The Definitive Guide to Latch Slide: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for latch slide

In an increasingly interconnected world, sourcing reliable latch slides can pose significant challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the quest for quality hardware that meets specific operational needs is paramount. This comprehensive guide on latch slides is designed to address this challenge by providing insights into various types, applications, and supplier vetting processes, enabling businesses to make informed purchasing decisions.

From surface-mounted latches to slide bolt options, understanding the diverse range of latch slides available is crucial. Each type serves distinct purposes across industries, including cabinetry, gate security, and partition installations. Furthermore, the guide delves into cost considerations, ensuring that buyers can balance quality with budget constraints.

Empowering B2B buyers with knowledge, this resource equips you with the tools to navigate the global market effectively. Learn how to evaluate suppliers, assess product specifications, and identify the best latch slide solutions for your specific requirements. Whether you are a manufacturer, distributor, or contractor, this guide will help streamline your procurement process, ensuring that you secure the right latch slides to enhance your operations and meet your clients’ expectations.

Understanding latch slide Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Mounted Latch Slide | Installed on the surface, often made of stainless steel | Furniture, cabinets, gates | Pros: Easy installation, durable materials. Cons: May not suit all aesthetic needs. |

| Gate Slide Bolt | Heavy-duty design, often with a locking mechanism | Outdoor gates, fences, industrial sites | Pros: High security, robust construction. Cons: Can be more expensive than simpler latches. |

| Offset Slide Bolt | Features an offset design for better alignment | Partitions, stalls, doors | Pros: Improved fit, versatile applications. Cons: Installation may require precise measurements. |

| Barrel Bolt | Cylindrical design, typically manual operation | Residential gates, sliding doors | Pros: Simple mechanism, cost-effective. Cons: Limited security features compared to locks. |

| Electronic Slide Latch | Integrated electronic locking system | High-security environments, smart homes | Pros: Enhanced security, remote access. Cons: Higher cost, requires power source. |

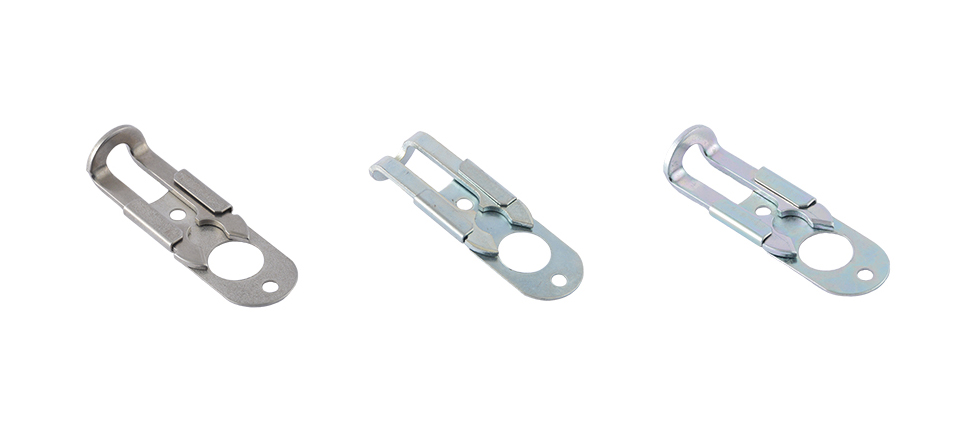

What Are the Characteristics and Suitability of Surface Mounted Latch Slides?

Surface mounted latch slides are primarily distinguished by their installation method, affixed directly onto the surface of the door or cabinet. Typically made from durable materials like stainless steel, they are ideal for applications in furniture, cabinets, and gates. The ease of installation makes them a popular choice for B2B buyers looking for efficient solutions. However, businesses should consider their aesthetic preferences, as surface-mounted designs may not blend seamlessly with all styles.

How Do Gate Slide Bolts Offer Security in B2B Applications?

Gate slide bolts are designed for heavy-duty use, often featuring a locking mechanism that enhances security. They are commonly utilized in outdoor applications such as gates and fences, making them suitable for industrial sites where security is paramount. While their robust construction provides excellent protection against unauthorized access, buyers should be aware that the cost may be higher than simpler latch options.

Illustrative image related to latch slide

What Makes Offset Slide Bolts Versatile for Various Industries?

Offset slide bolts are characterized by their unique design that allows for better alignment and fit. This feature is particularly beneficial in applications such as partitions and stalls, where precise alignment is crucial. B2B buyers appreciate their versatility across different environments. However, accurate measurements during installation are essential to avoid fit issues, which could lead to additional costs or time delays.

Why Choose Barrel Bolts for Simple and Cost-Effective Solutions?

Barrel bolts are known for their cylindrical design and straightforward manual operation. These latches are often used in residential gates and sliding doors, making them a cost-effective solution for buyers seeking simplicity. While they are easy to install and operate, their security features may not match those of more complex locking systems, which is a consideration for buyers focused on high-security needs.

What Are the Advantages of Electronic Slide Latches in Modern Security?

Electronic slide latches incorporate advanced technology to provide enhanced security features, including remote access capabilities. They are particularly suitable for high-security environments, including smart homes and commercial buildings. While the benefits of increased security and convenience are significant, potential buyers should consider the higher initial costs and the need for a reliable power source, which may not be feasible in all settings.

Key Industrial Applications of latch slide

| Industry/Sector | Specific Application of latch slide | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Machinery and Equipment Safety | Enhances operational safety and efficiency | Material durability, compliance with safety standards |

| Construction | Door and Gate Security | Provides reliable access control and theft prevention | Weather resistance, ease of installation, and maintenance needs |

| Transportation | Vehicle Cargo Management | Secures cargo and reduces damage during transit | Load capacity, compatibility with vehicle types |

| Hospitality | Cabinet and Furniture Security | Improves guest safety and protects valuable assets | Aesthetic design, ease of use, and security features |

| Agriculture | Farm Equipment and Storage Locking | Protects equipment and reduces theft risks | Corrosion resistance, strength, and ease of operation |

How is latch slide used in the manufacturing sector, and what are the benefits?

In the manufacturing sector, latch slides are crucial for securing machinery and equipment. They ensure that access points remain closed during operation, minimizing the risk of accidents and injuries. The robust construction of latch slides, often made from stainless steel, provides durability and resistance to wear and tear. For international buyers, especially in regions like Africa and South America, sourcing latch slides that meet local safety regulations and withstand environmental conditions is essential to maintain operational efficiency.

What role do latch slides play in construction applications?

Latch slides are integral in construction for securing doors and gates, providing a reliable locking mechanism. They enhance security by preventing unauthorized access to construction sites or secured areas. Buyers should consider factors such as weather resistance and ease of installation, especially in regions with extreme climates like the Middle East. Selecting latch slides that comply with local building codes can also ensure safety and legality in construction projects.

Illustrative image related to latch slide

How do latch slides contribute to transportation safety?

In the transportation industry, latch slides are used to secure cargo within vehicles, preventing movement that could lead to damage during transit. This application is critical for logistics companies that transport goods across long distances. Buyers must assess the load capacity and compatibility of latch slides with various vehicle types. Additionally, international buyers should consider sourcing products that meet transportation safety standards to avoid liabilities.

What benefits do latch slides offer in the hospitality industry?

In the hospitality sector, latch slides are often used in cabinets and furniture to secure valuable items and enhance guest safety. They provide a discreet yet effective means of protection, contributing to a positive customer experience. For buyers, the aesthetic design and ease of use are vital, particularly in high-end establishments in Europe. Ensuring that latch slides integrate seamlessly with existing furniture while offering robust security features is crucial for maintaining the brand’s reputation.

Why are latch slides important for agricultural applications?

In agriculture, latch slides are essential for securing farm equipment and storage facilities, thereby reducing theft risks. They play a vital role in protecting investments in machinery and supplies. Buyers should prioritize corrosion-resistant materials due to exposure to the elements, particularly in regions with high humidity or rainfall. Additionally, ease of operation is a key consideration for farmers who may need to access equipment quickly during busy seasons.

3 Common User Pain Points for ‘latch slide’ & Their Solutions

Scenario 1: Sourcing Durable Latch Slides for Harsh Environments

The Problem:

B2B buyers often face significant challenges when sourcing latch slides that need to endure extreme conditions, such as high humidity, corrosive environments, or heavy use. For instance, manufacturers in the food processing or chemical industries may require latch slides that resist rust and corrosion while ensuring smooth operation under these rigorous conditions. The stakes are high; using inferior materials can lead to equipment failure, safety hazards, and increased maintenance costs, ultimately affecting productivity and profitability.

The Solution:

To address these concerns, buyers should prioritize sourcing latch slides made from high-quality materials such as stainless steel or specialized alloys that offer enhanced corrosion resistance. It is crucial to verify that the products are rated for specific environmental conditions. Working with reputable suppliers who can provide detailed specifications, certifications, and performance testing results is essential. Additionally, consider custom solutions that can be tailored to meet specific operational needs, ensuring the latch slides will perform reliably in their intended application. Implementing a regular maintenance schedule, including inspections and cleaning, can also prolong the lifespan of latch slides in challenging environments.

Scenario 2: Ensuring Proper Installation of Latch Slides

The Problem:

Another common issue for B2B buyers is the improper installation of latch slides, which can lead to functionality problems, including difficulty in operation or even complete failure. For example, in the construction sector, contractors may struggle with ensuring that latch slides align correctly with door frames or cabinets, leading to gaps or misalignment. This can result in security vulnerabilities or product damage, which can be costly to rectify.

The Solution:

To ensure proper installation, it’s vital to provide comprehensive training for installation teams, focusing on the specific requirements of the latch slides being used. Buyers should look for suppliers that offer installation guides, videos, or even on-site support. Additionally, utilizing adjustable latch slides can help accommodate minor misalignments during installation. Establishing a checklist that includes measurements and alignment tests before finalizing the installation can further mitigate these issues. By prioritizing proper installation practices, buyers can significantly reduce the likelihood of operational problems down the line.

Scenario 3: Navigating Compliance and Regulatory Standards

The Problem:

B2B buyers must often navigate complex compliance and regulatory standards when selecting latch slides, especially in industries such as healthcare, food service, or pharmaceuticals. For example, latch slides used in medical facilities may need to comply with strict hygiene and safety regulations. Failure to meet these standards can result in fines, product recalls, and a tarnished reputation, which can have long-term implications for businesses.

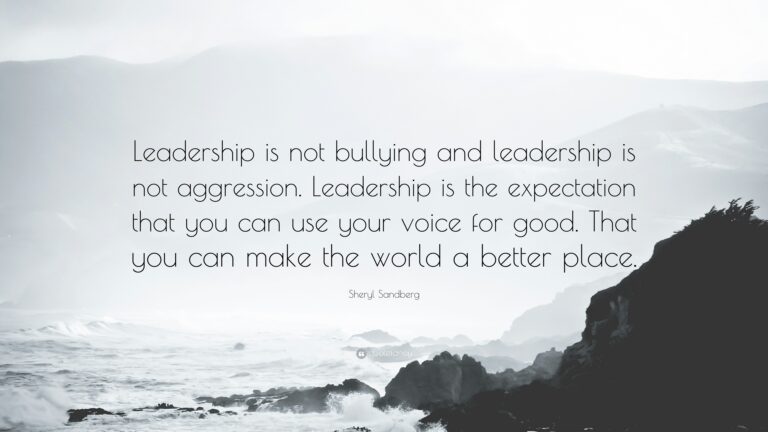

Illustrative image related to latch slide

The Solution:

To navigate these challenges effectively, buyers should familiarize themselves with the relevant industry standards and regulations that pertain to latch slides. Engaging with suppliers who are knowledgeable about compliance requirements and can provide products that meet or exceed these standards is crucial. It is also advisable to request documentation and certifications that prove compliance. Additionally, integrating compliance checks into the procurement process can help ensure that all purchased latch slides adhere to necessary regulations, thereby minimizing risk. Regular audits of both suppliers and products can also help maintain compliance over time, ensuring that businesses avoid costly legal issues.

Strategic Material Selection Guide for latch slide

What Are the Key Properties of Common Materials Used in Latch Slides?

When selecting materials for latch slides, it is crucial to consider their properties in relation to performance, durability, and application. Here, we analyze four common materials: stainless steel, zinc-coated steel, plastic, and brass.

How Does Stainless Steel Perform in Latch Slide Applications?

Stainless steel is renowned for its corrosion resistance and strength, making it an ideal choice for latch slides used in various environments. It can withstand high temperatures and pressures, which is essential for applications in industrial settings. The primary grades used include 304 and 316, with 316 offering superior resistance to chloride environments, making it suitable for coastal areas.

Pros: Stainless steel is highly durable, resistant to rust and corrosion, and requires minimal maintenance. Its aesthetic appeal also makes it suitable for applications where appearance matters.

Illustrative image related to latch slide

Cons: The main drawback is its higher cost compared to other materials. Additionally, stainless steel can be challenging to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel latch slides are compatible with a wide range of media, including water and chemicals, making them versatile for various industries.

What Are the Benefits of Zinc-Coated Steel for Latch Slides?

Zinc-coated steel, often referred to as galvanized steel, provides a cost-effective solution for latch slides, particularly in environments where exposure to moisture is a concern. The zinc coating offers a sacrificial layer that protects the underlying steel from corrosion.

Illustrative image related to latch slide

Pros: This material is relatively inexpensive and provides decent corrosion resistance, making it suitable for outdoor applications.

Cons: While the zinc coating protects against rust, it can wear off over time, especially in abrasive environments. This may necessitate more frequent replacements.

Impact on Application: Zinc-coated steel is suitable for applications where exposure to water is expected but not extreme. It is commonly used in agricultural and construction settings.

How Does Plastic Compare as a Material for Latch Slides?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is becoming increasingly popular for latch slides due to its lightweight and corrosion-resistant properties. It is non-conductive and can handle a range of temperatures.

Illustrative image related to latch slide

Pros: Plastic is lightweight, cost-effective, and resistant to various chemicals and environmental factors. It also allows for easy manufacturing and customization.

Cons: Plastic may not offer the same strength and durability as metals, making it less suitable for heavy-duty applications. It can also become brittle over time when exposed to UV light.

Impact on Application: Plastic latch slides are ideal for applications in environments where weight is a concern, such as in portable structures or lightweight equipment.

What Role Does Brass Play in Latch Slide Applications?

Brass, an alloy of copper and zinc, is often used for latch slides that require a combination of strength and aesthetic appeal. Its natural resistance to corrosion makes it suitable for various environments.

Illustrative image related to latch slide

Pros: Brass is durable and has a pleasing appearance, making it suitable for decorative applications. It also has good machinability.

Cons: Brass can be more expensive than other materials and may not be suitable for high-stress environments due to its lower tensile strength compared to steel.

Impact on Application: Brass latch slides are often used in residential applications and decorative furniture, where aesthetics are as important as functionality.

Summary Table of Material Selection for Latch Slides

| Material | Typical Use Case for latch slide | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial and marine applications | High corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Zinc-Coated Steel | Outdoor and construction settings | Cost-effective with decent corrosion resistance | Coating can wear off, requiring replacements | Low |

| Plastic | Lightweight and portable applications | Lightweight and customizable | Less strength and durability in heavy-duty use | Low |

| Brass | Residential and decorative furniture | Aesthetic appeal and good machinability | More expensive and lower tensile strength | Medium |

This material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions when sourcing latch slides, ensuring suitability for their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for latch slide

What Are the Main Stages of Manufacturing Latch Slides?

Manufacturing latch slides involves several critical stages that ensure the final product meets quality and performance standards. The main stages of the manufacturing process include:

-

Material Preparation: The first step involves selecting high-quality materials, typically stainless steel or other corrosion-resistant metals. These materials are then cut to size and prepared for the next stages. Proper material selection is crucial for durability, especially for applications in harsh environments like those found in Africa or South America.

-

Forming: In this stage, the prepared materials undergo processes such as stamping, bending, or machining. Stamping, for instance, is often used to create the main body of the latch slide, which ensures precision and uniformity. Advanced CNC (Computer Numerical Control) machines may also be employed to achieve intricate designs and specifications.

-

Assembly: After forming, the various components of the latch slide, such as the latch body, slide mechanism, and any additional hardware, are assembled. This step may involve manual labor or automated systems, depending on the production scale. Each component must fit together seamlessly to ensure functionality and reliability.

-

Finishing: The final stage involves surface treatment processes, such as polishing, coating, or plating. These processes not only enhance the aesthetic appeal of the latch slide but also improve its resistance to rust and wear. Common finishes include satin stainless steel, which provides a modern look while ensuring longevity.

What Quality Assurance Standards Are Relevant to Latch Slides?

Quality assurance is paramount in the manufacturing of latch slides to ensure compliance with international standards and to meet customer expectations. Key standards include:

-

ISO 9001: This international standard sets the criteria for a quality management system. Companies that adhere to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements. It is a widely recognized certification that can enhance supplier credibility.

-

CE Marking: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards. This certification is essential for B2B buyers in Europe, ensuring that the latch slides meet stringent safety and performance criteria.

-

API Standards: For latch slides used in the oil and gas industry, adherence to American Petroleum Institute (API) standards may be required. These standards ensure that components can withstand extreme conditions, which is particularly relevant for international buyers from the Middle East.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process, ensuring that any potential defects are identified and rectified promptly. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection occurs when raw materials arrive at the manufacturing facility. Materials are checked for compliance with specifications, and any non-conforming items are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC measures are implemented to monitor production quality in real-time. This may involve periodic inspections of components as they are formed and assembled, ensuring that any deviations from quality standards are addressed immediately.

-

Final Quality Control (FQC): Before products are packaged and shipped, FQC involves thorough testing of the finished latch slides. This may include functional tests, dimensional checks, and visual inspections to confirm that products meet all specifications and standards.

What Testing Methods Are Commonly Used for Latch Slides?

Various testing methods are employed to verify the quality and performance of latch slides. Common testing methods include:

-

Dimensional Testing: This involves measuring the physical dimensions of the latch slide to ensure they meet design specifications. Precision tools such as calipers and gauges are used to perform these measurements.

-

Functional Testing: This testing ensures that the latch slide operates as intended. Tests may include opening and closing mechanisms under various conditions to ensure reliability and ease of use.

-

Corrosion Resistance Testing: Given that latch slides are often exposed to moisture and other corrosive elements, tests such as salt spray testing are conducted to evaluate the durability of finishes and materials.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying supplier quality control processes is essential to mitigate risks associated with substandard products. Here are effective strategies:

-

Supplier Audits: Conducting audits allows buyers to evaluate the manufacturing processes, QC measures, and compliance with international standards. This firsthand observation can provide insights into the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should request documentation of quality control procedures, including inspection reports and testing results. These documents can provide evidence of the supplier’s adherence to quality standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s manufacturing and quality control practices. This is particularly useful for buyers in regions like Africa and South America, where local regulatory requirements may differ.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control in the manufacturing of latch slides. Here are some nuances to consider:

Illustrative image related to latch slide

-

Cultural Differences: Understanding cultural attitudes toward quality and business practices is crucial when engaging with suppliers from different regions. This can impact communication and expectations regarding quality assurance.

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers must ensure that suppliers comply with both local and international standards to avoid legal issues and ensure product safety.

-

Supply Chain Integrity: Establishing a reliable supply chain is critical for maintaining quality. Buyers should assess the entire supply chain, from raw material sourcing to distribution, to ensure that quality is preserved at every step.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing latch slides, ensuring that they receive high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch slide’

Introduction

This sourcing guide provides a structured checklist for B2B buyers looking to procure latch slides. A latch slide is essential hardware for ensuring secure closures in various applications, including cabinetry, gates, and industrial settings. By following this checklist, buyers can streamline their procurement process, ensuring they select the right products and suppliers for their needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to clearly outline your technical requirements. Determine the dimensions, materials (e.g., stainless steel, brass), and specific features (like surface-mounted or concealed) that are necessary for your application. This clarity will help you narrow down suppliers and products that meet your specific needs.

Step 2: Research Potential Suppliers

Start your sourcing journey by identifying potential suppliers who specialize in latch slides. Look for manufacturers with a strong reputation in the industry. Investigate their online presence, read reviews, and check their product range to ensure they can meet your specifications. Additionally, consider suppliers with experience in your specific region, as they may better understand local market demands and logistics.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is essential to ensure product quality and compliance with industry standards. Check for ISO certifications, and ensure that the materials used meet relevant safety and quality regulations. This step is vital to minimize risks associated with product failures and maintain compliance with local laws, especially in regulated industries.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the latch slides you are considering. Testing these samples allows you to assess their durability, functionality, and compatibility with your existing hardware. Pay attention to the ease of installation and any operational features that could impact your use case, such as locking mechanisms or weather resistance.

Step 5: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures and terms. Look not only at the unit price but also at shipping costs, lead times, and bulk purchase discounts. Understanding the total cost of ownership will help you make a more informed decision, ensuring you stay within budget while obtaining high-quality products.

Step 6: Assess After-Sales Support and Warranty

Good after-sales support can significantly impact your experience with a supplier. Inquire about warranty terms, return policies, and customer service responsiveness. A supplier that offers robust support can assist you with installation issues or product failures, ensuring long-term satisfaction with your purchase.

Step 7: Finalize Your Order with Clear Documentation

When ready to place your order, ensure that all agreements are documented clearly. This includes specifications, pricing, delivery timelines, and payment terms. Clear documentation will safeguard both parties and provide a reference point should any disputes arise during the transaction. Always keep a copy of the purchase order and any correspondence related to the transaction.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing latch slides, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for latch slide Sourcing

When sourcing latch slides, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis delves into the various cost components, price influencers, and strategic buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Latch Slide Manufacturing?

The total cost of latch slides consists of several critical components:

-

Materials: The choice of materials significantly impacts costs. Stainless steel, for instance, offers durability but can be pricier than plastic or aluminum. Buyers should consider the environmental conditions where the latch will be used to select the most cost-effective yet suitable material.

-

Labor: Labor costs can vary widely depending on the manufacturing location. For example, countries with lower labor costs may provide competitive pricing, but this can affect quality. Understanding the labor market in the supplier’s country is crucial.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities and equipment maintenance. Efficient production processes can help keep these costs down.

-

Tooling: Initial tooling costs can be substantial, especially for customized or specialized latch slides. Buyers should inquire about these costs upfront, as they can be a significant part of the total price.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but can add to costs. Buyers should evaluate how much emphasis suppliers place on QC and whether this aligns with their quality standards.

-

Logistics: Shipping costs can vary based on distance, volume, and mode of transport. Incoterms will dictate who bears these costs and responsibilities, influencing the overall price.

-

Margin: Suppliers typically add a margin to cover their costs and earn profit. This can vary based on market conditions, competition, and the supplier’s positioning.

What Influences Pricing for Latch Slides?

Several factors can influence the pricing of latch slides beyond the basic cost structure:

-

Volume/MOQ: Bulk orders often reduce per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to secure better pricing.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers must balance the need for customization with budget constraints.

-

Quality and Certifications: Higher-quality products or those with specific certifications (e.g., ISO standards) may come at a premium. Buyers should assess the necessity of these certifications based on their end-use requirements.

-

Supplier Factors: The supplier’s reputation, experience, and production capacity can influence pricing. Established suppliers may charge higher prices due to their reliability and service levels.

-

Incoterms: Understanding the chosen Incoterms is crucial, as they define responsibilities for shipping, insurance, and tariffs. This can impact the total landed cost of products.

How Can Buyers Optimize Costs in Latch Slide Sourcing?

-

Negotiation Strategies: Engage suppliers in discussions about pricing and terms. Highlight potential for future orders to leverage better rates.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term maintenance, durability, and replacement costs. A cheaper latch slide may lead to higher TCO if it fails prematurely.

-

Understand Pricing Nuances for International Markets: Buyers from different regions may face unique challenges, such as currency fluctuations or varying import duties. Research local market conditions and regulations to avoid unexpected costs.

-

Supplier Diversification: Avoid dependence on a single supplier by exploring multiple sources. This can enhance negotiating power and reduce risks associated with supply chain disruptions.

-

Evaluate Samples: Before making a large commitment, request samples to assess quality. This can prevent costly mistakes and ensure that the products meet specifications.

Conclusion

A thorough understanding of the cost structure and pricing dynamics is vital for B2B buyers in the latch slide market. By considering the various cost components, price influencers, and employing strategic sourcing tips, buyers can optimize their procurement processes and achieve better value for their investments. Always remember that prices can fluctuate based on market conditions, so staying informed is key to successful sourcing.

Alternatives Analysis: Comparing latch slide With Other Solutions

Exploring Alternative Solutions to Latch Slides

In today’s diverse market, the latch slide has established itself as a reliable solution for securing doors and gates. However, various alternatives can serve similar purposes, each with unique advantages and disadvantages. Understanding these alternatives enables B2B buyers to make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Latch Slide | Gate Slide Bolt | Barrel Bolt |

|---|---|---|---|

| Performance | High security and durability | Good security, moderate durability | Moderate security, easy to use |

| Cost | Moderate ($10-$20) | Low ($5-$15) | Low ($3-$12) |

| Ease of Implementation | Requires precise installation | Simple installation | Easy installation |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance |

| Best Use Case | Heavy-duty applications | Residential gates and doors | Interior doors and lightweight applications |

Detailed Breakdown of Alternatives

1. Gate Slide Bolt

Gate slide bolts are a straightforward and economical alternative to latch slides. They provide a decent level of security, making them suitable for residential gates and doors. Their installation is relatively simple, requiring basic tools and minimal expertise. However, while they are less expensive than latch slides, their durability can be a concern, especially in high-traffic areas or harsh weather conditions. B2B buyers in regions prone to extreme climates may find that gate slide bolts do not hold up as well over time compared to latch slides.

2. Barrel Bolt

Barrel bolts are another viable alternative, known for their simplicity and ease of use. These latches are typically used on interior doors and lightweight applications, making them less suitable for exterior use where security is paramount. The installation process is quick and does not require advanced skills, which is an advantage for businesses looking for efficient solutions. However, barrel bolts offer only moderate security and may not withstand substantial force, making them less ideal for high-security requirements. Buyers should consider the intended application carefully before opting for this solution.

Conclusion: How to Choose the Right Solution

When selecting between latch slides and their alternatives, B2B buyers should evaluate their specific requirements, including security needs, budget constraints, and installation capabilities. For heavy-duty applications requiring superior durability, latch slides are the preferred choice. On the other hand, for lighter use or budget-sensitive projects, gate slide bolts and barrel bolts can provide adequate solutions. Ultimately, understanding the context of use and the environmental factors will guide buyers in making the most appropriate choice for their projects.

Essential Technical Properties and Trade Terminology for latch slide

What Are the Key Technical Properties of a Latch Slide?

Understanding the technical specifications of latch slides is crucial for B2B buyers to ensure they select products that meet their operational requirements. Here are some essential properties to consider:

-

Material Grade

The material used in latch slides significantly impacts their durability and performance. Common materials include stainless steel, brass, and zinc-plated steel. Stainless steel, for example, is favored for its corrosion resistance, making it ideal for outdoor or humid environments. Selecting the right material can enhance the longevity of the product, reducing replacement costs. -

Finish Type

The finish of a latch slide not only affects aesthetics but also its resistance to wear and environmental factors. Options like satin, polished, or powder-coated finishes provide varying levels of protection against rust and scratches. A proper finish can enhance the product’s lifespan, making it a vital consideration for procurement. -

Mounting Style

Latch slides can be surface-mounted or recessed. Surface-mounted options are easier to install and adjust, while recessed types offer a cleaner look and may provide enhanced security. Understanding the installation requirements can streamline the procurement process and ensure compatibility with existing structures. -

Size and Centers

The dimensions of latch slides, including center-to-center spacing, are critical for ensuring a proper fit with the corresponding hardware. Incorrect sizing can lead to installation issues or compromised security. Buyers must verify the specifications to avoid costly missteps. -

Load Capacity

Each latch slide is rated for a specific load capacity, which indicates how much weight it can securely hold. This specification is essential for applications where heavy doors or gates are involved. Selecting a latch slide with an appropriate load capacity is crucial for safety and functionality. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions during manufacturing. For latch slides, tighter tolerances can ensure a better fit and improved performance. Understanding tolerance levels can help buyers assess product quality and reliability.

What Are the Common Trade Terms Related to Latch Slides?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms associated with latch slides:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of latch slides, understanding OEM relationships can help buyers identify quality standards and compatibility with existing products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget planning and inventory management. Buyers must understand MOQs to avoid overcommitting resources and ensure they meet supplier requirements. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This is an important tool for B2B buyers to compare costs and conditions across different vendors, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding these terms helps mitigate risks related to shipping, insurance, and customs, which is especially important for international buyers in Africa, South America, and the Middle East. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the goods. Knowing the lead time is essential for project planning and inventory management. Buyers should always inquire about lead times to ensure they align with operational timelines. -

Certification Standards

These standards indicate that a product meets specific quality and safety requirements. Familiarity with relevant certification standards (e.g., ISO, CE) can help buyers assess product reliability and compliance, particularly in regulated industries.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and ensure product performance.

Illustrative image related to latch slide

Navigating Market Dynamics and Sourcing Trends in the latch slide Sector

What Are the Current Market Dynamics and Key Trends in the Latch Slide Sector?

The latch slide sector is witnessing significant growth, driven by the increasing demand for secure and efficient hardware solutions across various industries. Key global drivers include the expansion of the construction sector, rising urbanization, and a growing focus on safety and security in residential and commercial spaces. Particularly in regions like Africa, South America, the Middle East, and Europe, buyers are increasingly prioritizing quality and durability in latch slide products, as these factors contribute to long-term operational efficiency.

Emerging technologies are also shaping the market landscape. The adoption of smart hardware solutions, such as electronically controlled latches, is on the rise, particularly in urbanized areas. B2B buyers are now looking for products that integrate seamlessly with IoT devices, allowing for enhanced security and user convenience. Additionally, automation in manufacturing processes is leading to improved production efficiency, which can translate into cost savings for buyers.

Sourcing trends indicate a shift towards direct procurement from manufacturers, especially for larger enterprises looking to optimize their supply chains. This trend is particularly relevant in Europe and the Middle East, where buyers are leveraging online platforms for bulk purchasing, benefiting from competitive pricing and reduced lead times. In South America and Africa, there’s a growing emphasis on local sourcing to reduce shipping costs and support regional economies.

How Are Sustainability and Ethical Sourcing Influencing B2B Buyers in the Latch Slide Sector?

Sustainability is becoming a critical consideration for B2B buyers in the latch slide sector. The environmental impact of manufacturing processes and materials used in products is under scrutiny, leading to a demand for sustainable alternatives. Buyers are increasingly favoring suppliers who prioritize eco-friendly practices, such as utilizing recycled materials or implementing energy-efficient manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are looking for partners who adhere to fair labor practices and responsible sourcing, particularly in regions where these issues can be prevalent. Certifications such as ISO 14001 (Environmental Management) and Fair Trade are gaining traction as buyers seek to align their procurement strategies with their corporate social responsibility goals.

Illustrative image related to latch slide

Materials like stainless steel, which is known for its durability and recyclability, are preferred choices among environmentally conscious buyers. Additionally, suppliers offering products with green certifications or those that use low-impact manufacturing processes are becoming more attractive to B2B buyers. This shift not only helps in reducing the overall carbon footprint but also enhances brand reputation and customer loyalty.

What Is the Brief Evolution and History of Latch Slides in the B2B Market?

The latch slide has evolved significantly from its early designs, which were primarily functional and utilitarian. Initially used in basic locking mechanisms for gates and cabinets, these devices have transformed into sophisticated hardware solutions that cater to a variety of applications, including security systems in residential and commercial properties.

Over the decades, advancements in materials technology have enabled the production of more robust and corrosion-resistant latches. The introduction of stainless steel and other durable materials has not only improved product longevity but has also expanded the range of design options available to manufacturers. As consumer preferences shifted towards aesthetics alongside functionality, latch slide designs began incorporating various finishes and styles, appealing to a broader market.

In recent years, the integration of technology into latch slide systems has marked a significant milestone in their evolution. The emergence of smart locks and electronic latches reflects a growing trend towards automation and connectivity, catering to the needs of modern consumers who prioritize convenience and security. This evolution highlights the latch slide’s adaptability and enduring relevance in an ever-changing market landscape.

Illustrative image related to latch slide

Frequently Asked Questions (FAQs) for B2B Buyers of latch slide

-

How do I select the right latch slide for my application?

When choosing a latch slide, consider the specific requirements of your application, including the material (e.g., stainless steel for corrosion resistance), size, and load capacity. Assess the environment in which the latch will be used; for instance, outdoor applications may require weather-resistant finishes. Additionally, evaluate the mounting type—surface-mounted latches are easier to install, while mortise types provide a cleaner look. Consulting with suppliers about your needs can also help ensure you select a latch that meets industry standards and performance expectations. -

What are the common materials used for latch slides and their benefits?

Latch slides are typically made from materials such as stainless steel, brass, and zinc-coated steel. Stainless steel is favored for its durability and resistance to corrosion, making it ideal for outdoor or humid environments. Brass offers a classic aesthetic and good corrosion resistance but may tarnish over time. Zinc-coated steel provides cost-effective protection against rust but may not be suitable for all applications. Understanding the advantages of each material can help you choose the best option for your specific use case. -

What is the minimum order quantity (MOQ) for latch slides?

The minimum order quantity (MOQ) for latch slides can vary significantly between suppliers, often ranging from 50 to 1,000 units. Factors influencing MOQ include the type of latch, customization options, and production capabilities. When negotiating with suppliers, clarify your requirements and ask if they can accommodate smaller orders, especially if you are testing a new product line. Building a relationship with suppliers can also lead to more flexible terms in future transactions. -

How can I ensure the quality of latch slides from international suppliers?

To ensure quality when sourcing latch slides internationally, consider implementing a thorough supplier vetting process. Look for suppliers with industry certifications (e.g., ISO 9001) and positive reviews from other B2B buyers. Request samples to evaluate product quality before committing to larger orders. Additionally, inquire about their quality assurance processes and standards for production. Establishing clear communication regarding your specifications and expectations is crucial to avoid any misunderstandings. -

What payment terms are common in international B2B transactions for latch slides?

Payment terms in international B2B transactions can vary widely but commonly include options such as letters of credit, wire transfers, or payment upon delivery. Many suppliers may require a deposit upfront, typically ranging from 30% to 50% of the total order value. It’s essential to discuss and agree upon payment terms before finalizing any contracts to ensure clarity and avoid potential cash flow issues. Building trust with your supplier can also facilitate more favorable payment arrangements over time. -

How do logistics and shipping impact the cost of latch slides?

Logistics and shipping significantly affect the total cost of latch slides, particularly for international orders. Factors such as shipping method (air vs. sea), weight, volume, and destination can influence shipping costs. Additionally, import duties and taxes may apply based on your country’s regulations. To minimize costs, consider consolidating orders, negotiating shipping terms with suppliers, or exploring different logistics providers. Proper planning for lead times can also help mitigate delays and unexpected expenses. -

What customization options are available for latch slides?

Many suppliers offer customization options for latch slides, including variations in size, finish, and design to meet specific requirements. Custom branding or engraving may also be available for businesses looking to enhance their product identity. When discussing customization, provide detailed specifications and request prototypes if necessary to ensure the final product aligns with your expectations. Keep in mind that custom orders may have longer lead times and higher MOQs. -

How can I track the status of my order for latch slides?

To track the status of your order for latch slides, ensure that your supplier provides a tracking number upon shipment. Most suppliers utilize logistics companies that offer online tracking tools for real-time updates. Maintain open communication with your supplier throughout the order process; they should be able to provide updates on production status, shipping timelines, and any potential delays. Establishing a good relationship with your supplier can facilitate smoother communication and prompt information sharing.

Top 1 Latch Slide Manufacturers & Suppliers List

1. Jacknob – Latch Slide Surface Mounted

Domain: jacknob.com

Registered: 1996 (29 years)

Introduction: {‘part_number’: ‘6309’, ‘description’: ‘LATCH-SLIDE-SURFACE MOUNTED – STAMPED S/S’, ‘sku’: ‘6309’, ‘finish_material’: ‘Satin Stainless Steel’, ‘centers’: ‘1-7/8’, ‘construction’: ‘Stamped’, ‘mount_type’: ‘Surface Mount’, ‘price’: ‘$10.00’, ‘size’: ‘Small’, ‘stock_status’: ‘In-Stock’, ‘categories’: [‘Surface Mounted Latches’, ‘Santana/Hiny Hiders’, ‘Bobrick’], ‘free_shipping_eligible’: ‘Yes’, ‘ship…

Strategic Sourcing Conclusion and Outlook for latch slide

What Are the Key Insights for B2B Buyers in the Latch Slide Market?

In summary, strategic sourcing of latch slide products presents a significant opportunity for international B2B buyers to enhance their procurement processes. By focusing on quality materials, such as stainless steel and robust construction methods, businesses can ensure the longevity and reliability of their latch slide solutions. The variety of styles and finishes available allows for customization to meet specific project needs, further adding value to the purchasing decision.

Moreover, understanding market dynamics—including pricing structures, shipping logistics, and local regulations—can empower buyers to negotiate better terms and optimize their supply chains. The emphasis on supplier relationships and product quality cannot be overstated; these factors are critical in achieving operational efficiency and customer satisfaction.

How Can B2B Buyers Prepare for the Future of Latch Slide Procurement?

Looking ahead, it is crucial for buyers from Africa, South America, the Middle East, and Europe to stay informed about emerging trends in the latch slide market. Engaging with reliable suppliers and leveraging digital platforms for sourcing can streamline procurement efforts and reduce costs. As the market continues to evolve, proactive buyers will position themselves to capitalize on innovations and maintain a competitive edge.

Take action today by exploring your sourcing options and aligning your procurement strategies with the best practices outlined in this guide. The future of latch slide sourcing is promising; ensure your business is ready to seize these opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.