The Definitive Guide to Latch Cable: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for latch cable

In today’s competitive landscape, sourcing high-quality latch cables presents a formidable challenge for international B2B buyers. With the increasing demand for reliable locking mechanisms across various industries, understanding the nuances of latch cable options becomes essential for businesses in regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Nigeria. This guide aims to equip decision-makers with the knowledge necessary to navigate the complexities of the latch cable market effectively.

Throughout this comprehensive resource, we will delve into the diverse types of latch cables available, their applications across different sectors, and the criteria for selecting the right supplier. By highlighting essential factors such as product specifications, installation requirements, and cost considerations, this guide empowers buyers to make informed purchasing decisions.

Additionally, we will provide actionable insights on how to vet suppliers effectively, ensuring that you partner with manufacturers who meet international quality standards and can deliver on time. Whether you are looking to enhance your product line or improve operational efficiency, understanding the global market for latch cables is crucial. This guide will serve as your roadmap, helping you optimize your sourcing strategy and secure the best products for your business needs.

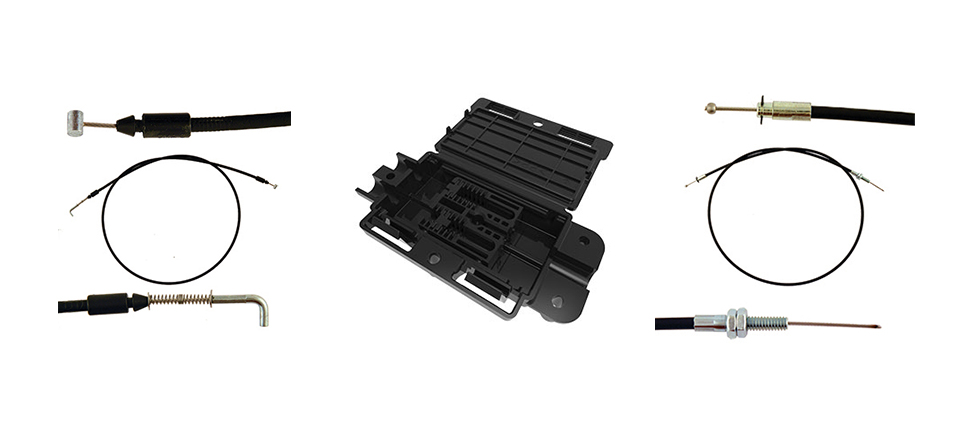

Understanding latch cable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automotive Latch Cable | Designed for vehicle doors; flexible and durable materials | Automotive repair and manufacturing | Pros: OEM compatibility, precise fit. Cons: May require specific vehicle knowledge for installation. |

| Garage Door Latch Cable | Typically made from stainless steel; designed for outdoor use | Residential and commercial garage doors | Pros: Rust-resistant, easy installation. Cons: Limited to specific door types. |

| Gate Latch Cable | Allows for gate operation from either side; often adjustable | Fencing, agricultural, and security gates | Pros: Versatile, enhances accessibility. Cons: Installation may require additional hardware. |

| Industrial Latch Cable | Heavy-duty construction for high-stress environments | Manufacturing and industrial equipment | Pros: High durability, withstands extreme conditions. Cons: Higher cost due to robust materials. |

| Custom Latch Cable Kits | Complete kits with cables, clips, and installation tools | Custom applications across various industries | Pros: All-in-one solution, saves time. Cons: May be overkill for simple applications. |

What Are the Characteristics of Automotive Latch Cables?

Automotive latch cables are engineered to facilitate the opening and closing of vehicle doors. These cables are typically made from high-strength materials that ensure durability and flexibility, allowing them to withstand the rigors of daily use. When purchasing, B2B buyers should consider compatibility with specific vehicle models, as many manufacturers produce cables tailored to particular makes and designs. Understanding the nuances of installation can also be crucial, as improper fitting can lead to functionality issues.

How Do Garage Door Latch Cables Differ?

Garage door latch cables are primarily constructed from rust-resistant stainless steel, making them ideal for outdoor applications. Their design allows for easy installation and reliable operation, which is essential for both residential and commercial settings. Buyers should evaluate the specific requirements of their garage doors, including weight and type, to ensure that the selected cable can support the intended use. Additionally, the cost-effectiveness of these cables can be a significant factor, especially for bulk purchases.

In What Situations Are Gate Latch Cables Most Useful?

Gate latch cables are versatile components that enable gate operation from either side, enhancing accessibility and convenience. Commonly used in fencing and agricultural settings, these cables often feature adjustable lengths to accommodate various gate sizes. B2B buyers should assess the installation requirements and compatibility with existing gate hardware. While these cables provide significant benefits, such as ease of use, they may necessitate additional components for proper installation, which can increase overall project costs.

What Are the Benefits of Industrial Latch Cables?

Industrial latch cables are designed for high-stress environments, often featuring heavy-duty construction that can withstand extreme conditions. These cables are critical in manufacturing and industrial settings where reliability is paramount. When purchasing, B2B buyers must consider the specific operational requirements and environmental factors that the cables will encounter. While these cables tend to be more expensive due to their robust materials, their longevity and performance can justify the investment.

Why Choose Custom Latch Cable Kits?

Custom latch cable kits offer an all-in-one solution for businesses that require tailored applications across various industries. These kits typically include everything needed for installation, from cables to clips and tools, simplifying the purchasing process. B2B buyers should evaluate the complexity of their projects to determine if a kit is the best fit; while they can save time and effort, they may also be more than necessary for simpler applications. The ability to customize can lead to enhanced efficiency and reduced downtime in operations.

Key Industrial Applications of latch cable

| Industry/Sector | Specific Application of latch cable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Door latch cables for vehicle access systems | Enhances vehicle security and user convenience | Ensure compatibility with vehicle models; consider durability under various environmental conditions. |

| Construction | Gate latch cables for site security | Provides secure access control to construction sites | Look for corrosion-resistant materials; evaluate installation ease and maintenance needs. |

| Manufacturing | Latch cables for machinery access panels | Improves safety and efficiency in machinery operation | Assess cable strength and load capacity; verify compliance with industry safety standards. |

| Agriculture | Latch cables for equipment access in farms | Facilitates quick access to machinery and reduces downtime | Consider weather-resistant materials; ensure ease of use in rugged conditions. |

| Home Improvement | Latch cables for garage doors and gates | Enhances functionality and safety of home access points | Evaluate ease of installation and long-term reliability; prioritize materials that withstand weather elements. |

How Are Latch Cables Used in the Automotive Industry?

In the automotive sector, latch cables are crucial for vehicle access systems, allowing drivers and passengers to open doors with ease. These cables connect the interior door handle to the latch mechanism, ensuring smooth operation. For international buyers, particularly in regions like Africa and South America, sourcing durable cables that can withstand extreme temperatures and humidity is essential. Additionally, ensuring compatibility with various vehicle models can streamline inventory management and reduce costs.

What Role Do Latch Cables Play in Construction Security?

In construction, latch cables are used in gate latch systems to secure site access points. They provide a reliable means of controlling entry, crucial for maintaining site security and protecting valuable equipment. Buyers should prioritize cables made from corrosion-resistant materials to withstand harsh weather conditions typical in regions like the Middle East. Furthermore, ease of installation can significantly reduce labor costs, making it a vital consideration for procurement.

How Are Latch Cables Implemented in Manufacturing Processes?

Manufacturing facilities utilize latch cables in access panels for machinery, enhancing safety and operational efficiency. These cables allow quick access to critical components for maintenance and troubleshooting, minimizing downtime. Buyers in this sector should focus on cables with high tensile strength and compliance with safety regulations to ensure they meet industry standards. Additionally, understanding the specific load capacities required for different machinery can inform better sourcing decisions.

Why Are Latch Cables Important for Agricultural Equipment?

In agriculture, latch cables are essential for providing secure access to machinery and equipment. They facilitate quick entry, which is crucial during peak operational times when efficiency is paramount. Buyers should seek weather-resistant cables that can endure exposure to the elements, especially in regions with variable climates. Moreover, ease of use is critical; cables should be designed for quick release and operation, which can significantly impact productivity on farms.

How Do Latch Cables Enhance Home Improvement Projects?

For home improvement projects, latch cables are often employed in garage doors and gates to enhance functionality and security. They ensure smooth operation, allowing homeowners to access their properties easily and securely. Buyers should consider the materials used in the cables, as those that are rust-resistant will provide longer service life, particularly in regions with high moisture. Additionally, evaluating the installation process can help homeowners and contractors save time and reduce costs during projects.

3 Common User Pain Points for ‘latch cable’ & Their Solutions

Scenario 1: Difficulty in Finding Durable Latch Cables for Harsh Environments

The Problem: B2B buyers often face challenges when sourcing latch cables that can withstand extreme environmental conditions. For companies operating in regions with high humidity, extreme temperatures, or corrosive elements—such as coastal areas or industrial settings—standard latch cables may degrade quickly, leading to frequent replacements. This not only increases operational costs but also affects the reliability of equipment, which can have downstream effects on productivity and customer satisfaction.

The Solution: To address this issue, buyers should prioritize sourcing latch cables made from corrosion-resistant materials such as stainless steel or specially coated alloys. When evaluating suppliers, request detailed specifications on the material properties and corrosion resistance ratings. Additionally, consider cables that come with warranties or certifications for durability in harsh conditions. Engaging with manufacturers that specialize in industrial applications can provide tailored solutions that meet specific environmental challenges, ensuring longevity and performance.

Scenario 2: Incompatibility with Existing Systems

The Problem: Another prevalent issue is the incompatibility of latch cables with existing hardware or systems. B2B buyers might find that the latch cables they purchase do not fit seamlessly with their current installations, leading to delays in operations and increased labor costs for modifications. This situation is especially common in industries where equipment is upgraded or retrofitted, and new components must work with legacy systems.

The Solution: To mitigate this risk, buyers should conduct a thorough compatibility assessment before procurement. This includes measuring existing installations and consulting technical documentation to ensure that new latch cables meet the required specifications. Engaging with suppliers who offer customization options can also provide a solution; they may offer made-to-order cables designed to fit specific hardware configurations. Furthermore, consider investing in a cable installation kit that includes connectors and adjustment tools to simplify the integration process.

Scenario 3: High Failure Rates and Maintenance Costs

The Problem: Frequent failures of latch cables can lead to increased maintenance costs and operational downtimes. B2B buyers often encounter situations where latch cables fail prematurely, resulting in the need for immediate replacements and causing workflow disruptions. This issue can stem from several factors, including poor-quality materials, improper installation, or inadequate maintenance practices.

The Solution: To reduce failure rates, it is essential to invest in high-quality latch cables from reputable manufacturers known for their reliability. Buyers should also implement a regular maintenance schedule to inspect and maintain latch cables, ensuring they are free from wear and tear. Training staff on proper installation techniques can further reduce the likelihood of issues arising from human error. Additionally, establishing a relationship with suppliers who provide ongoing support and advice can be invaluable, as they can offer insights on best practices for installation and maintenance, ultimately leading to lower total costs of ownership.

Strategic Material Selection Guide for latch cable

What are the Key Properties of Common Materials Used in Latch Cables?

When selecting materials for latch cables, it is crucial to consider their properties, performance, and suitability for various applications. Here, we analyze four common materials: stainless steel, nylon, galvanized steel, and aluminum.

Stainless Steel: A Durable Choice for Latch Cables

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it an ideal choice for latch cables used in harsh environments. It can withstand high temperatures and pressures, which is beneficial for automotive applications and outdoor installations.

Pros: Stainless steel offers high durability and longevity, making it suitable for applications where reliability is critical. Its resistance to rust and corrosion extends the lifespan of the latch cable, reducing maintenance costs.

Cons: The primary drawback is its higher cost compared to other materials. Manufacturing processes can also be more complex, requiring specialized equipment.

Impact on Application: Stainless steel latch cables are particularly effective in environments exposed to moisture and chemicals, such as coastal regions in Africa and the Middle East.

Considerations for International Buyers: Compliance with international standards such as ASTM A240 for stainless steel is essential. Buyers should also consider local corrosion resistance requirements, especially in humid climates.

Nylon: Lightweight and Flexible

Nylon is a synthetic polymer that offers flexibility and lightweight characteristics, making it suitable for applications requiring ease of installation and operation.

Pros: Its lightweight nature allows for easier handling and installation. Nylon is also resistant to abrasion and has good chemical resistance, making it suitable for various applications.

Cons: However, nylon may not withstand high temperatures as effectively as metals, which can limit its use in extreme conditions. It is also less durable than stainless steel, leading to potential replacements over time.

Impact on Application: Nylon latch cables are ideal for indoor applications or environments where temperature fluctuations are minimal, such as in South American automotive interiors.

Considerations for International Buyers: Ensure that the nylon used complies with relevant standards, such as ASTM D4066, particularly for applications in industries like automotive and construction.

Galvanized Steel: Cost-Effective and Strong

Galvanized steel is steel that has been coated with zinc to prevent corrosion, making it a cost-effective alternative to stainless steel for latch cables.

Pros: It offers good strength and durability at a lower cost than stainless steel. The zinc coating provides adequate corrosion resistance for many applications.

Cons: While galvanized steel is resistant to rust, it may not perform well in highly corrosive environments, leading to potential degradation over time. The manufacturing process can also be less environmentally friendly.

Impact on Application: This material is suitable for outdoor applications in regions with moderate weather, such as parts of Europe and Africa.

Considerations for International Buyers: Buyers should verify compliance with local standards for galvanized steel, such as EN 10025, especially in construction and agricultural applications.

Aluminum: Lightweight with Good Corrosion Resistance

Aluminum is another popular material for latch cables, known for its lightweight and good corrosion resistance properties.

Pros: Its lightweight nature makes it easy to handle, and it is resistant to rust, which is advantageous in humid environments. Aluminum also has a good strength-to-weight ratio.

Illustrative image related to latch cable

Cons: However, aluminum can be more expensive than galvanized steel and may not be as strong as stainless steel. Its performance under high-stress conditions can also be a concern.

Impact on Application: Aluminum latch cables are often used in applications where weight is a critical factor, such as in aviation or automotive sectors.

Considerations for International Buyers: Ensure that aluminum materials meet standards like ASTM B221 for structural applications, particularly in the aerospace and automotive industries.

Summary Table of Material Properties for Latch Cables

| Material | Typical Use Case for latch cable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Automotive and outdoor applications | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Nylon | Indoor automotive and general use | Lightweight and flexible | Limited temperature tolerance | Medium |

| Galvanized Steel | Outdoor applications in moderate climates | Cost-effective and strong | Moderate corrosion resistance | Low |

| Aluminum | Aviation and automotive lightweight uses | Good corrosion resistance | Less strength compared to steel | Medium |

This guide provides B2B buyers with critical insights into material selection for latch cables, enabling informed decisions that align with their operational needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for latch cable

What Are the Key Stages in the Manufacturing Process of Latch Cables?

The manufacturing process of latch cables involves several critical stages that ensure the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality materials, typically stainless steel or other corrosion-resistant alloys. These materials are sourced from reputable suppliers who adhere to international standards. The raw materials undergo rigorous inspections to ensure they meet the required specifications, including tensile strength and corrosion resistance.

-

Forming: During the forming stage, the prepared materials are shaped into the desired configurations. This may involve cutting, bending, or twisting the metal into specific forms that are essential for the cable’s functionality. Advanced techniques such as CNC machining and laser cutting are commonly employed to achieve precision and consistency in dimensions.

-

Assembly: The assembly stage involves connecting various components of the latch cable, such as the cable, fittings, and clips. This stage is crucial as it determines the operational efficiency of the latch cable. Automated assembly lines may be used to enhance efficiency, but manual assembly is often employed for more complex configurations where precision is paramount.

-

Finishing: The final stage of manufacturing is finishing, which enhances the durability and appearance of the latch cables. This may include processes such as coating for corrosion resistance, polishing for aesthetics, and applying protective coverings. Quality control checks are performed throughout this stage to ensure that the finished products meet the required specifications.

What Quality Assurance Standards Are Relevant for Latch Cables?

Quality assurance in the manufacturing of latch cables is governed by several international standards, ensuring that products are safe, reliable, and meet customer expectations.

-

ISO 9001: This is a widely recognized standard that outlines the criteria for a quality management system (QMS). Compliance with ISO 9001 signifies that the manufacturer has established effective processes for quality assurance, including customer satisfaction and continual improvement.

-

CE Marking: For manufacturers targeting the European market, CE marking indicates conformity with health, safety, and environmental protection standards. This is particularly important for latch cables used in automotive and construction applications.

-

API Standards: For latch cables used in the oil and gas industry, compliance with American Petroleum Institute (API) standards is essential. These standards ensure that the cables can withstand harsh environmental conditions and are suitable for specific applications.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) is integral to the manufacturing process of latch cables, with multiple checkpoints established to ensure compliance with quality standards.

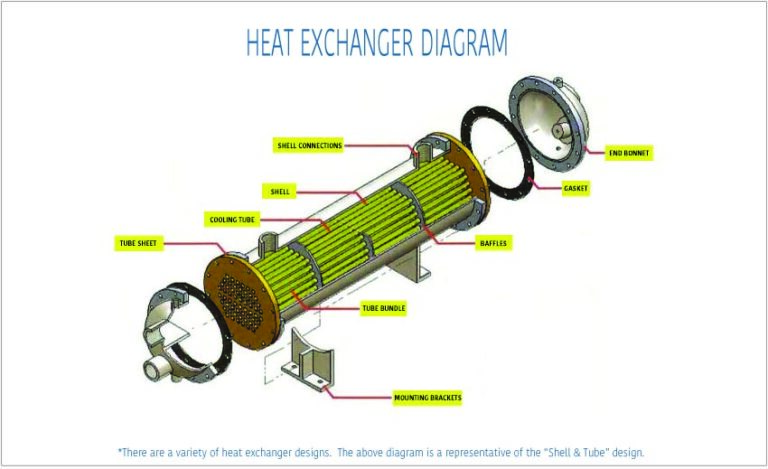

Illustrative image related to latch cable

-

Incoming Quality Control (IQC): This initial checkpoint occurs when raw materials arrive at the manufacturing facility. Materials are inspected for defects and compliance with specifications before they can be used in production. This step is crucial for preventing defects in the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, IPQC is implemented to monitor processes and detect issues early. Techniques such as statistical process control (SPC) are employed to ensure that production remains within specified limits. Regular inspections and testing during forming and assembly help identify problems before they escalate.

-

Final Quality Control (FQC): Once the latch cables are finished, FQC involves thorough inspections and tests to ensure that the products meet all specifications. This may include functional tests, dimensional checks, and corrosion resistance tests. Only products that pass FQC are shipped to customers.

What Common Testing Methods Are Used to Ensure Latch Cable Quality?

Testing methods for latch cables vary based on their intended use and industry requirements. Common testing methods include:

-

Tensile Testing: This measures the strength of the cable and its ability to withstand pulling forces without breaking. It is crucial for ensuring the cable can perform under load.

-

Corrosion Testing: Latch cables, especially those used outdoors or in corrosive environments, undergo tests to assess their resistance to rust and degradation. Salt spray testing is a common method used to simulate long-term exposure to harsh conditions.

-

Functional Testing: This involves testing the cable in real-life applications to ensure it performs as expected. This might include simulating opening and closing mechanisms to verify that the latch cable operates smoothly and reliably.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring product reliability.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Audits can be scheduled or surprise visits to assess adherence to international standards like ISO 9001.

-

Quality Assurance Reports: Requesting documentation from suppliers that outlines their quality control processes, testing methods, and results can provide transparency. These reports should detail compliance with relevant standards and any certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. These inspections can be conducted at various stages of production, ensuring that products meet the required specifications before shipment.

What Are the QC and Certification Nuances for International Buyers?

International buyers must navigate specific nuances in quality control and certification when sourcing latch cables from global suppliers.

-

Compliance with Local Regulations: Different regions may have varying regulations and standards that manufacturers must comply with. Understanding these requirements is crucial for ensuring that products are not only safe but also legally marketable in the target region.

-

Cultural Considerations: The approach to quality assurance may vary by region. For instance, some cultures may emphasize relationships and trust, while others may prioritize formal agreements and documentation. Buyers should consider these cultural factors when engaging with suppliers.

-

Language Barriers: Communication is vital for effective quality control. Buyers should ensure that technical specifications and quality requirements are clearly understood by suppliers, which may involve translation services or bilingual representatives.

By understanding the manufacturing processes, quality assurance standards, testing methods, and verification strategies for latch cables, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch cable’

In the world of industrial and automotive applications, sourcing the right latch cable is critical for ensuring operational efficiency and safety. This guide serves as a practical checklist to help B2B buyers navigate the procurement process effectively, ensuring that they secure high-quality products that meet their specific needs.

Illustrative image related to latch cable

Step 1: Define Your Technical Specifications

Begin by outlining the specific technical requirements of the latch cable you need. Consider factors such as length, material composition (e.g., stainless steel for corrosion resistance), and intended application (e.g., automotive doors, garage gates). Clearly defined specifications will facilitate better communication with suppliers and help in sourcing the most appropriate products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in latch cables. Look for companies with a solid track record in your industry and geographical region. Utilize online platforms, trade shows, and industry networks to gather a list of suppliers known for their reliability and quality.

Step 3: Evaluate Supplier Certifications

It’s vital to verify that potential suppliers hold the necessary certifications and adhere to industry standards. Look for ISO certifications or compliance with specific regional regulations, as this reflects a commitment to quality. Additionally, check for any product-specific certifications that may apply to the latch cables you intend to procure.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the latch cables you are considering. Testing samples will help you assess the quality and performance of the cables in real-world conditions. Pay attention to the material integrity, flexibility, and ease of installation, as these factors can significantly impact your operational efficiency.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Be cautious of prices that seem too good to be true, as they may indicate inferior quality. Look for transparent pricing that includes shipping, handling, and any potential duties, especially when dealing with international suppliers.

Illustrative image related to latch cable

Step 6: Check References and Reviews

Before finalizing your decision, reach out to other businesses that have previously worked with the suppliers you are considering. Ask for references and read online reviews to gain insights into their reliability, customer service, and product quality. This step will help you make an informed decision based on actual experiences.

Step 7: Establish Clear Communication Channels

Once you choose a supplier, establish clear lines of communication. Discuss expectations regarding delivery timelines, order quantities, and after-sales support. Effective communication is essential for resolving any potential issues and ensuring a smooth procurement process.

By following this checklist, B2B buyers can confidently navigate the sourcing process for latch cables, ensuring they select the best products that meet their operational requirements.

Comprehensive Cost and Pricing Analysis for latch cable Sourcing

What Are the Key Cost Components in Latch Cable Sourcing?

When sourcing latch cables, understanding the cost structure is critical for B2B buyers. The primary components include:

-

Materials: The choice of materials significantly affects the cost. Stainless steel, for example, offers durability and corrosion resistance but comes at a premium compared to standard steel. Buyers should evaluate the specific requirements of their applications to optimize material selection.

-

Labor: Labor costs vary by region. In high-wage countries, labor can constitute a larger portion of the total cost. Conversely, sourcing from regions with lower labor costs can offer savings, though this may come with trade-offs in quality or lead times.

-

Manufacturing Overhead: This includes utilities, maintenance, and administrative expenses associated with production. Established manufacturers often have optimized processes that can lower overhead costs, allowing them to offer competitive pricing.

-

Tooling: Custom tooling for unique latch cable designs can be a significant upfront investment. Buyers should consider whether they need off-the-shelf solutions or custom designs, as this will influence both initial costs and long-term pricing.

-

Quality Control (QC): Rigorous QC processes can add to the cost but are essential for ensuring product reliability. Certifications such as ISO or specific industry standards can also influence pricing.

-

Logistics: Shipping and handling costs can vary based on distance, shipping mode, and the complexities involved in international transport. Buyers should assess the total logistics costs when comparing suppliers.

-

Margin: Suppliers typically mark up costs to ensure profitability. Understanding the supplier’s margin can provide leverage in negotiations, especially when ordering in bulk.

What Price Influencers Should B2B Buyers Consider?

Several factors can influence the pricing of latch cables, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Buyers should determine if they can commit to larger quantities to benefit from volume discounts.

-

Specifications and Customization: Custom specifications can drive up costs. If standard products meet requirements, opting for these can reduce expenses significantly.

-

Quality and Certifications: Higher-quality materials and additional certifications can increase costs. Buyers must weigh the benefits of premium products against their specific application needs.

-

Supplier Factors: The reputation, location, and reliability of suppliers can impact pricing. Engaging with established suppliers may yield better service and quality assurance.

-

Incoterms: Understanding the chosen Incoterms can clarify responsibilities for shipping costs, insurance, and delivery. This knowledge is vital for budgeting and cost management.

How Can Buyers Negotiate Effectively for Latch Cables?

Negotiation is key in securing favorable terms and pricing. Here are some strategies:

-

Research Market Rates: Before negotiations, gather data on prevailing market prices for latch cables. This information can empower buyers during discussions.

-

Leverage Volume Commitments: If planning future orders, indicating potential volume can incentivize suppliers to offer better pricing.

-

Request Transparency: Ask suppliers to break down their pricing structure. Understanding where costs arise can help identify areas for negotiation.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the entire lifecycle cost, including maintenance and potential failures. A lower upfront cost may lead to higher long-term expenses if the product is of inferior quality.

What Pricing Nuances Exist for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of several nuances:

-

Currency Fluctuations: Exchange rates can impact costs significantly. It’s advisable to negotiate contracts in stable currencies to mitigate risks.

-

Import Duties and Taxes: Understanding the tariffs and taxes applicable to imported goods is essential for accurate cost calculations.

-

Cultural Differences: Negotiation styles can vary across cultures. Understanding local business etiquette can enhance communication and foster better relationships with suppliers.

-

Supply Chain Disruptions: Global events can affect lead times and availability. Building flexibility into contracts can help manage these risks.

Disclaimer on Indicative Prices

Prices for latch cables can vary widely based on the factors discussed. This analysis serves as a guideline, and actual costs may fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always engage with multiple suppliers to ensure competitive pricing and optimal sourcing strategies.

Alternatives Analysis: Comparing latch cable With Other Solutions

Exploring Viable Alternatives to Latch Cable

In the realm of securing and operating various mechanisms, latch cables are commonly utilized for their reliability and effectiveness. However, alternative solutions exist that can provide similar functionalities, each with its own set of advantages and drawbacks. Understanding these alternatives helps B2B buyers make informed decisions based on their specific operational requirements.

| Comparison Aspect | Latch Cable | Gate Latch System | Electric Latch Mechanism |

|---|---|---|---|

| Performance | High durability; good for manual use | Effective for gates; manual operation | Automated; remote access capability |

| Cost | Moderate (varies by material) | Generally low-cost | Higher initial investment |

| Ease of Implementation | Simple installation; minimal tools required | Easy to set up; no special tools needed | Requires electrical setup and wiring |

| Maintenance | Low; occasional checks needed | Low; periodic lubrication advised | Moderate; electrical components may require servicing |

| Best Use Case | Vehicles, doors, and hoods | Garden gates, outdoor fencing | Commercial properties, smart homes |

What Are the Benefits and Drawbacks of a Gate Latch System?

Gate latch systems serve as an effective alternative to latch cables, particularly for outdoor applications. These systems are typically low-cost and easy to install, making them an attractive option for garden gates and outdoor fencing. The manual operation of gate latches provides a straightforward method for securing access points without the need for complex mechanisms. However, the simplicity of these systems can be a drawback in scenarios requiring remote access or enhanced security features, limiting their functionality compared to electric solutions.

How Does an Electric Latch Mechanism Compare?

Electric latch mechanisms offer a modern approach to access control, utilizing electronic components to provide remote locking and unlocking capabilities. This technology is especially advantageous for commercial properties and smart homes where security and convenience are paramount. While electric latches offer high performance and advanced features, they come with a higher initial investment and may require more complex installation and maintenance compared to latch cables. Additionally, reliance on electrical systems can introduce vulnerabilities in areas prone to power outages.

How Can B2B Buyers Choose the Right Solution?

When selecting the most suitable solution for their needs, B2B buyers should consider various factors, including the specific application, budget constraints, and the desired level of convenience. For straightforward applications where manual operation suffices, latch cables or gate latch systems may be ideal. In contrast, for environments where security and automation are critical, investing in electric latch mechanisms could prove beneficial despite the higher costs. Ultimately, the choice should align with operational needs, ensuring reliability and efficiency in securing access points.

Essential Technical Properties and Trade Terminology for latch cable

What Are the Key Technical Properties of Latch Cables?

When considering latch cables for procurement, understanding their technical properties is crucial for ensuring functionality, durability, and compliance with industry standards. Here are some essential specifications that B2B buyers should evaluate:

-

Material Composition:

Latch cables are typically made from materials such as stainless steel, galvanized steel, or other corrosion-resistant alloys. Stainless steel is favored for its resistance to rust and wear, making it suitable for outdoor applications. Selecting the right material ensures longevity and performance under various environmental conditions. -

Cable Diameter:

The diameter of the cable is a critical specification that affects its strength and flexibility. Common diameters range from 1/16 inch to 1/4 inch. A thicker cable often provides more strength but may sacrifice flexibility. B2B buyers should assess the balance between strength requirements and the intended application to avoid premature failure. -

Tensile Strength:

This property measures the maximum load the cable can withstand before breaking. It is usually expressed in pounds or kilograms. Understanding the tensile strength is vital for applications where heavy loads are involved, such as automotive or industrial uses. Buyers must ensure that the selected cable can handle the expected stress to prevent safety hazards. -

Cable Length and Adjustability:

Latch cables come in various lengths, often ranging from a few inches to several feet. Some products offer adjustable lengths to accommodate different installations. Buyers should consider the specific installation requirements and ensure that the chosen cable can be effectively adjusted to fit the intended application. -

Operational Temperature Range:

Different materials and designs have varying tolerance levels to temperature fluctuations. Knowing the operational temperature range is essential for applications in extreme climates, ensuring that the cable maintains functionality without degrading. -

Corrosion Resistance Rating:

This rating indicates how well the cable can withstand environmental elements that may lead to corrosion. It is particularly important for applications exposed to moisture, chemicals, or saltwater. Buyers should prioritize cables with higher resistance ratings to enhance durability and reduce maintenance costs.

What Are Common Trade Terms Used in Latch Cable Procurement?

Familiarity with industry terminology can streamline communication and enhance negotiation outcomes. Here are several key terms relevant to latch cable procurement:

-

OEM (Original Equipment Manufacturer):

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of latch cables, OEM parts often guarantee compatibility and reliability, making them a preferred choice for many buyers. -

MOQ (Minimum Order Quantity):

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers assess their purchasing needs and manage inventory effectively. It can also influence pricing, as larger orders often lead to better rates. -

RFQ (Request for Quotation):

An RFQ is a document issued by a buyer to potential suppliers requesting pricing information for specific products. In the context of latch cables, an RFQ can help buyers compare prices and terms from different suppliers, leading to informed purchasing decisions. -

Incoterms (International Commercial Terms):

These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping arrangements. Understanding Incoterms is crucial for managing logistics and ensuring that both parties are aware of their obligations regarding shipping, insurance, and tariffs. -

Lead Time:

This term refers to the amount of time it takes from placing an order to receiving the goods. For latch cables, lead time can vary based on factors such as manufacturing capabilities and shipping distances. Buyers should consider lead times in their project planning to avoid delays. -

Certification Standards:

These are industry standards that products must meet to ensure safety and quality. For latch cables, certifications such as ISO or ASTM may be relevant. Understanding certification requirements helps buyers ensure compliance and enhances product reliability.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they procure the right latch cables for their applications.

Navigating Market Dynamics and Sourcing Trends in the latch cable Sector

What Are the Key Market Dynamics and Trends in the Latch Cable Sector?

The latch cable market is currently experiencing significant growth driven by multiple global factors. An increase in automotive production, particularly in emerging markets such as Nigeria and Brazil, has led to a heightened demand for high-quality latch cables. Additionally, the rise in construction activities across the Middle East and Europe has fueled the need for durable latch systems in gates and doors. Technological advancements in manufacturing processes, such as the adoption of automated assembly lines and improved material science, are also shaping the market. These innovations not only enhance product performance but also reduce costs, making it easier for international B2B buyers to source competitively priced latch cables.

Emerging trends indicate a shift towards customization and flexibility in product offerings. Buyers are increasingly seeking suppliers who can provide tailored solutions that meet specific operational requirements. Moreover, the integration of IoT (Internet of Things) technologies in latch systems is becoming a noteworthy trend, allowing for smart locking mechanisms that enhance security. B2B buyers should keep an eye on these technological advancements as they could represent new opportunities for collaboration and innovation.

How Can Sustainability and Ethical Sourcing Impact the Latch Cable Market?

Sustainability is becoming a critical factor in the latch cable sector, as businesses and consumers alike place greater emphasis on environmental responsibility. The production of latch cables can have significant environmental impacts, including resource depletion and pollution. Therefore, B2B buyers must prioritize suppliers who adhere to sustainable manufacturing practices. This includes using eco-friendly materials and processes that minimize waste and energy consumption.

Ethical sourcing is also gaining traction, with a focus on transparency and fairness throughout the supply chain. Buyers should consider suppliers that are certified for sustainability and ethical practices, such as ISO 14001 for environmental management or Fair Trade certifications. Furthermore, sourcing latch cables made from recycled or renewable materials not only reduces environmental impact but can also enhance brand reputation. As the global market shifts towards more responsible practices, aligning with suppliers who prioritize sustainability and ethics will be essential for long-term success.

What Has Been the Evolution of Latch Cables in the B2B Context?

The evolution of latch cables has been marked by significant advancements in materials and manufacturing techniques. Initially, latch cables were predominantly made from basic metals, which were prone to rust and wear. However, advancements in materials science have introduced options such as stainless steel and synthetic composites, which offer superior durability and corrosion resistance.

Over the years, the application of latch cables has expanded beyond automotive uses to include various industries such as construction, marine, and industrial machinery. This diversification has prompted suppliers to innovate further, leading to the development of specialized latch cables that meet specific operational needs. As a result, the market has seen an influx of products designed for both functionality and aesthetic appeal, catering to a broader spectrum of B2B buyers. Understanding this evolution is crucial for buyers looking to make informed decisions about their sourcing strategies in the latch cable sector.

Frequently Asked Questions (FAQs) for B2B Buyers of latch cable

-

How do I choose the right latch cable for my application?

Selecting the appropriate latch cable depends on several factors, including the specific application, load requirements, and environmental conditions. Assess the material—stainless steel offers durability and corrosion resistance, while plastic cables may be lighter and cost-effective. Consider the length and diameter of the cable to ensure it fits your installation needs. Reviewing manufacturer specifications and consulting with suppliers can provide insights into compatibility with existing systems, ultimately helping you make an informed choice. -

What are the common applications for latch cables in B2B settings?

Latch cables are widely used in various industries, including automotive, construction, and industrial equipment. In automotive applications, they facilitate door and hood operations, while in construction, they are often found in gate mechanisms. Additionally, latch cables play a critical role in securing compartments in machinery and equipment. Understanding the specific application will help you source the right type of latch cable that meets your operational requirements. -

What should I consider when vetting suppliers for latch cables?

When evaluating suppliers for latch cables, consider their reputation, quality certifications, and experience in your industry. Look for suppliers with positive reviews and testimonials from other B2B buyers. Assess their production capabilities, lead times, and compliance with international standards. It’s also essential to inquire about their warranty policies and after-sales support, as these factors can significantly impact your long-term satisfaction and operational efficiency. -

What customization options are available for latch cables?

Many manufacturers offer customization for latch cables to meet specific client needs, such as length, material, and design. You can request modifications based on the application, like adding protective sheathing or specific connector types. Discuss your requirements with potential suppliers, as they may provide tailored solutions that enhance performance and compatibility with existing systems. Customization can also lead to improved efficiency and safety in your operations. -

What is the typical minimum order quantity (MOQ) for latch cables?

The minimum order quantity for latch cables can vary significantly based on the supplier and the type of cable. Generally, MOQs range from 100 to 1,000 units. Suppliers may lower MOQs for established clients or larger contracts. It’s advisable to communicate your needs early in the negotiation process to find a supplier willing to accommodate your order volume, especially if you are looking for a pilot project or testing phase. -

What payment terms should I expect when sourcing latch cables internationally?

International suppliers often have varying payment terms, influenced by the nature of the transaction and the buyer’s creditworthiness. Common payment methods include wire transfers, letters of credit, and escrow services. Terms may require a deposit upfront, with the balance due upon shipment or delivery. Discuss payment flexibility and consider negotiating terms that align with your cash flow needs while ensuring the supplier’s security. -

How can I ensure quality assurance for latch cables?

To ensure quality assurance for latch cables, request samples before placing a bulk order. Establish clear specifications and quality standards with your supplier, including testing protocols for durability and performance. Many suppliers will provide certifications or documentation verifying compliance with international standards. Regular communication and scheduled audits can also help maintain quality throughout the production process, ensuring that the final product meets your expectations. -

What logistics considerations should I keep in mind when importing latch cables?

When importing latch cables, consider shipping costs, delivery times, and customs regulations in your country. Work with logistics partners experienced in handling industrial components to streamline the import process. Ensure you have the necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. Planning for potential delays and understanding your country’s import duties can help you manage costs and timelines effectively.

Top 5 Latch Cable Manufacturers & Suppliers List

1. Ideal Inc – Garage Door Latch Cables 2-Pack

Domain: idealinc.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Garage Door Latch Cables (2-Pack)”, “sku”: “SK7135”, “description”: “Replacement cables for garage door latches/locks that connect the middle latch to the slide locks on either end of the door.”, “included_items”: [“2 galvanized steel cables”, “2 ‘S’ hooks”], “cable_length”: “5′”, “wire_diameter”: “1/16″”, “price”: “US$ 12.37”, “packaging_info”: {“units_per_package”: 2, “package_…

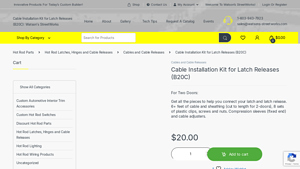

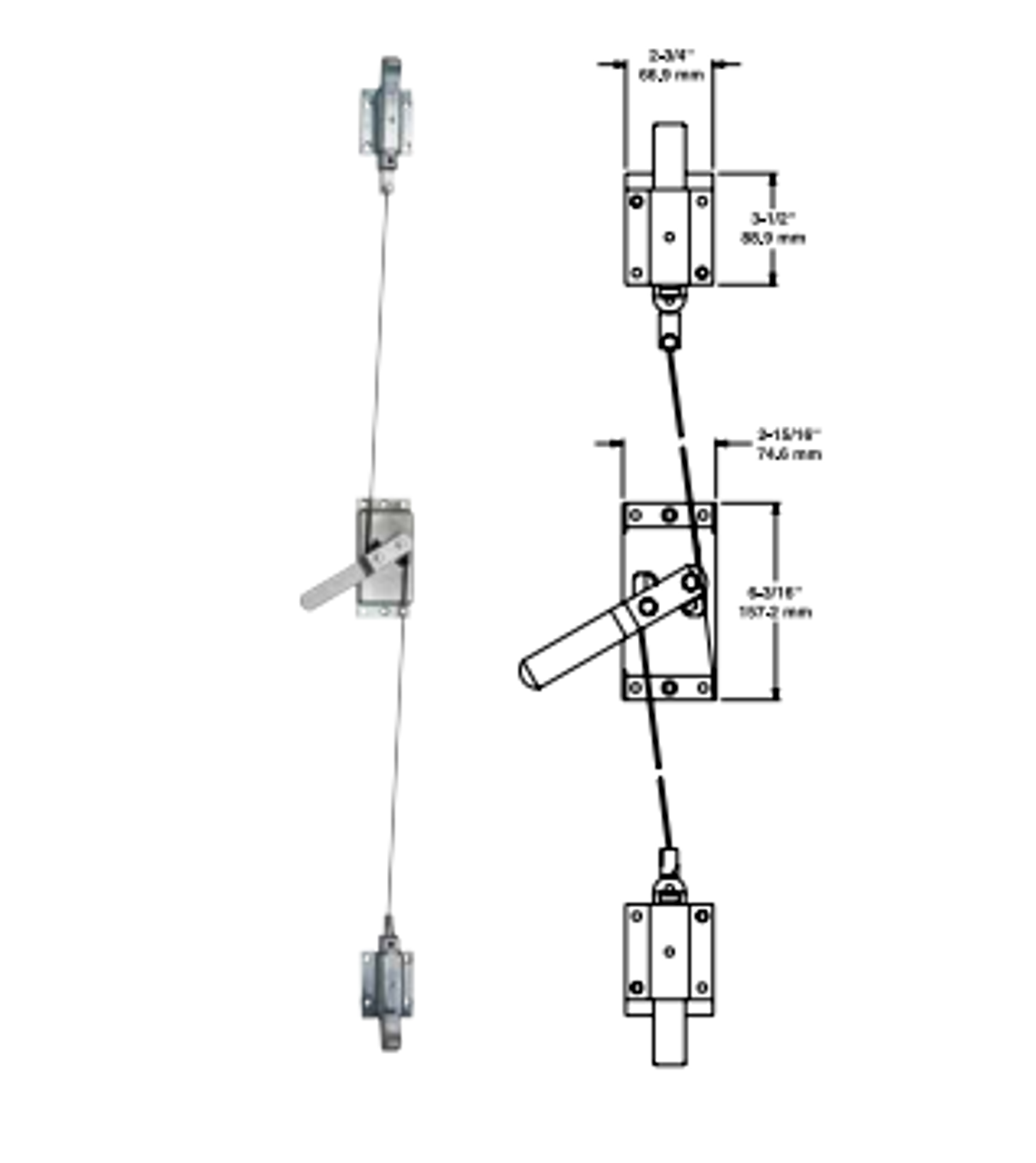

2. Watsons – B20C Cable Installation Kit

Domain: watsons-streetworks.com

Registered: 2000 (25 years)

Introduction: Product Name: B20C Cable Installation Kit for Latch Releases

Description: A complete kit for connecting latches and latch releases for two doors.

Contents: 6+ feet of cable and sheathing (cut to length for 2-doors), 8 sets of plastic clips, screws and nuts, compression sleeves (fixed end), and cable adjusters.

Price: $20.00

SKU: B20C

Category: Cables and Cable Releases

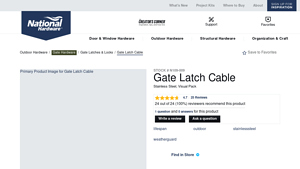

3. National Hardware – Gate Latch Cable

Domain: national-hardware.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “Gate Latch Cable”,”brand”: “National Hardware”,”model”: “N109-009″,”material”: “Stainless Steel”,”description”: “Designed for easy opening of gate latches from the opposite side. Steel wire constructions for maximum durability. Installs with most existing gate latches.”,”warranty”: “National Hardware’s Lifespan™ Limited Lifetime Warranty”,”packaging”: “Visual Pack”,”UPC”: “886780…

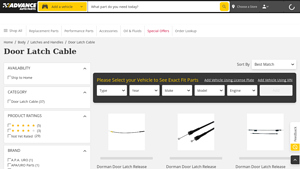

4. Advance Auto Parts – Door Latch Cable

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: Door Latch Cable – Advance Auto Parts

– Discounts: 15% OFF ORDERS $35+, 20% OFF $100+ (Online Only, Use Code PARTS4U, Exclusions Apply)

– Availability: Various options available for shipping to home or store pickup

– Category: Door Latch Cable

– Product Ratings: 5 (3), Not Yet Rated (29)

– Brands: A.P.A., URO, APA/URO Parts, Aftermarket, Dansk, Dorman (30), Dorman – Help (3)

– Price Range: $10 – …

5. Ford – Clip Remote Door Latch Cable

Domain: dealer.parts.ford.com

Registered: 1988 (37 years)

Introduction: This company, Ford – Clip Remote Door Latch Cable, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for latch cable

As the latch cable market continues to evolve, strategic sourcing emerges as a critical component for international B2B buyers aiming to optimize their supply chains. By understanding the diverse applications of latch cables—from automotive to security installations—buyers can make informed decisions that enhance product reliability and performance. Additionally, leveraging suppliers that offer durable materials and innovative designs can significantly reduce maintenance costs and improve customer satisfaction.

The importance of establishing strong relationships with suppliers cannot be overstated. Buyers should prioritize partnerships with manufacturers who demonstrate a commitment to quality, transparency, and responsiveness. This strategic alignment not only ensures a steady supply of high-quality latch cables but also fosters collaboration in product development and innovation.

Looking ahead, the latch cable market presents ample opportunities for growth, particularly in regions such as Africa, South America, the Middle East, and Europe. By investing in strategic sourcing initiatives, international buyers can position themselves to capitalize on emerging trends and technological advancements. Embrace this opportunity to enhance your product offerings and strengthen your market position—partner with trusted suppliers and drive your business forward in the latch cable sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.