The Definitive Guide to Lab Homogeniser: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for lab homogeniser

In today’s rapidly evolving global market, sourcing the right lab homogeniser can be a daunting task for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. With a plethora of options available, understanding the specific needs of your laboratory—whether it’s for pharmaceuticals, food and beverage, or biotechnology—can significantly impact your operational efficiency and product quality. This guide serves as a comprehensive resource to help you navigate the complexities of selecting a lab homogeniser, covering various types such as rotor-stator, ultrasonic, and high-pressure homogenisers, along with their distinct applications.

From identifying the best suppliers to understanding pricing structures and vetting potential partners, this guide is designed to empower international buyers to make informed purchasing decisions. You’ll learn how to evaluate product specifications, compare performance metrics, and consider essential factors such as maintenance and after-sales support. By equipping yourself with the knowledge to choose the right homogeniser, you can enhance your laboratory’s capabilities, ensuring consistent and reliable results that meet industry standards.

As you delve into this guide, anticipate actionable insights that will streamline your procurement process and help you secure the best possible equipment for your unique operational needs.

Understanding lab homogeniser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotor-Stator Homogenizers | Utilize a rotating blade within a stationary casing for mixing. | Biotechnology, food processing, pharmaceuticals. | Pros: Versatile, cost-effective. Cons: Limited to lower viscosity samples. |

| Bead Mill Homogenizers | Employ beads to achieve high shear forces for effective homogenization. | Cell disruption, tissue homogenization. | Pros: Efficient for tough samples. Cons: Higher maintenance due to bead wear. |

| Ultrasonic Homogenizers | Use high-frequency sound waves to create cavitation bubbles. | Nanoparticle dispersion, emulsification. | Pros: Excellent for small sample volumes. Cons: Can be expensive, requires careful handling. |

| High Pressure Homogenizers | Operate at high pressures to achieve thorough homogenization. | Dairy, cosmetics, pharmaceuticals. | Pros: Suitable for high viscosity materials. Cons: Higher initial investment and operational costs. |

| Paddle Blenders | Feature paddle-like mixing tools for gentle homogenization. | Microbial extraction, food applications. | Pros: Simple operation, effective for delicate samples. Cons: Slower processing time. |

What Are Rotor-Stator Homogenizers and Their Applications?

Rotor-stator homogenizers are among the most common types of lab homogenizers, known for their versatility and cost-effectiveness. They work by using a rapidly rotating blade within a stationary casing, generating shear and mixing forces to homogenize various samples. Ideal for applications in biotechnology, food processing, and pharmaceuticals, they are suitable for samples with low to medium viscosity. When considering a rotor-stator homogenizer, buyers should assess the sample types and desired throughput to ensure compatibility.

How Do Bead Mill Homogenizers Work and Where Are They Used?

Bead mill homogenizers utilize small beads to create intense shear forces, effectively disrupting cells and tissues. They are particularly effective for tough samples, such as plant materials and certain biological tissues. Commonly used in cell disruption and tissue homogenization, these homogenizers offer high efficiency but require regular maintenance due to bead wear. B2B buyers should consider sample types, bead material, and maintenance requirements when evaluating bead mill homogenizers.

What Are the Benefits of Ultrasonic Homogenizers?

Ultrasonic homogenizers leverage high-frequency sound waves to create cavitation bubbles, which collapse and generate high shear forces for effective homogenization. They are particularly well-suited for applications involving nanoparticle dispersion and emulsification, making them ideal for the pharmaceutical and cosmetic industries. While they excel with small sample volumes, buyers should be aware of the potential for higher costs and the need for careful handling to avoid overheating or damage.

What Should Buyers Know About High Pressure Homogenizers?

High pressure homogenizers operate at elevated pressures to achieve thorough homogenization, making them suitable for high-viscosity materials such as dairy products and cosmetics. They provide consistent results and are often used in industrial applications. However, the initial investment and operational costs can be significant. B2B buyers should evaluate their production scale and specific application needs to determine the suitability of high pressure homogenizers for their processes.

How Do Paddle Blenders Function and What Are Their Uses?

Paddle blenders are designed with paddle-like mixing tools that gently homogenize samples, making them ideal for sensitive applications like microbial extraction in food processing. They are easy to operate and provide effective results for delicate samples, but they typically have slower processing times compared to other homogenizer types. Buyers should consider the balance between sample sensitivity and processing speed when selecting paddle blenders for their laboratory needs.

Key Industrial Applications of lab homogeniser

| Industry/Sector | Specific Application of lab homogeniser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceutical | Formulation of drug compounds and emulsions | Ensures uniformity and stability in drug efficacy | Compliance with regulatory standards and quality control |

| Food and Beverage | Creation of stable emulsions and dispersions in products | Enhances product quality and shelf life | Ability to handle varying viscosities and sample sizes |

| Biotechnology | Cell disruption for DNA/RNA extraction | Increases yield and purity of genetic material | Equipment compatibility with biological samples |

| Cosmetics | Homogenization of creams and lotions | Improves texture and consistency of products | Need for hygienic and easy-to-clean designs |

| Agriculture | Homogenization of soil and plant samples for analysis | Facilitates accurate testing and research | Durability for rugged environments and sample versatility |

How is Lab Homogeniser Used in the Pharmaceutical Sector?

In the pharmaceutical industry, lab homogenisers are crucial for formulating drug compounds and emulsions. They ensure that active ingredients are uniformly distributed within a solution, enhancing the stability and efficacy of the final product. Buyers in this sector must consider equipment that meets stringent regulatory standards and offers robust quality control features. Additionally, the ability to process small sample volumes while maintaining high pressure is essential to achieve desired results.

What Role Does Lab Homogeniser Play in Food and Beverage Production?

In the food and beverage sector, lab homogenisers are employed to create stable emulsions and dispersions, particularly in products like sauces, dressings, and dairy items. The homogenisation process not only improves product quality but also extends shelf life by preventing separation. Businesses sourcing homogenisers should prioritize models capable of handling a range of viscosities and sample sizes, ensuring versatility in production. Furthermore, compliance with food safety regulations is a critical consideration for international buyers.

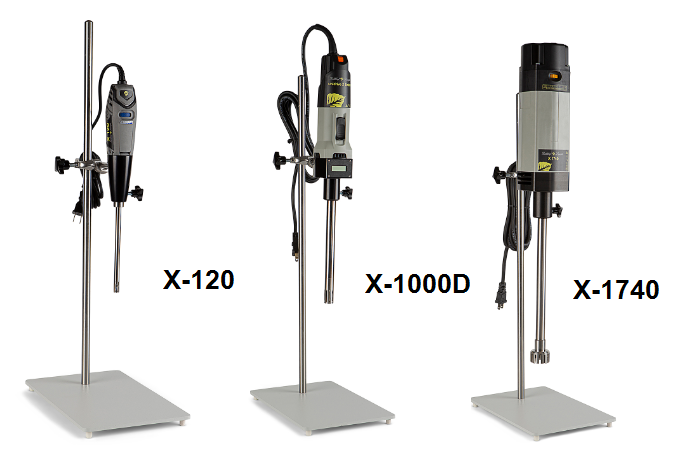

Illustrative image related to lab homogeniser

How is Lab Homogeniser Essential for Biotechnology Applications?

Biotechnology firms utilize lab homogenisers for cell disruption during DNA and RNA extraction processes. This application is vital for increasing the yield and purity of genetic material, which is crucial for research and development. Buyers in this field must ensure that the homogeniser is compatible with biological samples and can operate under sterile conditions to prevent contamination. Additionally, the ability to adjust parameters for different sample types is a significant advantage for successful outcomes.

Why is Lab Homogeniser Important in Cosmetics Manufacturing?

In the cosmetics industry, lab homogenisers are used to achieve the desired texture and consistency in creams, lotions, and serums. The homogenisation process ensures that all ingredients are well-blended, resulting in high-quality products that appeal to consumers. When sourcing homogenisers, businesses should look for equipment that is hygienic and easy to clean, as well as capable of producing consistent results across various batch sizes. This is particularly important for brands aiming to uphold their reputation for quality.

How Do Lab Homogenisers Benefit Agricultural Research?

In agricultural research, lab homogenisers are utilized to homogenize soil and plant samples for accurate testing and analysis. This process facilitates better understanding and research into soil health and crop performance. Buyers in this sector should consider equipment durability, as they may operate in rugged environments, and the versatility to handle different sample types and sizes. Ensuring that the homogeniser can withstand the demands of fieldwork while providing reliable results is key to successful agricultural studies.

3 Common User Pain Points for ‘lab homogeniser’ & Their Solutions

Scenario 1: Inconsistent Sample Quality Across Batches

The Problem: One of the primary challenges B2B buyers face when using lab homogenizers is achieving consistent sample quality across multiple batches. This inconsistency can arise from various factors, including variations in sample size, differences in the homogenization process, and equipment limitations. Such disparities can lead to unreliable test results, affecting product quality and reliability, especially in industries like pharmaceuticals or food processing where precision is crucial.

The Solution: To overcome this issue, buyers should invest in a homogenizer with programmable settings that allow for precise control over operational parameters such as speed, time, and pressure. This feature ensures that each batch is treated under identical conditions. Additionally, conducting preliminary tests to determine the optimal settings for specific sample types can help standardize results. When sourcing equipment, consider models that offer features like real-time monitoring and data logging, which can provide insights into the homogenization process, helping to fine-tune operations for consistent outcomes.

Scenario 2: Equipment Downtime and Maintenance Issues

The Problem: Frequent equipment downtime due to maintenance issues is a significant pain point for laboratories relying on homogenizers. This downtime not only disrupts workflow but can also lead to delayed project timelines and increased operational costs. Common problems include wear and tear on homogenizing heads, clogging, and motor failures, which can stem from improper usage or lack of routine maintenance.

The Solution: To mitigate these challenges, it’s crucial to implement a rigorous maintenance schedule that includes regular inspections and cleaning of the homogenizer components. Buyers should consider investing in models designed for easy disassembly and cleaning, which can streamline maintenance tasks. Additionally, manufacturers often provide user manuals with detailed maintenance guidelines; following these can significantly extend equipment lifespan. For proactive management, consider entering into service agreements with suppliers that offer ongoing support and timely replacement parts, minimizing the risk of unexpected downtime.

Illustrative image related to lab homogeniser

Scenario 3: Difficulty in Selecting the Right Homogenizer for Specific Applications

The Problem: Many B2B buyers struggle with selecting the right type of homogenizer tailored to their specific application needs. Given the variety of homogenizers available—ranging from rotor-stator to ultrasonic and high-pressure models—identifying the most suitable equipment can be overwhelming. This confusion can lead to poor purchasing decisions, resulting in inadequate performance for their intended applications, whether in research, food production, or pharmaceuticals.

The Solution: To make informed decisions, buyers should conduct thorough application research to understand the specific requirements of their processes. Engaging with manufacturers or suppliers for consultations can provide valuable insights into which homogenizer features are most relevant for their needs. Additionally, participating in demonstrations or seeking out user reviews and case studies can help buyers visualize the performance of different models in real-world scenarios. Finally, consider the scalability of the equipment; selecting a homogenizer that can accommodate future growth or changes in product lines can provide long-term value and flexibility.

Strategic Material Selection Guide for lab homogeniser

When selecting materials for lab homogenizers, it is crucial to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials used in the construction of lab homogenizers, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Stainless Steel in Lab Homogenizers?

Stainless steel is a widely used material in lab homogenizers due to its excellent mechanical properties and corrosion resistance. It can withstand high pressures and temperatures, making it suitable for demanding applications. Stainless steel is typically rated for temperatures up to 300°C and can handle pressures exceeding 2000 bar, depending on the grade.

Illustrative image related to lab homogeniser

Pros and Cons: The durability and resistance to corrosion are significant advantages, ensuring a long lifespan and minimal maintenance. However, the cost of high-quality stainless steel can be relatively high, and its manufacturing complexity may increase production time.

Impact on Application: Stainless steel is compatible with a variety of media, including biological samples and aggressive solvents, making it an ideal choice for pharmaceutical and food applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN. Additionally, the availability of stainless steel grades may vary by region, influencing procurement decisions.

How Does Glass Reinforced Plastic (GRP) Perform in Homogenizer Applications?

Glass Reinforced Plastic (GRP) is gaining popularity in lab homogenizers, particularly for applications requiring lower weight and enhanced chemical resistance. GRP can withstand temperatures up to 120°C and moderate pressures, making it suitable for less demanding homogenization tasks.

Illustrative image related to lab homogeniser

Pros and Cons: GRP is lightweight and resistant to corrosion, which can lower shipping costs and reduce wear over time. However, it is less durable than metals and may not perform well under extreme pressure or temperature conditions, limiting its use in high-stress environments.

Impact on Application: GRP is particularly effective for homogenizing samples in the cosmetic and pharmaceutical industries, where chemical compatibility is crucial.

Considerations for International Buyers: Buyers should verify that GRP products meet local regulations and standards, particularly in regions like the Middle East, where chemical exposure is a concern.

Illustrative image related to lab homogeniser

What Role Does Titanium Play in Lab Homogenizer Design?

Titanium is another high-performance material used in lab homogenizers, especially in applications that require high strength and corrosion resistance. Titanium can handle extreme temperatures (up to 600°C) and pressures, making it suitable for specialized applications in biotechnology and pharmaceuticals.

Pros and Cons: The primary advantage of titanium is its exceptional strength-to-weight ratio and resistance to corrosion, which enhances the longevity of the equipment. However, titanium is significantly more expensive than stainless steel and GRP, which may deter budget-conscious buyers.

Impact on Application: Titanium’s compatibility with aggressive chemicals makes it ideal for homogenizing samples that contain reactive substances.

Considerations for International Buyers: Buyers should be aware of the higher costs associated with titanium and ensure that they can source it from reliable suppliers, particularly in emerging markets like Nigeria and Brazil.

Why is Polypropylene a Viable Option for Lab Homogenizers?

Polypropylene is a cost-effective alternative for lab homogenizers, particularly in applications where chemical resistance and lower mechanical strength are acceptable. It can withstand temperatures up to 100°C and is suitable for low-pressure applications.

Pros and Cons: The affordability of polypropylene makes it an attractive option for laboratories on a budget. However, its lower durability and pressure tolerance may limit its use in high-performance applications.

Impact on Application: Polypropylene is commonly used in applications involving biological samples, where sterility and chemical resistance are essential.

Considerations for International Buyers: Buyers should consider the local availability of polypropylene products and ensure they meet relevant safety and quality standards.

Illustrative image related to lab homogeniser

Summary Table of Material Selection for Lab Homogenizers

| Material | Typical Use Case for lab homogeniser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Pharmaceutical and food applications | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Glass Reinforced Plastic (GRP) | Cosmetic and pharmaceutical applications | Lightweight and chemically resistant | Less durable under high pressure/temperature | Medium |

| Titanium | Biotechnology and specialized pharmaceutical applications | Exceptional strength and corrosion resistance | Very high cost | High |

| Polypropylene | Biological sample homogenization | Cost-effective and chemically resistant | Lower durability and pressure tolerance | Low |

This guide provides a comprehensive overview of the strategic material selection for lab homogenizers, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for lab homogeniser

What Are the Key Stages in the Manufacturing Process of Laboratory Homogenizers?

The manufacturing of laboratory homogenizers involves several critical stages that ensure the final product meets both functional and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing equipment.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing homogenizers is material preparation, where high-quality raw materials are selected based on their suitability for the intended applications. Common materials include stainless steel for durability and corrosion resistance, as well as specialized plastics for specific components. Suppliers often adhere to stringent material specifications to ensure that the homogenizers can withstand high pressures and varying temperatures during operation.

How Are Laboratory Homogenizers Formed?

Once the materials are prepared, they undergo various forming techniques. These may include machining processes like CNC milling and turning, which allow for precise shaping of components such as rotors and stators. Additionally, processes like injection molding may be employed for creating plastic parts. The choice of forming technique is critical, as it affects the homogenizer’s performance and longevity.

What Assembly Techniques Are Commonly Used?

After forming, the assembly stage brings together all the manufactured components. This stage often involves both manual and automated processes to ensure precision. Technicians assemble parts in a clean environment to minimize contamination risks. Attention to detail is paramount, as improper assembly can lead to equipment malfunction, affecting the homogenization process.

Illustrative image related to lab homogeniser

What Finishing Processes Are Necessary?

Finishing processes, including surface treatments like polishing and coating, enhance the performance and aesthetics of the homogenizers. These treatments can provide additional protection against wear and corrosion, which is particularly important for laboratory environments. Quality control checks are conducted at this stage to ensure that the finishing meets industry standards.

How Is Quality Assurance Implemented in Lab Homogenizer Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for laboratory homogenizers. It ensures that the equipment meets both international and industry-specific standards, which is crucial for B2B buyers.

What International Standards Should B2B Buyers Look For?

One of the most recognized international standards is ISO 9001, which outlines the requirements for a quality management system. Compliance with this standard indicates that the manufacturer has processes in place to consistently produce quality products. Additionally, certifications like CE mark indicate conformity with European health, safety, and environmental protection standards, while API standards may apply to specific applications in pharmaceuticals.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to the QA process. These checkpoints typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process. Materials must meet predefined specifications to ensure the quality of the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing checks are conducted to verify that processes are being executed correctly. This may include monitoring dimensions, tolerances, and operational parameters.

-

Final Quality Control (FQC): Once the homogenizers are assembled, they undergo final testing and inspection. This includes functional tests to ensure they operate as intended, as well as safety checks to confirm compliance with relevant standards.

What Common Testing Methods Are Used for Laboratory Homogenizers?

Testing methods for laboratory homogenizers vary based on the intended application and specific requirements. Common methods include:

-

Performance Testing: This assesses the homogenizer’s efficiency in achieving desired particle size reduction and uniformity. Performance metrics may include throughput rates and energy consumption.

-

Durability Testing: Homogenizers are subjected to stress tests to evaluate their longevity and reliability under extreme conditions. This helps to predict their performance over time.

-

Safety Testing: Ensuring that the equipment meets safety standards is critical. This includes testing for electrical safety, mechanical stability, and any potential hazards associated with operation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are several strategies:

What Are Effective Audit Techniques?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. Audits should focus on the manufacturing environment, equipment, and adherence to quality management systems. Buyers can look for evidence of regular internal audits and corrective actions taken in response to identified issues.

How Important Are Quality Reports?

Requesting quality reports from suppliers can provide insights into their manufacturing consistency. These reports may include data on defect rates, corrective actions, and results from various testing phases. Regularly updated reports can help buyers gauge supplier reliability.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct audits and tests to verify that the homogenizers meet the specified standards. This is particularly beneficial for buyers in regions where they cannot physically inspect the manufacturing process.

What Unique QC Considerations Exist for International B2B Buyers?

For international buyers, particularly in Africa, South America, the Middle East, and Europe, understanding regional regulatory requirements is essential. Different markets may have varying standards for laboratory equipment, necessitating careful scrutiny of supplier certifications.

How Do Regional Standards Affect Procurement?

Buyers should familiarize themselves with local regulations that may affect the import and use of laboratory homogenizers. For example, specific certifications may be required for equipment used in pharmaceutical applications in the European Union. Understanding these nuances can help buyers avoid delays and ensure compliance.

What Are the Risks of Non-compliance?

Non-compliance with international standards can result in significant risks, including legal penalties, increased costs, and potential harm to laboratory operations. Therefore, thorough due diligence is essential when selecting suppliers.

Illustrative image related to lab homogeniser

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance protocols for laboratory homogenizers equips B2B buyers with the knowledge to make informed purchasing decisions. By focusing on the key stages of manufacturing, relevant quality standards, and effective verification strategies, buyers can ensure they are investing in reliable and compliant equipment for their laboratories.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lab homogeniser’

To facilitate your procurement of a lab homogenizer, this guide offers a structured approach. By following these steps, you can ensure that you select the right equipment for your laboratory needs while minimizing risks and maximizing efficiency.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as the type of samples you will be homogenizing (e.g., biological, food, or chemical), the required volume capacity, and the desired homogenization method (e.g., rotor-stator, ultrasonic, or high-pressure). This step is crucial as it sets the foundation for your search, ensuring you target suppliers that meet your specific needs.

Illustrative image related to lab homogeniser

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers that specialize in lab homogenizers. Utilize industry-specific directories, attend trade shows, and leverage online platforms to compile a list of potential vendors. Look for companies with a strong reputation and experience in your field, as this often correlates with product quality and customer service.

Step 3: Evaluate Supplier Certifications

Verify the certifications and standards compliance of your shortlisted suppliers. Check for ISO certifications, CE marking, and any relevant industry-specific accreditations. Ensuring that suppliers adhere to recognized standards is vital for guaranteeing the quality and safety of the homogenizers you intend to purchase.

Step 4: Request Product Demonstrations

Before making a purchase, request product demonstrations or trials where feasible. This allows you to assess the performance of the homogenizers in real-world scenarios. Pay attention to ease of use, maintenance requirements, and the consistency of results, as these factors can significantly impact your laboratory’s efficiency.

Step 5: Compare Pricing and Warranty Options

Gather detailed quotations from multiple suppliers to facilitate a comprehensive price comparison. Look beyond the initial costs; consider the total cost of ownership, including maintenance, consumables, and potential upgrades. Additionally, inquire about warranty terms and after-sales support, as robust service agreements can save you money and hassle in the long run.

Step 6: Seek Customer Testimonials and Case Studies

Request testimonials or case studies from previous customers who have used the homogenizers you are considering. This feedback can provide valuable insights into the reliability and performance of the equipment in similar applications. Engaging with existing users can also reveal any potential issues and help you make a more informed decision.

Step 7: Finalize Your Purchase and Negotiate Terms

Once you have selected a supplier, finalize your order and negotiate the terms of purchase. Ensure clarity on delivery timelines, payment terms, and installation support. A well-structured agreement can help mitigate risks and establish a solid working relationship with your supplier, setting the stage for future collaborations.

By following these steps, you can streamline the sourcing process for lab homogenizers, making informed decisions that align with your laboratory’s objectives and operational requirements.

Comprehensive Cost and Pricing Analysis for lab homogeniser Sourcing

What Are the Key Cost Components in Lab Homogenizer Sourcing?

When sourcing lab homogenizers, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. High-quality stainless steel, for example, may increase initial expenses but can enhance durability and performance, ultimately reducing maintenance costs.

-

Labor: Labor costs encompass both direct and indirect expenses associated with manufacturing. Skilled labor may command higher wages but can lead to better craftsmanship and lower defect rates.

-

Manufacturing Overhead: This includes costs related to factory utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: The cost of specialized tooling for production can be substantial, particularly for custom homogenizers. Buyers should consider these costs when evaluating supplier pricing.

-

Quality Control (QC): Robust QC processes ensure product reliability and compliance with industry standards. While they add to costs, they can prevent costly recalls and reputation damage.

-

Logistics: Shipping, handling, and storage costs must be factored into the total expense. International shipping can particularly affect pricing due to tariffs and customs duties.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding typical margins in the industry can help buyers negotiate effectively.

How Do Price Influencers Impact Lab Homogenizer Costs?

Several factors influence the pricing of lab homogenizers, which buyers should consider:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often qualify for discounts, making it beneficial for institutions with ongoing needs.

-

Specifications and Customization: Custom features or specifications may lead to higher costs. Buyers should assess whether these customizations are necessary or if standard models suffice.

-

Materials: The quality and type of materials used in the homogenizer construction directly impact cost. For example, high-pressure homogenizers for specialized applications require more robust materials, leading to higher prices.

-

Quality and Certifications: Certifications such as ISO or CE can affect pricing as they indicate compliance with international standards. Buyers should weigh the benefits of certified equipment against the cost.

-

Supplier Factors: Supplier reputation, reliability, and location can also influence pricing. Established suppliers may charge more but offer better support and warranty options.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects the total landed cost. Terms like FOB (Free on Board) may shift responsibilities and risks between buyer and seller, impacting overall pricing.

What Buyer Tips Can Enhance Cost-Efficiency in Lab Homogenizer Sourcing?

To maximize value when sourcing lab homogenizers, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, particularly if you have multiple suppliers in consideration. Leverage quotes to negotiate better terms or discounts.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just upfront costs. Consider factors like maintenance, energy consumption, and potential downtime, which can affect long-term expenses.

-

Pricing Nuances for International Buyers: International buyers, especially from regions like Africa and South America, should be aware of additional costs such as import duties and taxes. Understanding local regulations can prevent unexpected expenses.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Comparing multiple suppliers can reveal pricing discrepancies and provide insights into market standards.

-

Consider Local Suppliers: Whenever possible, sourcing from local suppliers can reduce shipping costs and import duties, making the overall purchase more economical.

Conclusion

Understanding the cost structure and pricing influencers of lab homogenizers is essential for B2B buyers. By focusing on these aspects and employing strategic sourcing tactics, buyers can optimize their procurement process, ensuring they receive high-quality products at competitive prices. Always keep in mind that prices can vary widely based on specifications and supplier factors, making thorough research and negotiation critical in achieving the best deal.

Alternatives Analysis: Comparing lab homogeniser With Other Solutions

When considering laboratory homogenization, it is essential to evaluate various methods that can achieve similar results. While lab homogenizers are commonly used for sample preparation across different industries, there are alternative solutions that may better suit specific applications or budget constraints. This section explores viable alternatives to lab homogenizers, providing a comparative analysis to assist B2B buyers in making informed decisions.

| Comparison Aspect | Lab Homogeniser | Bead Mill Homogenizer | Rotor-Stator Homogenizer |

|---|---|---|---|

| Performance | High efficiency for a variety of samples; effective in achieving uniformity. | Excellent for hard-to-homogenize samples; ideal for cell lysis and tissue disruption. | Versatile; suitable for both soft and hard samples, providing good shear and mixing. |

| Cost | Moderate to high; prices range based on type and features (e.g., ultrasonic, high-pressure). | Generally lower initial investment; prices vary based on capacity and features. | Moderate cost; typically more affordable than high-pressure options. |

| Ease of Implementation | Requires space and may need specific training for optimal use. | Relatively easy to set up; portable models available for flexible use. | User-friendly, often requiring minimal training for effective operation. |

| Maintenance | Requires regular maintenance and calibration to ensure accuracy. | Low maintenance; cleaning is straightforward with minimal downtime. | Moderate maintenance; requires periodic checks to ensure optimal performance. |

| Best Use Case | Ideal for high-throughput applications and precise emulsification. | Best for biological samples, especially when high shear forces are needed. | Effective for a wide range of applications, from food processing to pharmaceuticals. |

What are the Advantages and Disadvantages of Using a Bead Mill Homogenizer?

Bead mill homogenizers utilize beads to mechanically disrupt cells and tissues. They are particularly effective for applications requiring high shear forces, making them a popular choice for biological samples. Their cost-effectiveness and portability are significant advantages, especially for labs with budget constraints. However, they may not achieve the same level of uniformity as some lab homogenizers, and sample volume limitations can be a drawback for larger-scale applications.

How Does a Rotor-Stator Homogenizer Compare to Lab Homogenizers?

Rotor-stator homogenizers are known for their versatility and ease of use. They can effectively homogenize a variety of sample types, from soft tissues to thicker suspensions, making them suitable for multiple industries. Their user-friendly design allows for quick operation, minimizing the need for extensive training. However, they may not reach the same high pressures as some lab homogenizers, which can limit their effectiveness in certain applications requiring finer emulsions or dispersions.

Conclusion: How Should B2B Buyers Decide on the Right Homogenization Solution?

When selecting the appropriate homogenization solution, B2B buyers should consider factors such as the specific application, budget, and operational requirements. Lab homogenizers excel in high-throughput scenarios and precise emulsification but may come with higher costs and maintenance demands. Alternatively, bead mill and rotor-stator homogenizers offer distinct advantages in terms of cost and ease of use, making them suitable for various laboratory settings. By assessing these factors, buyers can make a well-informed decision that aligns with their unique operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for lab homogeniser

What Are the Key Technical Properties of Lab Homogenisers?

Understanding the technical specifications of lab homogenisers is essential for B2B buyers looking to invest in reliable and efficient equipment. Here are several critical specifications to consider:

1. Pressure Capacity

The pressure capacity of a homogeniser is a vital specification, often measured in bars or psi. This property determines the machine’s ability to homogenise viscous materials and create nano-emulsions or dispersions. A higher pressure capacity (e.g., up to 2000 bar) allows for more effective processing of challenging samples, making it crucial for industries such as pharmaceuticals and food production. For businesses, investing in a homogeniser with appropriate pressure capabilities ensures consistent product quality and reduces the need for multiple processing stages.

2. Sample Volume

The sample volume capacity indicates the minimum and maximum amount of material the homogeniser can process at one time. This specification is critical for scaling up from laboratory tests to production levels. For B2B buyers, understanding the required sample volume helps in selecting a homogeniser that meets both current and future production needs, thereby optimizing workflow and minimizing downtime.

3. Material Grade

The material grade refers to the construction materials used in the homogeniser, which often includes stainless steel or specialized alloys. High-grade materials are essential for ensuring durability, chemical resistance, and hygiene standards, especially in industries like food and pharmaceuticals. Choosing a homogeniser made from appropriate material grades can significantly affect maintenance costs and longevity, providing a better return on investment.

4. Homogenisation Method

Lab homogenisers employ various methods such as rotor-stator, ultrasonic, or high-pressure techniques. Each method has distinct advantages depending on the application, such as particle size reduction or cell disruption. Understanding these methods allows B2B buyers to select equipment that meets specific application requirements, enhancing product development and research outcomes.

5. Power Consumption

The power consumption of a homogeniser, typically measured in watts, indicates its energy efficiency. High-performance homogenisers may require more power but can lead to quicker processing times and better results. Evaluating power consumption is vital for cost management, especially for businesses aiming to reduce operational expenses while maintaining high productivity.

What Are Common Trade Terms Used in the Lab Homogeniser Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or equipment that are used in another company’s end products. In the homogeniser market, an OEM may provide parts or complete systems that are branded by another company. Understanding this term helps buyers identify reliable suppliers and potential partnerships for custom solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers, as it affects inventory management and purchasing decisions. Buyers should align their order quantities with their production needs to avoid excess inventory or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers to request pricing and terms for specific products or services. This process is important for B2B transactions, allowing buyers to compare offers and negotiate better deals based on their requirements.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers involved in cross-border transactions, as it clarifies the costs and risks associated with shipping homogenisers.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. In the context of lab homogenisers, understanding lead times is essential for project planning and inventory management. Buyers should factor in lead times when making purchasing decisions to ensure timely availability of equipment for their operations.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when purchasing lab homogenisers, ensuring they select the right equipment for their specific applications and operational needs.

Navigating Market Dynamics and Sourcing Trends in the lab homogeniser Sector

What Are the Current Market Dynamics and Key Trends in the Lab Homogeniser Sector?

The lab homogeniser market is witnessing significant growth, driven by the increasing demand for advanced homogenization technologies across various sectors including pharmaceuticals, biotechnology, food and beverage, and cosmetics. As research and development activities expand globally, particularly in emerging markets such as Nigeria and Brazil, there is a heightened need for efficient sample preparation tools. The homogenisers are evolving to meet the requirements for higher throughput and better quality results, with innovations such as ultrasonic and high-pressure homogenisers gaining traction.

Moreover, the trend towards miniaturization is leading to the development of compact, benchtop homogenisers that deliver high performance while occupying less space. This is particularly appealing to laboratories in regions with limited space or resources. Additionally, the integration of smart technologies into homogenisation processes is becoming increasingly common. Remote monitoring and automation features are now available, allowing laboratories to enhance their productivity and operational efficiency.

Illustrative image related to lab homogeniser

International buyers should also note the growing emphasis on sourcing equipment that supports sustainable practices. This is not only a regulatory requirement in many regions but also a market expectation, particularly among environmentally conscious consumers. As a result, suppliers that prioritize energy-efficient models and offer solutions designed for sustainable operations are likely to stand out in the competitive landscape.

How Is Sustainability and Ethical Sourcing Influencing the Lab Homogeniser Market?

Sustainability is becoming a crucial factor for B2B buyers in the lab homogeniser sector. With the global push towards environmentally friendly practices, laboratories are increasingly seeking homogenisers that minimize environmental impact. This includes equipment that reduces energy consumption, utilizes recyclable materials, and adheres to green manufacturing processes.

Ethical sourcing is equally important, as suppliers are expected to maintain transparent supply chains and ensure fair labor practices. Buyers are encouraged to seek out manufacturers who possess recognized sustainability certifications, such as ISO 14001, which demonstrates commitment to environmental management systems. Furthermore, exploring homogenisers made from eco-friendly materials not only aligns with sustainability goals but can also enhance a brand’s reputation in the marketplace.

Illustrative image related to lab homogeniser

In many regions, particularly in Africa and South America, buyers are becoming more informed about the origins of their equipment and the broader implications of their sourcing decisions. This shift is prompting manufacturers to adopt more sustainable practices, not only to meet regulatory standards but also to fulfill customer expectations for responsible sourcing.

What Is the Brief History and Evolution of Lab Homogenisers Relevant to B2B Buyers?

The evolution of lab homogenisers has been marked by significant technological advancements since their inception in the early 20th century. Initially, homogenisation was achieved through simple mechanical means, which often resulted in inconsistent sample quality. The introduction of rotor-stator designs in the 1960s revolutionized the process, allowing for finer and more uniform particle size reduction.

As research demands grew, particularly in biopharmaceutical applications, the need for high-pressure homogenisers emerged in the late 20th century. These devices enabled the processing of tougher materials and improved the efficiency of cell disruption, which is critical for extracting biomolecules.

Today, lab homogenisers incorporate advanced technologies such as ultrasonic waves and automated controls, making them indispensable tools in modern laboratories. This evolution reflects a broader trend towards precision, efficiency, and adaptability in laboratory equipment, catering to the diverse needs of international B2B buyers across various sectors. Understanding this historical context can help buyers make informed decisions about which technologies best suit their specific applications.

Illustrative image related to lab homogeniser

Frequently Asked Questions (FAQs) for B2B Buyers of lab homogeniser

-

1. How do I choose the right lab homogenizer for my application?

Choosing the right lab homogenizer depends on several factors, including the type of samples you will be processing, the desired particle size, and the volume of your samples. Consider whether you need a rotor-stator, ultrasonic, or high-pressure homogenizer based on your specific application, such as cell disruption or emulsification. Additionally, evaluate the throughput requirements and whether you need features like programmability or digital interfaces. It’s also wise to consult with suppliers for recommendations tailored to your specific needs. -

2. What is the best homogenizer for processing biological samples?

For processing biological samples, ultrasonic homogenizers are often recommended due to their effectiveness in cell disruption and sample preparation. They provide precise control over parameters like amplitude and pulse duration, allowing for optimal results. High-pressure homogenizers are also suitable for larger volumes and can achieve finer emulsions, making them ideal for pharmaceutical and biotechnology applications. Always ensure the homogenizer can handle the specific type of biological material you are working with, whether it’s tissues, cells, or microbial samples. -

3. What are the standard payment terms when purchasing a lab homogenizer internationally?

Payment terms for international purchases can vary by supplier, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may offer net 30 or net 60 terms for established buyers. It’s essential to clarify payment methods (such as wire transfer, credit card, or letters of credit) and any potential currency fluctuations that may impact the total cost. Always ensure to review the supplier’s payment policy and negotiate terms that suit your financial processes. -

4. How can I vet suppliers for lab homogenizers in international markets?

To effectively vet suppliers, start by researching their reputation through online reviews and industry forums. Request references from previous clients and inquire about their experience with the product quality and customer service. Additionally, consider visiting their facility if possible, or request a virtual tour to assess their manufacturing capabilities. Certifications like ISO or GMP can also indicate adherence to quality standards. Engaging in a trial order can be a prudent step to evaluate product performance before committing to larger purchases. -

5. What customization options are available for lab homogenizers?

Many suppliers offer customization options to meet specific application needs, such as modified rotor designs, specialized materials for sample compatibility, or unique size configurations. Some manufacturers may also provide customizable software features for automated processes. It is advisable to discuss your specific requirements with the supplier during the inquiry phase to explore available modifications. Ensure that any customizations do not compromise the homogenizer’s efficiency or performance. -

6. What are the minimum order quantities (MOQs) for lab homogenizers?

Minimum order quantities can vary widely depending on the supplier and the specific model of the homogenizer. Some manufacturers may allow single unit purchases, especially for standard models, while others may set MOQs for customized or high-demand equipment. It’s beneficial to inquire about MOQs upfront, as they can affect your procurement strategy. If you are looking for multiple units, negotiating a better price or payment terms may also be possible. -

7. What quality assurance measures should I expect when buying a lab homogenizer?

Reputable manufacturers should provide quality assurance documentation, including performance specifications and compliance with international standards. Look for suppliers that conduct rigorous testing of their homogenizers before shipment, such as functionality tests and quality checks. Requesting a certificate of conformity or a warranty can also safeguard your investment. Additionally, inquire about after-sales support and maintenance services to ensure ongoing quality and performance of the equipment. -

8. How does logistics impact the purchase of lab homogenizers from international suppliers?

Logistics plays a crucial role in the timely delivery of lab homogenizers. Consider factors such as shipping methods, lead times, and potential customs delays when planning your order. It’s important to discuss logistics with your supplier, including whether they handle shipping or if you need to arrange it independently. Additionally, ensure that you understand any import duties or taxes that may apply to your purchase. Clear communication regarding shipping terms can help prevent unexpected costs and delays.

Top 7 Lab Homogeniser Manufacturers & Suppliers List

1. Homogenizers.net – BeadBug™ Homogenizer

Domain: homogenizers.net

Registered: 2008 (17 years)

Introduction: {“products”: [{“name”: “BeadBug™ Homogenizer”, “description”: “Homogenize 3 samples with this tiny, inexpensive benchtop homogenizer.”, “price”: “$998 USD”, “sale_price”: “$849 USD”, “reviews”: 8}, {“name”: “Scilogex D500 Homogenizer”, “description”: “Rapidly homogenize, disperse, and emulsify samples in 10mL to 5000ml of liquid.”, “price”: “$1,509 USD”, “sale_price”: “$1,207 USD”, “reviews”: 6}, …

2. GEA – Laboratory Homogenizers

Domain: gea.com

Registered: 1995 (30 years)

Introduction: GEA laboratory homogenizers are small and compact devices designed for continuous operations, ideal for high pressure treatment of nano-particles, nano-dispersions, nano-emulsions, and cell disruption. They can achieve a maximum pressure of 2000 bar and are suitable for various applications including biotechnology, pharmaceuticals, cosmetics, chemicals, dairy, food, and beverages. The homogenizers…

3. PRO Scientific – Homogenizers

Domain: proscientific.com

Registered: 1997 (28 years)

Introduction: PRO Scientific offers a range of homogenizers suitable for laboratory and industrial homogenization, including rotor-stator homogenizers, automated homogenizers, and handheld options. Key features include high shear mixing capabilities with speeds up to 35,000 rpm, precision homogenization with stainless steel generator probes, and the ability to homogenize a variety of samples such as tissue, pla…

4. Cole-Parmer – Homogenizers

Domain: coleparmer.com

Registered: 1994 (31 years)

Introduction: This company, Cole-Parmer – Homogenizers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Revvity – Omni Homogenizers

Domain: revvity.com

Registered: 2020 (5 years)

Introduction: Homogenizers offered include bead mills, rotor-stator homogenizers, mixers, and automated homogenizers. Revvity provides a comprehensive selection of Omni homogenizers suitable for various lab throughput needs and sample types. Key features include:

– Bead Mill Homogenizers: Reliable for consistent sample homogenization across diverse sample types.

– Rotor Stator Homogenizers: High-shear homogen…

6. Thomas Scientific – Homogenizers

Domain: thomassci.com

Registered: 1995 (30 years)

Introduction: This company, Thomas Scientific – Homogenizers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. SPX Flow – Laboratory Homogenizers

Domain: spxflow.com

Registered: 2014 (11 years)

Introduction: {“Product Type”: “Laboratory Homogenizers”, “Description”: “Compact, versatile design specifically developed for Research and Development laboratories.”, “Key Features”: {“Performance and Convenience”: [“Smooth, quiet, and reliable operation”, “Compact footprint ideal for benchtop use”, “Field-replaceable and reversible tungsten carbide pump valve seats”, “Digital pressure display and electronic s…

Strategic Sourcing Conclusion and Outlook for lab homogeniser

In conclusion, the strategic sourcing of laboratory homogenizers is essential for enhancing operational efficiency and product quality across diverse industries such as pharmaceuticals, food and beverage, and biotechnology. By understanding the various types of homogenizers available—ranging from rotor-stator to ultrasonic systems—buyers can make informed decisions that align with their specific application needs. Additionally, leveraging partnerships with reputable suppliers ensures access to cutting-edge technology, competitive pricing, and ongoing support, ultimately driving innovation and sustainability in production processes.

As the demand for high-performance homogenization continues to rise globally, particularly in emerging markets like Nigeria and Brazil, international B2B buyers must remain proactive in sourcing equipment that meets rigorous quality standards while being adaptable to local conditions. Engaging with suppliers that offer comprehensive testing and customization options will be pivotal in maximizing the value derived from these investments.

We encourage stakeholders to explore the latest advancements in homogenization technology and consider how strategic sourcing can propel their operations forward. The future of laboratory homogenizers is bright, with continuous innovations poised to meet the evolving needs of diverse industries. Take the next step towards optimizing your laboratory processes by engaging with trusted homogenizer suppliers today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.