can streamline the procurement process and ensure that all necessary specifications are communicated.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with these terms is crucial for B2B buyers engaged in global transactions, as they define who is responsible for shipping, insurance, and tariffs.

5. Customization

Customization refers to the ability to modify standard products to meet specific client requirements. For linear screw actuators, this might include alterations in size, lead, or motor type. Understanding customization options allows buyers to optimize products for unique applications, enhancing operational efficiency.

6. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. This term is critical for supply chain management, as longer lead times can affect project timelines. Buyers should always inquire about lead times to ensure that they align with their operational needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline procurement processes, and enhance the efficiency of their operations in various industries.

Navigating Market Dynamics and Sourcing Trends in the linear screw actuator Sector

What Are the Key Trends Driving the Linear Screw Actuator Market?

The linear screw actuator market is experiencing robust growth driven by several global factors. The increasing automation in manufacturing processes across various sectors, including automotive, medical devices, and robotics, is a key driver. As industries seek to enhance operational efficiency, the demand for high-precision and reliable linear motion solutions is on the rise. Furthermore, the shift towards smart manufacturing and Industry 4.0 technologies is fueling interest in advanced linear actuators that integrate seamlessly with digital systems.

In addition to automation, the growing emphasis on compact designs is shaping sourcing trends. International buyers, particularly from regions such as Africa, South America, and the Middle East, are looking for linear screw actuators that offer high torque in smaller packages. This shift is evident in the increasing popularity of stepper motor linear actuators, which combine compactness with precision and efficiency. Emerging technologies, such as IoT-enabled actuators, are also gaining traction, allowing for real-time monitoring and control, further appealing to tech-savvy buyers.

Sourcing strategies are evolving, with a focus on local suppliers to reduce lead times and transportation costs. Buyers are increasingly considering suppliers that offer customization options, enabling them to tailor solutions to specific application requirements. As such, understanding market dynamics and being agile in sourcing decisions is crucial for international B2B buyers navigating this landscape.

How Is Sustainability Influencing Sourcing Decisions for Linear Screw Actuators?

Sustainability is becoming a pivotal consideration in the sourcing of linear screw actuators. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers that adopt sustainable practices, such as using eco-friendly materials and minimizing carbon footprints.

Illustrative image related to linear screw actuator

Ethical sourcing plays a significant role in supplier selection. Companies are seeking partners who demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices meet ethical standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers aiming to build trust with buyers.

Moreover, the trend towards ‘green’ products is influencing the materials used in linear screw actuators. Manufacturers are exploring alternatives to traditional materials, opting for recyclable or biodegradable options wherever feasible. As awareness of environmental issues continues to rise, B2B buyers are encouraged to incorporate sustainability criteria into their procurement processes, thereby aligning with global sustainability goals and enhancing their corporate social responsibility profiles.

How Have Linear Screw Actuators Evolved Over Time?

The evolution of linear screw actuators has been marked by significant technological advancements aimed at enhancing performance and versatility. Initially designed for basic linear motion tasks, these actuators have transformed into sophisticated systems capable of high precision and reliability.

In the early stages, traditional lead screw mechanisms dominated the market, but the introduction of stepper motors has revolutionized the sector. By combining lead screws with stepper motors, manufacturers have been able to create compact, efficient solutions that cater to diverse applications, from medical devices to industrial automation.

Today, innovations such as integrated encoders for real-time feedback and IoT connectivity are shaping the future of linear screw actuators. This evolution reflects a broader trend towards automation and smart technologies, driving demand for actuators that not only perform tasks but also integrate into intelligent systems. For B2B buyers, understanding this evolution is crucial for making informed purchasing decisions that align with their operational needs and future growth strategies.

Illustrative image related to linear screw actuator

Frequently Asked Questions (FAQs) for B2B Buyers of linear screw actuator

-

How do I solve compatibility issues with existing machinery when sourcing linear screw actuators?

To address compatibility issues, it’s crucial to gather detailed specifications of your existing machinery, including load capacity, travel distance, and mounting requirements. Engage with potential suppliers to discuss these specifications and seek their expertise in recommending suitable actuator configurations. Additionally, consider requesting samples or prototypes to test compatibility before committing to a larger order. Clear communication regarding your application needs will help suppliers provide tailored solutions that seamlessly integrate into your existing systems. -

What is the best type of linear screw actuator for automation applications?

For automation applications, stepper motor linear actuators are often recommended due to their precision and control capabilities. They provide accurate positioning and repeatability, making them ideal for tasks like robotic arms, conveyor systems, and CNC machines. When selecting the actuator, consider factors such as load requirements, speed, and environmental conditions. Collaborating with suppliers who offer customizable solutions can also ensure you get an actuator that meets the specific demands of your automation project. -

What factors should I consider when choosing a supplier for linear screw actuators?

When choosing a supplier, evaluate their industry experience, product quality, and customer service. Look for certifications that ensure adherence to international quality standards. Assess their ability to provide technical support and customization options, as well as their responsiveness to inquiries. Additionally, consider their logistics capabilities, including shipping times and costs, especially if you are sourcing from different continents like Africa or South America. Reading customer reviews and testimonials can also provide insight into their reliability. -

What are the minimum order quantities (MOQs) for linear screw actuators?

Minimum order quantities can vary significantly among suppliers, typically ranging from a few units to several hundred. It’s essential to inquire about MOQs early in the negotiation process. Some manufacturers may offer lower MOQs for standard products, while custom solutions might require higher quantities. If you’re a smaller business or a startup, discuss your needs with the supplier to explore potential flexibility in order sizes or combined orders to meet MOQ requirements. -

What payment terms should I expect when sourcing linear screw actuators internationally?

Payment terms can differ based on the supplier’s policies and the nature of your business relationship. Common arrangements include upfront payments, partial payments, or net terms (e.g., 30 or 60 days post-delivery). When dealing with international transactions, consider using secure payment methods such as letters of credit or escrow services to protect both parties. It’s advisable to clarify payment expectations upfront and to ensure that all terms are documented in the purchase agreement. -

How can I ensure quality assurance for linear screw actuators?

To ensure quality assurance, request detailed specifications and certifications from the supplier that demonstrate compliance with international standards. Consider asking for samples or conducting on-site inspections before making large purchases. Additionally, implementing a quality control process upon receipt of the actuators can help identify any defects. Engaging suppliers who offer warranties or guarantees on their products can also provide additional peace of mind regarding the quality of the actuators. -

What logistics considerations should I be aware of when importing linear screw actuators?

When importing linear screw actuators, consider shipping times, costs, and customs regulations in your country. Research the most efficient shipping methods, whether by air or sea, based on your urgency and budget. Additionally, ensure compliance with local import regulations, including tariffs and taxes. Work closely with your supplier to obtain necessary documentation, such as invoices and packing lists, to facilitate smooth customs clearance and delivery. -

Can I customize linear screw actuators to meet specific application needs?

Yes, many suppliers offer customization options for linear screw actuators to meet specific application requirements. Customizations may include variations in size, lead screw pitch, motor type, and mounting configurations. When discussing your needs with suppliers, provide detailed information about your application and any unique challenges you face. This will help them recommend solutions that not only fit your specifications but also enhance the performance and efficiency of your systems.

Top 7 Linear Screw Actuator Manufacturers & Suppliers List

1. Thomson – Stepper Motor Linear Actuators

Domain: thomsonlinear.com

Registered: 2008 (17 years)

Introduction: Thomson stepper motor linear actuators combine a hybrid stepper motor and a precision lead screw in one compact envelope. They are offered in three configurations: rotating screw (MLS), rotating nut (MLN), and actuator (MLA). The MLS assemblies actuate by having the stepper motor rotate a lead screw to translate a load attached to the lead nut. The MLN assemblies actuate by rotating a nut within t…

2. PBC Linear – LSR1005T Linear Slide Rail

Domain: pbclinear.com

Registered: 2008 (17 years)

Introduction: {“product_name”:”LSR1005T-0300-NCF231-NNN-NNN”,”type”:”Linear Slide Rail”,”dimensions”:”100 mm length, 5 mm width”,”load_capacity”:”Up to 300 N”,”material”:”Aluminum”,”features”:”Corrosion-resistant, low friction, high precision”,”applications”:”Industrial automation, robotics, and machine design”}

3. AutomationDirect – Lead Screw Driven Linear Actuators

Domain: automationdirect.com

Registered: 1999 (26 years)

Introduction: Lead screw driven linear actuators are designed for precise linear motion applications. They offer a range of load capacities and travel lengths, making them suitable for various industrial and automation tasks. Key features include high accuracy, durability, and ease of integration into existing systems. These actuators are ideal for applications requiring controlled movement, such as positioning…

4. NSK – Monocarrier Actuator

Domain: nsk.com

Registered: 1996 (29 years)

Introduction: NSK Monocarrier is a multi-functional actuator that is lightweight and compact, featuring an all-in-one structure that integrates a ball screw, linear guide, and support bearings. It is designed for long-life and maintenance-free operation, suitable for a wide range of applications. Key features include: Chrome plating for superb anti-rust capability, high load capacity using rollers as rolling el…

5. Tolomatic – Roller Screw Linear Actuators

Domain: tolomatic.com

Registered: 1996 (29 years)

Introduction: Roller Screw Linear Actuators for Heavy Duty Applications: Tolomatic offers electric, high force, heavy duty, and hygienic roller screw linear actuators. Key features include precision-ground threads that match multiple precision-ground rollers in the nut, providing efficient force transmission and longer life due to increased contact points. Standard planetary roller screws have a high Dynamic Lo…

6. Haydon Kerk Pittman – Lead Screw Linear Actuators

Domain: haydonkerkpittman.com

Registered: 2016 (9 years)

Introduction: Lead Screw Linear Actuators are used to generate precise linear motion by pairing an electric motor with a lead screw. They can be constructed in various ways depending on the interface requirements. There are three common styles of linear actuators: external linear style, non-captive style, and captive style. Key considerations for selecting a style include stroke (amount of linear travel require…

7. Deltron – High-Performance Linear Motion Actuators

Domain: deltron.com

Registered: 1996 (29 years)

Introduction: Deltron Precision manufactures high-performance linear motion actuators, including ball screw and lead screw actuators, designed for precision, efficiency, and durability in industrial applications. Key features include:

– Types: Lead screw and ball screw options.

– Applications: Used in manufacturing, packaging, food and beverage, aerospace, medical diagnostic equipment, 3D printers, machine tool…

Strategic Sourcing Conclusion and Outlook for linear screw actuator

In the evolving landscape of industrial automation, linear screw actuators have emerged as pivotal components, driving efficiency and precision across various applications. As global B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of these systems is crucial. The versatility of linear screw actuators, available in configurations such as rotating screw and nut assemblies, allows for customization that meets specific operational needs. This adaptability not only enhances performance but also reduces installation complexities and overall costs.

Strategic sourcing plays a vital role in optimizing procurement processes. By partnering with reliable manufacturers and suppliers, buyers can ensure access to high-quality components while leveraging innovations that enhance productivity. Engaging with experts in the field can yield insights into the latest technologies, helping companies stay competitive in a rapidly changing market.

Looking forward, the demand for linear screw actuators is set to rise, driven by advancements in automation and the growing need for precision in manufacturing. Now is the time for international B2B buyers to invest in these technologies, ensuring they are equipped to meet future challenges. Embrace the potential of linear screw actuators to elevate your operational capabilities and drive sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.